Valve accessory valve rod manufacturing processing system

A technology for processing systems and accessories, applied in the direction of manufacturing tools, metal processing equipment, grinding workpiece supports, etc., can solve the problem of uneven clamping force of the valve stem, achieve increased clamping force, increased contact area, and improved installation firmness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

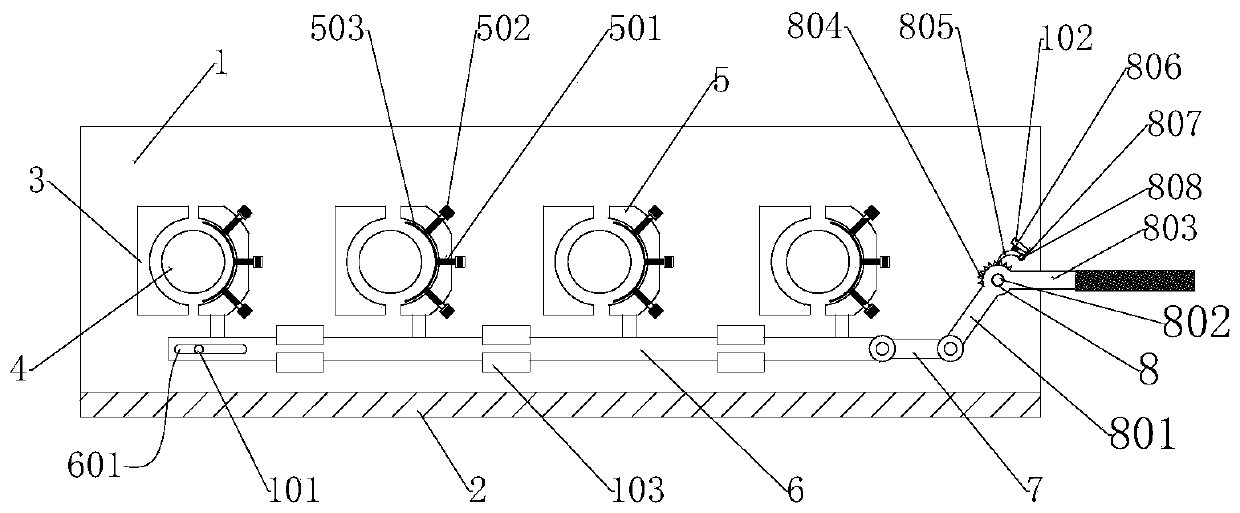

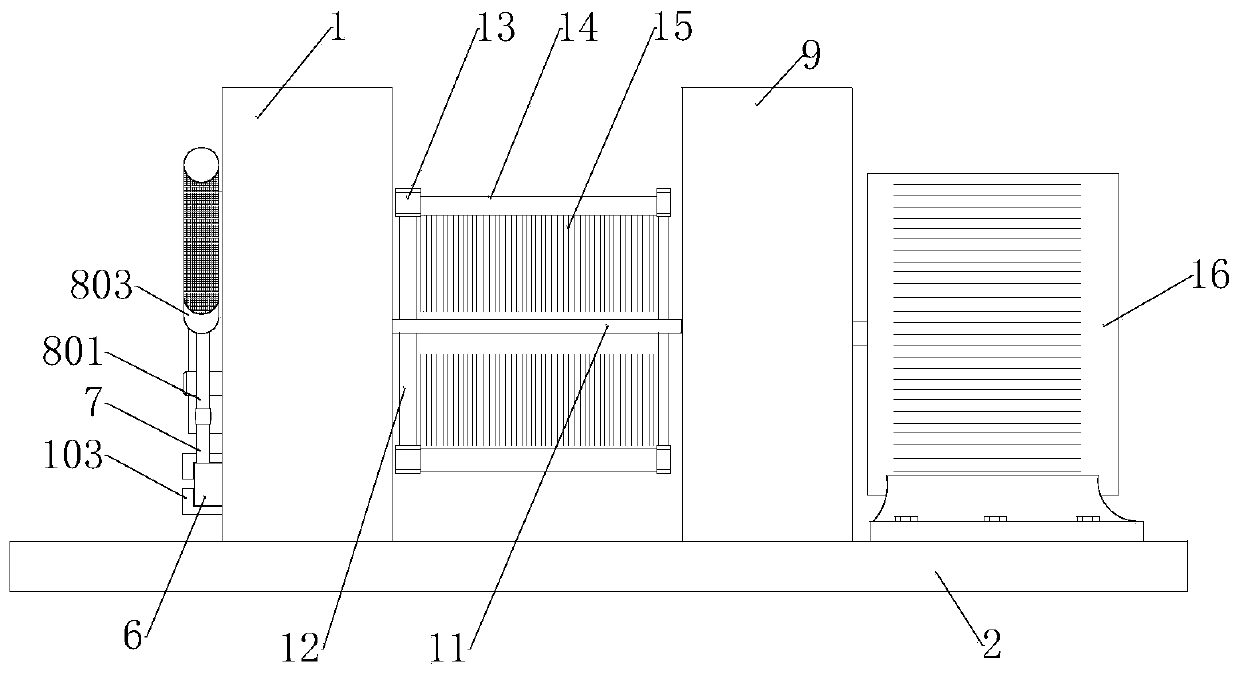

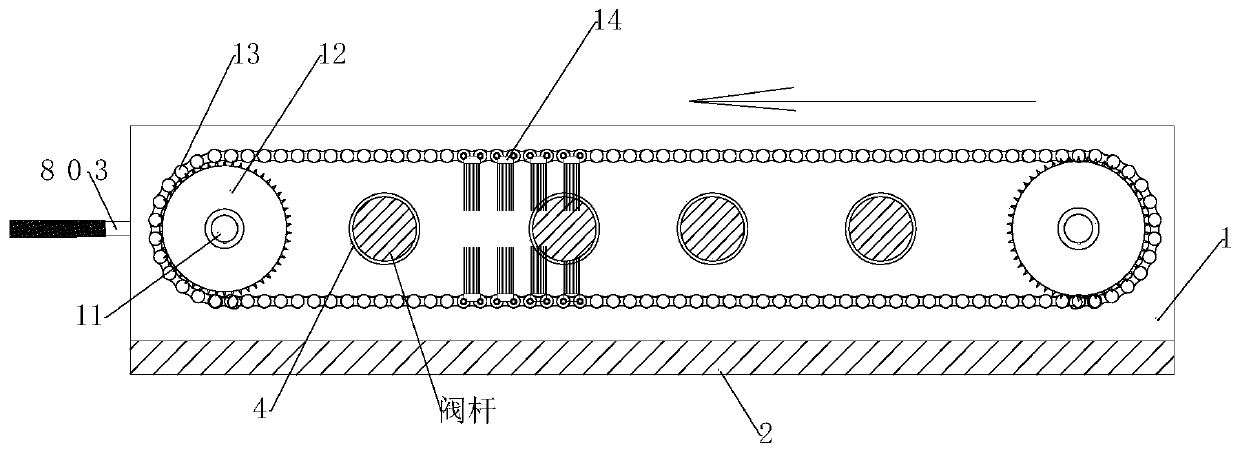

[0039] see Figure 1-7 , is a schematic diagram of the overall structure of a valve stem manufacturing and processing system for valve accessories, including a bottom support plate 2, a first support plate 1, and a second support plate 9, the bottom support plate 2 is a square plate placed horizontally, and the bottom support plate 2 The first support plate 1 and the second support plate 9 that are oppositely arranged are fixed on the top of the top, and two symmetrically arranged sprocket shaft rods 11 are connected between the first support plate 1 and the second support plate 9, and the second support plate 9 The rear side wall is fixedly equipped with a motor 16, the output shaft of the motor 16 is equipped with gears, and the motor 16 drives the symmetrically arranged two-wheel sprocket shaft rods 11 to rotate in the same direction through gear meshing transmission, and the two ends of each sprocket shaft rod 11 are fixed with Sprocket 12, wherein two sprockets 12 are adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com