Auxiliary frame for door/window

A technology for doors and windows and attached frames, which is applied in the direction of the base frame and condensed water discharge, etc., which can solve the problems of single metal structure, inconvenient installation and replacement of doors and windows, poor heat preservation and energy saving effect, etc., to enhance the firmness of installation, facilitate the removal of doors and windows, and facilitate The effect of installation positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

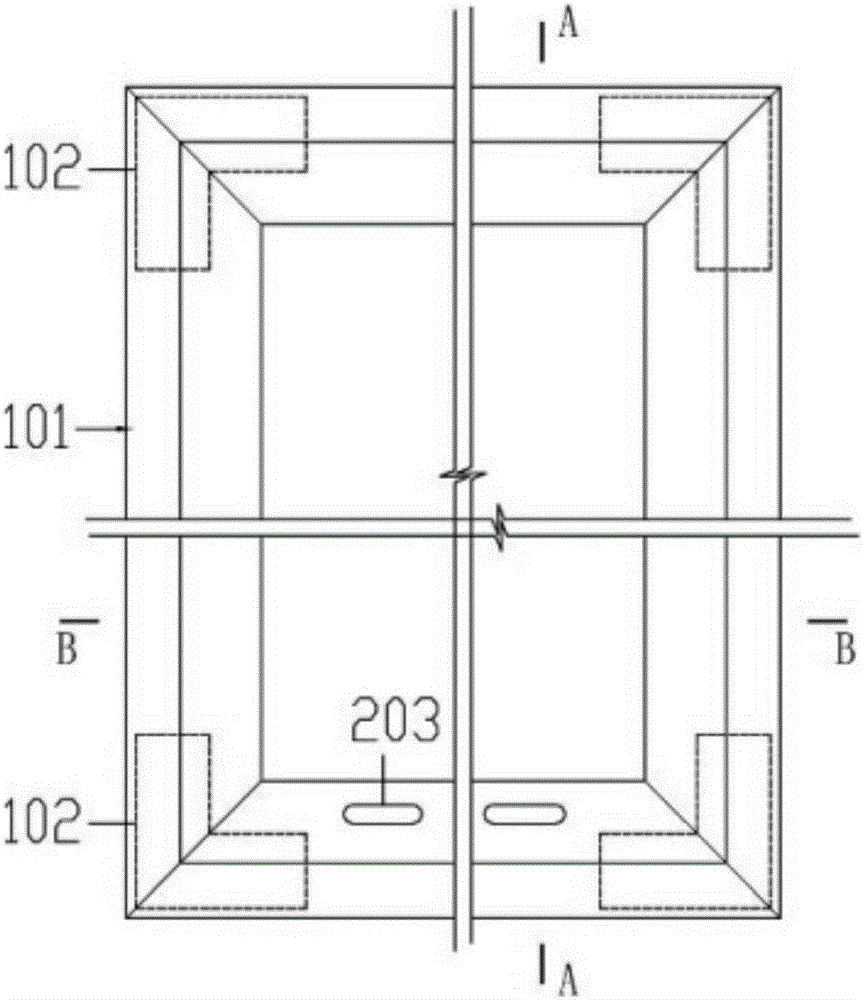

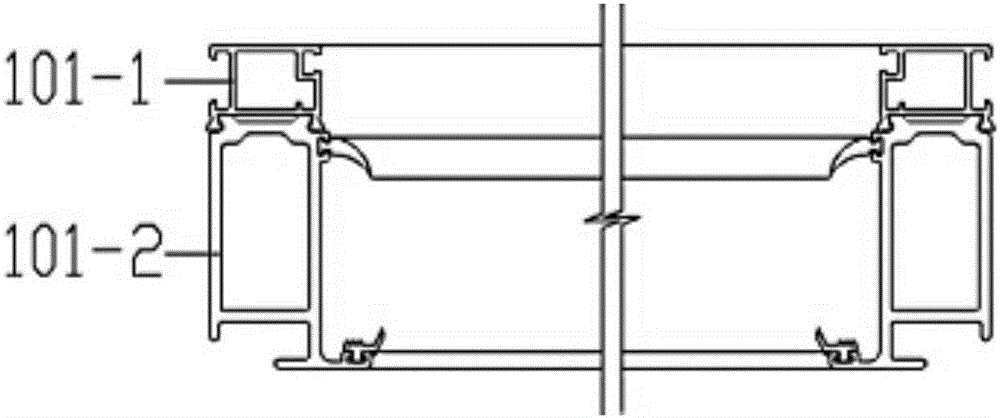

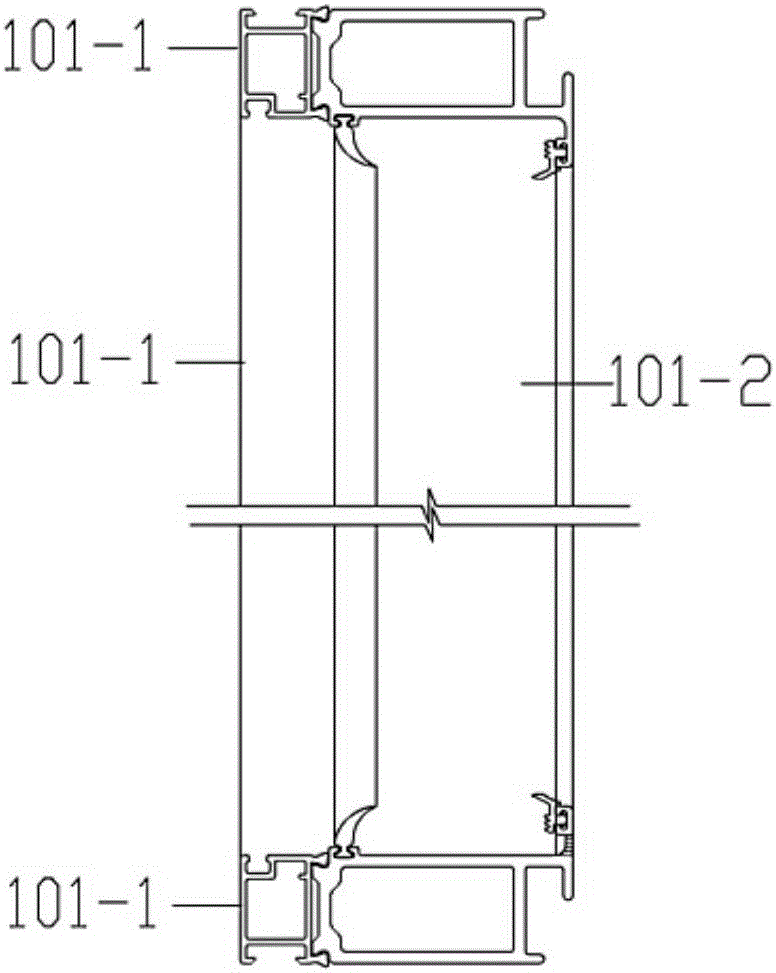

Image

Examples

Embodiment approach

[0034] Figure 4 The shown inner frame installation edge 201-1 is the first embodiment of the inner frame installation edge of the present invention, and the inner frame installation edge of the present invention can also adopt such Figure 5 The side strip 201-2 protruding from the side plane of the door and window shown in the inner frame is adopted Figure 4 or Figure 5 When installing the side of the inner frame shown, the specific connection and installation method between the attached frame and the door and window are as follows: Figure 10 , Figure 11 As shown, the door and window 300 is installed through multiple sets of crimping components composed of connecting pressing pieces 301 and screws 302, and one set of crimping components is composed of at least one screw and one connecting pressing piece. At this time, the inner sides of each side At least one connection pressing piece or screw inlet must be provided on the frame installation side or the door and windo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com