Patents

Literature

263results about How to "Improve installation firmness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-blocking explosion-proof valve and preparation method thereof

ActiveCN111490212ASmall compression strokeFlexible selectionCell lids/coversCell sealing materialsEngineeringMechanical engineering

The invention discloses an anti-blocking explosion-proof valve which comprises a piston, a valve body, a spring and a connecting shaft. A first through hole is formed in a connecting shaft in a penetrating mode, and a protective cover is installed on the valve body around an outer side of the spring. The valve body comprises a plurality of first air leakage gaps corresponding to the protective cover, and first air holes are formed in a cavity between the first air leakage gaps and the protective cover. The piston comprises a piston body, a breathable membrane and an upper cover, a second through hole longitudinally penetrates through the piston body and corresponds to the first through hole, a plurality of through grooves horizontally penetrate through the second through hole and are connected with the second through hole, and second breathable holes are formed in cavities between the through grooves and the upper cover. The invention further discloses a preparation method of the anti-blocking anti-explosion valve. According to the anti-blocking explosion-proof valve, the protective cover is arranged on the outer side of the spring such that combustion eruption objects are effectively prevented from accumulating and adhering to the spring to shorten the compression stroke of the spring, and the opening effect and the exhaust pressure relief efficiency of the explosion-proof valve are prevented from being affected.

Owner:DONGGUAN PUW EPTFE MATERIAL CO LTD

Stone dry-hanging construction process

InactiveCN103850417AIntegrity guaranteedImprove installation firmnessCovering/liningsFalseworkFirst Fill

The invention discloses a stone dry-hanging construction process. Steel tube couplers are adopted to build a double-row scaffold, the scaffold body is firmly anchored on a main structure, and putlogs are laid on the scaffold from the top down; a special big plumb or a theodolite is first used for vertically finding out the verticality of stones to be dry-hung, drilling and grooving are carried out, holes which are 8mm to 10mm in diameter are drilled at positions on a wall, which correspond to the grooves and holes of the stone slabs, one end of each stainless steel expansion bolt is inserted into one of the holes and fixed, and after the holes are drilled and the expansion bolts as anchoring parts are fixed, drilling and grooving are then carried out at corresponding positions on the stone slabs, avoiding the positions of rebars on a column or the wall; embedding glue is first filled in the bolt holes, the surfaces are cleaned, the dust in the gaps is cleaned off, plastic adhesive tapes which are 10mm to 15mm wide are stuck close to the gaps, a glue gun is used for filling sealing glue, the surfaces of the stone slabs are cleaned, waxed and polished, and the scaffold is dismantled. By means of the reasonable operation steps, the process can ensure the integrity of the stones, meanwhile, the mounting firmness of the stones is high, consequently, the stones cannot easily come off, and the service lives of the stones are prolonged.

Owner:SICHUAN YAHAO REAL ESTATE DEV

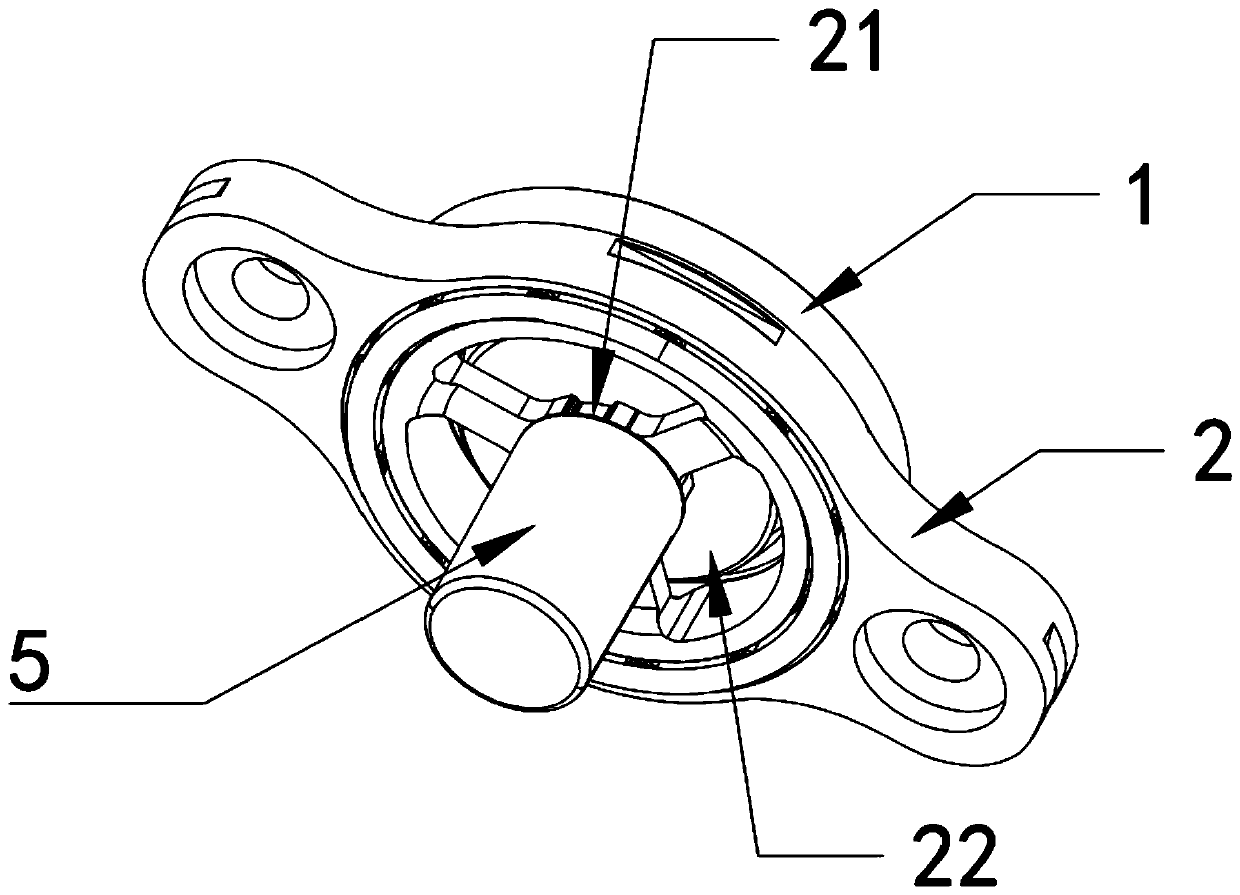

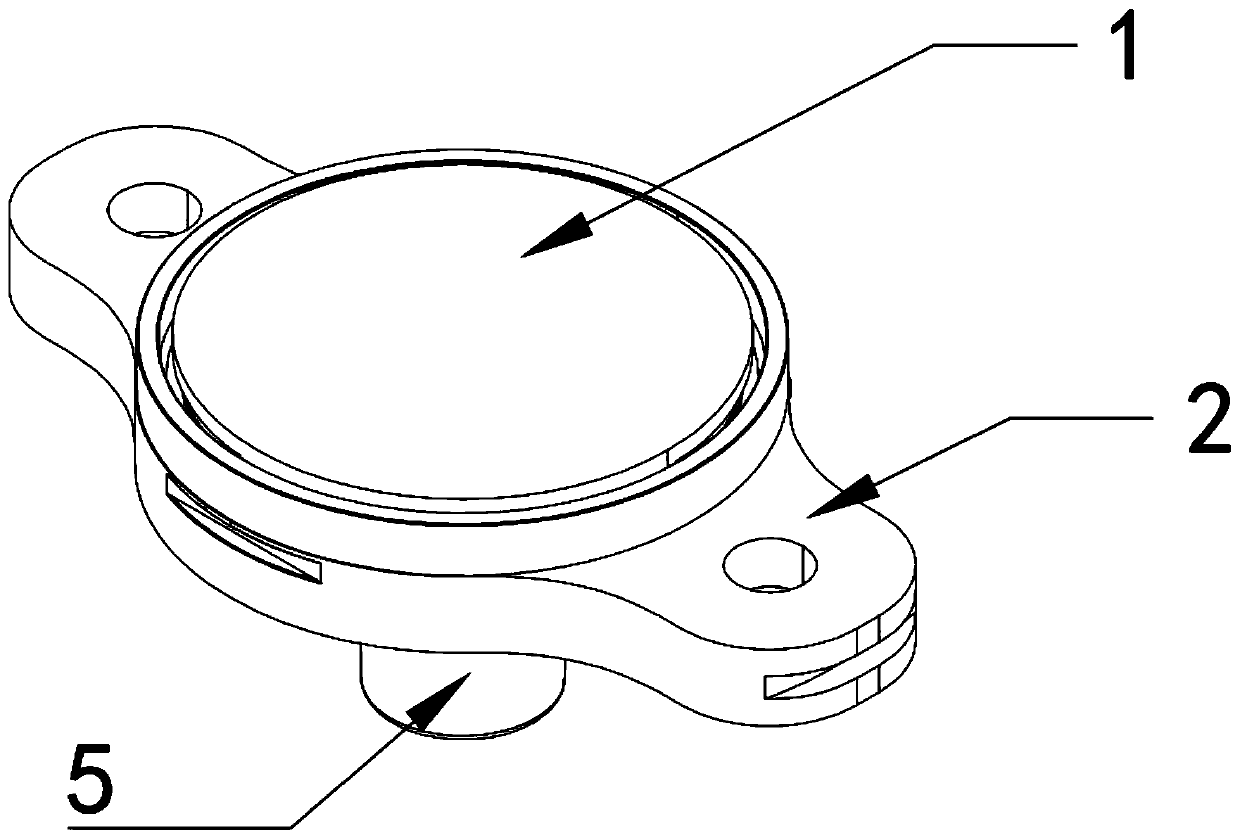

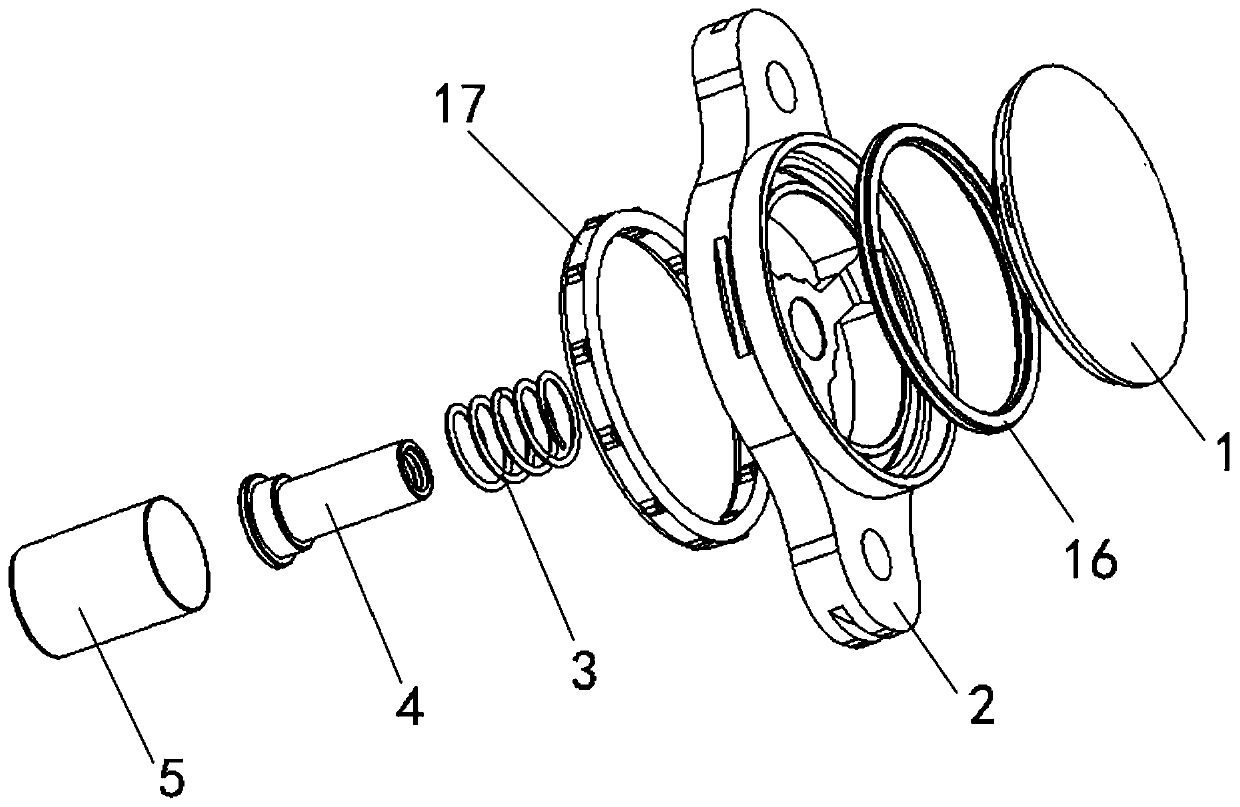

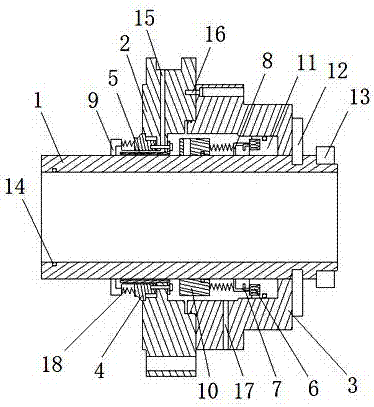

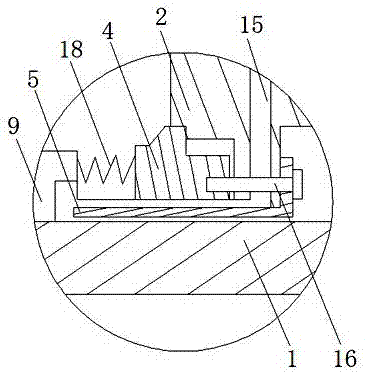

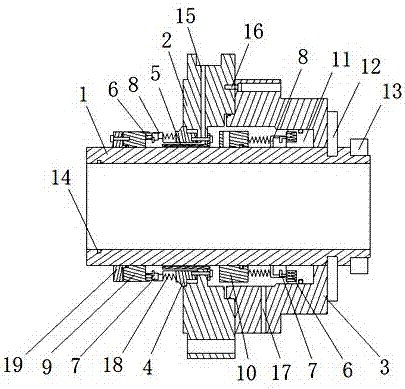

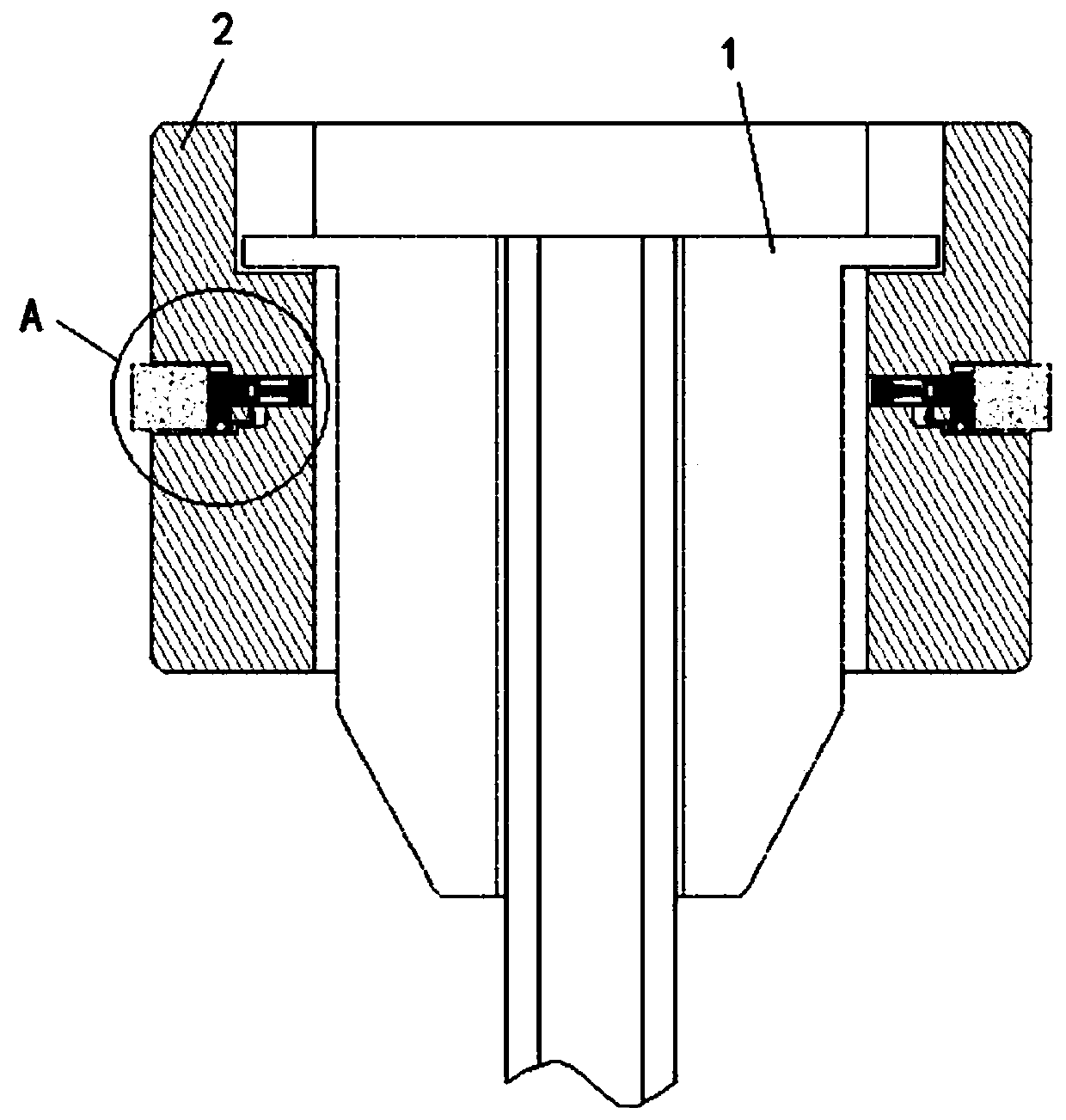

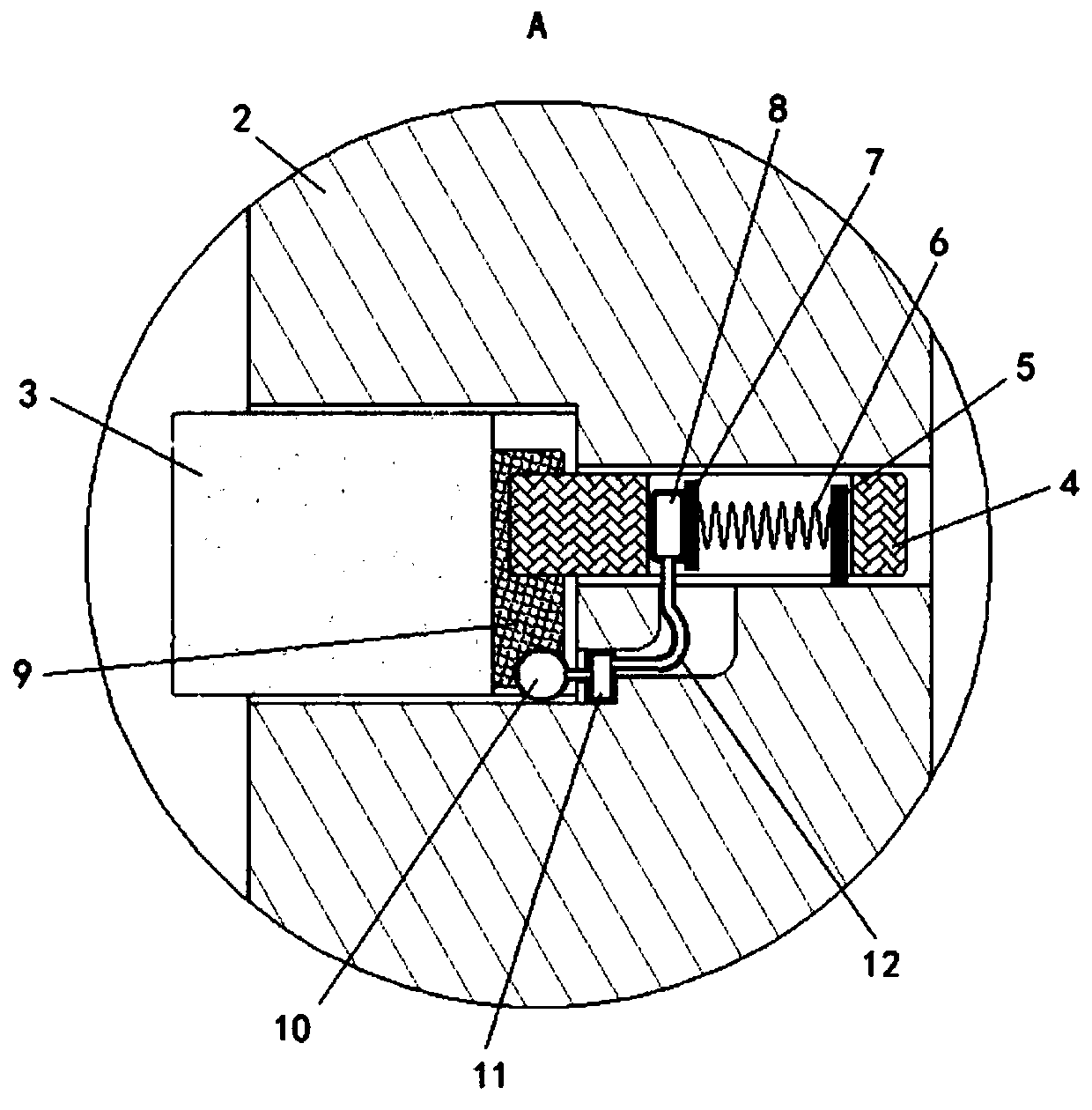

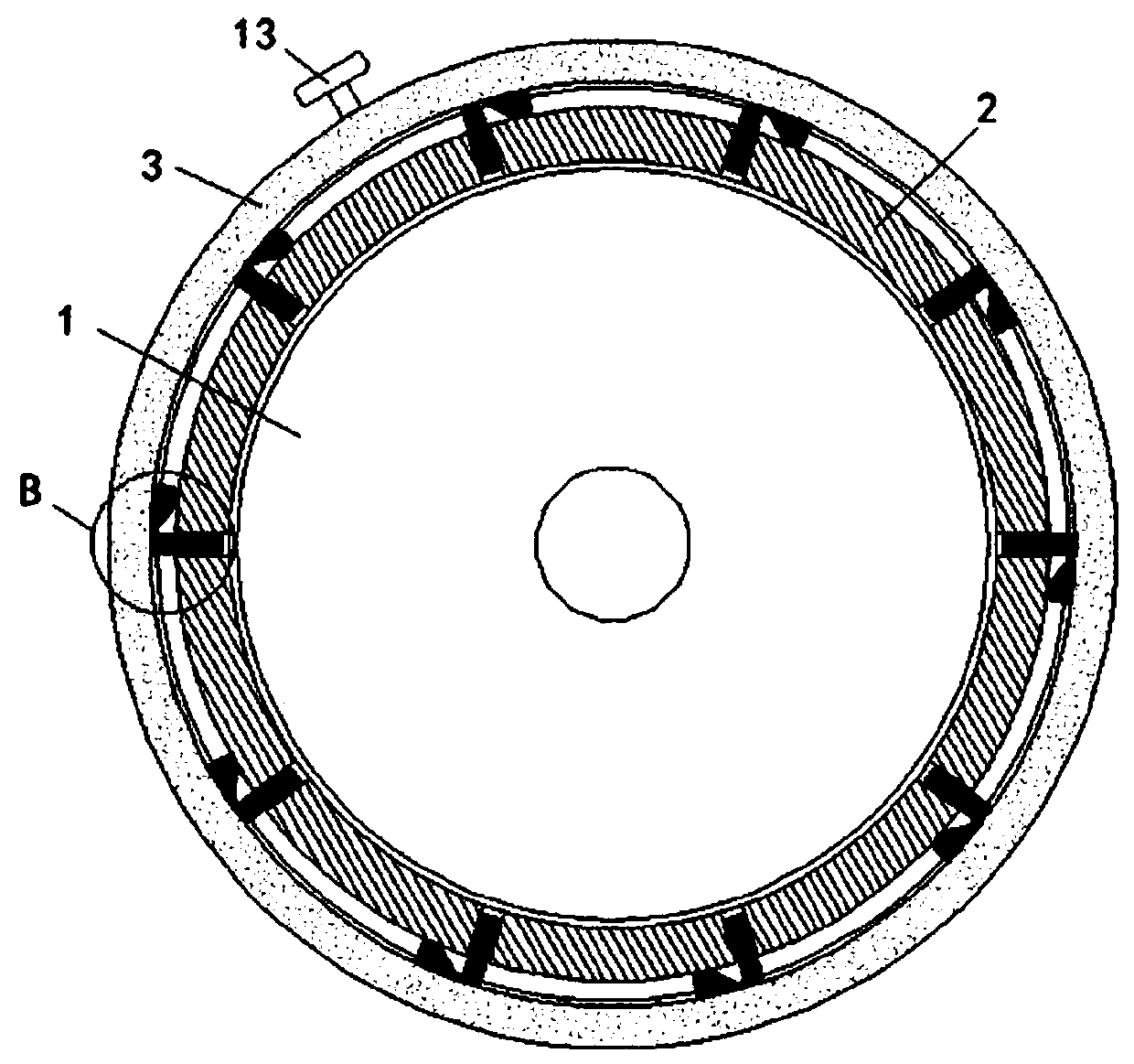

A magnetic levitation energy-saving blower mechanical seal

ActiveCN105864434BImprove sealingImprove installation firmnessEngine sealsPump componentsEngineeringAir blower

The invention discloses a novel mechanical sealing part of a magnetic suspension energy-saving air blower. The mechanical sealing part comprises a shaft sleeve, a first sealing ring, a second sealing ring, a buffer block, a flow guide ring, a magnetic controller, a dynamic ring and a static ring, and is characterized in that a retainer ring, a positioning ring, a fixing ring, a limiting ring, a fastening ring and a seal ring are arranged on the shaft sleeve, and the seal ring is arranged between the shaft sleeve and the positioning ring; the first sealing ring is provided with a guide-in groove; one end of the second sealing ring is connected with the shaft sleeve; the second sealing ring is connected with the first sealing ring through a connected screw and is provided with a guide-out groove; the dynamic ring is arranged on the magnetic controller; and the static ring is connected with the dynamic ring and is connected with the positioning ring through springs. The magnetic controller can adjust the magnetism obtaining amount of the mechanical sealing part according to the pressure of the air blower, the rotating speed of the air blower and the input amount of static electricity, so that the magnetic mechanical sealing part reaches a frictionless state, and the leak-tightness sealing effect is ensured.

Owner:WUHU ZHONGTIAN SEALS

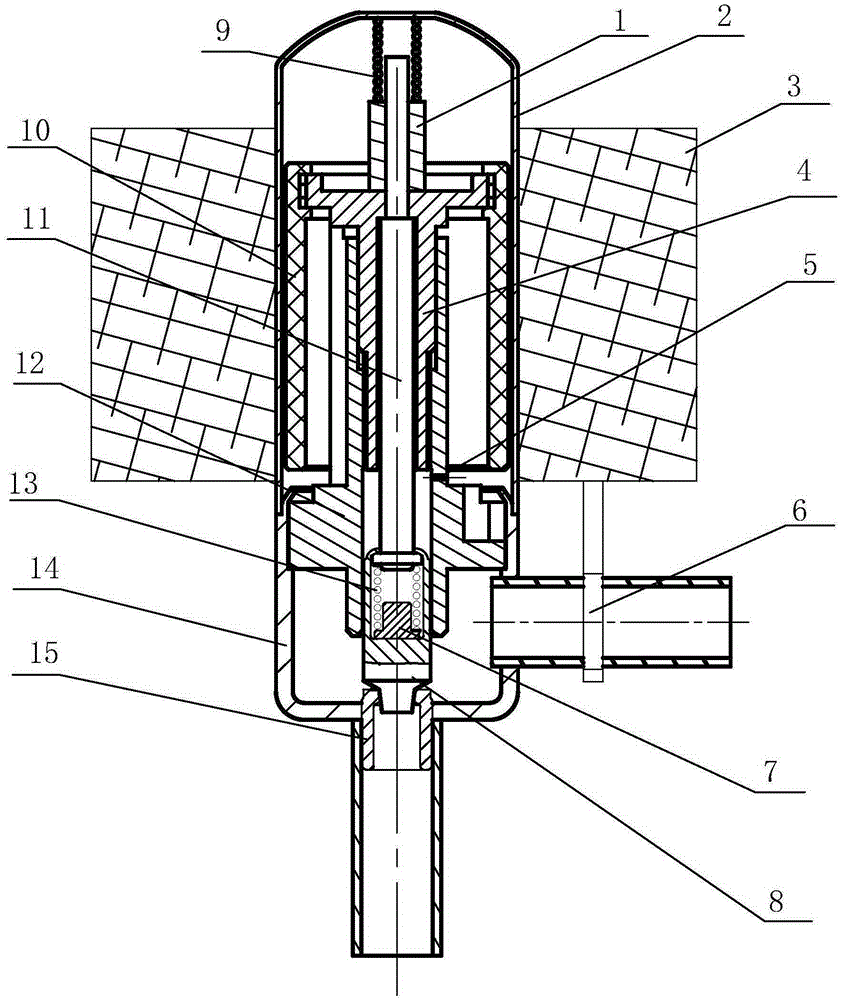

Thread transmission type electronic expansion valve

InactiveCN106766418AIncrease the support surfaceImprove installation firmnessOperating means/releasing devices for valvesEfficient regulation technologiesCavity wallButt joint

The invention relates to a thread transmission type electronic expansion valve, and belongs to valves. An existing electronic expansion valve is large in running noise, and abrasion or clamping of a magnetic steel sleeve is prone to occurrence; the thread transmission type electronic expansion valve is characterized in that a backward step end face leaning shoulder is arranged on the outer circle face of a front base sleeve, the opening end of a back base sleeve is in butt joint with the step end face leaning shoulder in a fixedly welding manner to form a straight-cylinder-shaped shell with two ends closed, a front section of a nut sleeve is inserted into an inner cavity wall of the front base sleeve, and an end face leaning shoulder on the inner cavity wall and an inward turning edge of the opening end of the front base sleeve are used for limiting and fixing; a valve is installed in a hollow inner cavity of a valve rod sleeve fixed to the magnetic steel sleeve in a penetrating manner, the back end of the valve extends out of the back end of the magnetic steel sleeve, and a spacer bush and a spring arranged outside the valve rod in a sleeving manner are used for back stroke limiting; and the valve rod sleeve is matched with inner threads in an axial through hole of the nut sleeve through outer threads to drive the valve rod to move, a buffer connecting piece connected with the front end of the valve rod is arranged on the front section of the axial through hole of the nut sleeve to conduct guide supporting on the valve rod, circumferential limiting protrusions and limiting leaning shoulders which are matched with each other are arranged for front stroke limiting, and the collision noise and friction are reduced.

Owner:新昌县儒岙镇锦云机械厂

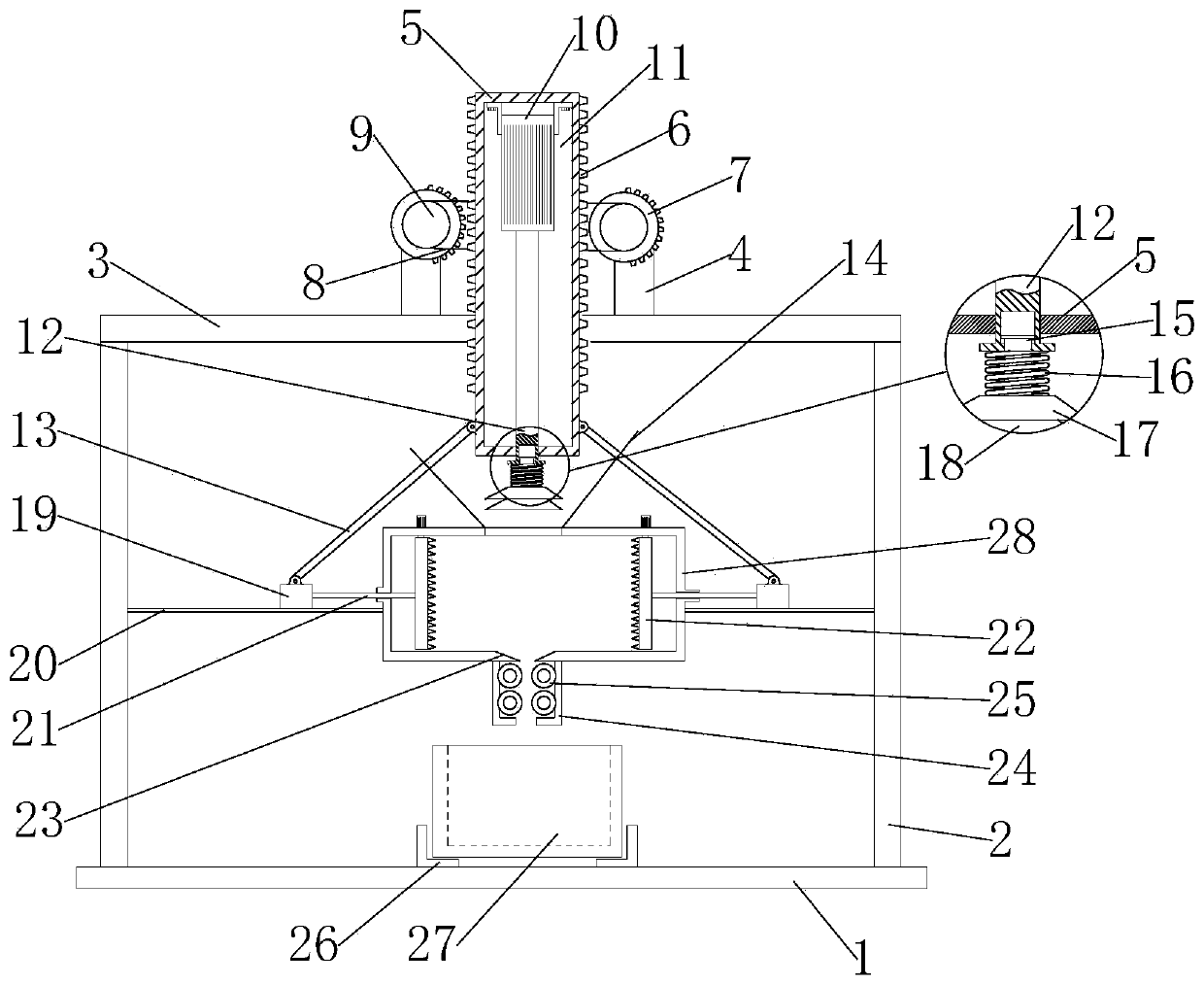

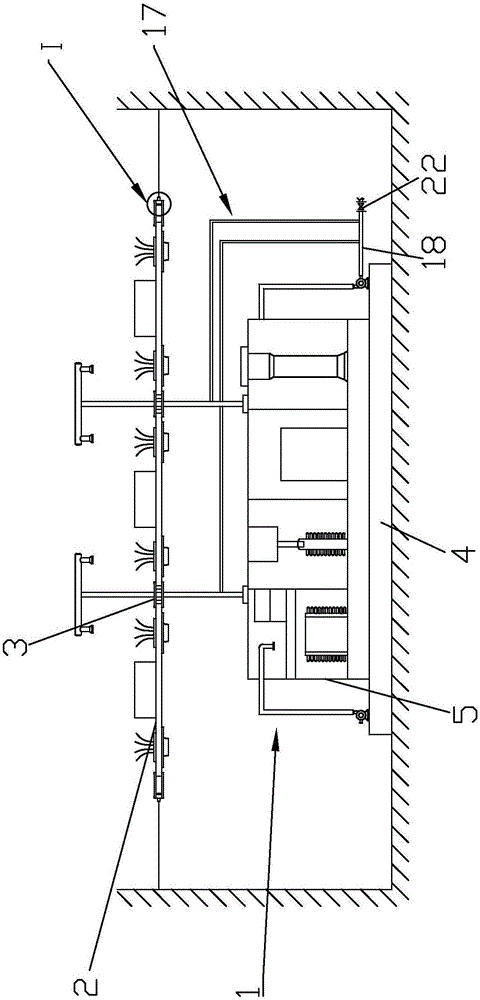

Printing ink box processing machine

ActiveCN111282625AImprove extrusion crushing efficiencyPrevent slippingGrain treatmentsEngineeringPrinting ink

The invention discloses a printing ink box processing machine, and relates to the technical field of printing equipment. The printing ink box processing machine comprises a base, the base is of a square plate structure horizontally fixed to the ground, and supporting ribs erected at the top end of the base are symmetrically fixed to the left side and the right side of the top end of the base; andthe top ends of the symmetrical supporting ribs on the two sides are connected with a horizontally-fixed cross beam frame, a lifting column is installed in a sliding hole of the cross beam frame in asliding fit mode, and the lifting column is vertically installed above the base. According to the printing ink box processing machine, cutting blades are installed in compression assemblies, all the cutting blades on the rack are driven by the motor to rotate, in the process that the compression assemblies on the two sides in an extrusion box conduct extrusion towards the middle, waste making contact with the compression assemblies is cut at equal intervals through the cutting blades, the purpose that the compression assemblies conduct sheet cutting while conducting extrusion is achieved, andthe extruding and crushing efficiency of the compression assemblies is improved.

Owner:湖南至简复印机再制造有限公司

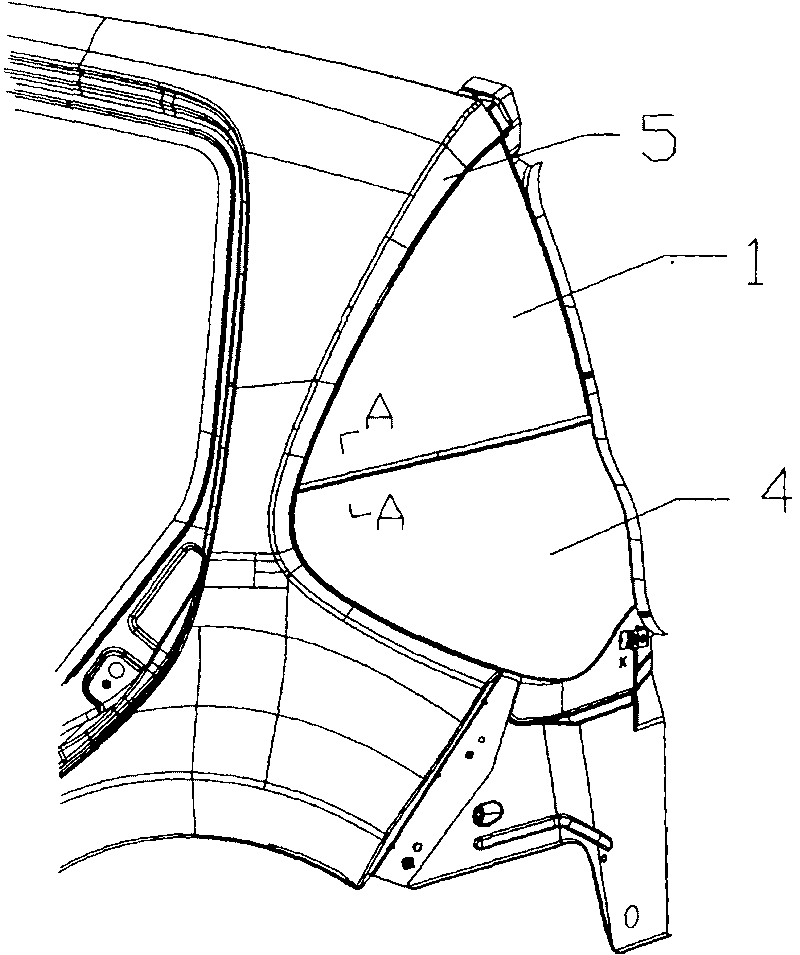

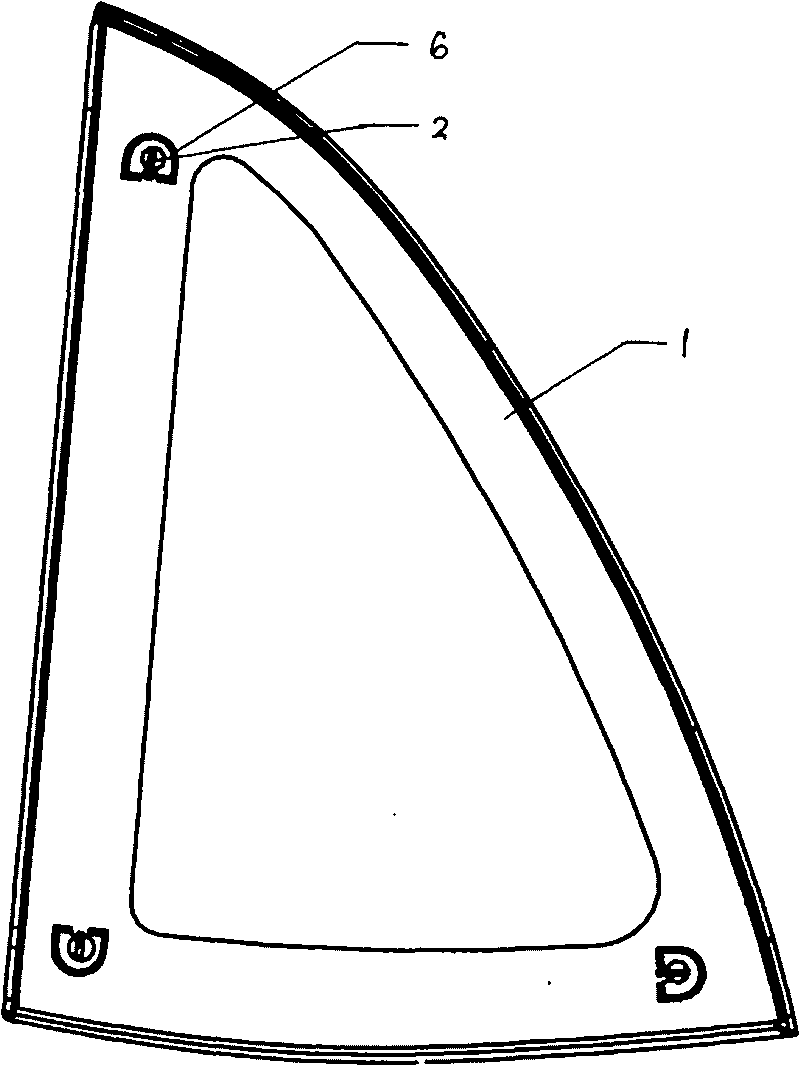

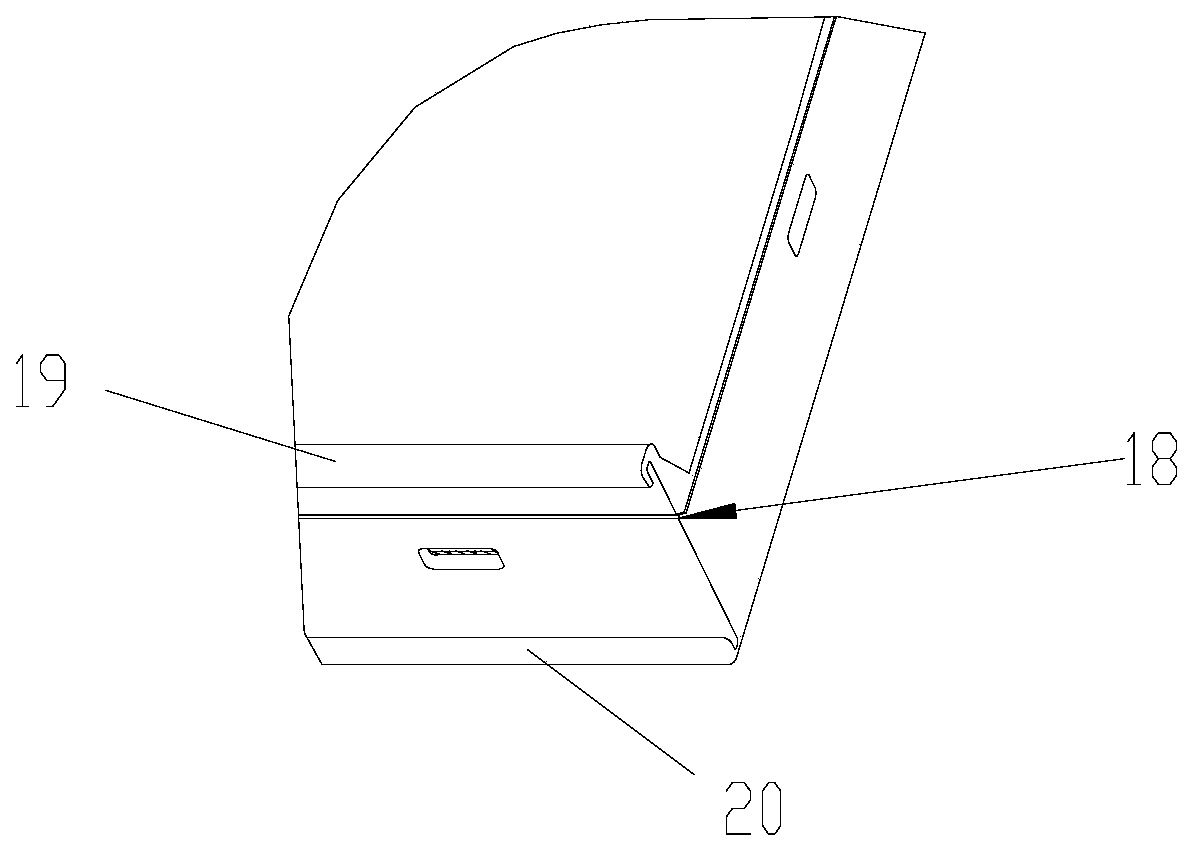

Automobile triangular window positioning and mounting structure

InactiveCN101700734AThe improvement gap is large,Good conditionWindowsWindscreensEngineeringInjection moulding

The invention provides an automobile triangular window positioning and mounting structure comprising a triangular window, clips, glass cement, an outer cover on the side wall of the automobile body and the like. The triangular window is molded by injecting; the edge of the inner side of the triangular window is provided with a plurality of clip mounting bases; the clip mounting bases and the triangular window are molded integrally by injecting; the clips on the triangular window are fixed in the clip mounting bases; positioning holes are disposed on the frame of the triangular window on the outer cover, wherein the positions of the positioning holes correspond to the positions of the clips on the triangular window; the glass cement is evenly adhered to the periphery of the inner side of the triangular window; and triangular window is fixed on the outer cover by the clips and the glass cement. In the automobile triangular window positioning and mounting structure, the clips are used for mounting the triangular window, the glass cement is used for adhering, fixing and sealing the triangular window, and the clips on the triangular window and the positioning holes disposed on the corresponding positions of the automobile body are used for positioning to improve the mounting precision of triangular window, thus the triangular window can be mounted more firmly, the gaps among the triangular window and the peripheral parts can be kept more uniform.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

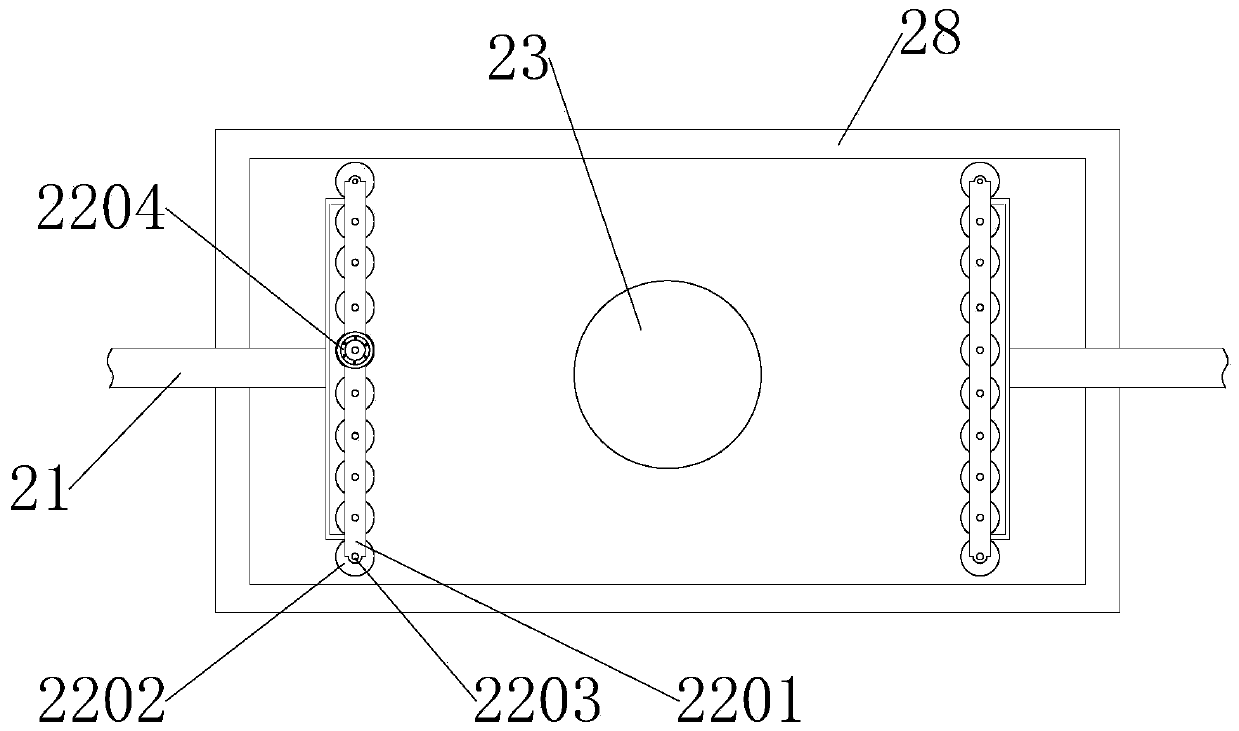

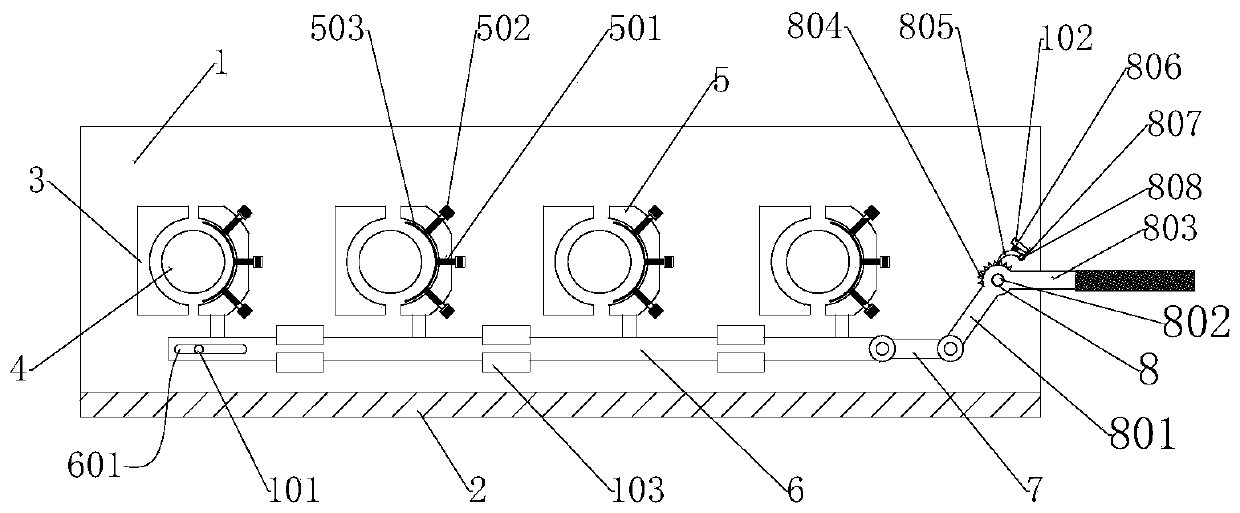

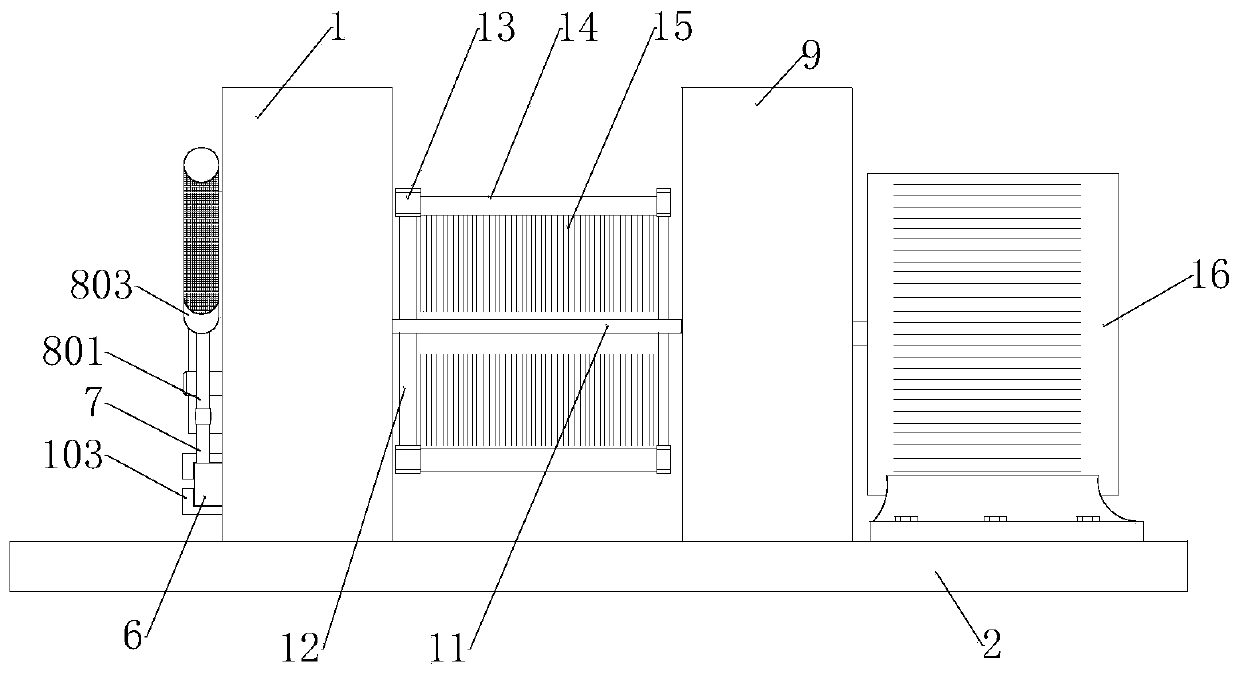

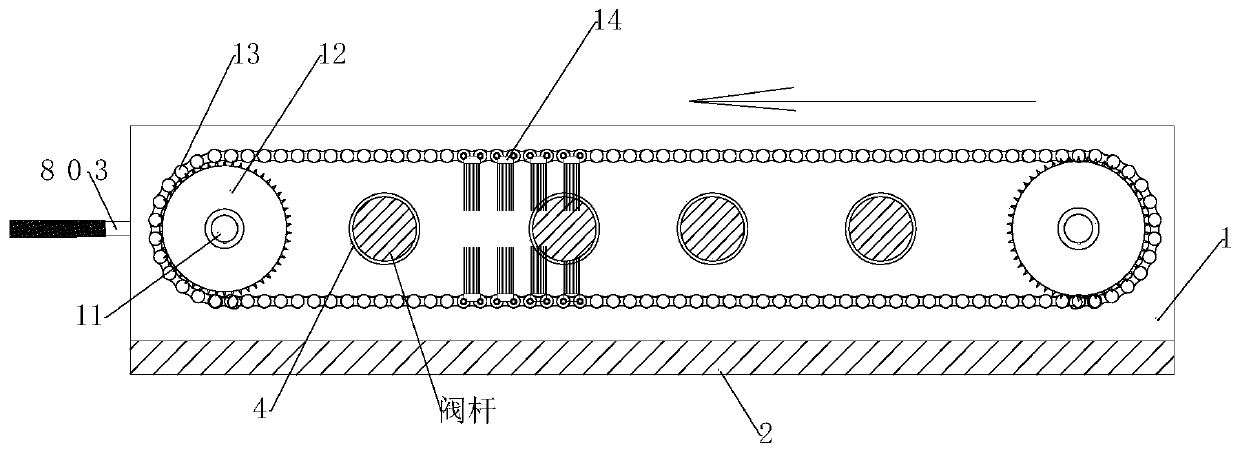

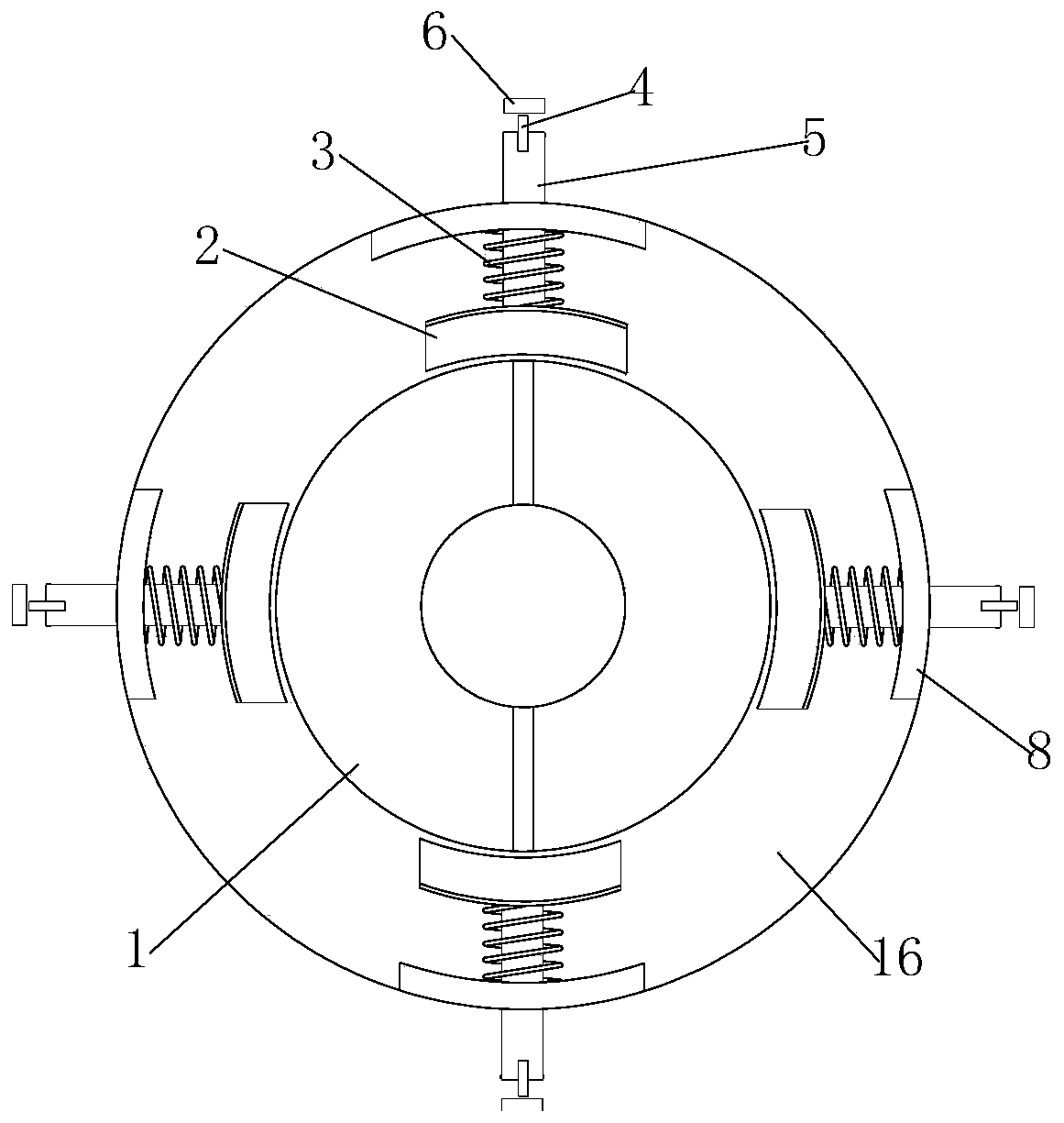

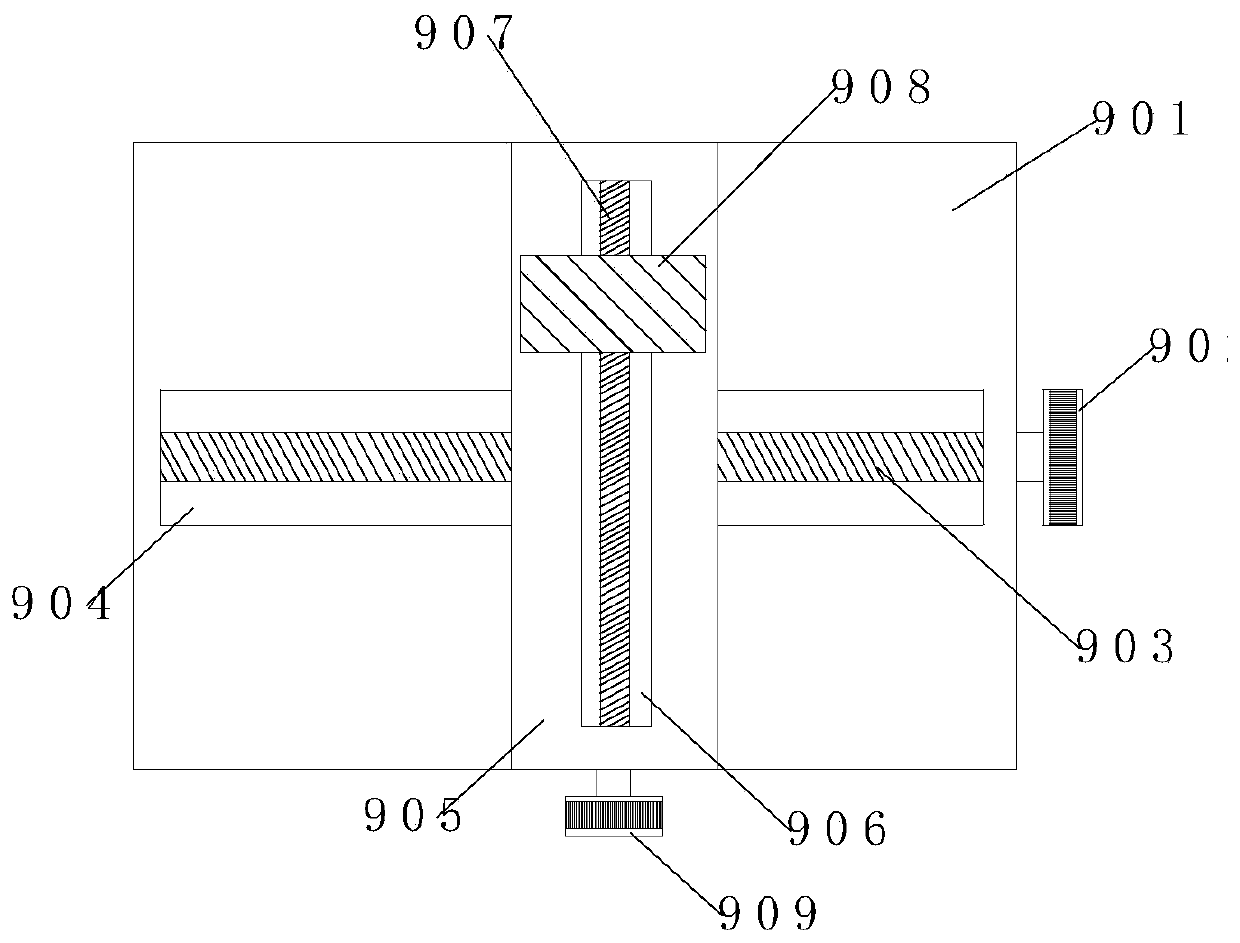

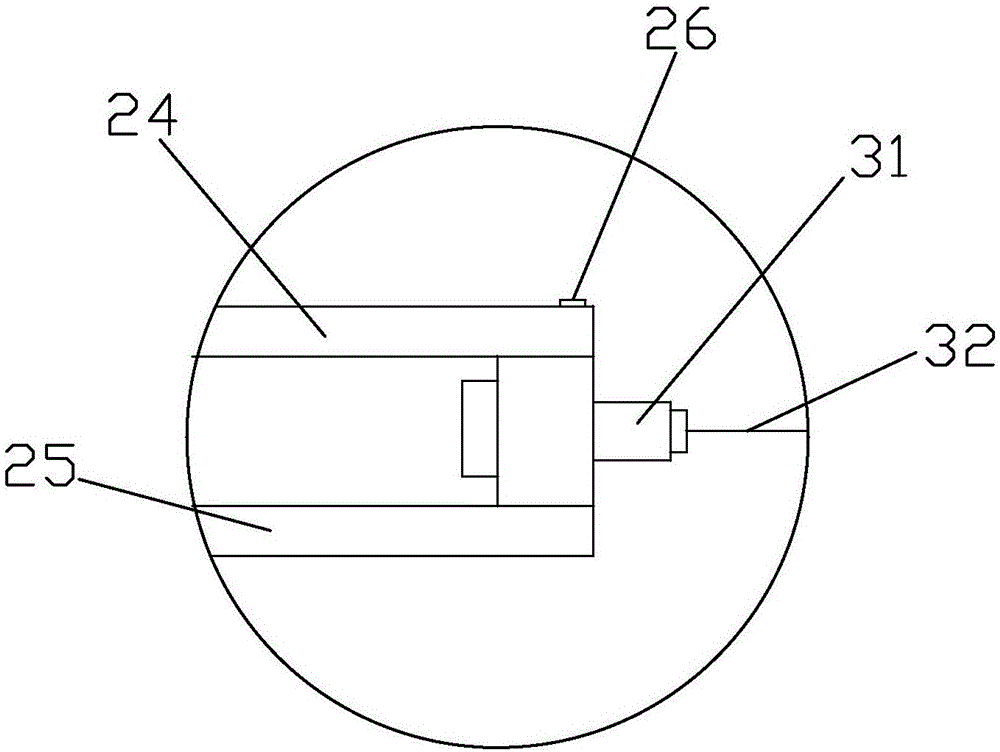

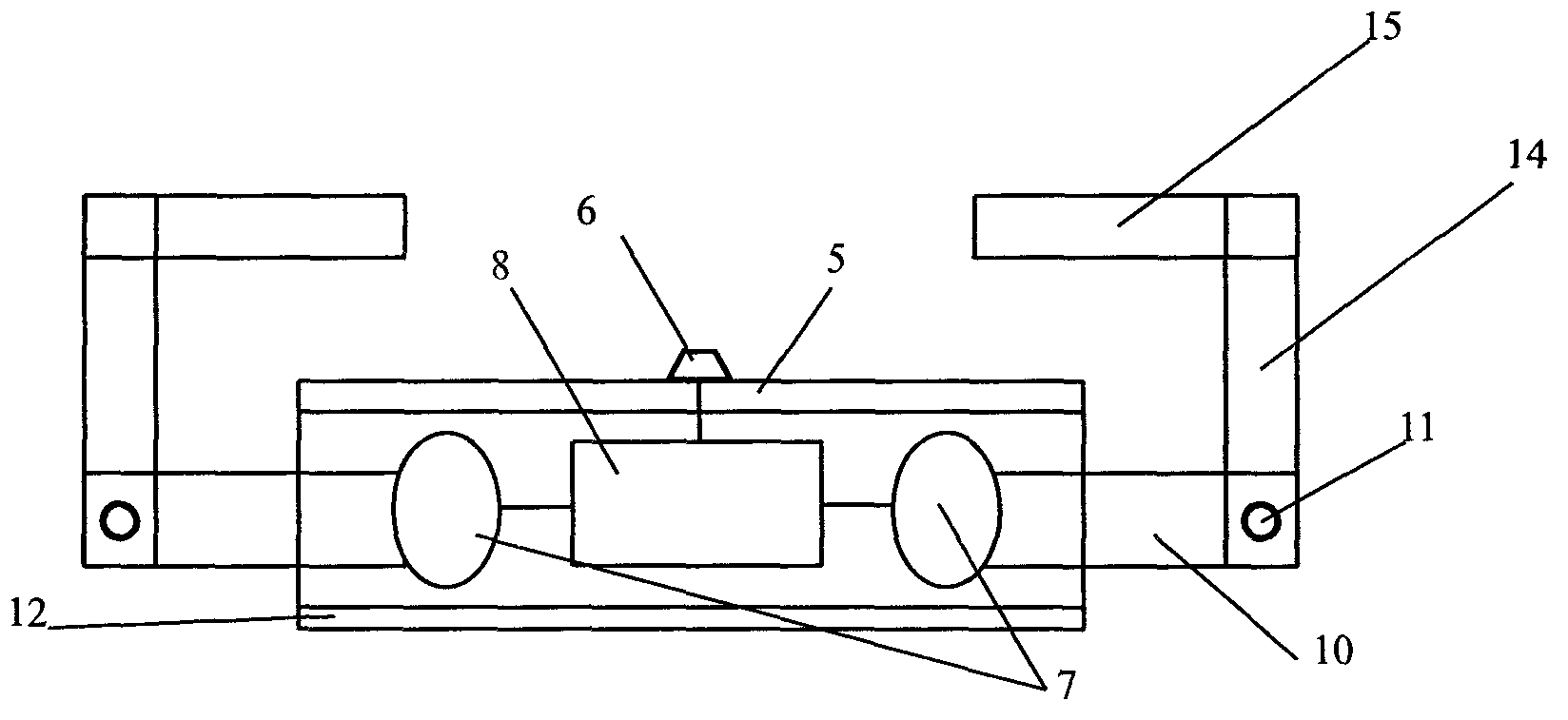

Valve accessory valve rod manufacturing processing system

ActiveCN110744367AImprove installation firmnessIncrease contact areaRevolution surface grinding machinesGrinding work supportsStructural engineeringSprocket

The invention discloses a valve accessory valve rod manufacturing processing system, and relates to the technical field of valve machining. The valve accessory valve rod manufacturing processing system comprises a bottom supporting plate, a first supporting plate and a second supporting plate, the bottom supporting plate is a square plate which is horizontally arranged, the first supporting plateand the second supporting plate which are oppositely arranged are fixed to the top end of the bottom supporting plate, two chain wheel shaft rods which are symmetrically arranged are connected betweenthe first supporting plate and the second supporting plate, chain wheels are fixed to the two ends of each chain wheel shaft rod, two of the chain wheels are close to the opposite face of the first supporting plate, and the other two chain wheels are close to the opposite face of the second supporting plate. According to the valve accessory valve rod manufacturing processing system, fixed clamping jaws and movable clamping jaws are arranged to be two semi-arc-shaped clamping jaws, therefore, circular clamping faces are formed after the fixed clamping jaws and the movable clamping jaws are attached to each other, the contact area with valve rods can be increased through the circular clamping faces, the outer circular faces of the valve rods are clasped, and the installing firmness of the valve rod is improved.

Owner:安徽安荣新能源科技有限公司

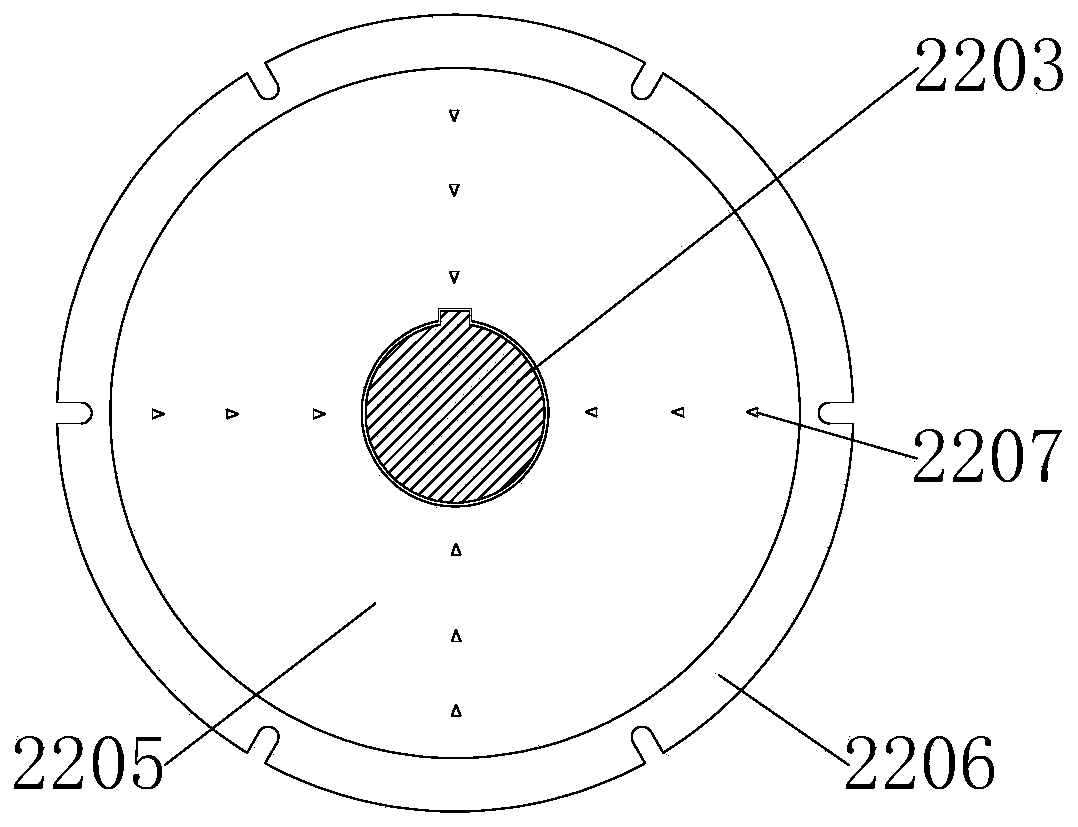

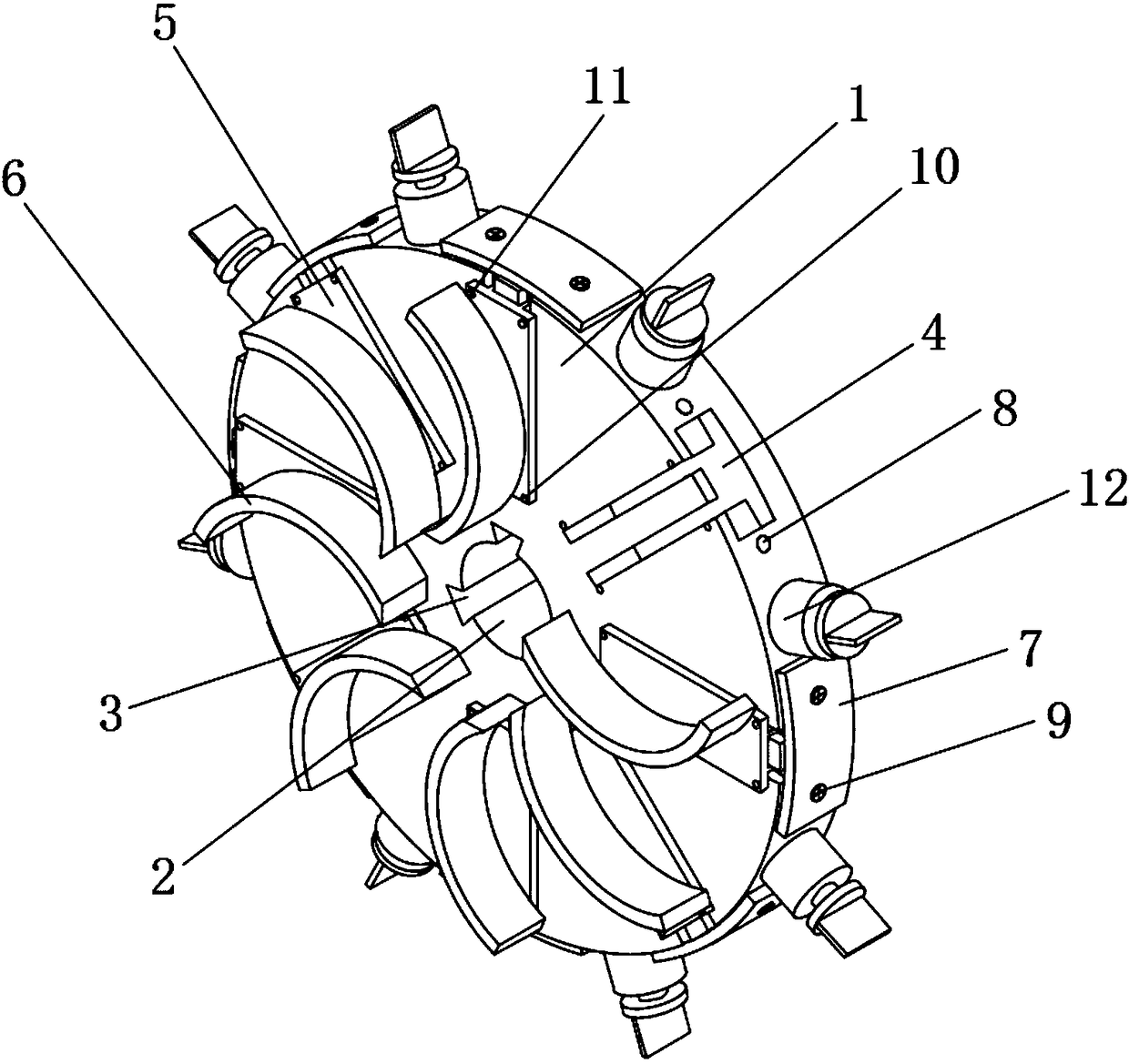

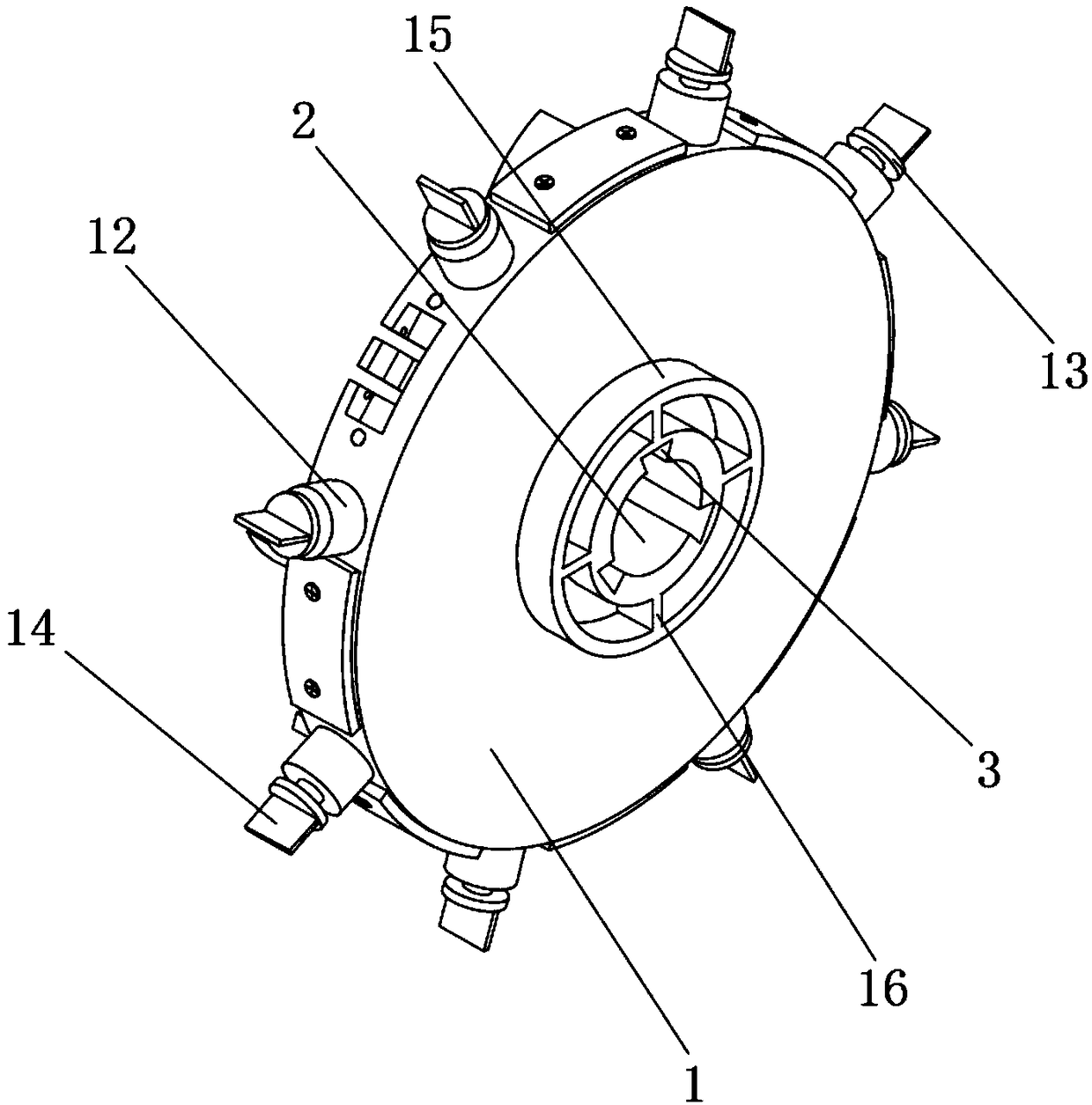

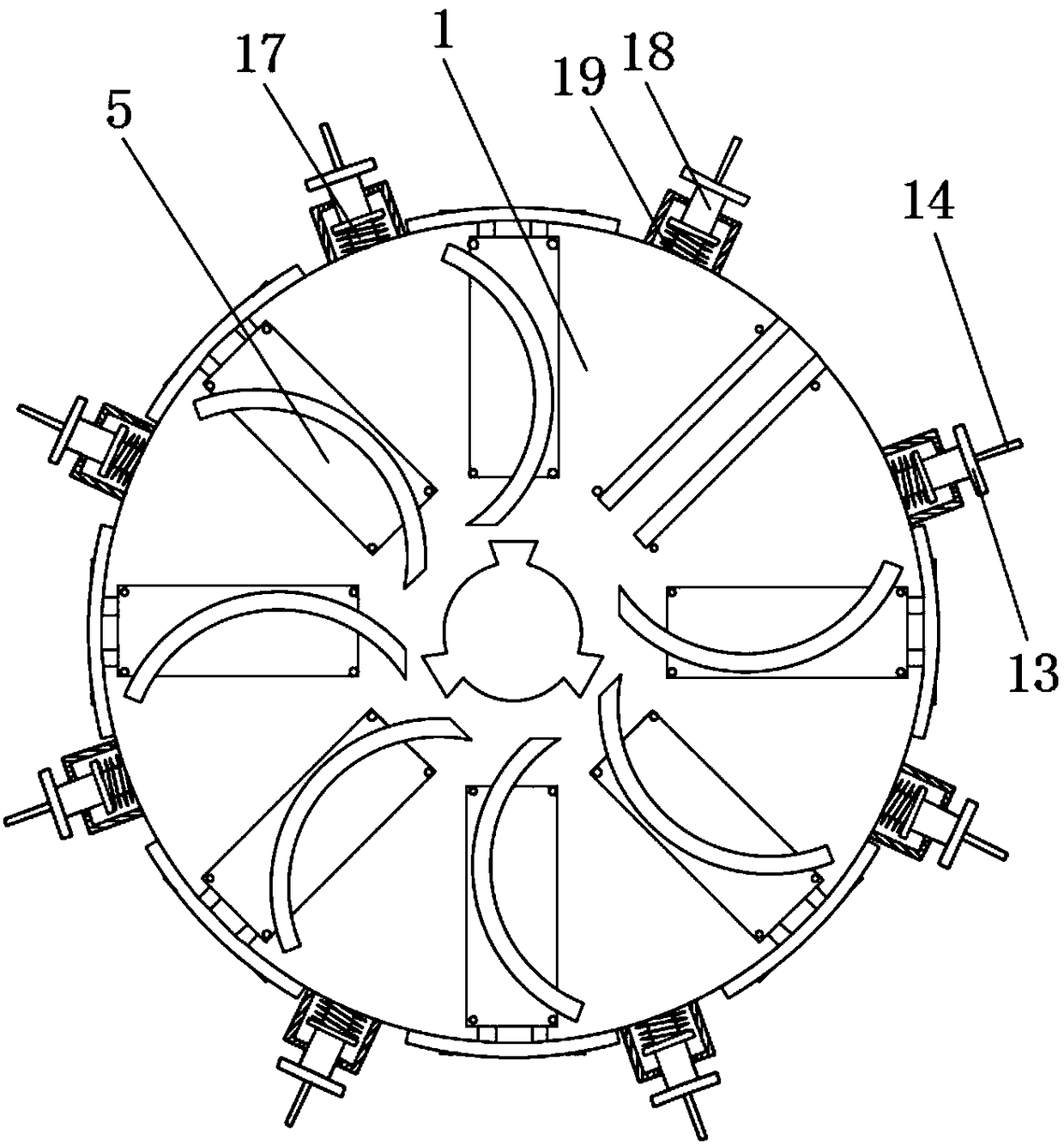

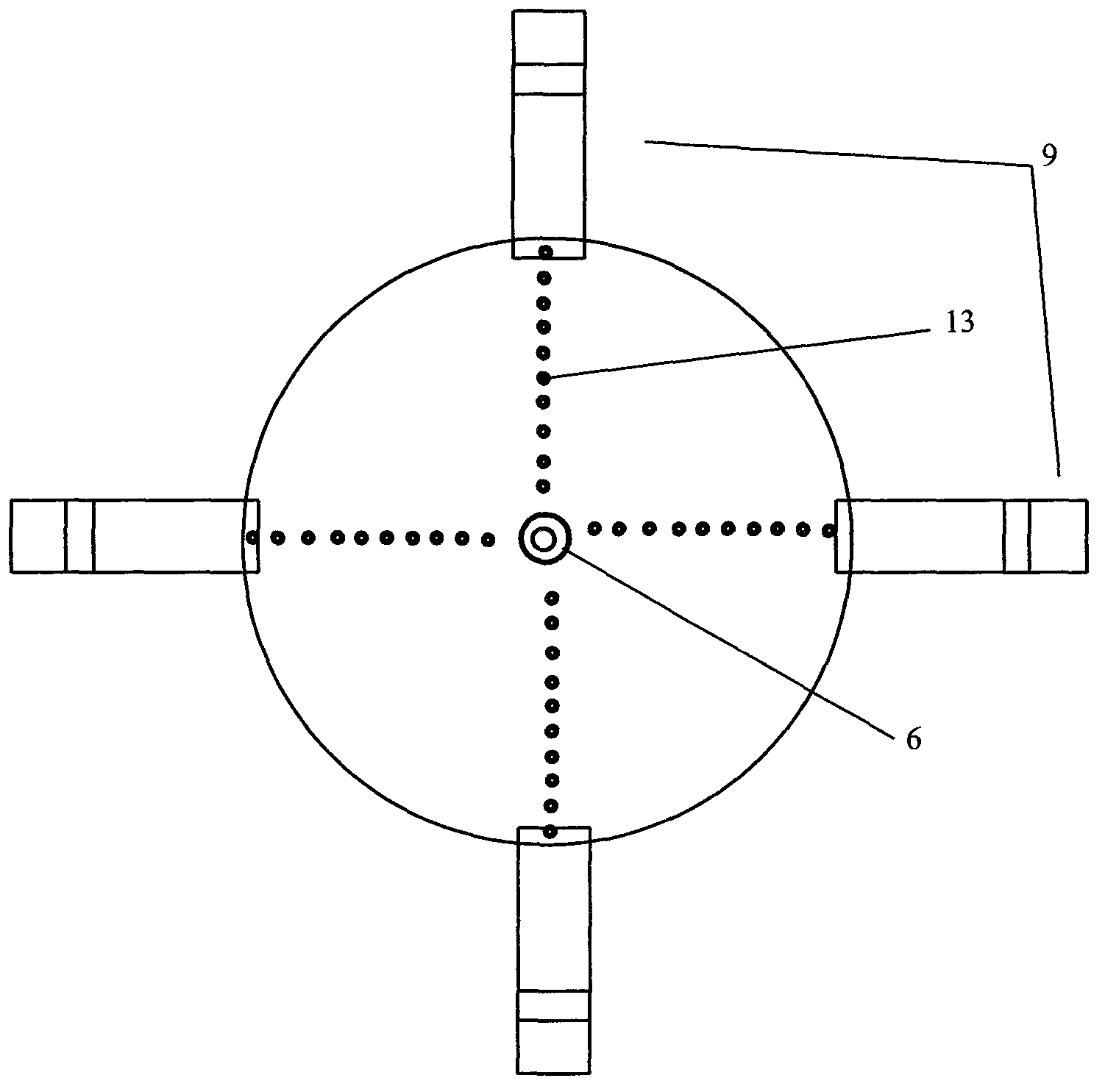

Impeller used for marine centrifugal pump

The invention discloses an impeller used for a marine centrifugal pump. The impeller comprises a wheel disc. A mounting hole is formed in the circle center of the side surface of the wheel disc, and mounting grooves are formed in the inner side surface of the mounting hole; eight sliding grooves are evenly formed in the peripheral side surface of the wheel disc, sliding blocks are slidably connected in the sliding grooves, and the section shapes of the sliding grooves and the section shapes of the sliding blocks are both in T shapes; blades are arranged on the side surfaces of the sliding blocks; fixing devices corresponding to the sliding blocks are arranged on the peripheral side surface of the wheel disc; eight fixing blocks are evenly arranged on the peripheral side surface of the wheel disc; and the eight fixing blocks and the eight sliding grooves are arranged at equal angles. According to the impeller used for the marine centrifugal pump, the separated blades are adopted, the blades of different types can be conveniently mounted according to the use requirement, the blades are convenient to replace when damaged in the using process, overall replacement of the impeller is notneeded, resource waste and the economic loss are reduced, and energy saving and environmental protection are facilitated.

Owner:JIANGSU JIANGDA FLUID TECH CO LTD

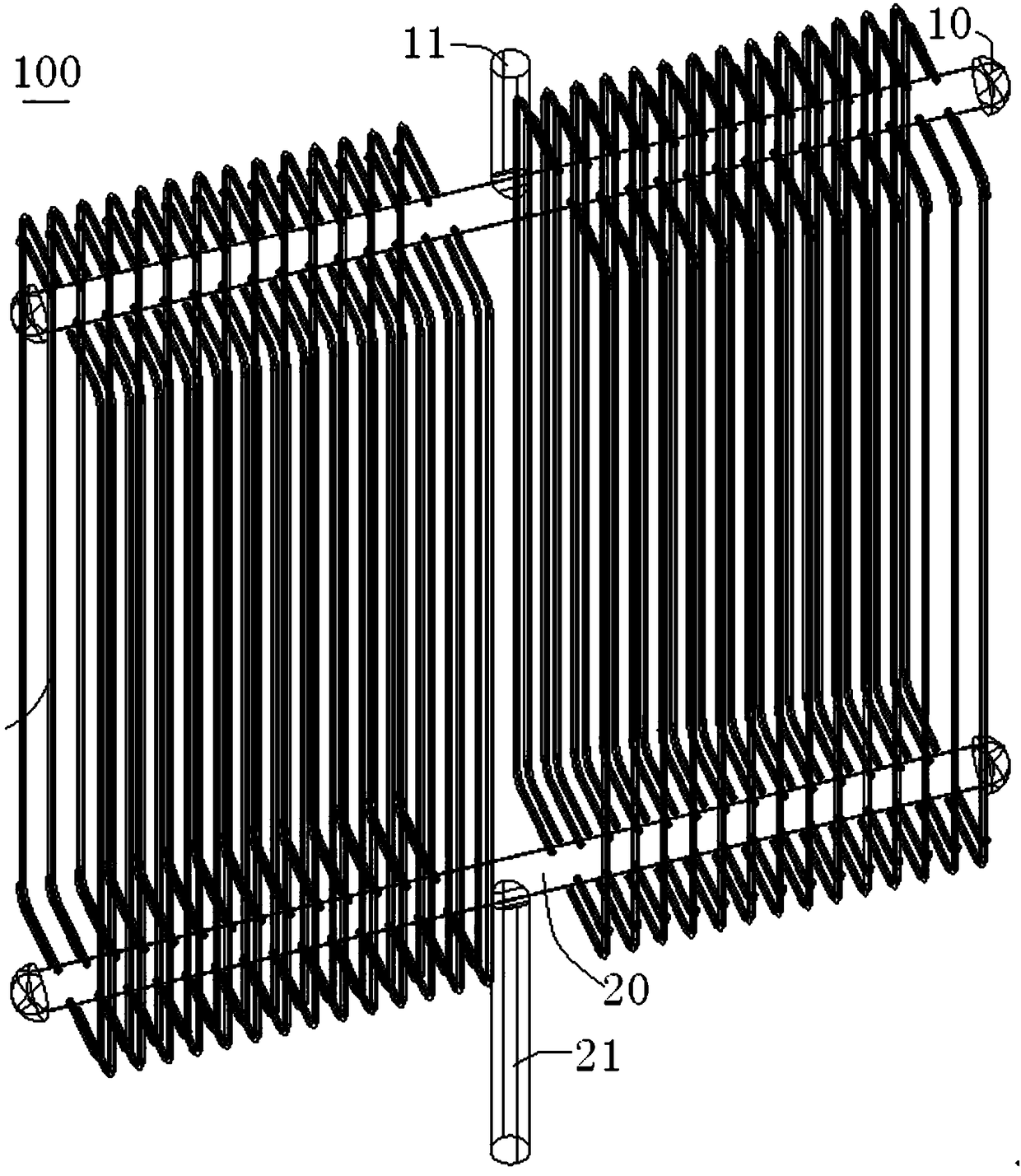

Passive containment heat exchanger system

ActiveCN108630327ACompact structureSmall footprintNuclear energy generationCooling arrangementEngineeringSystem integrity

The invention discloses a passive containment heat exchanger system, comprising a concrete containment; a steel containment, a built-in support member, a built-in heat exchanger, an external support frame, an external air cooler and a penetration member, wherein the steel containment is arranged in the concrete containment; the built-in support member is arranged on the inner wall of the steel containment; the built-in heat exchanger is arranged on a mounting part of the built-in support member; the external air cooler is arranged in an installation cavity of the external support frame; the penetration piece member is arranged on the built-in support member and is in communication with an inlet and an outlet of the built-in heat exchanger, and the two ends of the penetration member extendout of the steel containment and the concrete containment to communicate with an inlet and an outlet of the external air cooler, respectively. The passive containment heat exchanger system disclosed by the embodiment of the invention has a compact structure and saves space, and has the advantages that the seismic performance is improved, the system integrity is ensured and the heat exchange capability is enhanced.

Owner:国核示范电站有限责任公司

Hidden type automobile roof plate installation buckle assembly

InactiveCN106931010AImplement complete hidden settingsImproved traditional installation modeSheet joiningSuperstructure subunitsMechanical engineeringWedge shape

A hidden type automobile roof plate installation buckle assembly comprises a clamping base and a buckle matched with the clamping base. The hidden type automobile roof plate installation buckle assembly is characterized in that the clamping base comprises a bottom plate formed in a stamped mode; screw holes are evenly formed in the periphery portion of the bottom plate; a convex part is further formed in the middle of the square bottom plate in a stamped mode, and strip-shaped clamping grooves are formed in the upper end face of the convex part; the buckle comprises a cap capable of being fixedly connected with an automobile roof, clamping columns are fixedly arranged on one end face of the cap, and the other end of each clamping column is provided with a wedge-shaped check block; and the width of the strip-shaped clamping grooves adapts to the thickness of the clamping columns, and the wedge-shaped check blocks are rubber pieces capable of generating compression deformation. Through the installation mode of the hidden type buckle assembly developed by the invention, the buckle can be well prevented from being exposed, the exterior height of the roof plate product is kept coincident, and the whole roof plate is more attractive.

Owner:HEFEI LIANGJUN AUTOMOTIVE MATERIALS CO LTD

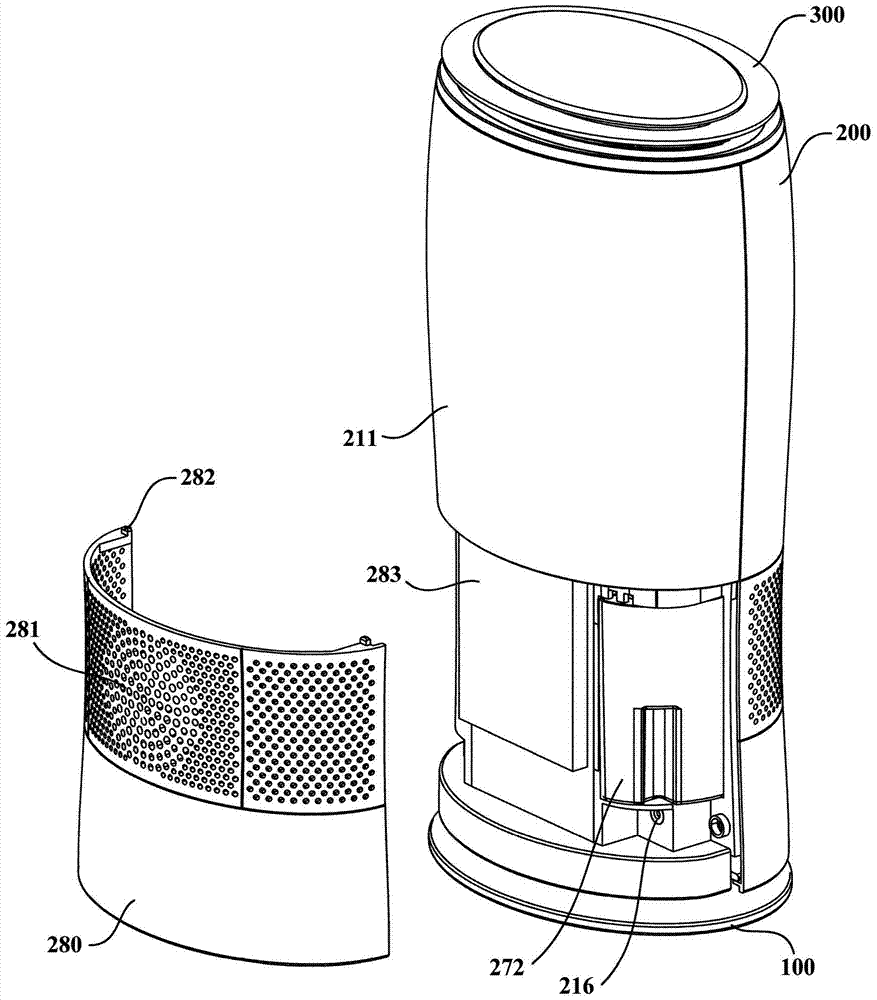

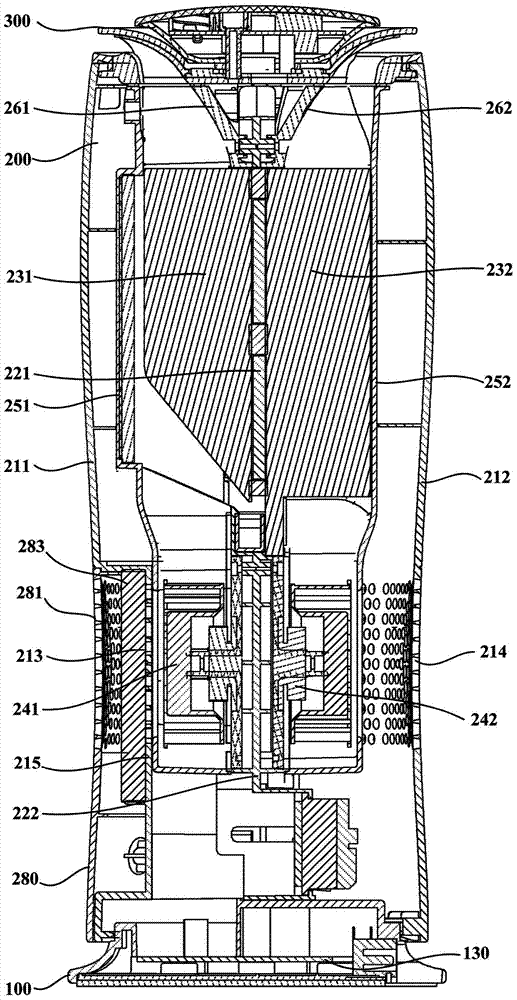

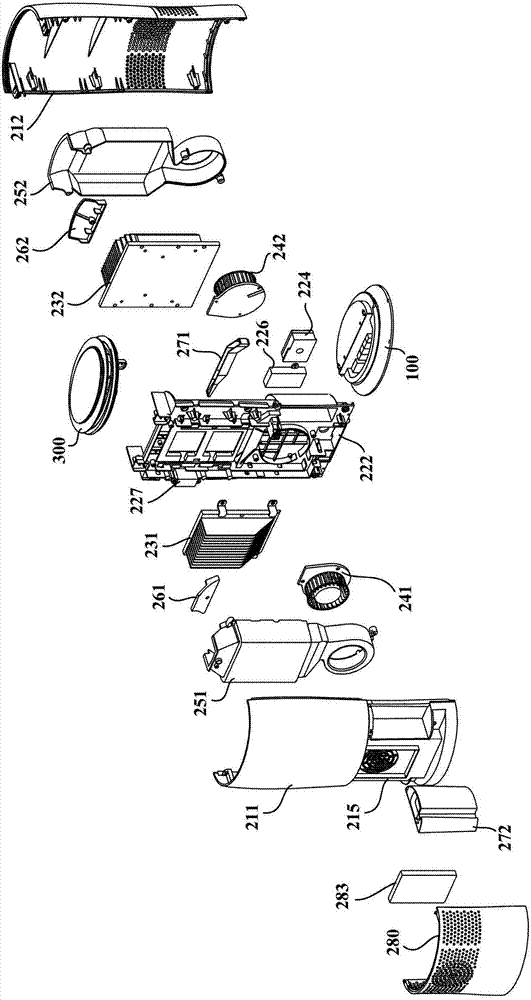

Table top air conditioner

ActiveCN104266283AImprove disassembly efficiencyImprove installation efficiencyHeating and ventilation casings/coversMachines using electric/magnetic effectsEngineering

The invention relates to a table top air conditioner. The table top air conditioner is provided with a machine body, the machine body comprises a machine body shell and a maintaining cover plate, maintaining openings are formed in the peripheral wall of the machine body shell, at least one buckle hole is formed in the upper frame edge of the maintaining openings respectively, at least one magnetic ring with a centre annular hole is arranged on the lower portions of the maintaining openings respectively, a mounting screw penetrates the center annular hole of each magnetic ring, the maintaining cover plate is configured to operably open and close the mainlining openings, at least one buckle projecting tongue which corresponds to each buckle hole is arranged at edges of the upper end of the maintaining cover plate, and at least one magnetic attraction part which corresponds to each magnetic ring is mounted on the lower portion of the maintaining cover plate. According to the table top air conditioner, parts which are usually required to be taken out of and put in the table top air conditioner can be conveniently taken out and put back by means of the maintaining openings and the maintaining cover plate, the upper end of the maintaining cover plate is connected with the upper ends of the maintaining openings in a clamping mode, lower ends of the maintaining cover plate and the maintaining openings are connected in a magnetic attraction mode, and thereby, the assembling and disassembling efficiency of the maintaining cover plate can be remarkably increased.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

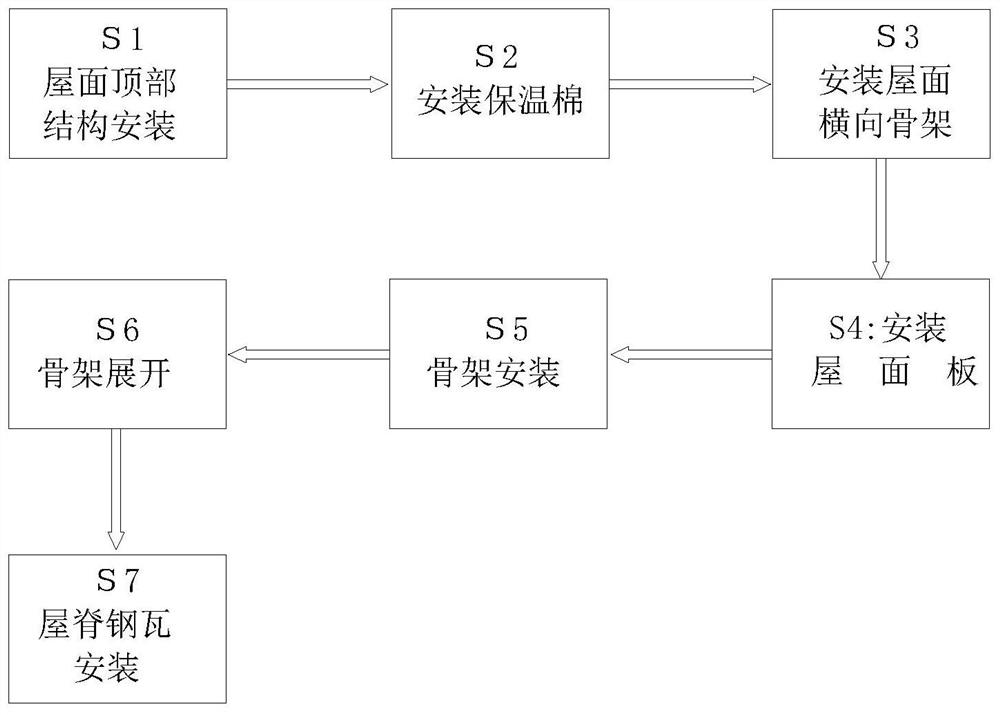

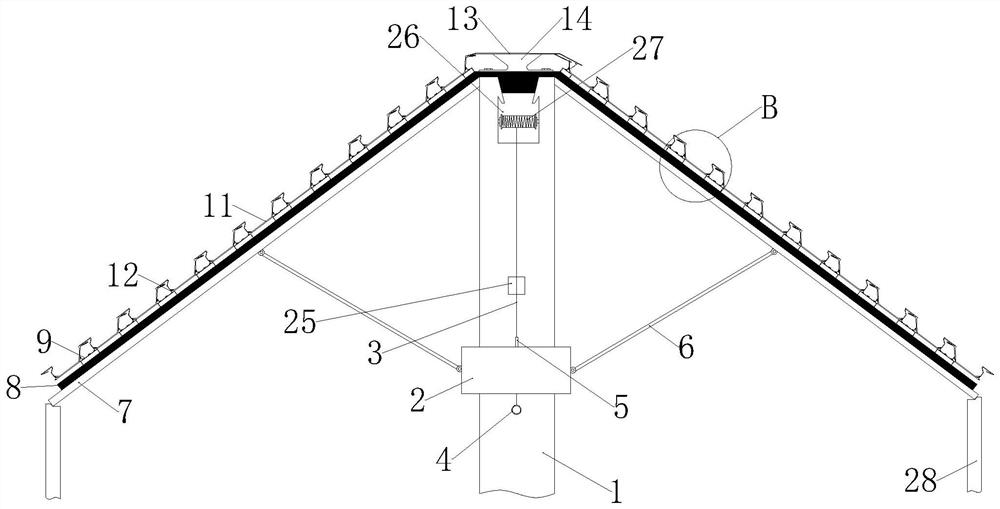

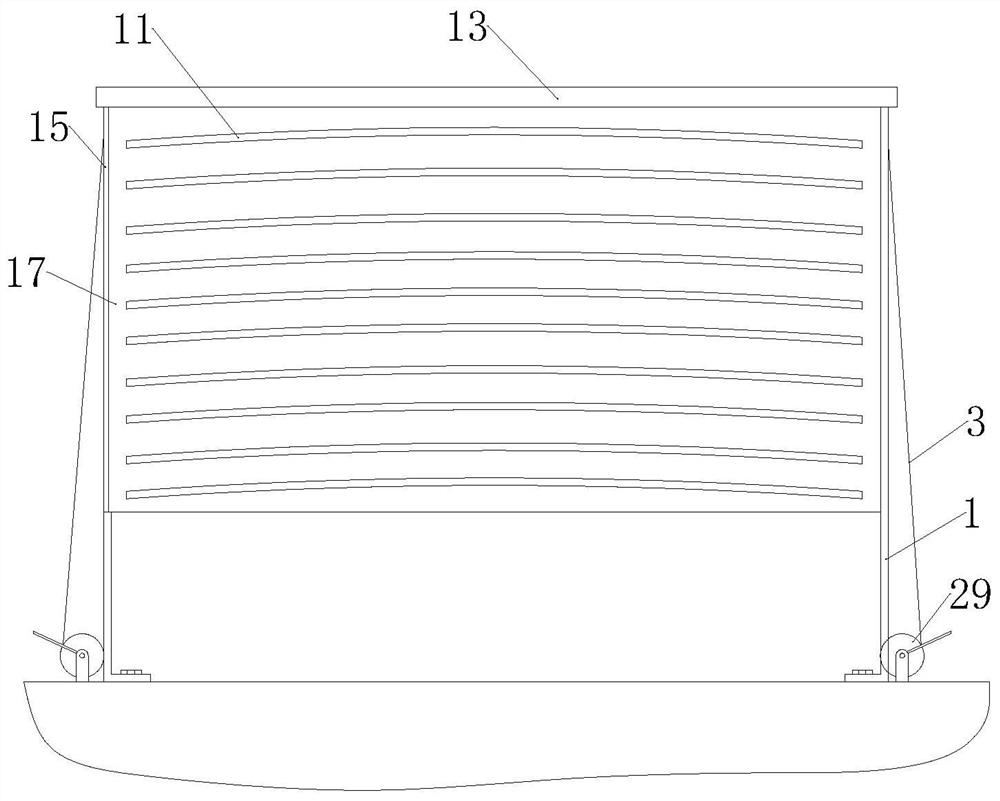

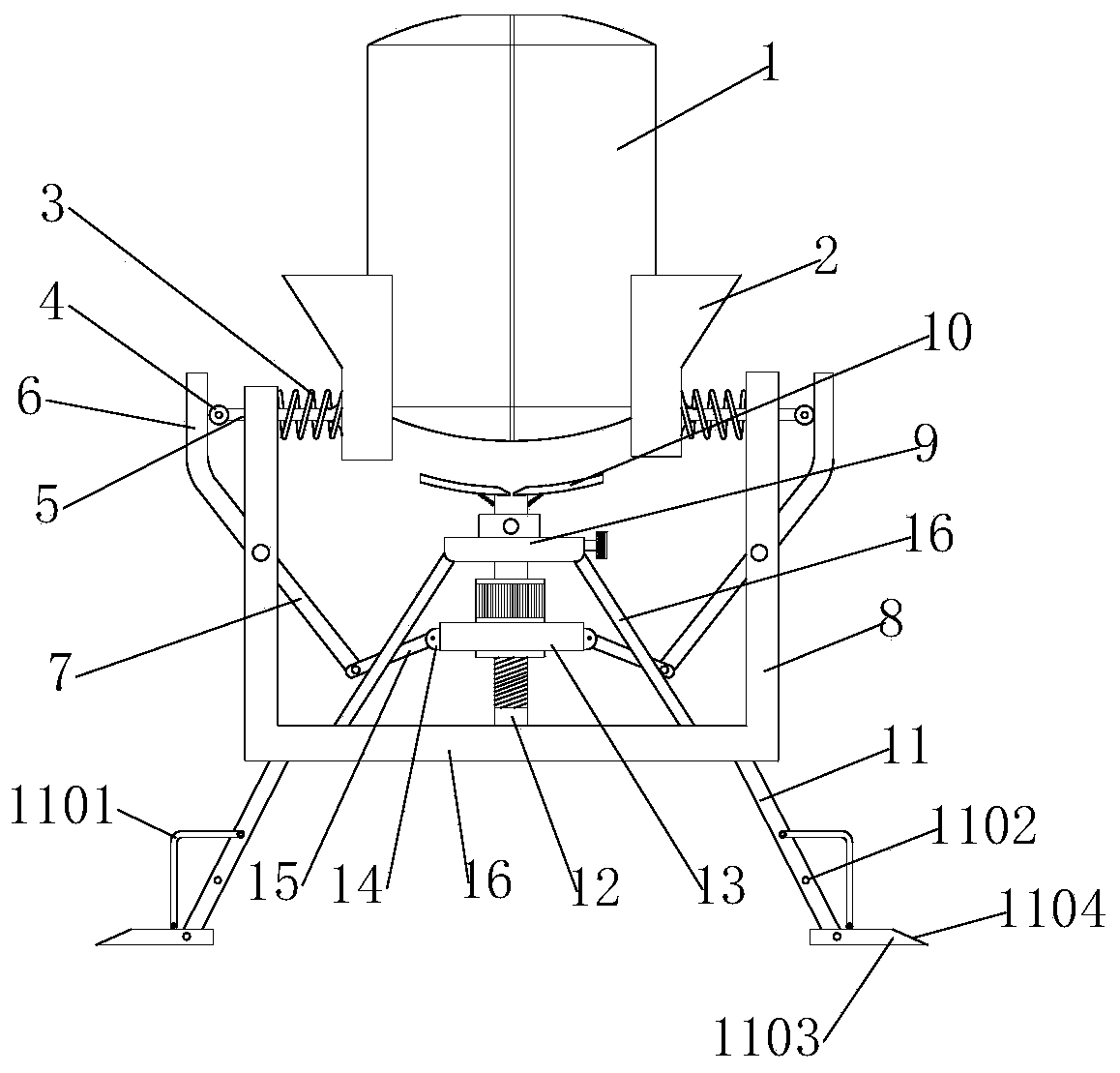

Ridge waterproof construction building steel structure installation method

ActiveCN112144769AImprove firm performanceEasy to operateBuilding roofsRoof covering insulationsArchitectural engineeringLap joint

The invention discloses a ridge waterproof construction building steel structure installation method, and relates to the technical field of building construction steel structures. The ridge waterproofconstruction building steel structure installation method is specifically completed through cooperation of a ridge waterproof construction building steel structure installation device. The ridge waterproof construction building steel structure installation device comprises two supporting wingceltis bars vertically and fixedly installed on the ground and wall frameworks symmetrically installed atthe left side and the right side of each supporting wingceltis bar, and the wall framework on each side is vertically and fixedly installed on the ground. According to the ridge waterproof construction building steel structure installation method, roof longitudinal frameworks at the two sides of the supporting wingceltis bars are unfolded to form a ridge, the operation simplicity of ridge construction is improved, the situation that workers need to climb to a roof of a house and lay ridge tiles one by one traditionally is avoided, the construction safety is improved, and the production efficiency is improved,' and the roof longitudinal frameworks unfolded towards the two sides are in lap joint with the top ends of the wall frameworks at the two sides, and therefore the firmness of the unfolded ridge structure is further improved.

Owner:佛山市固盈建材有限公司

Anti-corrosion fiberglass vertical chemical storage tank

ActiveCN110758927APlace stableImprove corrosion resistanceLarge containersChemical storageHolding tank

The invention discloses an anti-corrosion fiberglass vertical chemical storage tank, and relates to the technical field of chemical equipment. The storage tank comprises a storage tank body and a base. The base is horizontally arranged, the bottom end of the base is provided with multiple supporting legs which are distributed at equal intervals, the bottom end of each supporting leg is inclined outwards, the top end of the base is fixedly provided with multiple supporting frames which are distributed at equal distances, the supporting frames are erected and fixed to the top end of the base, aclamping plate is arranged at the position, close to the top end, of the inner wall of each supporting frame, the back of each clamping plate is fixedly provided with a shaft rod erected on the clamping plate, and each shaft rod is horizontally put. A tray is arranged on the top end of an adjusting assembly, through cooperation adjusting between two screws of the adjusting assembly, the tray can move to any position from the top end of the adjusting assembly, through fine adjusting of the screws, the tray generates fine moving on the bottom of the storage tank, and through fine adjusting, thetray can be conveniently adjusted to be completely attached to the bottom end of the storage tank.

Owner:浙江晨扬生物油脂有限公司

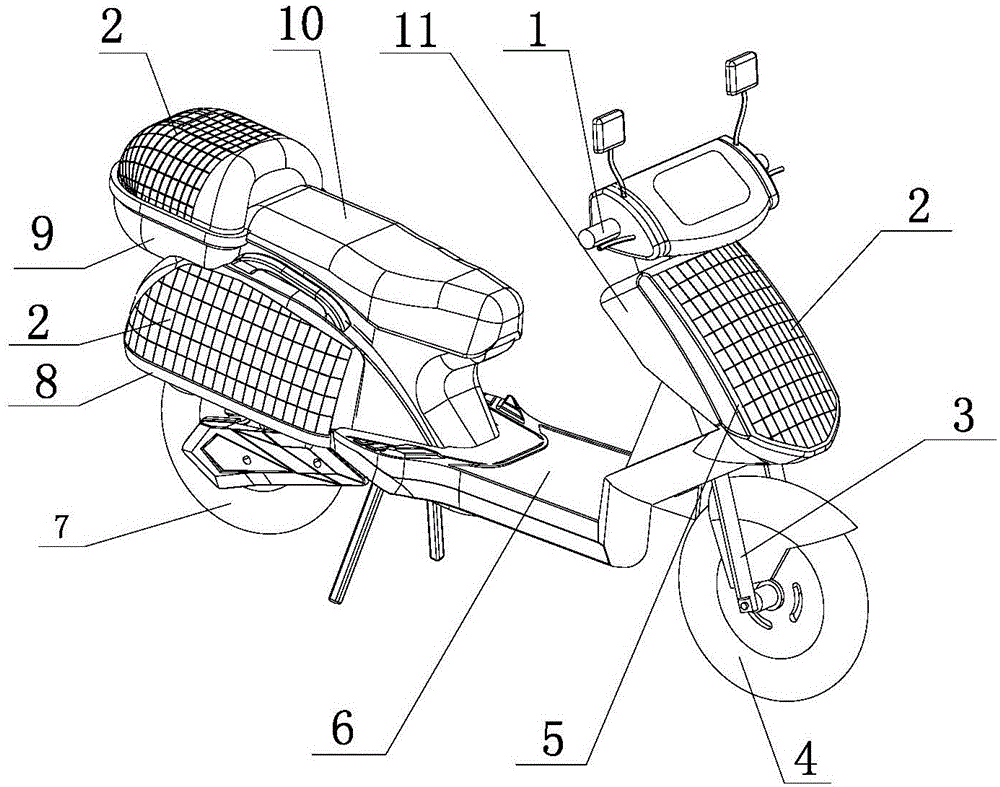

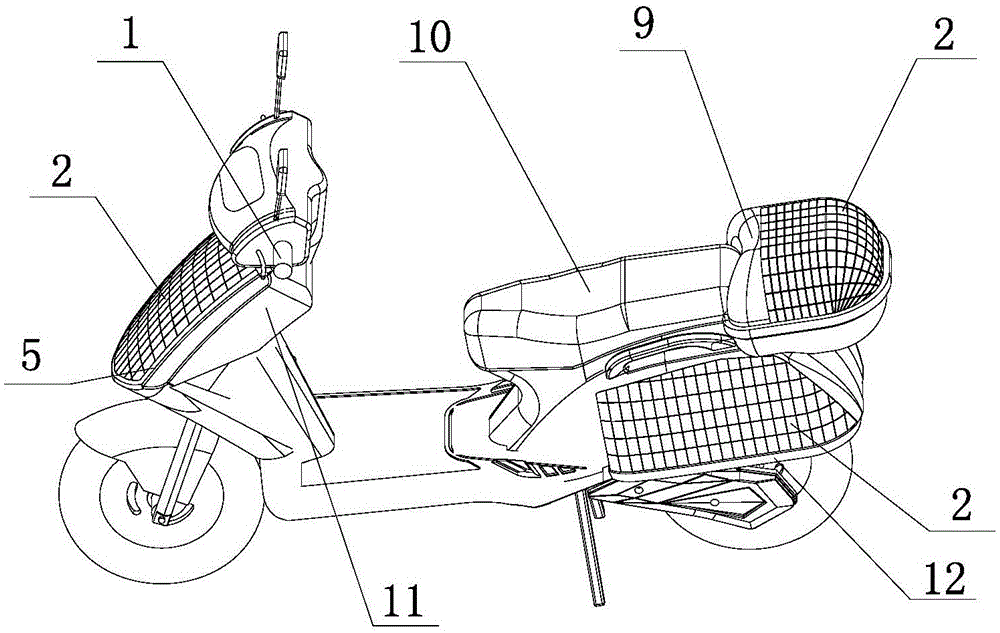

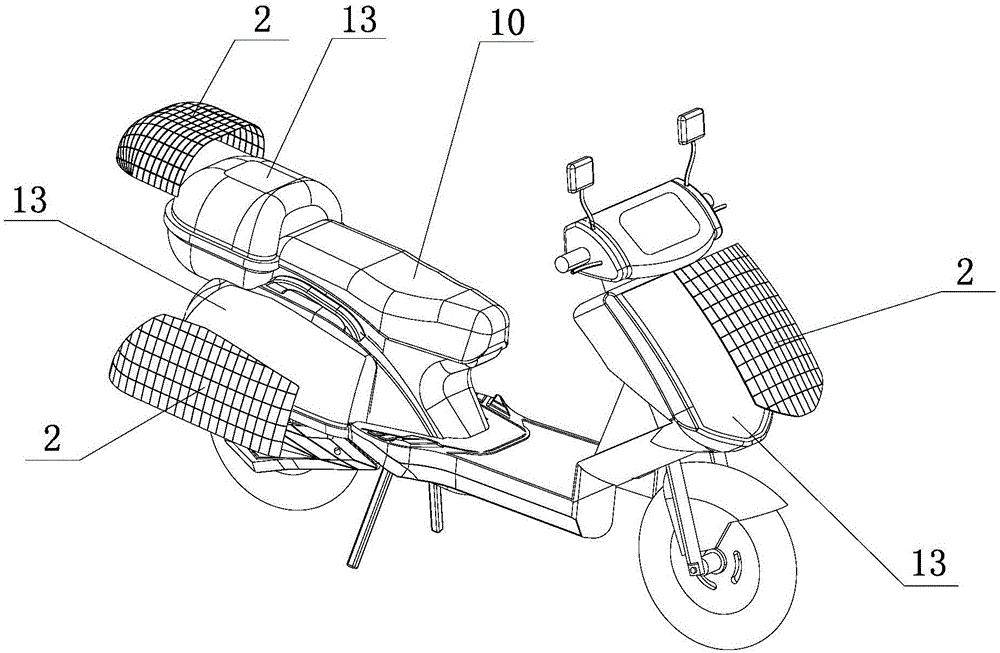

Novel photoelectric electric vehicle

InactiveCN105000105AIncrease the lighting areaExtend the light timeVehicular energy storageMotorcyclesVehicle frameElectric vehicle

The invention discloses a novel photoelectric electric vehicle, and belongs to the field of electric vehicles. The novel photoelectric electric vehicle comprises a vehicle body, a handlebar, a front fork, a vehicle seat, a front wheel, a rear wheel, a tool box, a shock absorber, a storage battery, a vehicle lamp and a wheel driving motor which form a two-wheel electric vehicle. An outer shell of the vehicle body comprises a front wall, a pedal plate, a left guard board and a right guard board. The front wall is provided with a front side panel, and the left guard board and the right guard board are located on the two sides of the vehicle seat; the tool box is arranged on the rear side of a vehicle frame, and the outer surface of the tool box, the outer surface of the front side panel, the outer surface of the left guard board and the outer surface of the right guard board are provided with arc-shaped surfaces; and the arc-shaped surface of the front side panel, the arc-shaped surface of the tool box, the arc-shaped surface of the left guard board and the arc-shaped surface of the right guard board are all provided with respectively-corresponding same-shaped bottom face grooves. Arc-shaped surface photoelectric boards in same shape are embedded in the bottom face grooves in the same shape, and a whole surface is formed by the surfaces of the front side panel, the tool box, the left guard board and the right guard board and the arc-shaped surfaces of the corresponding photoelectric boards; and electrode lines of the photoelectric boards are connected with the storage battery, the vehicle lamp and the wheel driving motor through the controller. The problems that the conversion efficiency of an existing photoelectric board is low, and the vehicle is not attractive are solved.

Owner:XINCHANG CHAOYAN NEW ENERGY VEHICLE IND CO LTD

Circulating water purification system and method applicable to lakes

ActiveCN106380042ALow running costLess investmentWater aerationTreatment involving filtrationElectrolysisWater quality

The invention discloses a circulating water purification system and method applicable to lakes. The system comprises a water purification device and ecological floating plates, wherein a connecting device is arranged between every two ecological floating plates; the water purification device comprises a base and a water purification chamber; the water purification chamber is arranged on the base; and the water purification chamber is sequentially provided with a filtering and flocculating chamber, a negative oxyanion electrolysis release chamber, a membrane bioreaction chamber and an oxygen aeration chamber which are sequentially arranged from left to right. The method comprises the following steps: (a) preparing for construction; (b) constructing a temporary cofferdam; (c) pumping water in the construction area; (d) building the water purification device; (e) installing the ecological floating plates; (f) installing a water supply device; and (g) carrying out water conditioning. The system is simple, feasible, scientific and convenient, has the advantages of environment friendliness, no pollution, low cost and high efficiency, and can implement accurate control. The treated lake water is clean and pollution-free. The system well solves the problem of lake water pollution.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

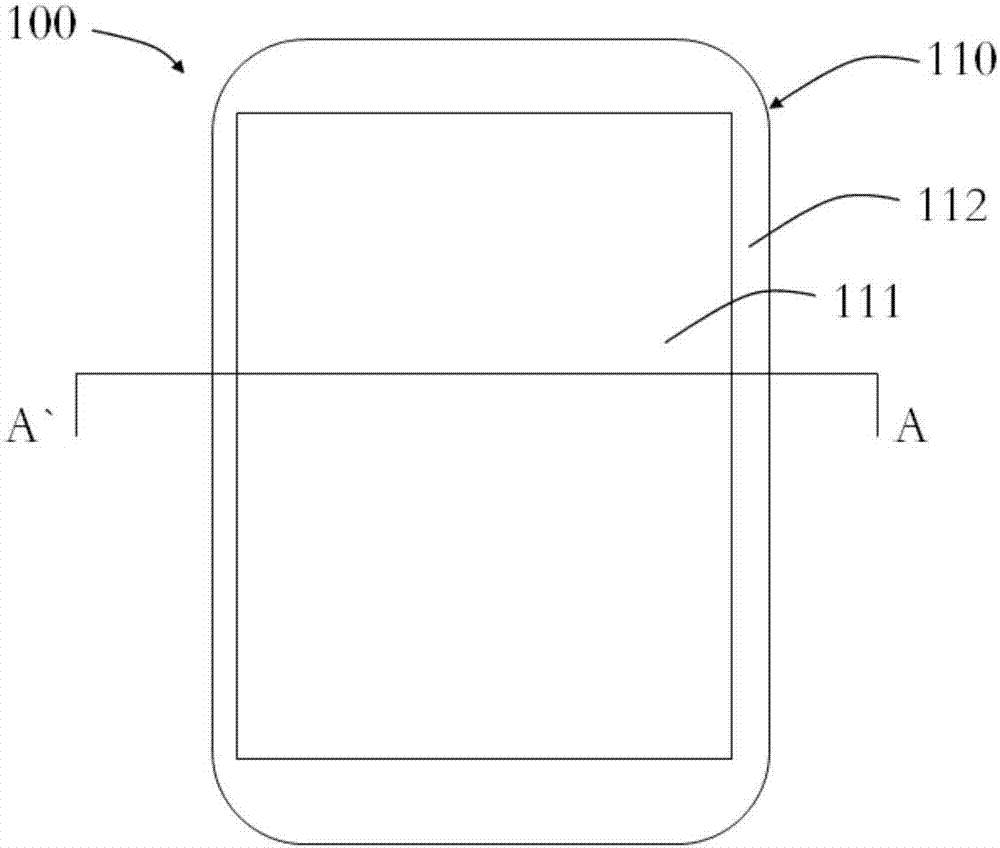

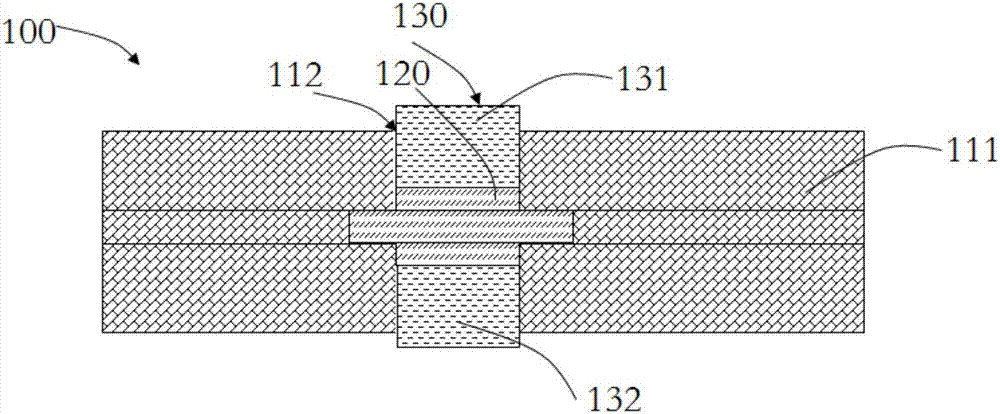

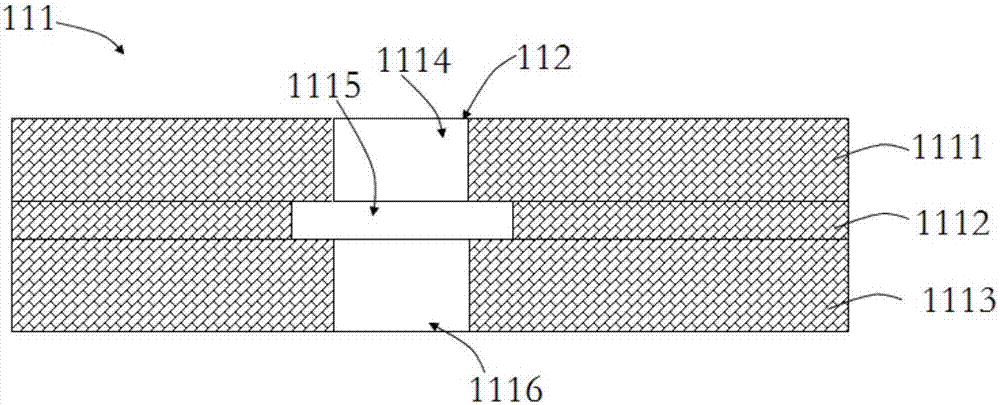

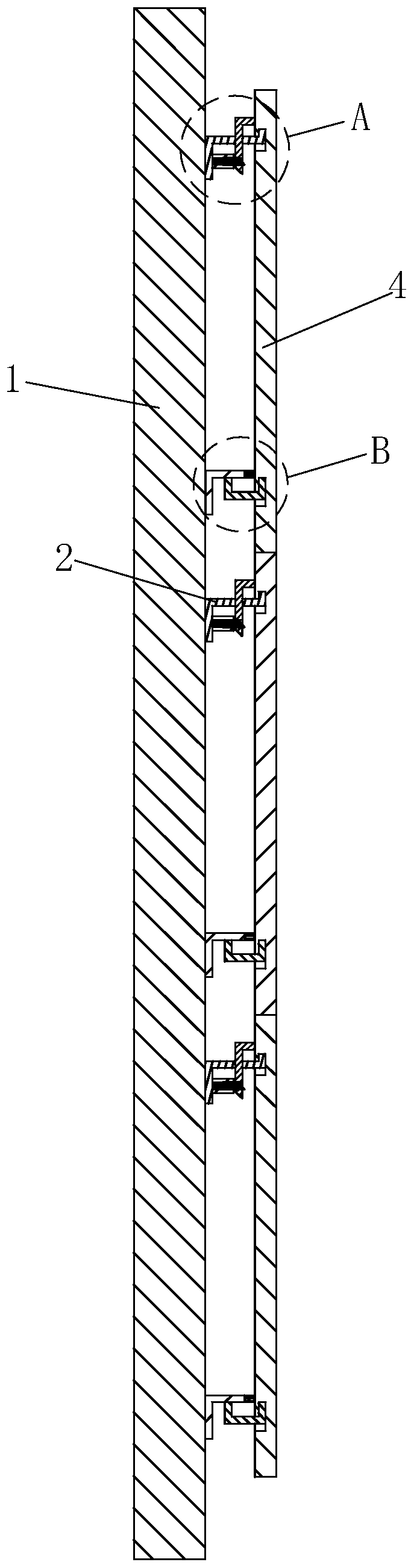

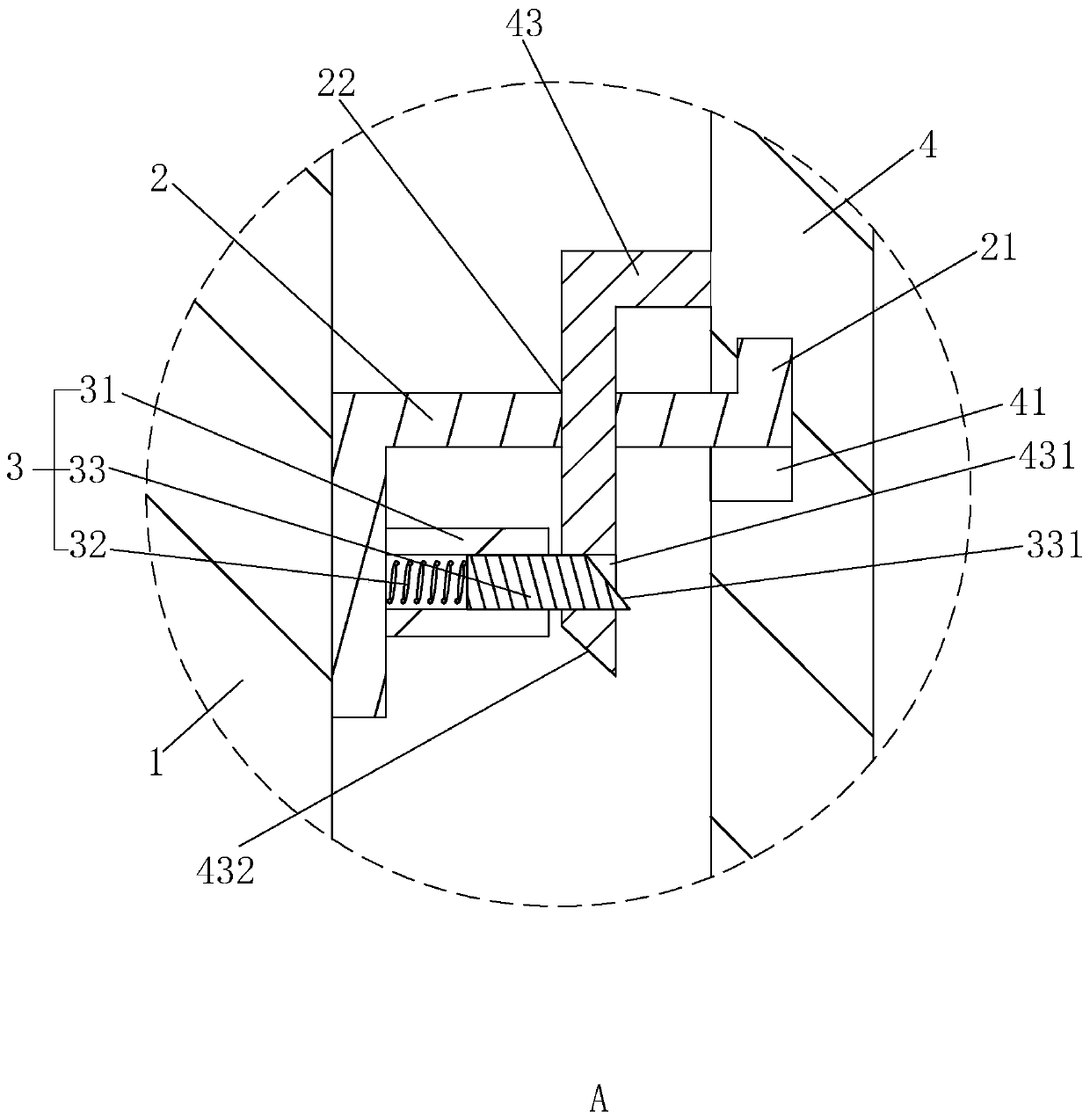

Display device and mobile terminal

The invention provides a display device which comprises a display screen, an insertion part and a camera module. The display screen comprises a display portion and a non-display portion adjacent to the display portion, the display portion is provided with an insertion channel, the insertion part is fixed in the insertion channel and comprises a light-transmitting cover plate, a first boss and a second boss, the first boss and the second boss are respectively arranged on two opposite sides of the light-transmitting cover plate in a protruding mode, the first boss protrudes towards one side of a user, and the second boss protrudes towards the side deviating from the user. The camera module comprises a first lens module and a second lens module, wherein the first lens module and the second lens module are fixed to the first boss and the second boss respectively. The invention provides a mobile terminal. The installing stability of the camera module is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

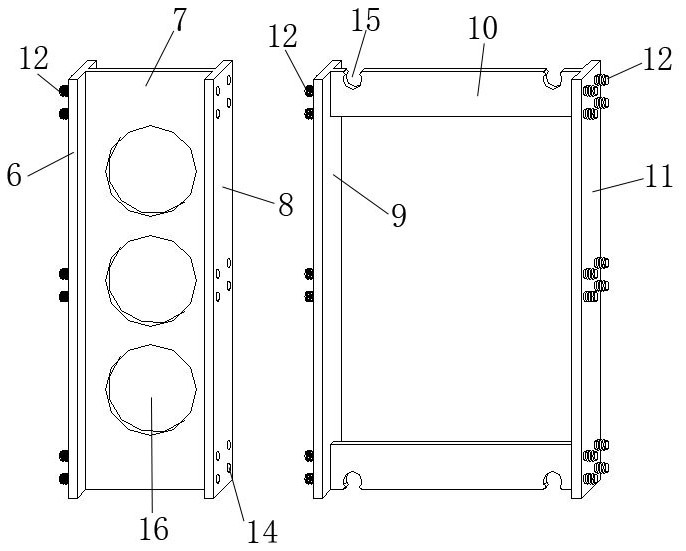

Modulus slot type aluminum profile enclosure

InactiveCN102831936ALess consumablesSimplify the assembly processInstrument housingElectromagnetic shieldingEngineering

The invention discloses a modulus slot type aluminum profile enclosure which consists of a panel, a rear plate and a modulus slot type frame, wherein round grooves or convex columns are arranged at the four corners in the modulus slot type frame, and multiple dovetail grooves are uniformly arranged on the walls inside; and the panel and the rear plate are fixed in the round grooves or convex columns of the modulus slot type frame by bolts. The dovetail grooves can realize stable insertion of electrical appliances, instruments, meters and electronic circuit boards; and the modulus slot type aluminum profile enclosure can save multiple parts, consumes a few materials, is very simple to assemble, can save energy and reduce consumption, has the characteristics of electromagnetic shielding, strong deformation resistance, safety, reliability and the like, and can realize quick batch production.

Owner:江苏省长虹电器实业有限公司

Kidney puncture device capable of avoiding slipping of needle handle in using process for nephrology department

ActiveCN111481270AImprove stabilityImprove clamping stabilitySurgical needlesVaccination/ovulation diagnosticsEngineeringMechanical engineering

The invention provides a kidney puncture device capable of avoiding slipping of a needle handle in the using process for the nephrology department. The device comprises a puncture needle handle and amounting sleeve; fastening plates which are uniformly distributed are movably inserted into the inner wall of the mounting sleeve; a vertical plate inserted into the fastening plate is fixed in the mounting sleeve; an airbag I is fixedly mounted on one side, close to a torsion ring, of a base plate; a wedge-shaped block is fixedly connected to the inner wall of the torsion ring; an air bag II is fixedly mounted below the fastening plate; the air bag II is communicated with the air bag I through a hollow ring and a breather pipe; by rotating the torsion ring, the wedge-shaped block extrudes thefastening plates and the air bag II at the same time; the fastening plate extends towards the inner side and is abutted against the outer wall of the puncture needle handle, and the stability of thepuncture needle handle is enhanced; air in the air bag II is extruded into the air bag I, the size of the air bag I is increased, the fastening plates continue to be pushed, and the clamping firmnessis further enhanced; different air bags I can be adjusted by arranging the hollow ring, and it is guaranteed that all the fastening plates can be abutted against the puncture needle handle.

Owner:JILIN UNIV FIRST HOSPITAL

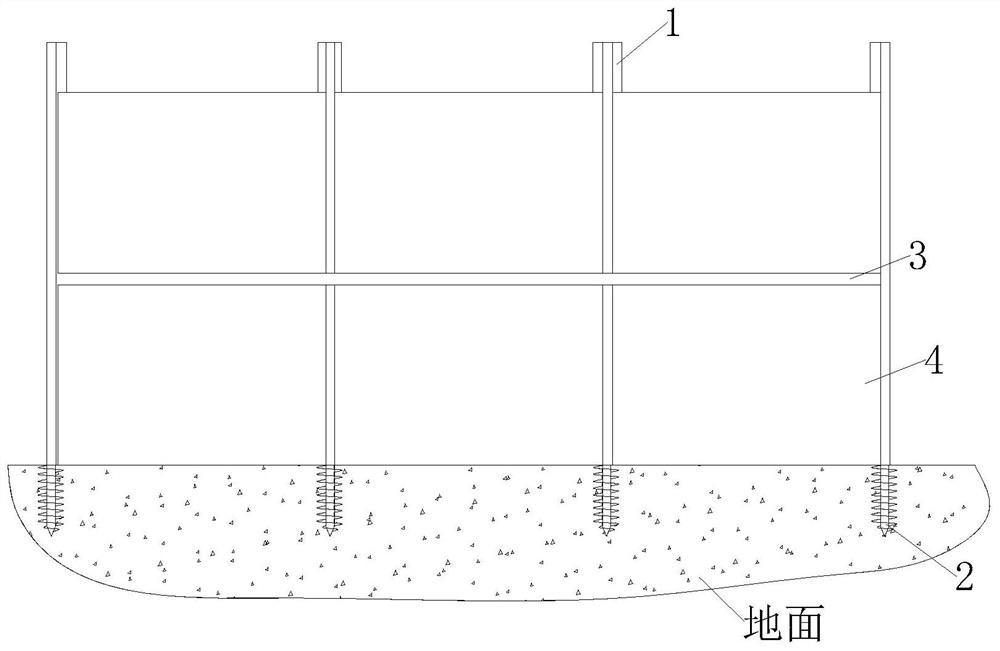

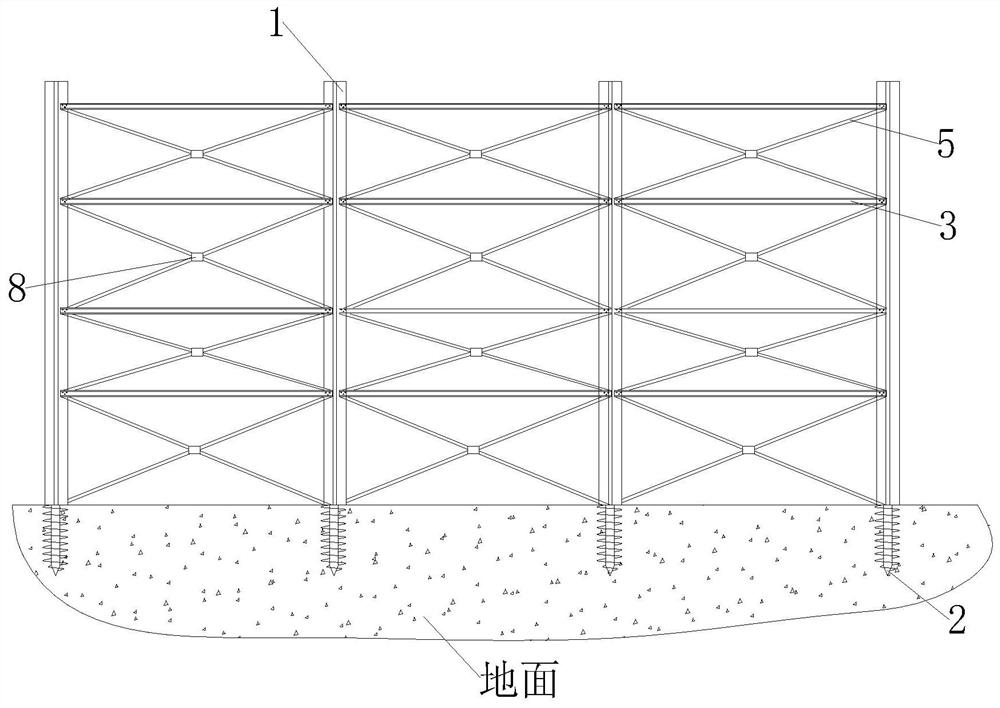

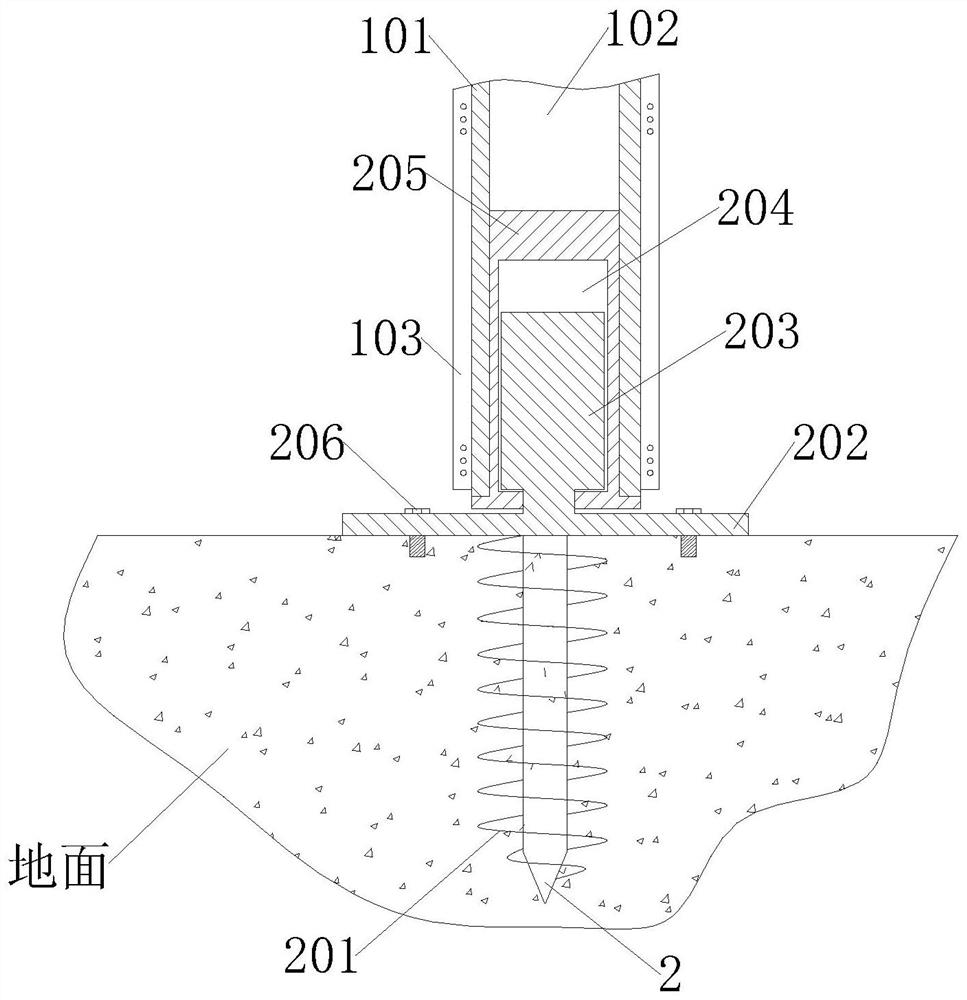

Composite assembly type building steel structure

ActiveCN112196102APrevent tippingImprove security and firmnessStrutsPillarsArchitectural engineeringScrew thread

The invention provides a composite assembly type building steel structure, and relates to the technical field of steel structure construction. The composite assembly type building steel structure comprises support columns and wallboards, wherein the support columns are vertically arranged on the ground or a cement surface at equal intervals, and the wallboards are arranged between every two adjacent support columns; the bottom of each support column is provided with a bottom fixing foot, and each bottom fixing foot is fixedly installed on the ground or the cement surface; and a plurality of transversely-fixed cross beams are fixedly connected between every two adjacent supporting columns at equal intervals, and a supporting beam is fixedly connected with the middles of every two adjacent cross beams. According to the composite assembly type building steel structure, the supporting columns are erected on the ground or the cement surface at equal intervals, the bottom ends of the supporting columns are installed on the bottom fixing feet and driven into the ground through threaded rods at the bottoms of the bottom fixing feet, and threads on the surfaces of the threaded rods are meshed with soil at the bottom of the ground so that the bottom fixing feet are fixedly installed on the ground; and locking bolts are driven into the edge of a bottom fixing disc at equal intervals so asto lock the peripheries of the bottom fixing feet.

Owner:漳州市工程咨询中心有限公司

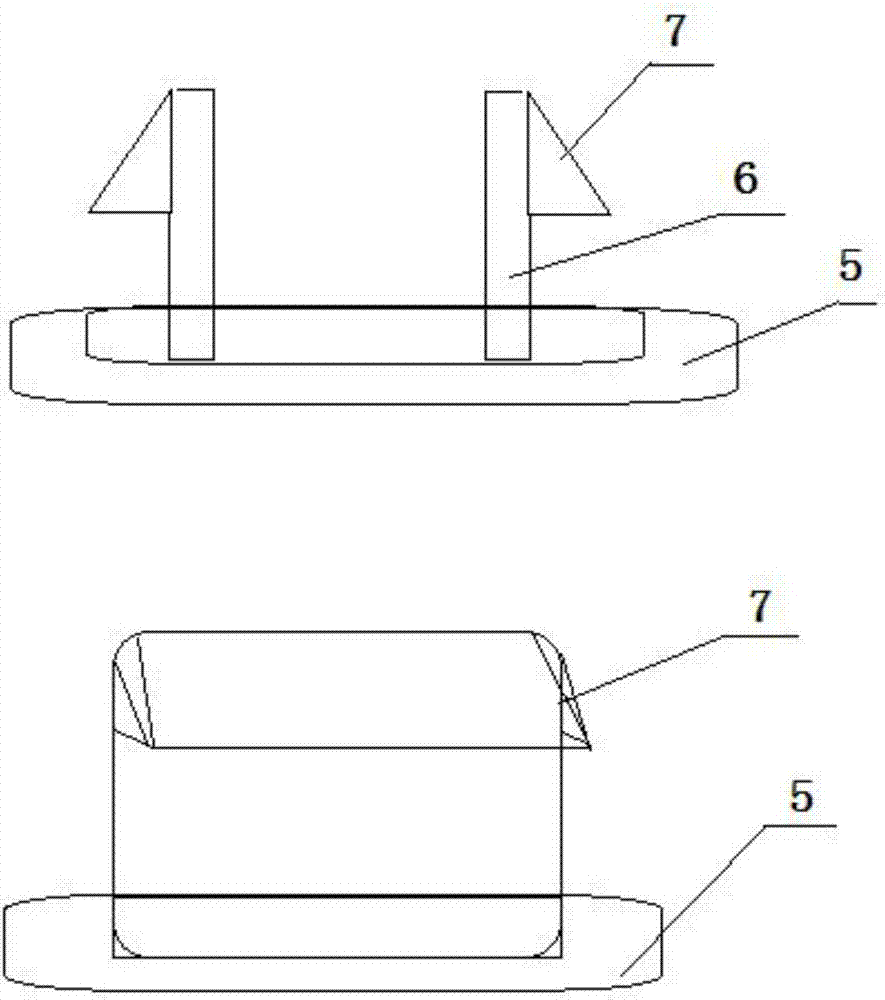

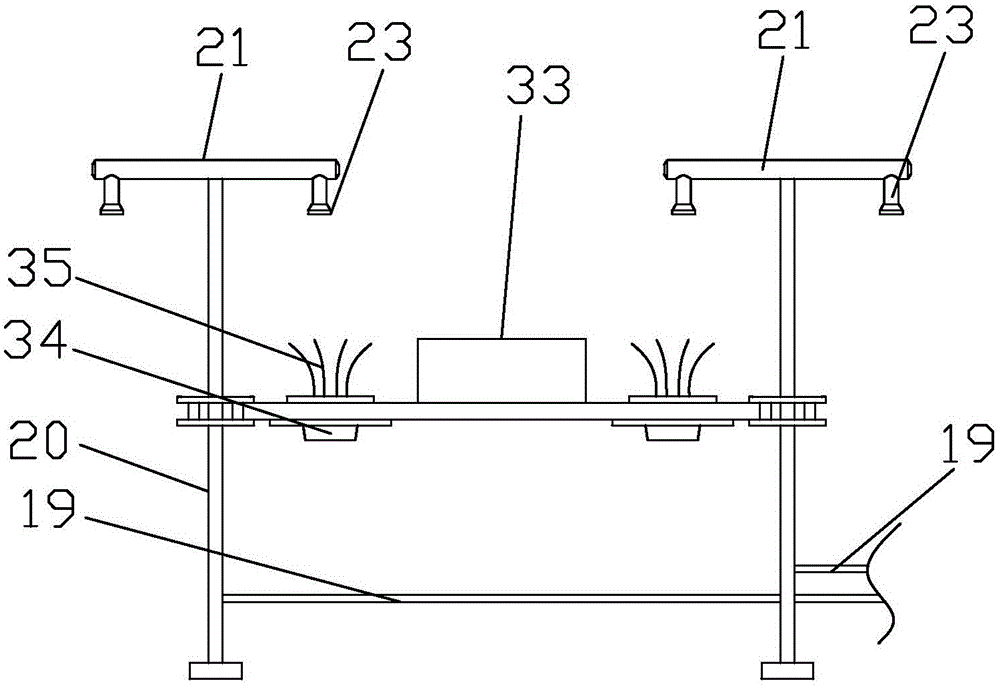

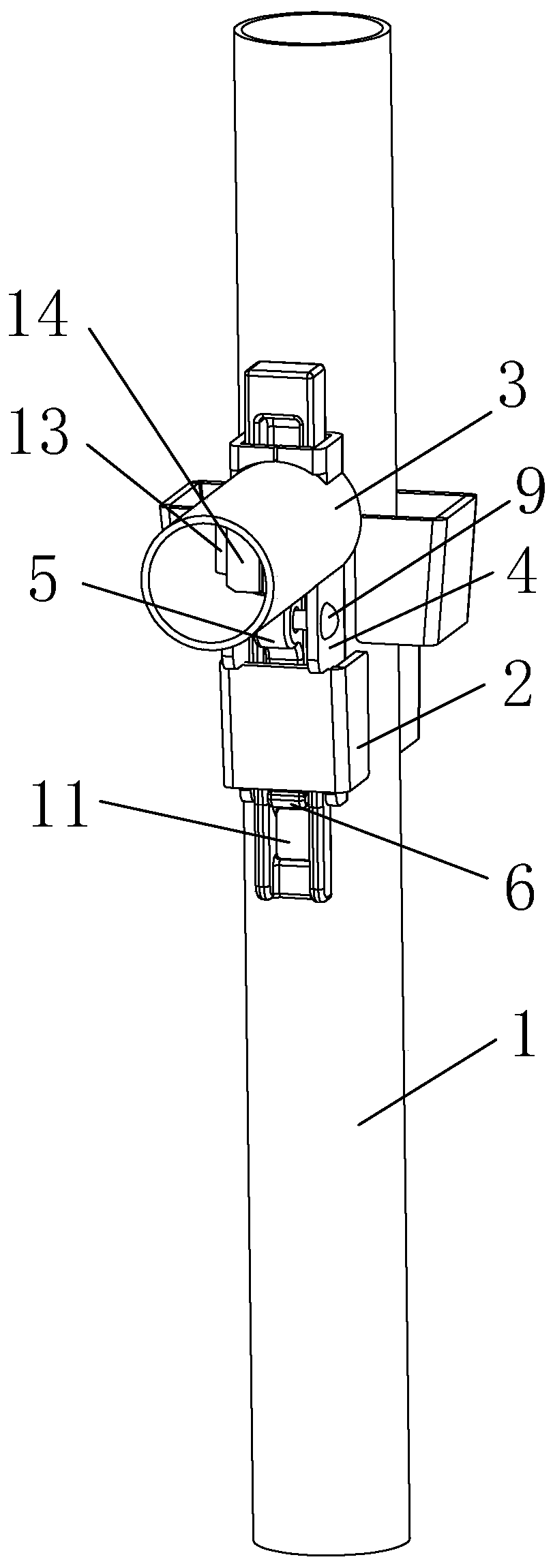

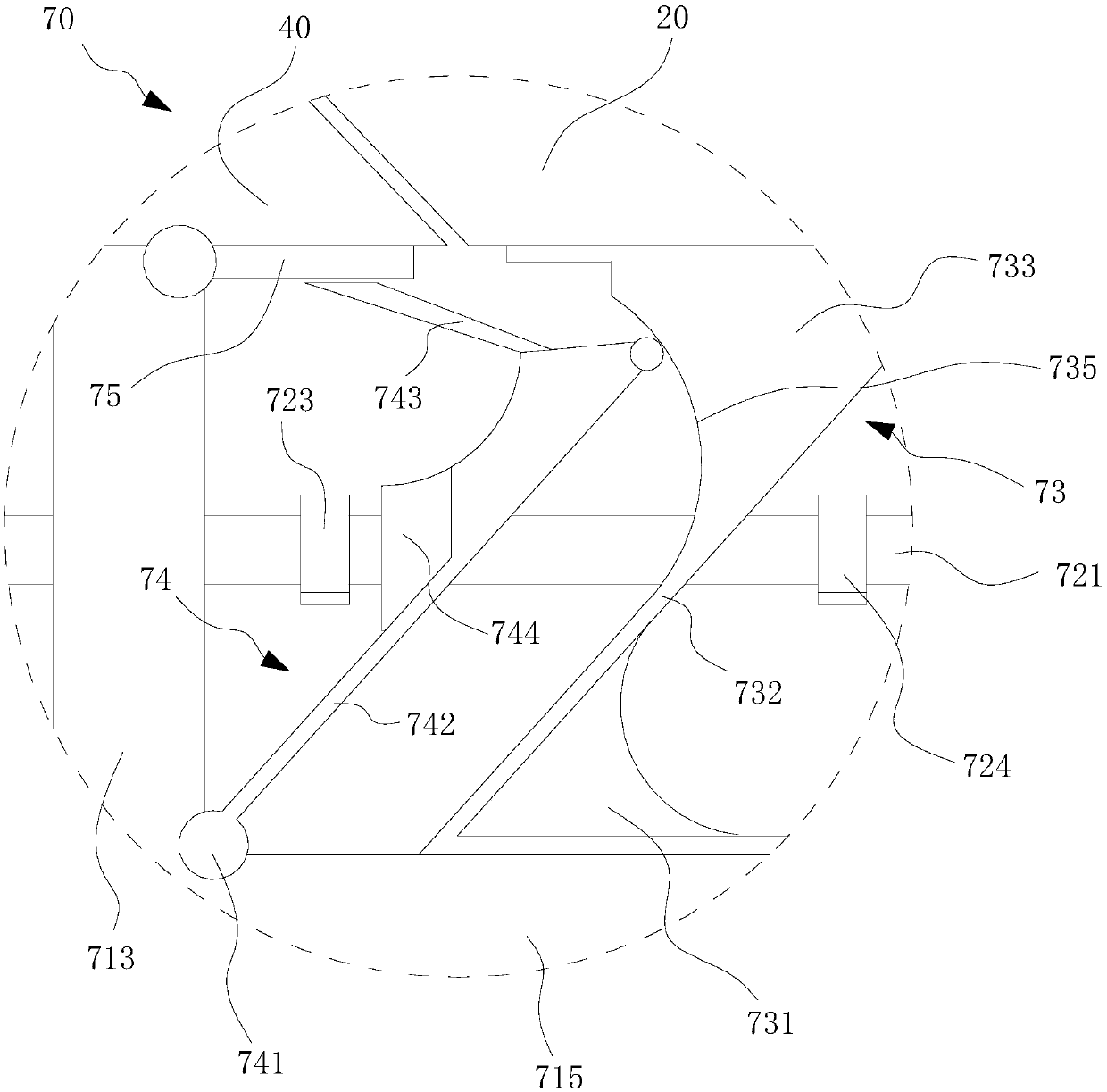

Scaffold

PendingCN109898836AAvoid separationImprove installation firmnessScaffold connectionsEngineeringMechanical engineering

The invention relates to the technical field of building construction, in particular to a scaffold. The scaffold comprises a first connecting tube, a bayonet socket is mounted on the side wall of thefirst connecting tube, and the first connecting tube is connected with a second connecting tube through the bayonet socket; and a clamping seat is mounted to the end, connected with the first connecting tube, of the second connecting tube, a clamping block is rotatably mounted on the clamping seat, a locking block locked with the bayonet socket is mounted on the clamping block, and a push block pushing the locking block to abut against the bayonet socket is movably mounted in the clamping seta. The scaffold has the beneficial effects that the structure is simple, mounting and disassembly are convenient, the clamping block, the locking block and the bayonet socket form self-locking limiting, and the mounting soundness of the scaffold is effectively improved.

Owner:上海森大机械制造有限公司

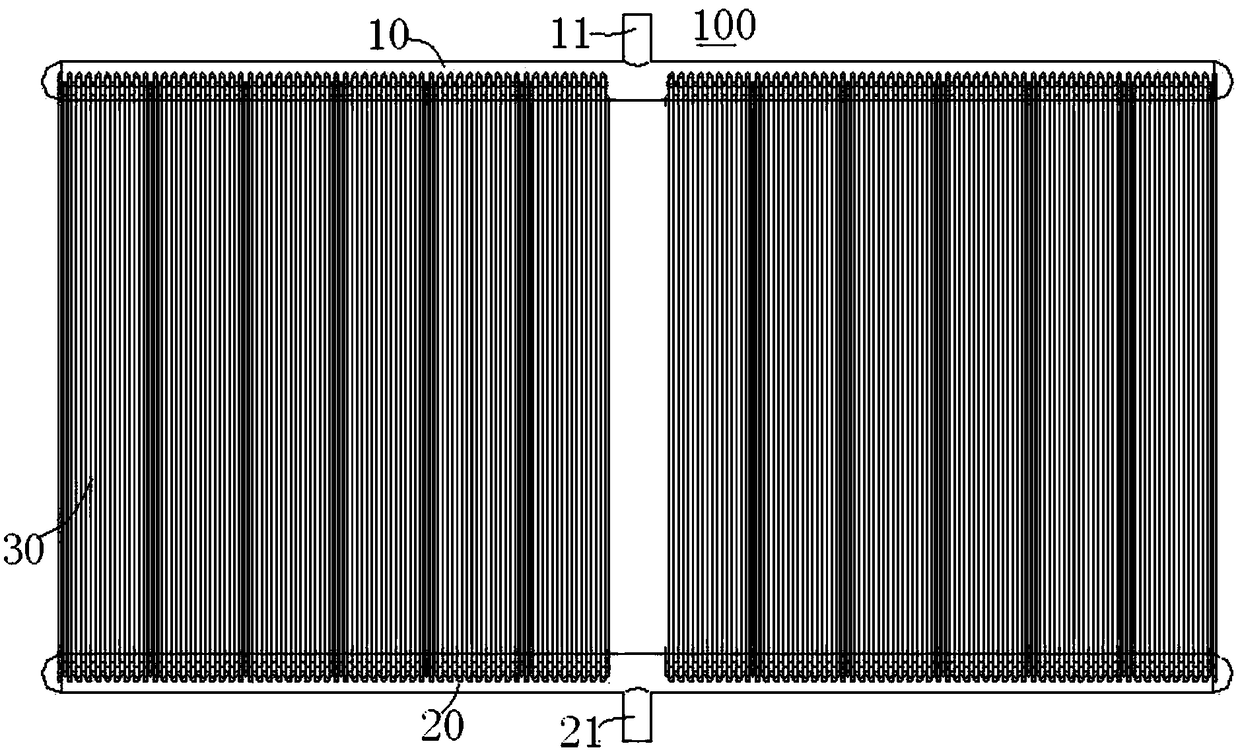

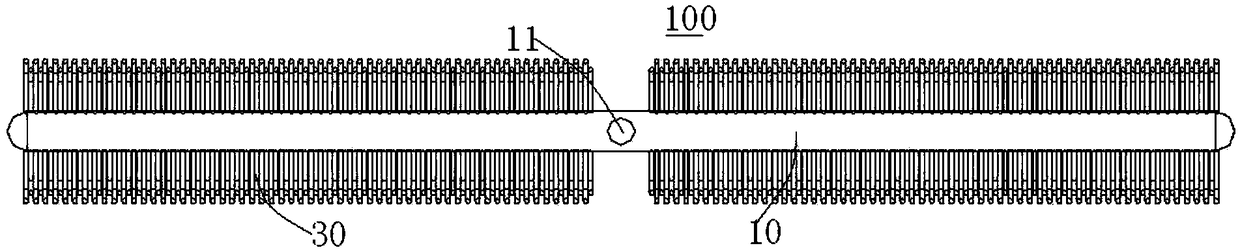

Mounting structure of photovoltaic bushes

ActiveCN109104141AImprove installation firmnessPhotovoltaic supportsPhotovoltaic energy generationEngineeringElectrical and Electronics engineering

Owner:王强

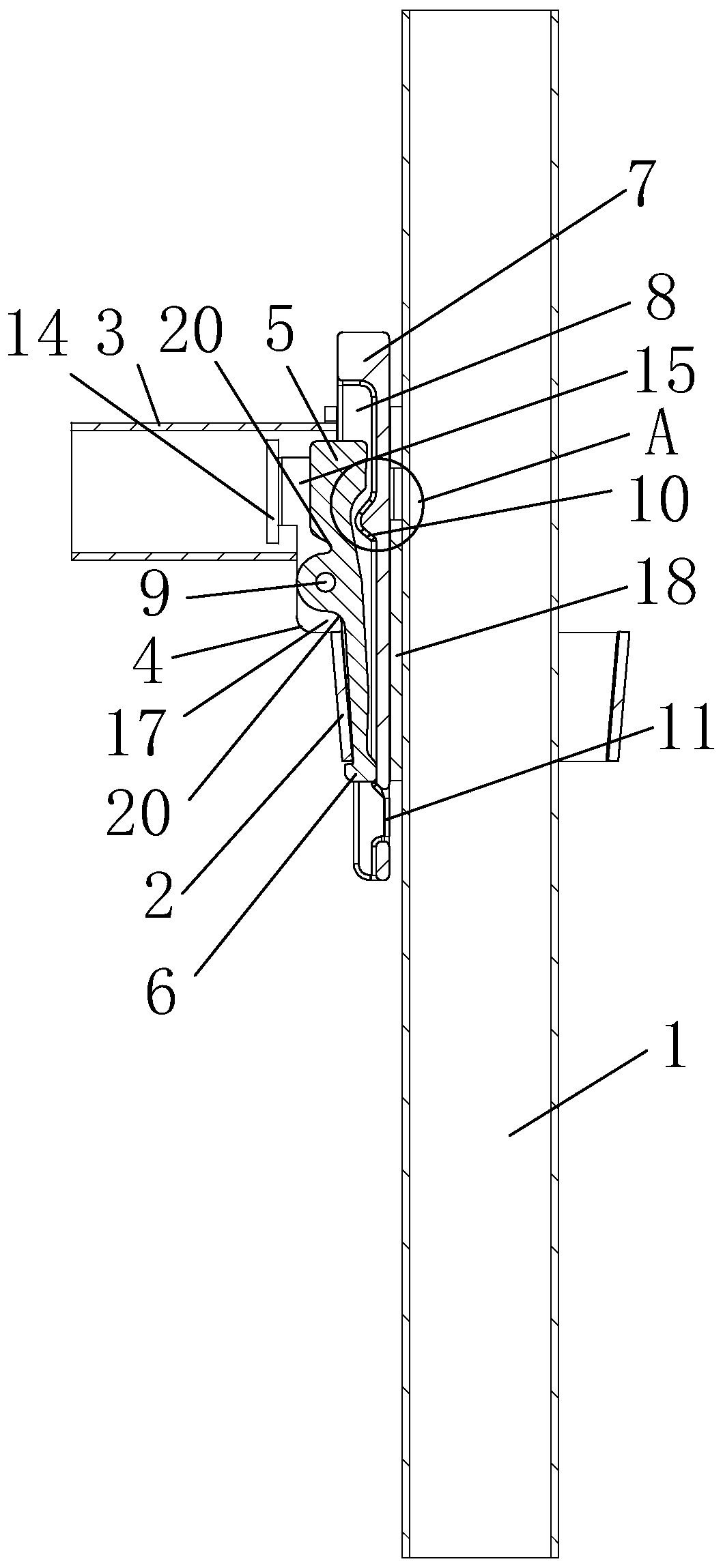

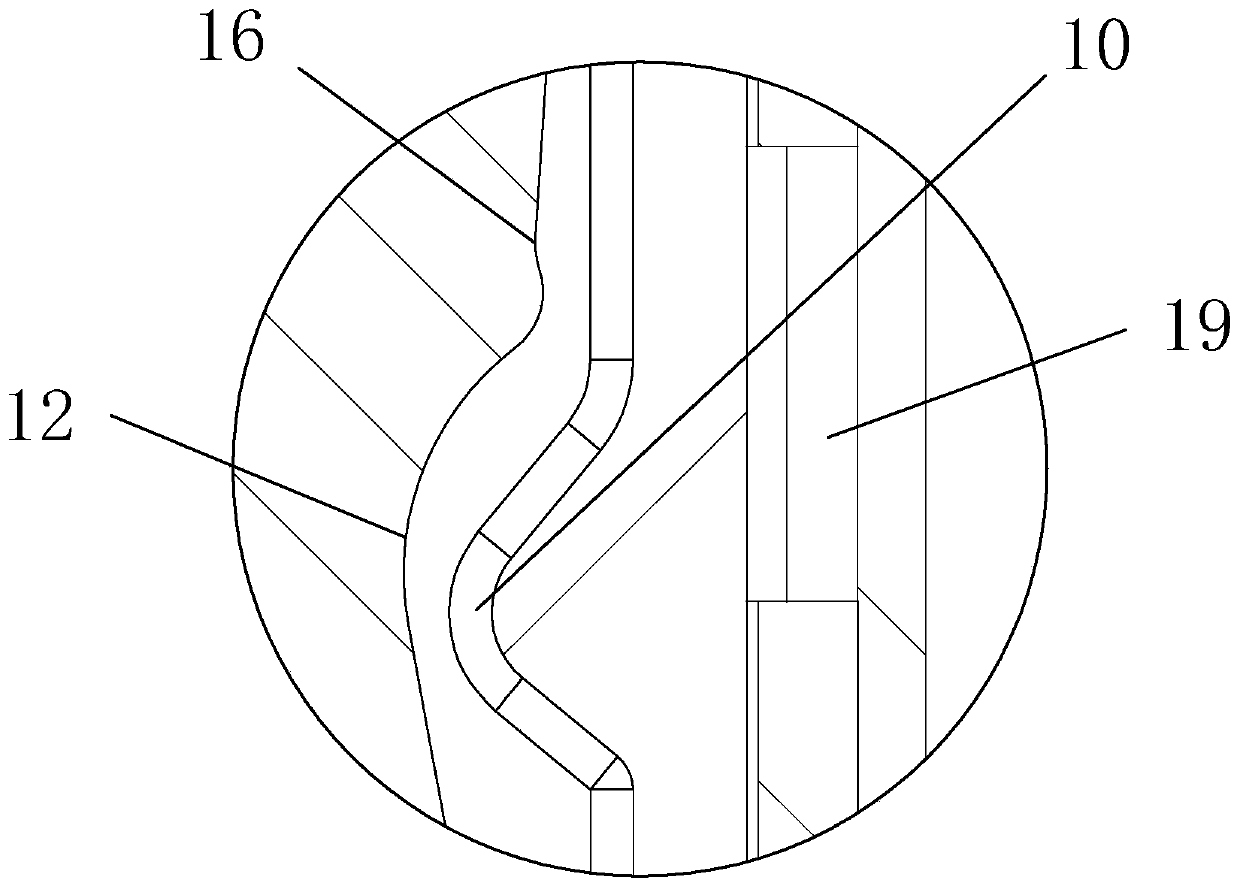

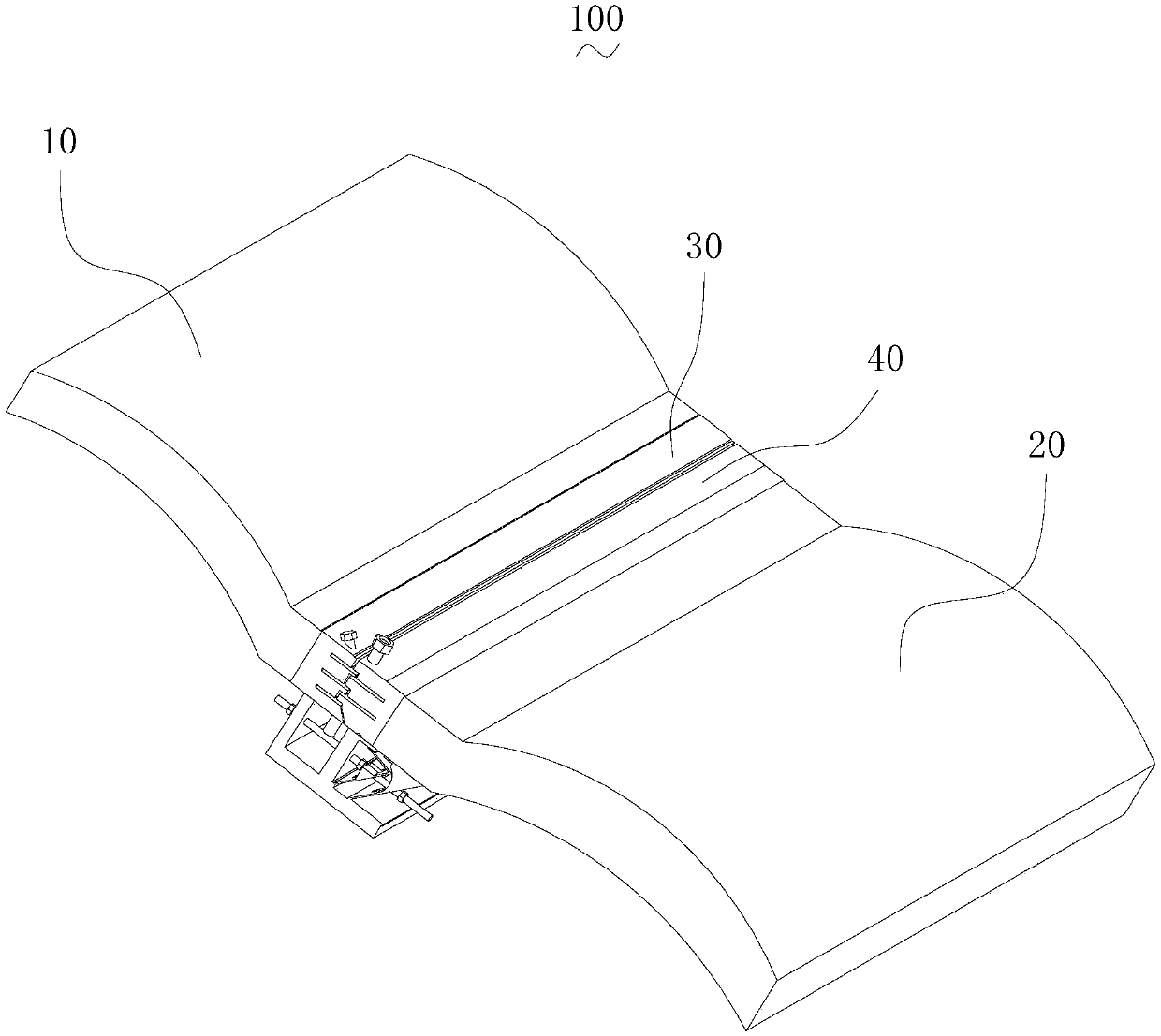

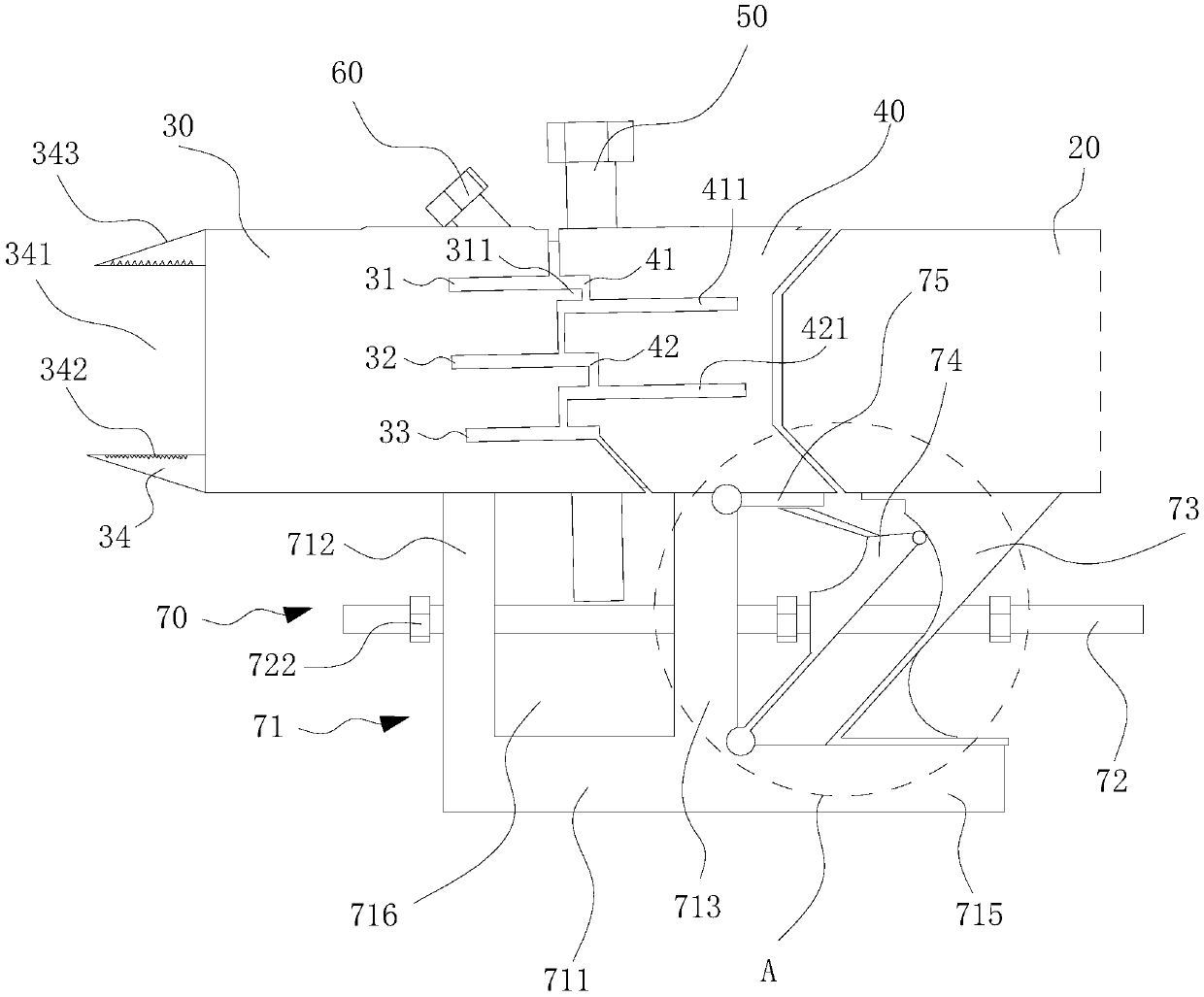

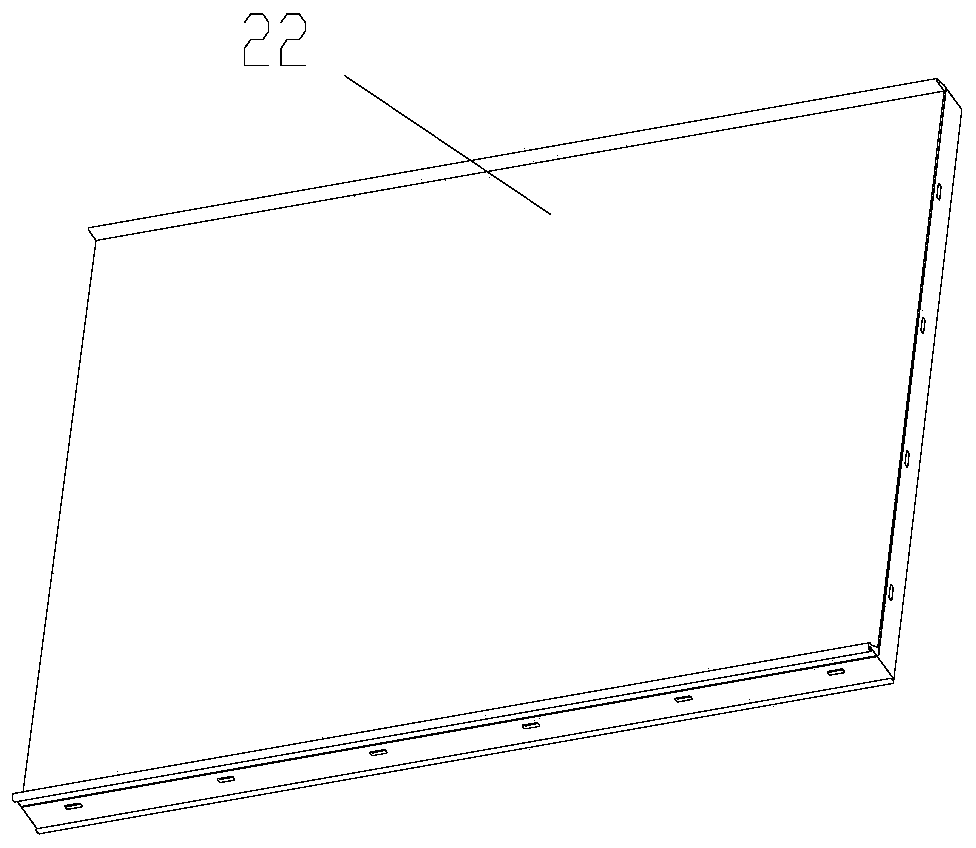

Curtain wall installation structure and installation method

The invention relates to a curtain wall installation structure and an installation method, and belongs to the technical field of building construction. The curtain wall installation structure comprises multiple pieces of angle steel fixedly installed on a wall body, curtain wall plates are installed at the ends, away from the wall body, of the angle steel, the four corners of each curtain wall plate correspond to the angle steel correspondingly, and hooks which are bent vertically upwards are fixedly arranged at the ends, away from the wall body, of the angle steel located at the top ends of the curtain wall plates; L-shaped hook grooves are formed in the positions, right opposite to the hooks, of the curtain wall plates, the L-shaped hook grooves extend vertically upwards after horizontally extending into the curtain wall plates, and the opening size of the L-shaped hook grooves is not smaller than the height of the hooks in the vertical direction; and a limiting block horizontally facing the wall body is fixedly arranged at the end, away from the L-shaped hook groove, of each curtain wall plate, a limiting groove is formed in the upper surface of the angle steel located at the bottom end of each curtain wall plate, and a pressing assembly used for pressing the corresponding limiting block is arranged in the corresponding limiting groove. The curtain wall installation structure and installation method have the effects that falling is not being prone to occurrence, and the safety is improved.

Owner:北京当代创新建设工程有限责任公司

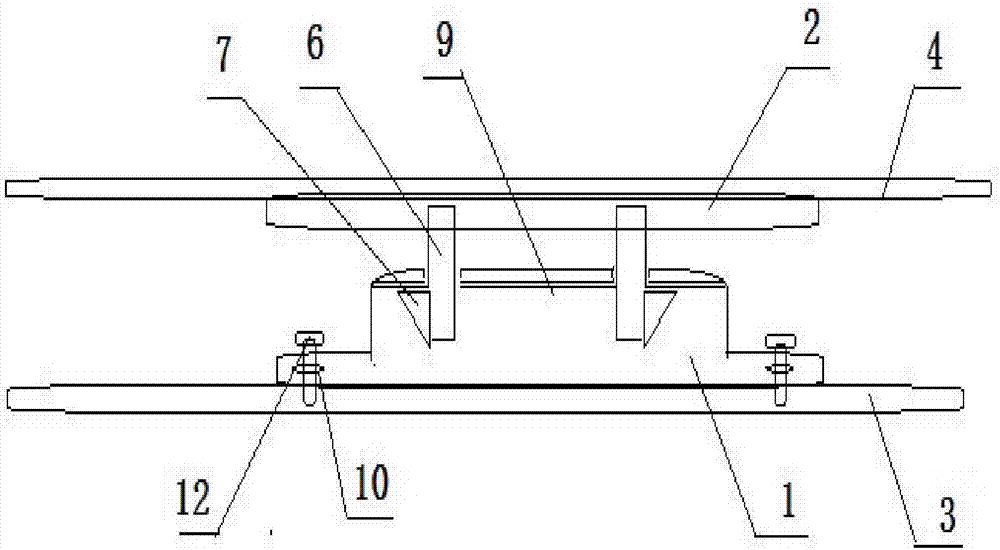

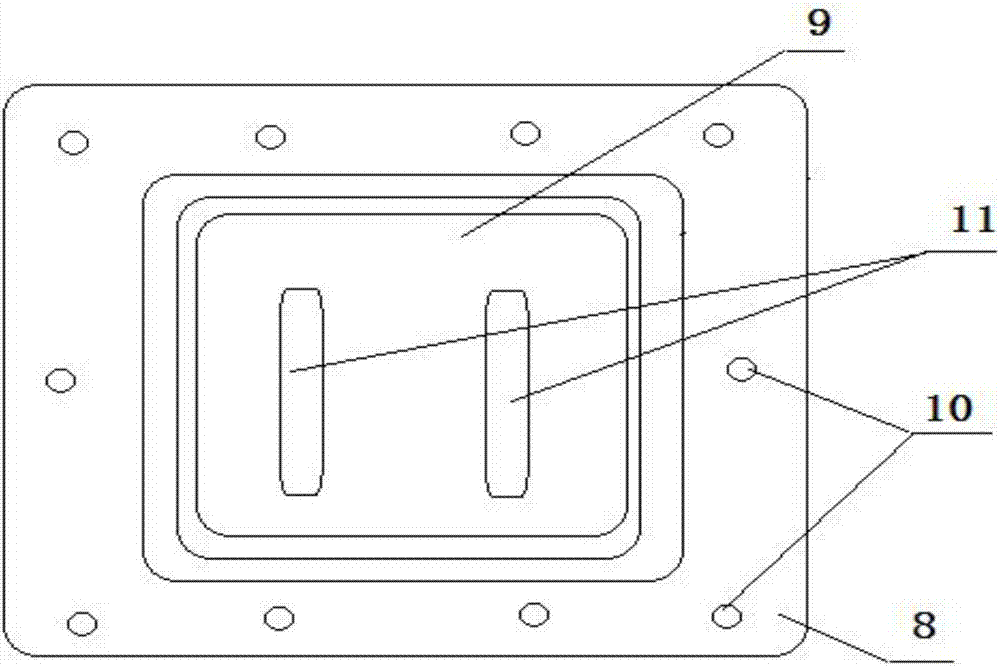

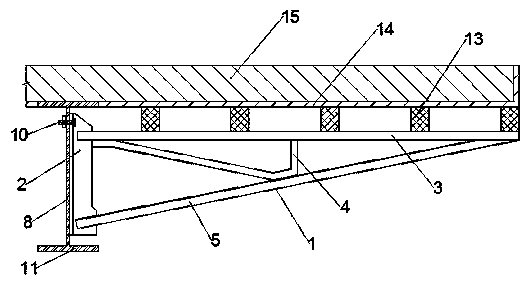

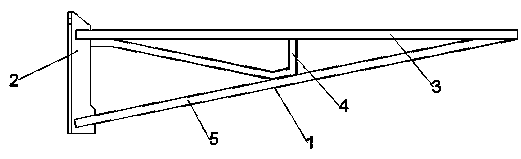

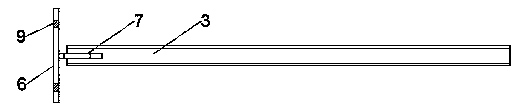

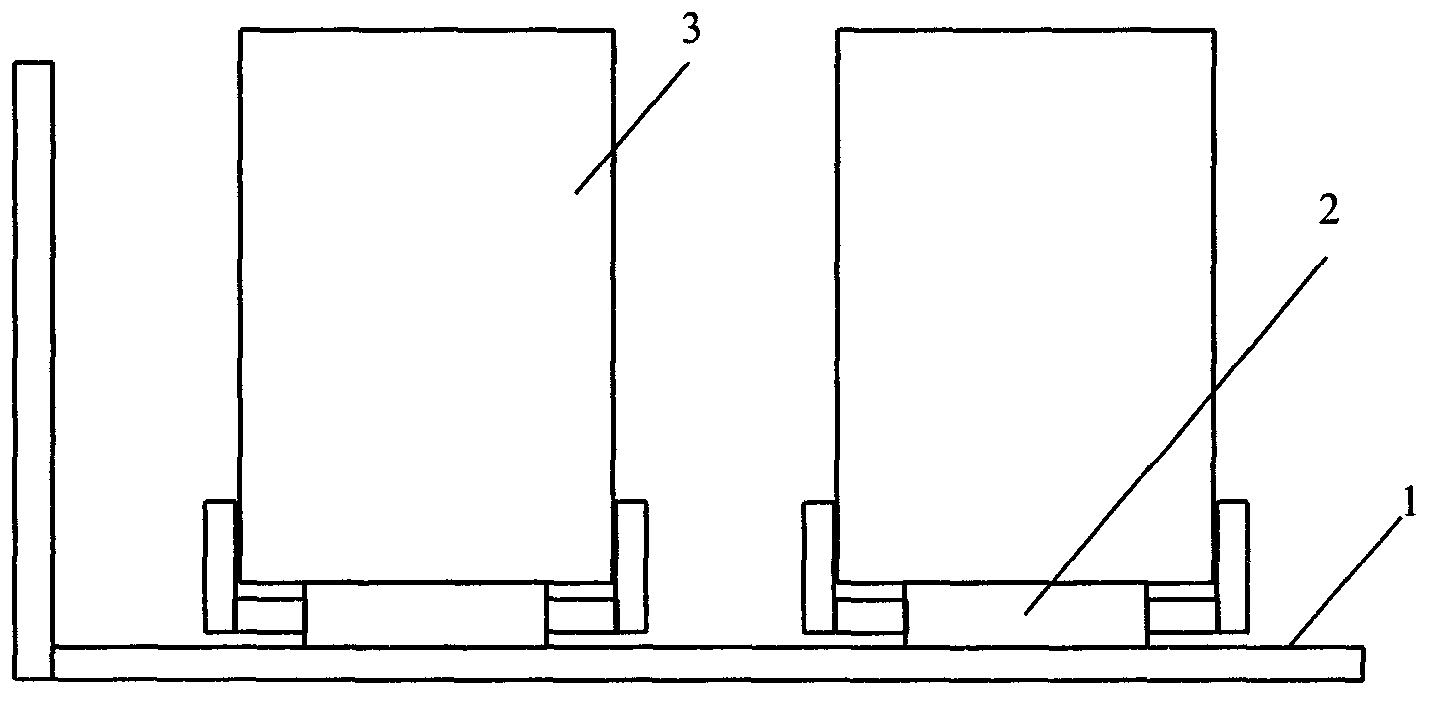

Truss type formwork support for suspended cast-in-place plate and using method thereof

PendingCN110700579AImprove stabilityImprove installation firmnessForms/shuttering/falseworksBuilding support scaffoldsFalseworkFloor slab

The invention relates to a truss type formwork support for a suspended cast-in-place plate and a using method thereof. The truss type formwork support is mainly suitable for a suspended cast-in-placefloor system in steel structure engineering, structurally comprises a truss chord member and a quick dismounting connector, and is characterized in that the truss chord member comprises a horizontal fixed upper chord member, a bent web and an obliquely upward fixed lower chord member, the quick dismounting connector comprises a vertical plate and a connecting plate, the connecting plate is fixed to the vertical center line of the vertical plate, and the upper chord member and the lower chord member of the truss chord member are fixed to the quick dismounting connector. During installation, theformwork support is pre-screwed on a structural steel beam through bolts, the formwork support and the structural steel beam are hoisted to a corresponding position of the steel column together, fineadjustment is carried out, and the bolts are tightened. During dismounting, the bolts are unscrewed and then screwed off after wood lumps, wood formworks and the like above are detached, and finallythe formwork support is taken down through a lifting hook. The formwork support has the advantages of being low in disassembly and assembly difficulty, high in construction safety and the like. Compared with a traditional full scaffold, the construction progress is accelerated, the steel consumption is reduced, and the cost is reduced.

Owner:浙江久筑建筑技术有限公司

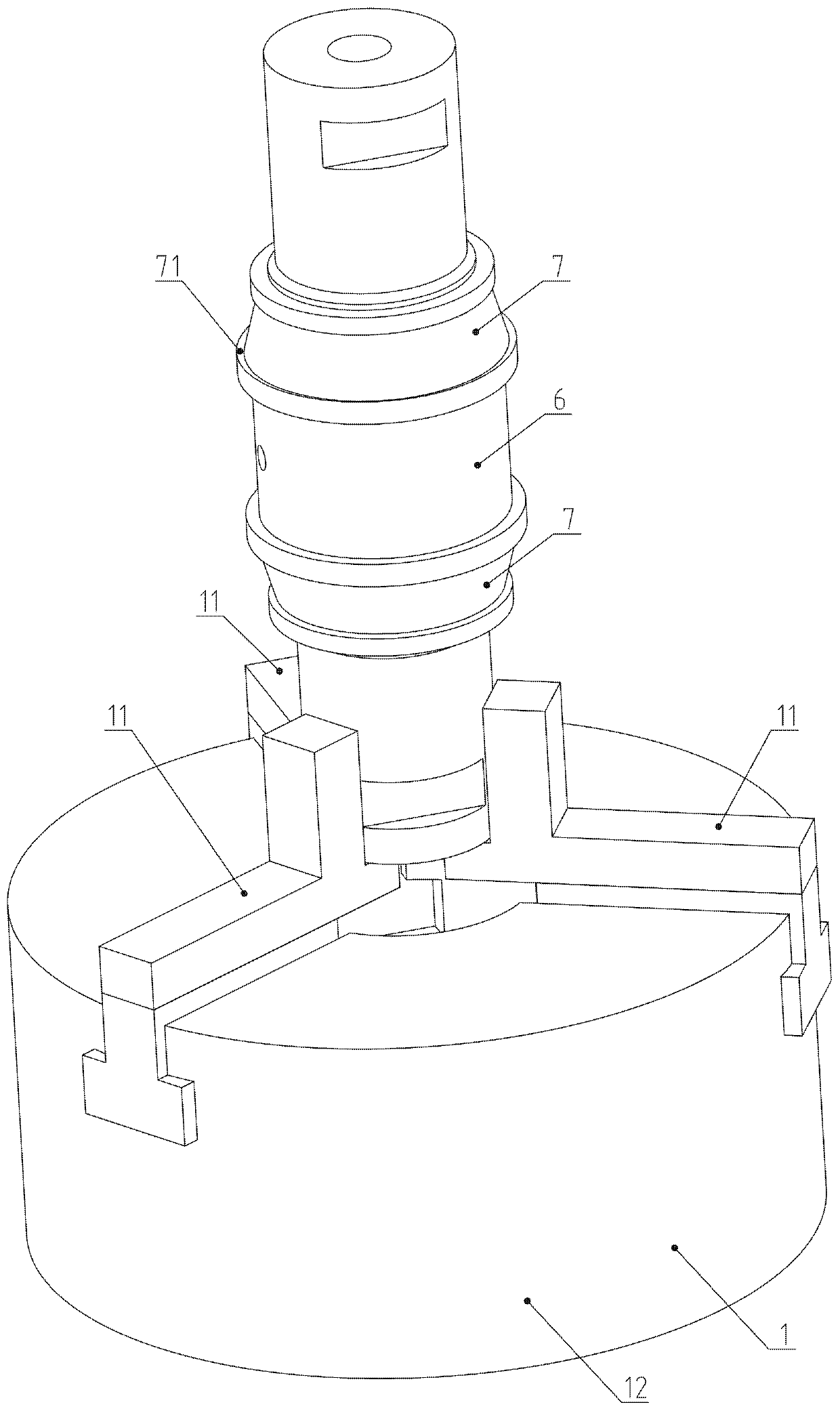

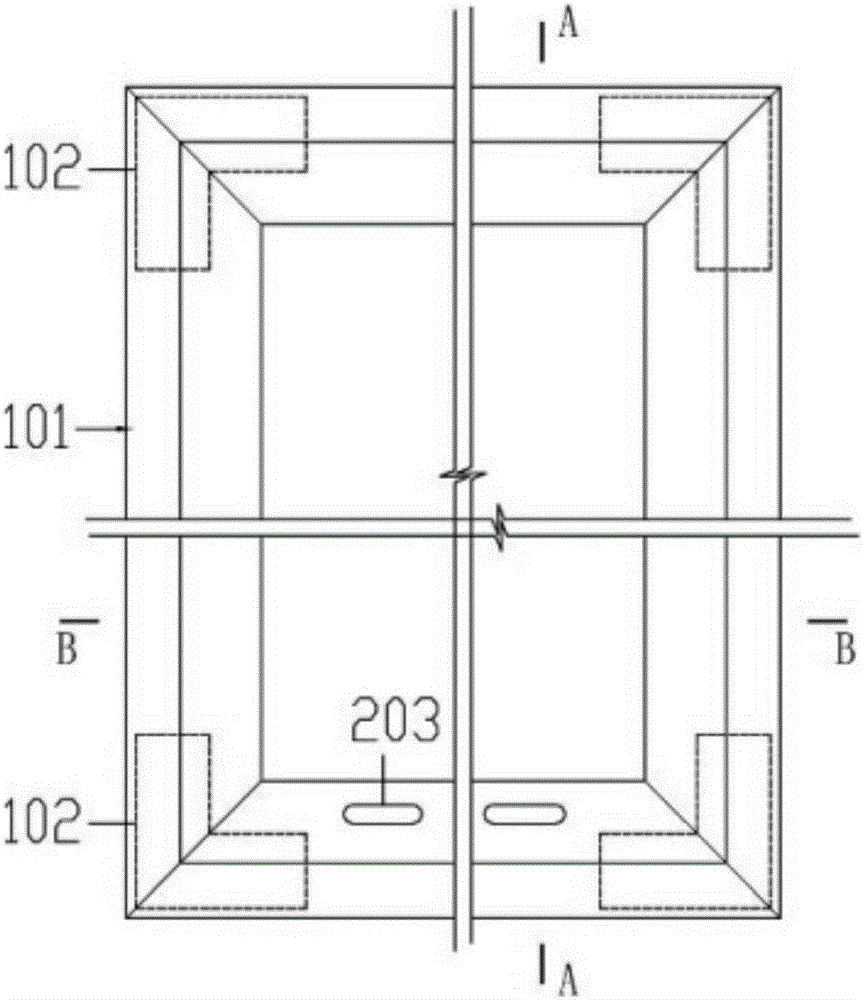

Automated bucket loading system

InactiveCN104139727AReduce labor intensityAchieve loadingLoad securingLoading/unloadingAutomatic controlEngineering

For achieving a vertical mounting method, further facilitating automatic loading of bucket-structured objects, enabling bucket structures to be loaded without being aligned to a base, greatly simplifying a loading process and achieving firm mounting of the bucket structures, the invention discloses an automated bucket loading system. The automated bucket loading system comprises a base body, a sensing base platform, a jack catch, a pressing type start button, a base internal gear adjusting system and an automatic control system. The automated bucket loading system can greatly reduce the labor intensity of works, accurately and efficiently achieve loading the bucket structures and improves the mounting firmness of the bucket structures on a trailer.

Owner:蔡驰宇

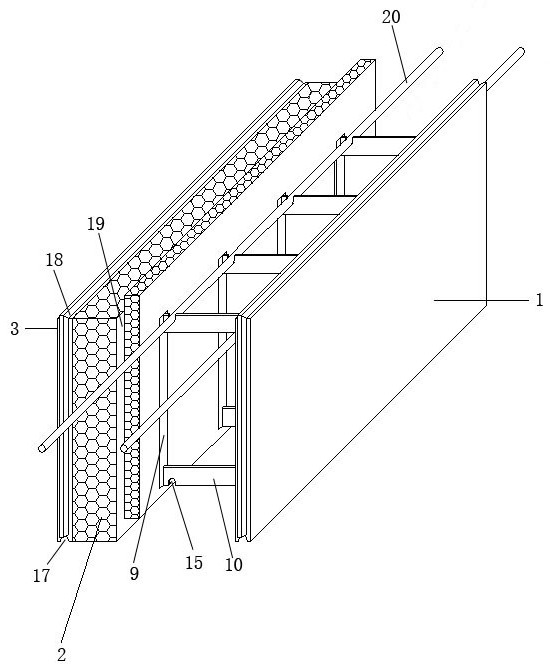

Heat preservation integrated wall body non-dismantling formwork capable of being connected quickly

PendingCN113565317ALow production costIncreased lateral stiffness and resistance to bending deformationForms/shuttering/falseworksHeat proofingPhysicsRebar

The invention provides a heat preservation integrated wall body non-dismantling formwork capable of being rapidly connected. The heat preservation integrated wall body non-dismantling formwork comprises a non-dismantling outer wall heat preservation formwork, a connecting piece, a non-dismantling inner wall formwork, an inner prefabricated reinforcing mesh and an outer prefabricated reinforcing mesh; the connecting piece comprises a heat preservation layer outer parallel plate, a heat preservation layer web plate, a heat preservation layer inner parallel plate, a pouring layer outer parallel plate, a pouring layer web plate and a pouring layer inner parallel plate; the heat preservation layer outer parallel plate and the heat preservation layer inner parallel plate are perpendicular to the heat preservation layer web plate; the pouring layer outer parallel plate and the pouring layer inner parallel plate are perpendicular to the pouring layer web plate; the heat preservation layer outer parallel plate is connected with the outer prefabricated reinforcing mesh; the pouring layer inner parallel plate is connected with the inner prefabricated reinforcing mesh; and poured wall body main steel bar fixing grooves are formed in the upper end and the lower end of the pouring layer web plate. The heat preservation integrated wall body non-dismantling formwork has the advantages that the structural strength is high, the installation is firm, steel bars in a poured wall body are accurately installed, the quality of the poured wall body is guaranteed, and the construction efficiency is high.

Owner:HEBEI ANNENG GREEN BUILDING TECH CO LTD

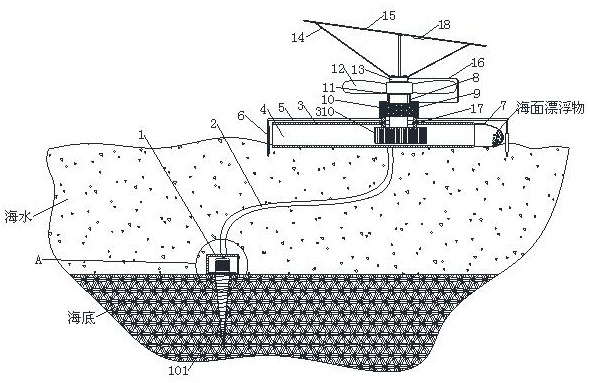

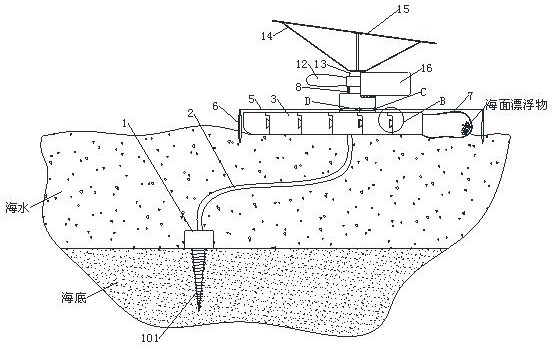

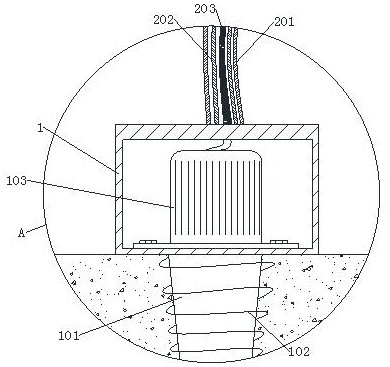

Solar photovoltaic power station used on sea

ActiveCN112054750AImprove installation firmnessGuaranteed to workPhotovoltaic supportsBatteries circuit arrangementsElectric energyPhotovoltaic power station

The invention provides a solar photovoltaic power station used on the sea surface, and relates to the technical field of solar power generation. The solar photovoltaic power station comprises a floating plate floating on the sea surface and a fixator arranged at the bottom of the floating plate, the fixator falls into the seabed position, the middle position of the bottom of the floating plate isconnected with a tensioning rope, the bottom of the tensioning rope is fixedly connected to the fixator, a fixed shaft rod is arranged in the middle of the top end of the floating plate, a power generation plate supporting frame is fixed to the top end of the fixed shaft rod, an obliquely-fixed photovoltaic power generation panel is fixedly installed at the top end of the power generation plate supporting frame, and a storage battery is arranged at the bottom of the photovoltaic power generation panel. The obliquely-fixed photovoltaic power generation panel is installed at the top end of the floating plate, the photovoltaic power generation panel absorbs solar energy at the top end of the power generation panel supporting frame, light energy is converted into electric energy through the photovoltaic power generation panel to be stored in the storage battery, and the electric energy stored by the storage battery is used in the later period.

Owner:金华智果智能科技有限公司

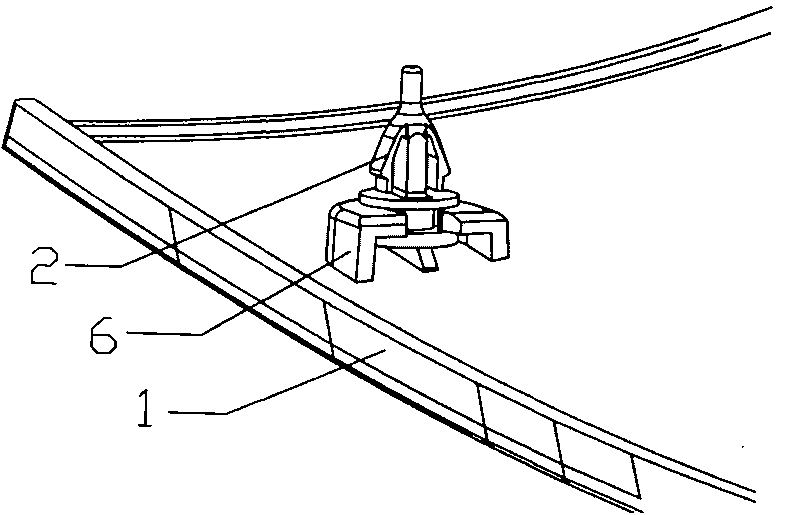

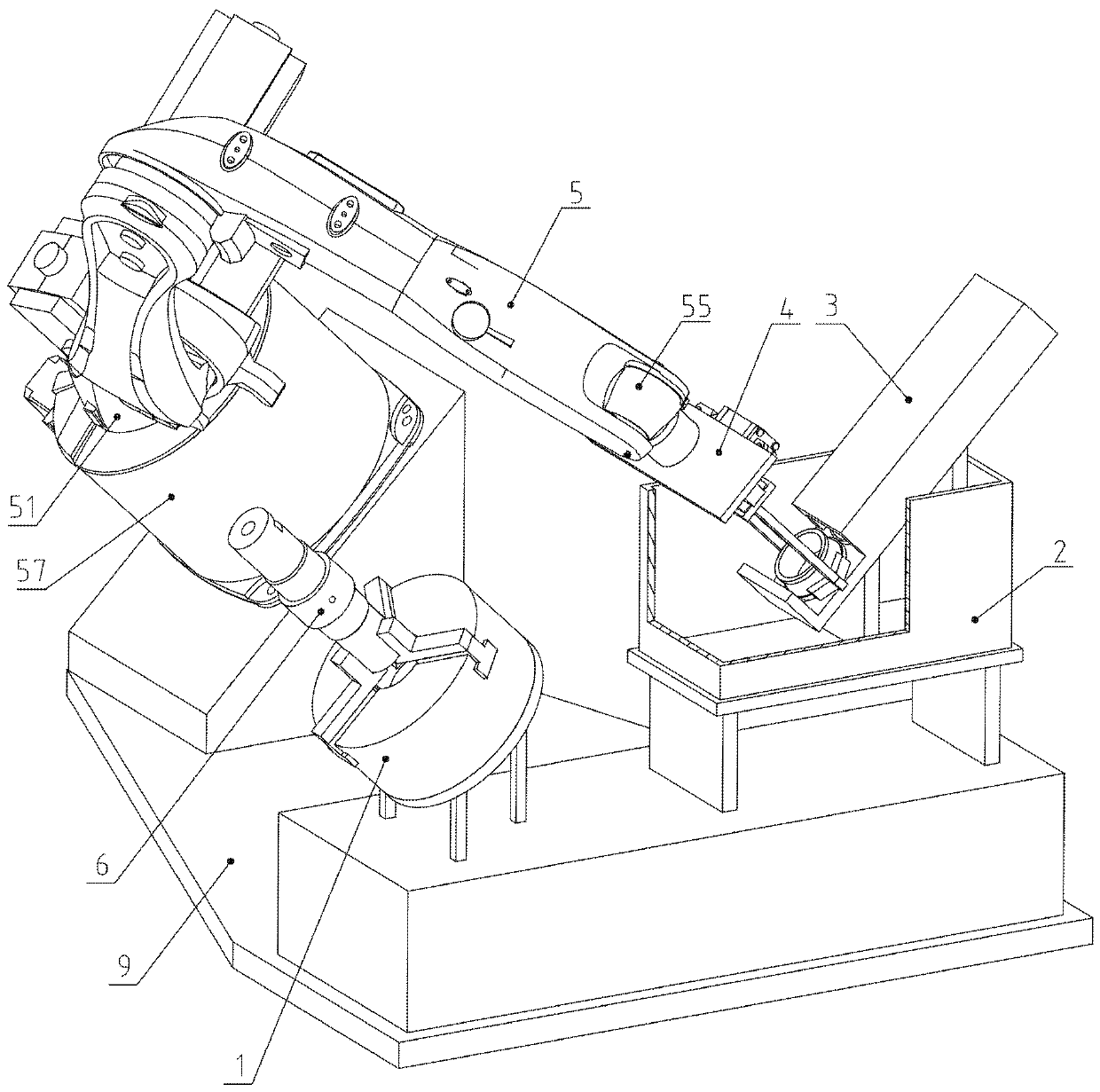

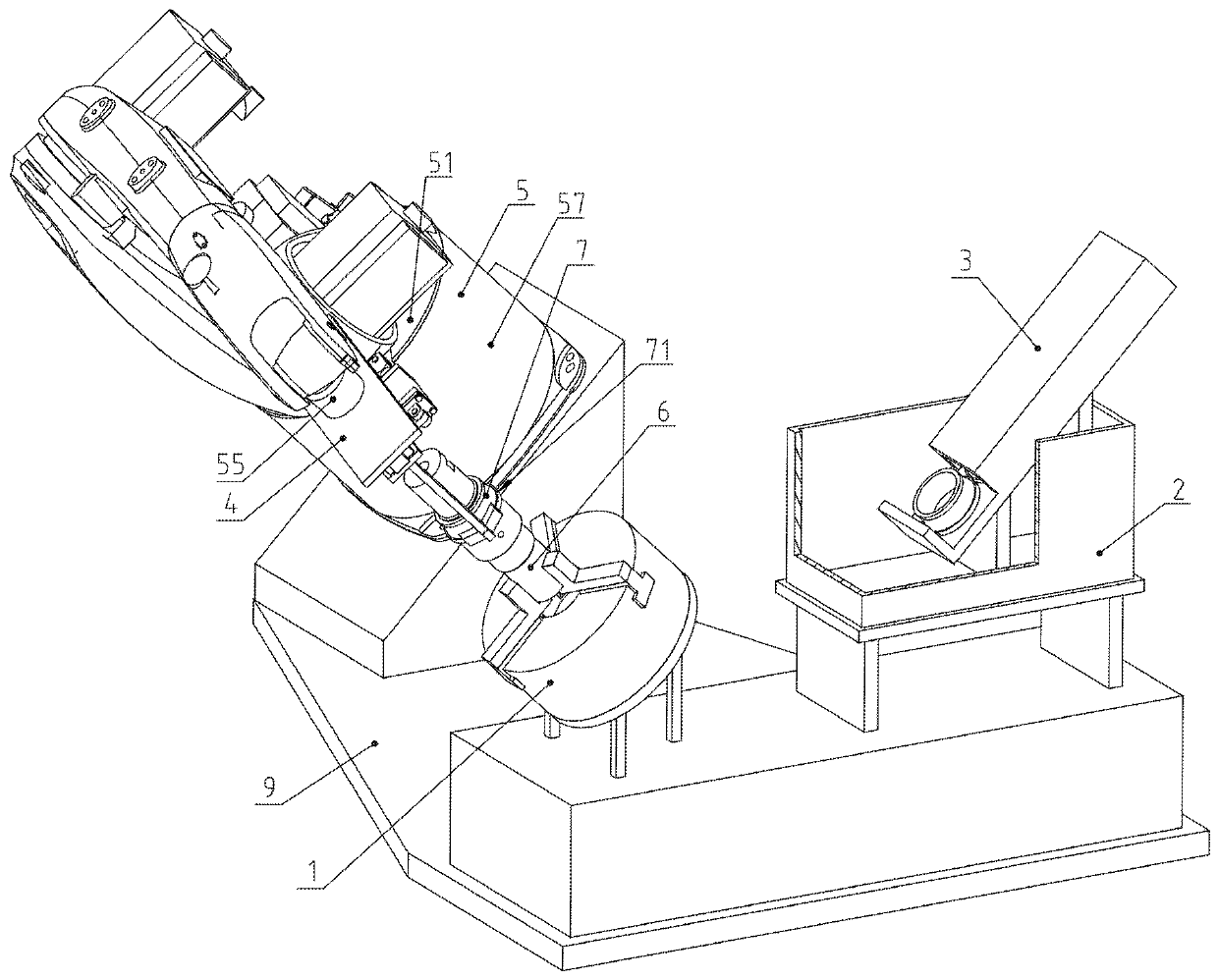

Intelligent and rapid installation equipment for high-temperature bearing inner rings of roller cage shoe and normal-temperature middle shaft of roller cage shoe

ActiveCN109551169AImprove installation firmnessQuality improvementMetal working apparatusEngineeringTransformer oil

The invention belongs to the technical field of mining machinery equipment manufacturing, and relates to intelligent and rapid installation equipment for high-temperature bearing inner rings of a roller cage shoe and a normal-temperature middle shaft of the roller cage shoe. The bearing inner rings are put in from a feed inlet, the bearing inner rings slide down on lower supporting inclined surface of a bearing inner ring slide way, and the bearing inner ring at the lowermost slides to an opening of the lower end of the bearing inner ring slide way, is blocked by a stop block at the tail end of the bearing inner ring slide way, is positioned and is completely immersed in transformer oil to be heated to 80-100 DEG C. A six-axis robot drives a manipulator, and a first finger and a second finger are immersed under the liquid level of the transformer oil to hold the bearing inner rings tightly, The six-axis robot drives the manipulator, so that the bearing inner rings quickly sleeve mounting sections of the bearing inner rings. According to the intelligent and rapid installation equipment for the high-temperature bearing inner rings of the roller cage shoe and the normal-temperature middle shaft of the roller cage shoe, the intelligent and automatic machining level is improved, the working efficiency is improved, the labor intensity of workers is greatly reduced, the interference amount of assembling is increased, the mounting firmness is improved, the surface scratch of the middle shaft of a roller is avoided, the quality of the roller cage shoe is improved, and the safety ofthe roller cage shoe is improved.

Owner:JIANGSU HUATIAN MACHINERY EQUIP

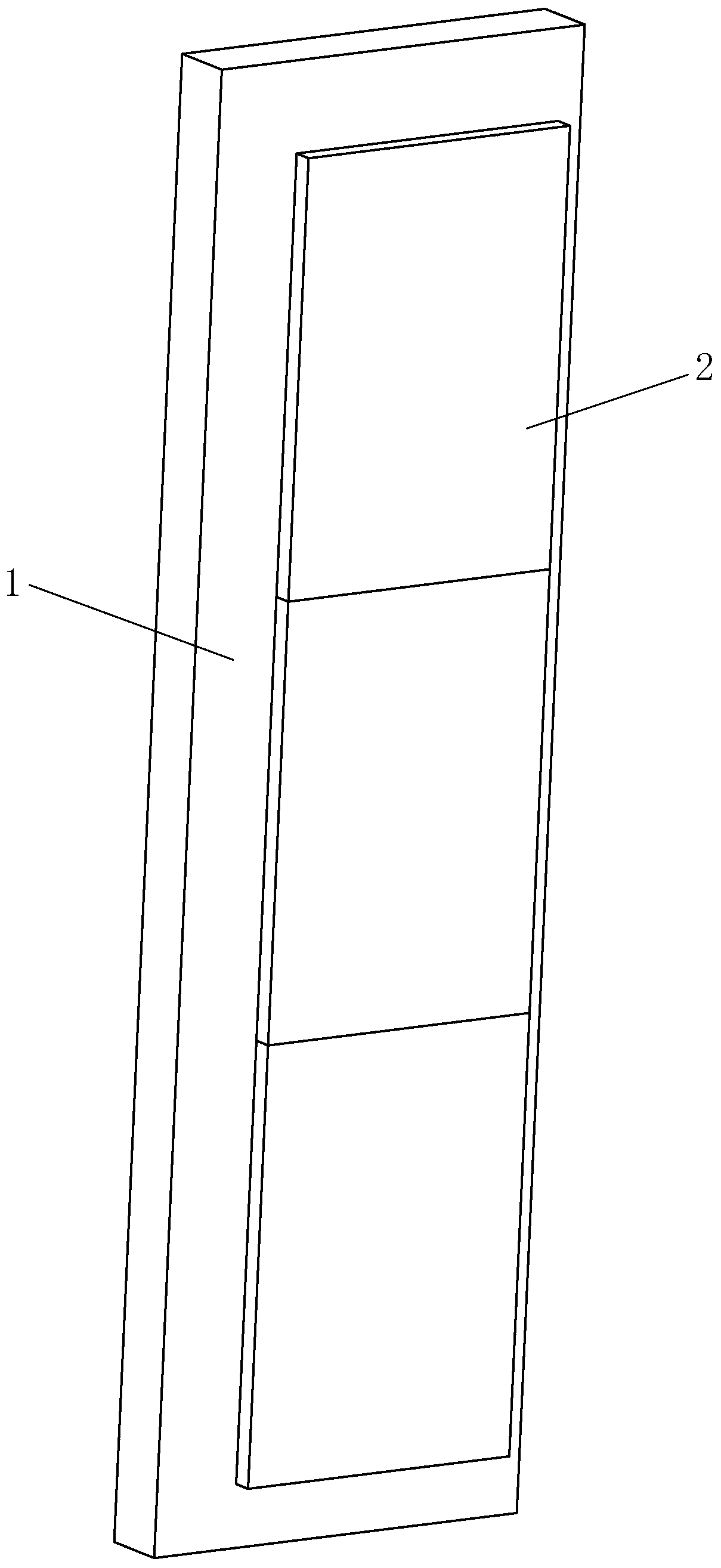

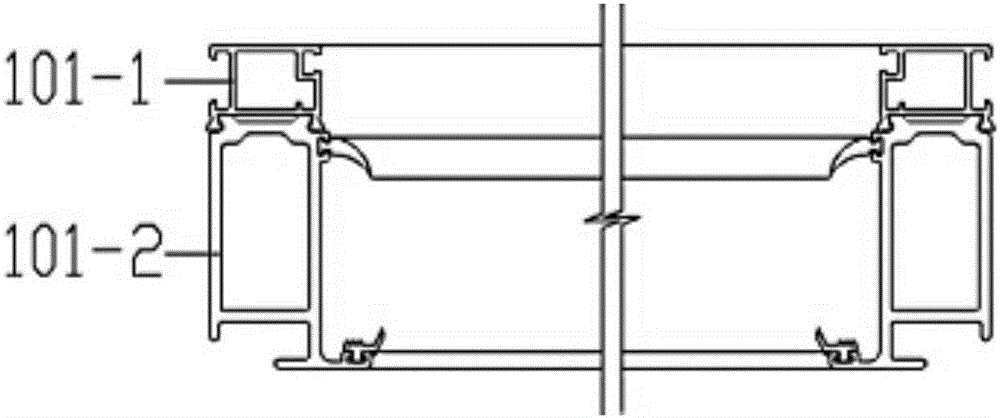

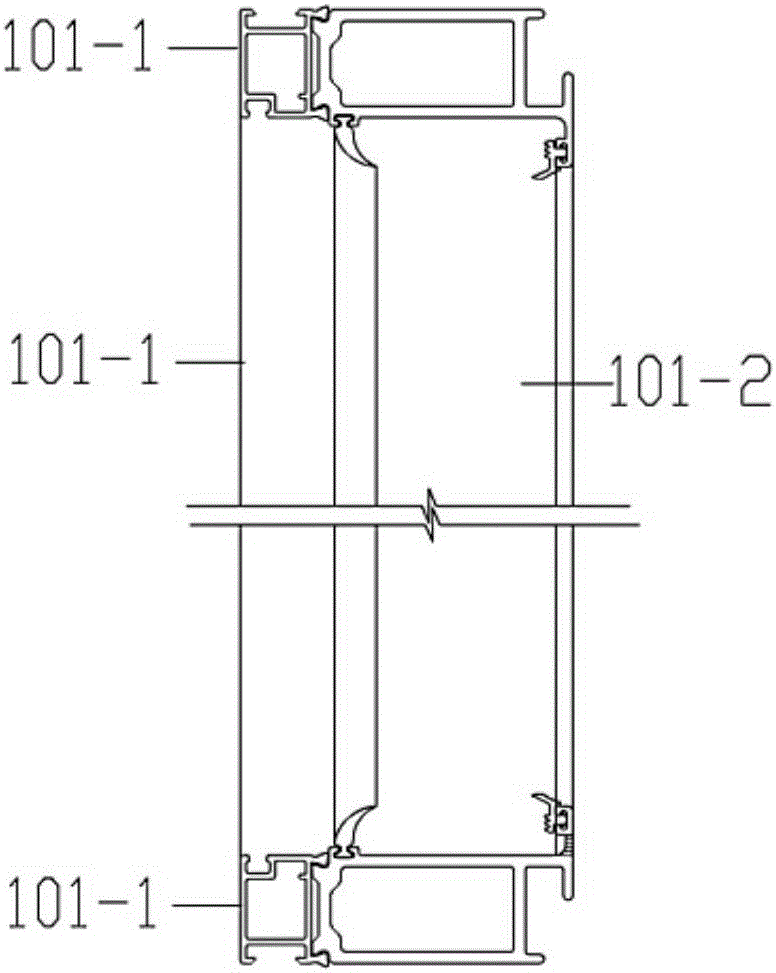

Auxiliary frame for door/window

ActiveCN105089426AHigh strengthFall preventionCondensed water drain-offBase framesLower borderClassical mechanics

The invention provides an auxiliary frame for a door / window. A border of the auxiliary frame is formed by tightly clamping, inlaying and combining an inner frame made of a metal material and an outer frame made of a heat insulation nonmetal material; the inner frame is provided with an inner frame mounting edge along the length direction; and an outer edge opening at the door / window side of the outer frame is provided with a flange facing to the door / window, wherein at least one drainage and vent hole is formed in a flange arranged on a lower border. The composite auxiliary frame for the door / window, which is made of the metal material and the nonmetal material, is convenient to dismount and mount the door / window and also has the advantages of high strength of a metal auxiliary frame and heat insulation of the nonmetal material . The flange arranged at the door / window side of the outer frame is convenient to mount and locate the door / window and can be used for preventing the door / window from falling towards the outside before the door / window is fixed. In addition, slurry loading troughs for pouring cement slurry are arranged in the inner frame and the outer frame, and notches facing to different directions are designed for the slurry loading troughs, so that the auxiliary frame can have a large enough loading force with a wall in all directions, and the mounting firmness of the auxiliary frame and the wall is sufficiently improved.

Owner:NANJING RUIGU WINDOW DECORATION

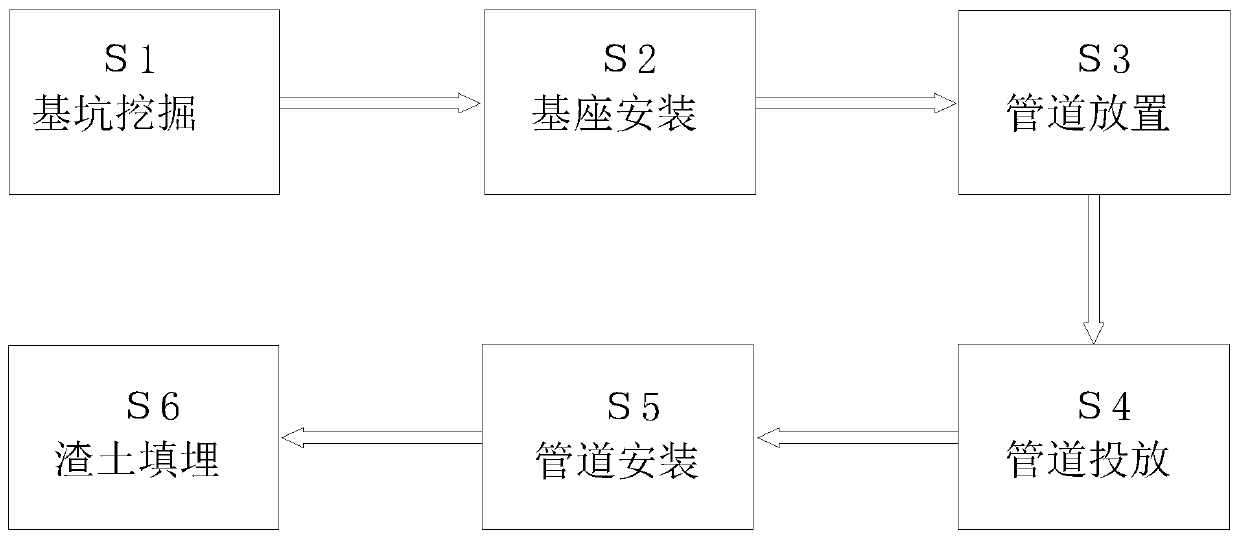

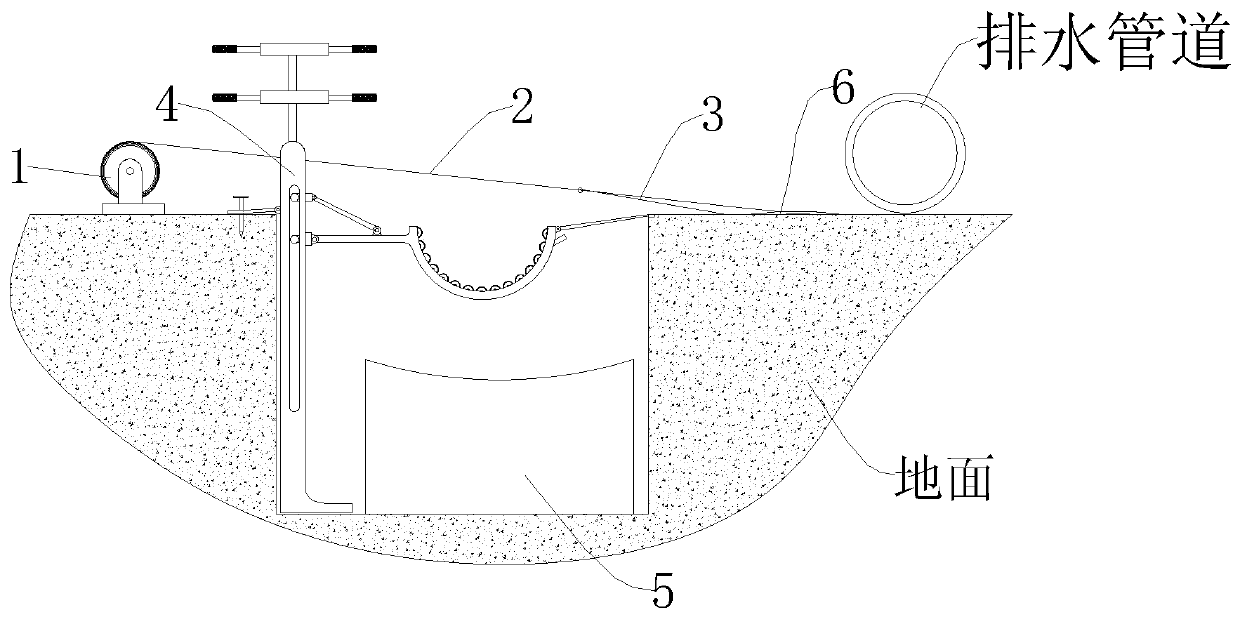

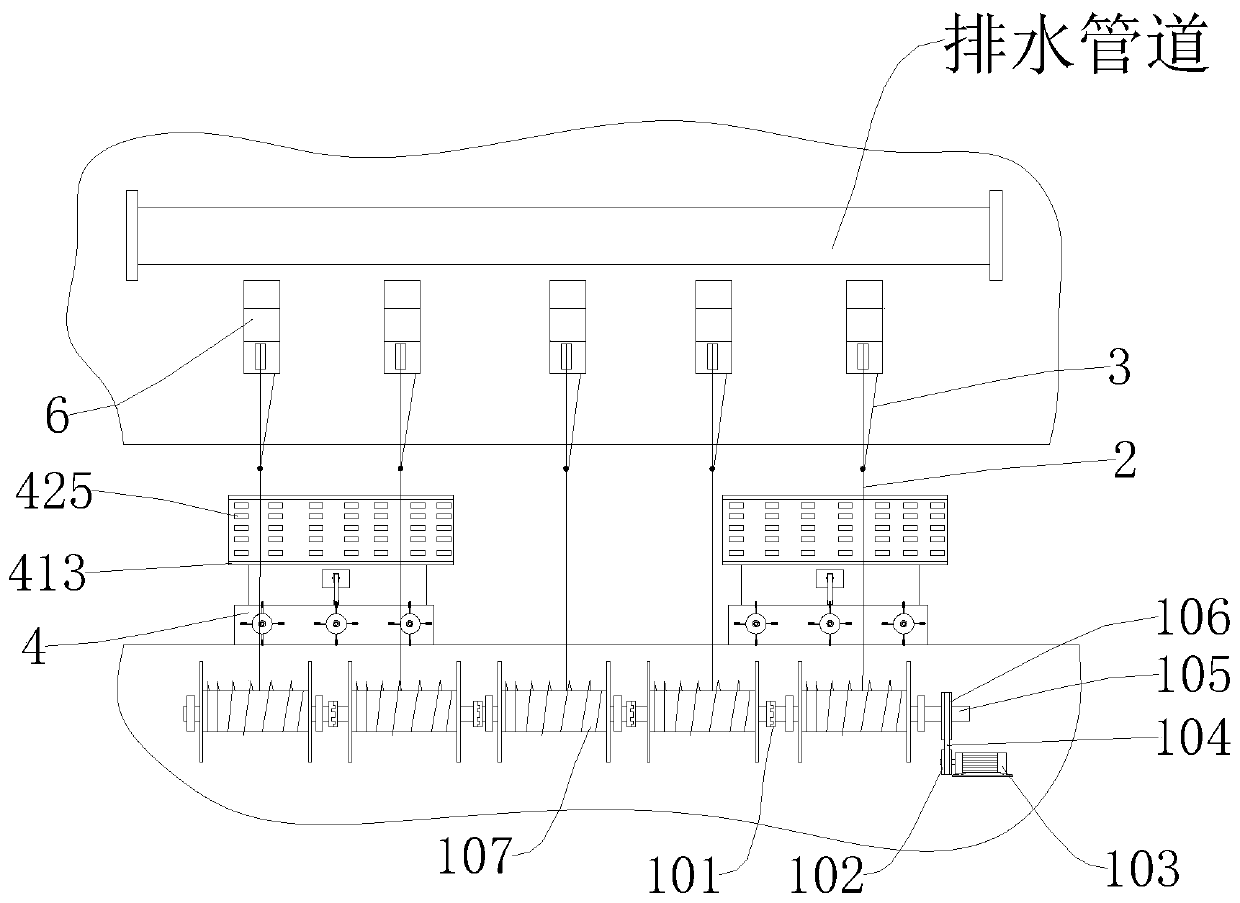

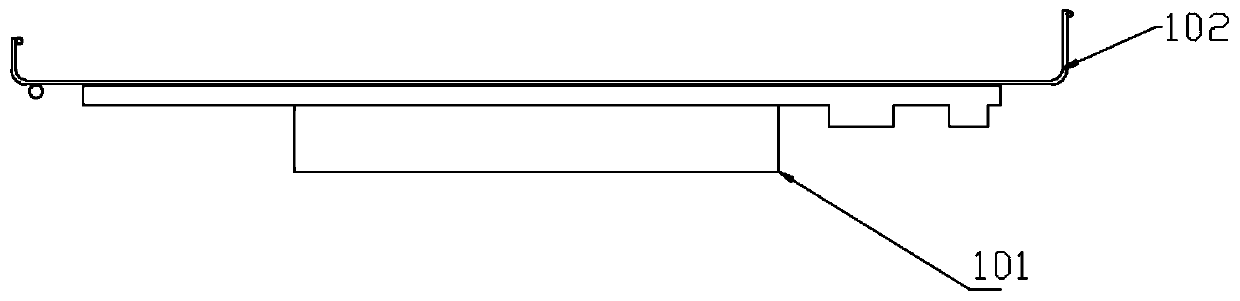

Laying construction method of drainage pipeline for sewage disposal

InactiveCN111457160AAccurate placementImprove firm performancePipe laying and repairLifting devicesArchitectural engineeringStructural engineering

The invention discloses a laying construction method of a drainage pipeline for sewage disposal, relates to the technical field of sewage discharge, and in particular relates to a laying constructionmethod of the drainage pipeline for sewage disposal. The method comprises the following steps: S1, excavating a foundation pit, namely, excavating the foundation pit for laying the drainage pipeline on the ground through which sewage flows, wherein the opening of the foundation pit faces upwards, and the side wall of the foundation pit is perpendicular to the bottom surface of the foundation pit;and S2, mounting bases, namely, placing the bases used for supporting the drainage pipeline in the foundation pit excavated in the step S1, wherein a plurality of bases are placed, and every two adjacent bases are fixed to the bottom face of the foundation pit at equal intervals. A guide plate is fixed to the top end of each tray, each guide plate is arranged to be of a square-block-shaped flat plate structure, the top end of each guide plate is erected on the ground on the other side of the foundation pit, so that the drainage pipeline can roll to the side wall edge of the foundation pit conveniently, and the drainage pipeline rolls into the trays through guiding of the guide plates.

Owner:李胜成

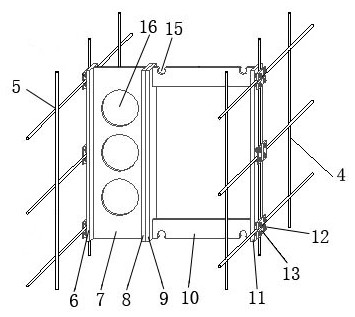

Shelf in which RFID antenna is integrated and cold closet

InactiveCN109869975AEasy to assembleImprove installation firmnessDomestic cooling apparatusLighting and heating apparatusElectrical and Electronics engineeringCloset

The invention belongs to the field of intelligent cabinet new retail, and discloses a shelf in which an RFID antenna is integrated and a cold closet. The shelf comprises a shelf cover plate and a shelf bottom plate. An RFID antenna containing region is formed between the shelf cover plate and the shelf bottom plate. The RFID antenna is arranged in the RFID antenna containing region. All the corresponding side portions of the shelf cover plate and the shelf bottom plate are connected to extrude and fix the RFID antenna on the inner side. The problem about mounting and fixing of the RFID antennais effectively solved.

Owner:AUCMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com