Volume-adjustable lactic acid beverage filling equipment

A technology for lactic acid beverages and filling equipment, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of cumbersome adjustment, large error of solenoid valve and flowmeter, slow speed, etc., and achieve high capacity accuracy and flexible adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

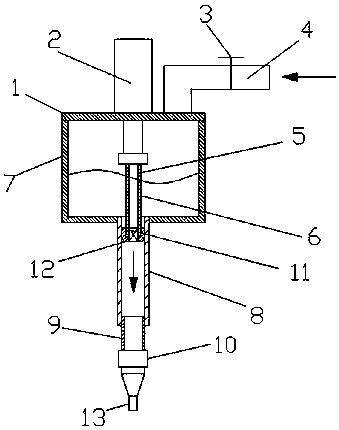

[0014] Combine below figure 1 And further illustrate the technical solution of the present invention through specific examples.

[0015] A capacity-adjustable lactic acid beverage filling device, comprising: a nozzle 9, a liquid storage box 7, a cover plate 1, a straight cylinder 8 and a piston 12, the cover plate 1 is arranged on the top of the liquid storage box 7 for sealing, and the The cover plate 1 is provided with a liquid supply pipeline 4, which is externally connected to a liquid storage tank of lactic acid beverage. The liquid supply pipeline 4 is provided with a first valve 3 to provide the liquid storage box 7 with a lactic acid beverage solution.

[0016] The bottom of the liquid storage box 7 is provided with a straight cylinder installation hole, the top of the straight cylinder 8 is arranged in the straight cylinder installation hole, the nozzle 9 is arranged at the bottom of the straight cylinder 8, and the cover plate 1 is provided with a lifting drive point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com