Composite assembly type building steel structure

A steel structure, prefabricated technology, applied in building structures, buildings, columns, etc., can solve the problems of ground or cement floor damage, difficulty in restoring structural strength, etc., to shorten construction time, improve installation firmness, and improve safety and firmness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following will further illustrate the present invention in combination with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in this application and The features in the embodiments can be combined with each other.

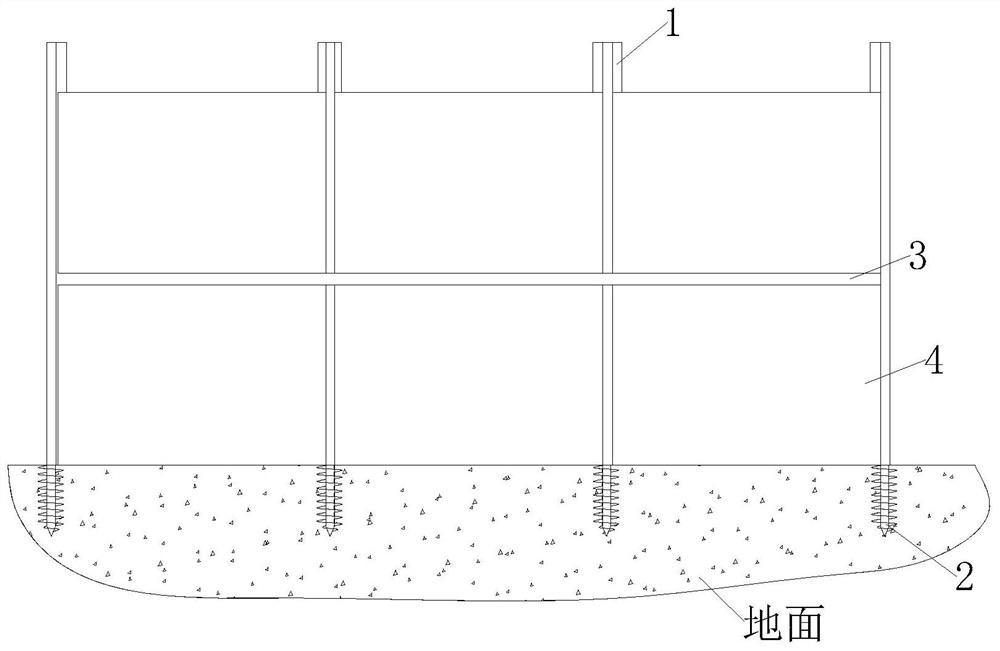

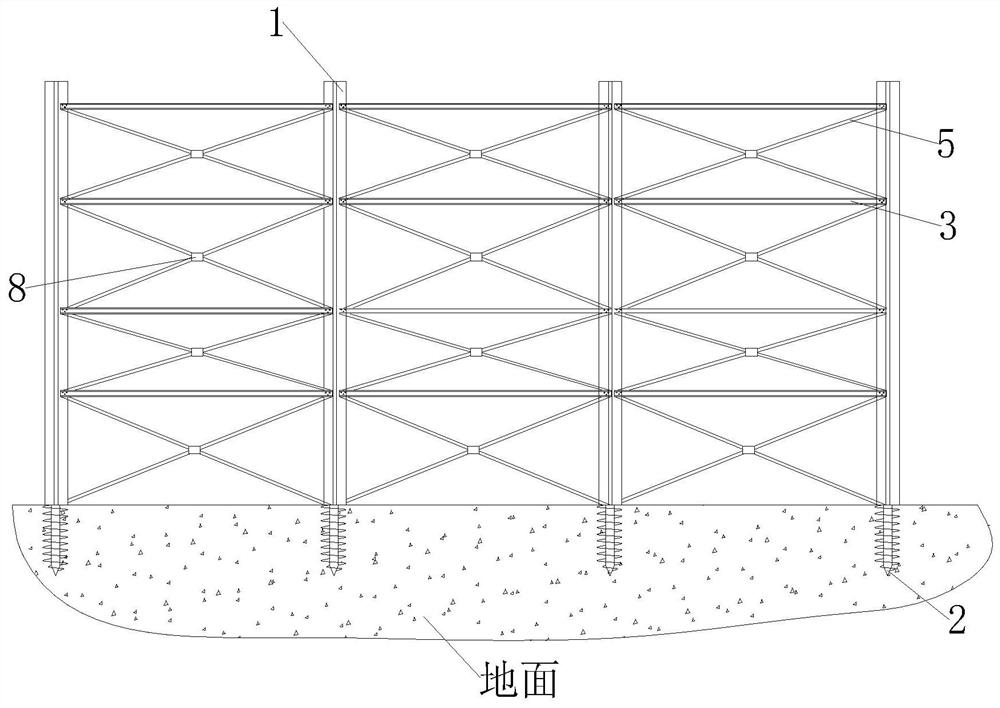

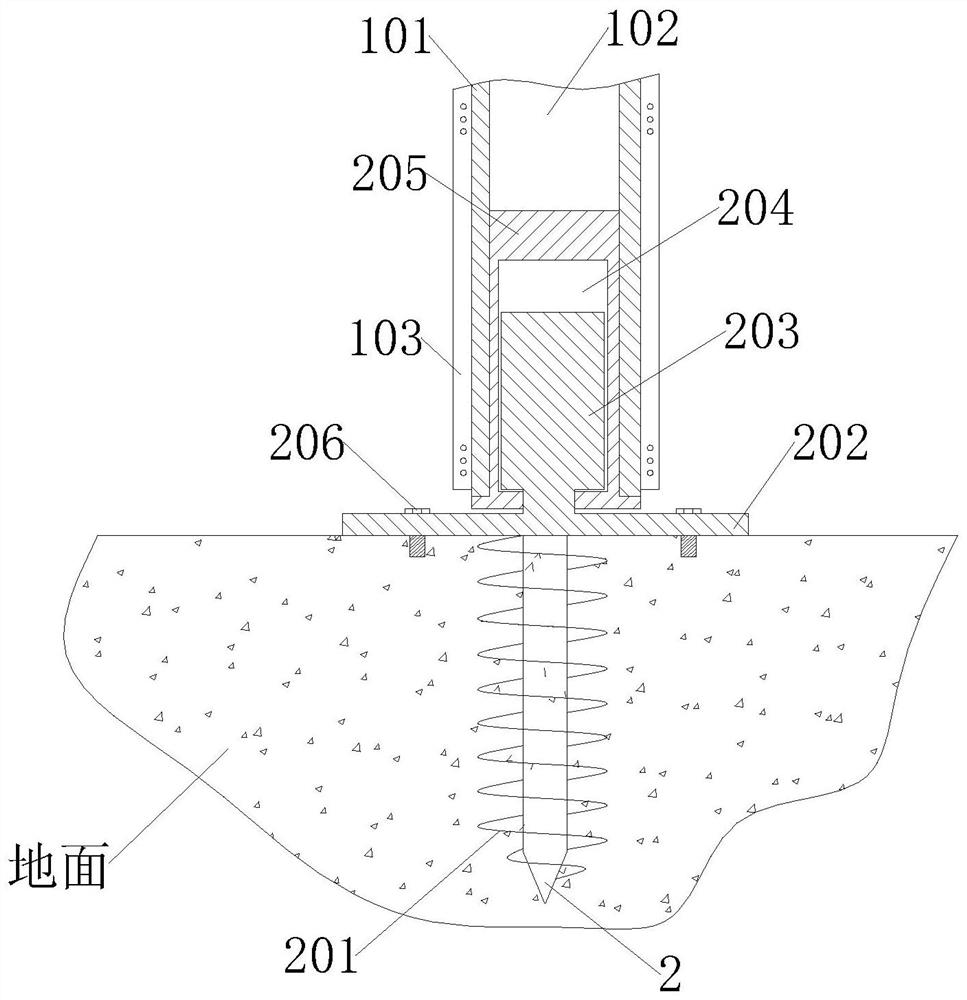

[0042]SeeFigure 1-12, Is a composite fabricated building steel structure,

[0043]A composite fabricated building steel structure, including support columns 1 erected on the ground or cement surface at equal intervals, and wall panels 4 installed between two adjacent support columns 1, each support column 1 having a bottom Fixed foot 2, each bottom fixed foot 2 is fixedly installed on the ground or cement surface; a plurality of transverse fixed beams 3 are fixedly connected between two adjacent support columns 1 at equal intervals, and the middle of two adjacent beams 3 are fixedly connected There is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com