Laying construction method of drainage pipeline for sewage disposal

A technology for drainage pipelines and sewage treatment, which is used in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/pipe fittings, etc. , the effect of precise location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

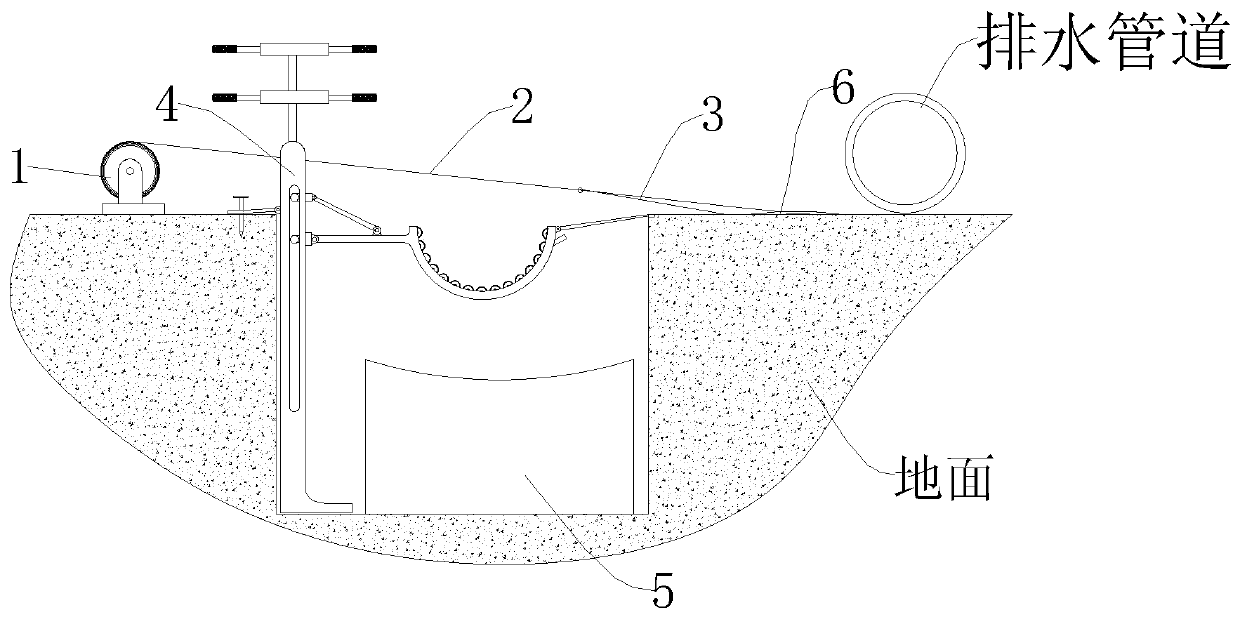

[0044] see Figure 1-7 , which is a schematic diagram of the overall structure of a construction method for laying drainage pipes for sewage treatment;

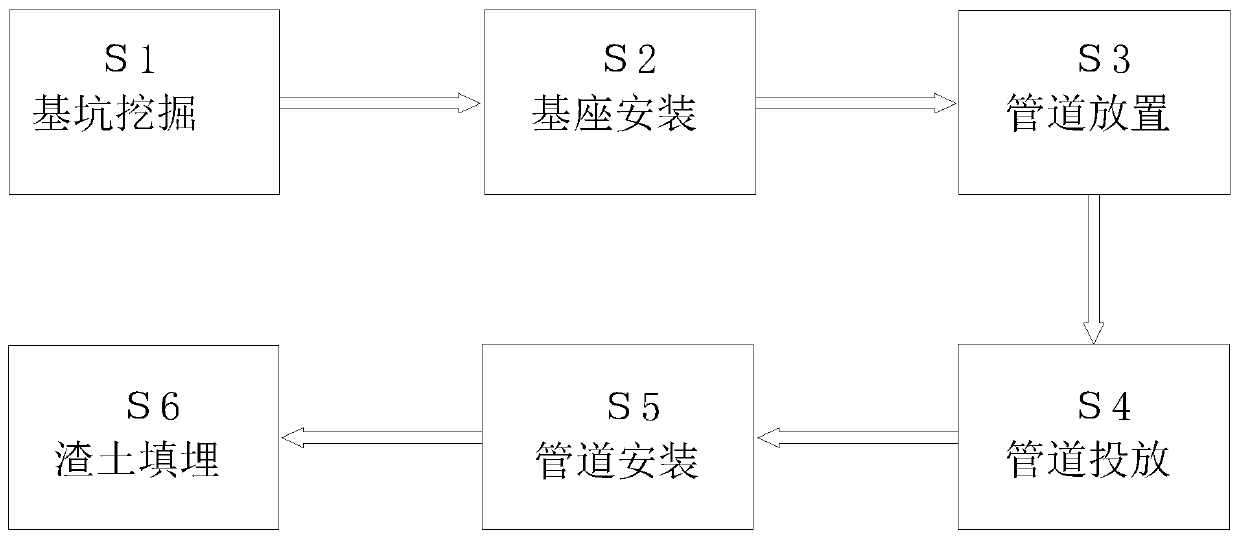

[0045] A construction method for laying drainage pipes for sewage treatment, comprising the following steps:

[0046] S1. Foundation pit excavation: Excavate a foundation pit for laying drainage pipes on the ground where the sewage flows. The opening of the foundation pit faces upward, and the side wall of the foundation pit is perpendicular to the bottom surface of the foundation pit;

[0047] S2. Base installation: place bases 5 for supporting drainage pipes in the foundation pit excavated in step S1, place multiple bases 5, and fix the two adjacent bases 5 on the bottom of the foundation pit at equal intervals ;

[0048] S3, pipeline placement: place the drainage pipeline for laying near the foundation pit that has been excavated in step 1, and place the axis of the drainage pipeline to be parallel to the side wall of th...

Embodiment 2

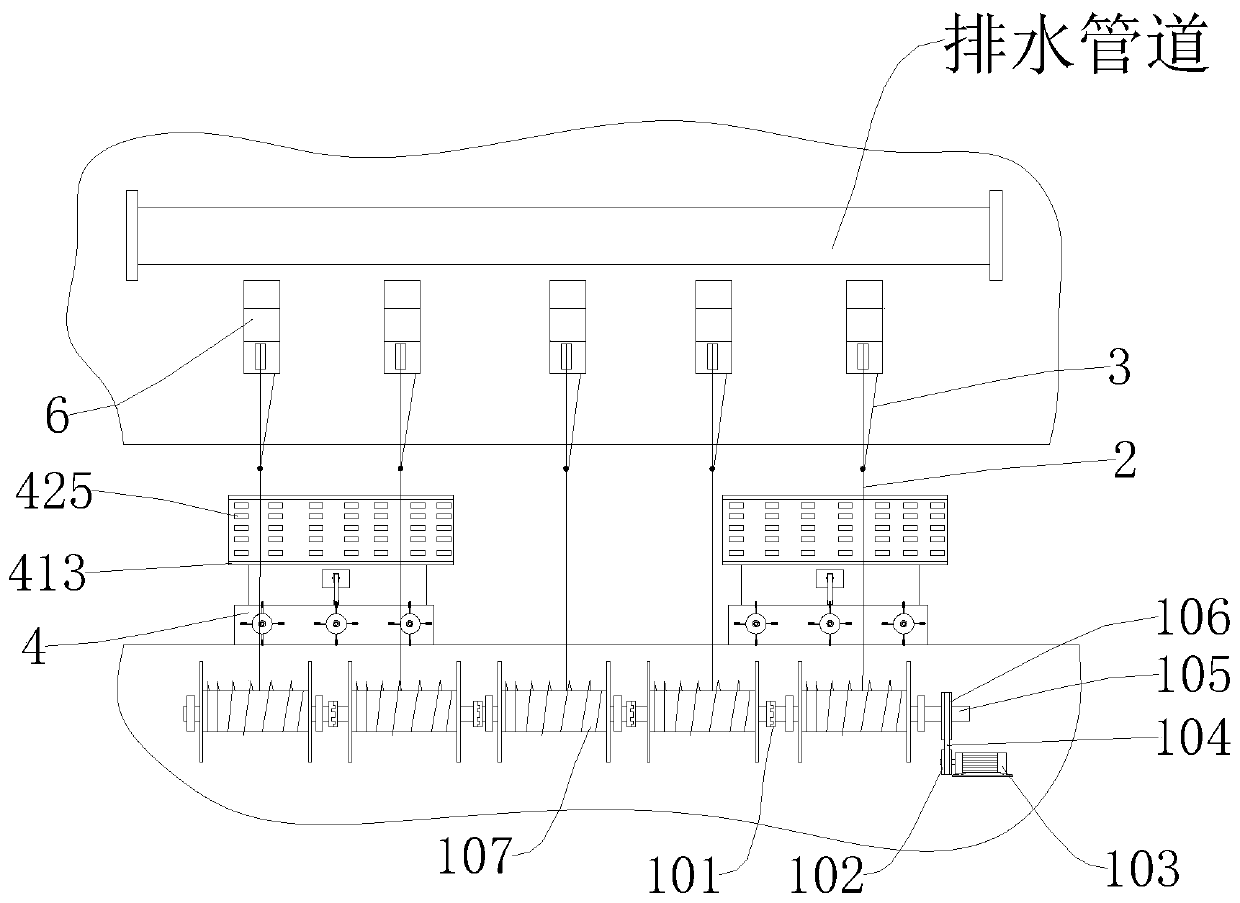

[0068] The content of this embodiment is the same as that of the above-mentioned embodiment 1, and the specific similarities will not be elaborated in this embodiment, and the specific differences are:

[0069] see figure 1 , figure 2 or image 3 , which is a schematic diagram of the overall structure of another construction method for laying drainage pipes for sewage treatment;

[0070] A construction method for laying drainage pipes for sewage treatment, comprising the following steps:

[0071] S1. Foundation pit excavation: Excavate a foundation pit for laying drainage pipes on the ground where the sewage flows. The opening of the foundation pit faces upward, and the side wall of the foundation pit is perpendicular to the bottom surface of the foundation pit;

[0072] S2. Base installation: place bases 5 for supporting drainage pipes in the foundation pit excavated in step S1, place multiple bases 5, and fix the two adjacent bases 5 on the bottom of the foundation pit a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com