Patents

Literature

38results about How to "Capacity adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

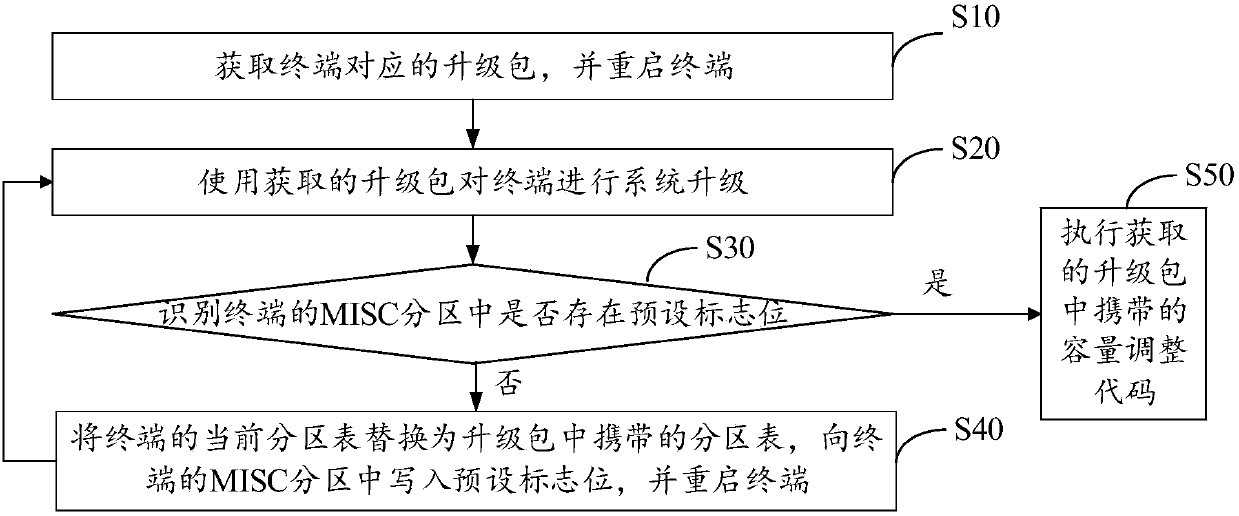

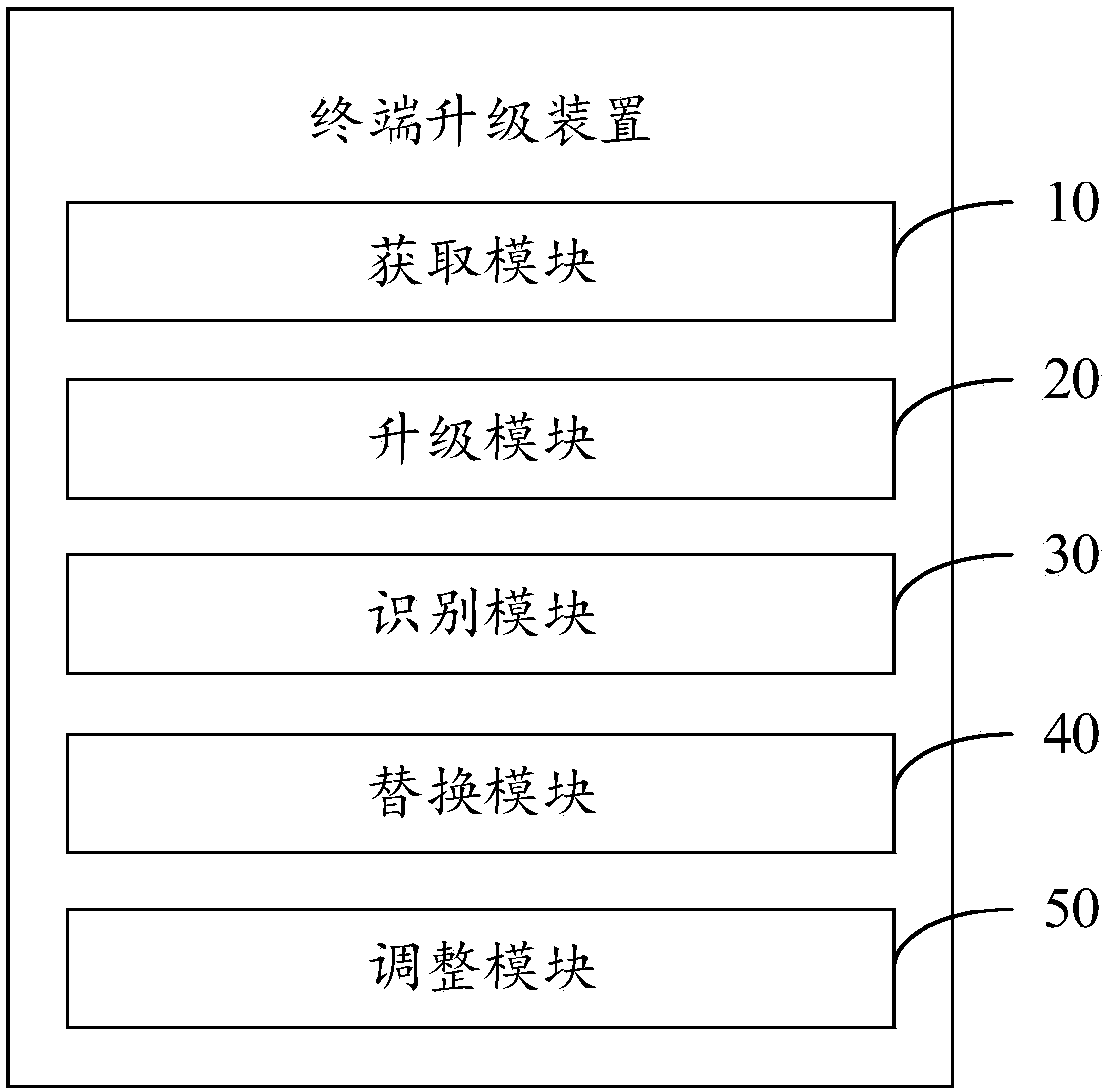

Terminal updating method and device

InactiveCN107643898AOvercoming the shortcomings of fixed capacityCapacity adjustmentSoftware deploymentSoftware engineeringComputer terminal

The invention discloses a terminal updating method. The terminal updating method comprises the following steps: Step A, acquiring an updating package corresponding to a terminal, and restarting the terminal; Step B, carrying out system updating on the terminal through the updating package; Step C, identifying whether a preset flag bit exists in an MISC partition of the terminal or not, carrying out Step D if the preset flag bit does not exist in the MISC partition of the terminal, and carrying out Step E if the preset flag bit exists in the MISC partition of the terminal; Step D, replacing a current partition table of the terminal with a partition table carried by the updating package, writing the preset flag bit into the MISC partition, and carrying out Step B after the terminal is restarted; and Step E, executing a capacity adjustment code carried by the updating package, so that the capacity of a user data partition of the terminal is adjusted to the capacity of a user data partition in the partition table used as a replacement. The invention further discloses a terminal updating device. The terminal updating method and device provided by the invention has the advantage that theproblem that the capacity of the user data partition of the terminal is fixed is solved.

Owner:ZTE CORP

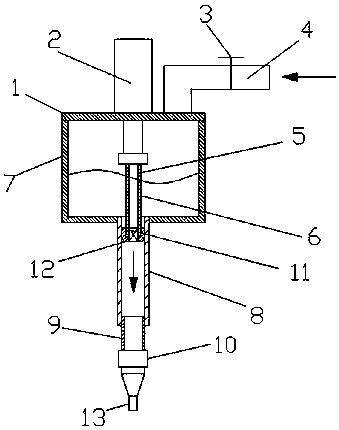

Volume-adjustable lactic acid beverage filling equipment

The invention discloses volume-adjustable lactic acid beverage filling equipment. The volume-adjustable lactic acid beverage filling equipment comprises a spray nozzle, a liquid storage box, a cover plate, a straight cylinder and a piston, wherein the cover plate is arranged at the top part of the liquid storage box for sealing; a straight cylinder installing hole is formed in the bottom part of the liquid storage box; the top part of the straight cylinder is arranged in the straight cylinder installing hole; the spray nozzle is arranged at the bottom part of the straight cylinder; the cover plate is provided with a lifting driving device pointing to the straight cylinder installing hole; the liquid storage box is internally provided with a hollow pipe connected with a telescopic rod of the lifting driving device; the piston is arranged at the bottom part of the hollow pipe; a through hole communicated with the hollow pipe is formed in the piston; a one-way valve of which a liquid outlet is formed in the top part is arranged in the through hole. The volume-adjustable lactic acid beverage filling equipment disclosed by the invention has the advantages that single filling volume canbe adjusted through expansion and contraction quantity of the lifting driving device, the adjusting is flexible, and the accuracy of the filling volume is high.

Owner:江苏好彩头食品有限公司

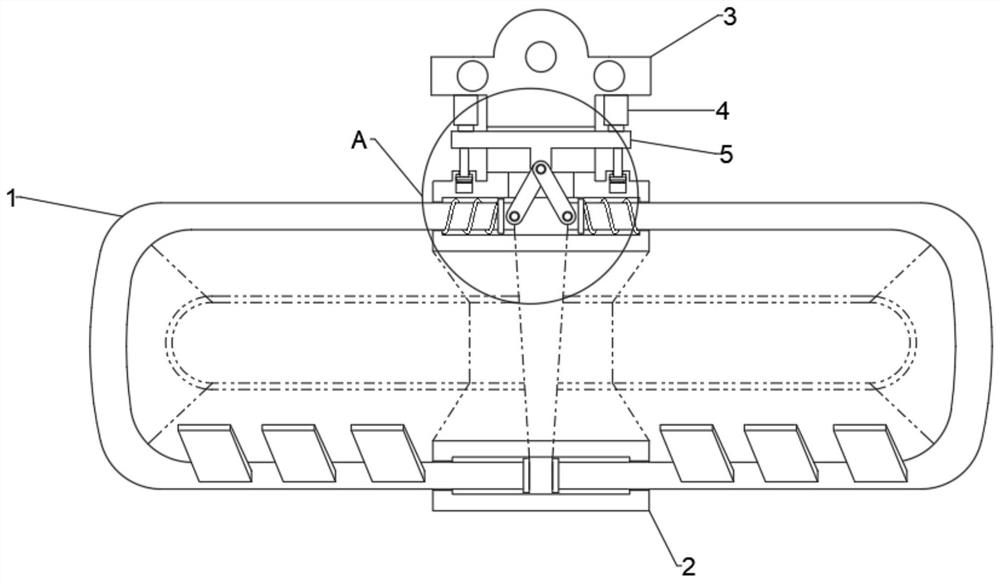

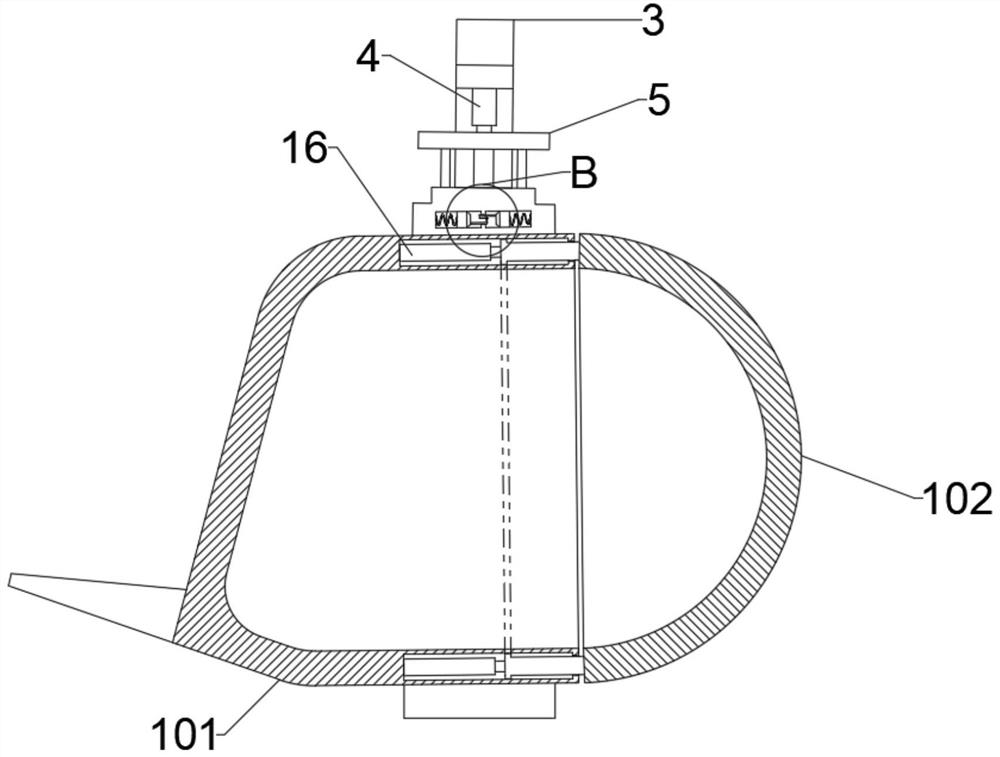

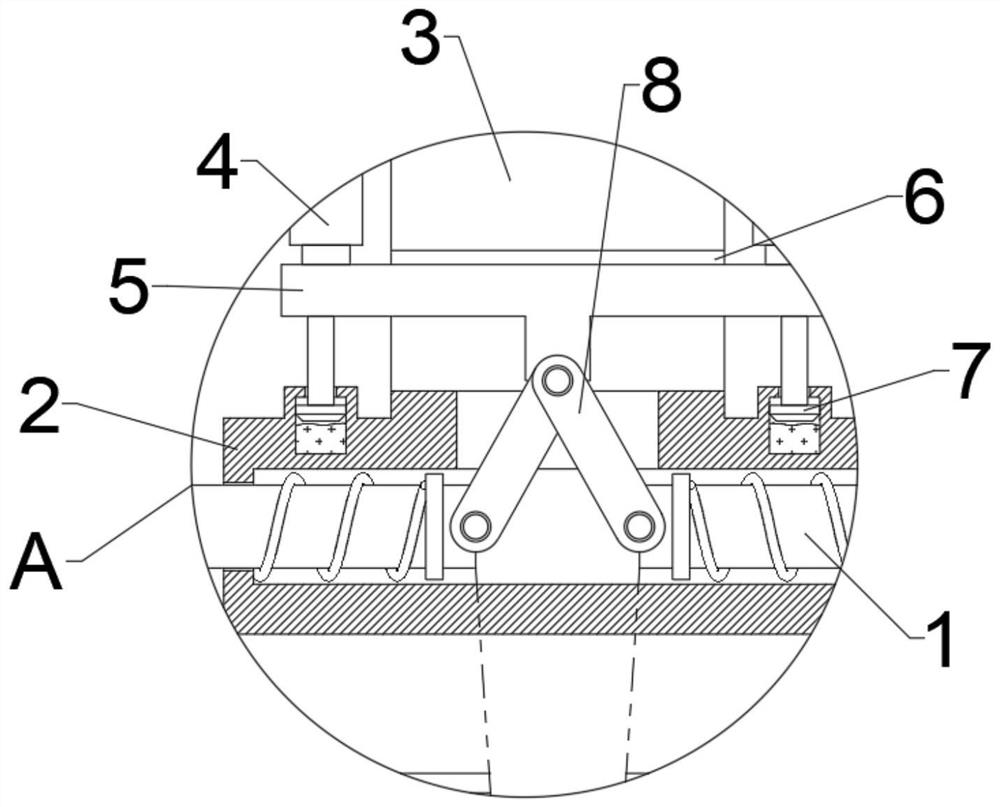

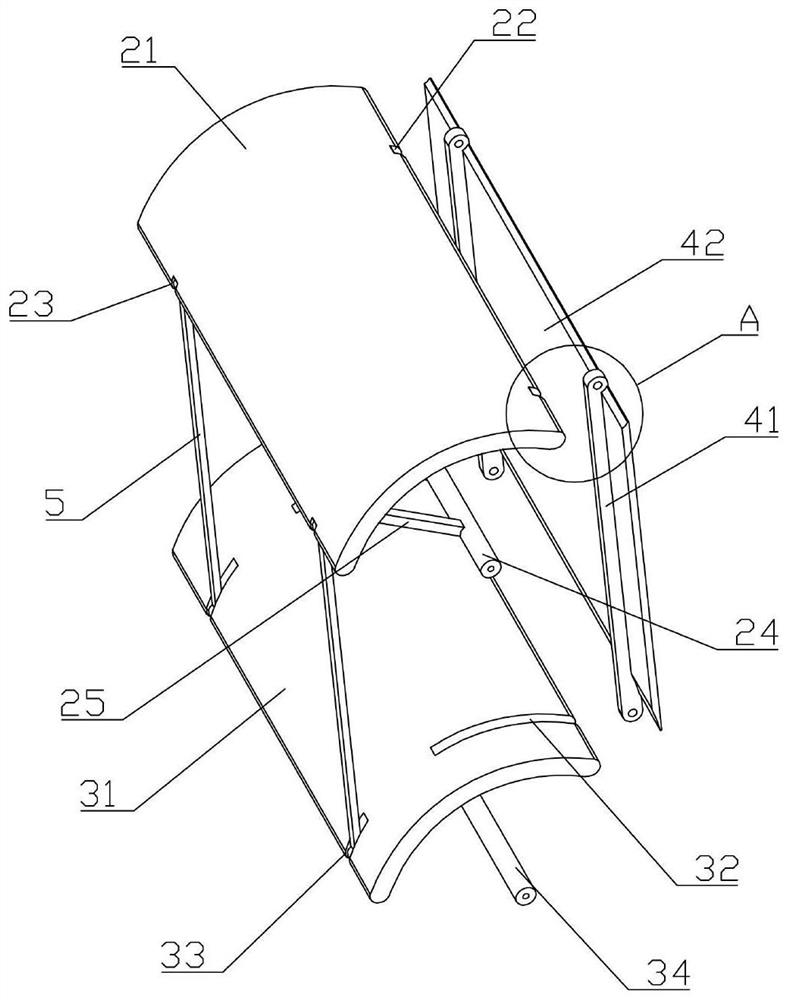

Expandable excavator bucket

InactiveCN112663701AImprove practicalityCapacity adjustmentMechanical machines/dredgersHydraulic cylinderEngineering

The invention relates to the technical field of excavator buckets, in particular to an expandable excavator bucket. The bucket comprises two side buckets and a middle bucket, the side buckets are symmetrically arranged relative to the middle bucket, one ends of the side buckets are inserted into the middle bucket, a connector is fixedly installed on the middle bucket, an expansion driving mechanism is arranged between the connector and the middle bucket and comprises a plurality of symmetrically-arranged hydraulic cylinders and a sliding plate, a sliding groove is formed in the connector, the sliding plate is installed in the sliding groove in a sliding manner, the sliding plate is connected with the connector through the hydraulic cylinders, and the side buckets are elastically connected with the middle bucket. Driving rods are hinged between one ends of the side buckets and the sliding plate; and by arranging expanding mechanisms in the two directions, the situation that a traditional bucket cannot be adjusted is avoided, and the practicability of the bucket is improved.

Owner:郴州市天地青龙工程机械设备有限公司

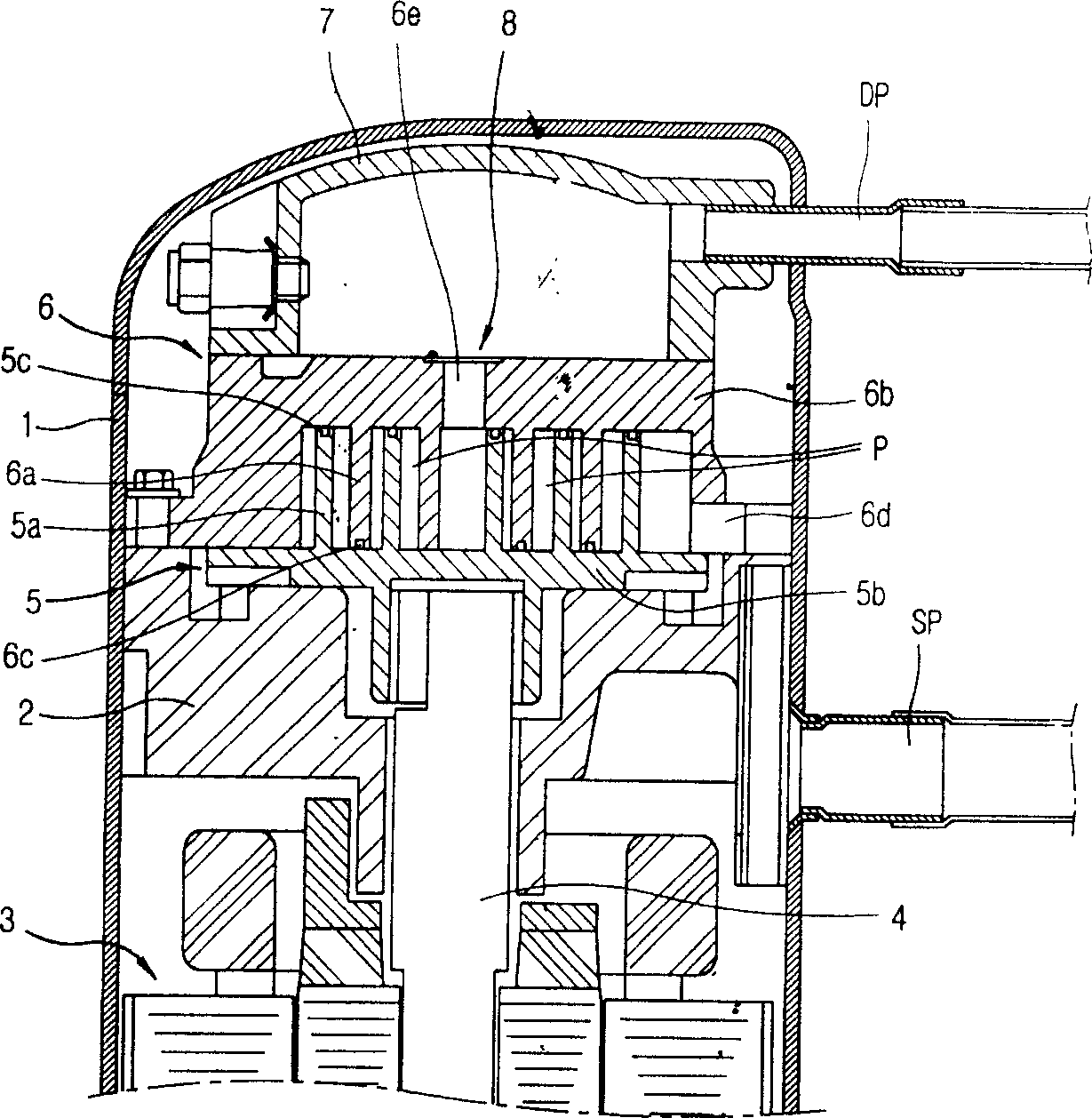

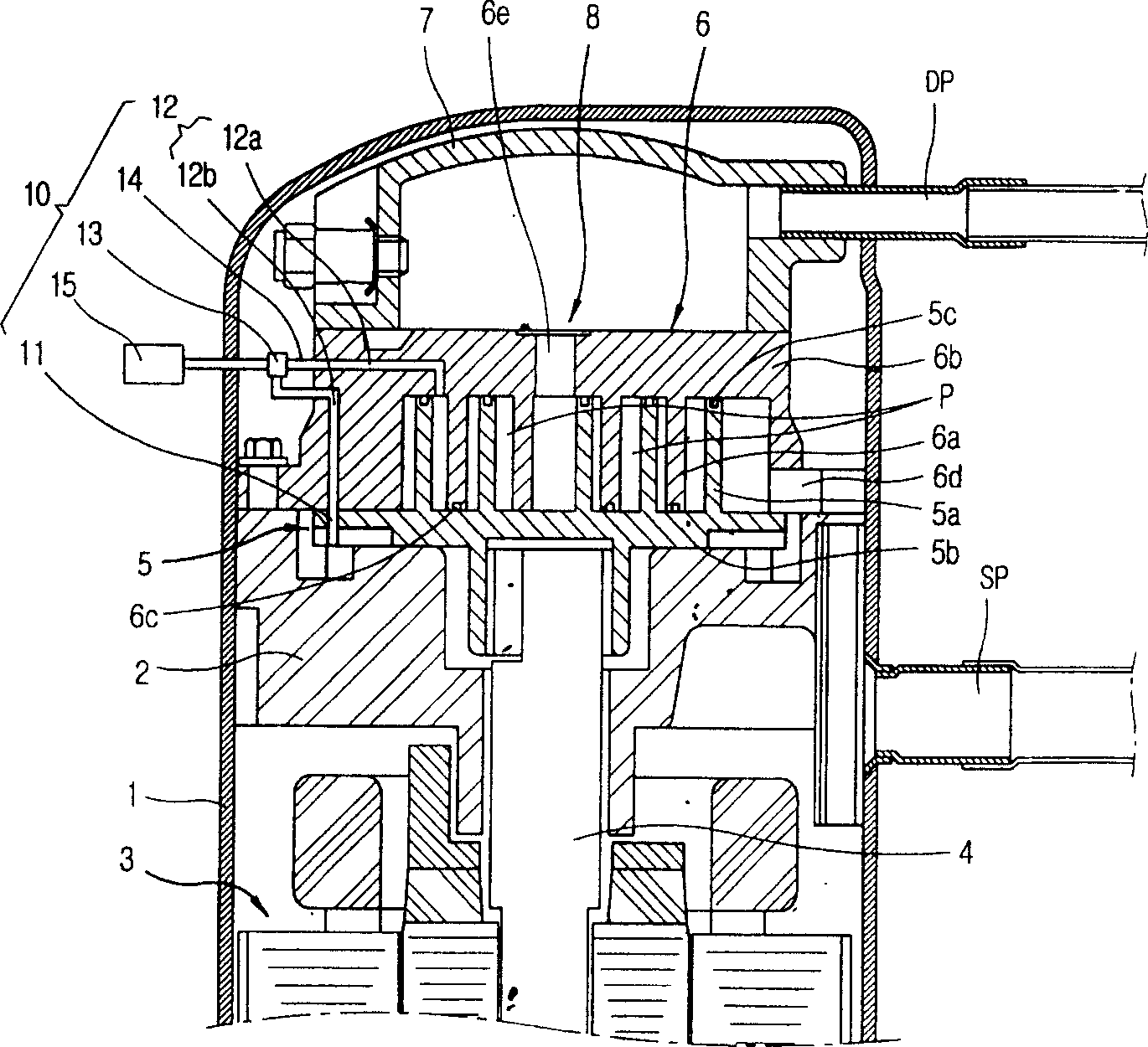

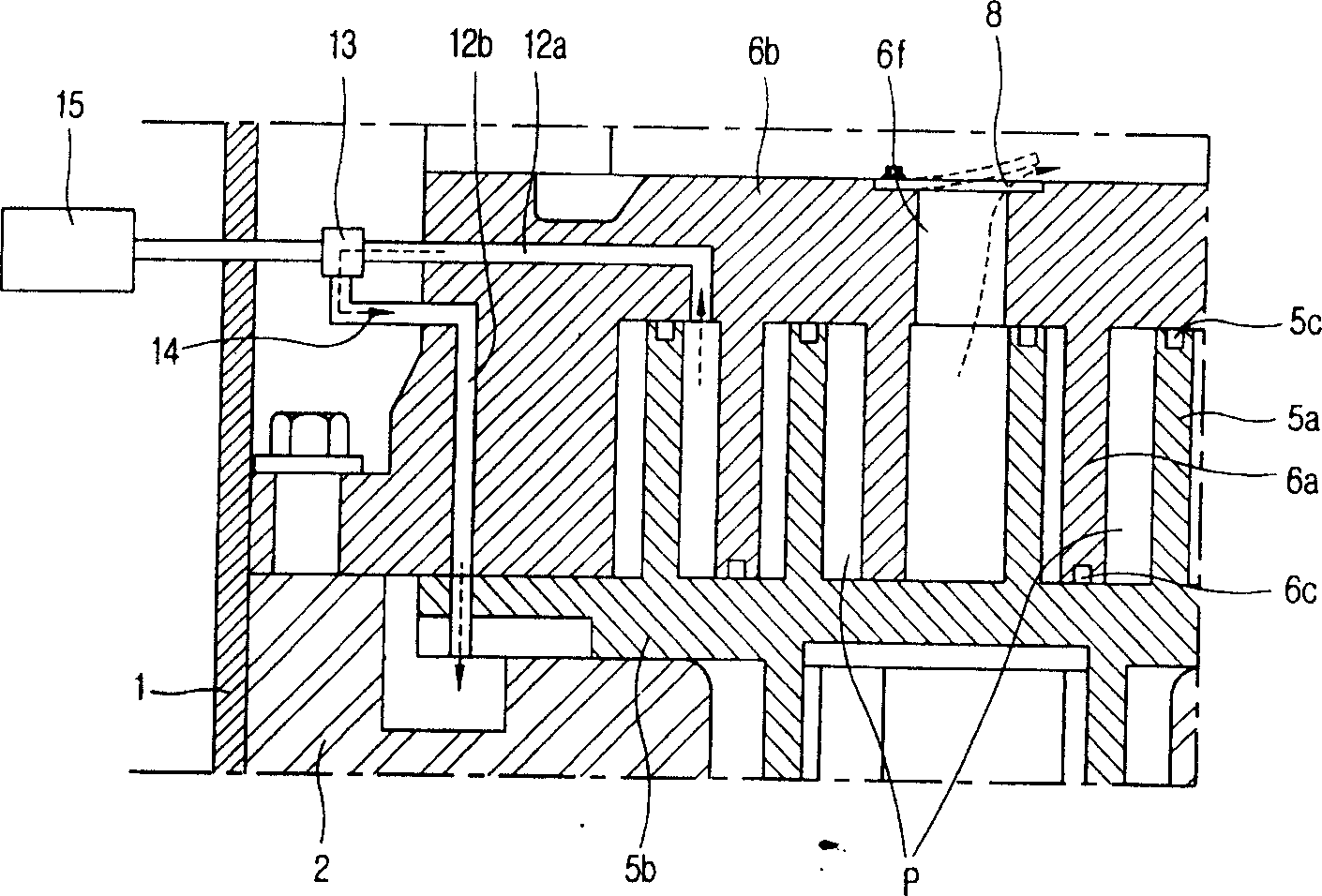

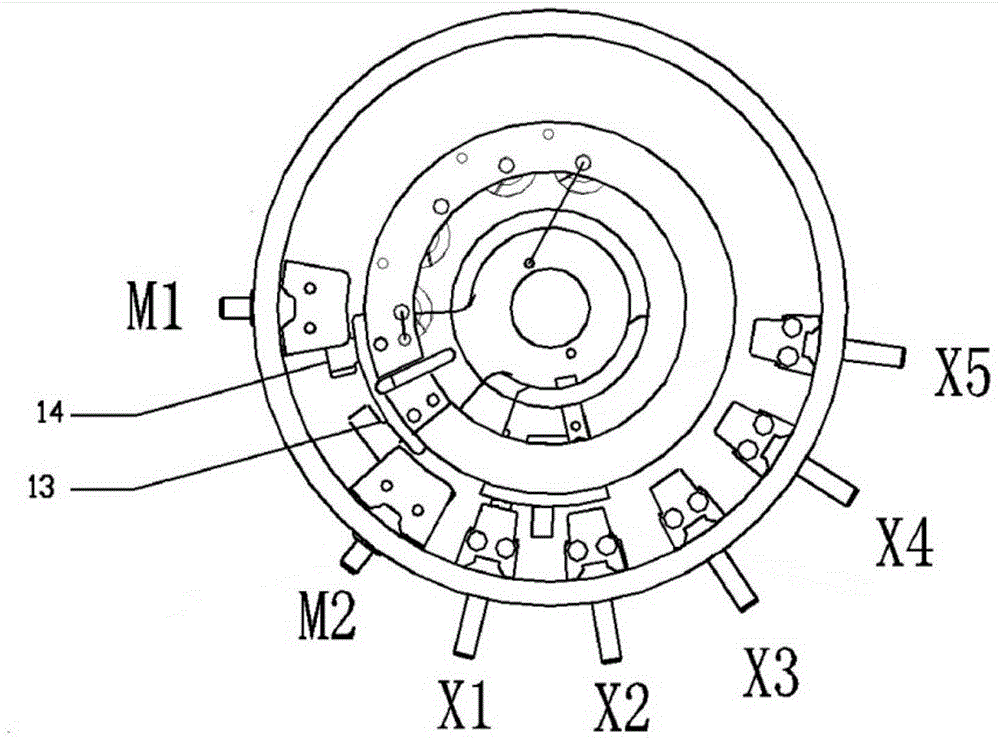

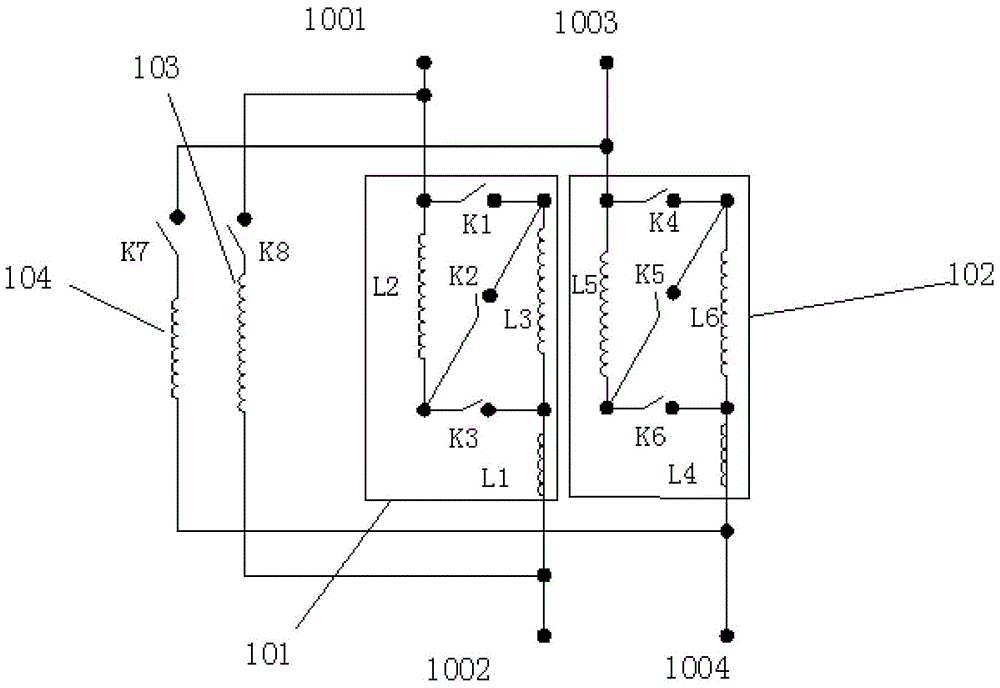

Capacity changing device for vortex type compressor

InactiveCN1566705ACapacity adjustmentRelieve pressureRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention is about a capacity changing device of scroll compressor, comprising a scroll for composing the compressing chamber, a static scroll disk fixed in the casing forming more than one side path from the compressing chamber to the outside; an air exhaust regulating valve arranged in the middle of the fixed side path for switching it; a valve controlling part for controlling the open-close of the air exhaust regulating valve connected to it by wires; and a dynamic scroll disk connected to the electric mechanism formed with a scroll on one side for gearing with the scroll of the static scroll disk to form the compressing chamber and formed with more than one side path for periodically connected to the fixed side path out let. The invention can reduce the manufacturing cost of the scroll compressor with variable capacity.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

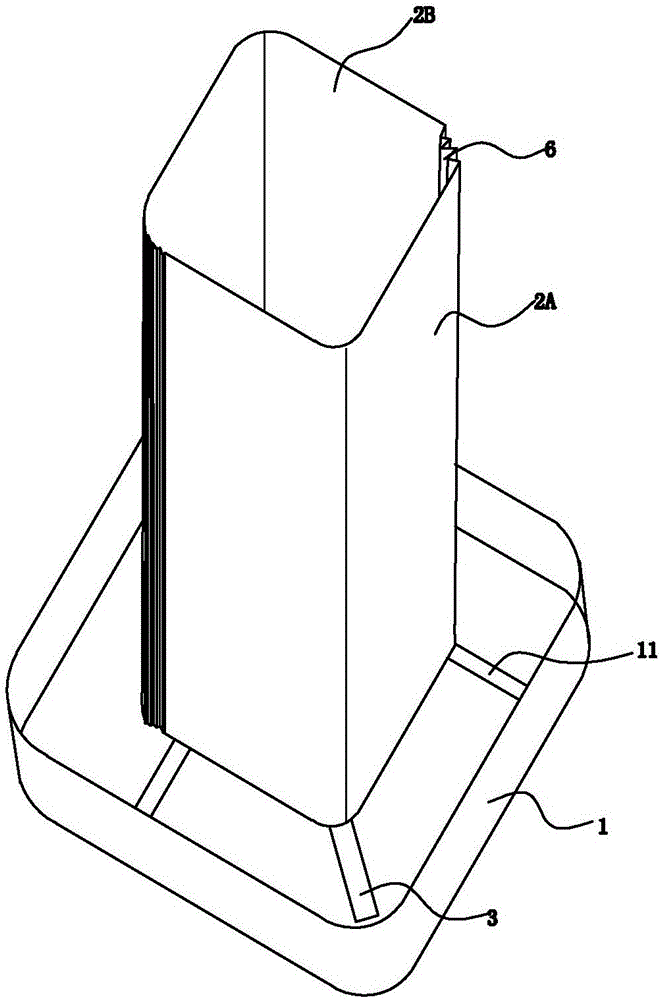

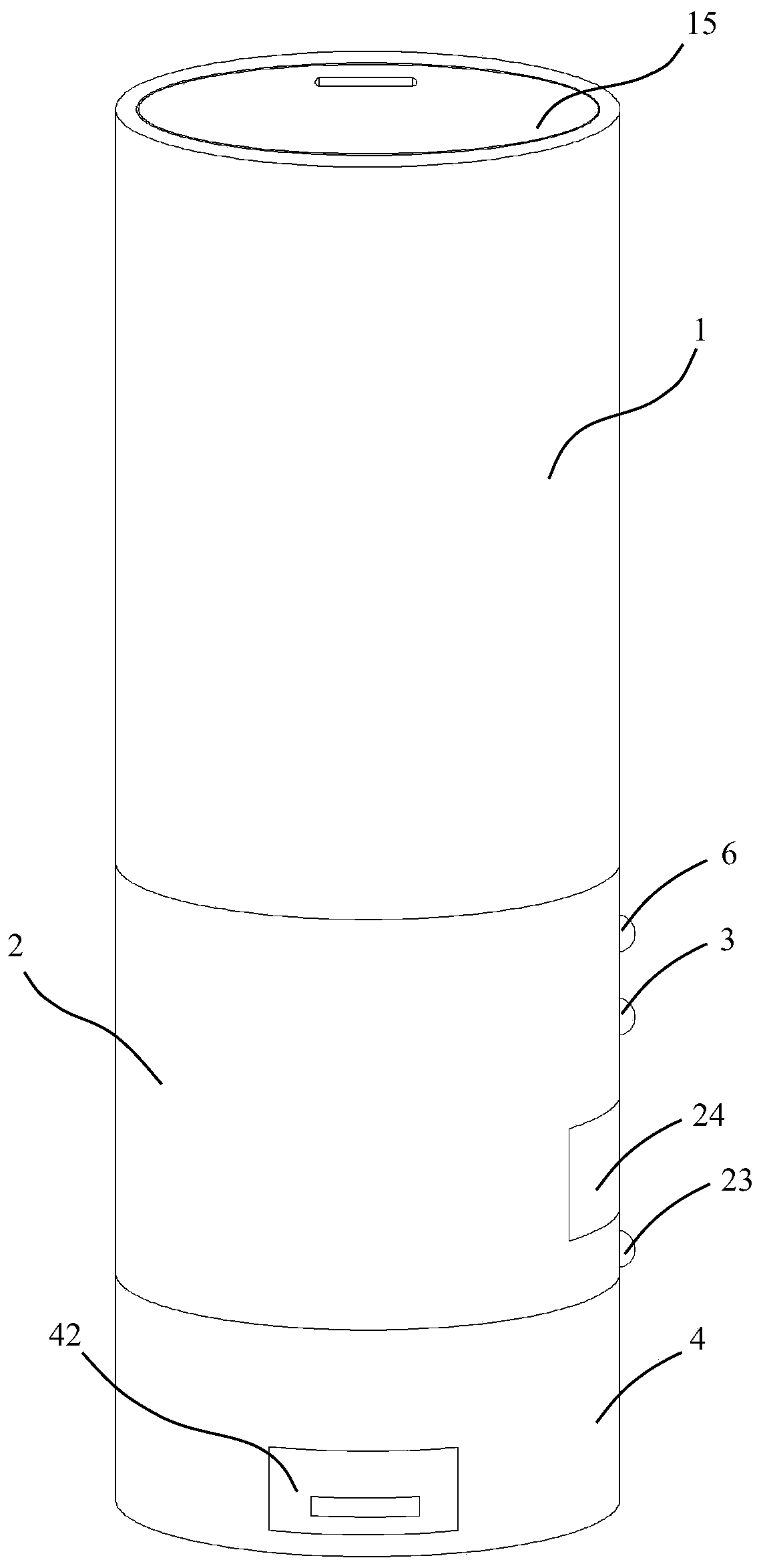

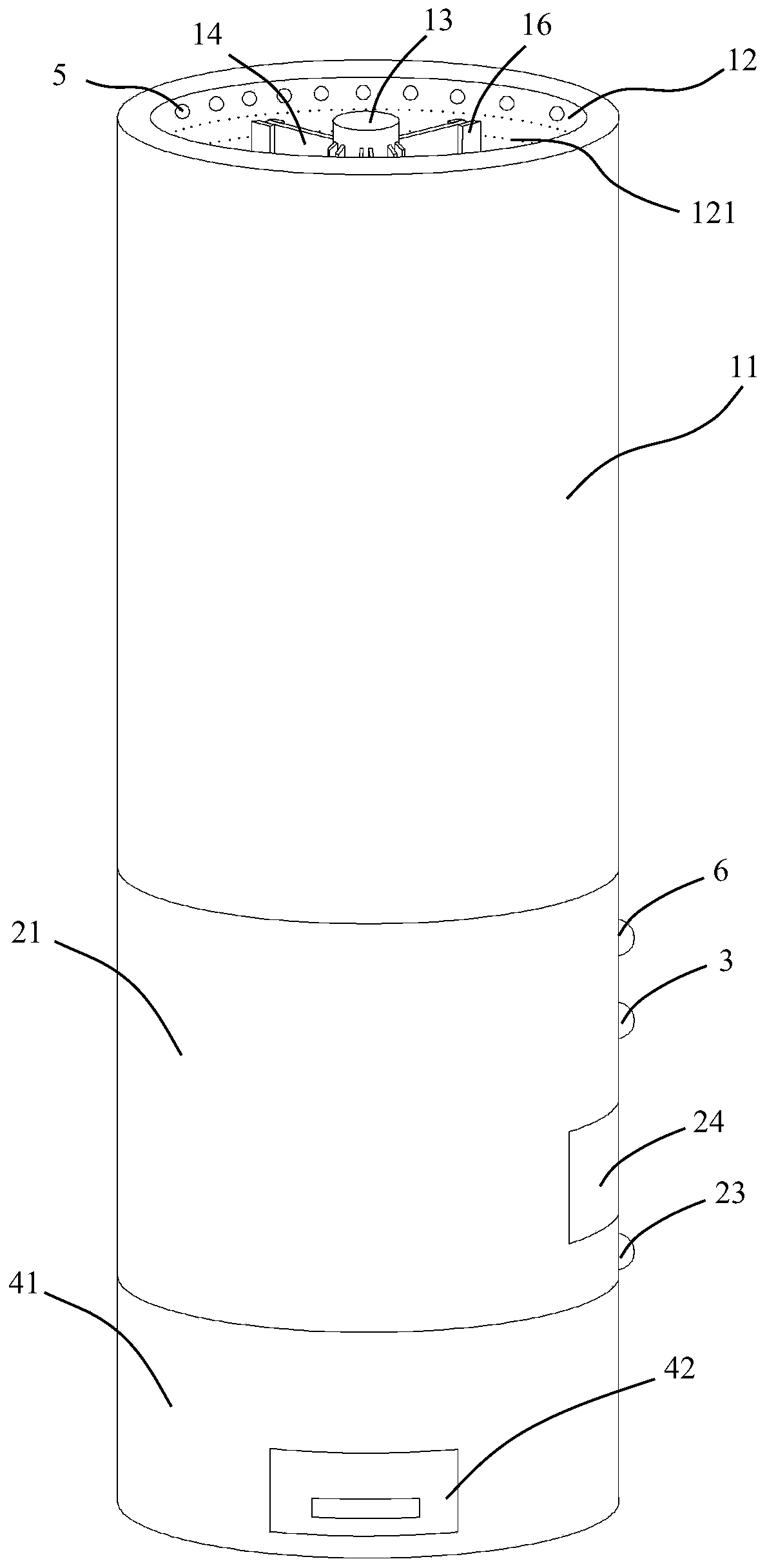

Garbage can with expandable volume

Owner:绍兴市潘珍科技有限公司

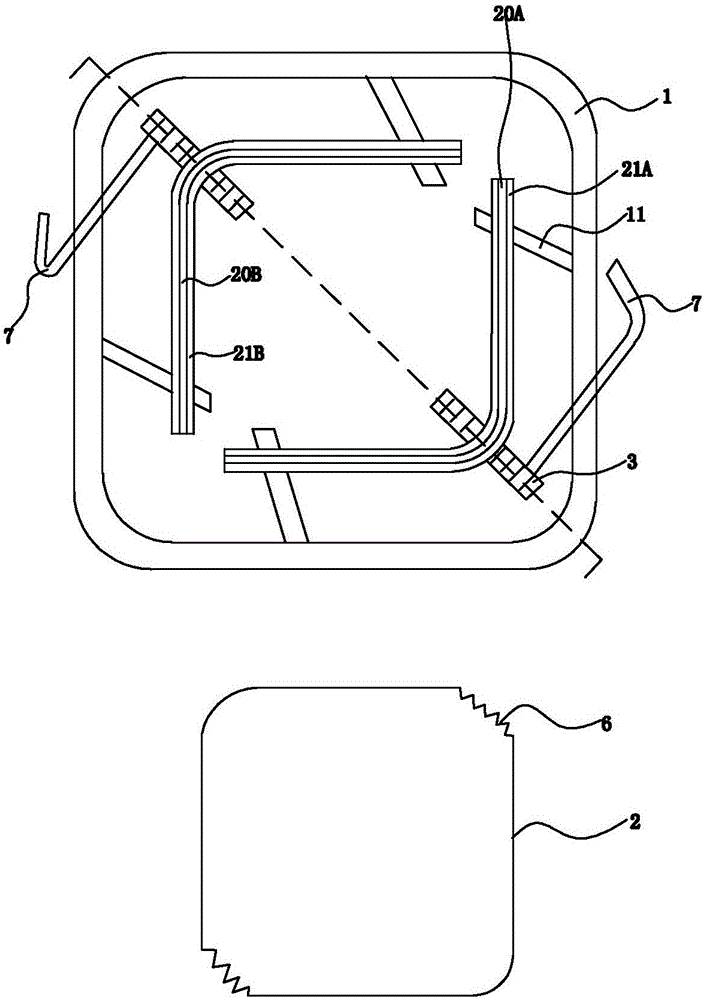

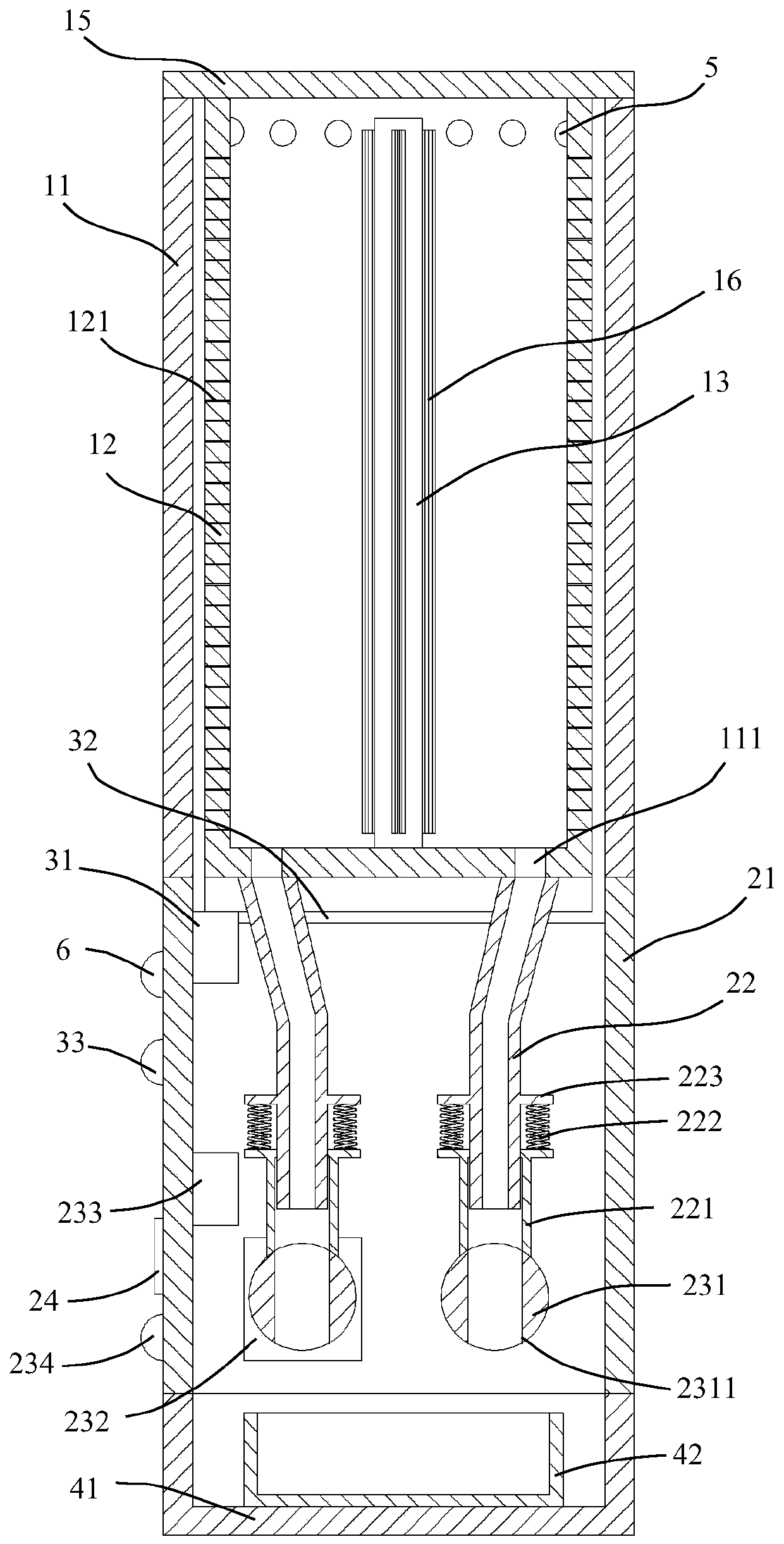

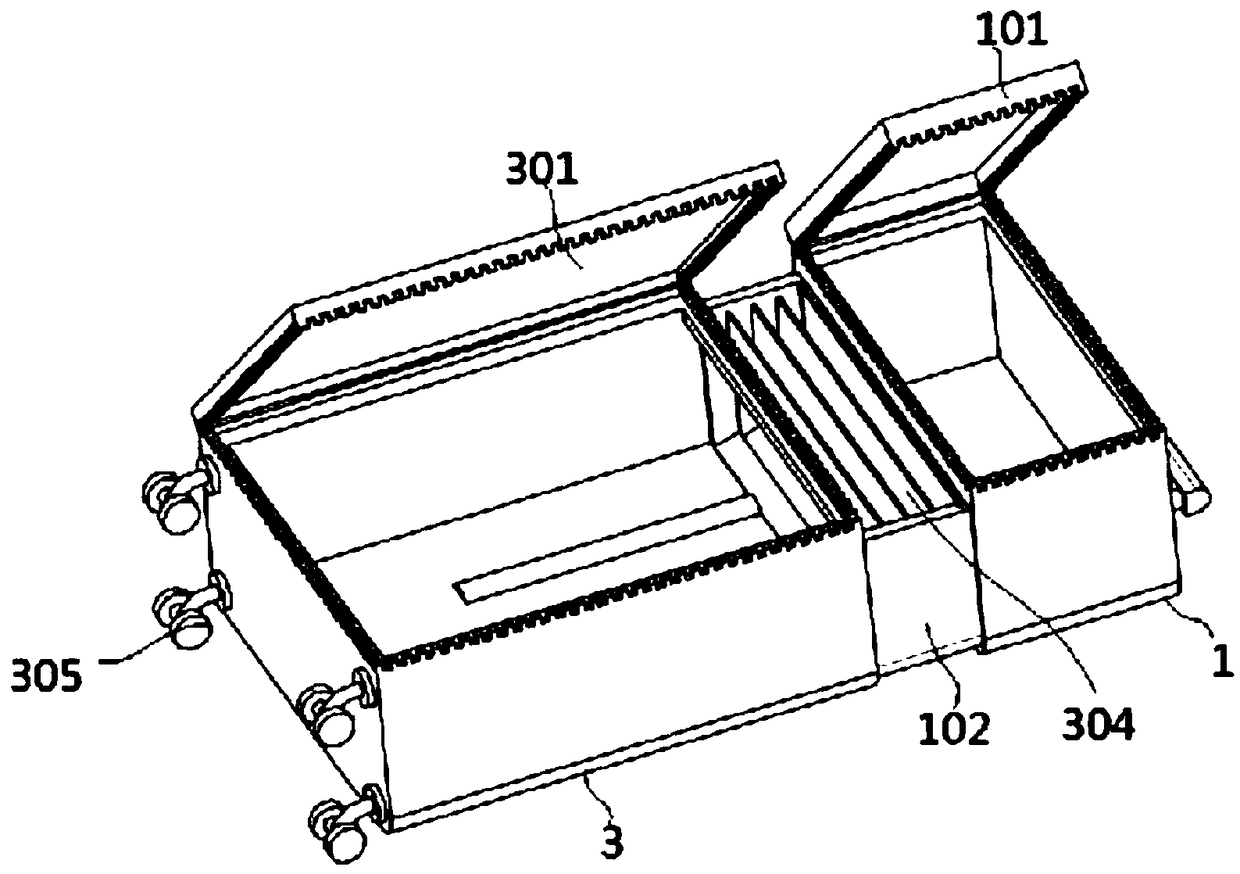

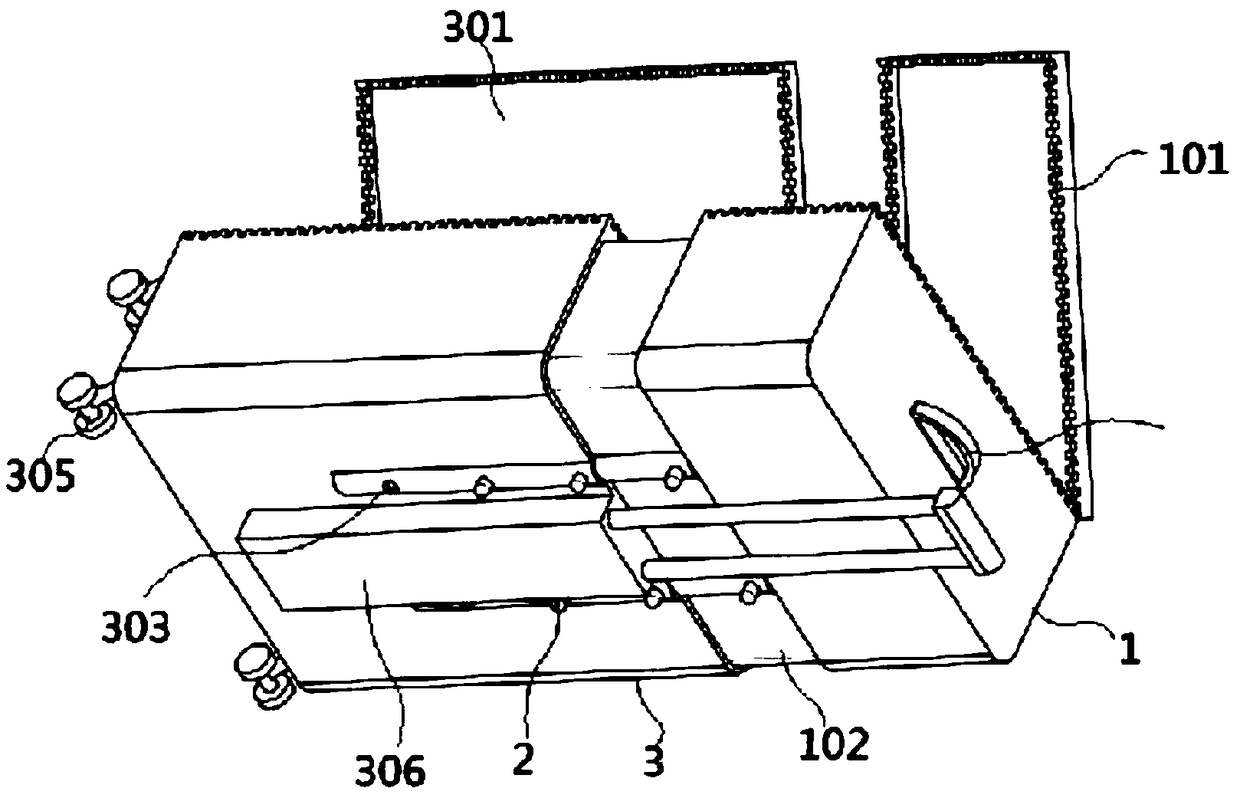

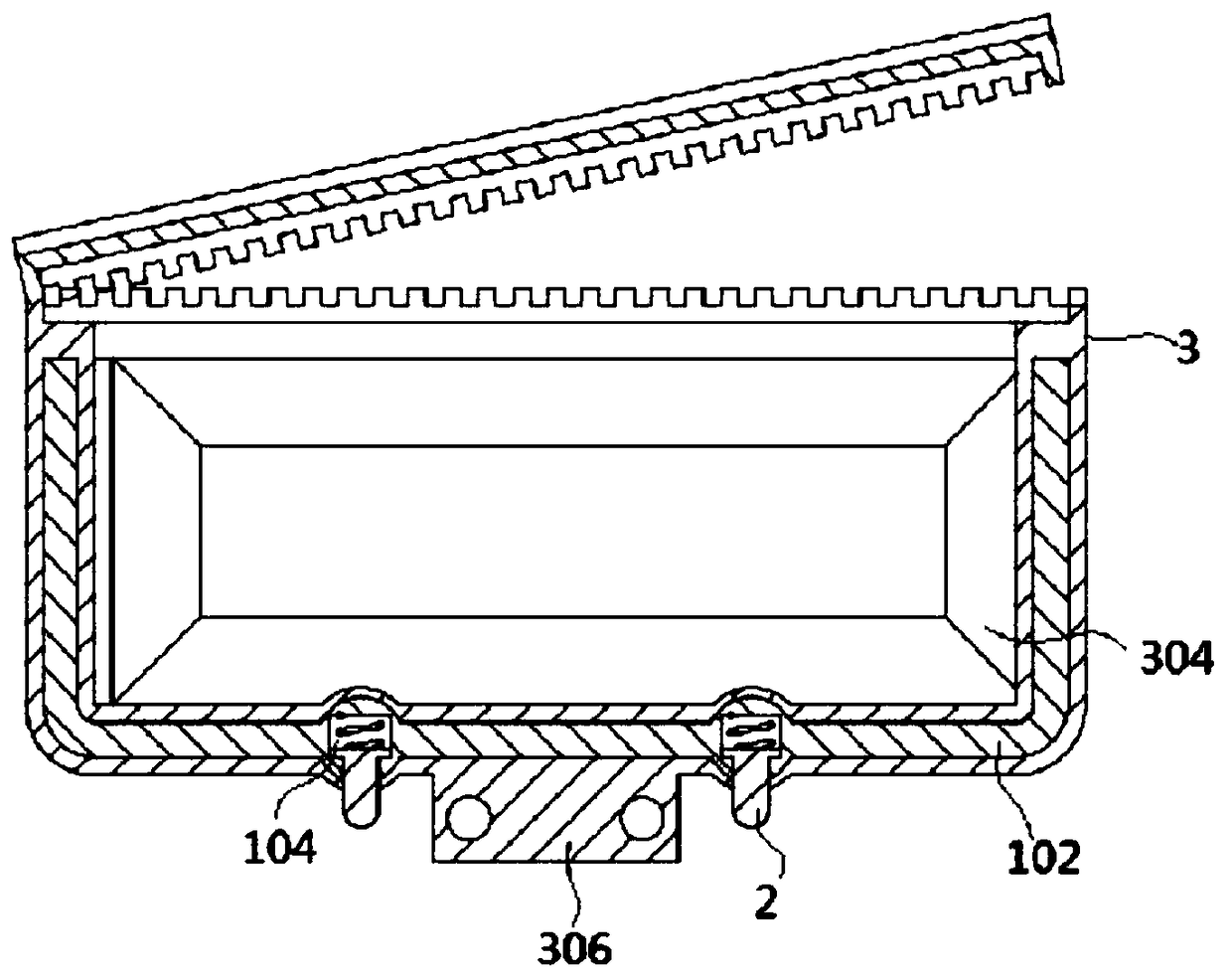

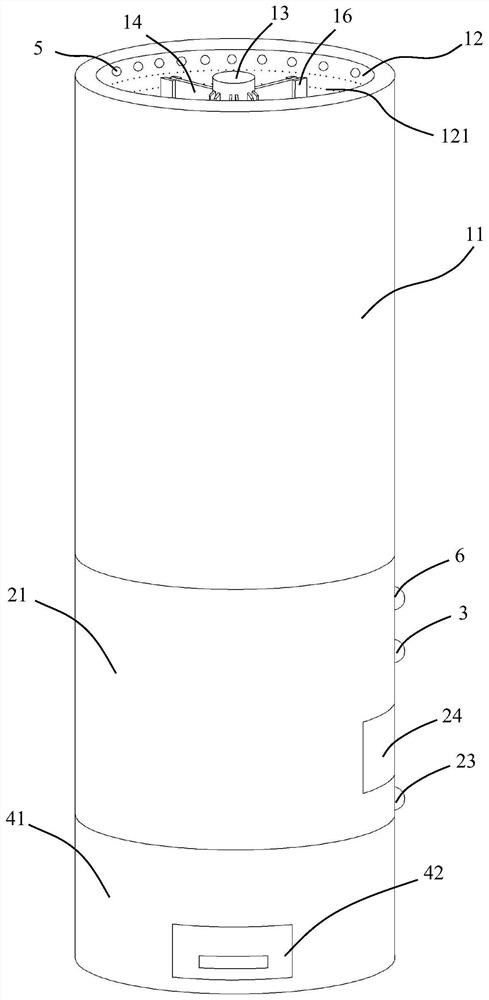

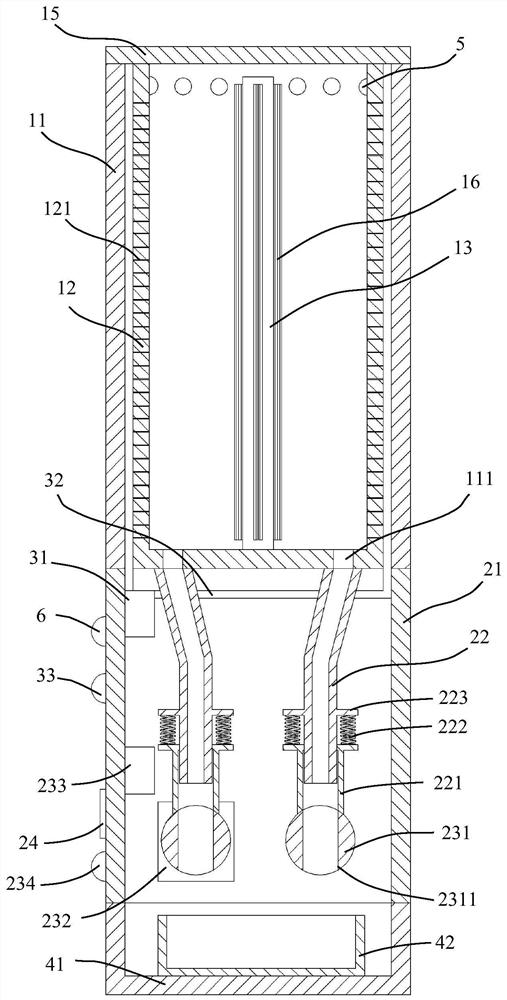

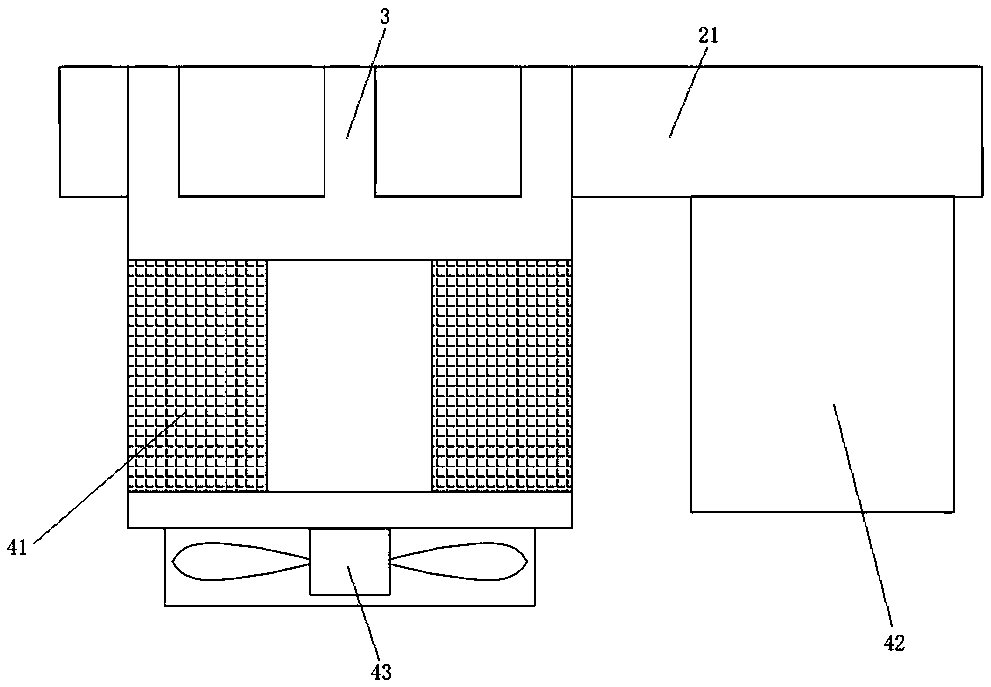

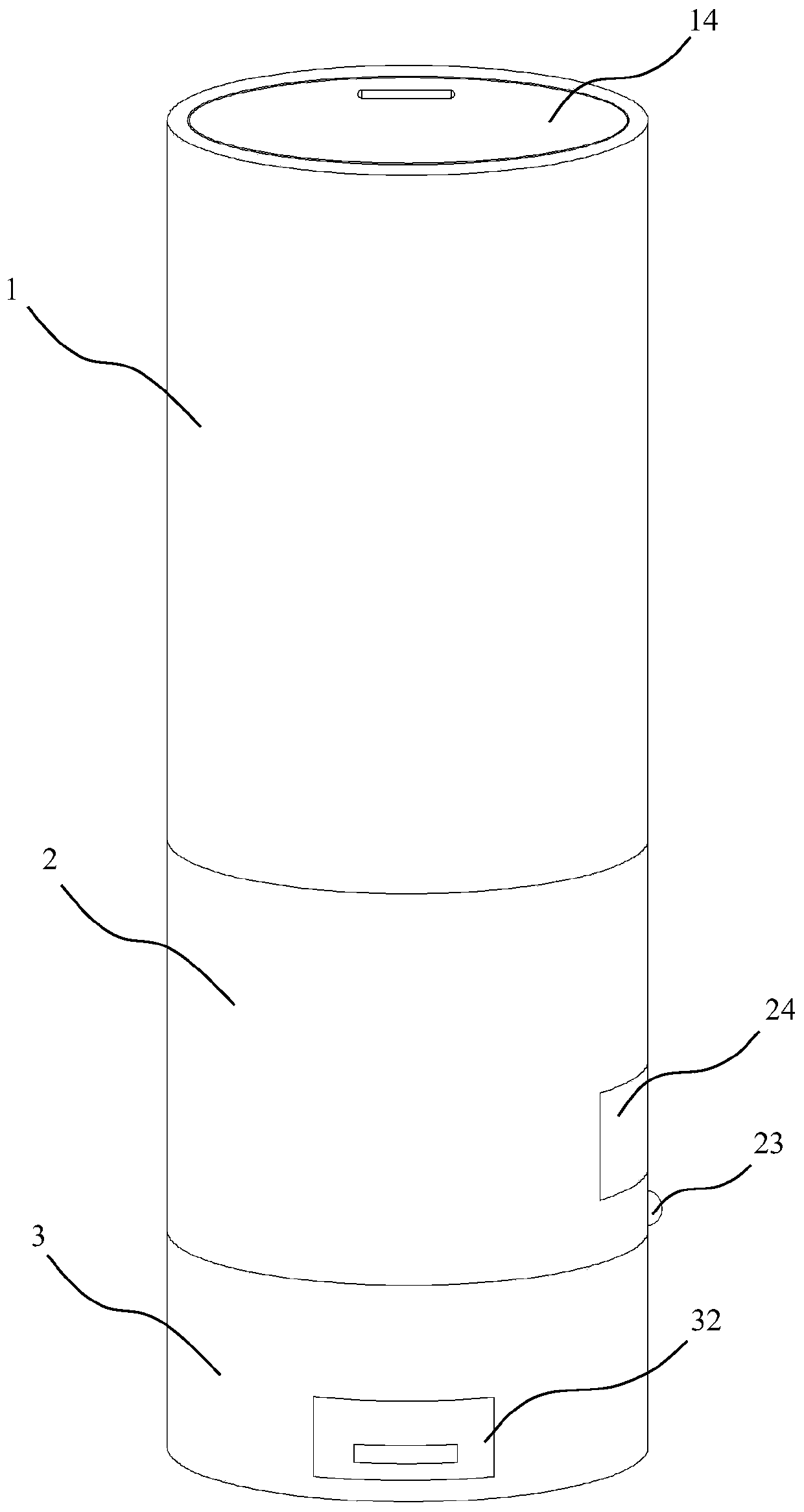

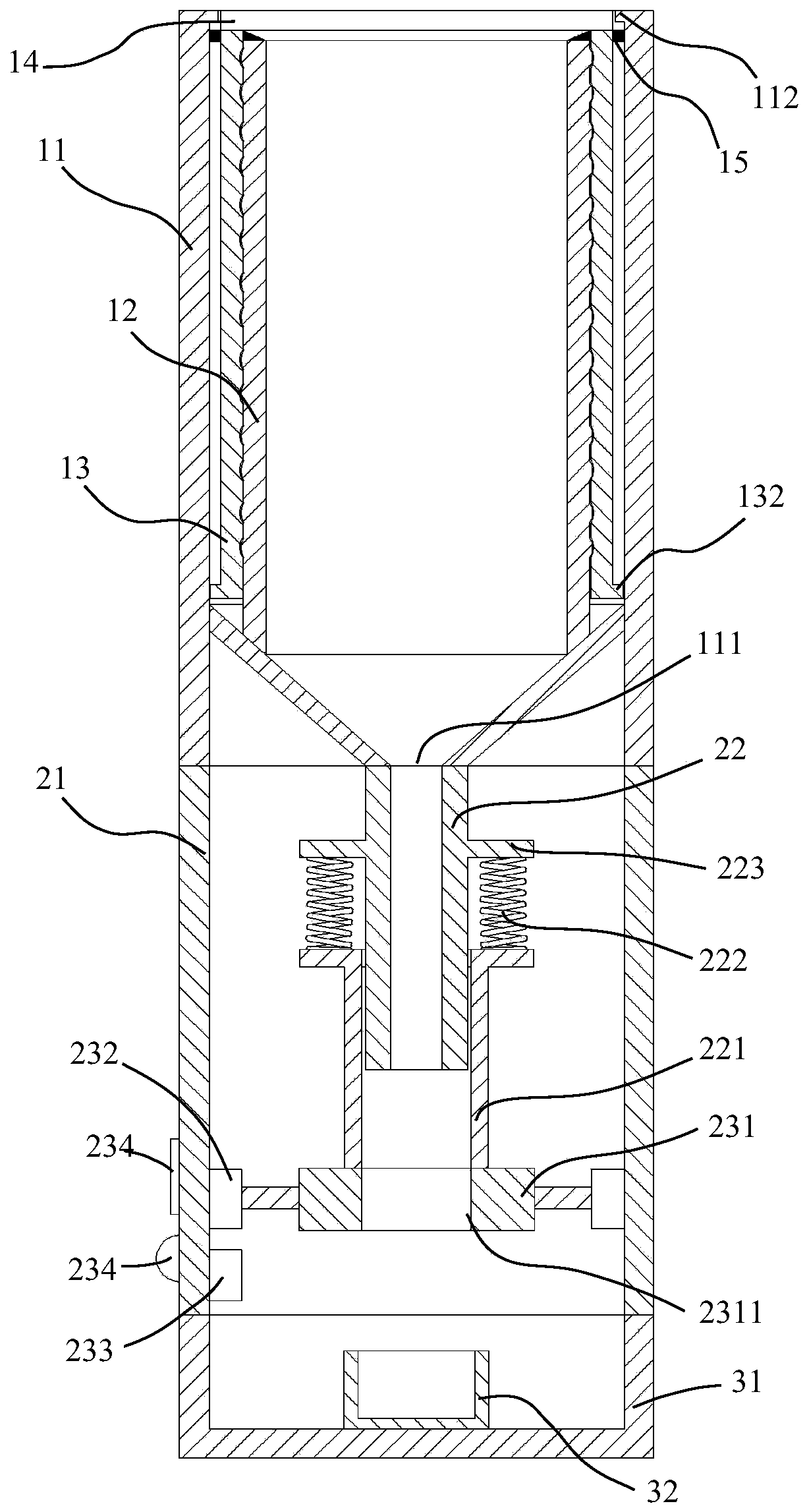

Intelligent rice storage barrel

ActiveCN110606262ARealize automatic rice outputFree adjustment of storage capacityLinings/internal coatingsContainers preventing decayAir pumpEngineering

The invention discloses an intelligent rice storage barrel comprising a rice storage part, a control part, an air supply part and a rice discharge part. The rice storage part comprises an outer barrel, an inner barrel, a stand column, insertion plates and a cover body. The control part comprises an enclosing plate, rice discharge pipes and an electronic control assembly. The air supply part comprises an air pump and an air pipe. The rice discharge part comprises a bottom box and a drawing box. According to the intelligent rice storage barrel, by regulating the insertion plates, the volume-adjustable multi-rice-bin function is achieved, various different types of grain can be stored in the rice storage barrel at the same time, and meanwhile, the storage capacity for the various types of grain can be freely regulated according to requirements; meanwhile, by means of control of the air supply part, ventilation treatment can be conducted on the inner portion, and the moisture prevention and insect prevention effects are good; and by means of control of the electronic control assembly, automatic rice discharge can be achieved for the different types of grain, the automation degree and the intellectualization degree are high, and use is convenient.

Owner:ZHEJIANG NORMAL UNIVERSITY

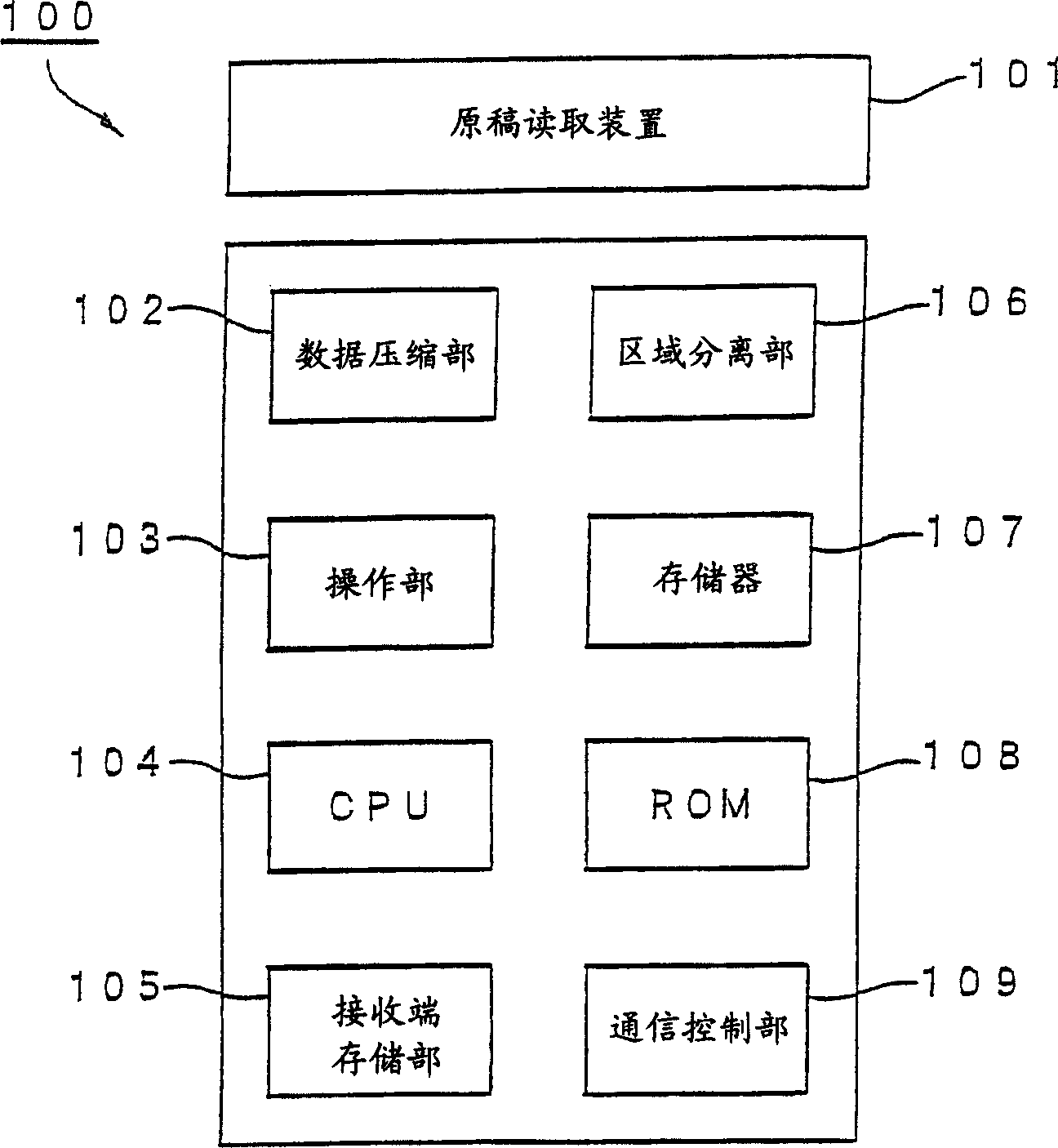

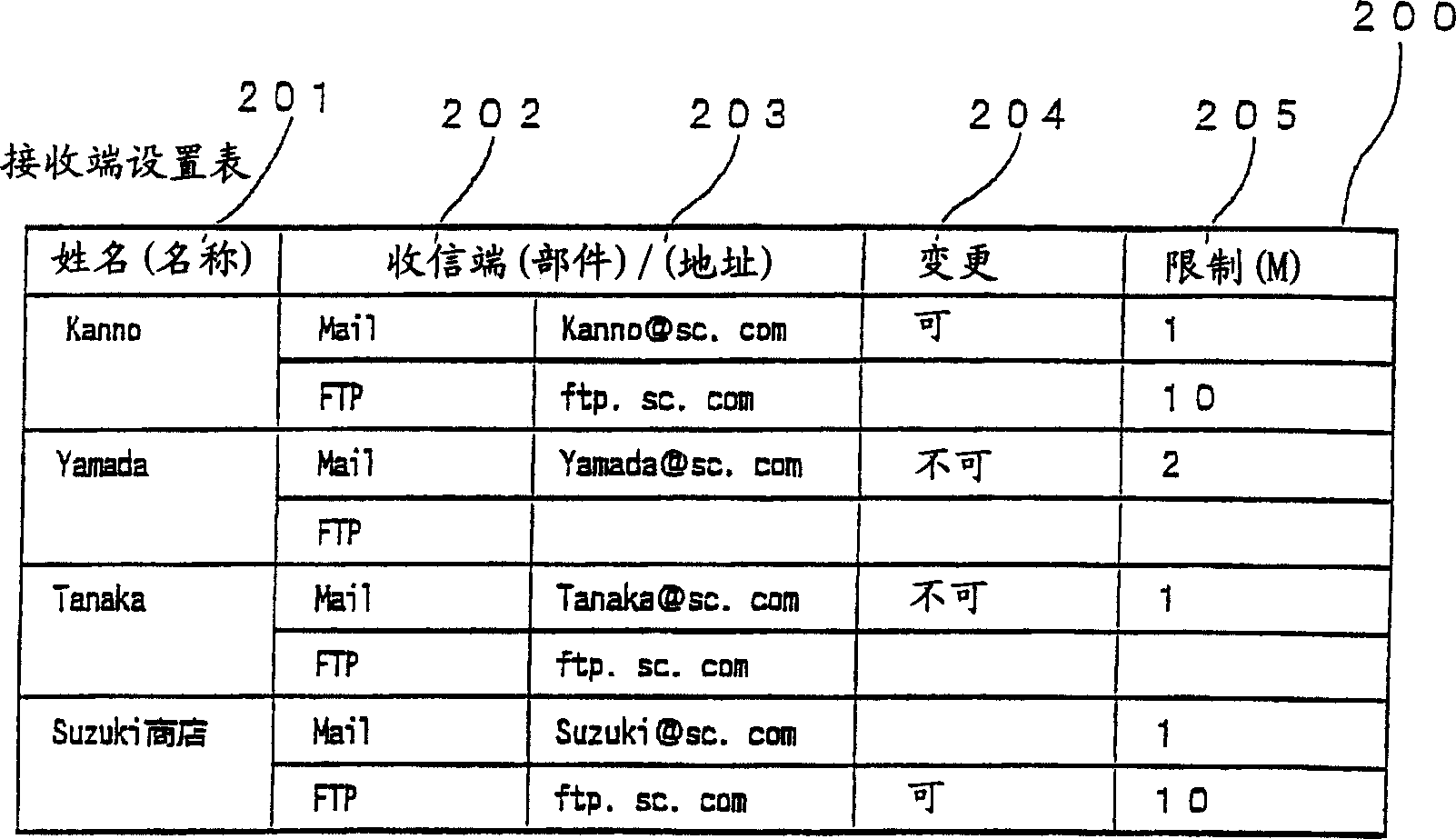

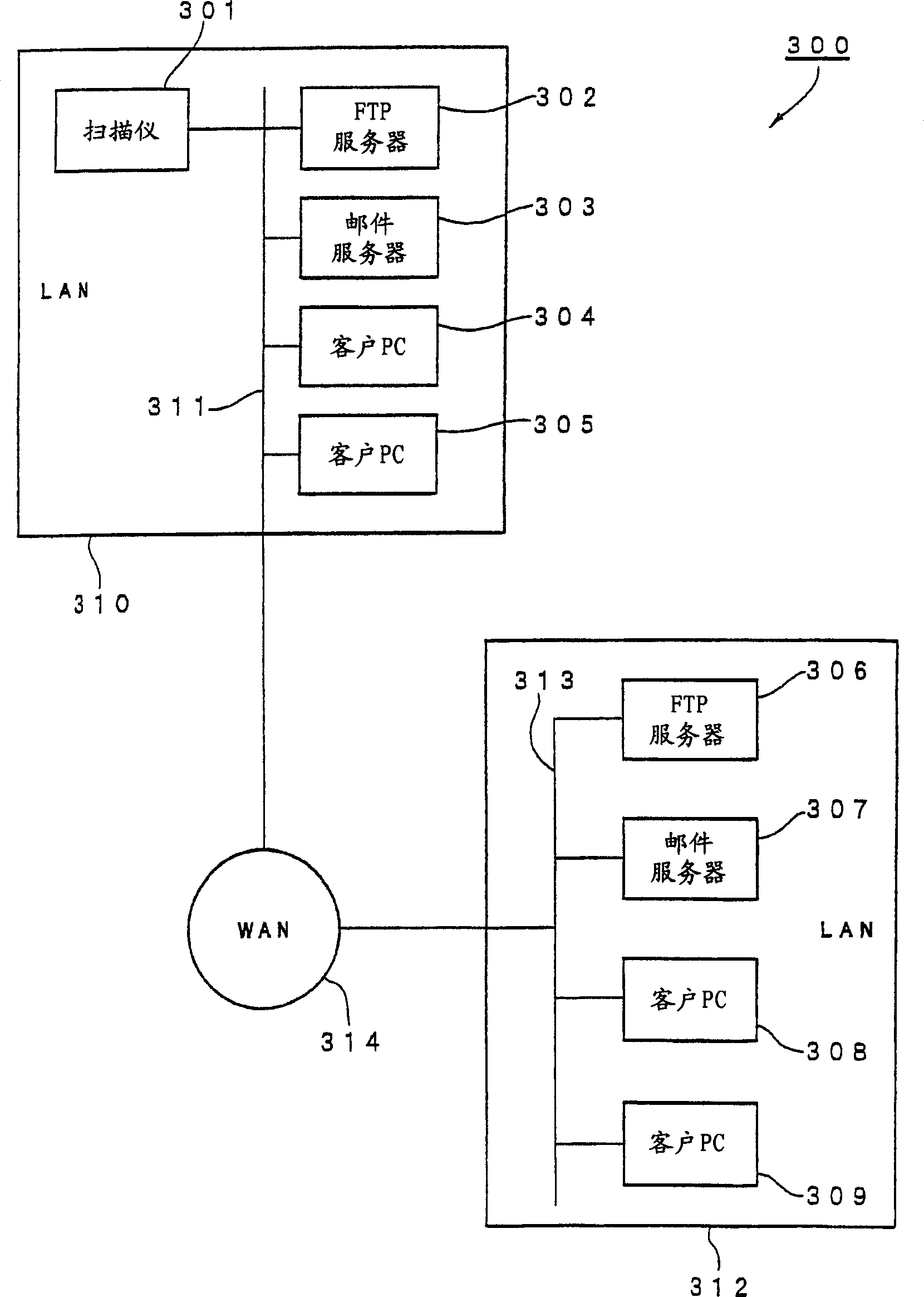

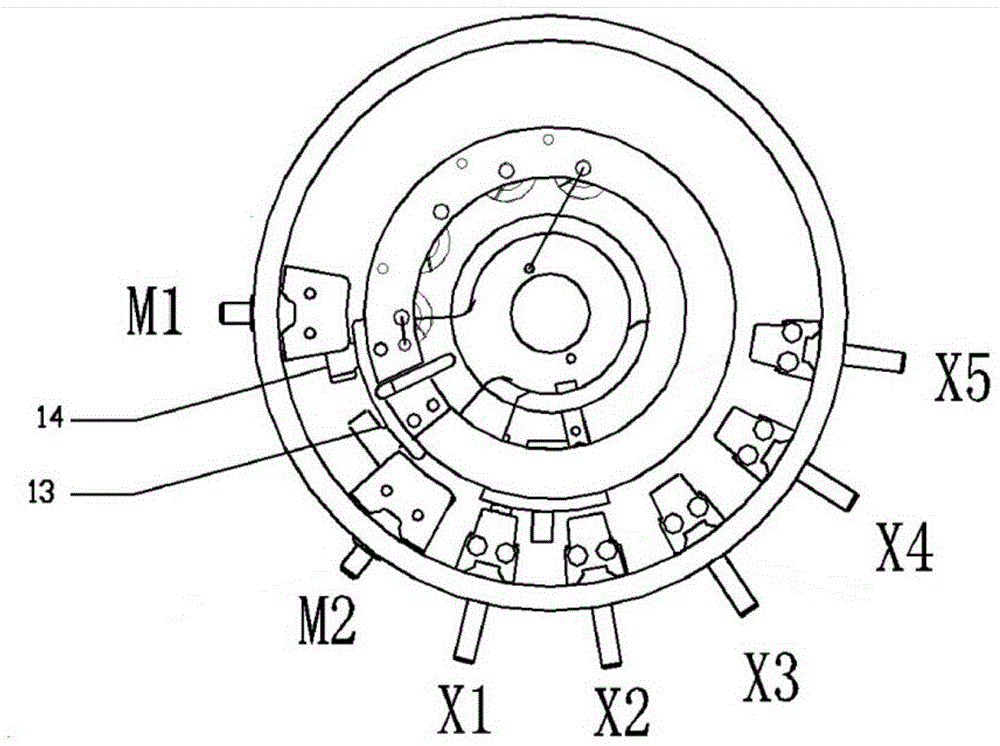

Reading data transmitting apparatus

InactiveCN1507260ACapacity adjustmentImprove data compression ratioPictoral communicationComputer hardwareData compression

An apparatus for transmitting read data comprises a document reader 101, a data compression unit 102, a data transmission means and a CPU 104. The document reader 101 reads in a document having been subjected to predetermined data processing. The data compression unit 102 performs compression of the read data with a designated file format. The CPU 104 checks the limitation on transmission capacity set in advance for each data transmission means. When the volume of data compressed for transmission falls within the limited range of transmission capacity set for the data transmission means, the read data is transmitted to a destination designated by the user via the data transmission means designated by the user.

Owner:SHARP KK

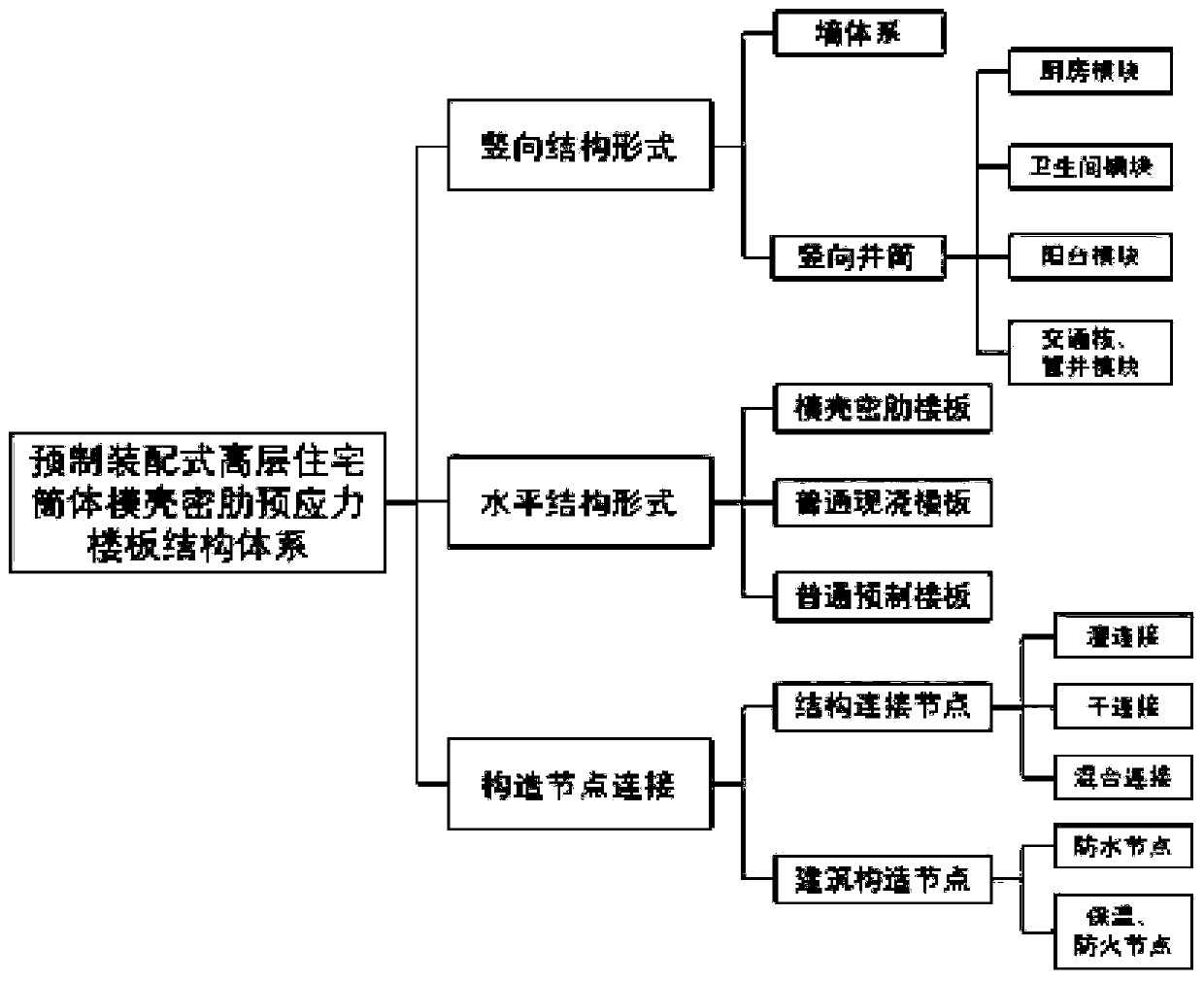

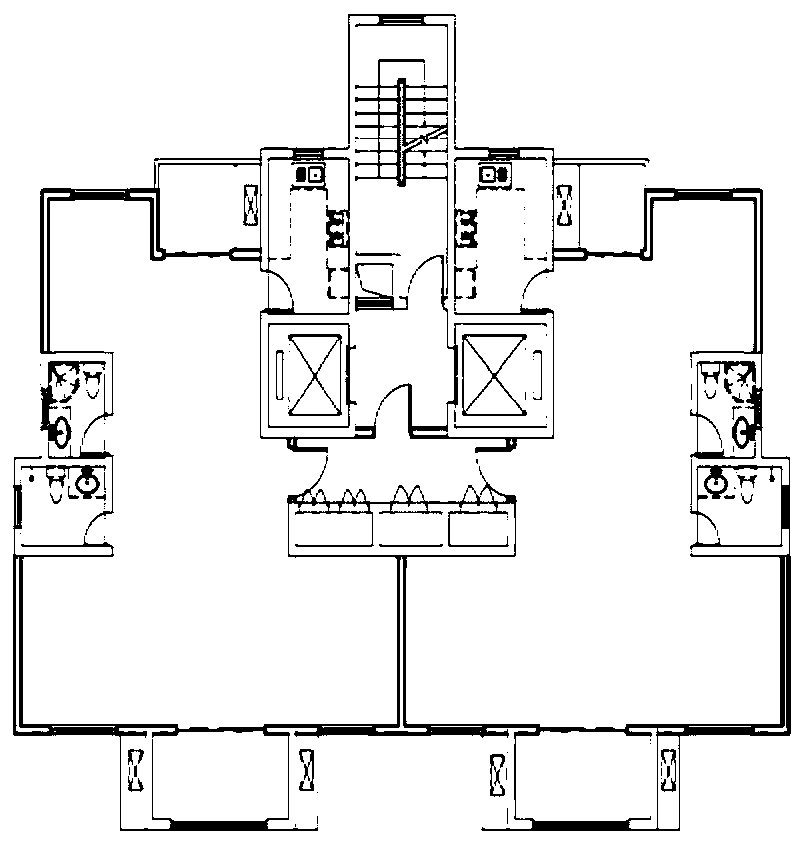

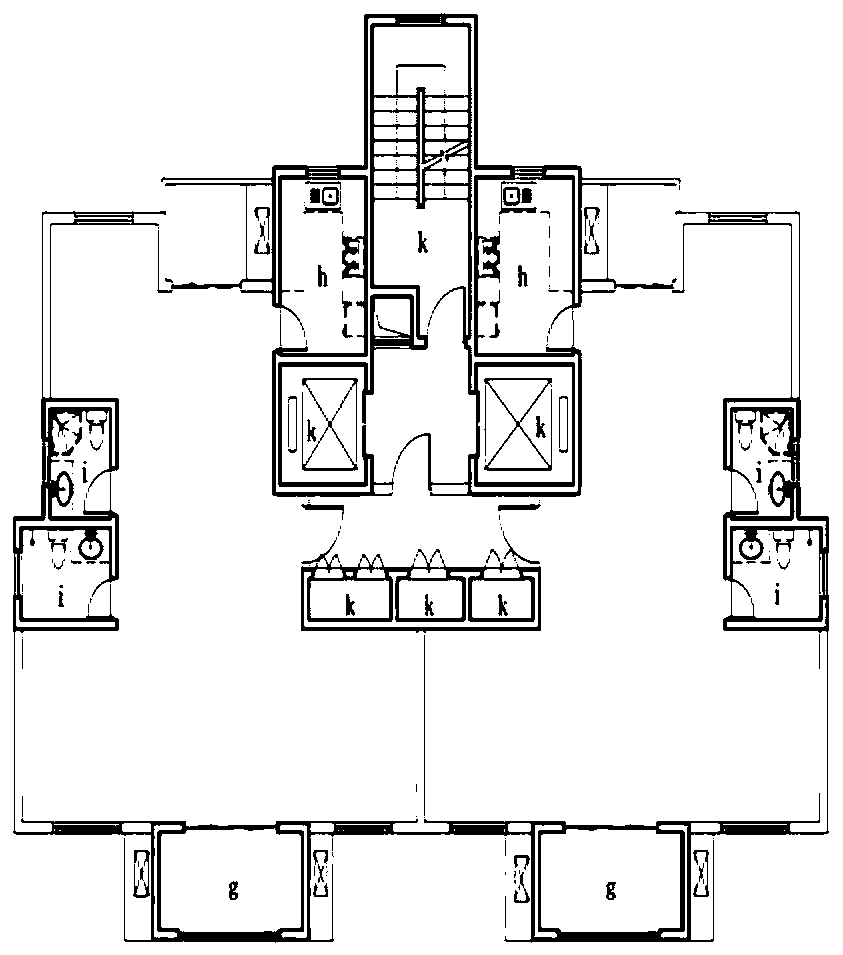

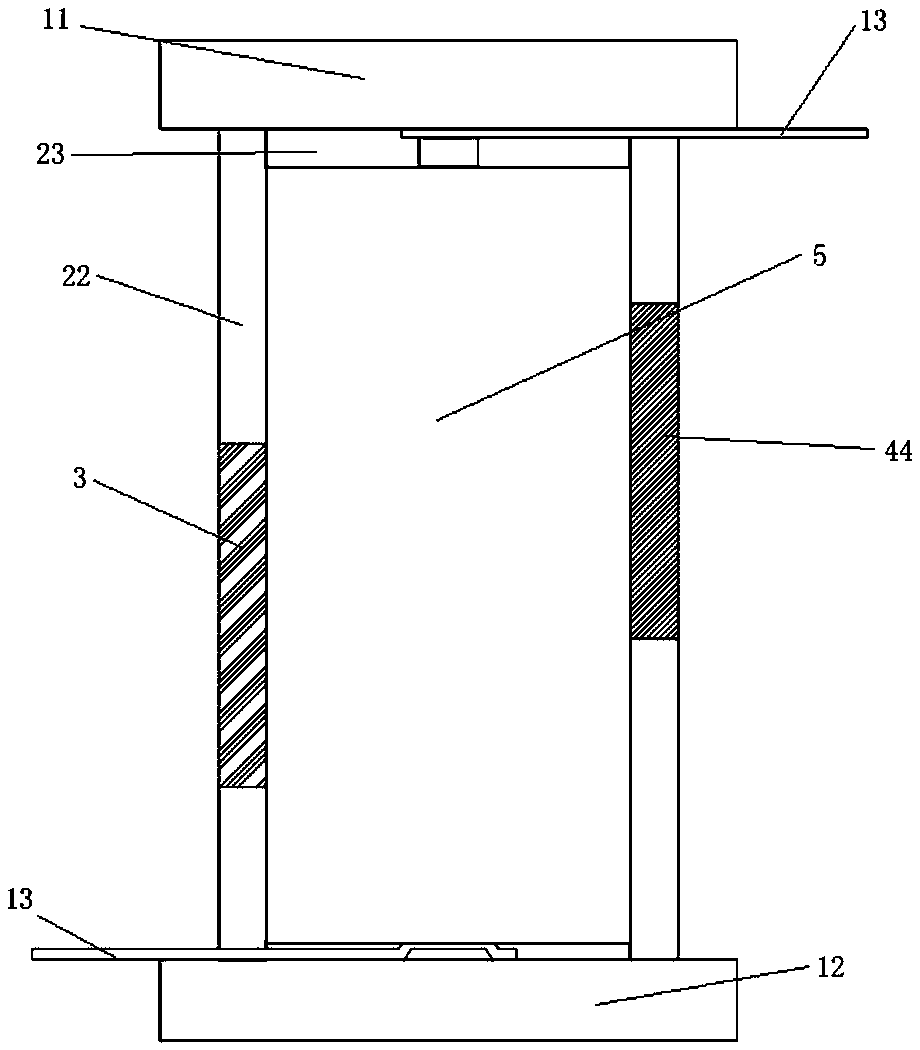

Prefabricated type high-rise residential barrel shuttering dense-rib prestressed floor structure system

PendingCN110565987AIncrease variety richnessIncrease production capacityFloorsDwelling buildingReinforced concreteRebar

The invention relates to a prefabricated type high-rise residential barrel shuttering dense-rib prestressed floor structure system. The prefabricated type high-rise residential barrel shuttering dense-rib prestressed floor structure system is characterized by involving a vertical barrel structure, horizontal floor structures and construction connection nodes, wherein the construction connection nodes comprise a structural connection point and a building construction node, the vertical barrel structure is connected with the horizontal floor structures through the construction connection nodes together to form a high-rise residential building overall structure. The prefabricated type high-rise residential barrel shuttering dense-rib prestressed floor structure system has the beneficial effects that a barrel shuttering dense-rib prestressed floor structure system is adopted, the variety richness of prefabricated components can be improved, the industrial chain of prefabricated component products is prolonged, and the production efficiency of the prefabricated high-rise residential industry is improved; and the number of a reinforced concrete shear wall can be reduced, and conditions are created for various requirements of a functional room in an unit, so that a user can flexibly arrange and use the room according to the requirements of the user on the premise that the structural components are not damaged or changed by the user.

Owner:TIANJIN CHENGJIAN UNIV

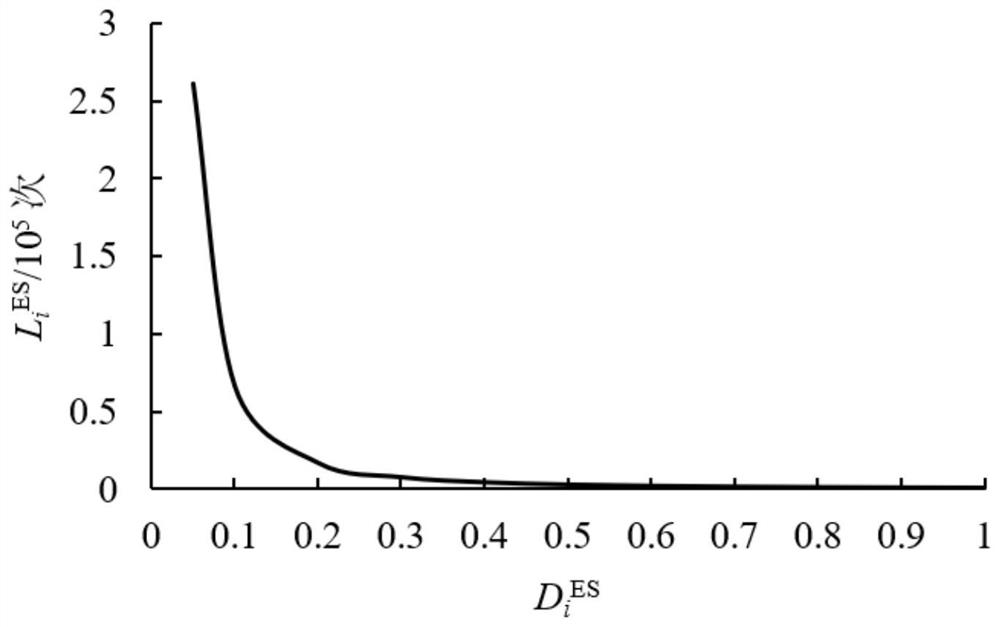

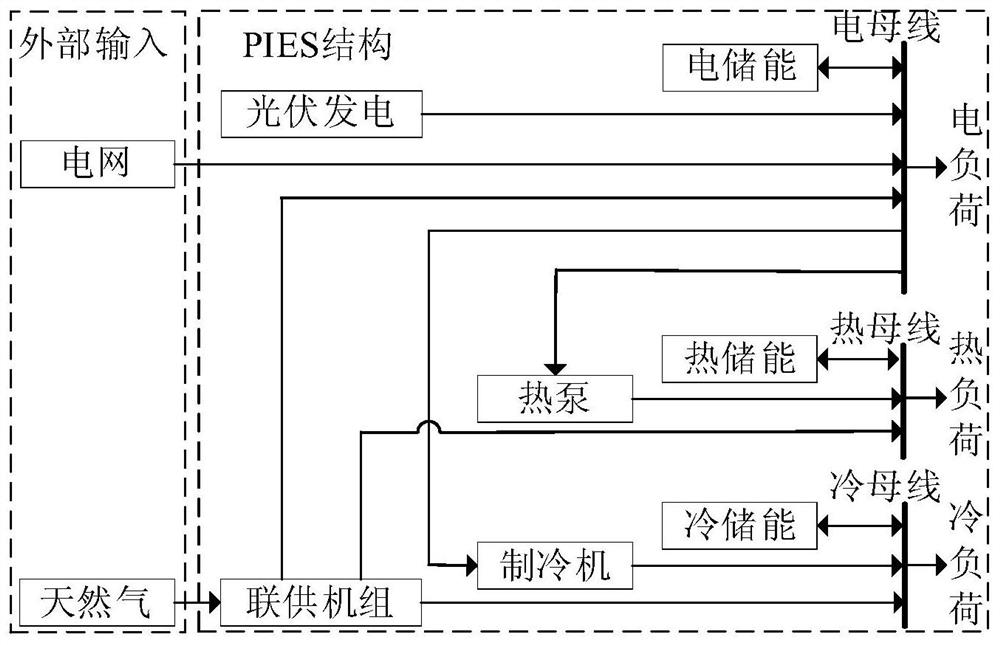

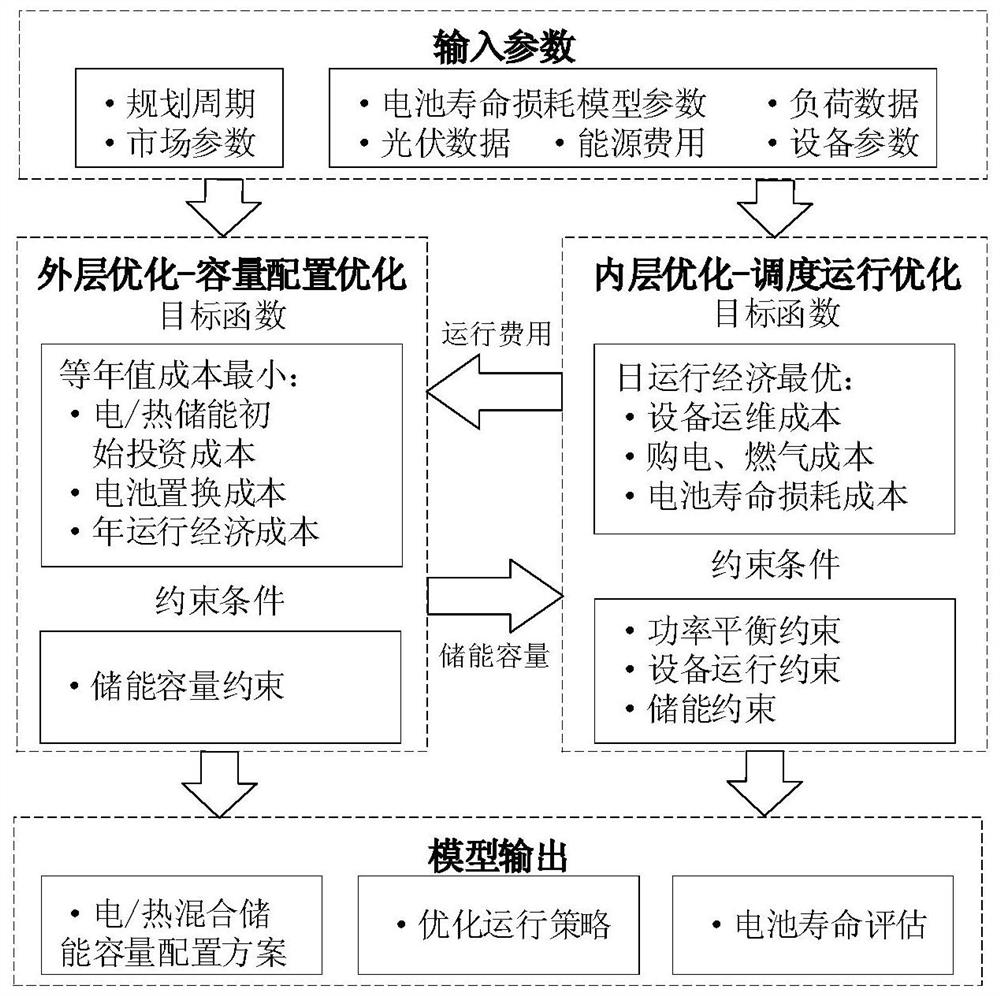

Comprehensive energy electric/thermal hybrid energy storage configuration method considering battery life loss

PendingCN112365299AEnergy storage capacity adjustmentCapacity adjustmentMarket predictionsSystems intergating technologiesEnergy systemIndustrial engineering

The invention discloses a comprehensive energy electric / thermal hybrid energy storage configuration method considering battery life loss. The method comprises the following steps: modeling the batterylife loss; establishing an energy storage-containing comprehensive energy system model consisting of an energy production unit, an energy conversion unit, an energy storage unit, an energy transmission unit and an energy consumption unit; taking the minimum annual value cost in the comprehensive energy planning period as a first objective function of the outer-layer planning model, and taking theminimum daily operation cost as a second objective function of the inner-layer optimization model; and solving the double-layer model to obtain a corresponding energy storage configuration scheme. According to the method, the capacity planning problem and the operation optimization problem of the system under the energy storage planning capacity are considered, and quantitative evaluation and calculation can be performed on the battery life loss so as to avoid the risk of overestimating the energy storage investment benefit, better adapt to the characteristic of multi-energy complementation of the comprehensive energy, improve the planning -operation economy of the comprehensive energy system and improve the energy utilization rate of the system. The battery life is prolonged.

Owner:TIANJIN UNIV +1

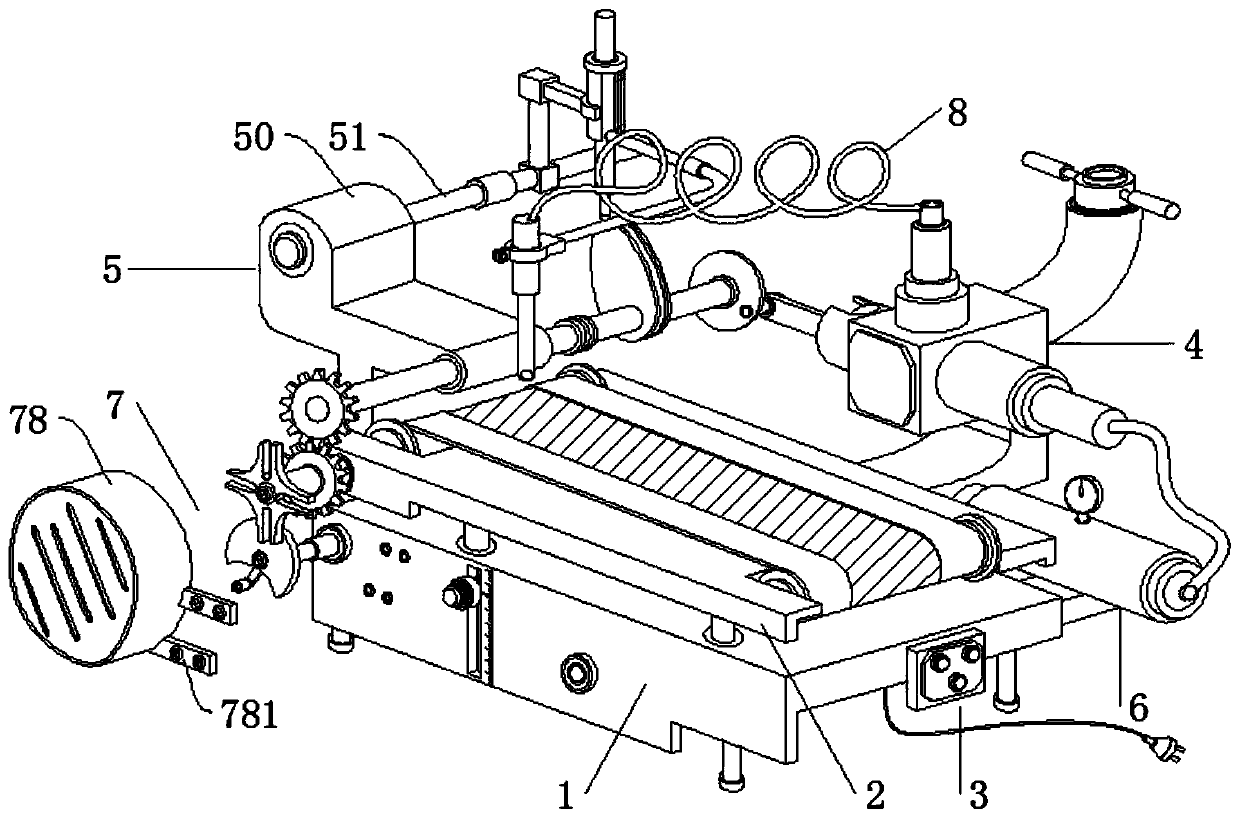

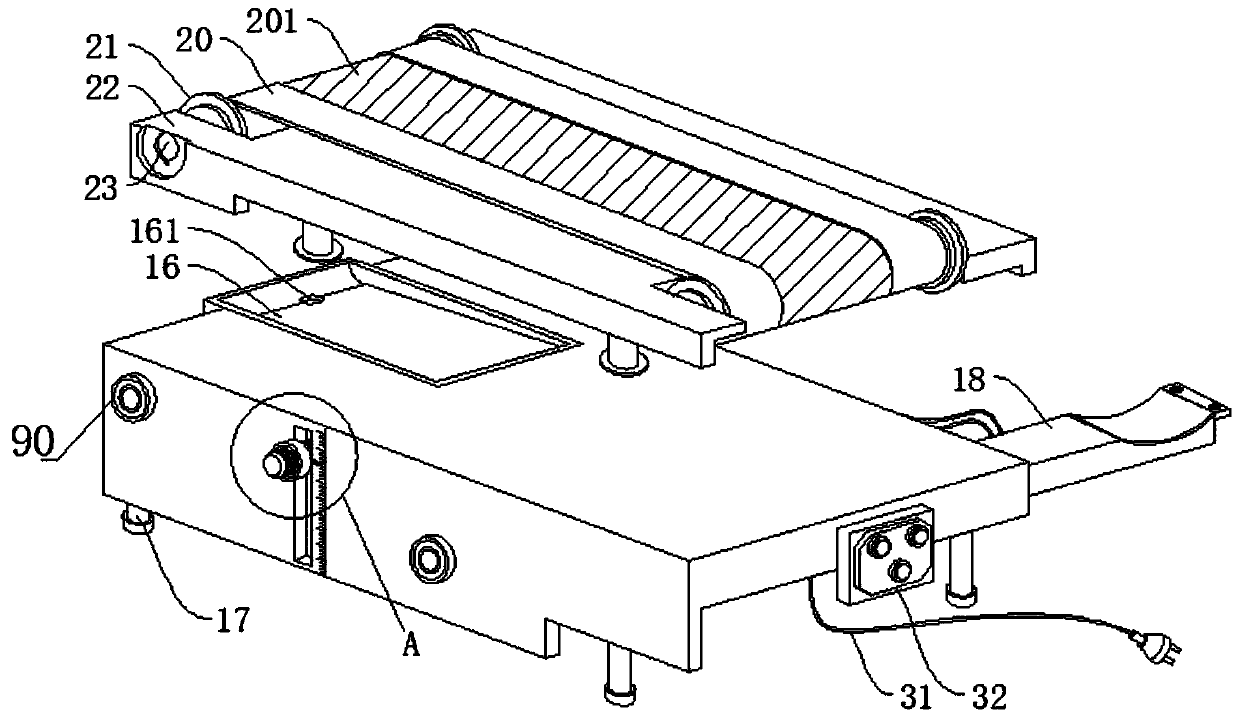

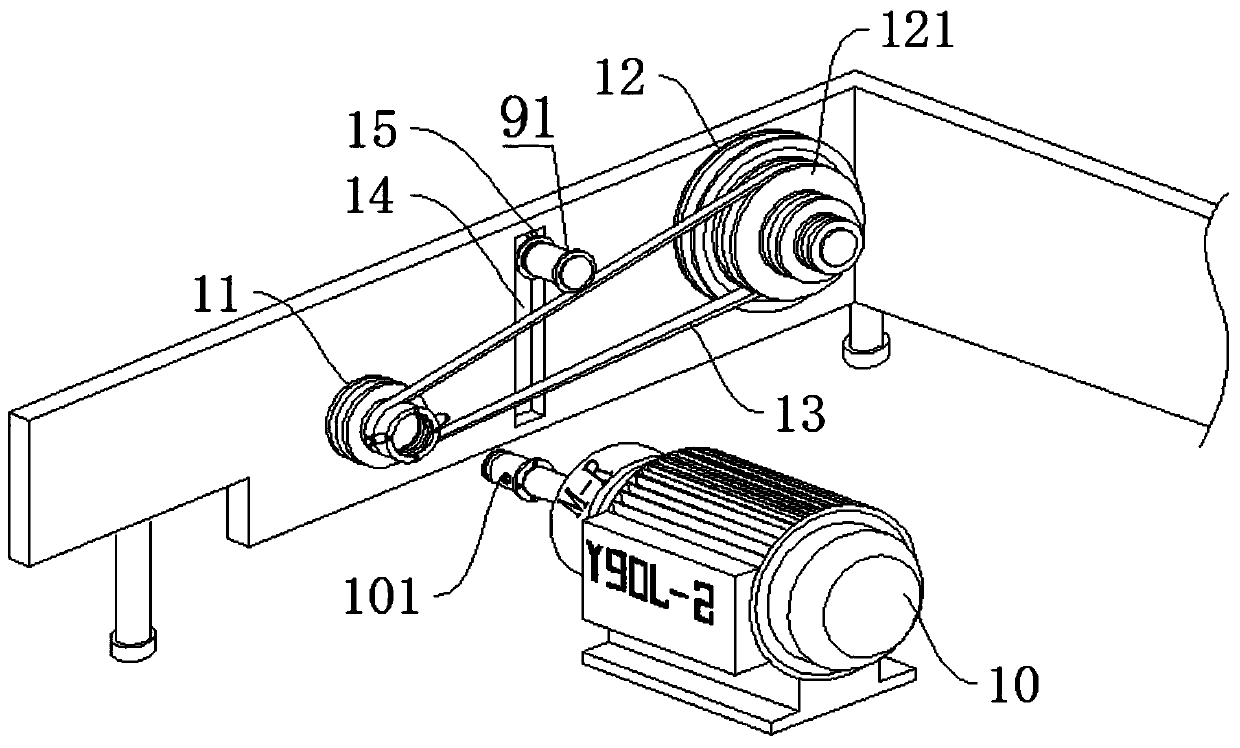

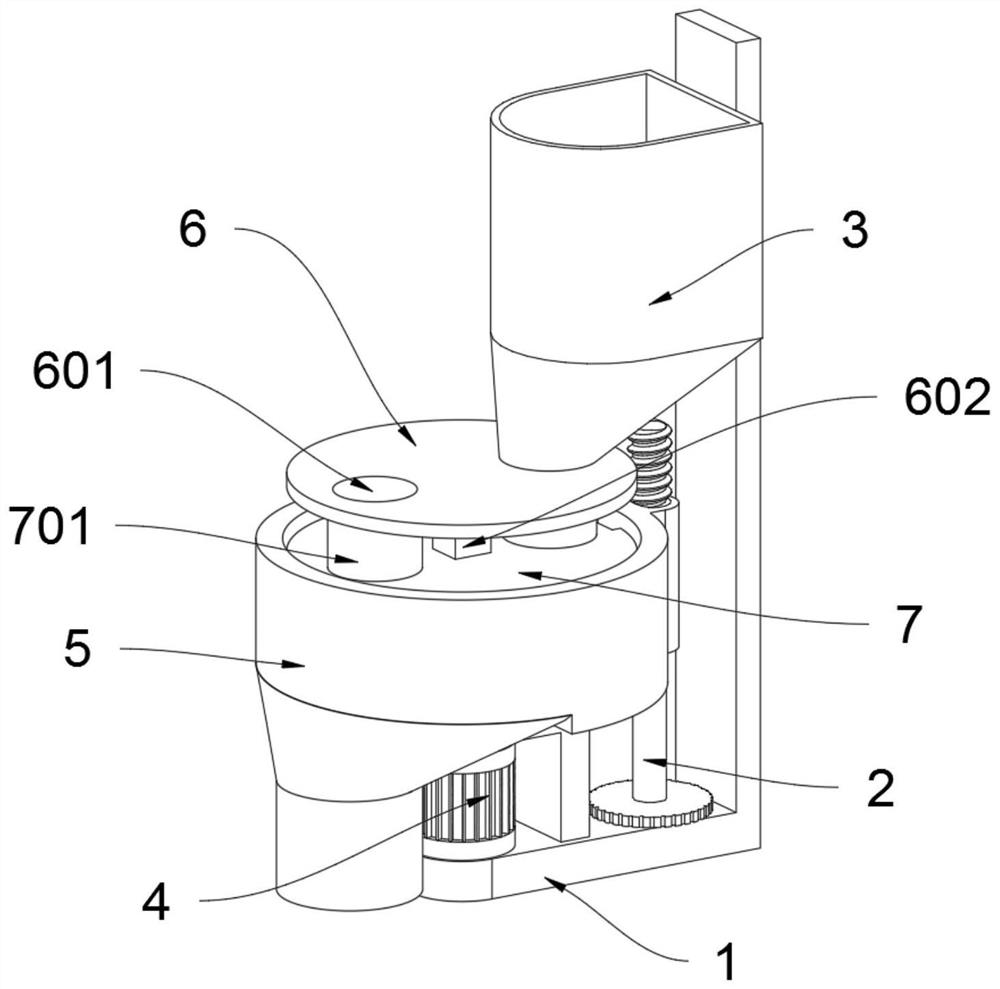

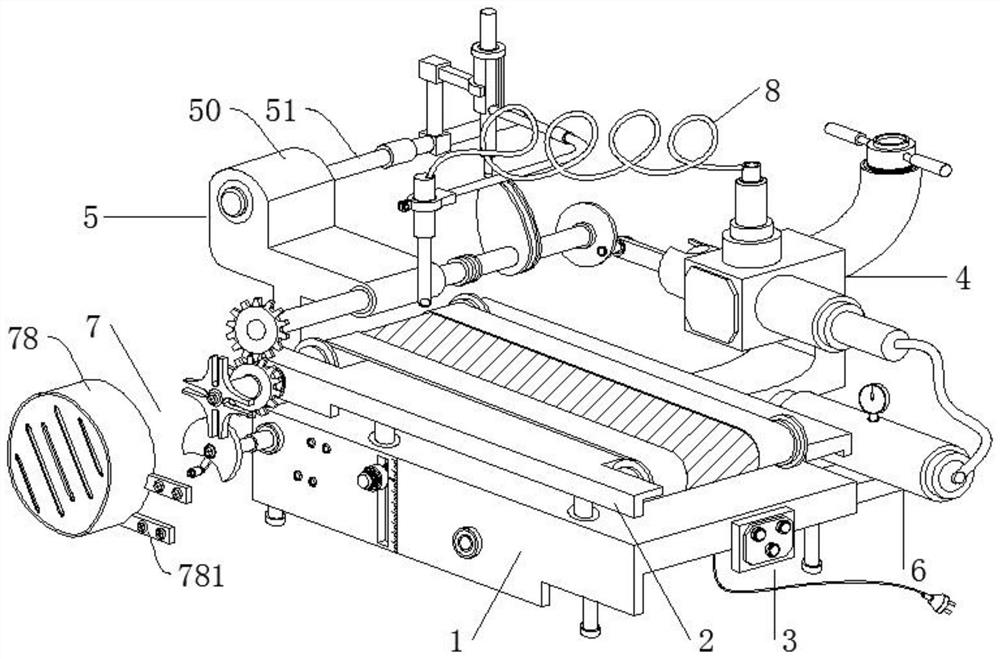

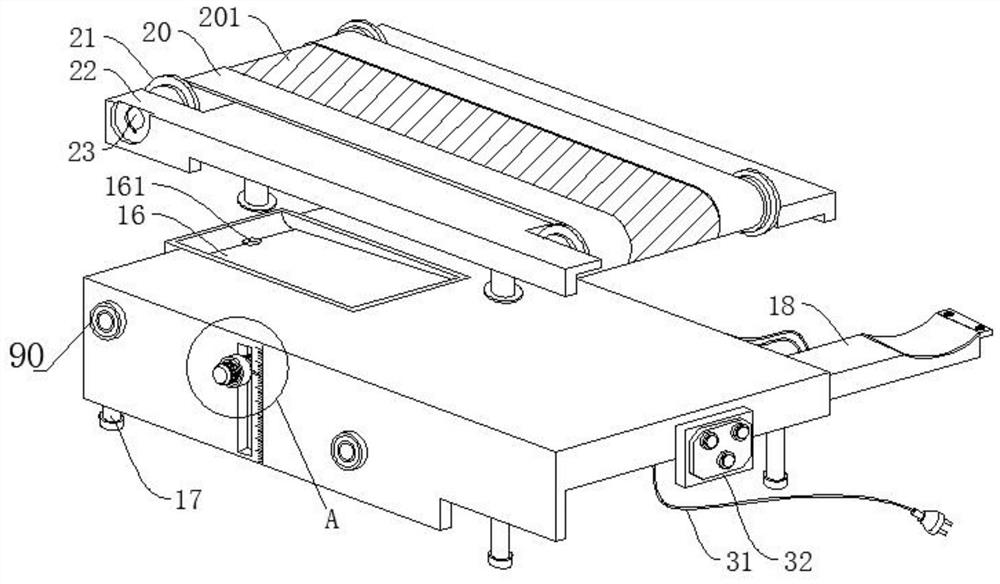

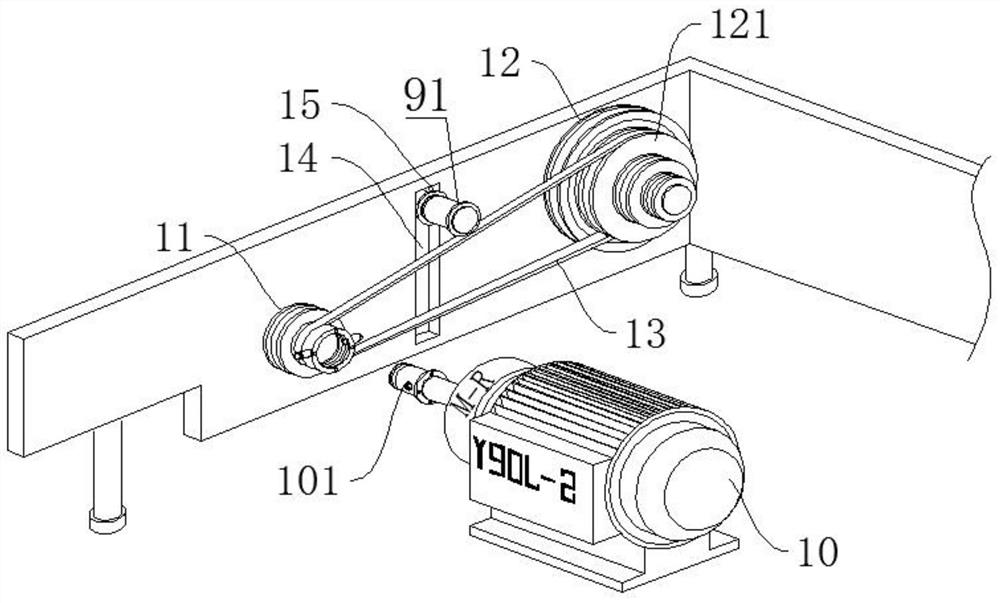

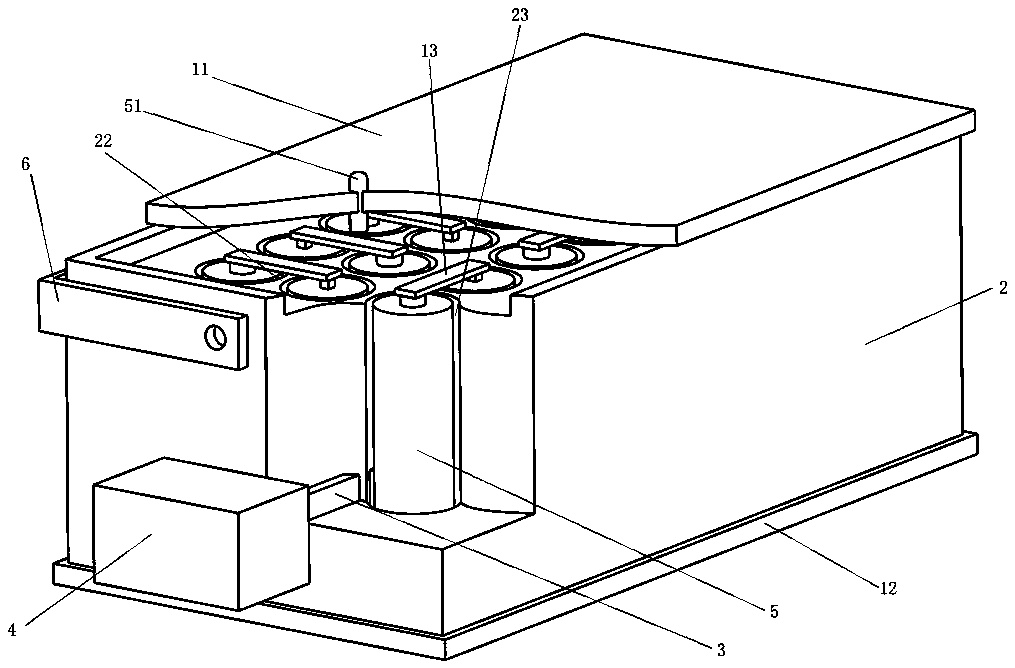

Energy-saving continuity liquid fodder filling machine

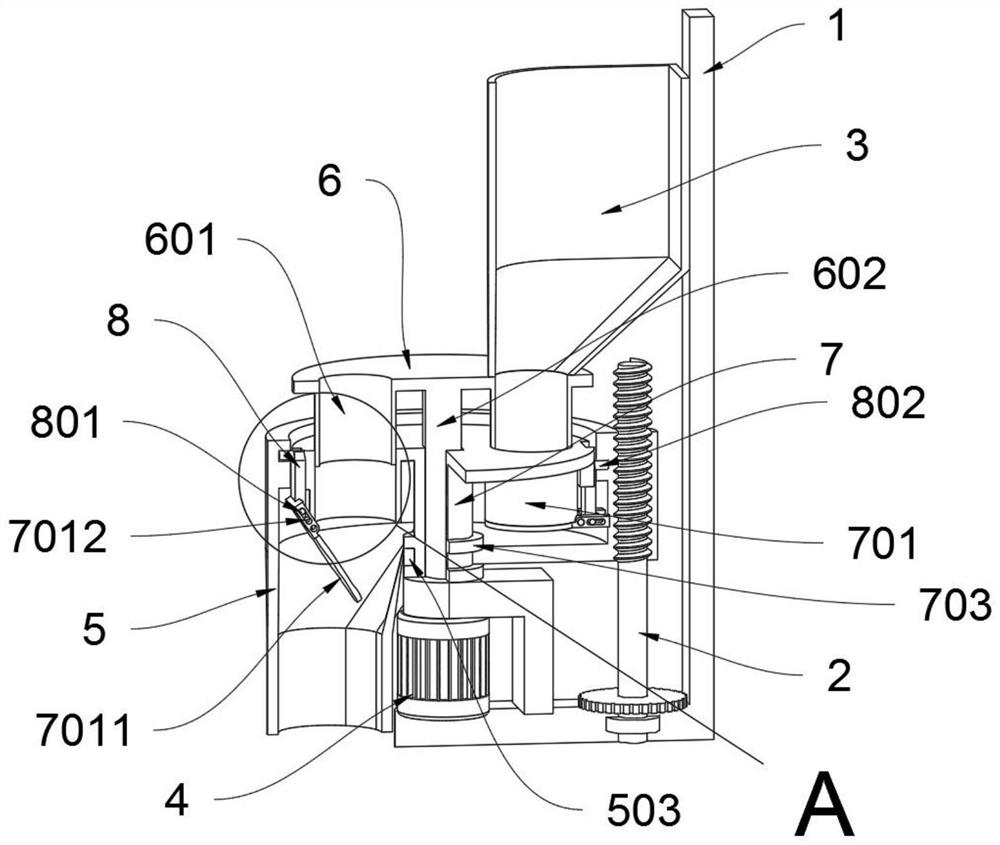

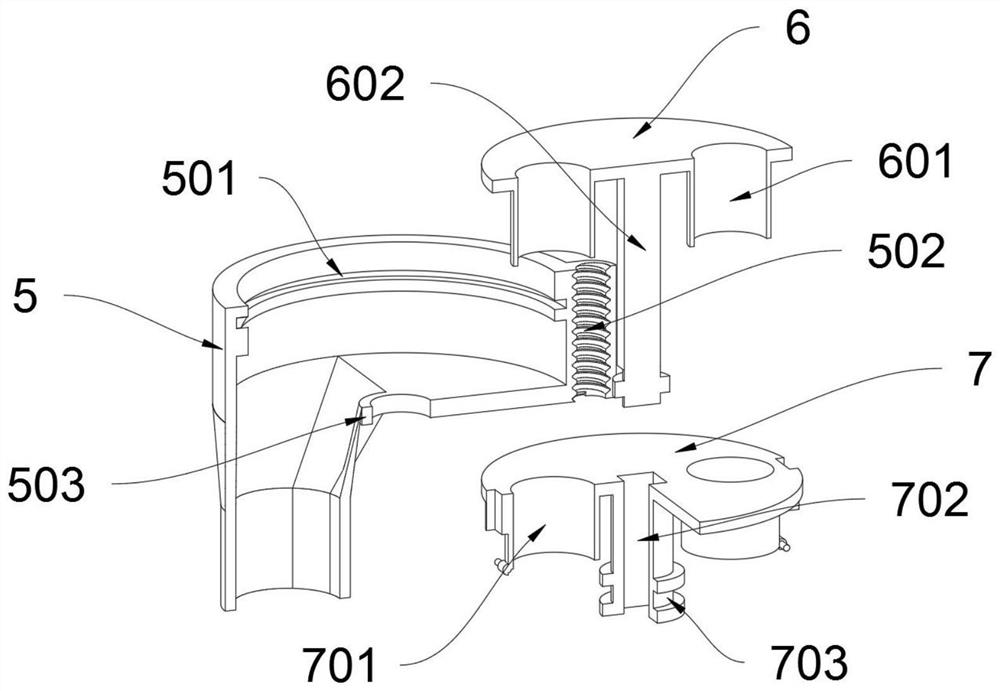

ActiveCN110240106ARealize the purpose of energy savingGuaranteed stabilityLiquid bottlingMotor driveEngineering

The invention discloses an energy-saving continuity liquid fodder filling machine which comprises a base, a working table and a power source. The working table and the power source are arranged on the top and one side of the base correspondingly. A supporting arm is connected to one side of the base. A pressurizing mechanism is carried on the supporting arm. A feeding system, a moving mechanism and a transmission assembly are arranged on three side faces in the anti-clockwise direction of the base correspondingly. Supporting feet are installed on the bottom of the base and the bottom of the working table correspondingly. The working table is erected on the top of the base and fixedly connected with the base through the supporting feet. Compared with an existing liquid fodder filling machine, the energy-saving continuity liquid fodder filling machine is easy to assemble, the repair and maintenance cost is low, meanwhile, the filling machine operates by the adoption of the single-motor drive motion structure, the intermittent filling mode is achieved, thus an energy source is saved greatly, moreover, the speed and the capacity of fluid fodder of the filling machine can be adjusted, and production of liquid fodder is met effectively.

Owner:宁夏绿健源生物科技有限公司

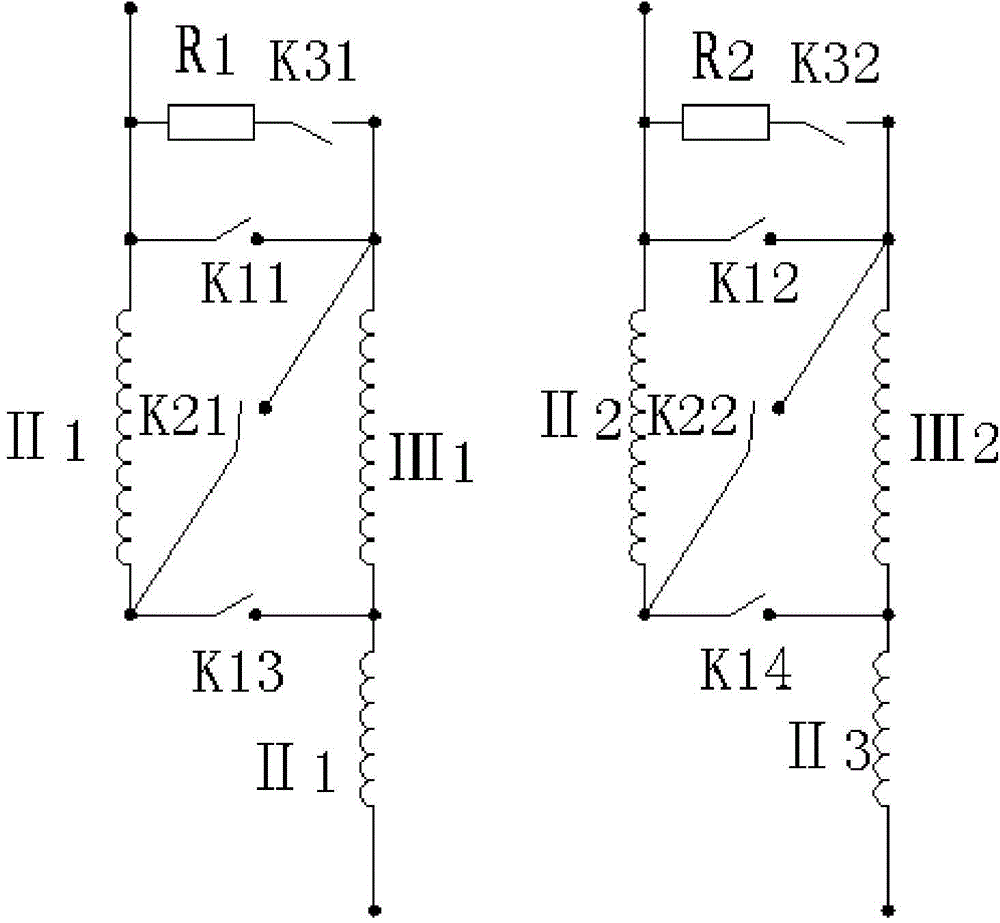

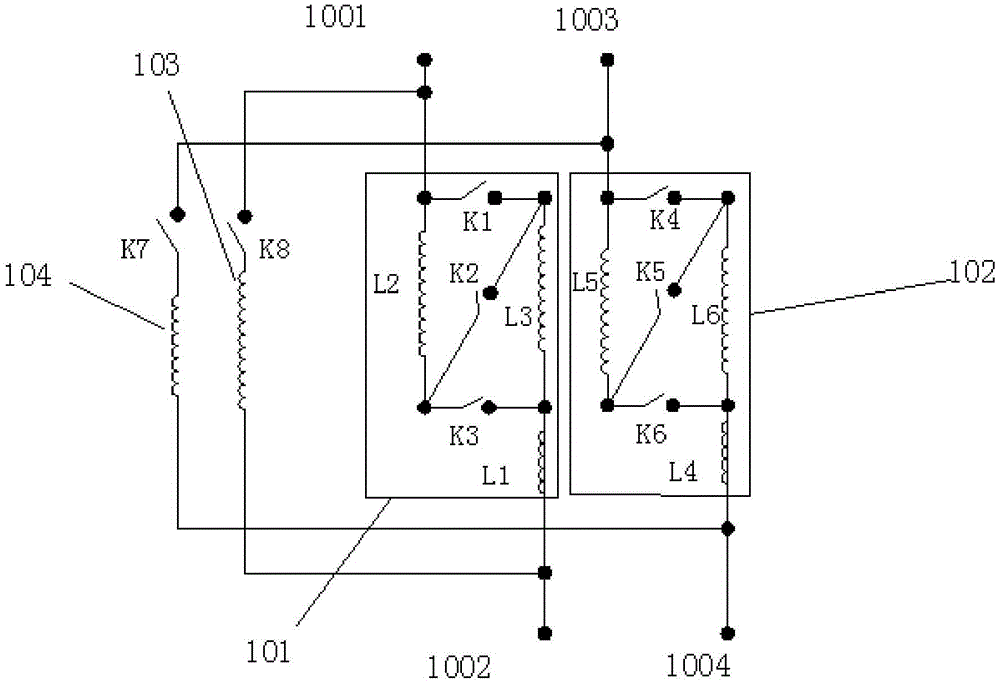

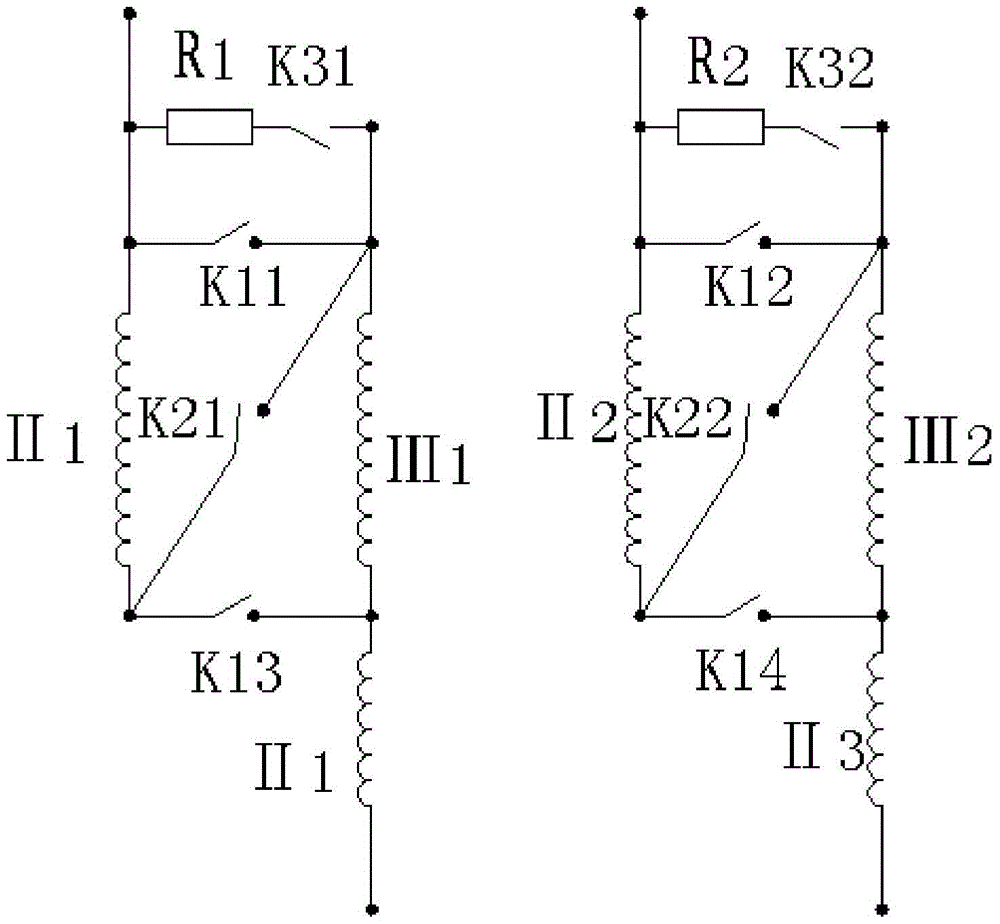

On-load regulated capacity transformer

ActiveCN104377017ACapacity adjustmentTransformers/inductances coils/windings/connectionsVariable inductancesTransformerLoad following power plant

The invention provides an on-load regulated capacity transformer, and particularly relates to the field of power accessories. According to the on-load regulated capacity transformer provided by an embodiment of the invention, two ends of a common capacity-adjustable circuit transformer bank are connected to second circuit transformer banks in parallel; when the capacity is required to be adjusted, the second circuit transformer banks replace a first circuit transformer bank, or the first circuit transformer bank and the second circuit transformer banks bear load together; the first circuit transformer bank can also stop working thoroughly, when the capacity of the first circuit transformer bank is adjusted, the first circuit transformer bank can be shut down, the capacity of the first circuit transformer bank can be adjusted in a powerless environment or under the condition of small load, the specification of an on-load switch is not required to be limited, and the capacity can be adjusted via any mature on-load switches.

Owner:北京博瑞莱智能科技集团有限公司

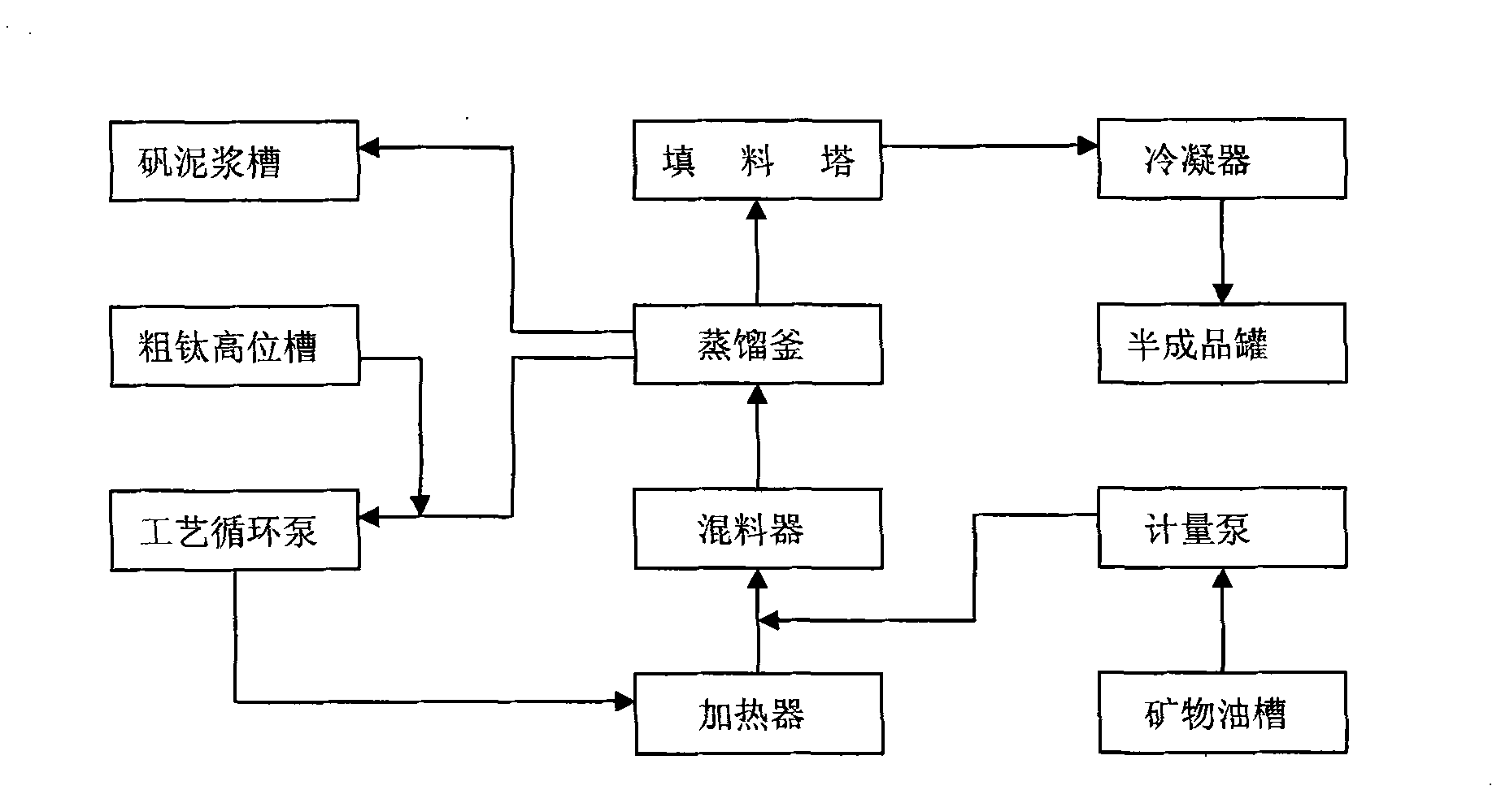

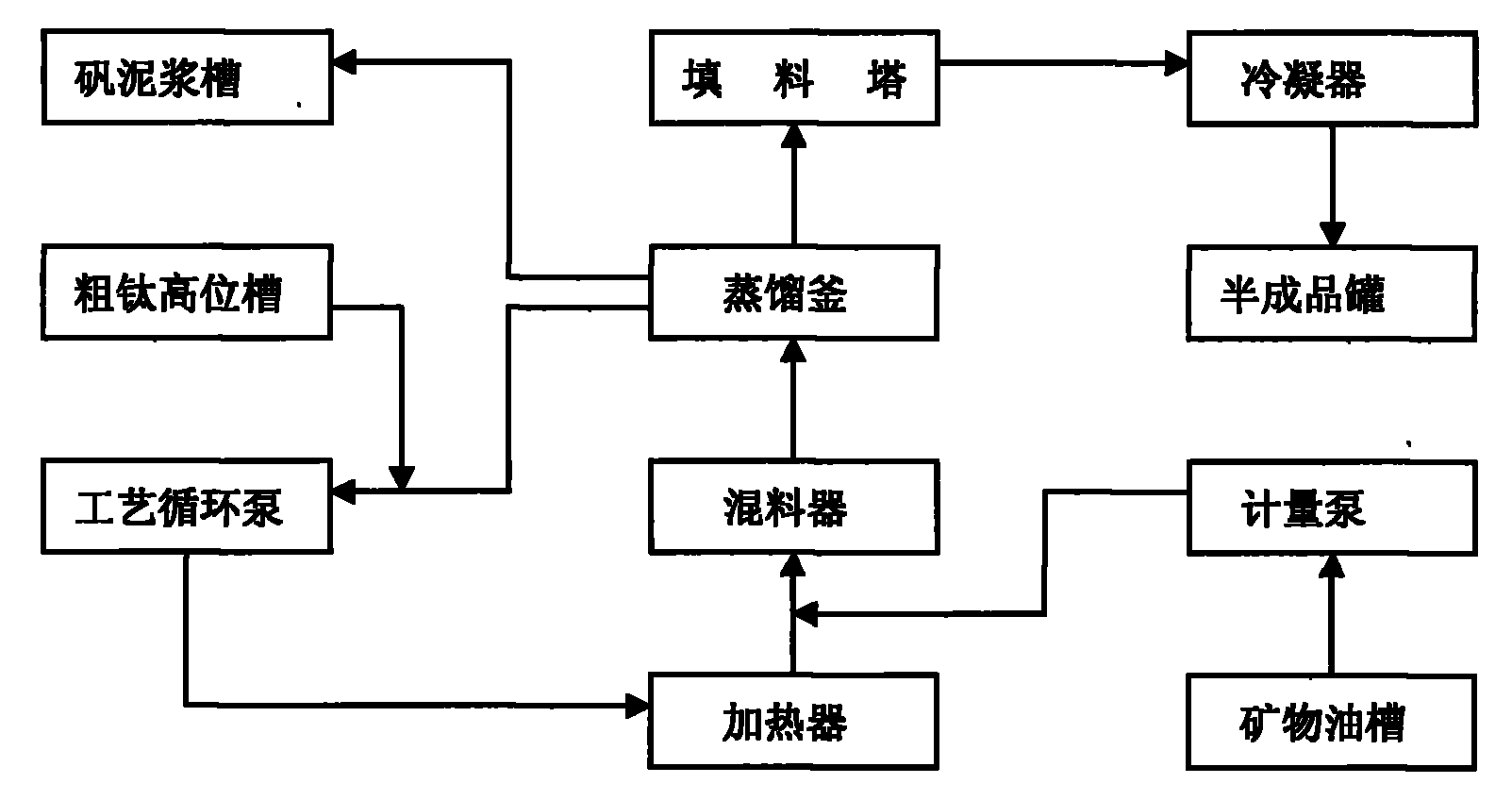

TiCl4 refining continuous vitriol alum removing process

InactiveCN101302035BReduce manufacturing costReduce processing costsTitanium halidesDistillationSlurry

The invention relates to a process and a special device for refining and removing alum continuously for TiCL4, which solves the problems that the TiCL4 has production cost, needs frequent washing, replacement and supplementation of copper wires, can not implement continuous operation, has high labor intensity and cause environmental pollution. The process is as follows: mineral oil and rough TiCL4 is added into a circulating system according to a proportion of between 1.2 to 1000 and 1.6 to 1000, and VOCL3 in the mineral oil and the TiCL4 contacts adequately and react to generate a high boil point matter; materials are forced to be circulated and heated by a circulating pump, and the heating temperature is between 137 and 145 DEG C; the mineral oil and the TiCL4 are continuously added into the circulating system according to the output requirement, so as to realize the continuous production; a semi-finished product of the TiCL4 is obtained after distillation, and the high boil point matter and other high boil point impurities in the distillation are removed. The special device for finely producing and removing alum continuously for the TiCL4 consists of a rough tatinium overhead tank, the circulating pump, a heat exchanger, a mixer, a distillation kettle, an alum slurry tank, a packing tower, a condenser, a semi-finished tank, a mineral oil grove and a metering pump.

Owner:常松峰

Deformable suitcase

PendingCN108634517ACapacity adjustmentIncrease storage capacityLuggageOther accessoriesEngineeringBlind hole

Owner:NANJING INST OF MECHATRONIC TECH

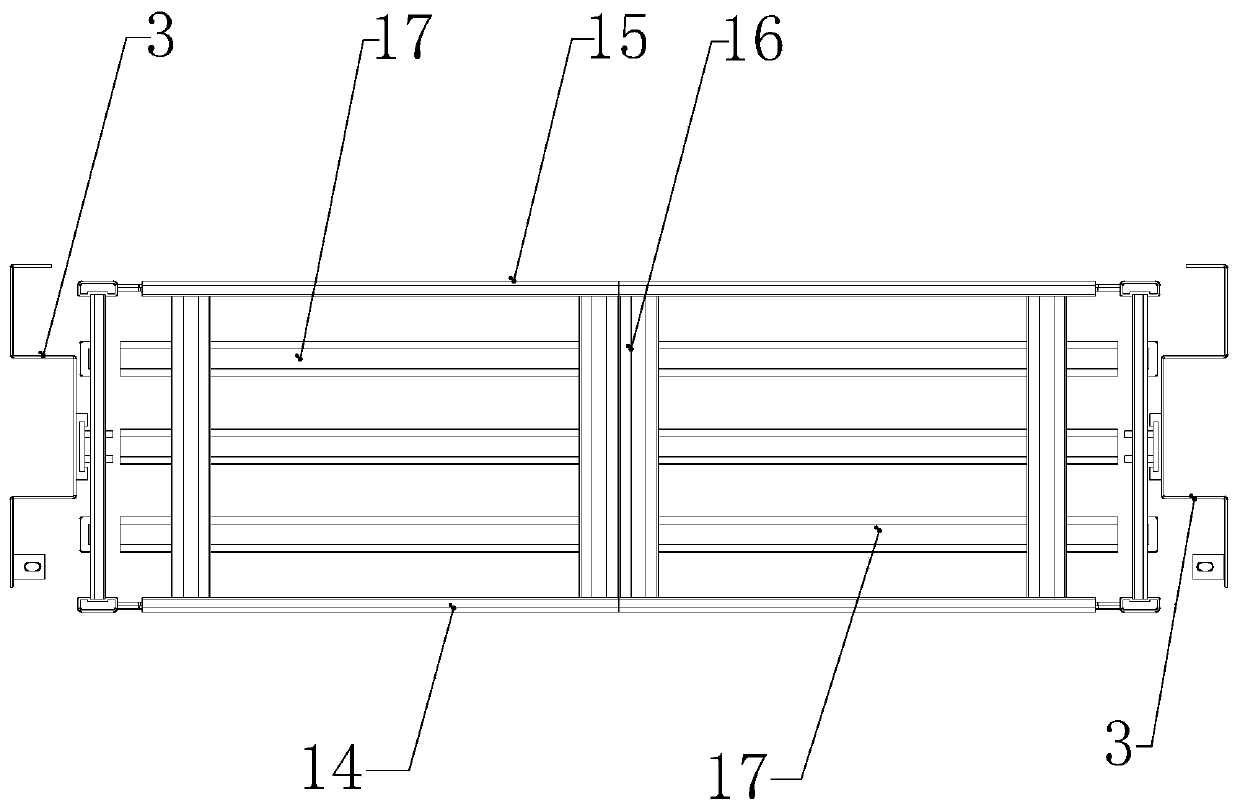

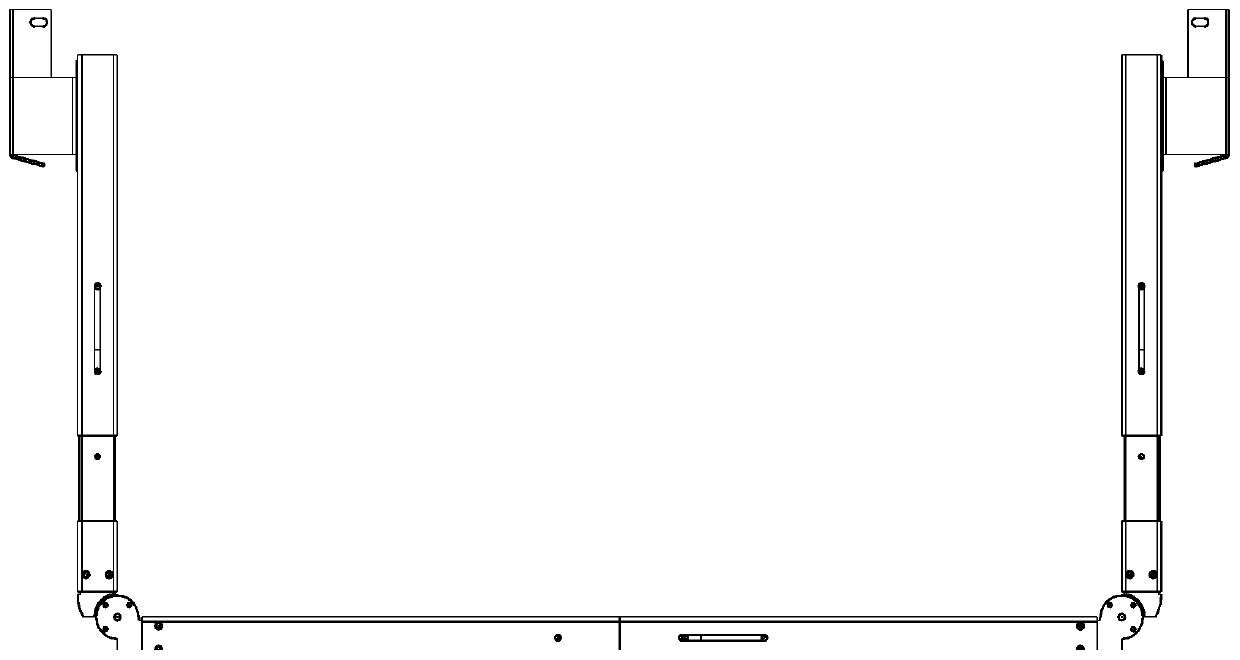

Portable push-and-pull type cargo box fence

PendingCN110329363AFirmly connectedChange capacityLoading-carrying vehicle superstructuresPush and pullEngineering

Owner:河南汇众泓科技发展有限公司

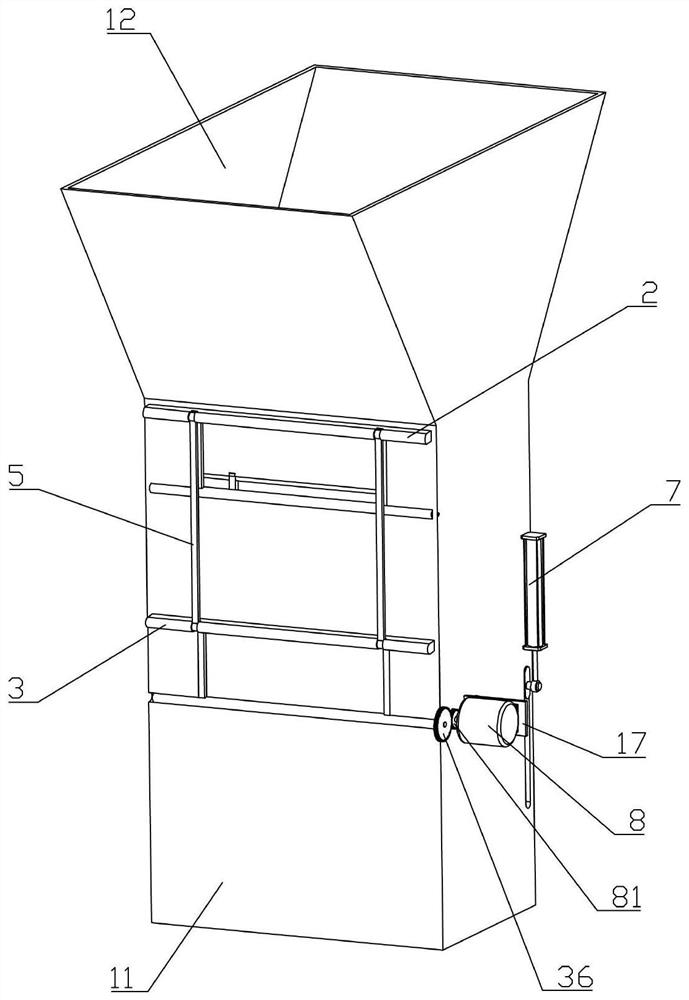

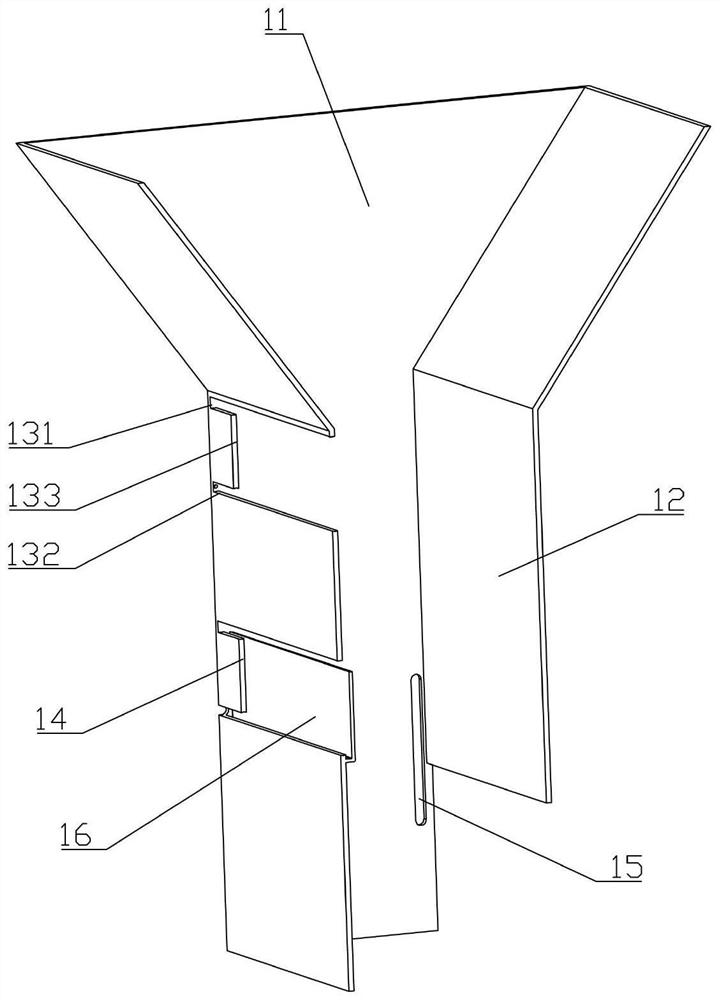

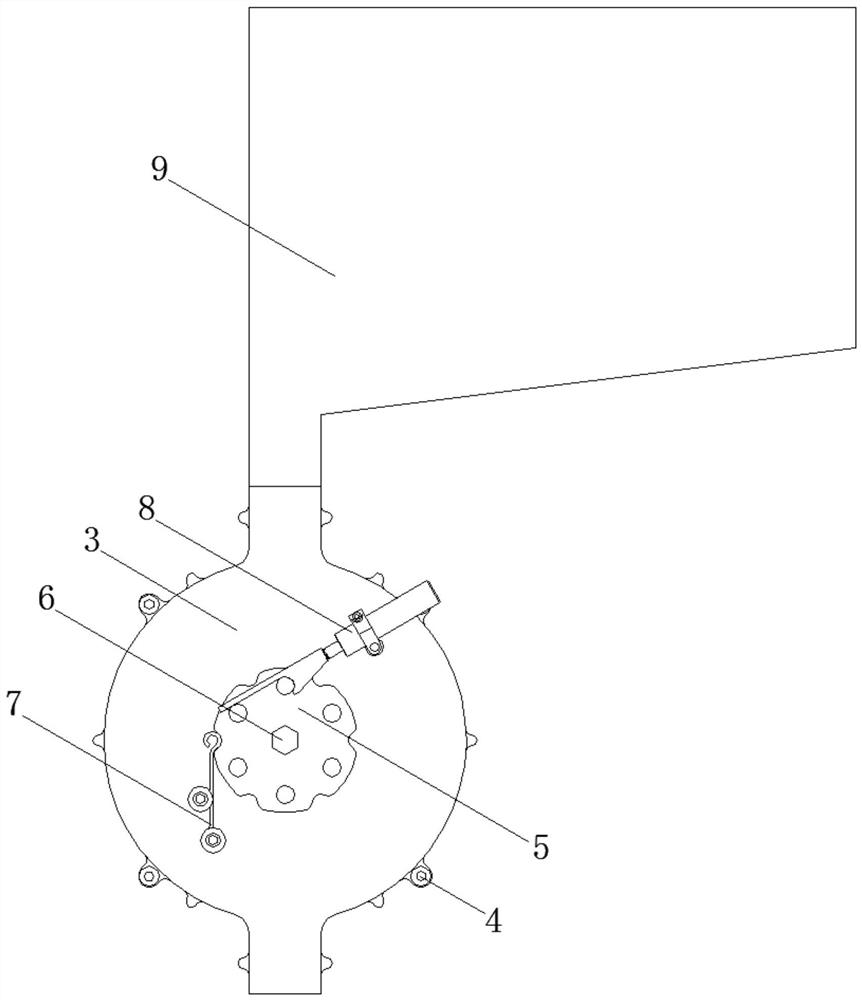

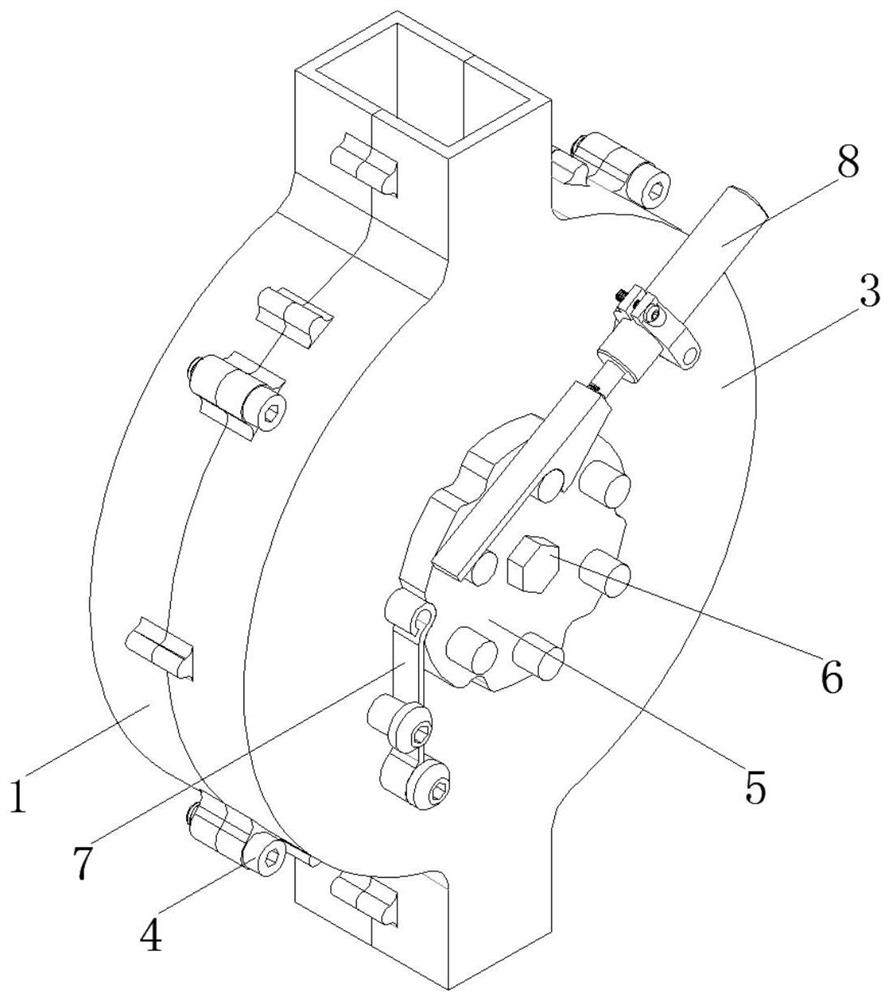

Variable-capacity metering tube for tobacco shred blending

ActiveCN112021632AChange spacingCapacity adjustmentTobacco preparationStructural engineeringMechanical engineering

The invention belongs to the technical field of tobacco processing, and particularly relates to a variable-capacity metering tube for tobacco shred blending, which comprises a metering tube body and ablanking hopper positioned above the metering tube body, a first mounting groove and a second mounting groove are formed in the metering tube body, the first mounting groove comprises a first slidinggroove, a rotating shaft groove and an avoiding groove, the second mounting groove and the first mounting groove are the same in structure, a first adjusting piece is mounted in the first mounting groove, a second adjusting piece is mounted in the second mounting groove, the first adjusting piece comprises a first arc-shaped plate and a first rotating shaft, a first connecting plate is mounted between the first rotating shaft and the first arc-shaped plate, and the second adjusting piece comprises a second arc-shaped plate and a second rotating shaft; a linkage rod and a first striker plate are hinged between the first arc-shaped plate and the second arc-shaped plate, and a first gear is mounted at one end of the second rotating shaft to solve the problem that the debugging result is seriously affected due to the fact that materials are easily blocked or disjointed as the capacity of an existing metering pipe cannot be adjusted.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

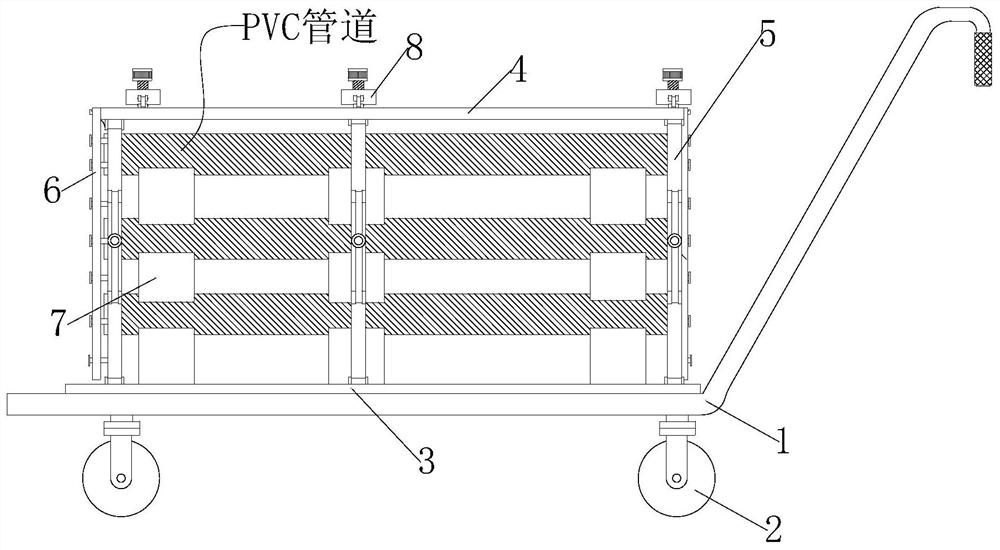

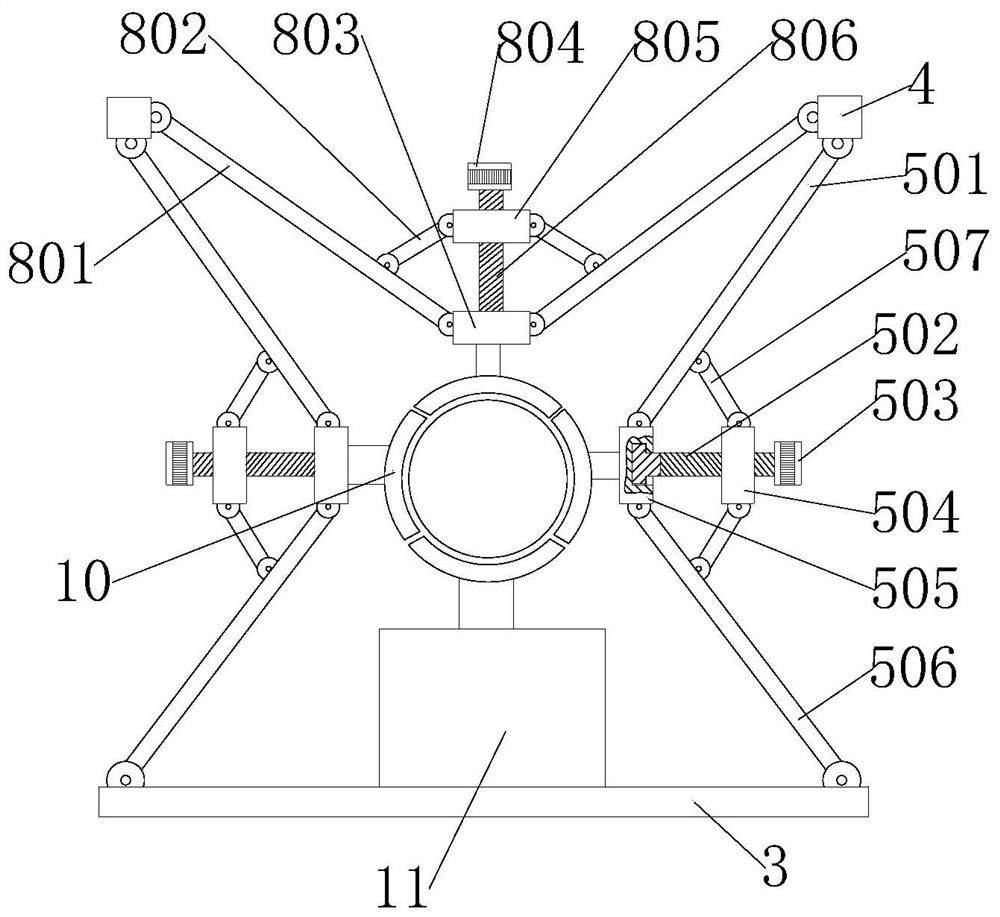

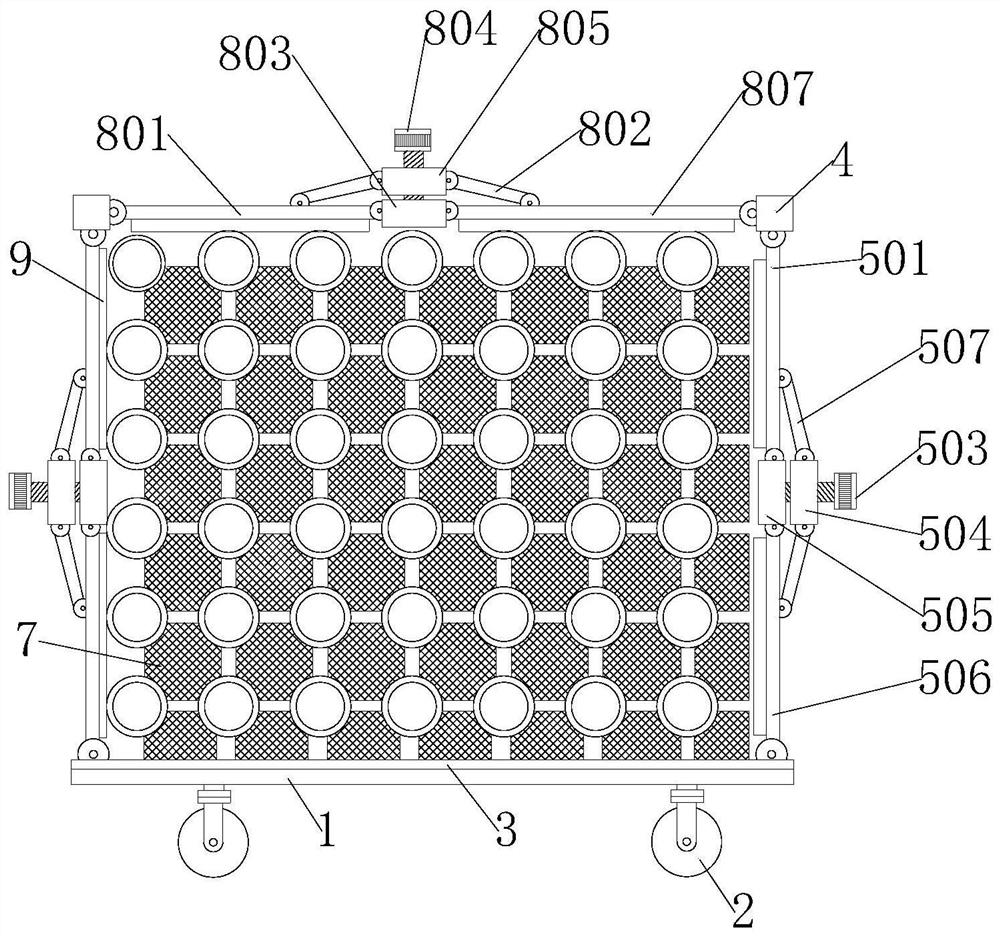

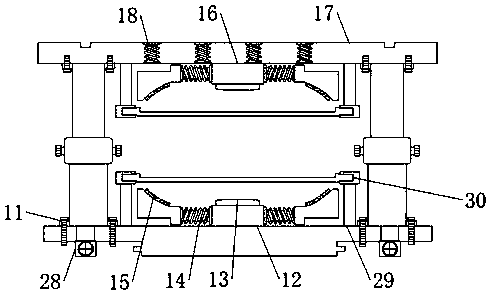

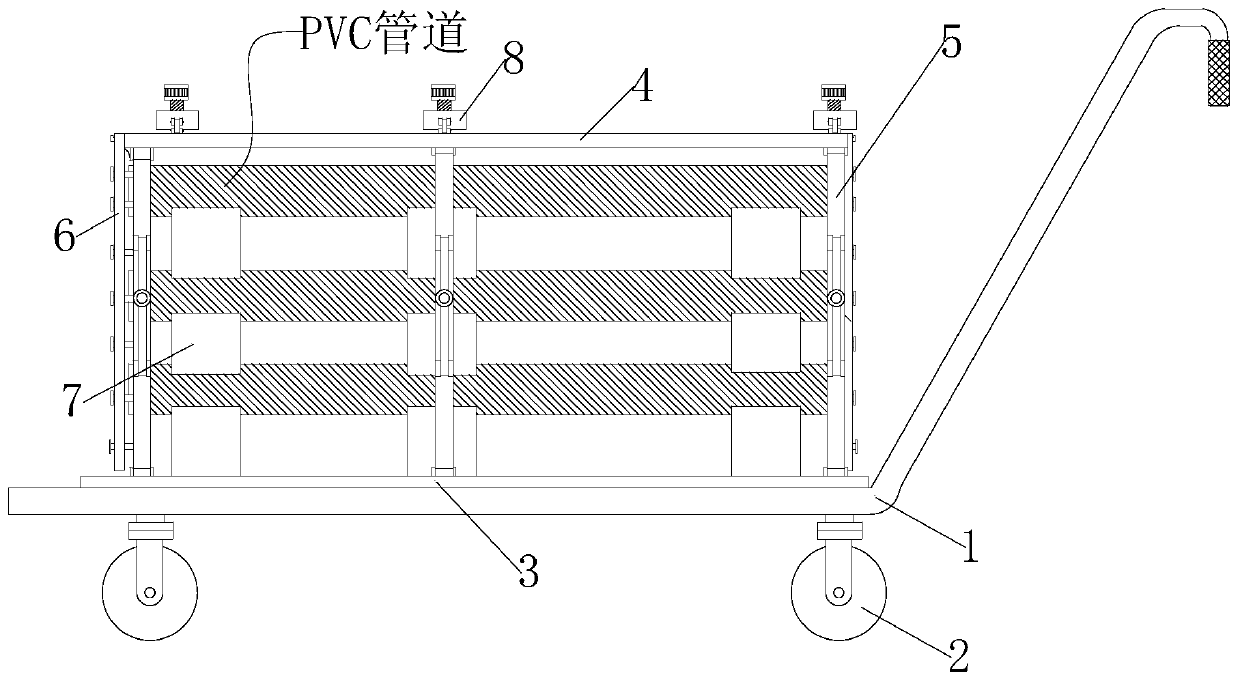

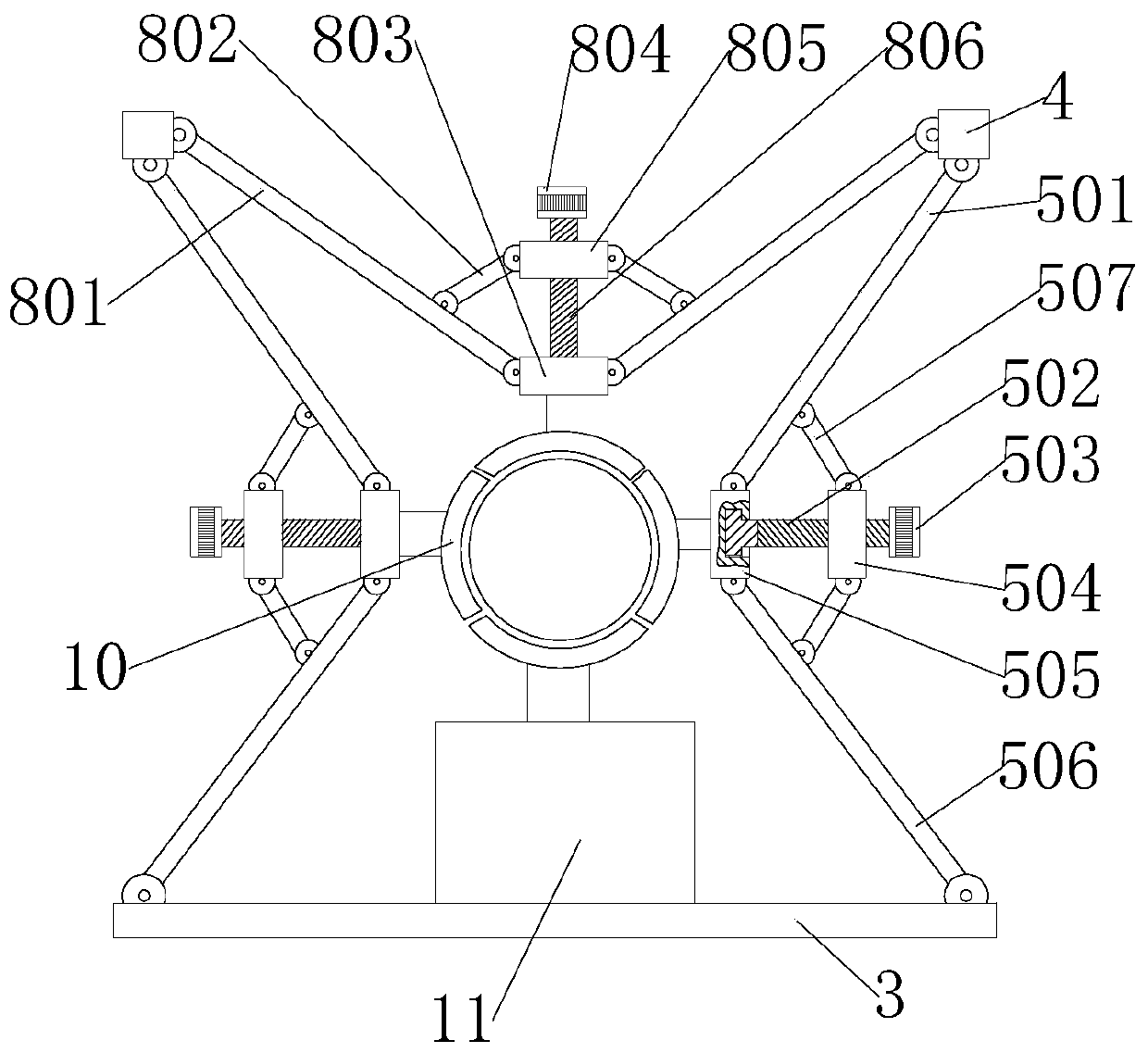

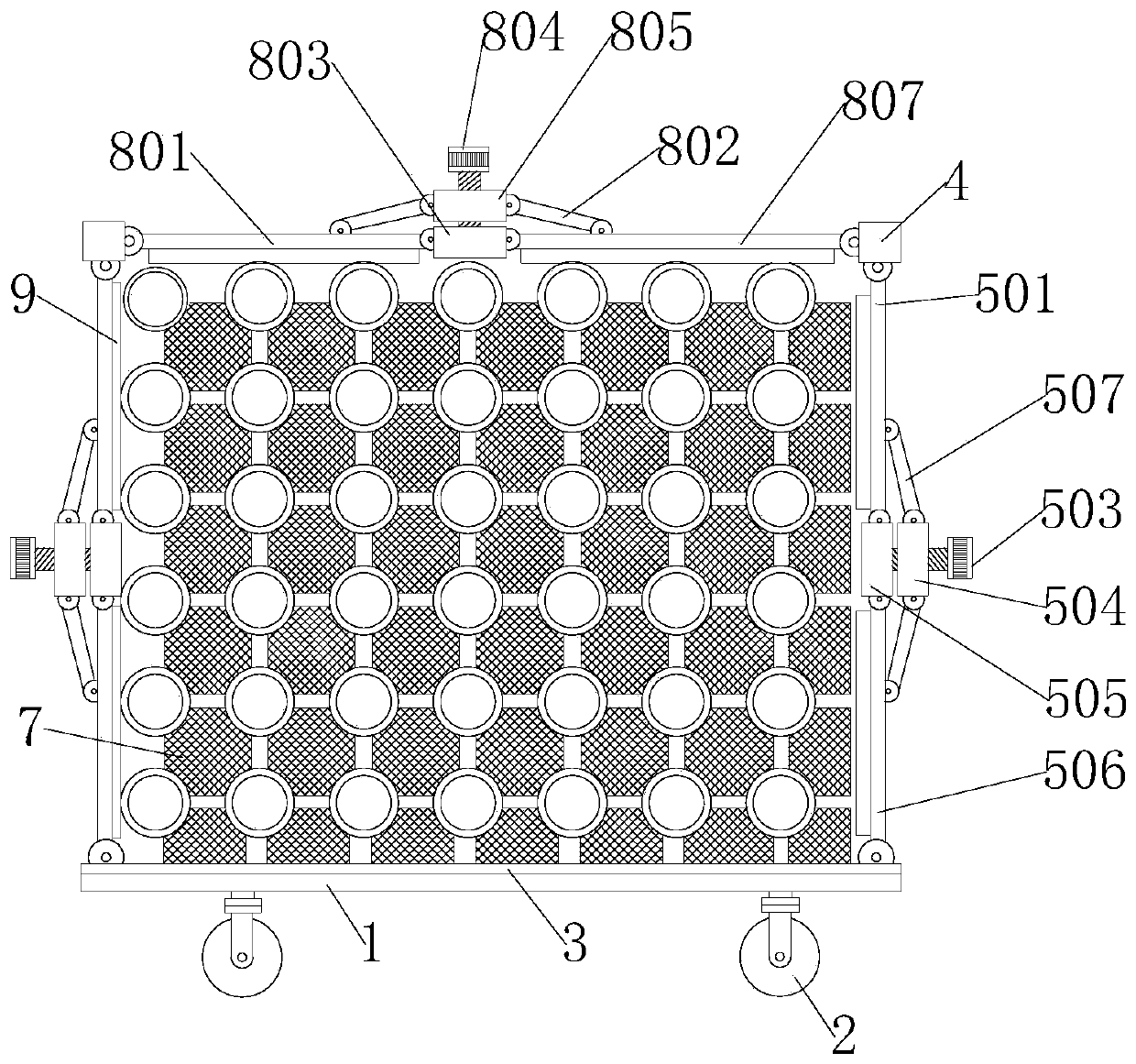

A pvc pipe conveying fixture for sewage discharge

ActiveCN110962904BClamping capacity adjustmentCapacity adjustmentHand carts with multiple axesHand cart accessoriesStructural engineeringSewage treatment

The invention discloses a PVC pipeline conveying fixture for sewage discharge, which relates to the technical field of sewage treatment equipment and includes a base, a top fixing plate, a side connecting rod, and a top connecting rod. The PVC pipe conveying fixture for sewage discharge is mainly connected by a base and a side. Rods and top connecting rods are spliced end to end. The base is a square plate arranged horizontally. There are a plurality of side connecting rods hinged symmetrically on the front and rear sides of the top of the base. Two adjacent side connecting rods on each side equally spaced between. In the present invention, a disk-shaped magnetic block is embedded at the center of the top of each connecting column; two adjacent pads are connected through the magnetic block. The connecting columns of two adjacent pads are quickly attracted together by the magnetic block, which improves the operational efficiency during installation, facilitates quick disassembly of the pads when taking out the PVC pipe from the fixture, and improves the ease of installation and operation of the pads.

Owner:福建泉州业德弗科技有限公司

OLTC

ActiveCN104377017BCapacity adjustmentTransformers/inductances coils/windings/connectionsVariable inductancesStopped workTransformer

The invention provides an on-load regulated capacity transformer, and particularly relates to the field of power accessories. According to the on-load regulated capacity transformer provided by an embodiment of the invention, two ends of a common capacity-adjustable circuit transformer bank are connected to second circuit transformer banks in parallel; when the capacity is required to be adjusted, the second circuit transformer banks replace a first circuit transformer bank, or the first circuit transformer bank and the second circuit transformer banks bear load together; the first circuit transformer bank can also stop working thoroughly, when the capacity of the first circuit transformer bank is adjusted, the first circuit transformer bank can be shut down, the capacity of the first circuit transformer bank can be adjusted in a powerless environment or under the condition of small load, the specification of an on-load switch is not required to be limited, and the capacity can be adjusted via any mature on-load switches.

Owner:北京博瑞莱智能科技集团有限公司

Spiral conveying equipment for corn starch processing workshop

The invention discloses spiral conveying equipment for a corn starch processing workshop, relates to the technical field of discharging devices, and solves the problems that existing spiral conveying equipment cannot quantitatively discharge materials and only can continuously discharge the materials. The spiral conveying equipment for the corn starch processing workshop comprises a top plugging disc, wherein the top plugging disc is inserted into a bottom control disc. When the device is used, raw materials conveyed by a spiral conveyor can be quantitatively discharged in a grouped mode through rotation of the top plugging disc, the raw materials continuously output by the spiral conveyor can enter a storage hopper to be temporarily stored, quantitative material receiving and quantitative material discharging can be alternately achieved when the top plugging disc rotates, use is convenient, and the quantitative discharge capacity of the device can be adjusted, so that raw materials of different volumes can be grouped according to needs, and the device is high in adaptability and convenient and flexible to use.

Owner:宁夏马氏兄弟粮油产业发展有限公司

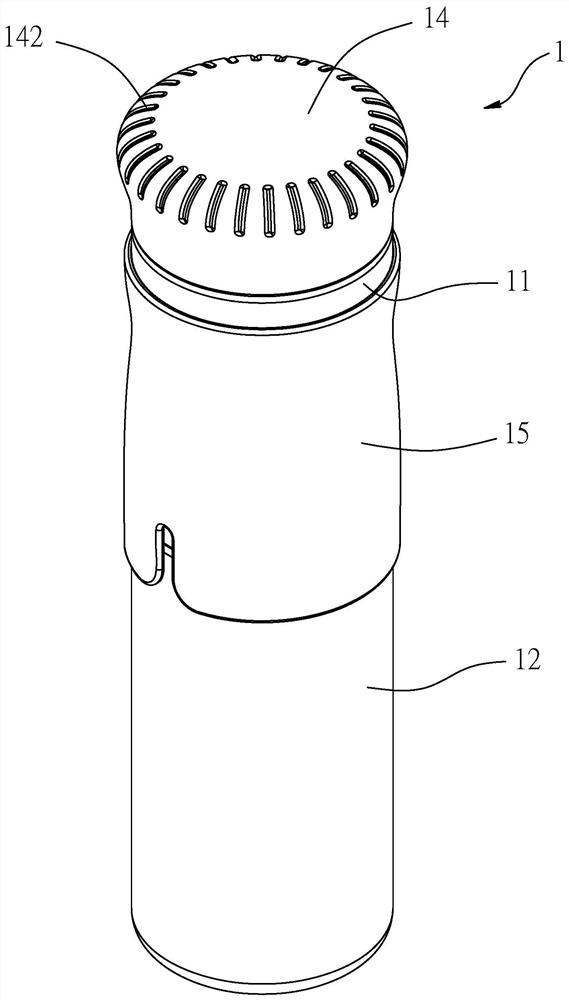

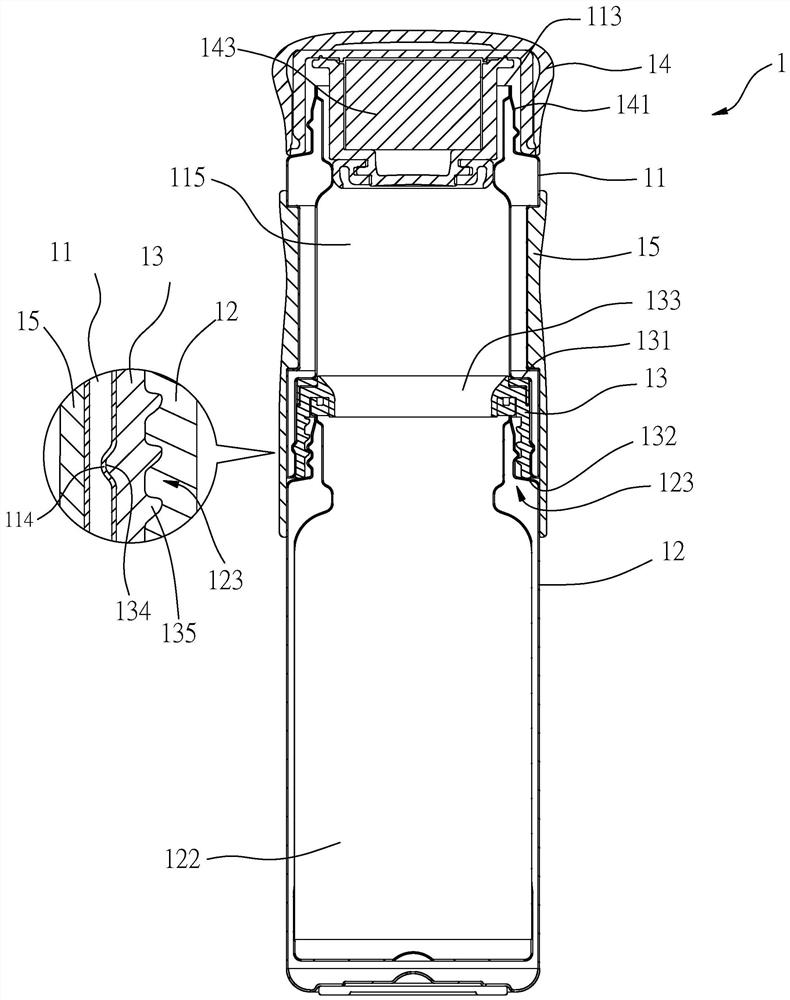

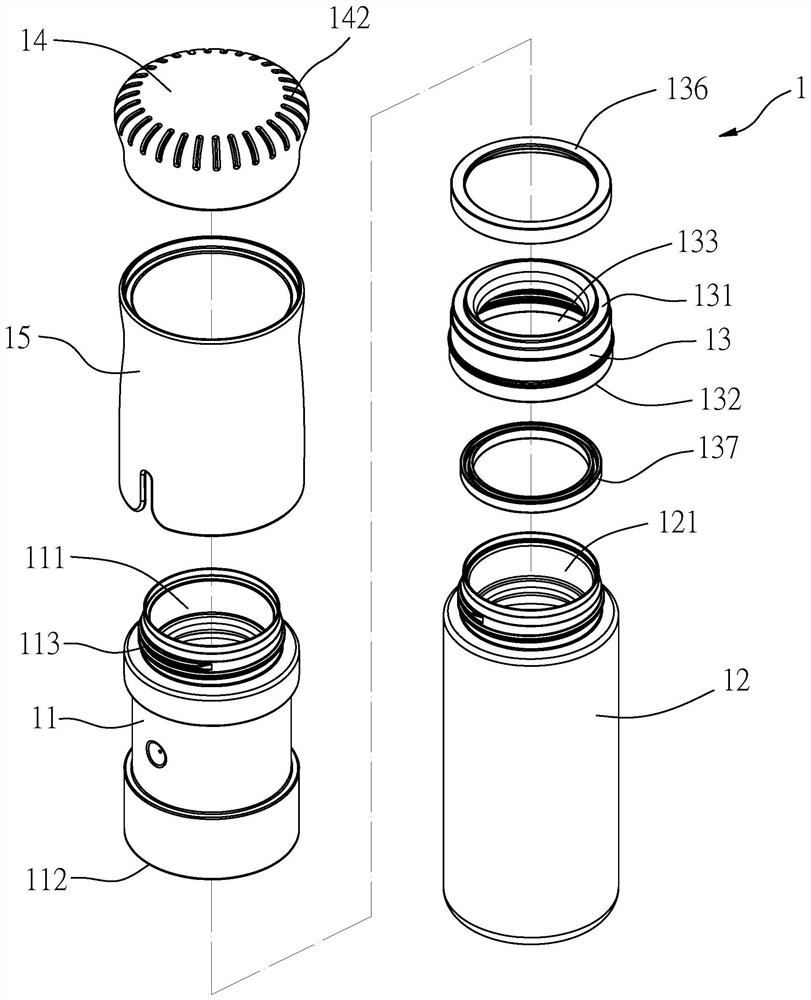

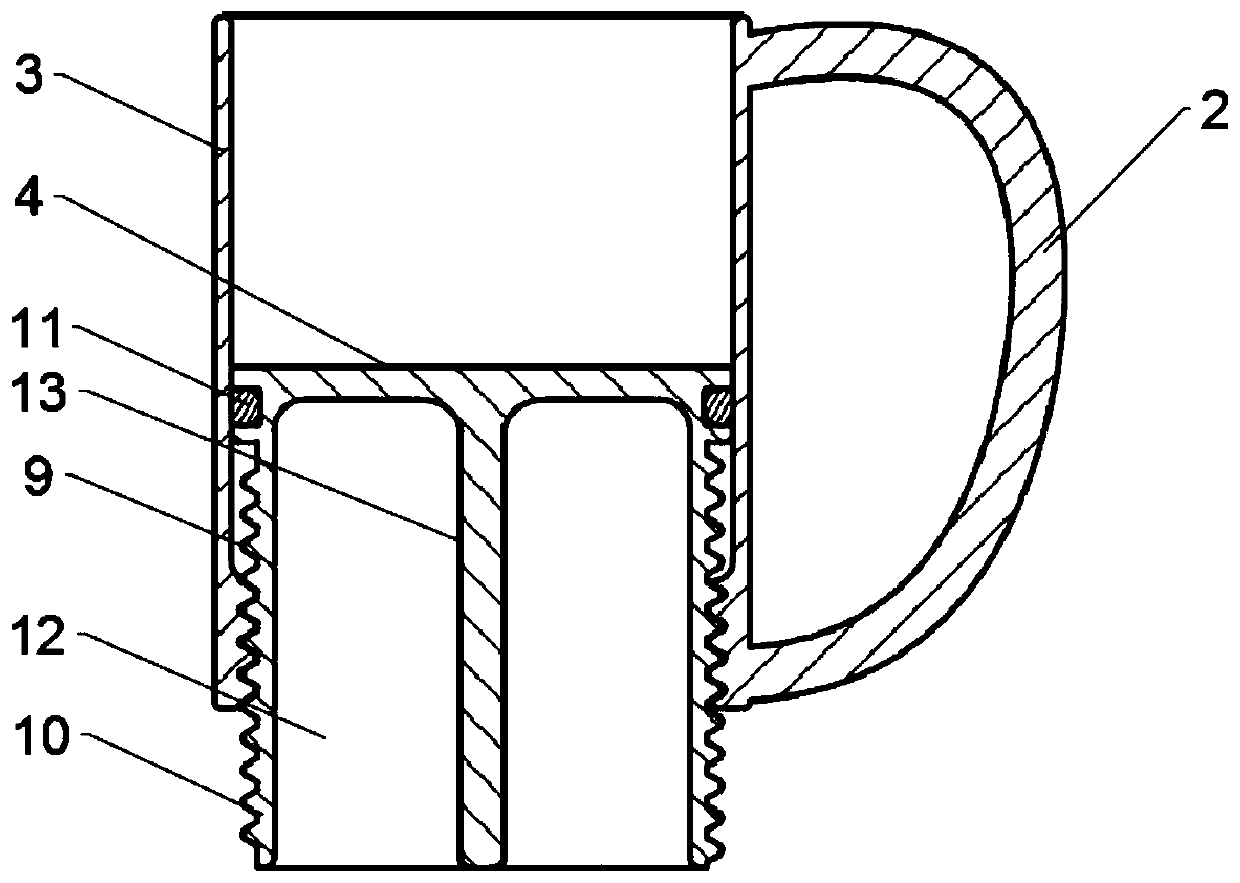

Detachable combined cup

InactiveCN111904233AIncrease capacityIncrease changeTravelling sacksDrinking vesselsEngineeringBottle

The invention relates to a detachable combined cup, in particular to a detachable combined cup with different cup bodies capable of being replaced. The detachable combined cup comprises a first cup body, a second cup body, a connecting piece and a bottle plug. Therefore, according to the detachable combined cup disclosed by the invention, by virtue of the hard body design of the first cup body andthe second cup body, a user can detach the cup to form an independent state for use and can also screw the cup to form an overlapped state for use, so that the total volume of liquid contained in thecup can be effectively adjusted according to the demand of the user, the number of cup bodies can be increased elastically, and the capacity and change of the whole cup are enlarged.

Owner:王淑惠

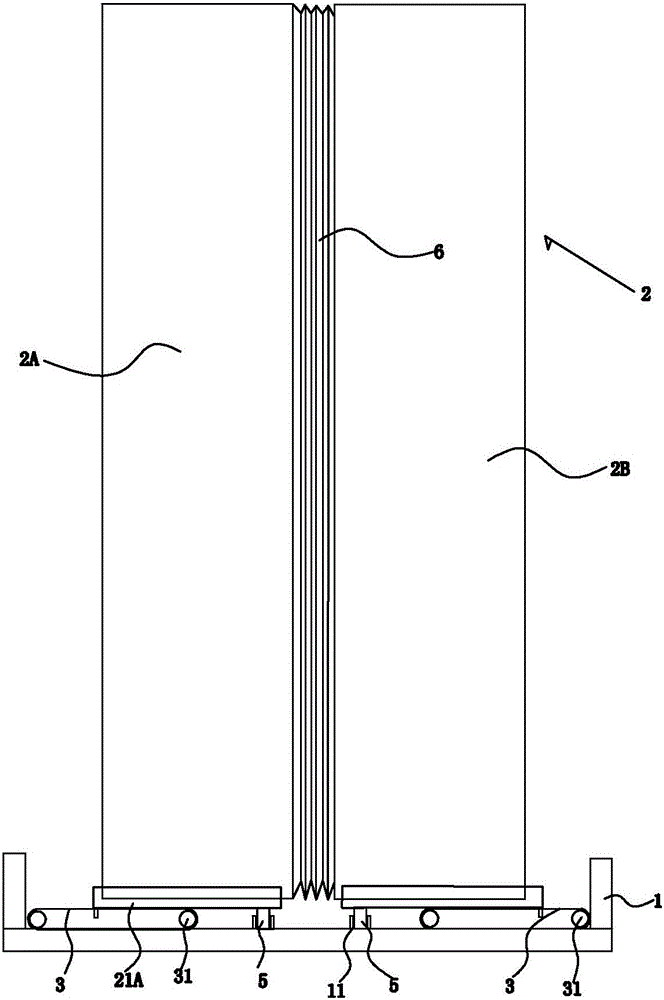

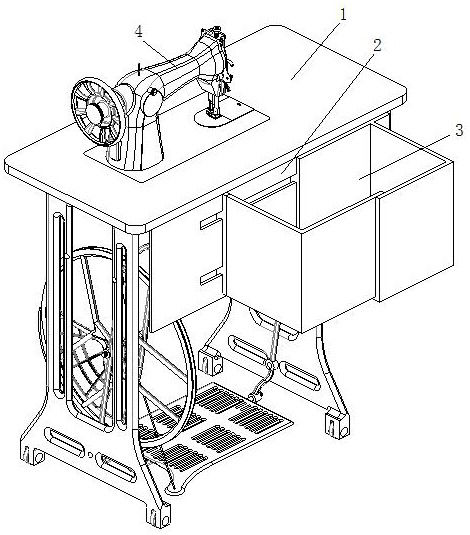

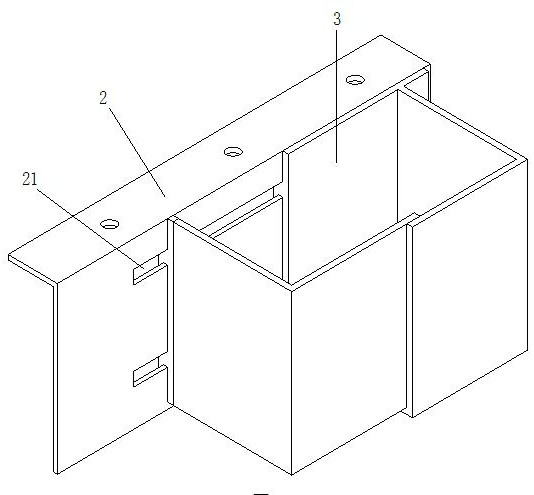

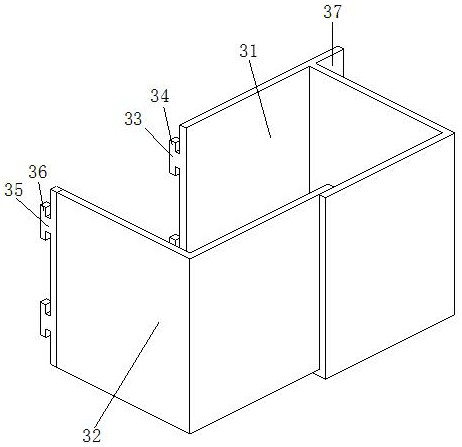

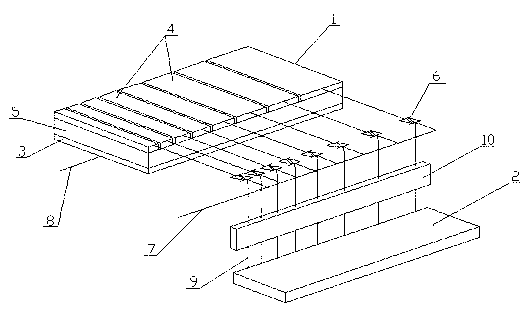

Sewing machine convenient for assembly line processing and installation mode thereof

InactiveCN112609347ACapacity adjustmentEasy to increase useSewing-machine elementsEngineeringAssembly line

The invention relates to the field of sewing machines, in particular to a sewing machine convenient for assembly line processing. The sewing machine comprises a base; a connecting plate is fixed at the discharging end of the base; a telescopic basket is fixed on the connecting plate; and the telescopic basket comprises a fixed basket and a movable basket. According to the invention, the connecting plate and the telescopic basket are installed on the edge of the base corresponding to the discharging position; the movable basket of the telescopic basket is matched with a sliding groove of the connecting plate, so that the capacity of the telescopic basket can be adjusted, and the applicability of the telescopic basket to different products is improved; and meanwhile, the telescopic basket is arranged on the base, so that the situation that a worker frequently bends down to place processed clothes or take to-be-processed clothes can be avoided, and the body health of the worker is guaranteed.

Owner:泉州市博凯工业设计有限公司

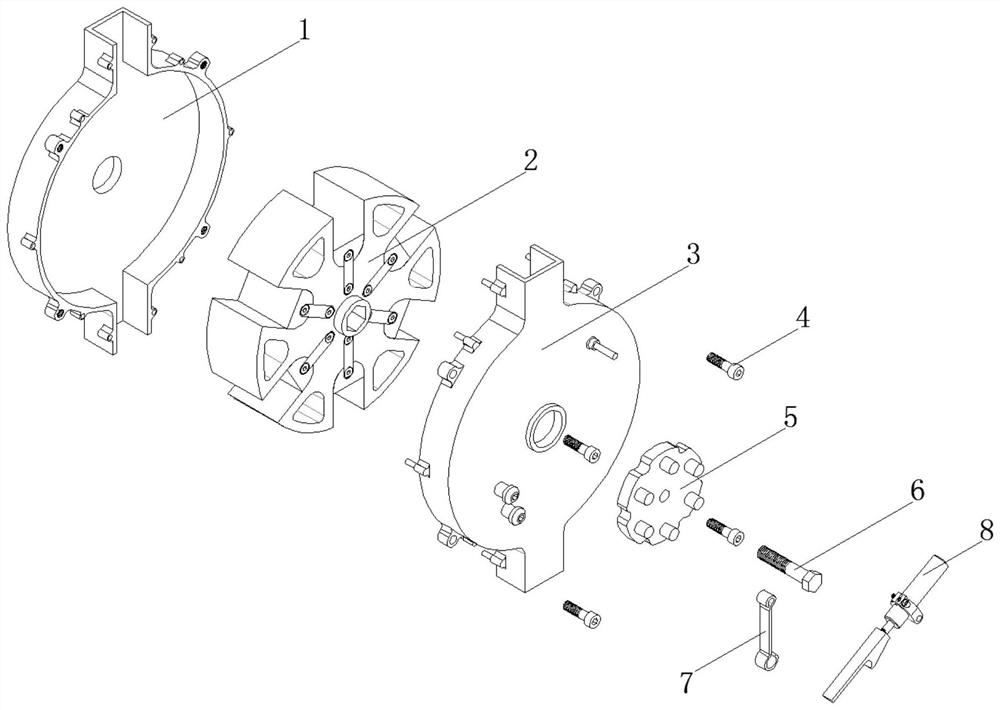

Seed sowing device for fruit planting

InactiveCN111937544AControl delivery rateSimple delivery rateSeed depositing seeder partsAgricultural engineeringStructural engineering

The invention discloses a seed sowing device for fruit planting. The seed sowing device comprises a left shell, a rotating core, a right shell, a shell connecting screw, a rotating disc, a disc connecting screw, an elastic steel bar, a telescopic rod and a seed box. The seed box is located above the left shell and the right shell. The left shell and the right shell are connected through the shellconnecting screw. The rotating core is located in the inner space of the left shell and the right shell. The rotating disc is connected with the rotating core through the disc connecting screw. The elastic steel bar is fixed between the two sets of steel bar bases of the right shell. The telescopic rod is rotationally connected with the steel bar bases through a rod clamp on the outer side of thetelescopic rod. The outline of the seed box is of a rectangular box-shaped structure. The seed box is formed by bending and welding a steel plate. The bottom surface of the seed box is an inclined surface. The lower end of the seed box is of a vertical square cylindrical structure. The middle part of the left shell is of a circular shell-shaped structure. The seed sowing device for fruit plantingcan adjust the seed feeding speed and the seed feeding quantity, and is suitable for general popularization and application.

Owner:肖煜

A smart rice storage bucket

ActiveCN110606262BRealize automatic rice outputFree adjustment of storage capacityLinings/internal coatingsContainers preventing decayAgricultural scienceAgricultural engineering

The invention discloses an intelligent rice storage barrel comprising a rice storage part, a control part, an air supply part and a rice discharge part. The rice storage part comprises an outer barrel, an inner barrel, a stand column, insertion plates and a cover body. The control part comprises an enclosing plate, rice discharge pipes and an electronic control assembly. The air supply part comprises an air pump and an air pipe. The rice discharge part comprises a bottom box and a drawing box. According to the intelligent rice storage barrel, by regulating the insertion plates, the volume-adjustable multi-rice-bin function is achieved, various different types of grain can be stored in the rice storage barrel at the same time, and meanwhile, the storage capacity for the various types of grain can be freely regulated according to requirements; meanwhile, by means of control of the air supply part, ventilation treatment can be conducted on the inner portion, and the moisture prevention and insect prevention effects are good; and by means of control of the electronic control assembly, automatic rice discharge can be achieved for the different types of grain, the automation degree and the intellectualization degree are high, and use is convenient.

Owner:ZHEJIANG NORMAL UNIVERSITY

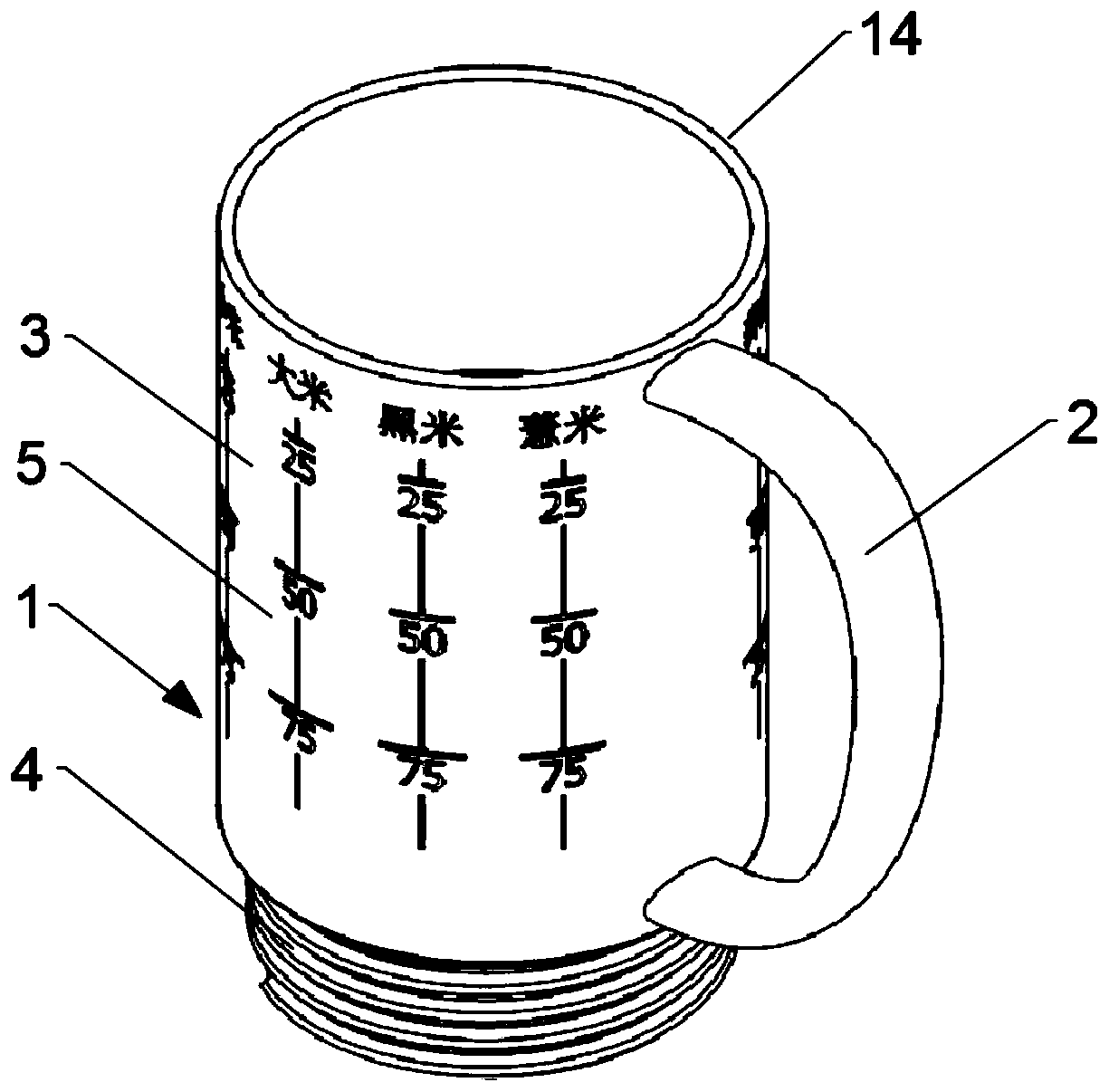

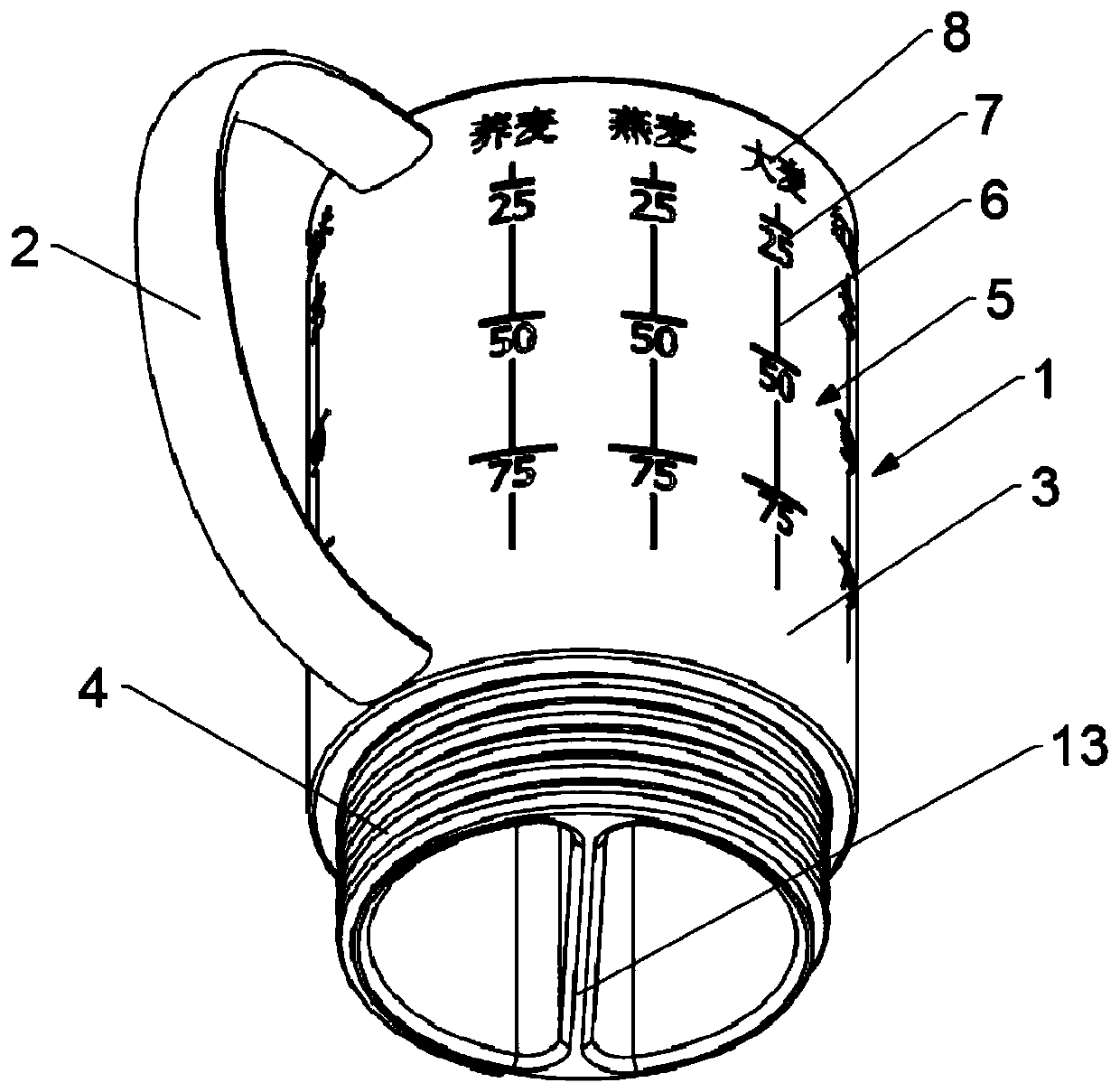

Staple food quantitative weighing cup

PendingCN110864757ACapacity adjustmentCapacity can be adjusted at willNon-fluent solid material measurement calibrationMechanical engineeringStaple food

The embodiment of the invention discloses a staple food quantitative weighing cup. The cup comprises a cup body and a cup handle connected to the side edge of the cup body, wherein the cup body comprises a transparent cup body and a cup core, the cup core is rotationally installed inside the transparent cup body and can move up and down along the inner wall of the transparent cup body, the containing volume of the transparent cup body is changed through the up-and-down movement of the cup core, and graduated scales used for reading the weight of staple food in corresponding varieties in the cup are arranged on the outer wall of the transparent cup body. According to the embodiment, the upper surface of the cup core is rotated to a corresponding scale line of one corresponding graduated scale, then the staple food is contained in the cup till the staple food is higher than a cup opening, then the cup opening is leveled off by hand or any other article, and the remaining amount of the staple food in the cup is a wanted amount; the position of the cup core can be adjusted at a time and is maintained unchanged when the cup is used thereafter; after the cup is filled up with a materialwhich needs to be weighed, the cup opening is leveled off, then weighing is completed once, and therefore weighing is convenient, fast and accurate to perform every time.

Owner:北京市大兴区疾病预防控制中心 +1

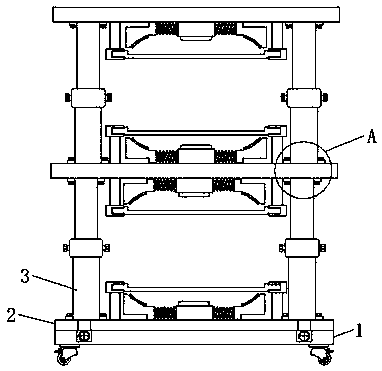

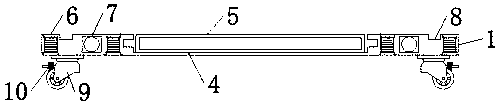

Portable mobile device

InactiveCN110901722AImprove convenienceDecrease productivityHand carts with multiple axesHand cart accessoriesEngineeringStructural engineering

The invention discloses a portable mobile device. The portable mobile device comprises a device base, a mounting plate and a top mounting plate; the top of the device base is movably connected with the mounting plate; the top of the mounting plate is fixedly connected with the top mounting plate; universal wheels are fixedly connected to the bottom end of the device base. A fixing hole penetratesthrough one side of the front surface of the device base; the other side of the top end of the device base is fixedly connected with a fixing groove. The middle part of the device base is fixedly connected with a mounting groove; a bottom fixing bolt is connected to one side of the mounting plate in an embedded manner; the bottom fixing bolts improve the stability of the device main body; the sponge mat prolongs the service life of the device; the convenience of the device body is greatly improved through the mounting and dismounting mechanism, transported objects are protected through the adjustable protection mechanism, the application range of the device body is widened through the device capacity adjusting mechanism, workers can adjust the device conveniently through limiting blocks, and the portable mobile device is suitable for being used by mobile devices and has wide development prospects in the future.

Owner:余娜娜

An energy-saving continuous liquid feed filling machine

ActiveCN110240106BMeet normal productionAdjustable speedLiquid bottlingAgricultural scienceAgricultural engineering

The invention discloses an energy-saving continuity liquid fodder filling machine which comprises a base, a working table and a power source. The working table and the power source are arranged on the top and one side of the base correspondingly. A supporting arm is connected to one side of the base. A pressurizing mechanism is carried on the supporting arm. A feeding system, a moving mechanism and a transmission assembly are arranged on three side faces in the anti-clockwise direction of the base correspondingly. Supporting feet are installed on the bottom of the base and the bottom of the working table correspondingly. The working table is erected on the top of the base and fixedly connected with the base through the supporting feet. Compared with an existing liquid fodder filling machine, the energy-saving continuity liquid fodder filling machine is easy to assemble, the repair and maintenance cost is low, meanwhile, the filling machine operates by the adoption of the single-motor drive motion structure, the intermittent filling mode is achieved, thus an energy source is saved greatly, moreover, the speed and the capacity of fluid fodder of the filling machine can be adjusted, and production of liquid fodder is met effectively.

Owner:宁夏绿健源生物科技有限公司

PVC pipeline conveying clamp for sewage discharge

ActiveCN110962904AClamping capacity adjustmentCapacity adjustmentHand carts with multiple axesHand cart accessoriesStructural engineeringSewage treatment

The invention discloses a PVC pipeline conveying clamp for sewage discharge and relates to the technical field of sewage treatment equipment. The clamp comprises a base, a top fixing plate, a side connecting rod and a top connecting rod, the PVC pipeline conveying clamp for sewage discharge is mainly formed by splicing the base, side connecting rods and a top connecting rod end to end, the base isa horizontally-arranged square plate, the multiple side connecting rods are symmetrically hinged to the front side and the rear side of the top end of the base, and every two adjacent side connectingrods on each side are arranged at equal intervals. A disc-shaped magnetic block is embedded into the circle center of the top end of each connecting column; every two adjacent cushion blocks are connected through a magnetic block. The connecting columns of every two adjacent cushion blocks are rapidly attracted through the magnetic blocks, the operation efficiency during installation is improved,the cushion blocks can be rapidly disassembled conveniently when a PVC pipeline is taken out of the clamp, and the installation operation simplicity of the cushion blocks is improved.

Owner:福建泉州业德弗科技有限公司

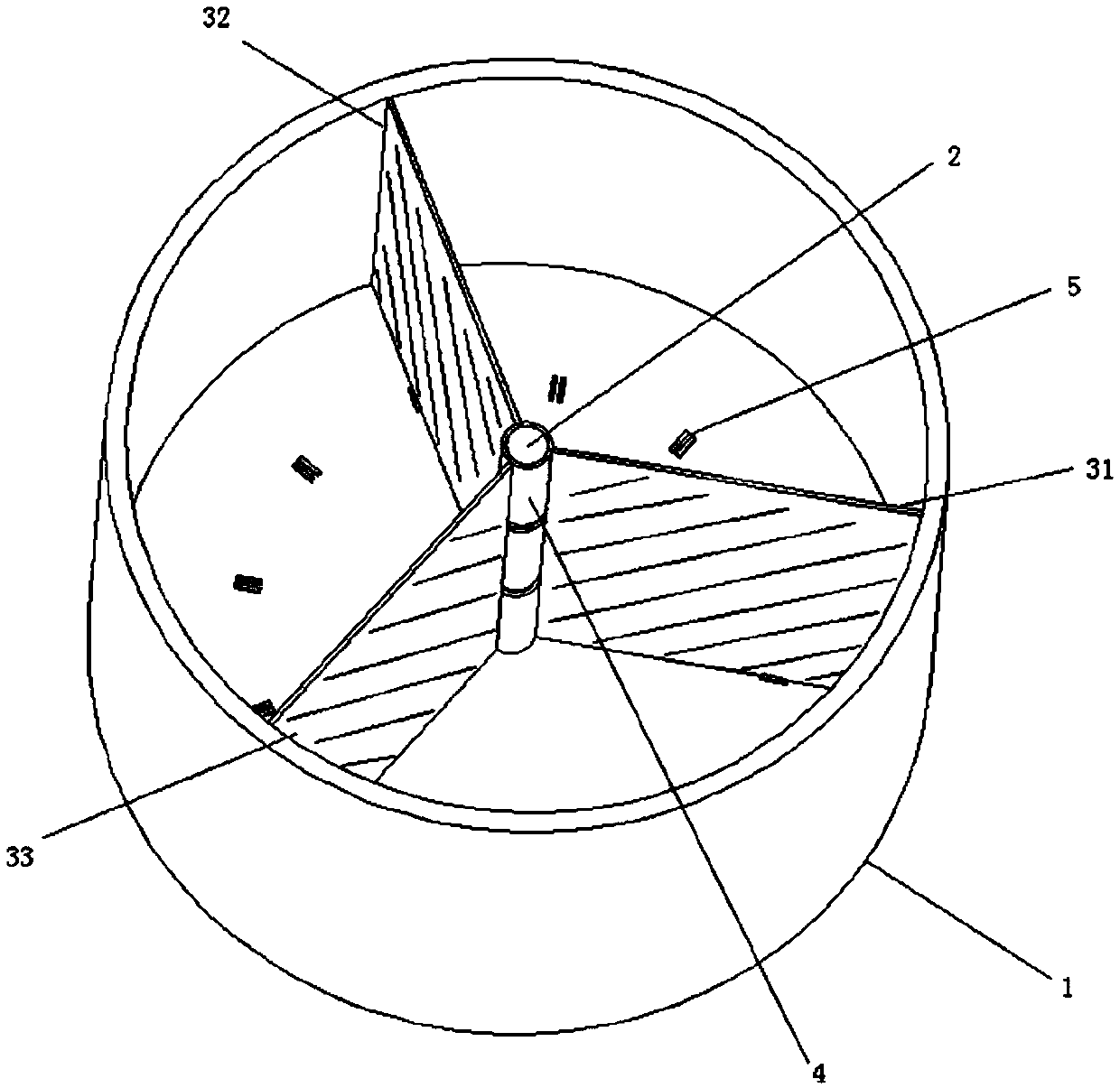

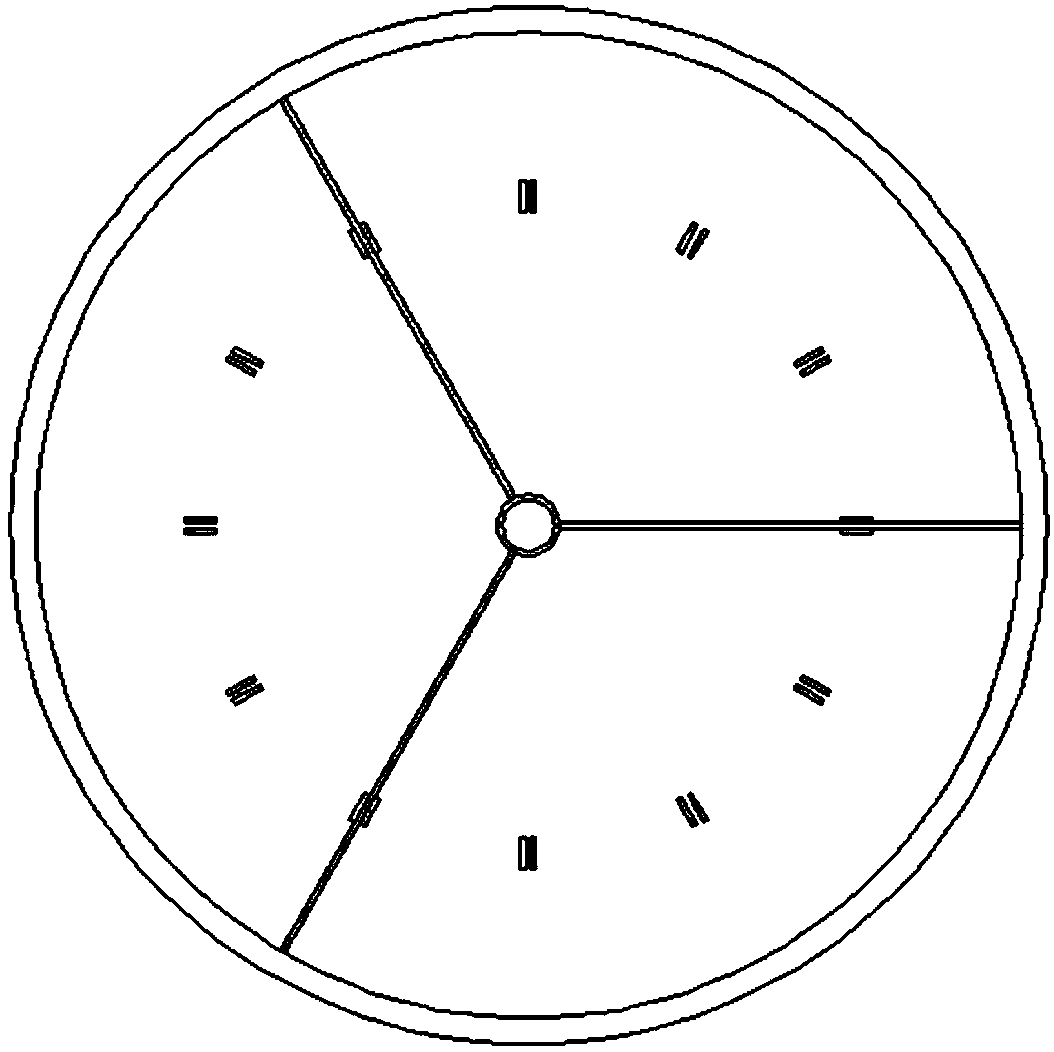

Capacity-adjustable lunch box

The invention relates to a capacity-adjustable lunch box. The capacity-adjustable lunch box includes a box body, a box cover, and a plurality of partitions, wherein the bottom center of the box body is provided with a stand column, the partitions sleeve the stand column, the box cover is buckled on the box body, the box body is a cylindrical box body, each partition includes a square plate and a cylindrical connecting portion, the square plates are connected to the cylindrical connecting portions which sleeve the stand column, the square plates divide the inside of the box body into a plurality of fan-shaped accommodation spaces, a plurality of limiting grooves are arranged at the bottom of the box body in a circular array manner, and the width of the limiting grooves is the same as the thickness of the partitions. The capacity-adjustable lunch box has a simple overall structure, is relatively low in production cost, reduces labor cost, and is more beneficial to people's daily needs.

Owner:TAISHAN SHIHENG PACKAGING MATERIAL CO LTD

Programmable regulating non-polar capacitor based on high dielectric material

InactiveCN102420049BCapacity adjustmentSave materialCapacitor with electrode area variationCapacitancePolymer capacitor

Owner:HENAN UNIV OF SCI & TECH

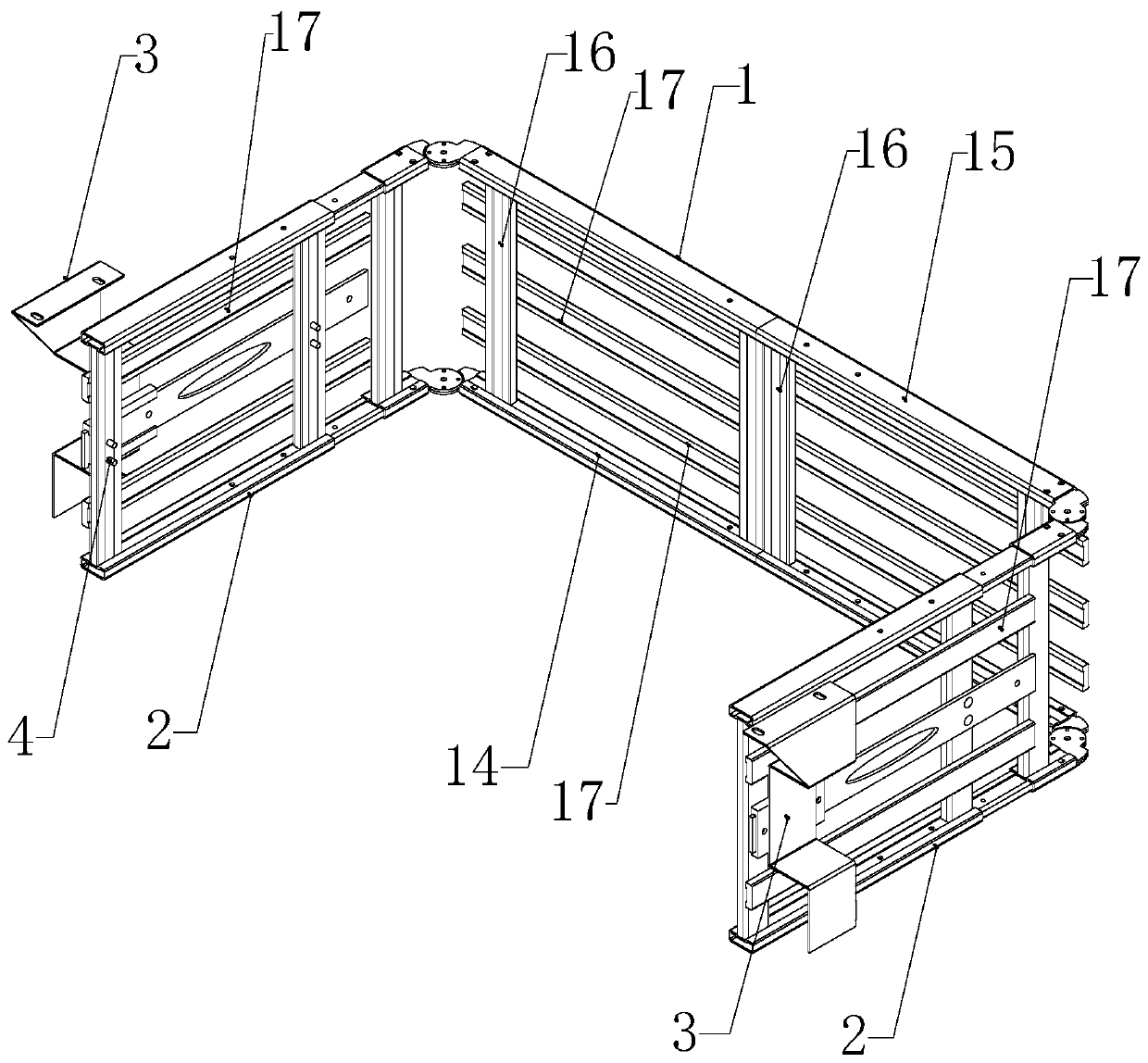

Novel battery pack structure

PendingCN108493506ACapacity adjustmentLow costCell component detailsSecondary cells servicing/maintenanceElectrical batteryElectric energy

A novel battery pack structure comprises an upper pole plate, a lower pole plate, a battery holder, a power management device, a heat management device and single batteries, the battery holder comprises a base body, isolation walls arranged in the base body and a plurality of spaced mounting chambers formed by the isolation walls, and the single batteries are arranged in the mounting chambers; theupper pole plate and the lower pole plate are detachably fixedly connected to the upper side and the lower side of the battery holder, the upper pole plate and the lower pole plate are provided withpole pieces, and the pole pieces are serially connected with the single batteries; the power management device is fixedly connected to the battery holder and is connected with every single battery; and the heat management device includes heat conducting plates embedded in the isolation walls and a heat recovery device connected with the heat conducting plates. The novel battery pack structure hasthe advantages of simple structure, good battery monitoring effect, good temperature regulation effect, energy saving, emission reduction and strong use flexibility.

Owner:福州鼎烯飞扬科技有限公司

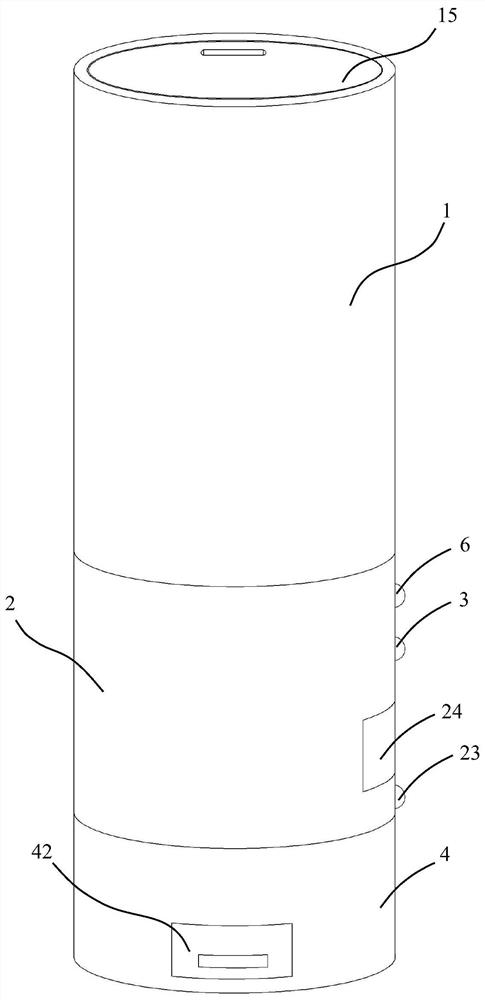

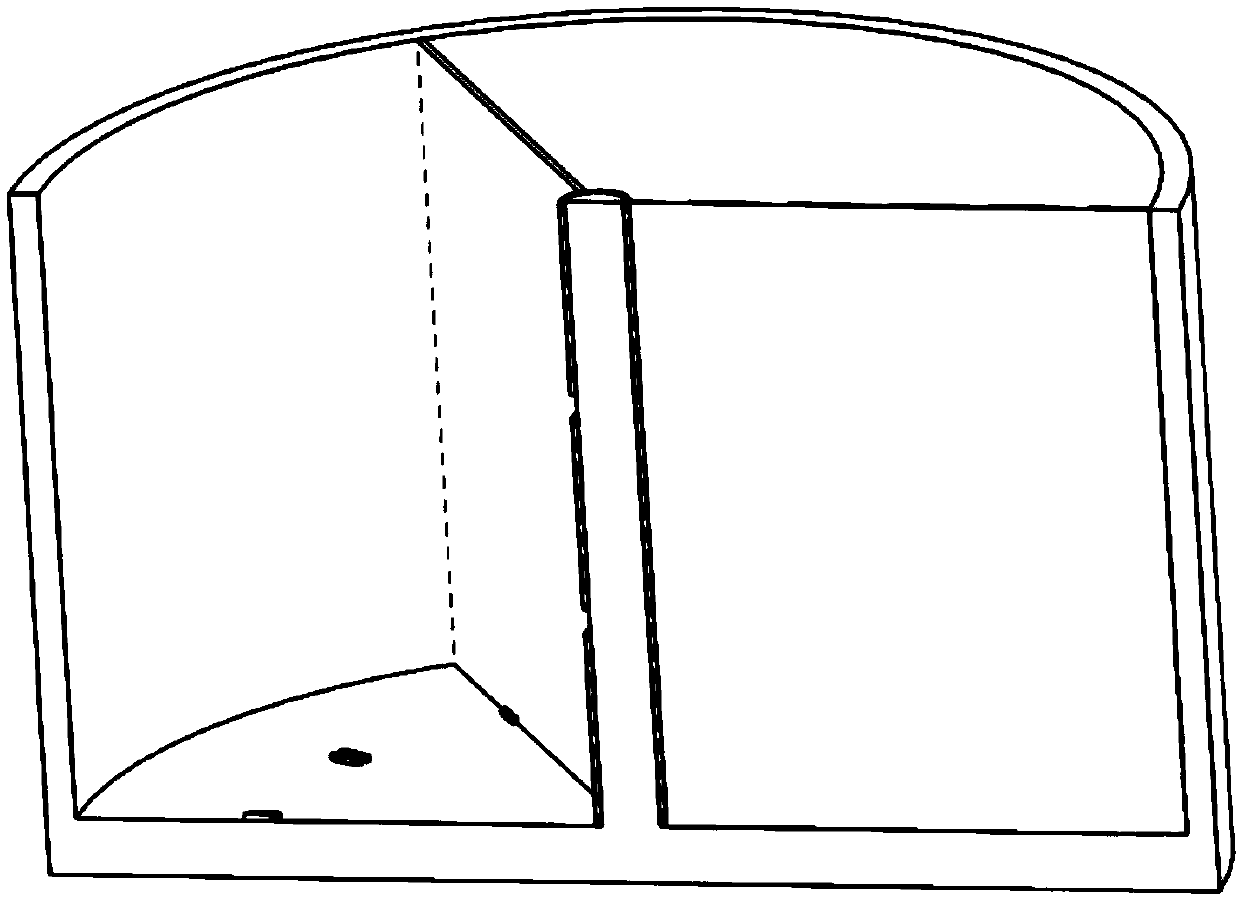

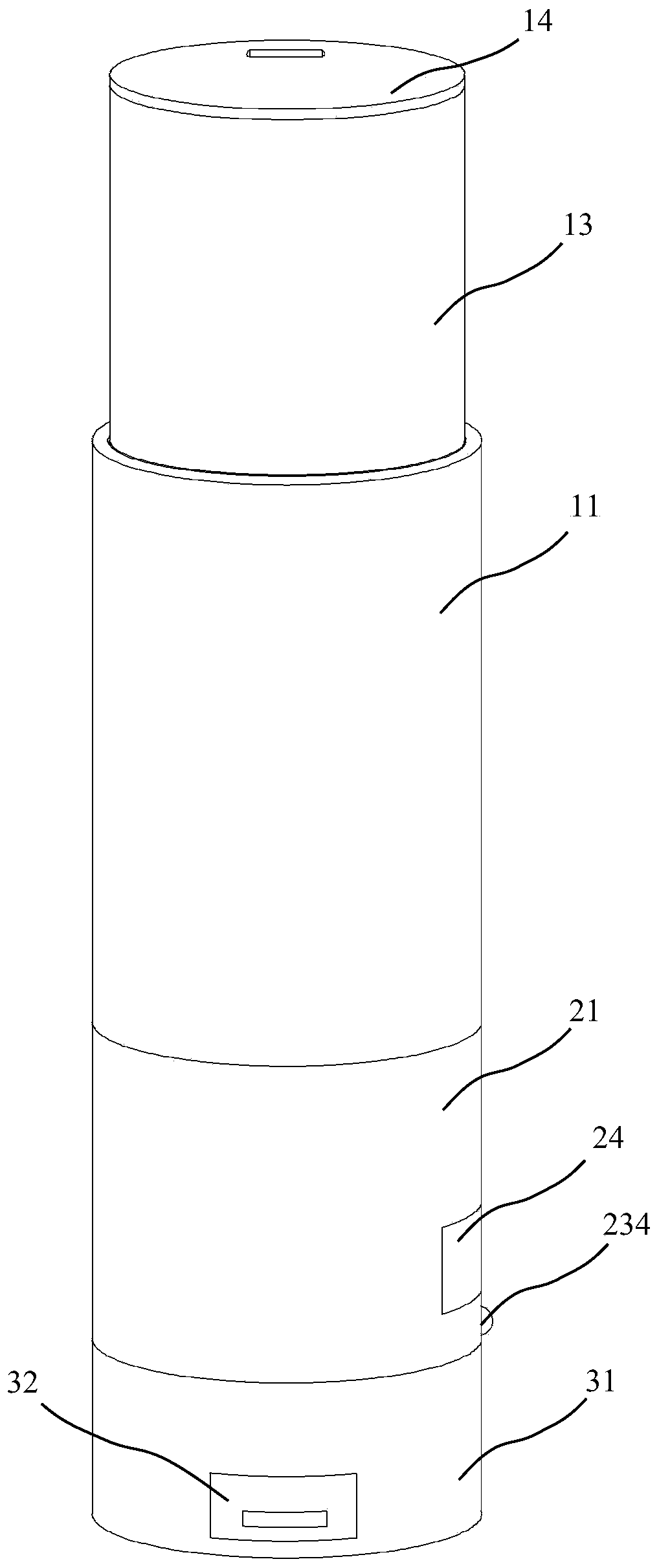

Intelligent rice storage barrel with adjustable capacity

InactiveCN110419969ACapacity adjustmentExtend height adjustmentKitchen equipmentEngineeringElectric control

The invention discloses an intelligent rice storage barrel with an adjustable capacity. The intelligent rice storage barrel comprises a rice storage part, a control part and a rice discharging part, wherein the rice storage part comprises an outer barrel, an inner barrel, a telescopic barrel and a cover body; the control part comprises a surrounding plate, a rice discharging pipe and an electric control assembly; the rice discharging part comprises a bottom box and a drawing box; by virtue of thread rotary control between the telescopic barrel and the inner barrel, the extending height of thetelescopic barrel can be adjusted, so that the capacity of the rice storage barrel can be adjusted, and the use requirements of different rice storage quantities can be met; and by controlling the electric control assembly, the automatic rice discharging can be realized, the automation degree and the intelligent degree are high, and the use is convenient.

Owner:ZHEJIANG NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com