Intelligent and rapid installation equipment for high-temperature bearing inner rings of roller cage shoe and normal-temperature middle shaft of roller cage shoe

A bearing inner ring, high temperature bearing technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as incorrect installation position, scratches on the surface of the roller center shaft, and reduced production efficiency, and achieves improved installation firmness, Avoid surface scratches and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

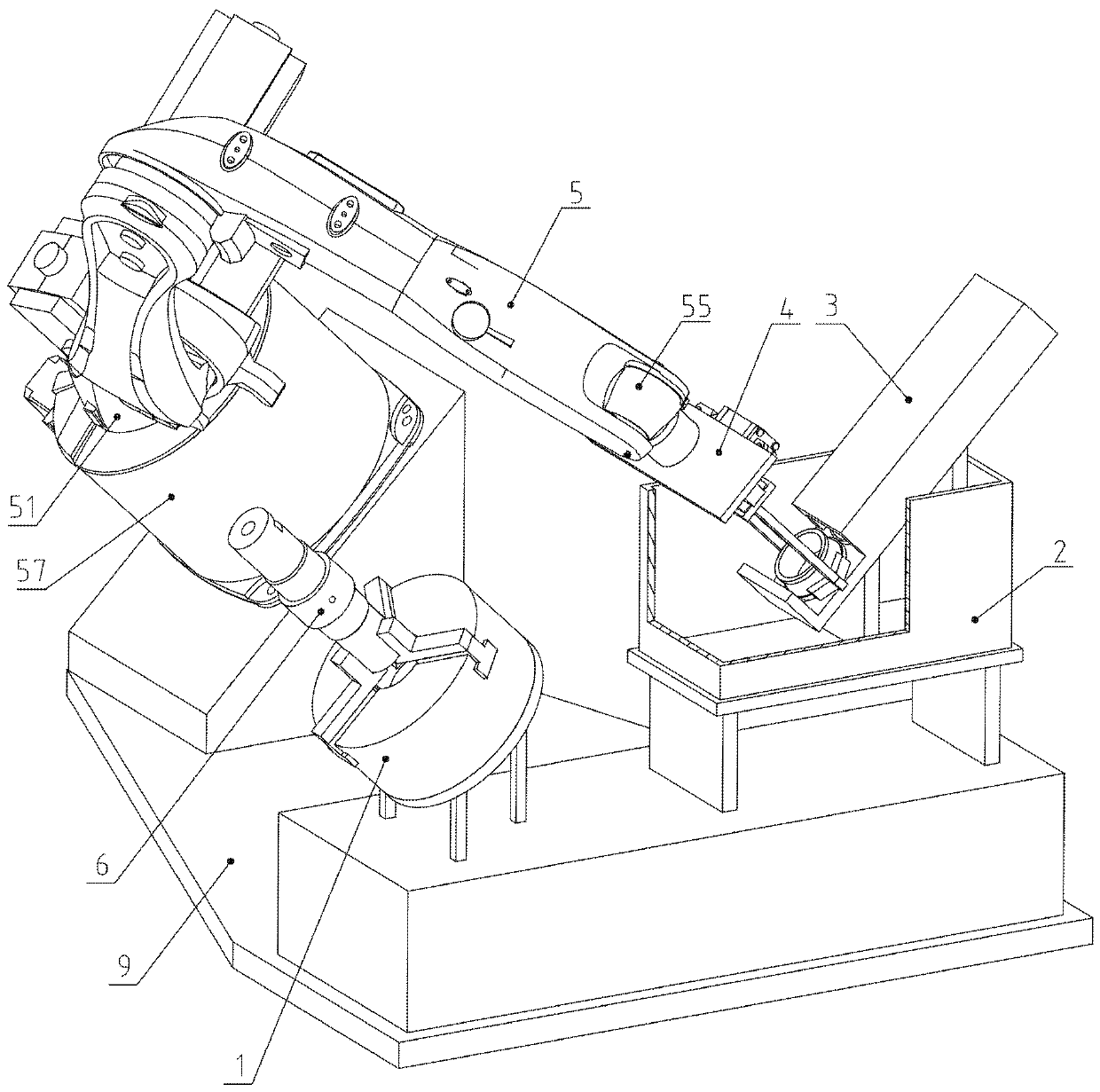

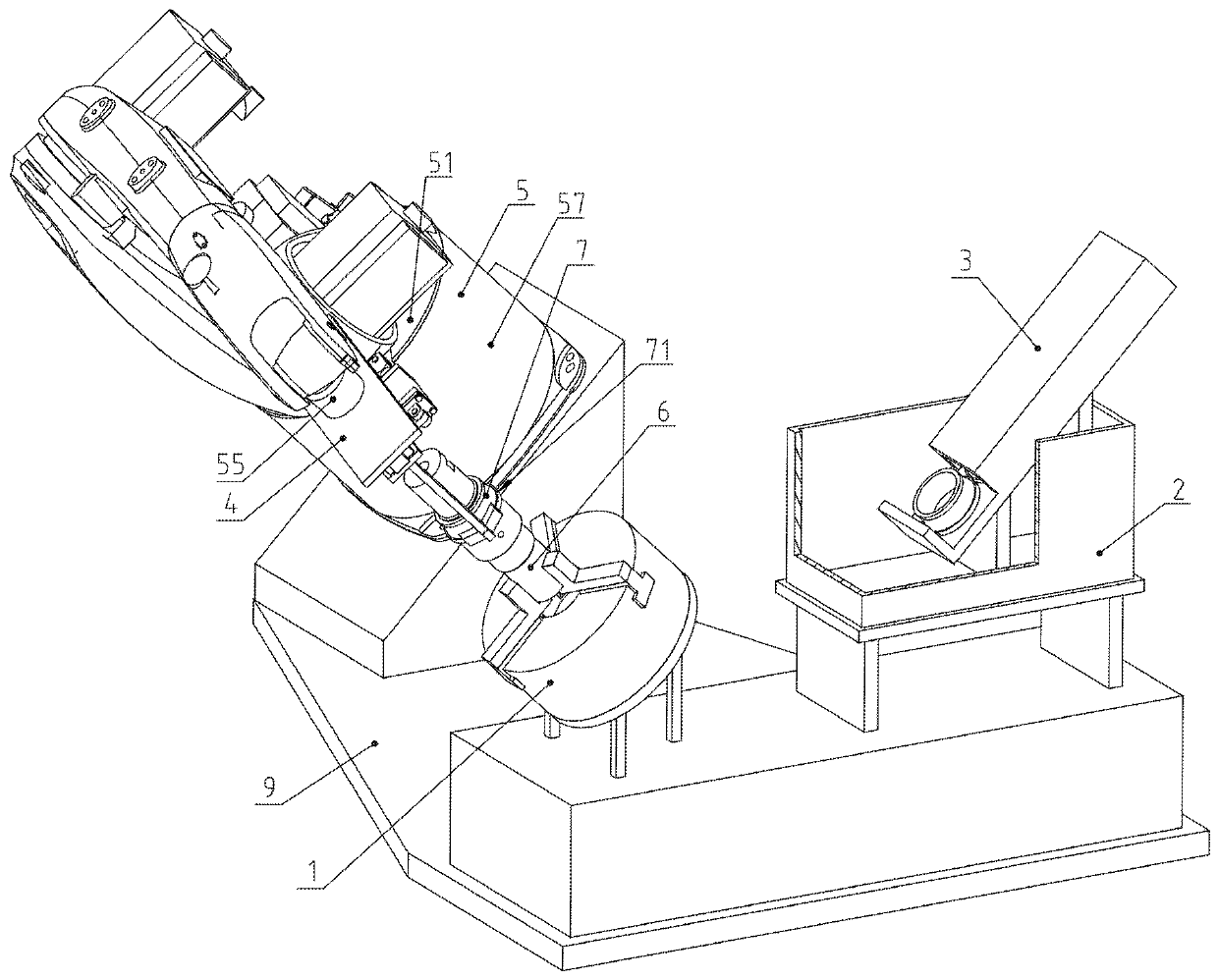

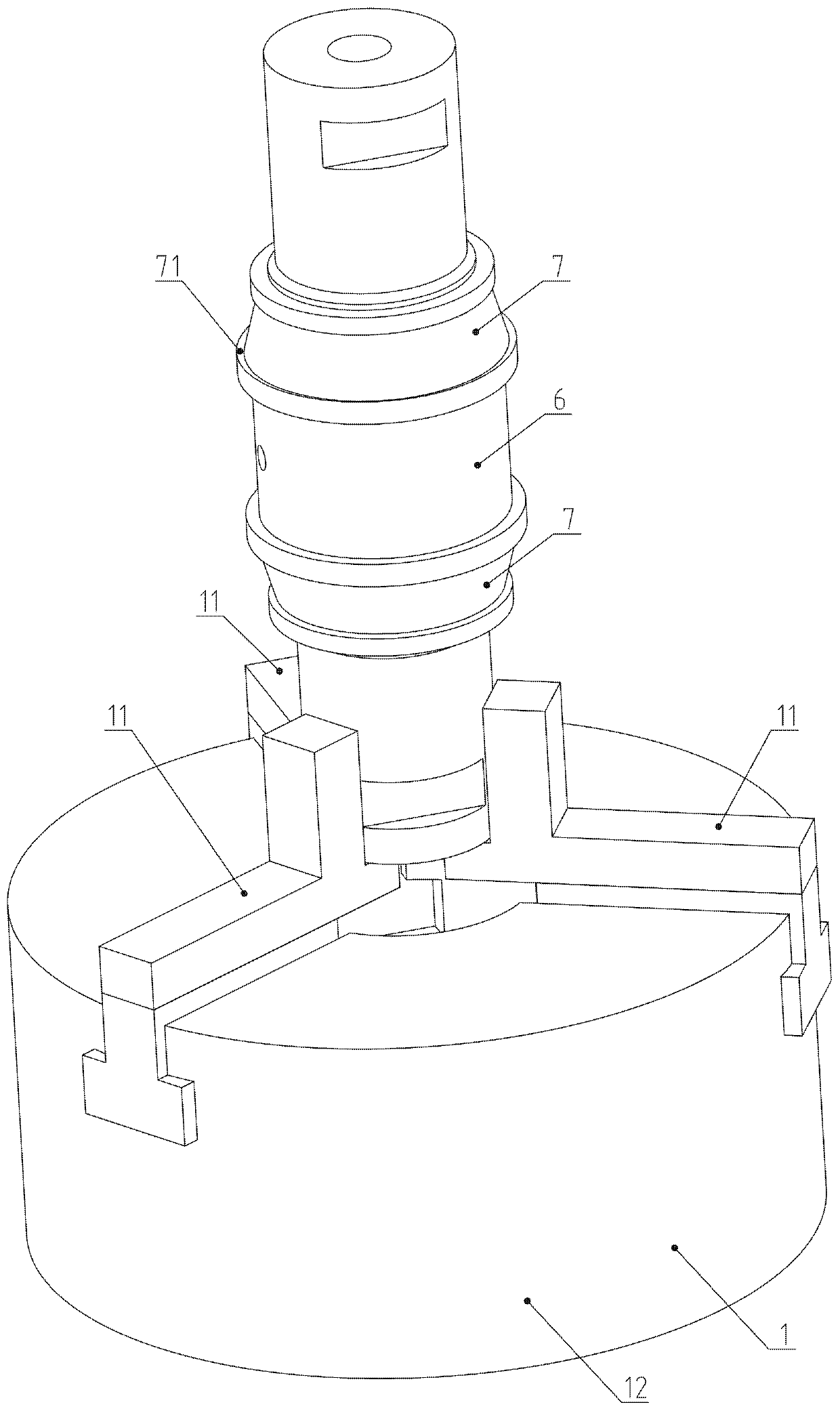

[0051] Example: see Figure 1 to Figure 15 .

[0052] An intelligent rapid installation device for the inner ring of the high-temperature bearing of the roller lug and the middle shaft at room temperature, including a pneumatic chuck 1, an oil bath 2, a positioner 3, a manipulator 4, a six-axis robot 5 and a frame 9;

[0053] The locator 3 is in the shape of a long cylinder, and the bearing inner ring slideway 31 is arranged in the locator 3. The cross section of the bearing inner ring slideway 31 is rectangular, and the bearing inner ring slideway 31 is arranged obliquely. 34 forms an included angle of 45 degrees with the horizontal plane, and the slanted upward opening of the bearing inner ring slideway 31 is the feed inlet 35, and the slanted downward end of the bearing inner ring slideway 31 is only the supporting slope under the bearing inner ring slideway. 34, the opening 32 at the lower end of the slideway of the inner ring of the bearing that is open on the other thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com