Heat preservation integrated wall body non-dismantling formwork capable of being connected quickly

A technology of quick connection and free formwork removal. It is applied in the directions of heat preservation, formwork/formwork/work frame, formwork/formwork/work frame connecting parts, etc. problems, to achieve the effect of increasing lateral stiffness and resistance to bending deformation, improving structural strength and installation firmness, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

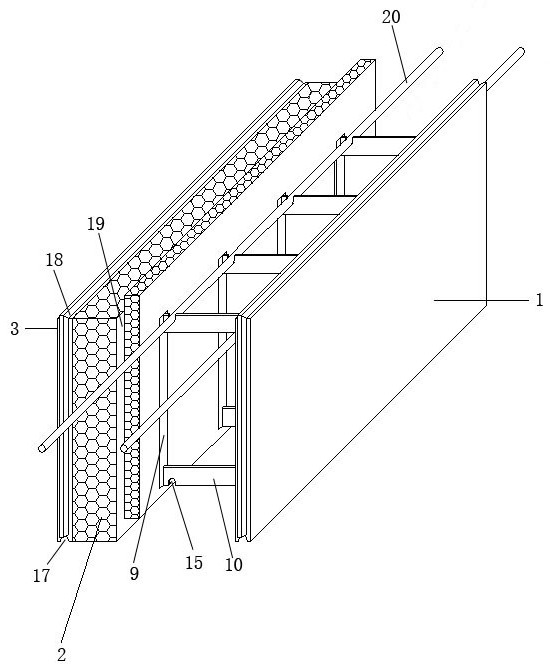

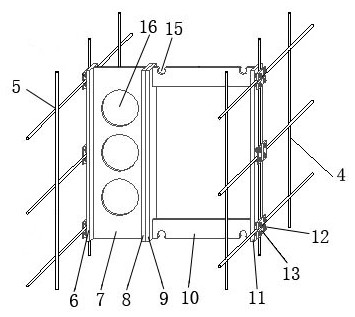

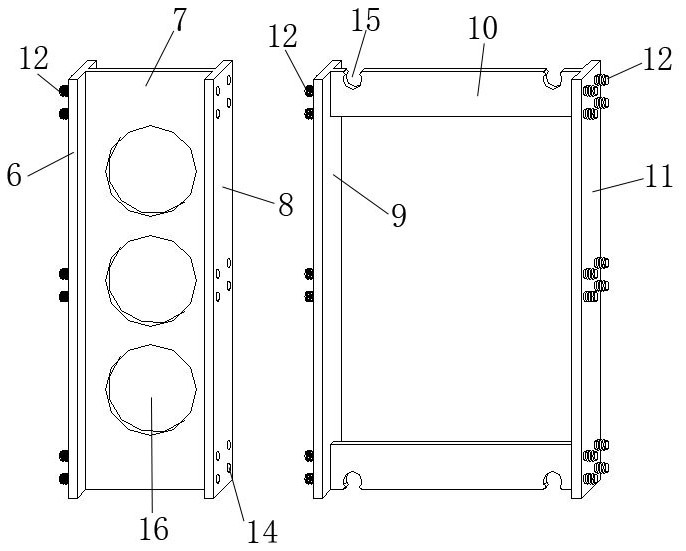

[0021] see Figure 1 to Figure 3 As shown, the present invention provides a thermal insulation integrated wall formwork that can be quickly connected without dismantling, including a non-dismantling external wall thermal insulation formwork, connectors and a non-disassembly internal wall formwork 1, and the non-disassembly external wall thermal insulation formwork includes thermal insulation boards Layer 2 and the prefabricated panel 3 on the outer concrete surface, the non-demolition-free interior wall formwork is a concrete prefabricated panel, the inner prefabricated steel mesh 4 is arranged in the concrete prefabricated panel of the non-demolition-free interior wall formwork, and the outer concrete surface prefabricated panel is provided with an outer Prefabricated steel mesh sheet 5; there are several connectors, and a plurality of connectors are connected side by side between the insulation formwork of the non-demolition external wall and the formwork of the interior wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com