PVC pipeline conveying clamp for sewage discharge

A technology for pipeline transportation and sewage discharge, which is applied in transportation and packaging, multi-axis trolleys, trolley accessories, etc. problems, to achieve uniform force, avoid uneven force, and improve the effect of installation firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

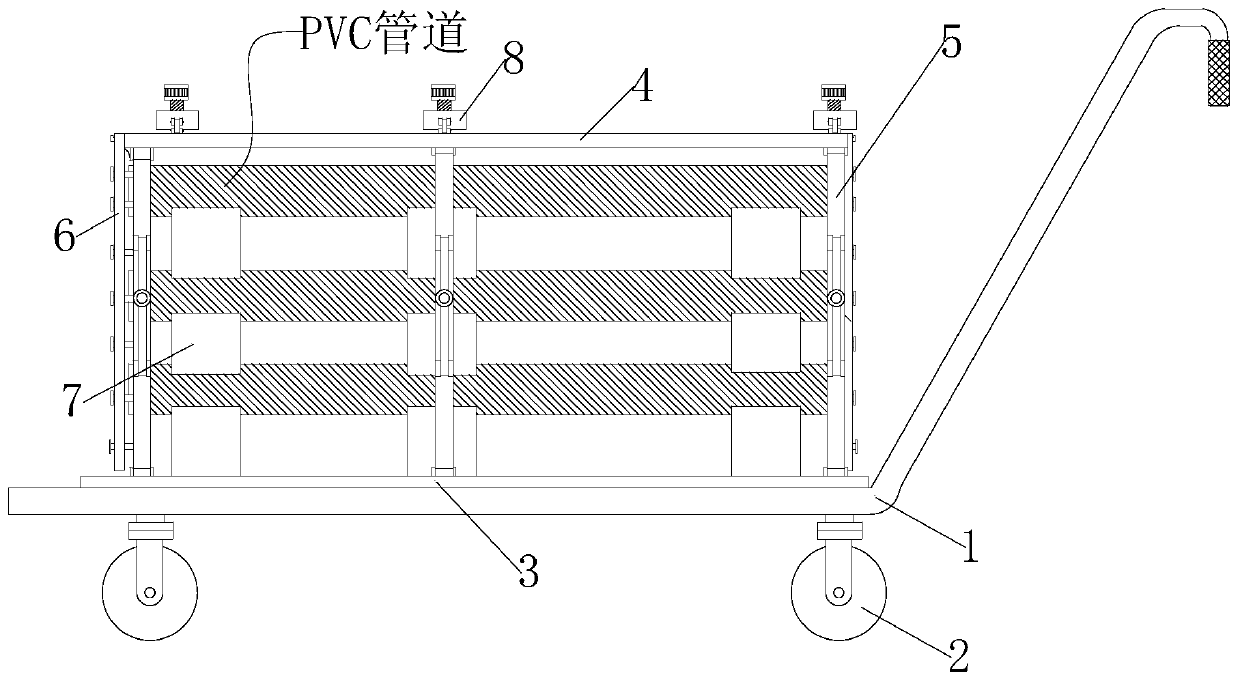

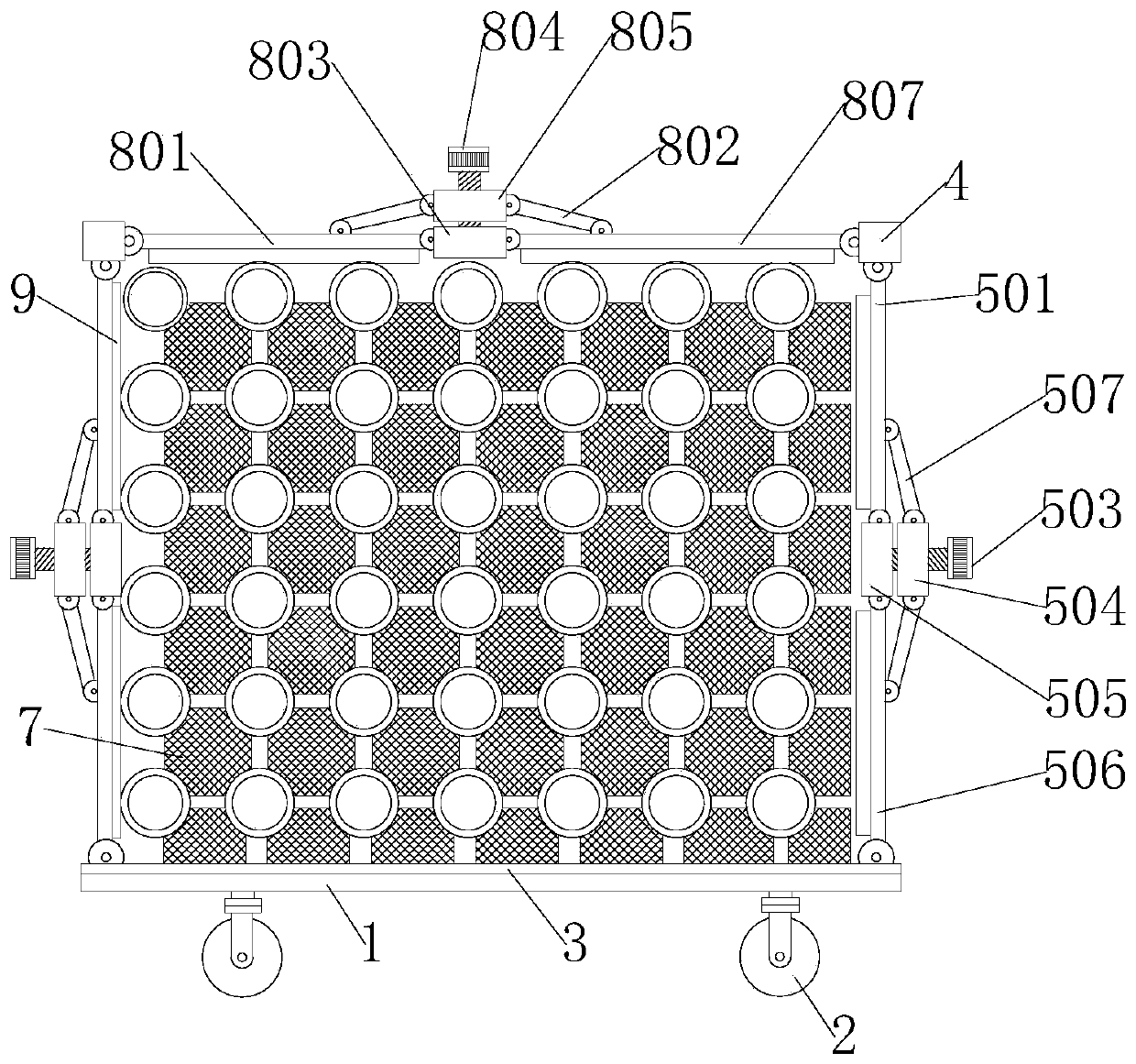

[0035] see figure 1 as well as Figure 3-Figure 6 , is a schematic diagram of the overall structure of a PVC pipe conveying fixture for sewage discharge, a PVC pipe conveying fixture for sewage discharge, including a base 3, a top fixing plate 4, a side connecting rod 5, and a top connecting rod 8, and the PVC pipe conveying fixture for sewage discharge The pipeline conveying fixture is mainly composed of base 3, side connecting rod 5 and top connecting rod 8 spliced end to end. The two adjacent side connecting rods 5 on the side are equally spaced, and the top of the side connecting rods 5 on each side is hinged with a vertically installed top fixing rod 4, and a top connecting rod 8 is hinged between the top fixing rods 4 on both sides. A plurality of top connecting rods 8 are installed in the middle of the top fixing plates 4 on both sides at equal distances; The connecting rod 5 and the top connecting rod 8 bind the PVC pipes, the bottom end of the base 3 is equipped w...

Embodiment 2

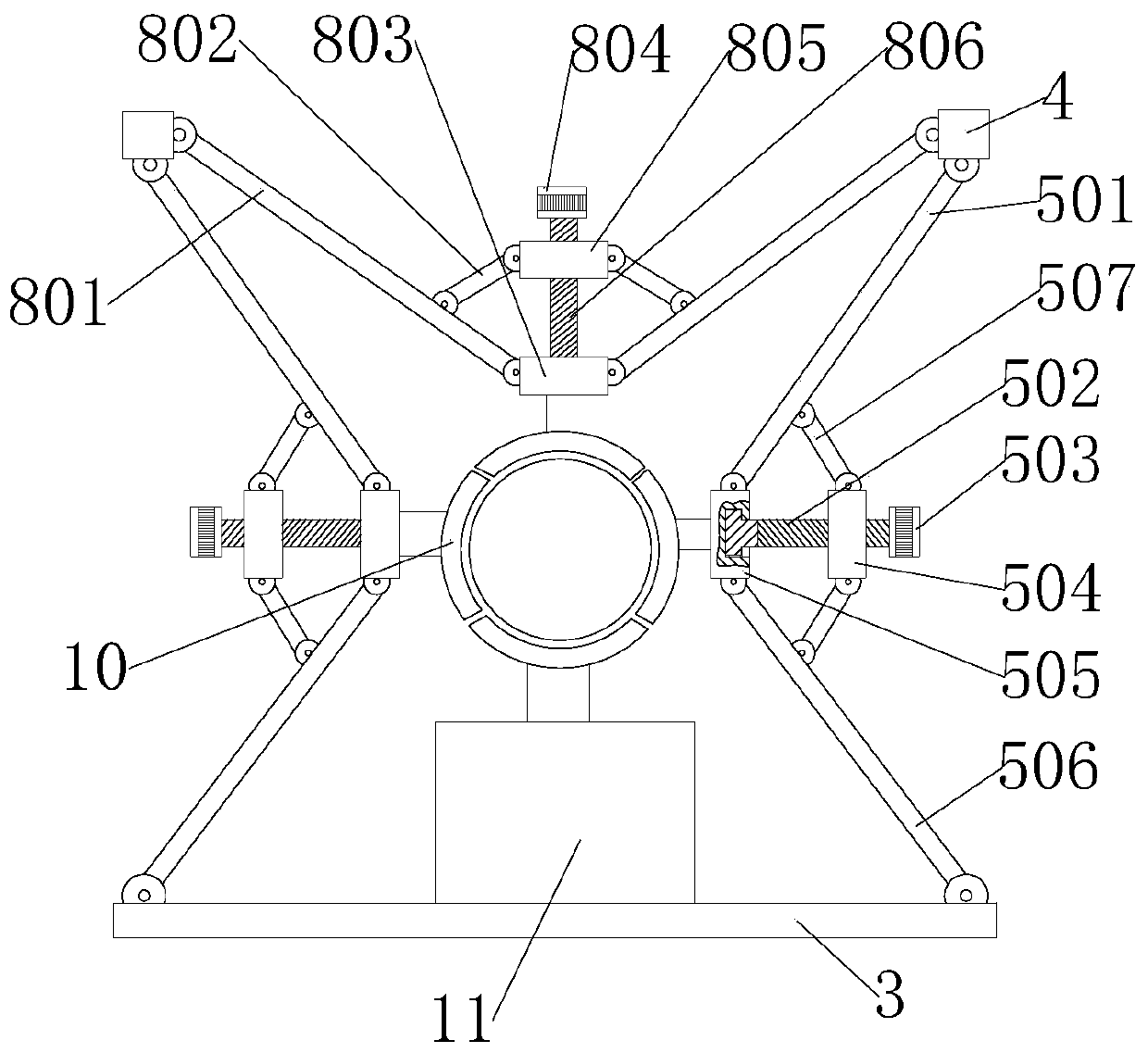

[0053] see figure 1 and figure 2 , is a schematic diagram of the overall structure of another PVC pipeline conveying fixture for sewage discharge. This embodiment has the same content as the above-mentioned embodiment 1, and the same will not be described in this embodiment. The specific difference is that :

[0054] The bottom end of each first hinged seat 505 is equipped with jaws 10, the bottom end of each second hinged seat 803 is equipped with jaws 10, and the top of base 3 is equipped with a square bottom fixed seat 11, the bottom fixed seat The top of 11 is equipped with clamping jaw 10.

[0055] The bottom end of each first hinge seat 505 is provided with a threaded hole, and the bottom end of each second hinge seat 803 is provided with a threaded hole. The plate is provided with a concave arc surface, and the convex surface of the clamping jaw 10 is provided with a cylindrical rod, and the outer surface of the cylindrical rod is provided with threads, and the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com