Prefabricated type high-rise residential barrel shuttering dense-rib prestressed floor structure system

A high-rise residential and prefabricated assembly technology, applied in the direction of floors, residential buildings, building components, etc., can solve the problems of limiting the production efficiency of prefabricated component factories, failing to meet the needs of variable spaces, and difficult to improve design and construction efficiency. Achieve the effect of balancing production capacity and market supply and demand, increasing variety richness, and reducing on-site workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

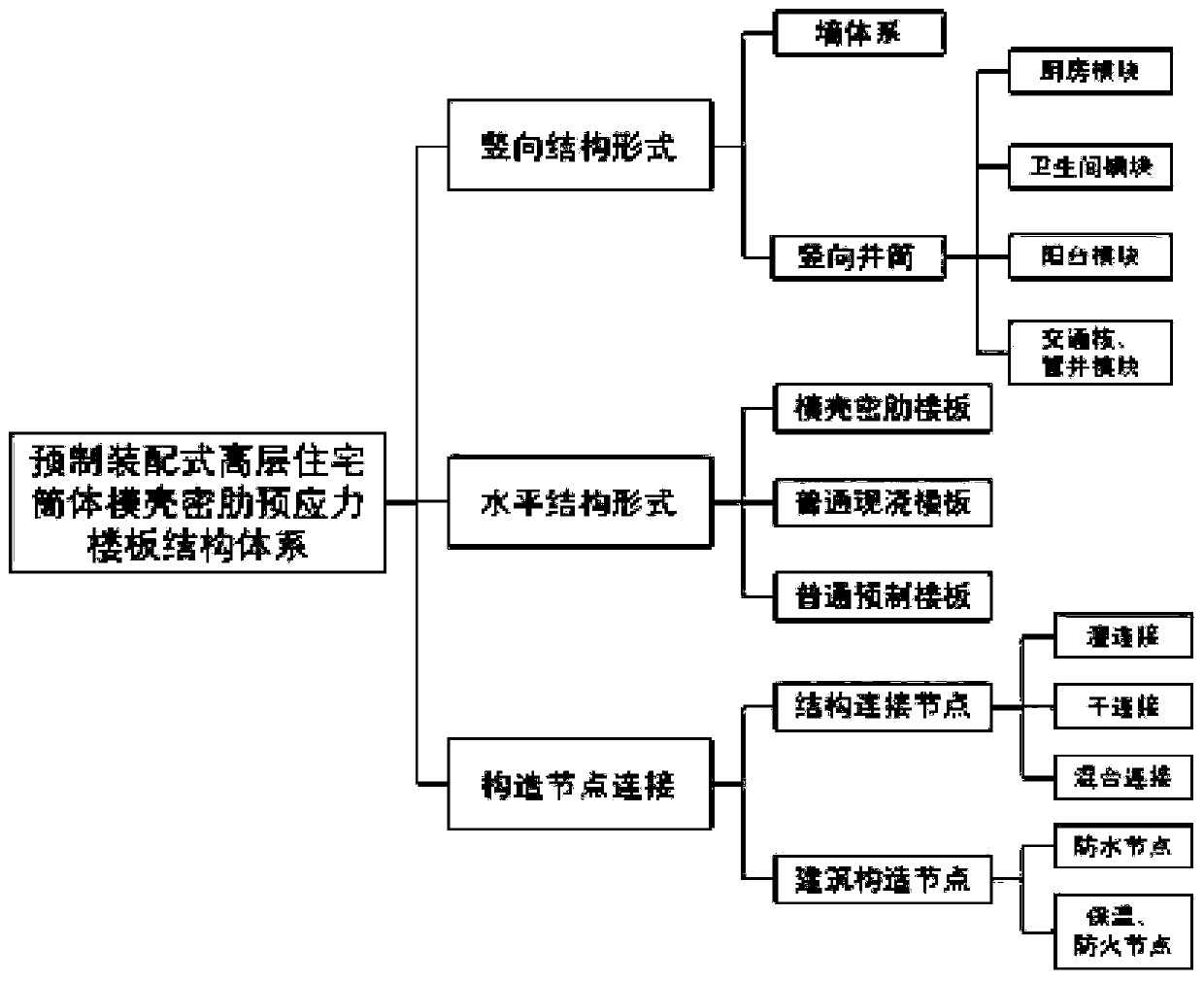

[0040] The structural system of prefabricated high-rise residential tubular formwork and ribbed slab includes three parts: vertical structure form, horizontal structure form and structural node connection. Among them, the vertical structure includes the shear wall part and the shaft formed by functional spaces such as kitchen, bathroom, balcony, traffic core, and tube well. The horizontal structure mainly refers to the floor structure system, including prefabricated formwork and ribbed floors, ordinary cast-in-place floors (beams) and ordinary prefabricated floors. The vertical structure and the horizontal structure do not exist independently but interact. These two parts also need the assistance of connecting nodes to form the overall structure of the building. While achieving structural safety and good earthquake resistance, the assembly rate can be improved and the space adaptability can be realized. Variety.

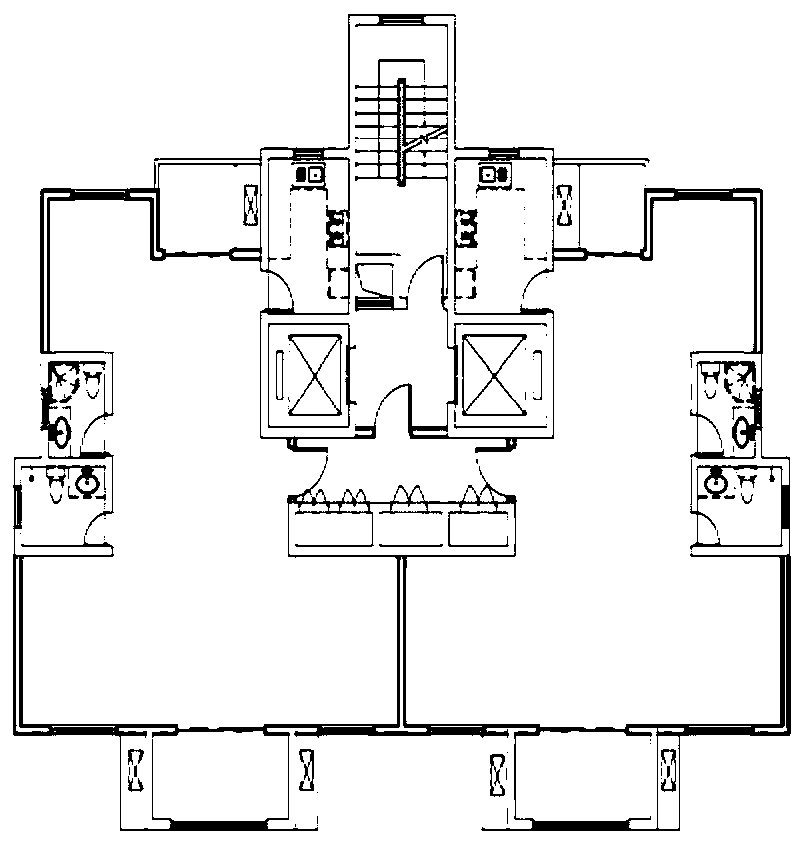

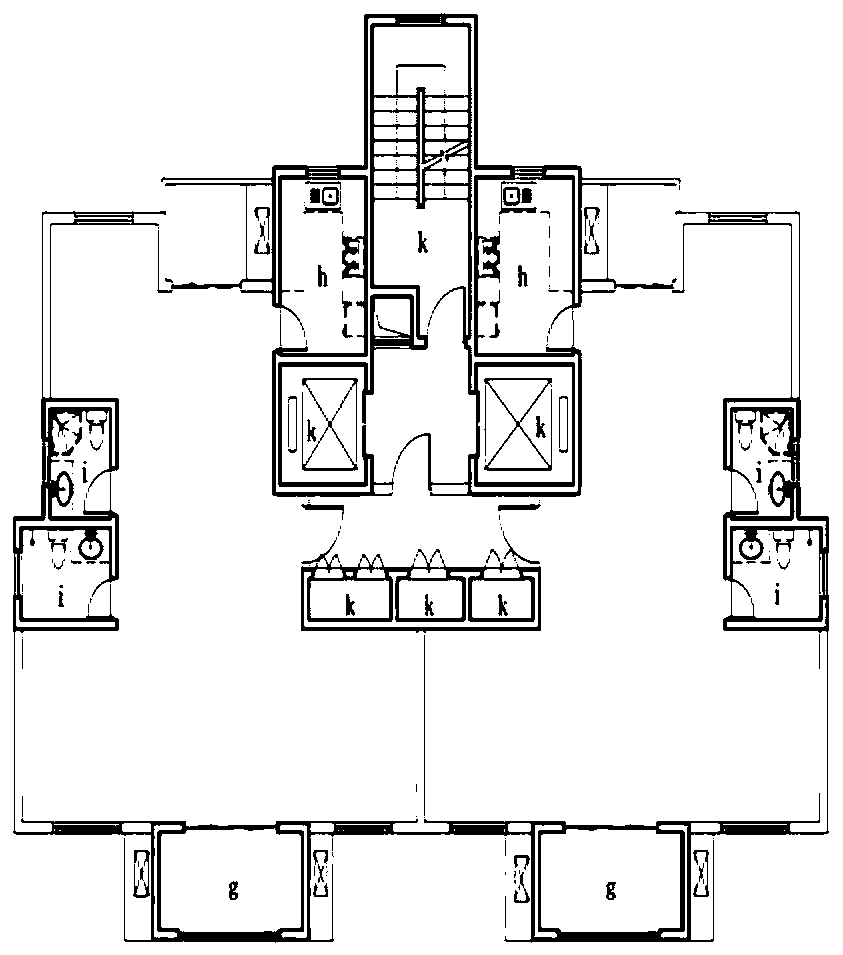

[0041] as attached diagram 2-1 Situation of the wall system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com