Patents

Literature

253results about How to "Fit fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

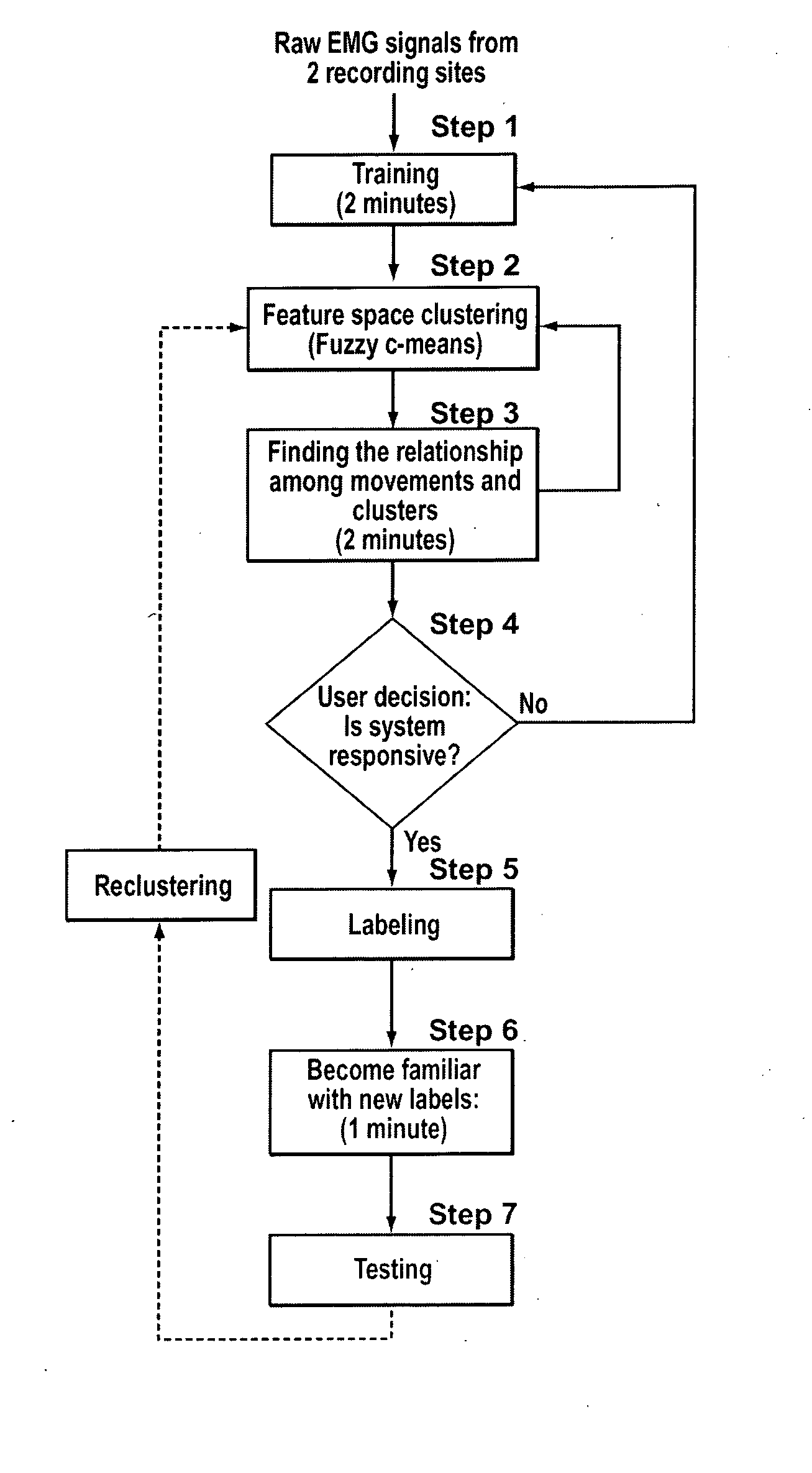

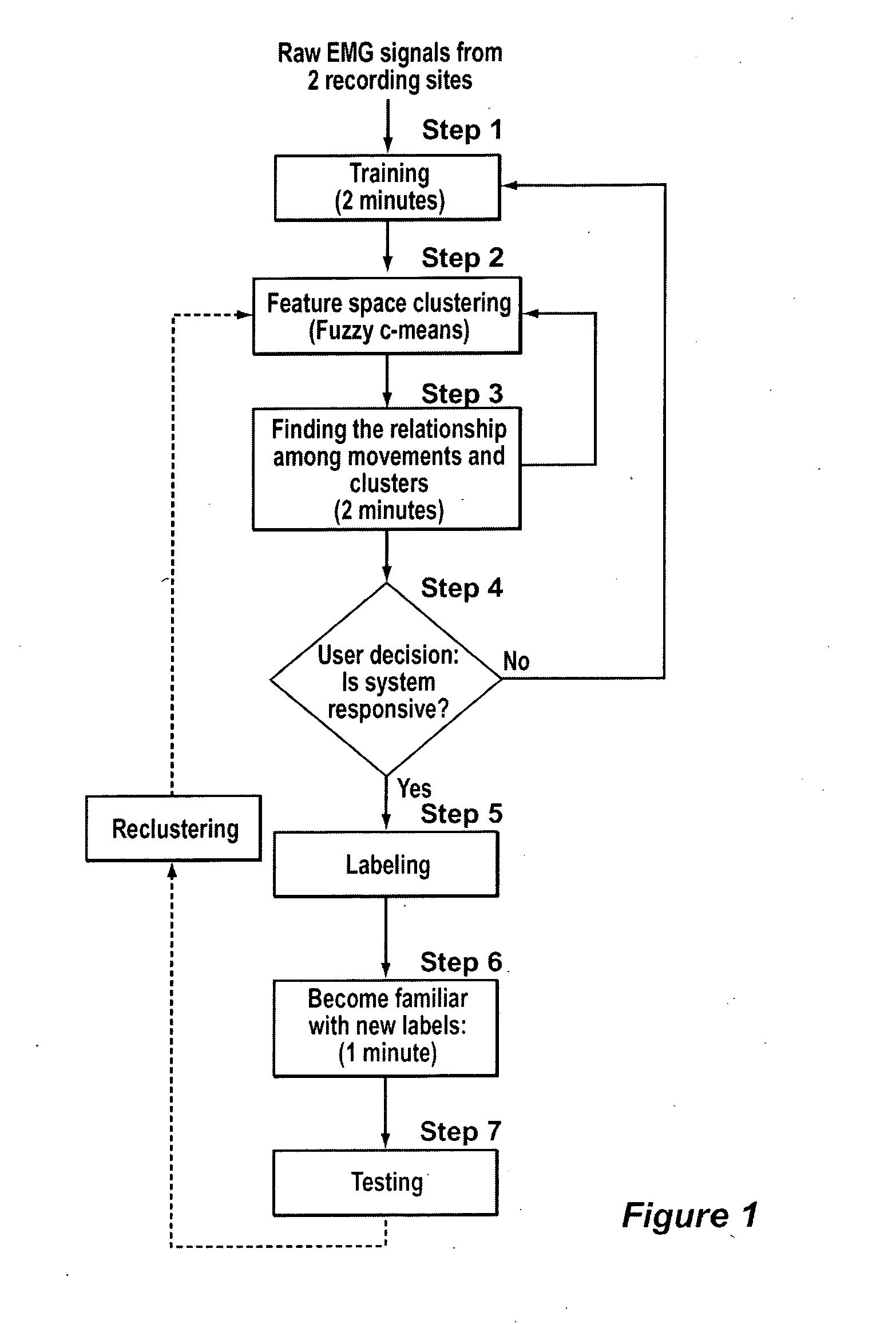

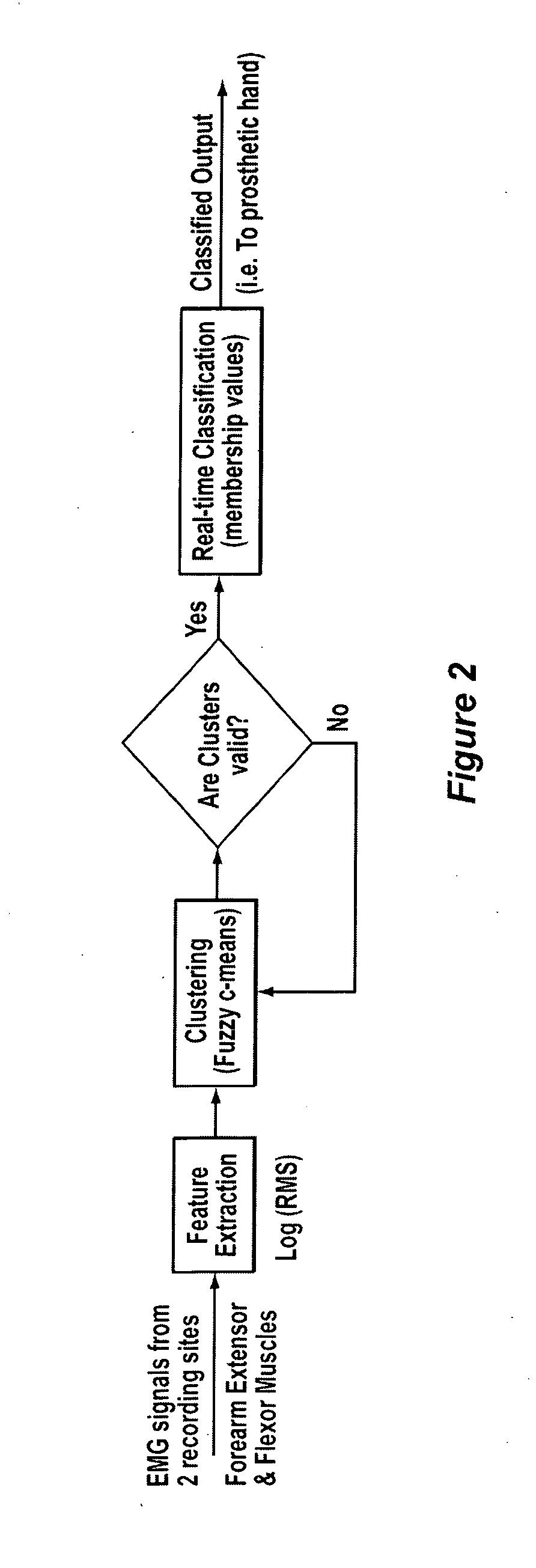

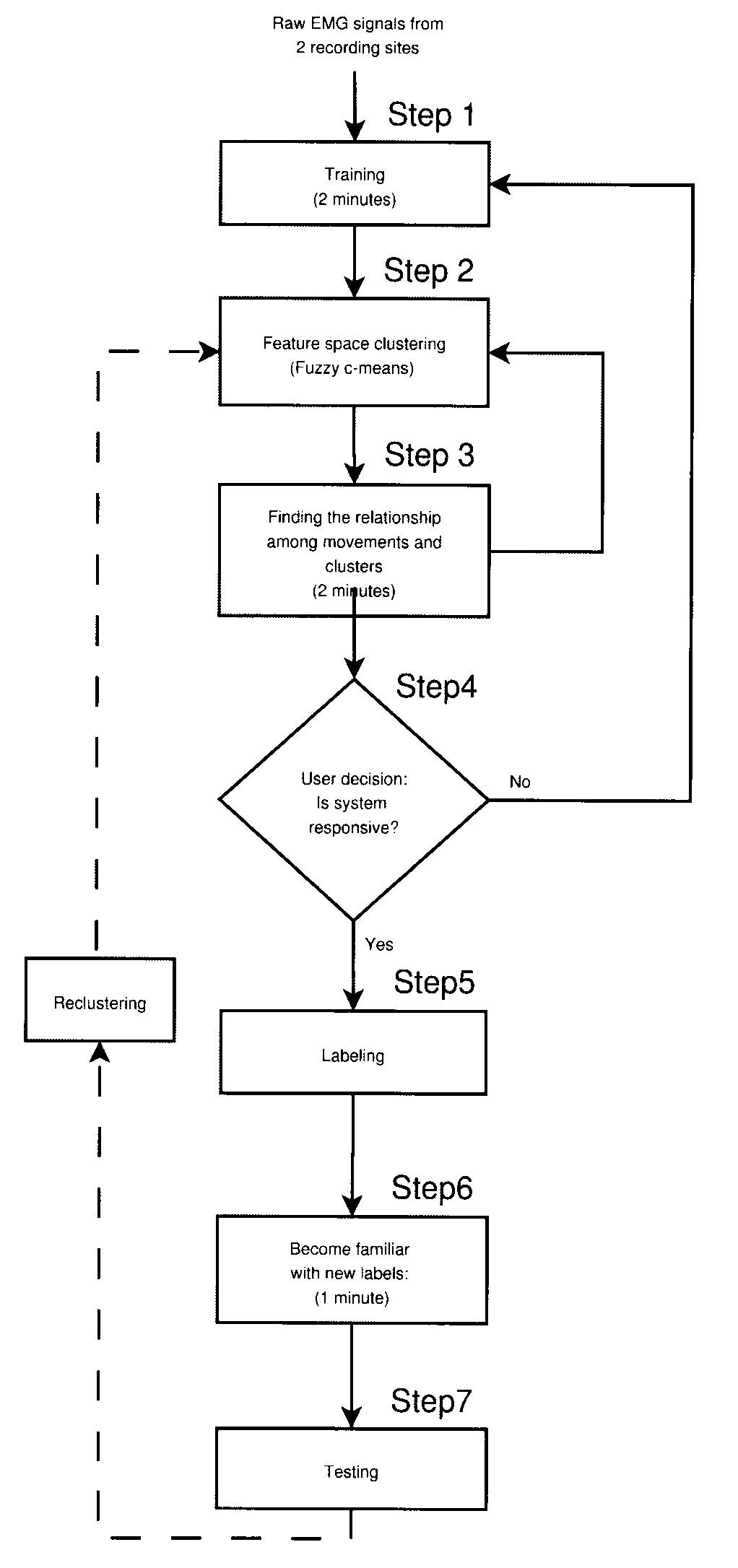

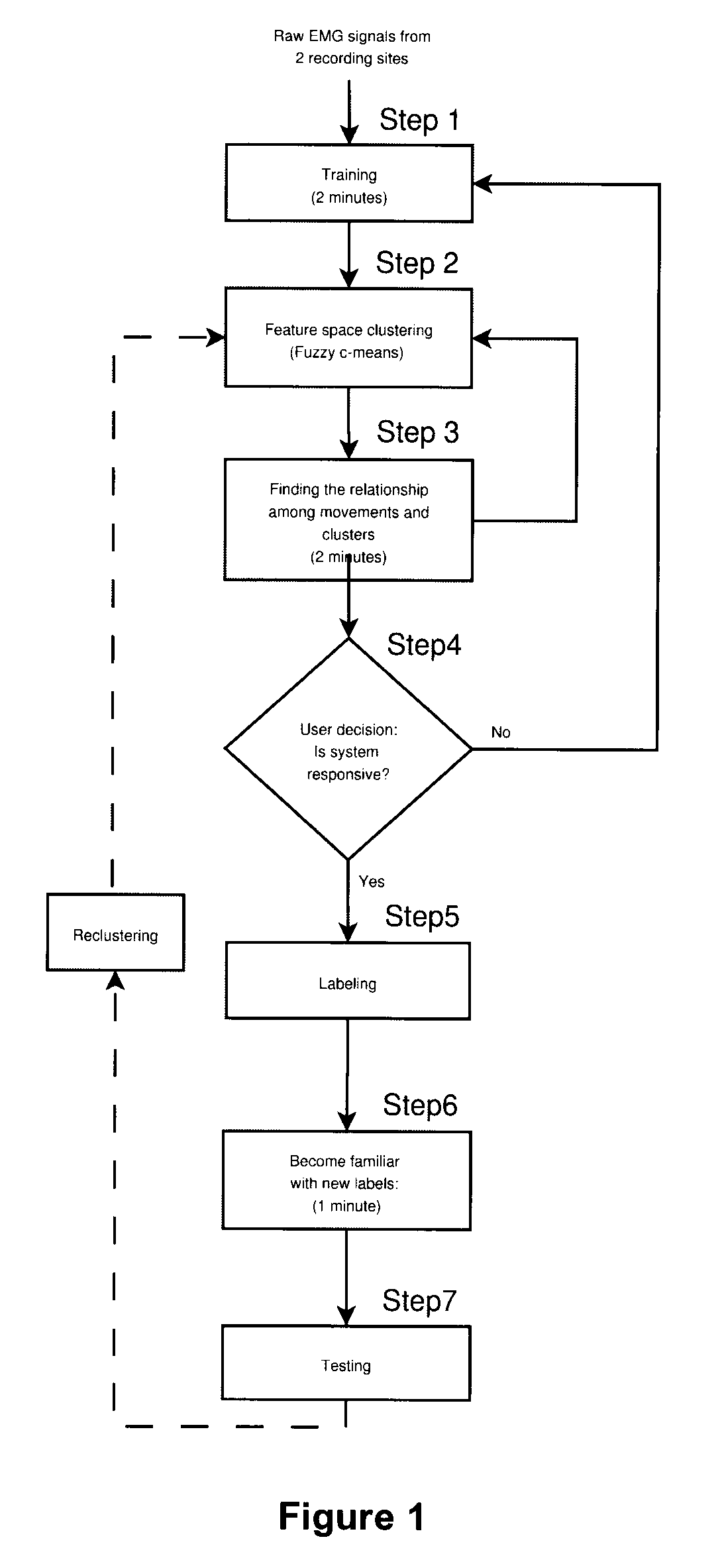

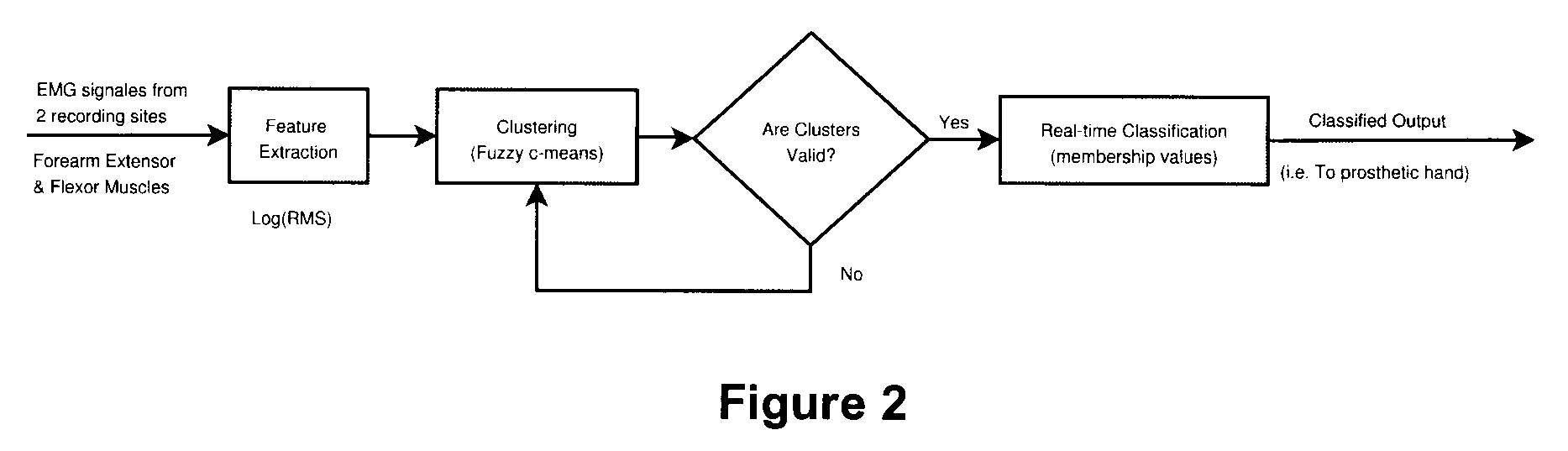

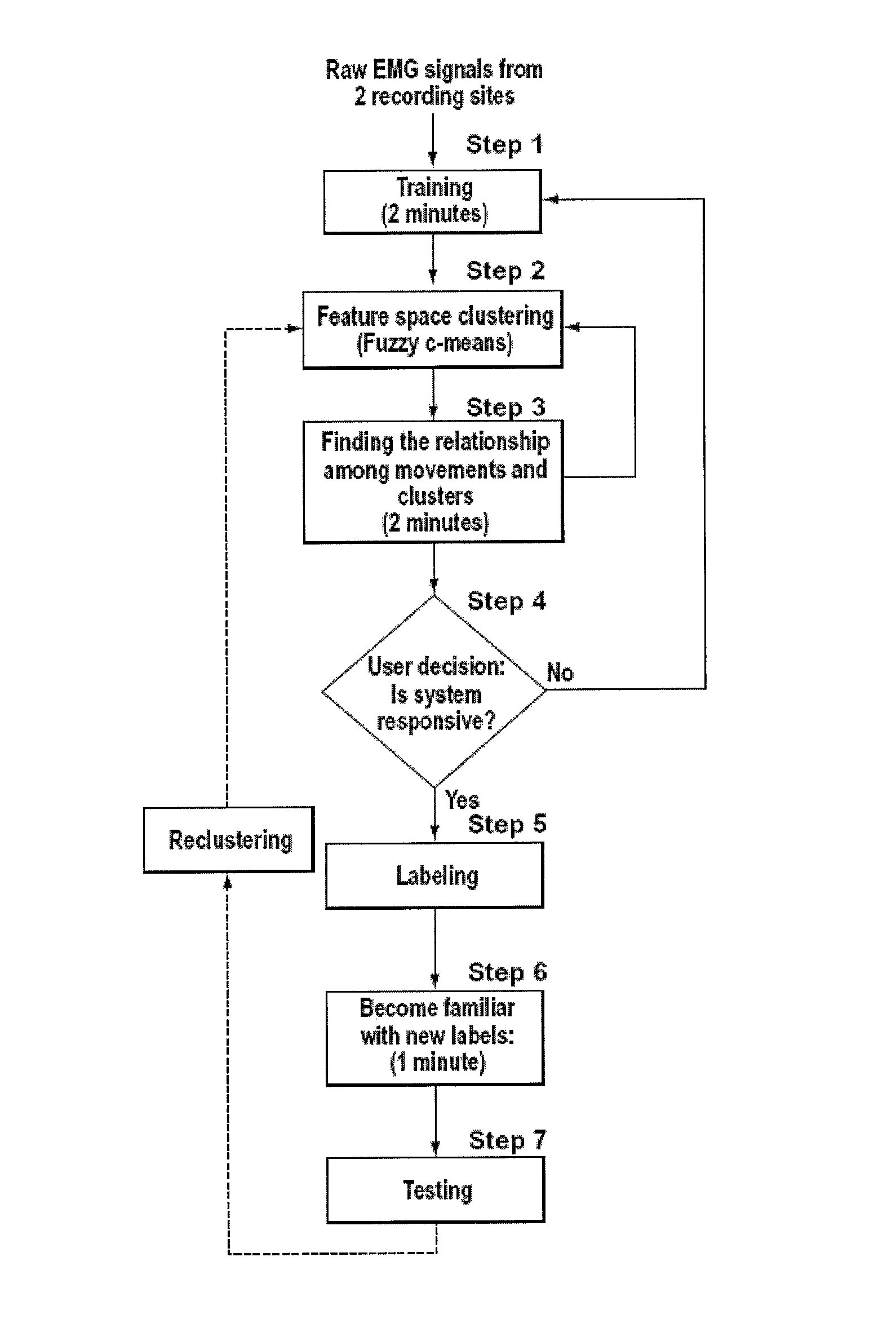

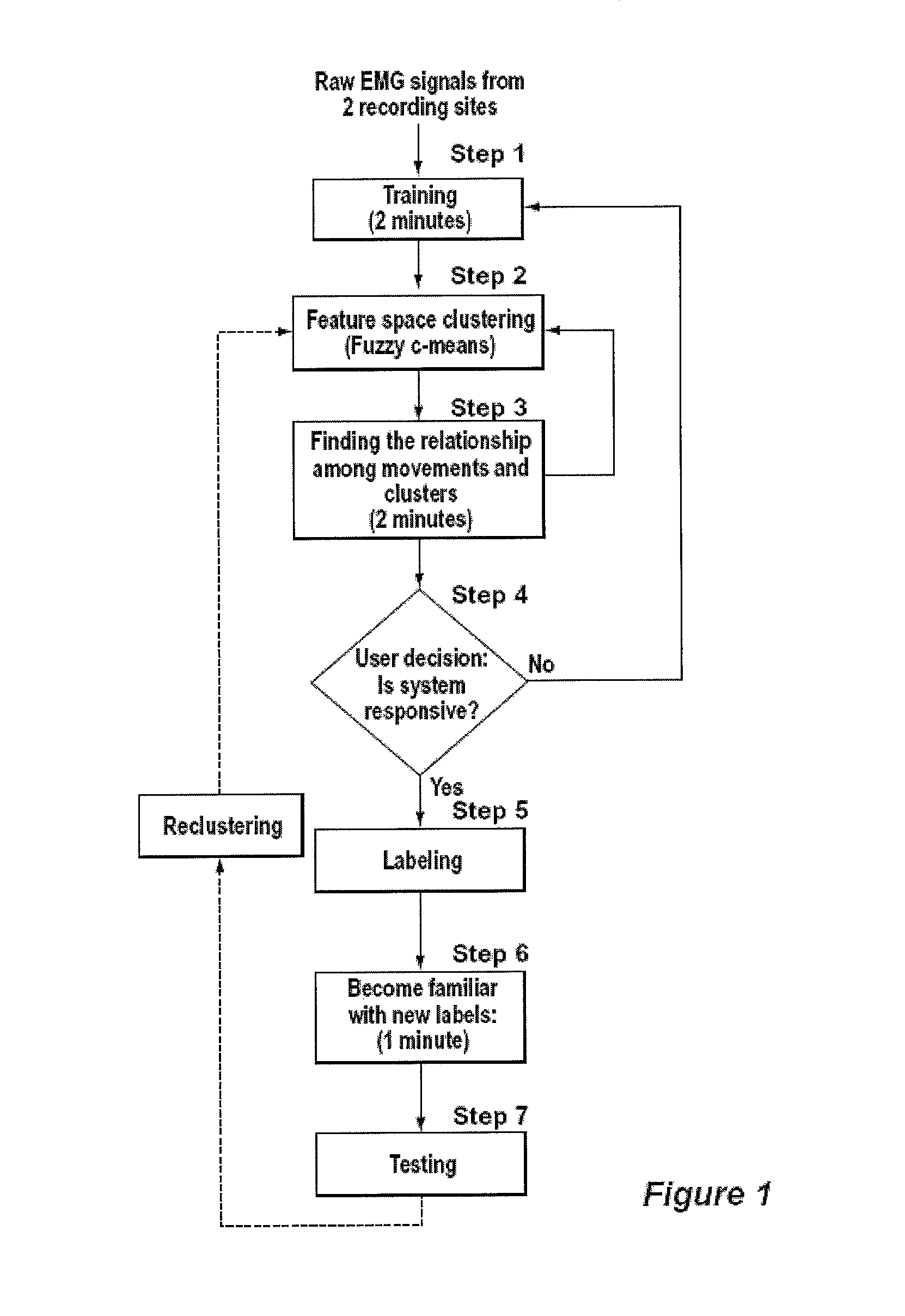

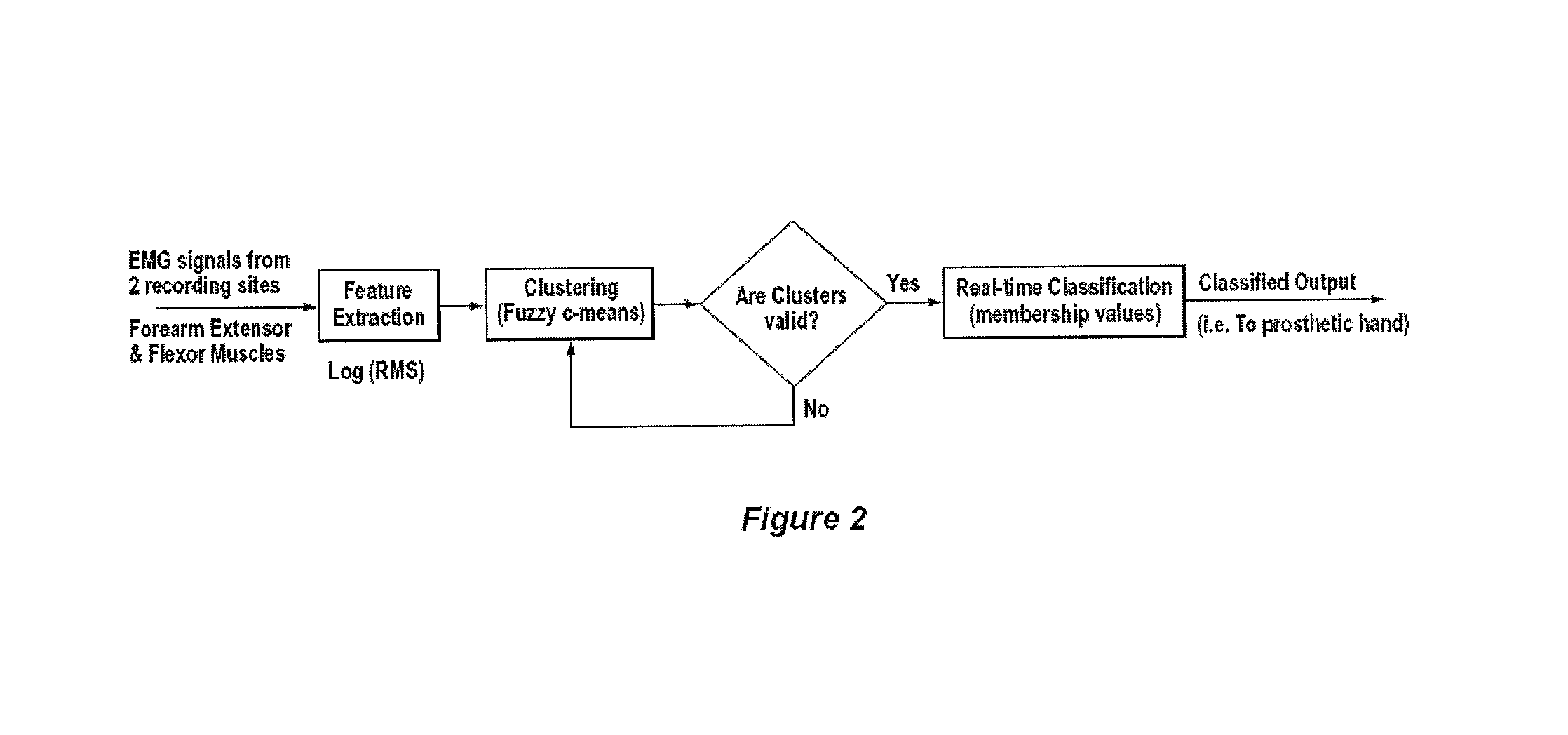

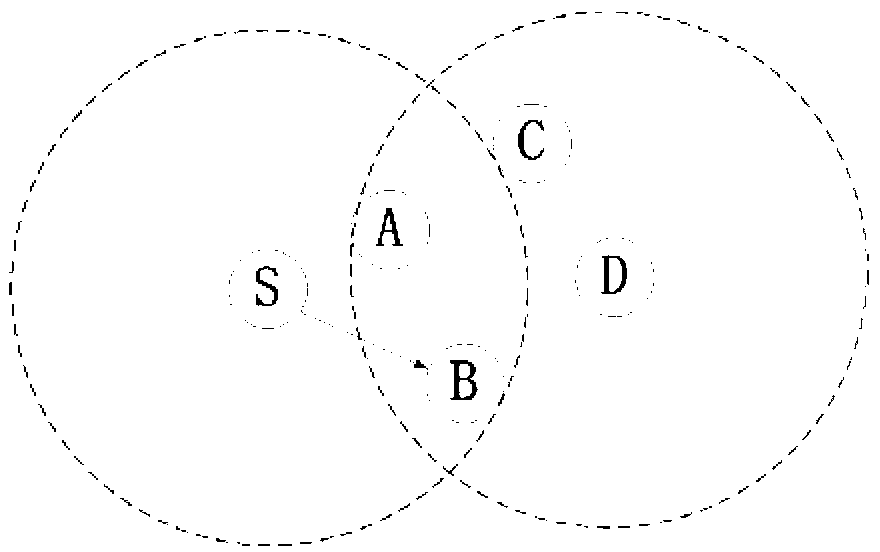

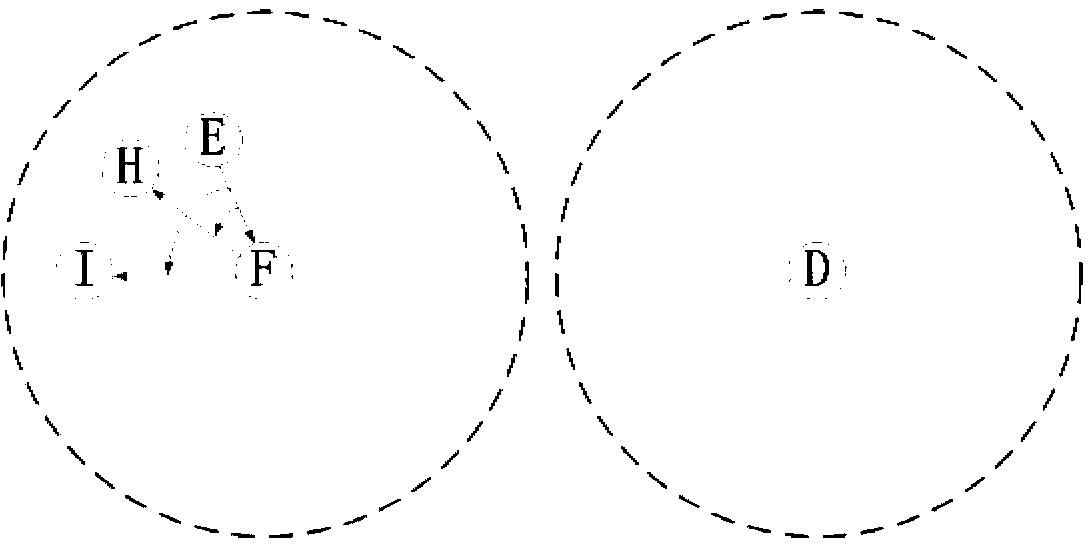

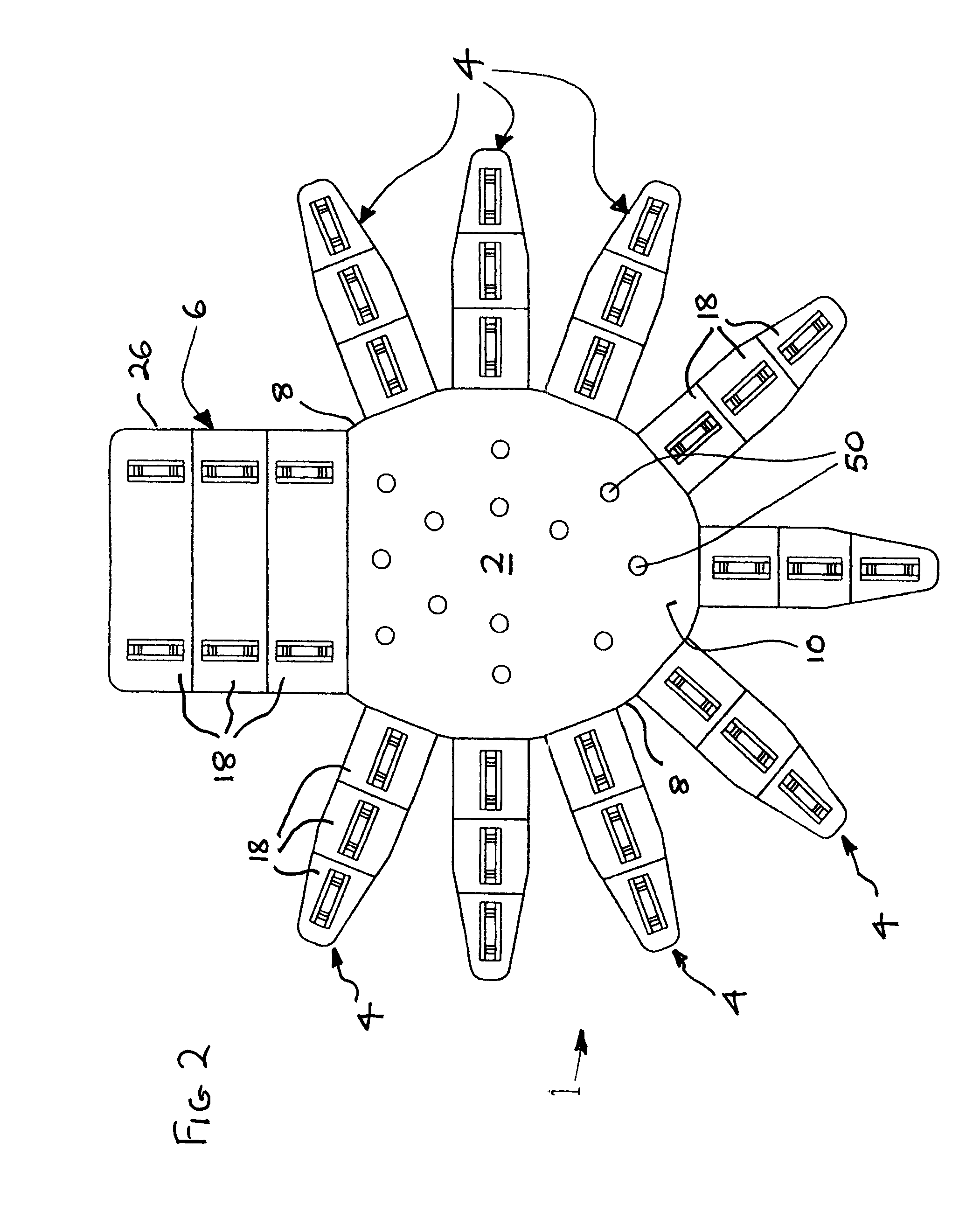

Method, system and apparatus for real-time classification of muscle signals from self-selected intentional movements

InactiveUS20080058668A1Improve abilitiesEasy to operateMedical data miningElectromyographyMuscle contractionSelf training

A new method, system and apparatus is provided that enables muscle signals that correspond to muscle contractions to be mapped to one or more functions of an electronic device such as a prosthetic device or gaming apparatus. Muscle signals are classified in real-time from self-selected intentional movements. A self-training protocol allows users to select and label their own muscle contractions, and is operable to automatically determine the discernible and repeatable muscle signals generated by the user. A visual display means is used to provide visual feedback to users illustrating the responsiveness of the system to muscle signals generated by the user.

Owner:HOLLAND BLOORVIEW KIDS REHABILITATION HOSPITAL

Method, system and apparatus for real-time classification of muscle signals from self -selected intentional movements

InactiveUS20100293115A1User training can be minimizedImprove performanceMedical data miningElectromyographyMuscle contractionSelf training

A new method, system and apparatus is provided that enables muscle signals that correspond to muscle contractions to be mapped to one or more functions of an electronic device such as a prosthetic device or gaming apparatus. Muscle signals are classified in real-time from self-selected intentional movements. A self-training protocol allows users to select and label their own muscle contractions, and is operable to automatically determine the discernible and repeatable muscle signals generated by the user. A visual display means is used to provide visual feedback to users illustrating the responsiveness of the system to muscle signals generated by the user.

Owner:HOLLAND BLOORVIEW KIDS REHABILITATION HOSPITAL

Method, system and apparatus for real-time classification of muscle signals from self-selected intentional movements

InactiveUS8437844B2User training can be minimizedSimple designMedical data miningElectromyographyMuscle contractionSelf training

A new method, system and apparatus is provided that enables muscle signals that correspond to muscle contractions to be mapped to one or more functions of an electronic device such as a prosthetic device or gaming apparatus. Muscle signals are classified in real-time from self-selected intentional movements. A self-training protocol allows users to select and label their own muscle contractions, and is operable to automatically determine the discernible and repeatable muscle signals generated by the user. A visual display means is used to provide visual feedback to users illustrating the responsiveness of the system to muscle signals generated by the user.

Owner:HOLLAND BLOORVIEW KIDS REHABILITATION HOSPITAL

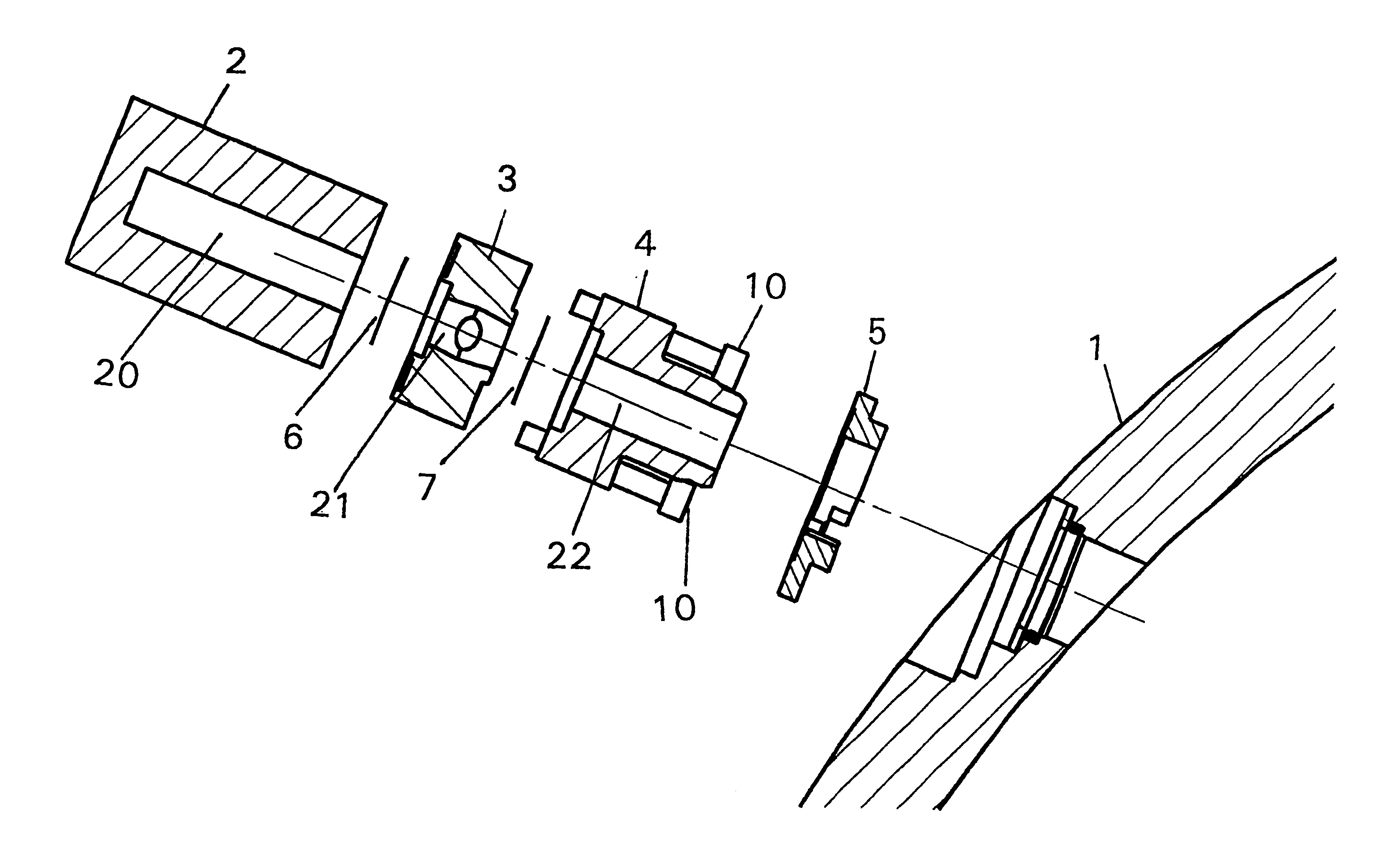

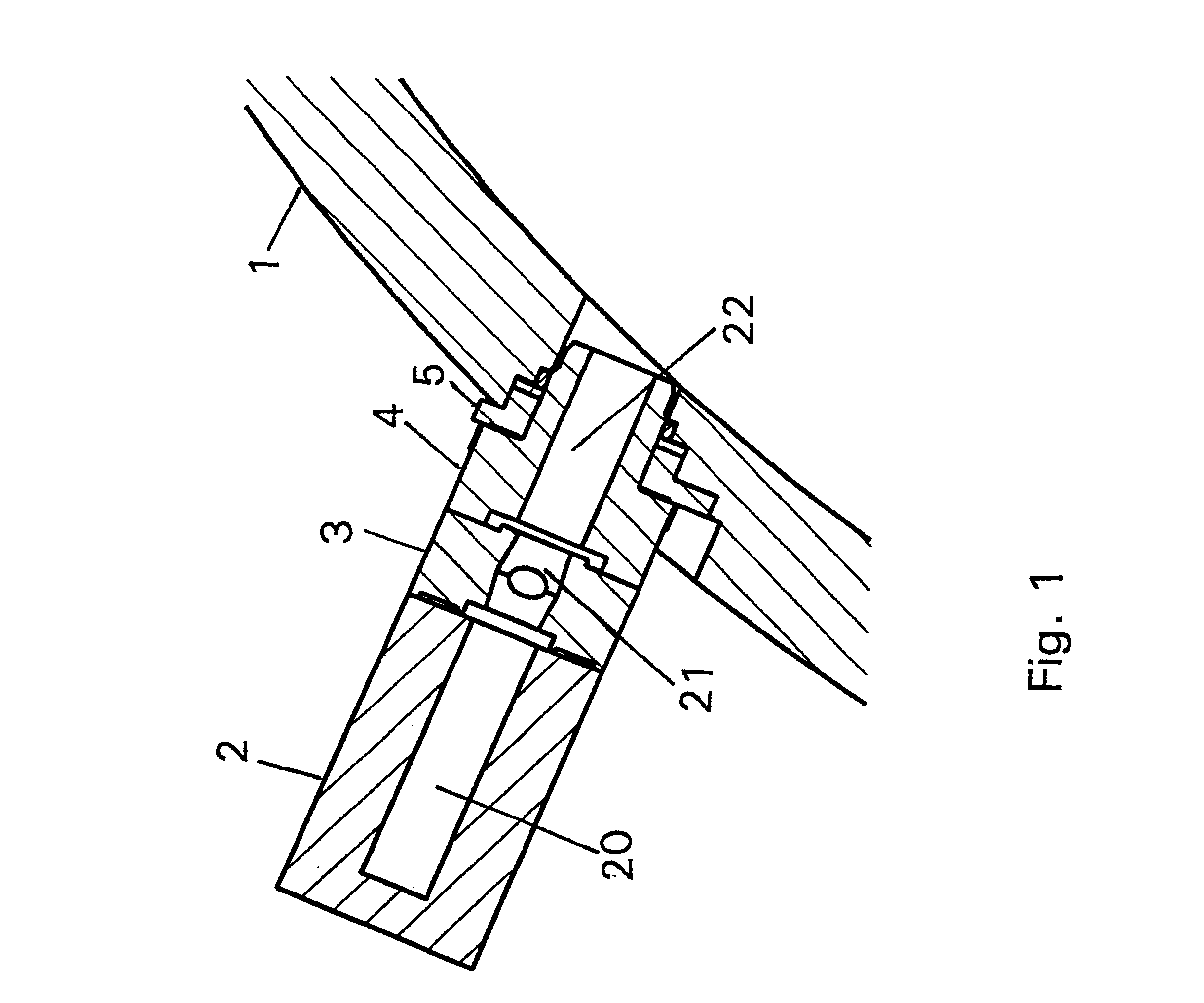

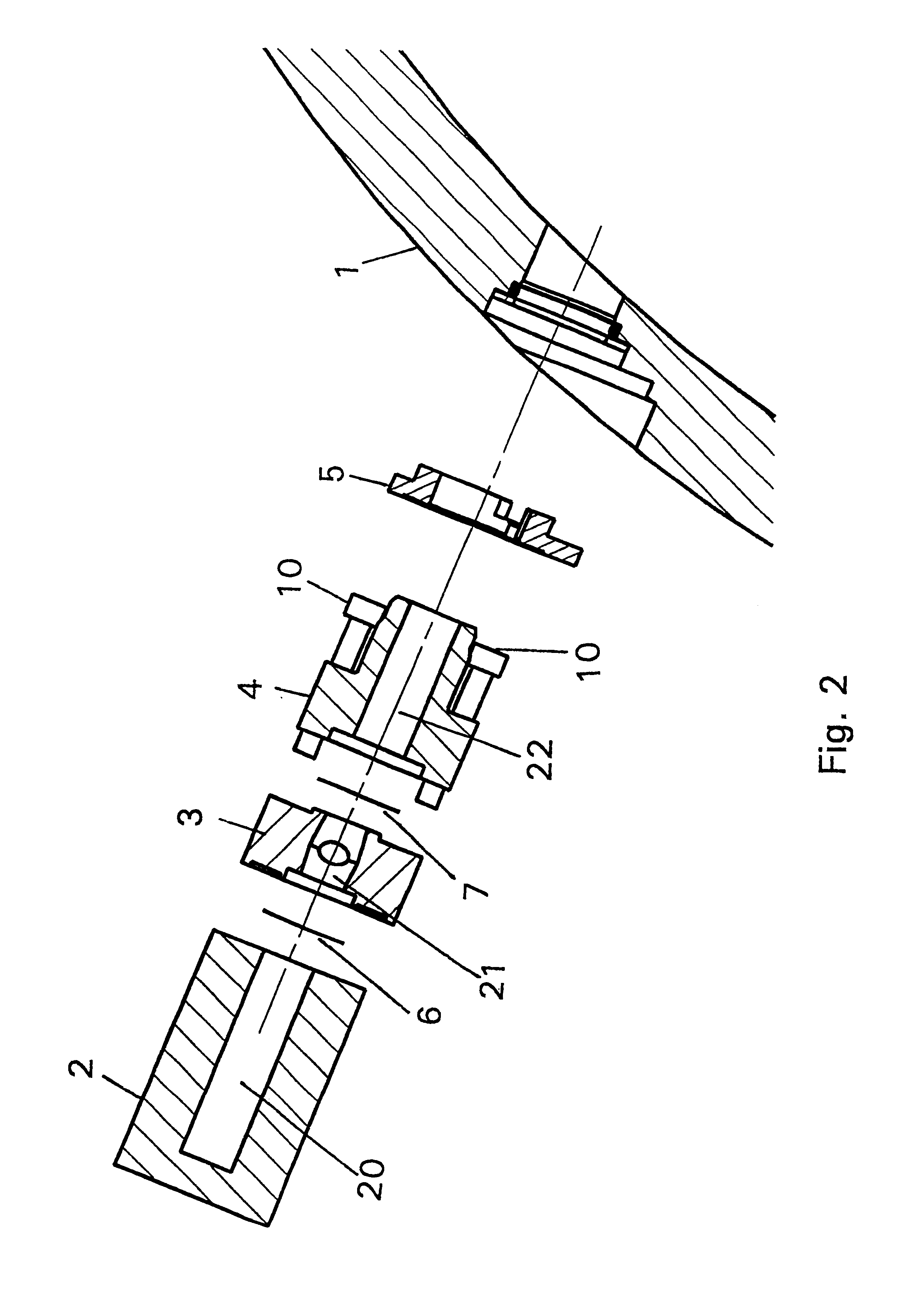

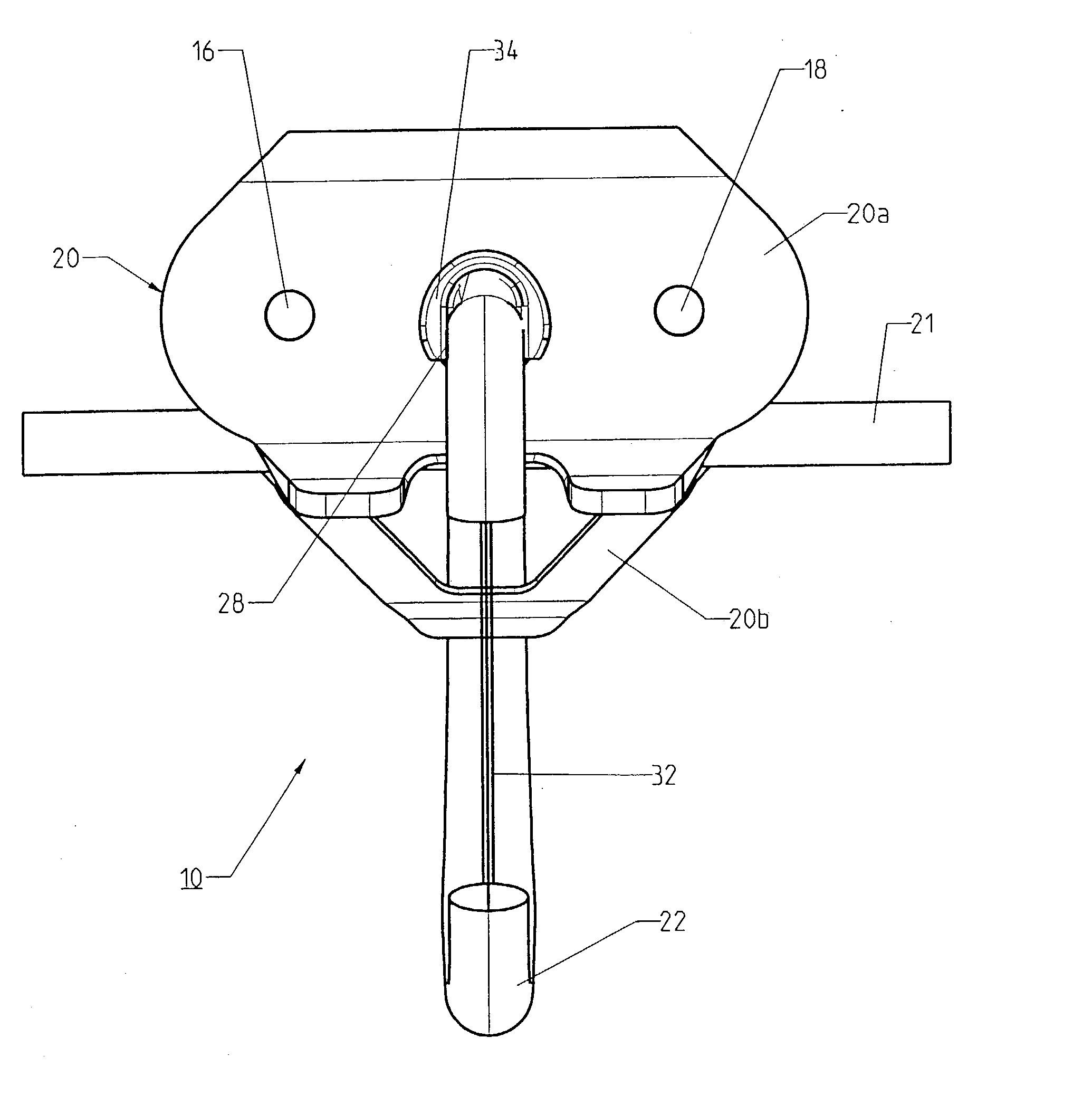

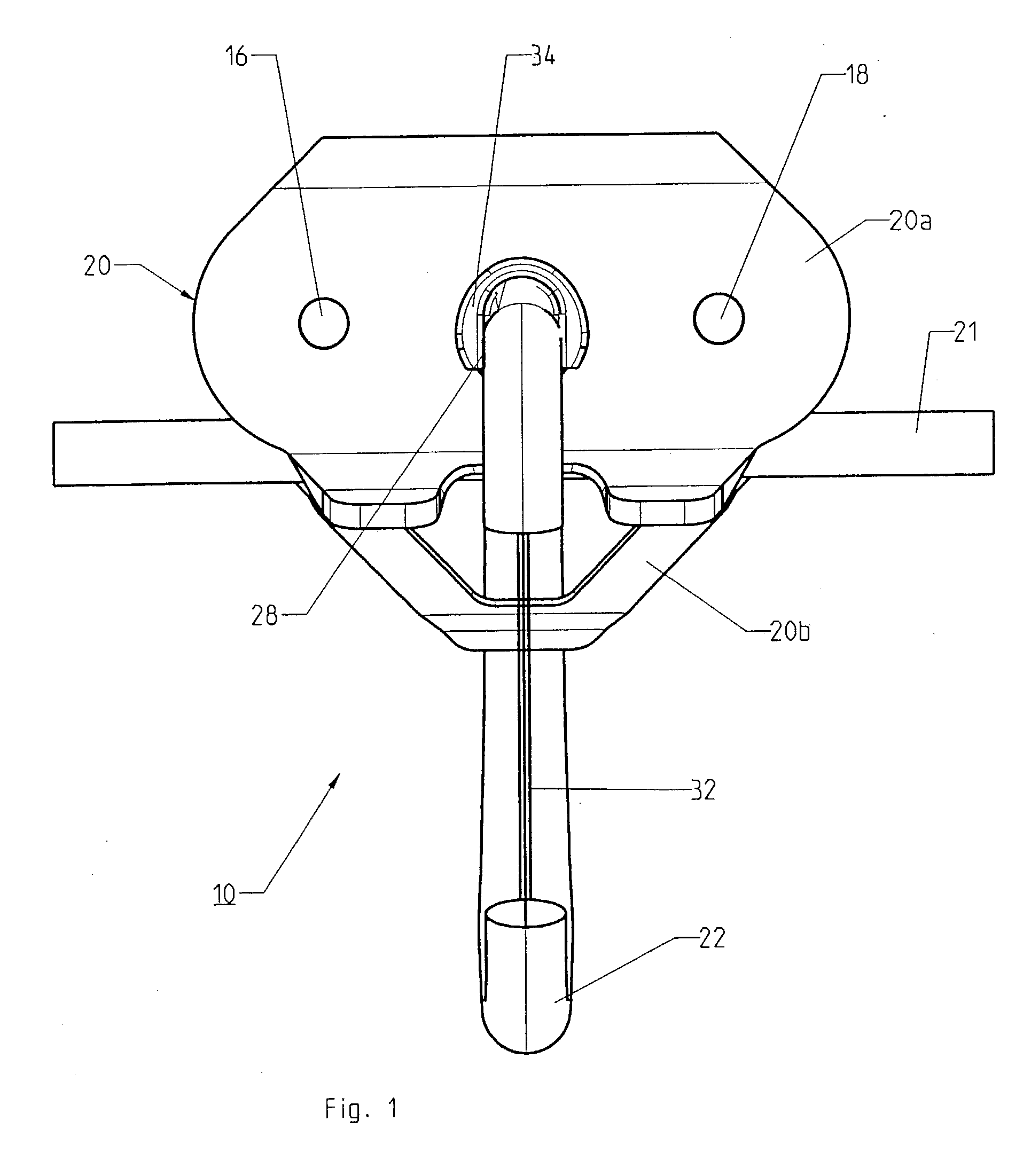

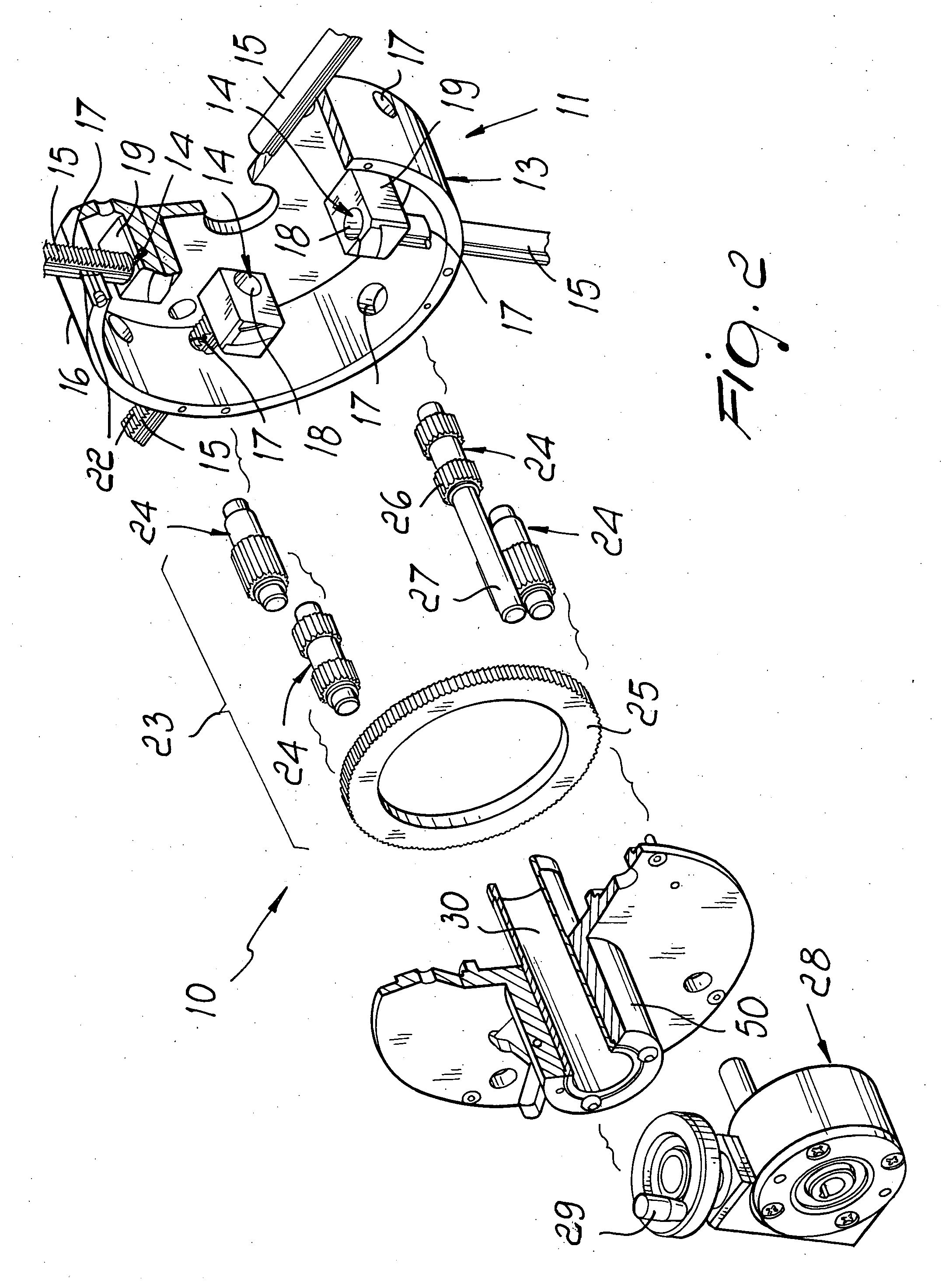

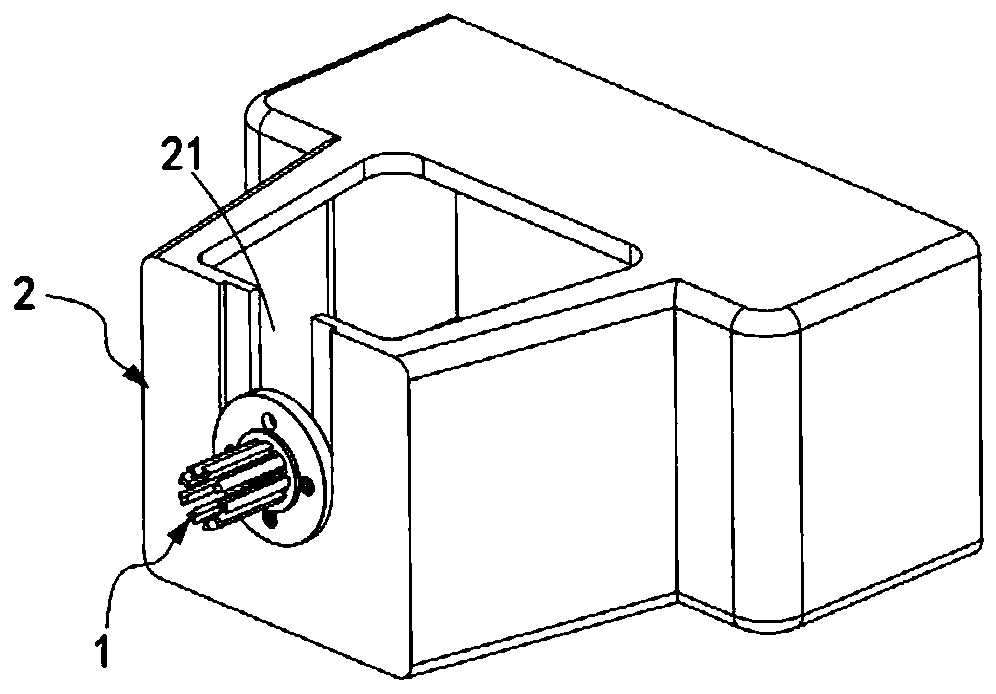

Device for fitting of a target in isotope production

InactiveUS6433495B1Minimize radiationFit fastThermometer detailsBeam/ray focussing/reflecting arrangementsInterior spaceIsotope

A device is disclosed for simple and quick disconnection of a target assembly at a cyclotron accelerator producing an ion beam irradiating the target assembly for PET radioisotope production. The device consists of a target body presenting a target space for introduction of target media to be irradiated by the ion beam from the cyclotron accelerator. The target body is separated into three portions by means of two separation window foils. The first separation window separates the internal space of a first body portion from a further internal space portion of a second target body portion and the second separation window separates a further internal space of the second target body portion from an internal space of a third target body portion being in communication with the vacuum space of the cyclotron. This third body portion forms a bayonet fitting to a corresponding bayonet fitting fixed to the cyclotron vacuum casing at a position where the ion beam is extracted, whereby the corresponding bayonet fitting also constitutes an insulating member. The device can by a small twisting be quickly released from the vacuum casing of the cyclotron after the vacuum has been removed for necessary maintenance and service.

Owner:GEMS PET SYST

Temporary protective shrouds for protecting windows and fixtures during construction

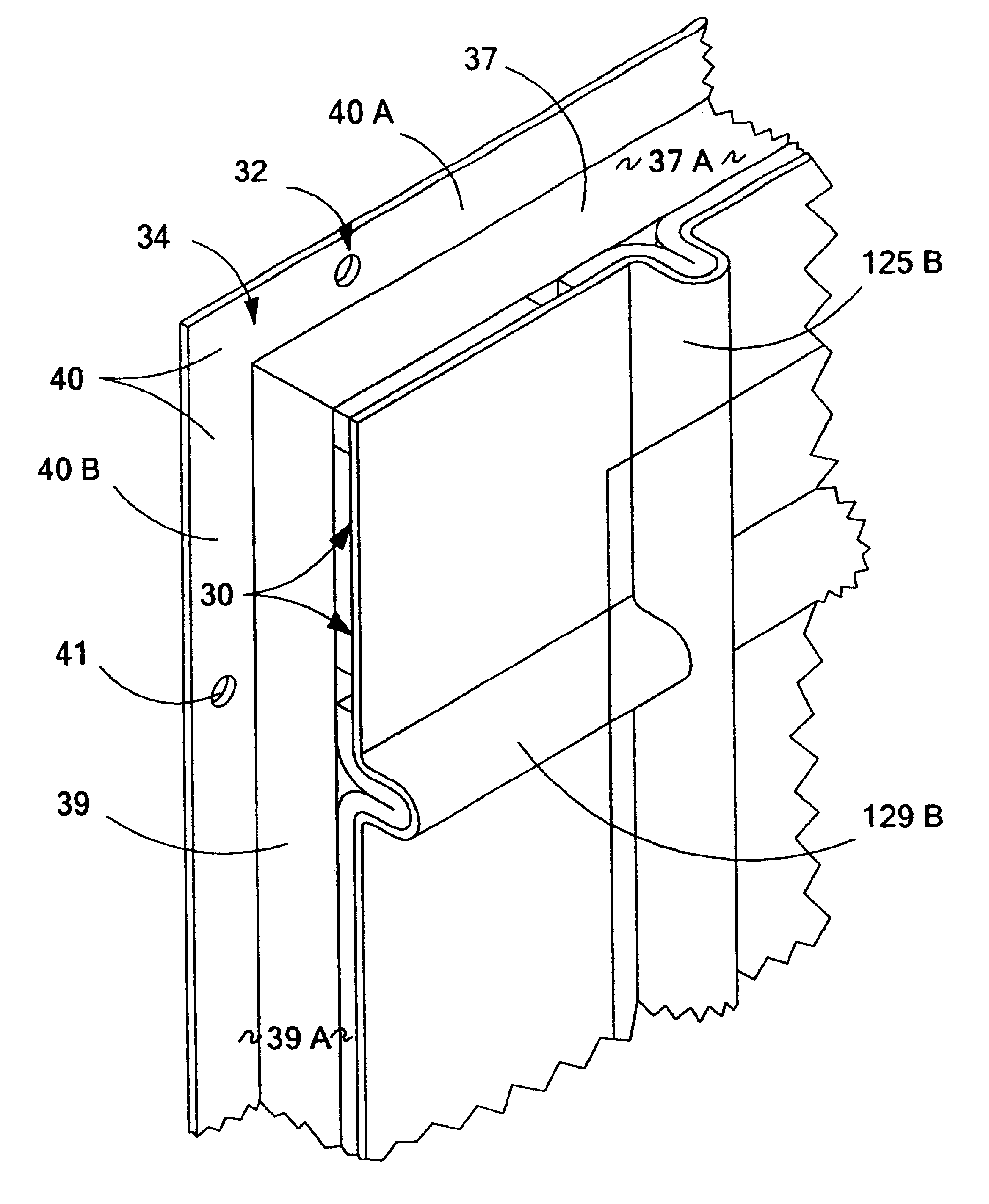

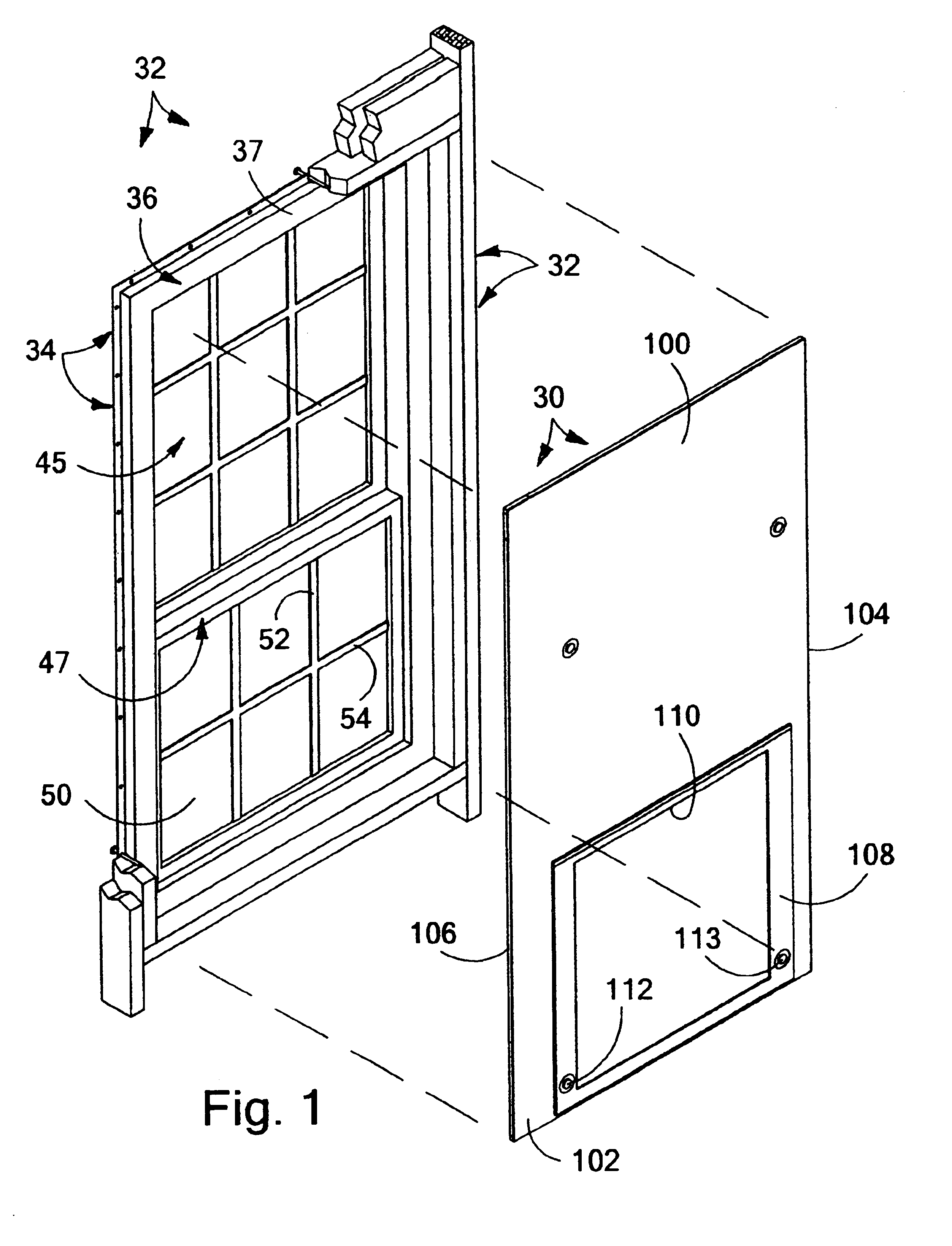

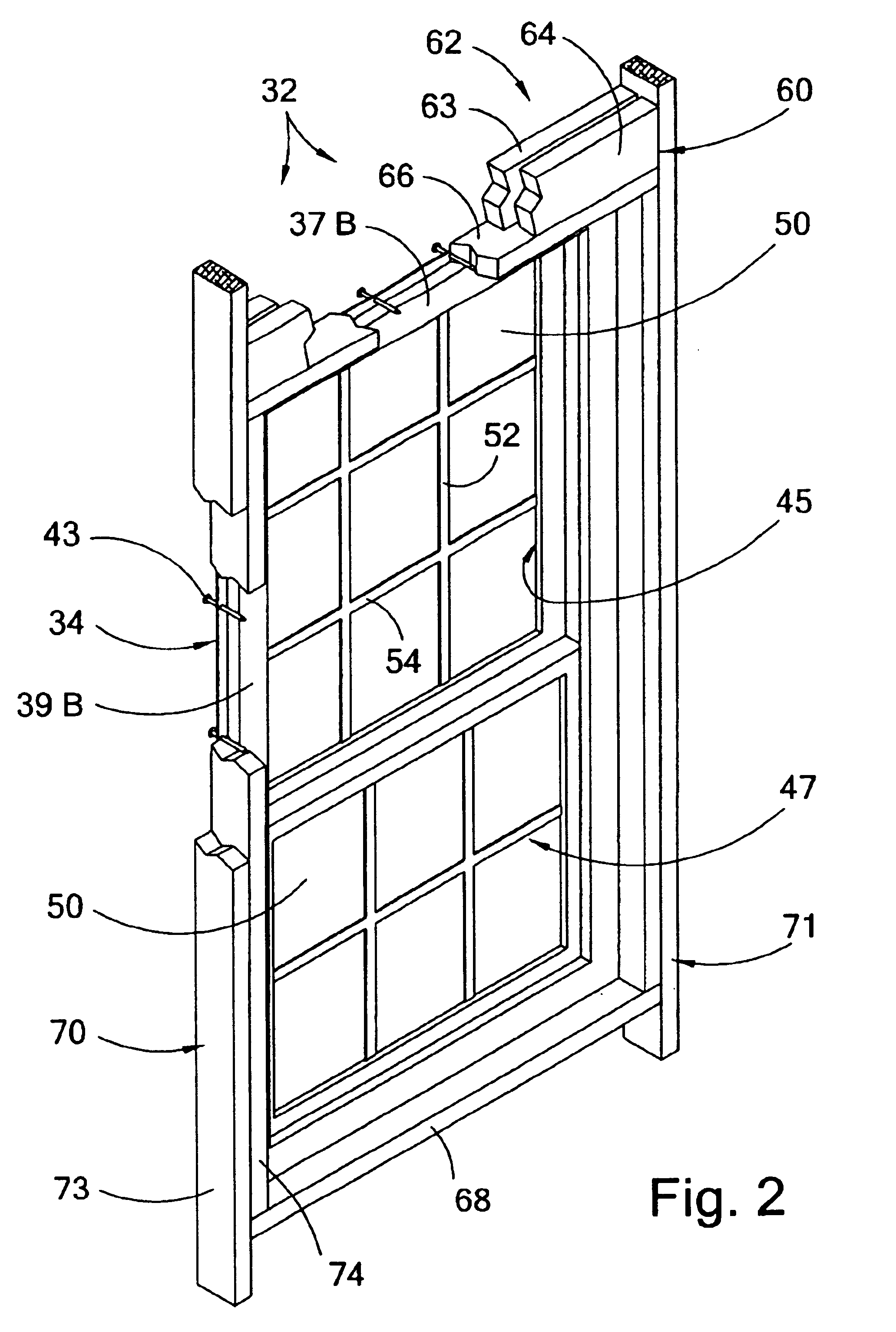

InactiveUS6865850B1Easy to adjustQuickly and easily removedDoor/window protective devicesTents/canopiesWallingEngineering

Protective shrouds for temporarily protecting window assemblies, bathroom fixtures, and diverse prefabricated modules used in construction. The shrouds are fabricated from translucent plastic sheet material of polypropylene or polyethylene. A lower open port is selectively blocked by a foldable ventilation panel held in a deployed state by magnets. Rear mounted adhesive strips affix the shroud to the window. Top and side strips are bifurcated to enable rapid adjustments in height and length. When the tear away strips are removed, the exposed adhesive surface is pressed upon the target structure. Slight dimensional adjustments are made by pinching the sheet together, forming creases aligned with strip bifurcations, to gather material and shorten the shroud length or width. During subsequent dry-walling, shroud edges are captivated by wall board segments. Afterwards, the exposed junction between covered shroud and adjacent sheet rock portions is cut, and the shroud is torn away and discarded.

Owner:CAMPBELL PHILLIP R

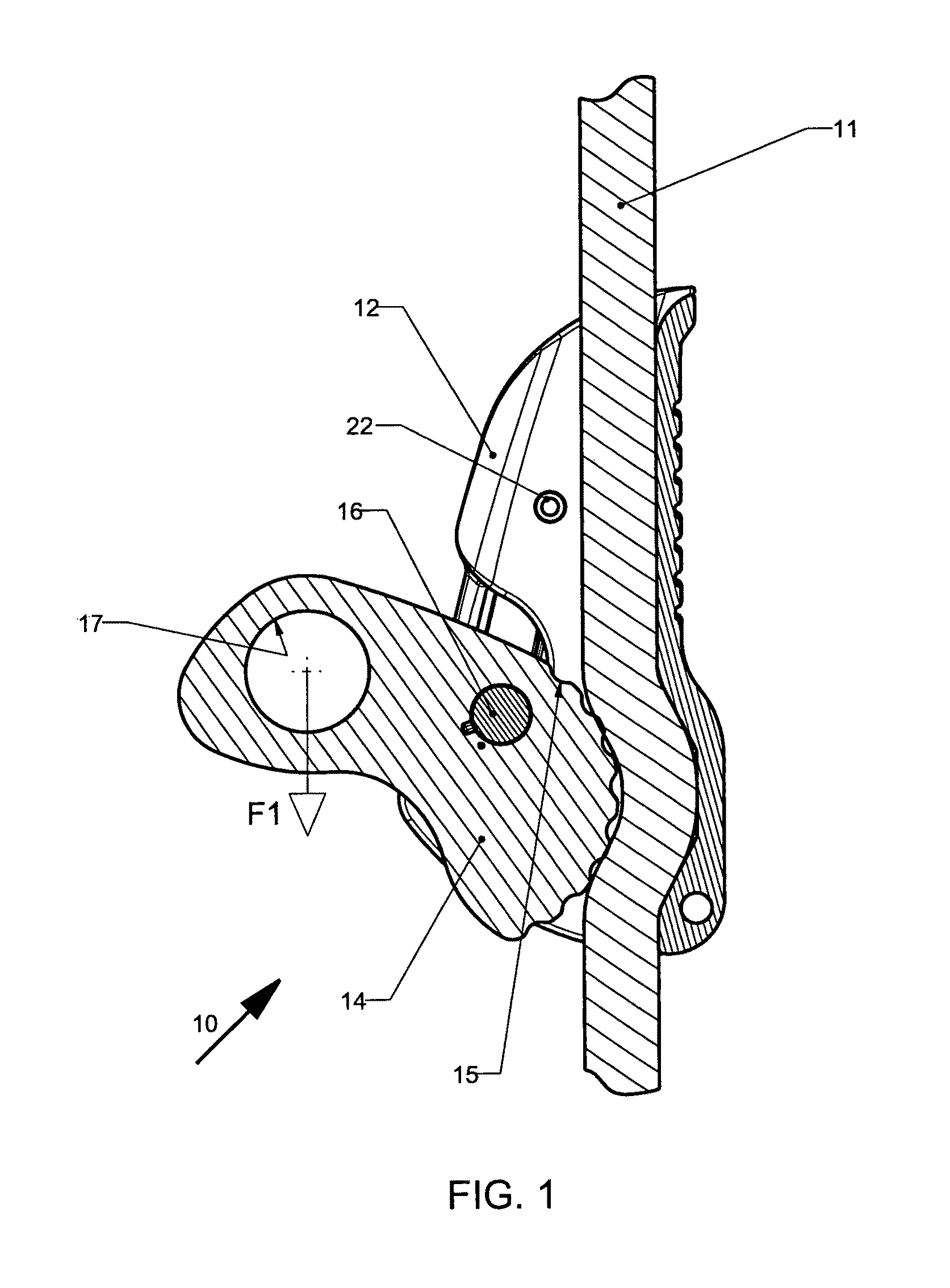

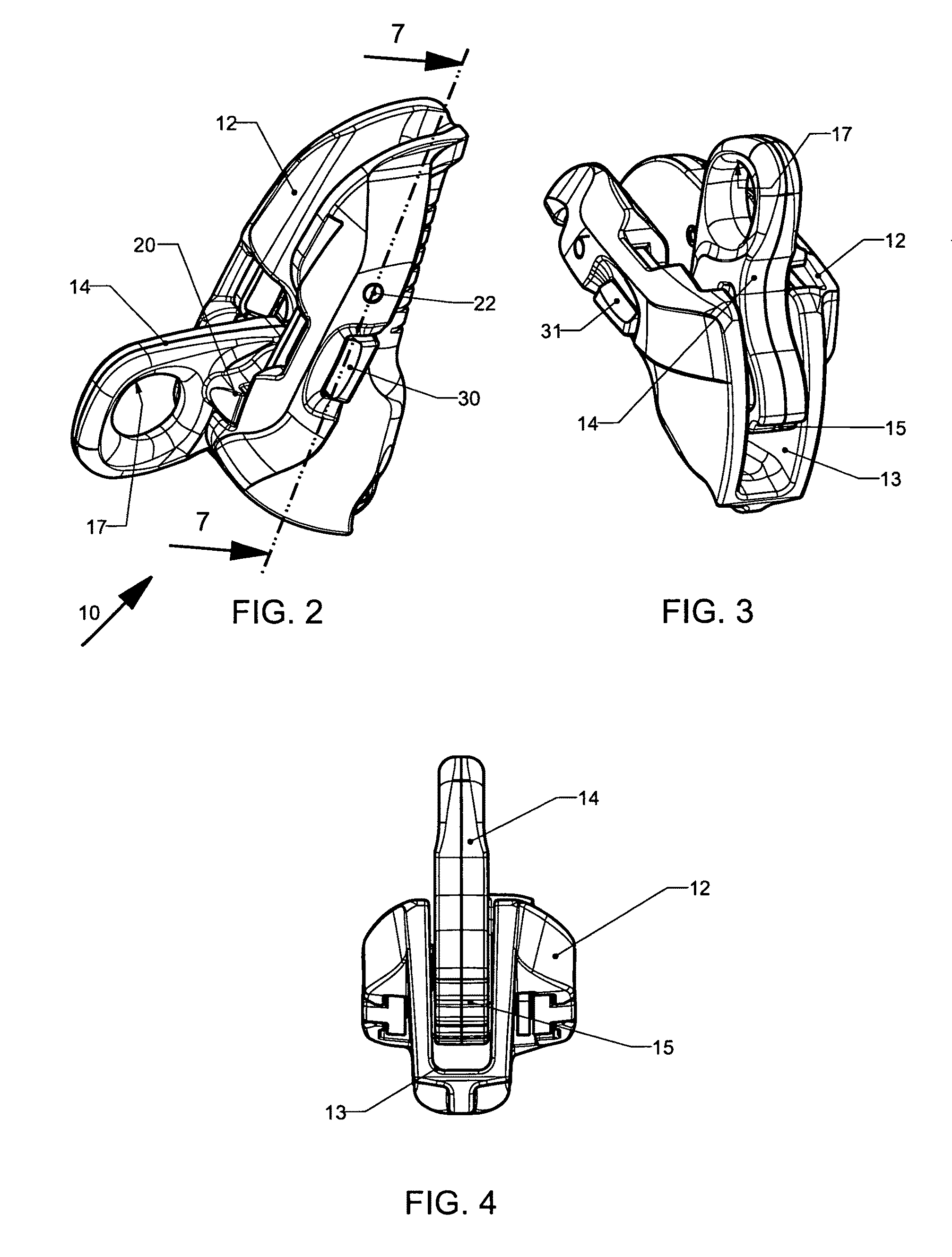

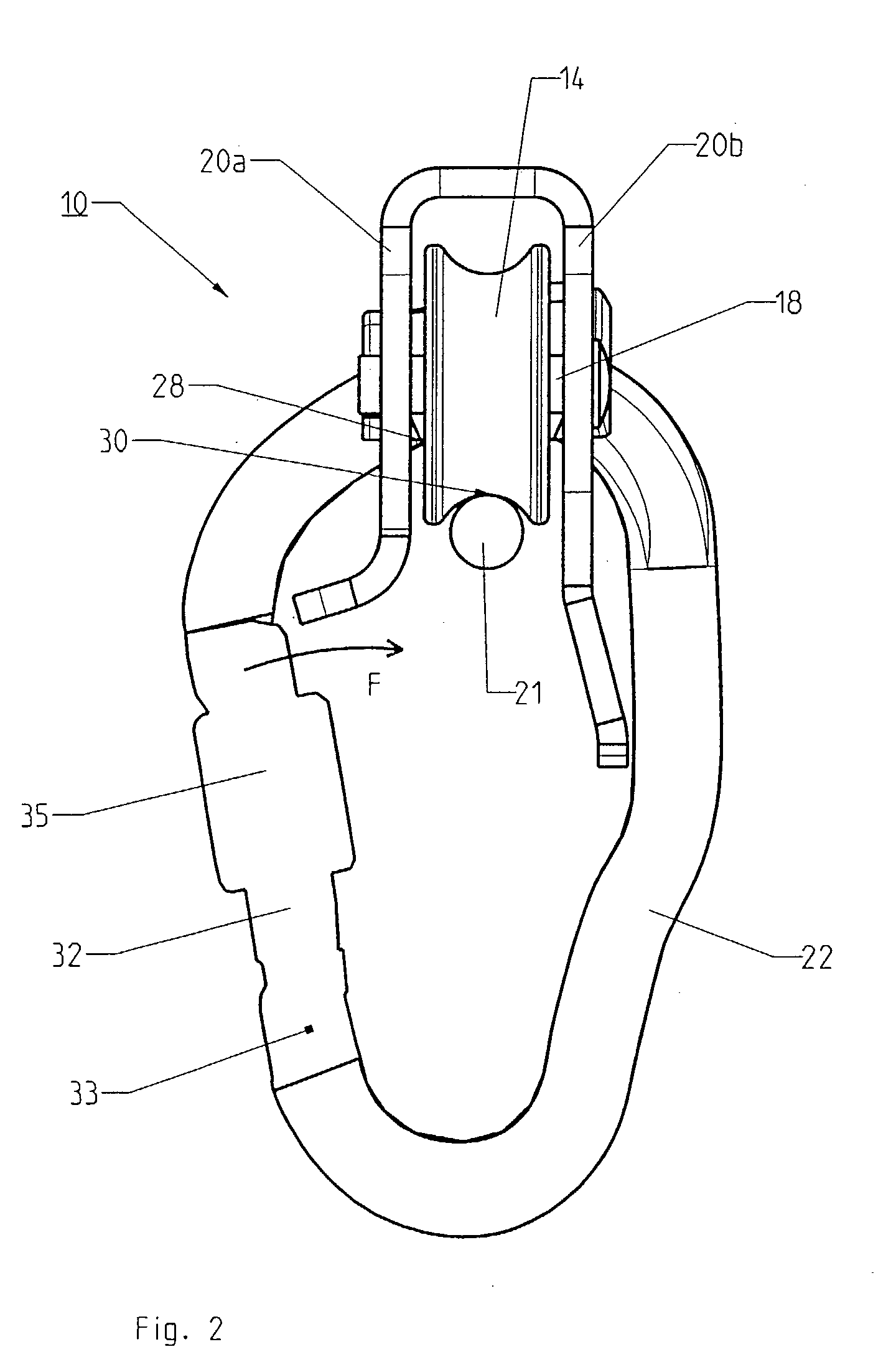

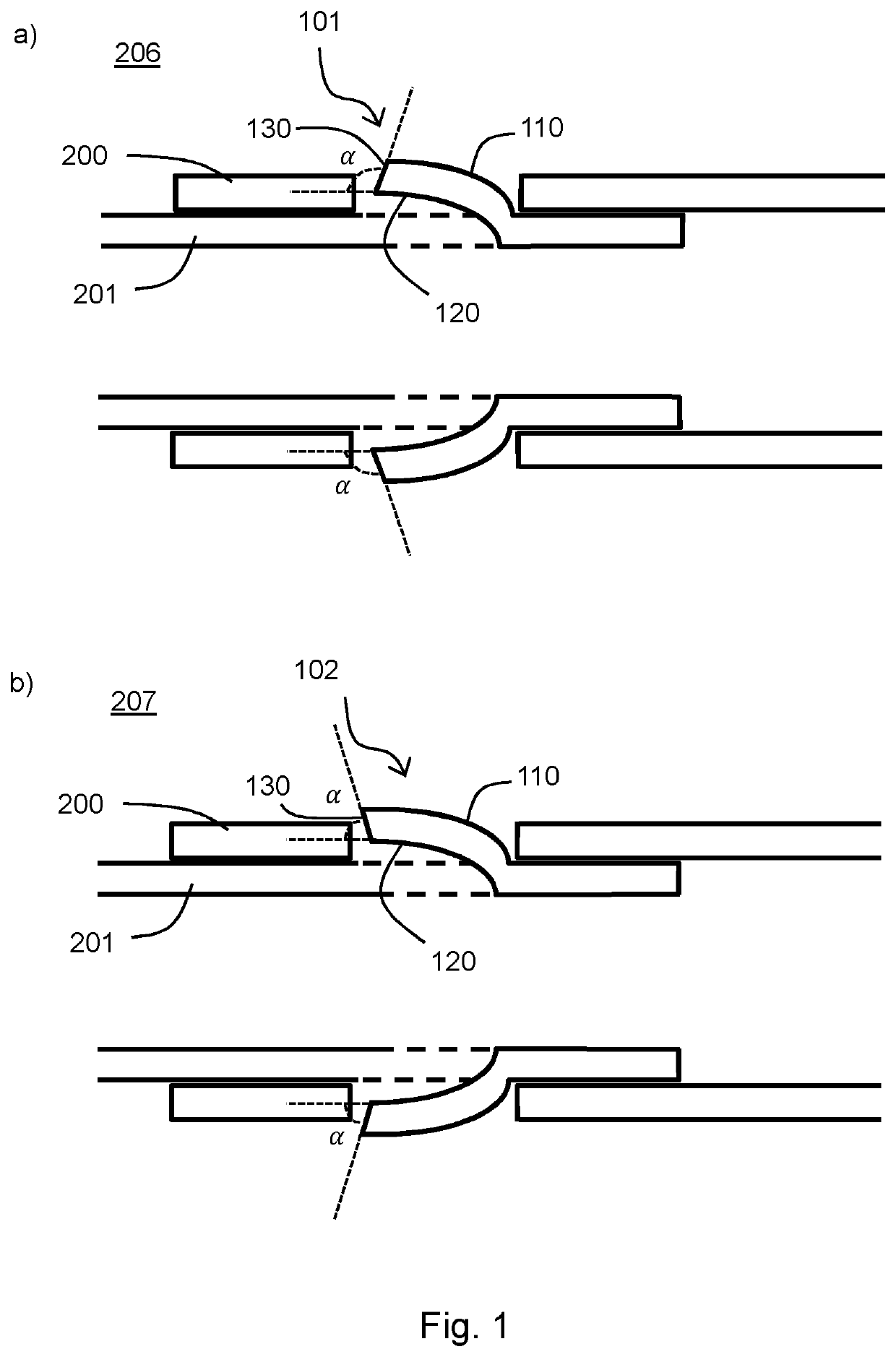

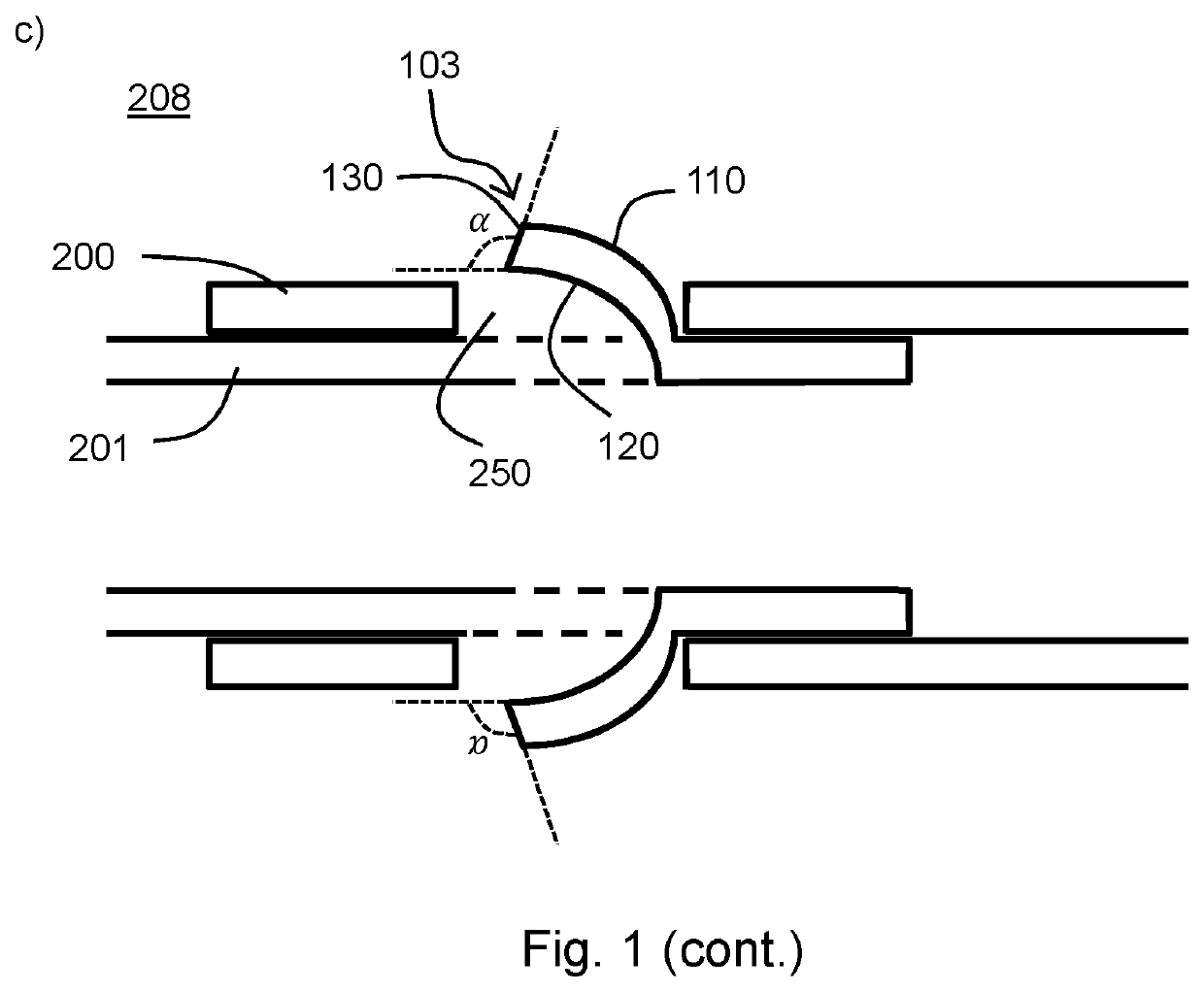

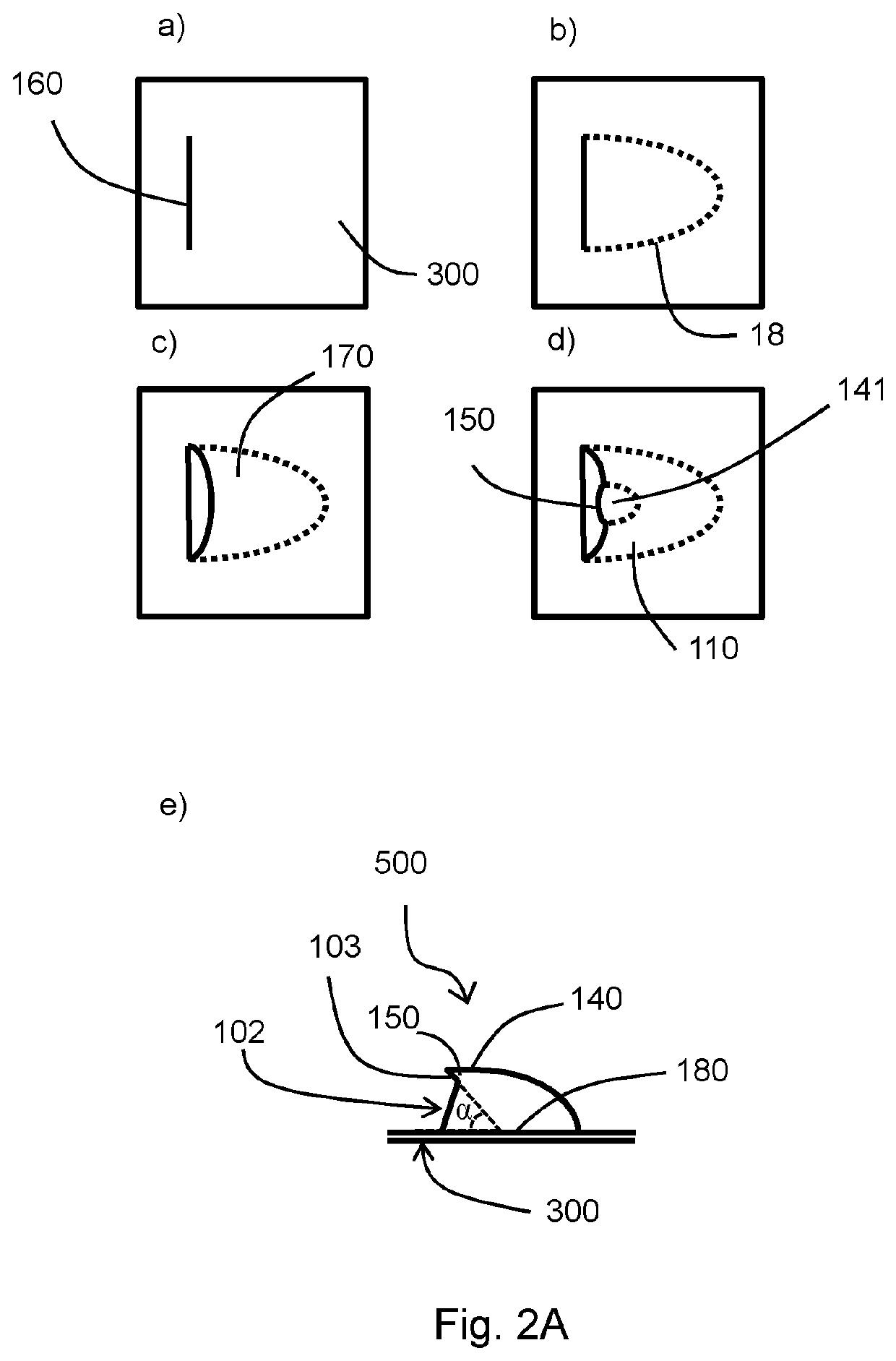

Ascender device with cam for belaying on a fixed rope

Owner:ZEDEL CORP

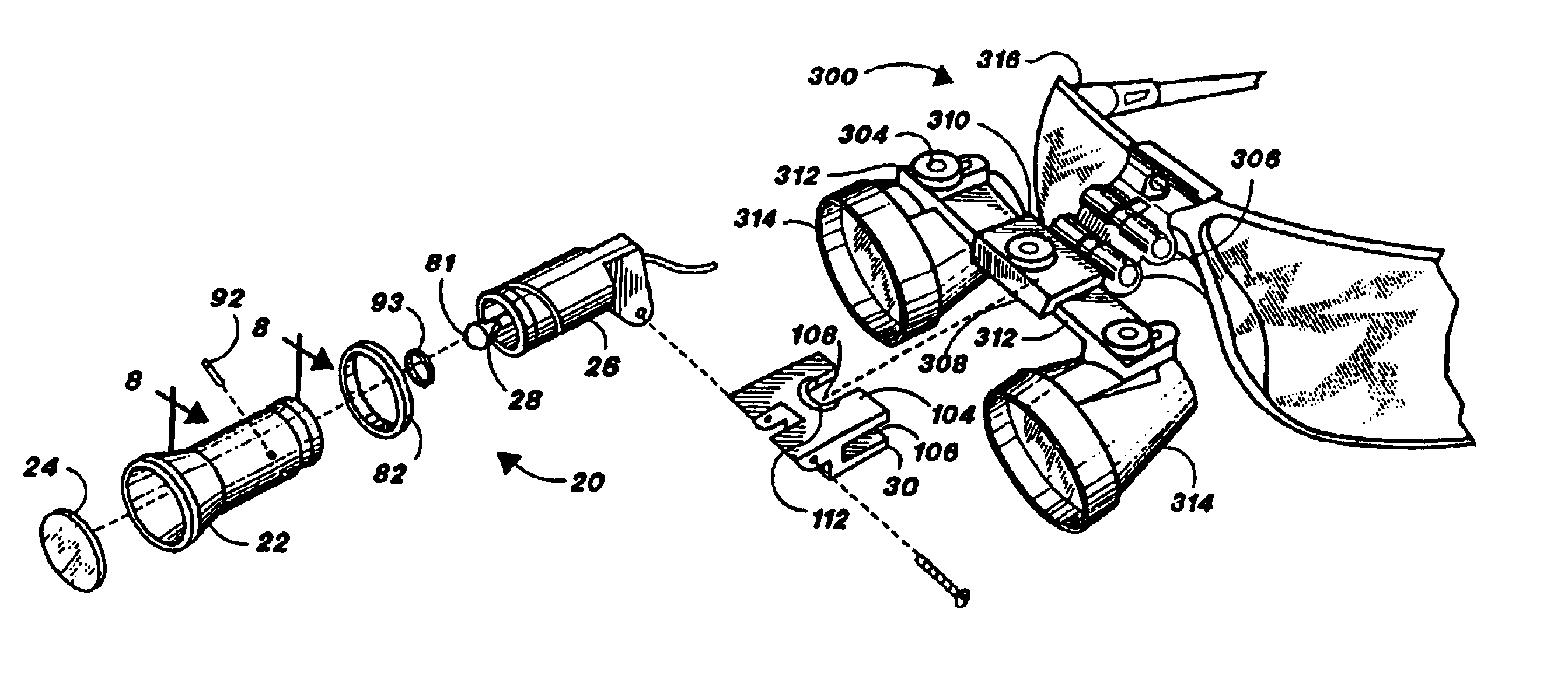

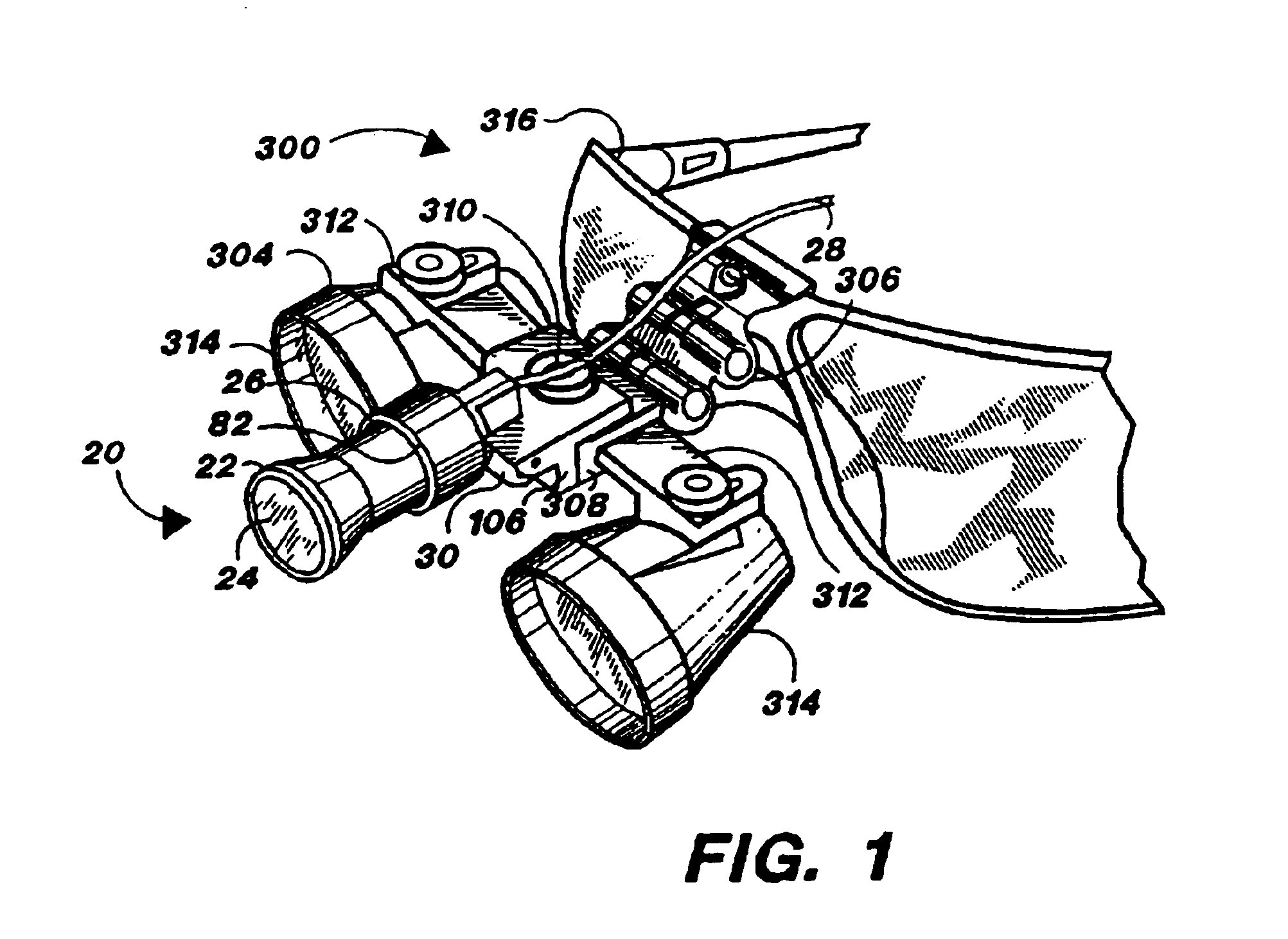

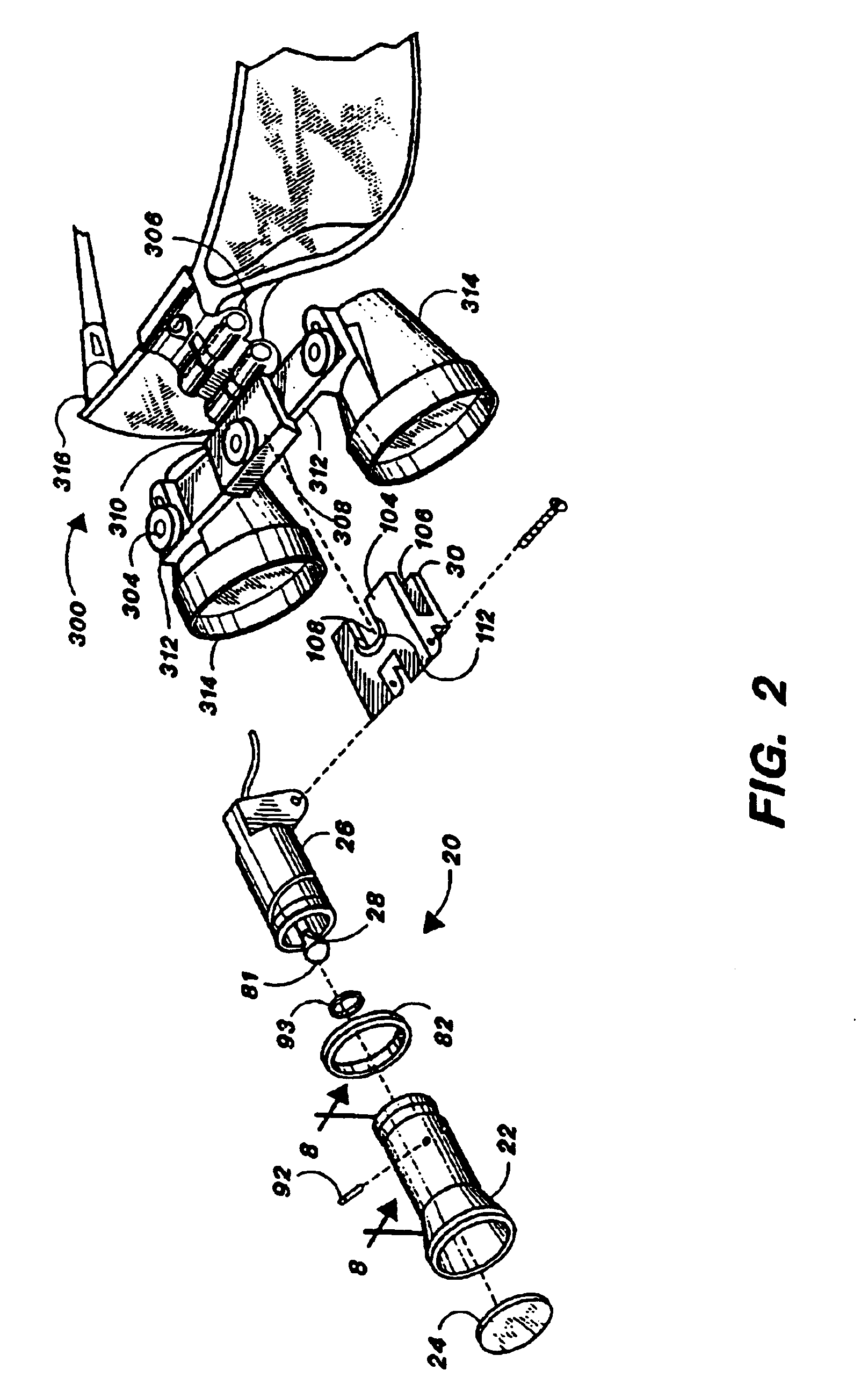

Illumination assembly for dental and medical applications

InactiveUSRE39162E1Fit fastAutomatically illuminateMechanical apparatusLighting support devicesMagnifying glassLight guide

A small, lightweight, high intensity illumination assembly for use in dental and medical applications. The illumination assembly includes attachment means for removable attachment to headgear such as eyeglasses, face shields, or headbands, and lenses, loupes, and binoculars associated with such headgear. The illumination assembly is able to achieve extremely light weight by using only a single optical element therein, e.g., an aspheric condensing lens, binary optical element, or holographic optical means, and by piping illumination to the optical element from a remote light source by use of a flexible light guide, e.g., a fiberoptic bundle.

Owner:THE KERR

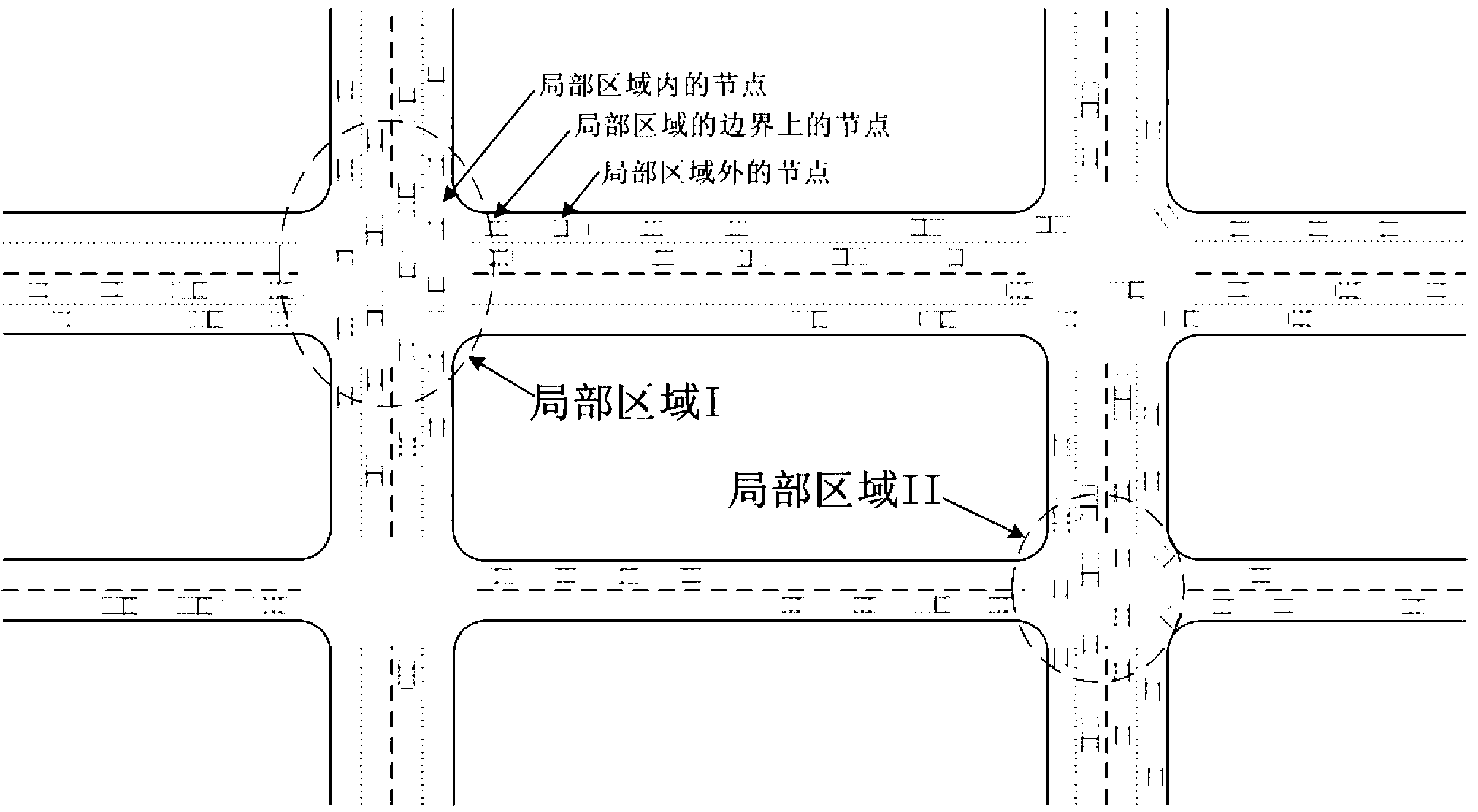

Optimization method for wireless mobile network route selection

InactiveCN103200642AImprove performanceImprove delivery success rateWireless network protocolsWireless mesh networkMessage delivery

The invention discloses an optimization method for wireless mobile network route selection, and belongs to the field of wireless mobile networks. The specific technical scheme includes: according to the number of neighbors of network nodes, dynamically defining local areas in a network in real time, partitioning the nodes with the number of the neighbors larger than a defined value into the local areas with large intensity, routing the nodes in the local areas according to network topology of the local areas of current sending nodes and based on a unisource shortest route, and routing the nodes outside the local areas by adoption of a routing protocol based on geographic locations; and if routing fails, the sending nodes store messages to be sent, and after T time, performing the routing selection again. The optimization method for the wireless mobile network routing selection can be applied to high dynamic wireless mobile networks including vehicle-mounted self-organization networks and the like. According to the optimization method for the wireless mobile network routing selection, the routing based on the geographic locations is fully combined with the routing based on the network topology, the routing based on the geographic locations and the routing based on the network topology are called according to occasions, a message delivery success rate is increased, time delay is reduced, and overall performance of the network is enhanced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

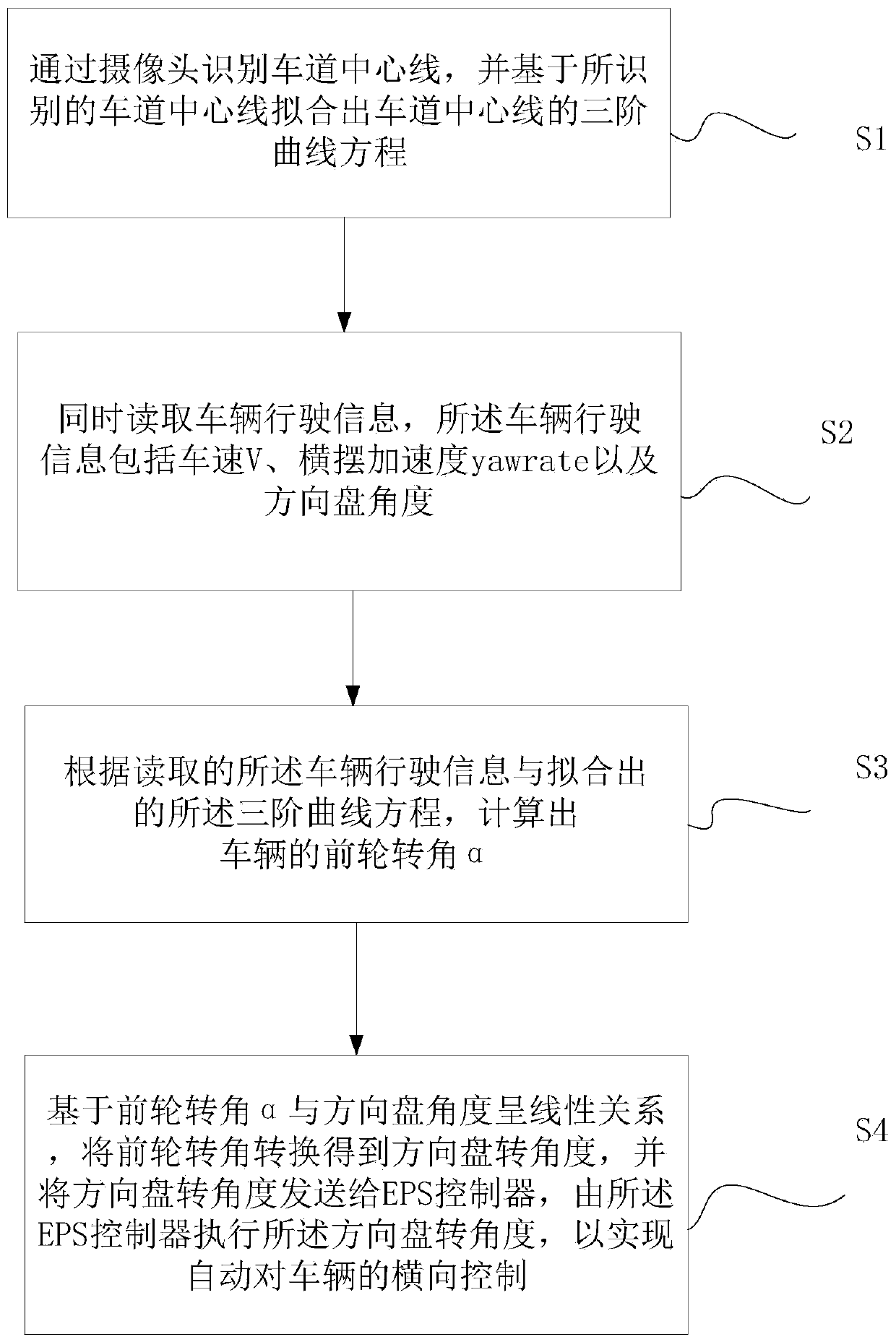

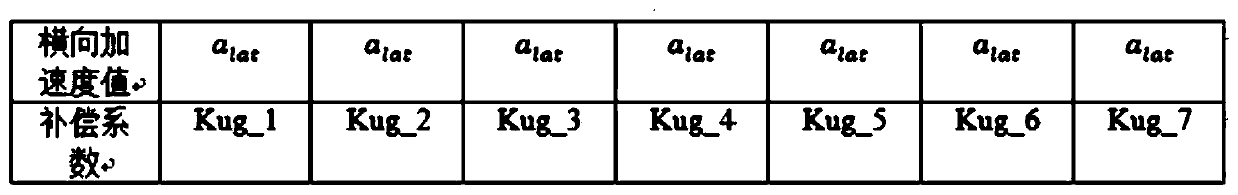

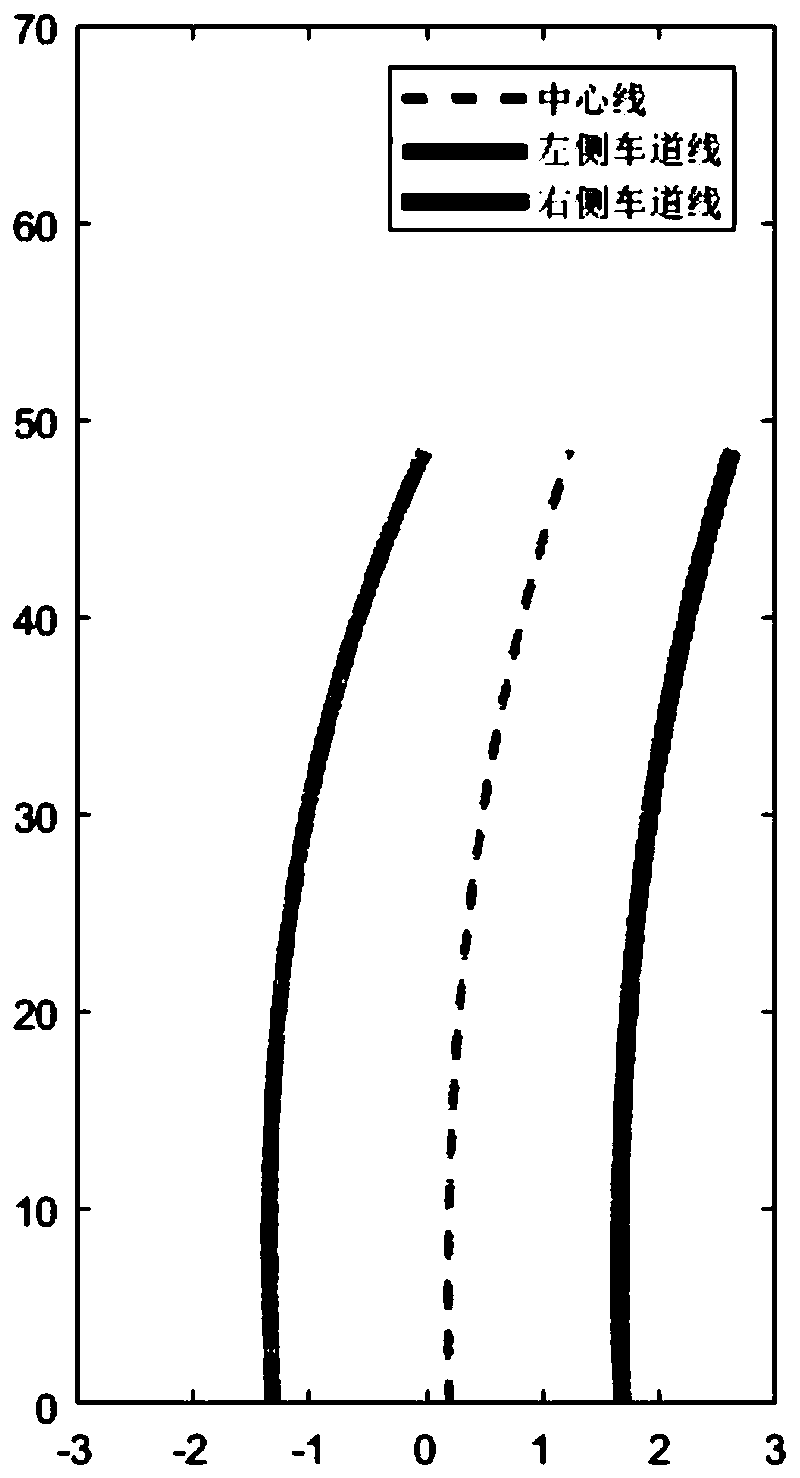

Vehicle automatic driving transverse control method and system

ActiveCN111487971ALateral Control RealizationSimplified lateral control algorithm for autonomous drivingElectric energy managementPosition/course control in two dimensionsSteering wheelVehicle driving

The invention provides a vehicle automatic driving transverse control method and system, and relates to the technical field of automatic driving. The method comprises the steps: recognizing a lane center line through a camera, and fitting a lane center line three-order curve equation; meanwhile, reading vehicle driving information, wherein the vehicle driving information includes a vehicle speed V, a yawing acceleration yawrate and a steering wheel angle; calculating a front wheel turning angle alpha of the vehicle according to the read vehicle driving information and the fitted third-order curve equation; and finally, based on a linear relation between the front wheel rotation angle alpha and the steering wheel angle, acquiring a steering wheel rotation angle beta through conversion, executing the steering wheel rotation angle beta through an EPS controller, and making the vehicle enter an automatic driving state. According to the method, a vehicle automatic driving transverse controlalgorithm is simplified, complex calculation can be completed without too many calibration parameters and through using a small calculation memory, production cost is reduced, meanwhile, adaptation to multiple vehicle models can be rapidly ensured, and an application range is widened.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

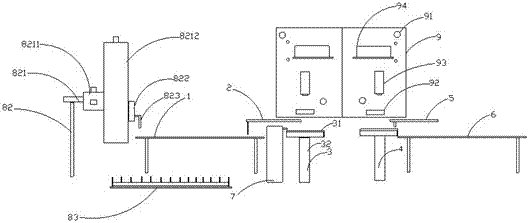

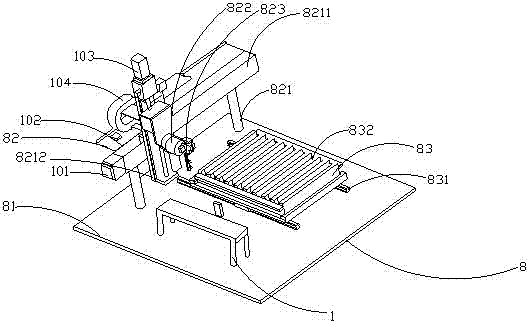

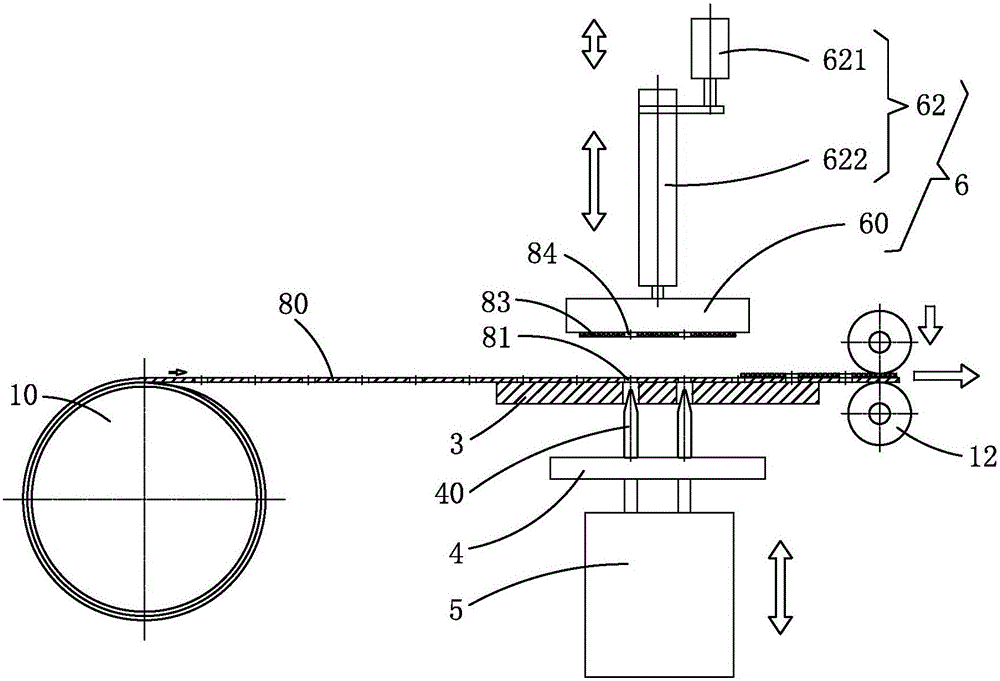

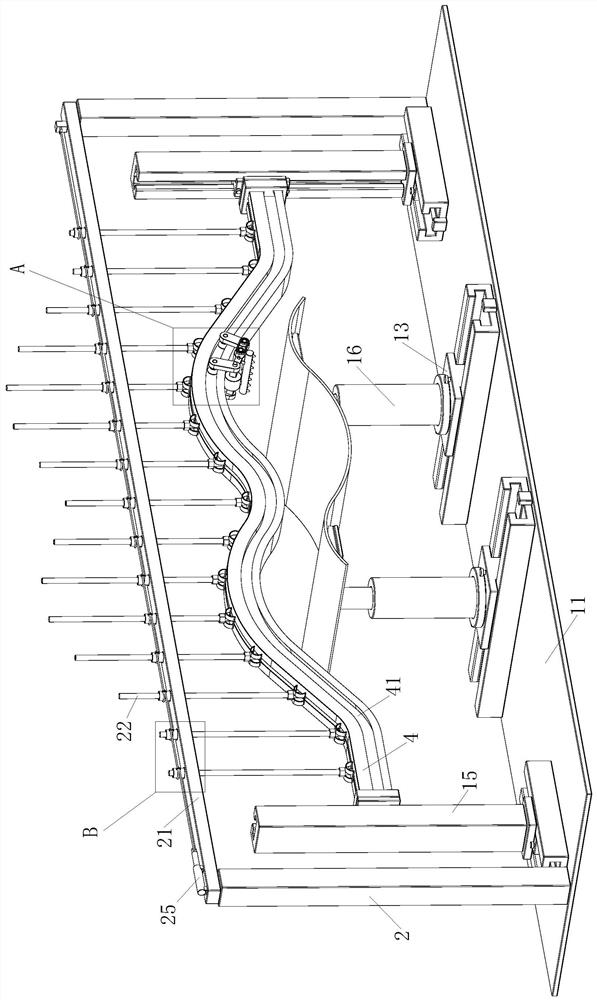

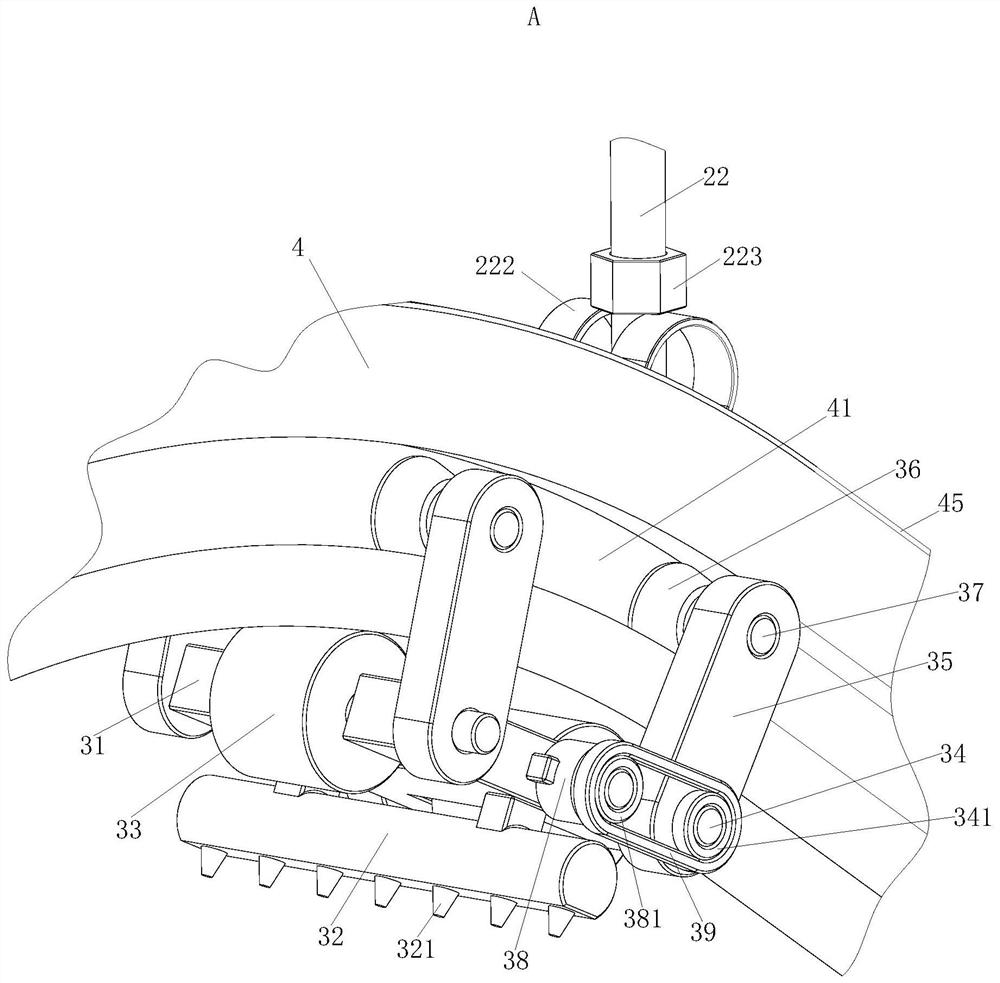

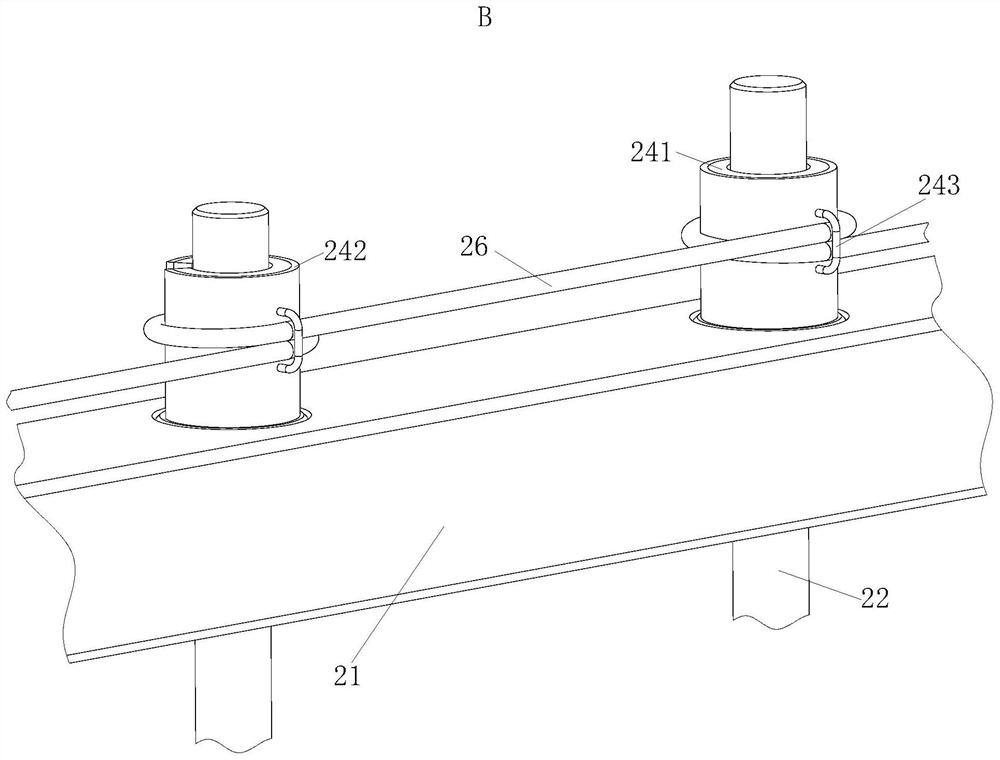

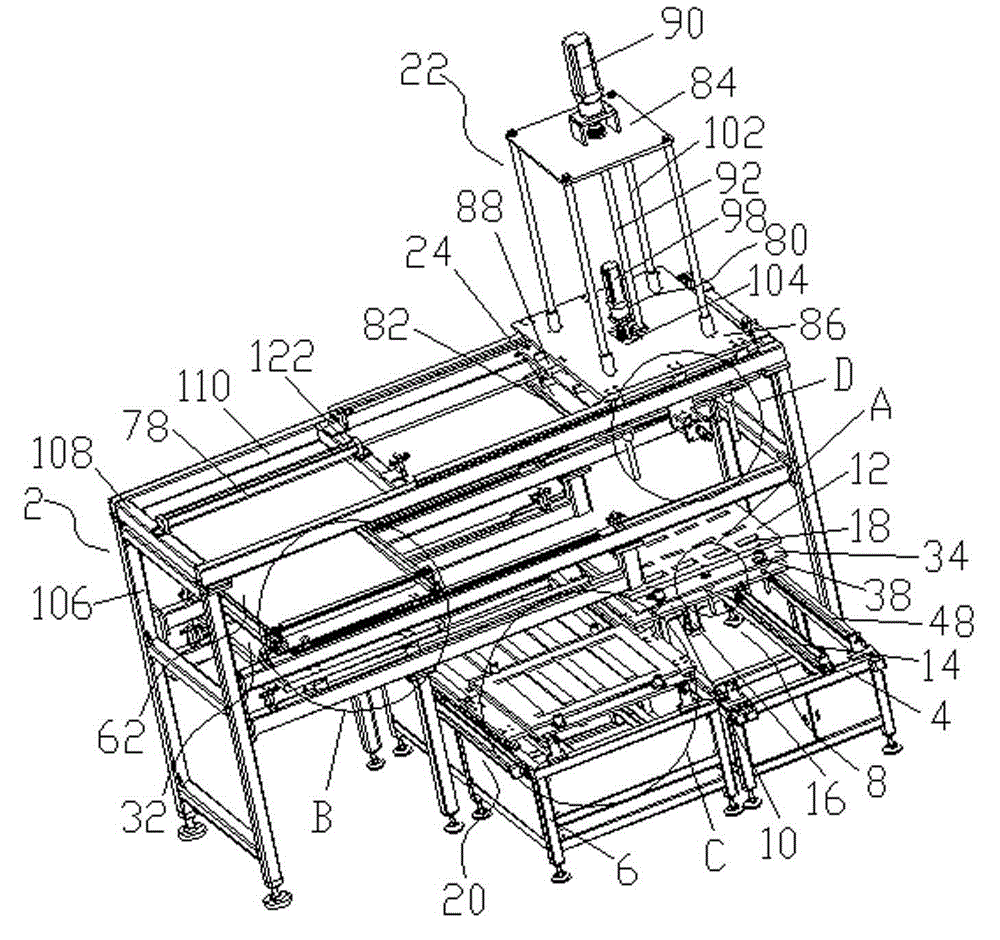

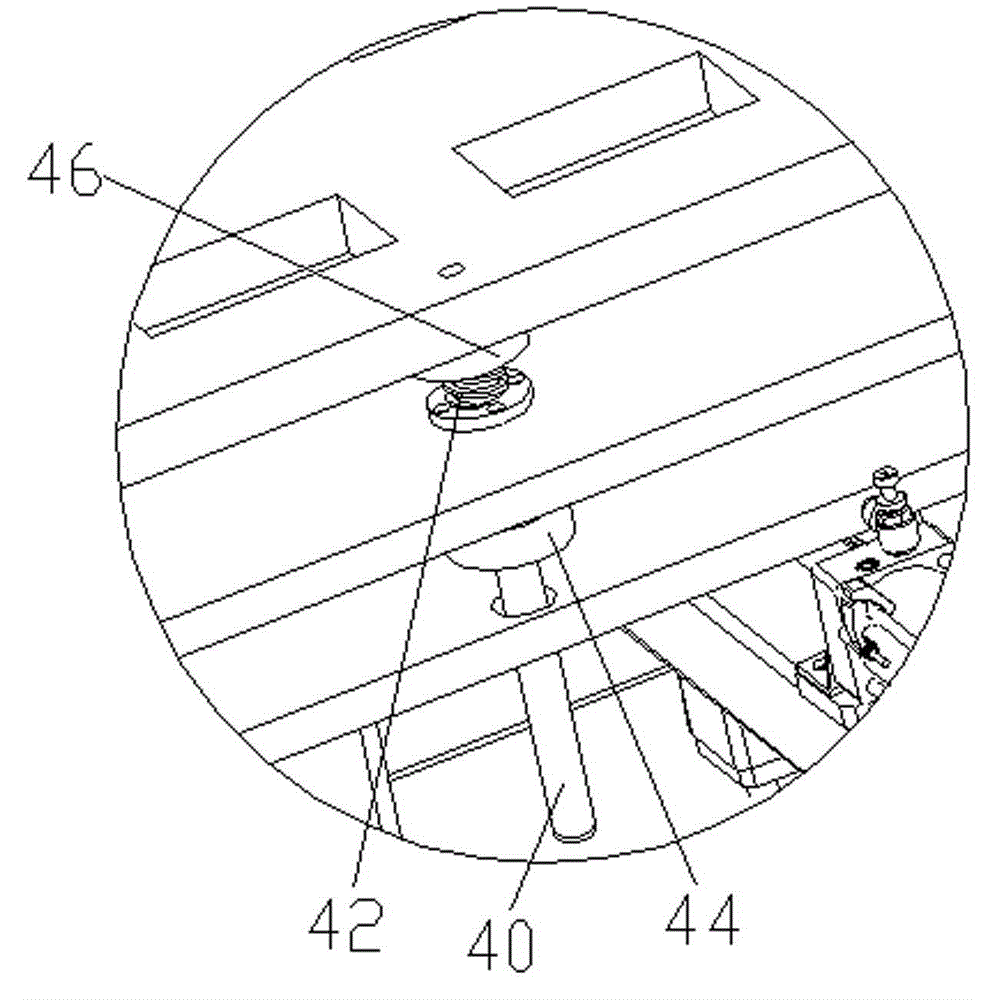

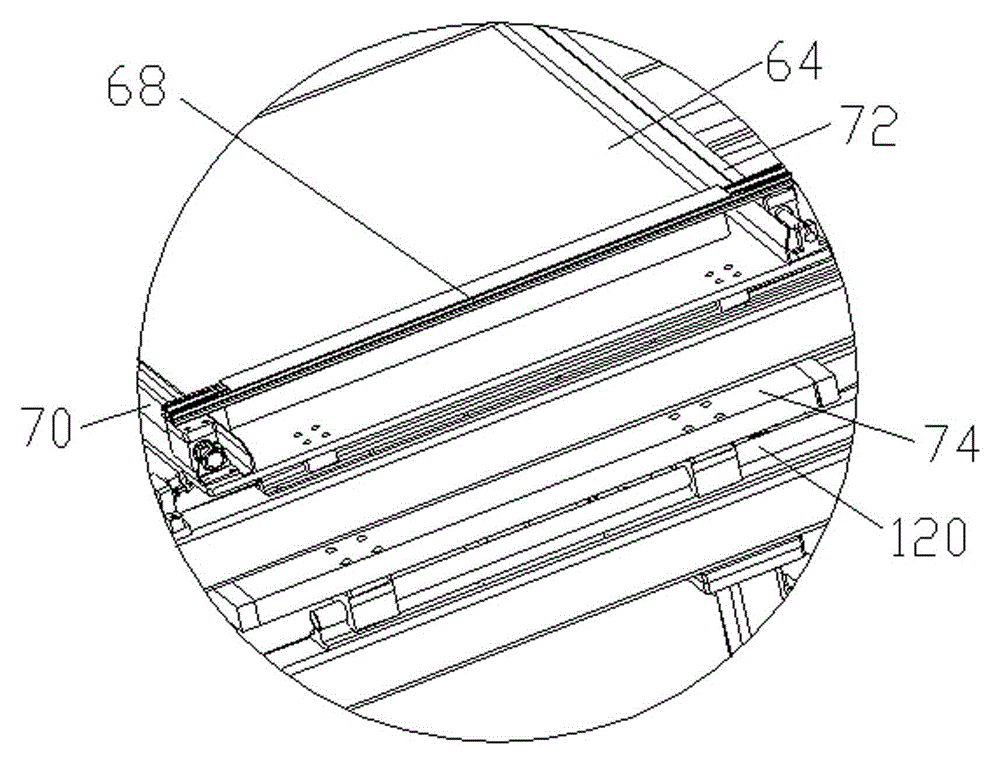

Full-automatic LCD glass surface mounting machine

The invention relates to a surface mounting machine, and discloses a full-automatic LCD glass surface mounting machine. The full-automatic LCD glass surface mounting machine is provided with a servo motor and a PLC and successively comprises a loading device, a first transmission belt, a glass feeding device, a first surface mounting platform, a first surface mounting machine, a second surface mounting platform, a second surface mounting machine, a transport adsorption device and a second transmission belt according to a passing-through sequence of glass chips; the particular running process of full-automatic LCD glass surface mounting machine includes the steps that the loading device transports the glass chips to the first transmission belt, the glass feeding device transports the glass chips to the first surface mounting platform, the first surface mounting platform completes the surface mounting and transports the glass chips to the second surface mounting platform, and the second surface mounting platform completes the surface mounting and transports the glass chips to the second transmission belt through the transport adsorption device. According to the full-automatic LCD glass surface mounting machine, the PLC is adopted to take control, and the accurate and rapid attachment between base chips and substrates is achieved through the servo motor, ball screws, a linear guide rail, an auxiliary pneumatic system, a vision sensor and a mechanical positioning device; the full-automatic LCD glass surface mounting machine is safe and reliable in running, convenient to operate, accurate in positioning and high in attachment accuracy, and the production efficiency is greatly improved.

Owner:株洲晶彩电子科技有限公司

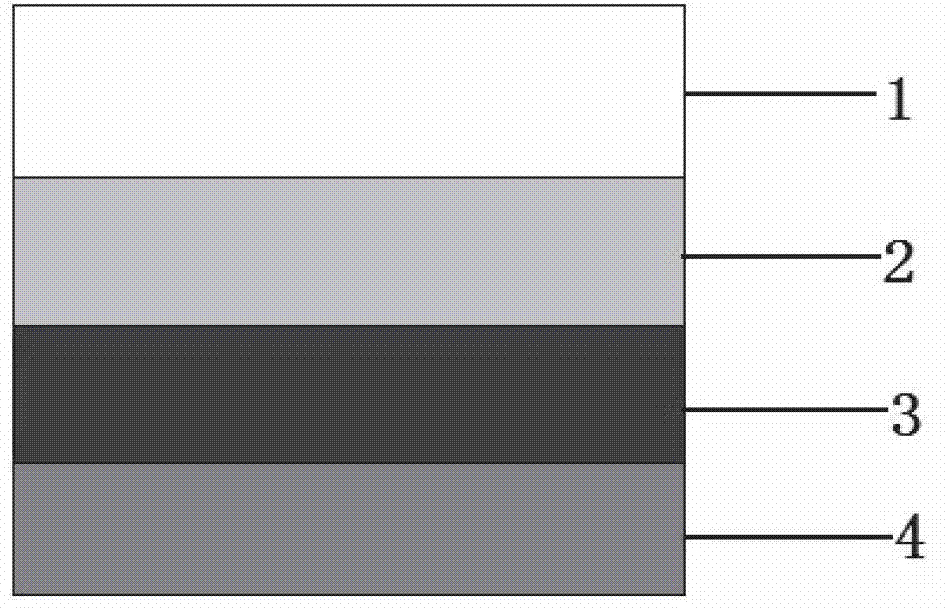

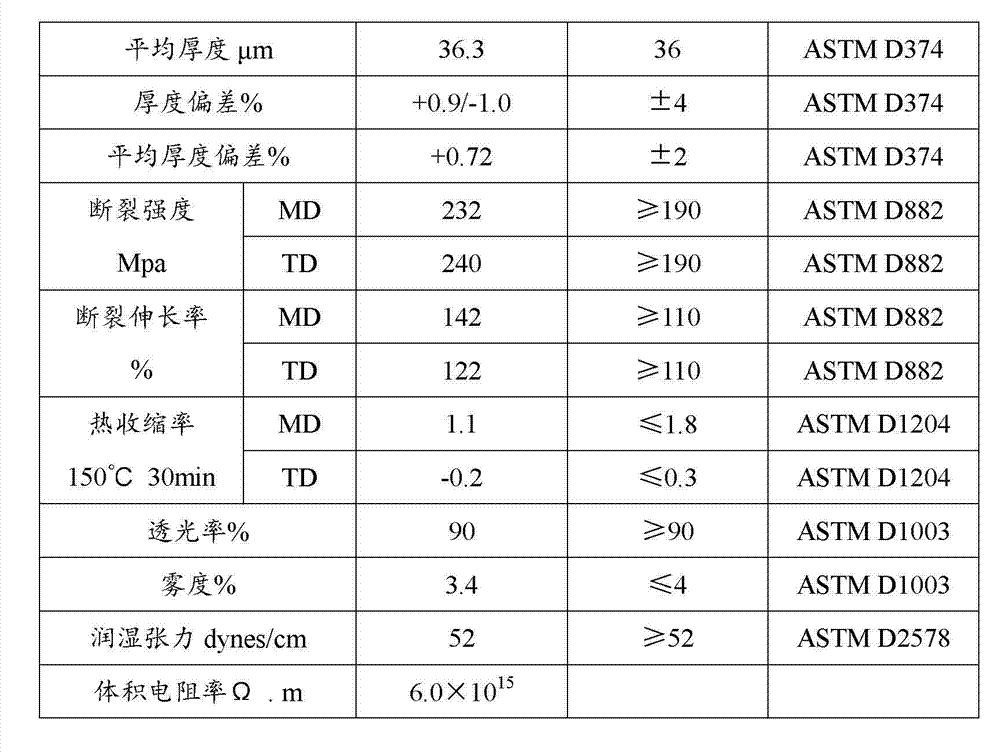

Anti-static self-exhaust protection adhesive tape and preparation method thereof

ActiveCN103589351AImprove antistatic performanceImprove thermal stabilityFilm/foil adhesivesPolyurea/polyurethane coatingsAdhesiveStatic performance

The invention provides an anti-static self-exhaust protection adhesive tape and a preparation method thereof. The anti-static self-exhaust protection adhesive tape successively comprises a base material (1), an adhesive layer (3) and a release film (4); and an anti-static layer (2) is arranged between the base material (1) and the adhesive layer (3). The anti-static self-exhaust protection adhesive tape possesses excellent anti-static performance, the anti-static performance also possesses excellent thermal stability, a defect of pollution caused by transference of ionic additives onto the surface of the anti-static self-exhaust protection adhesive tape is avoided, quick attachment can be realized when the anti-static self-exhaust protection adhesive tape is contacted with the surface of glass or a mirror plane, and the anti-static self-exhaust protection adhesive tape possesses self-exhaust performance.

Owner:SHENZHEN MOMA TECH CO LTD

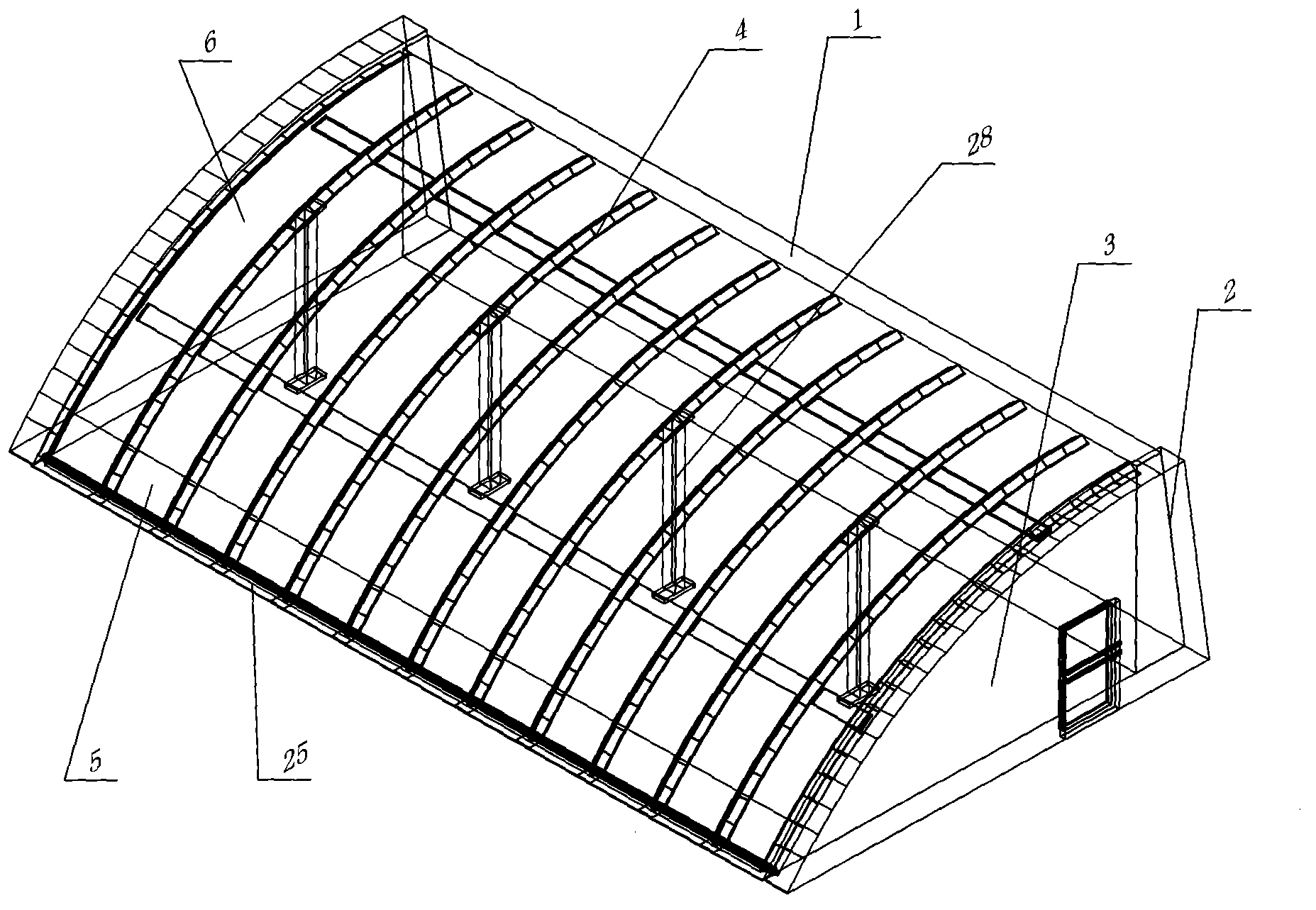

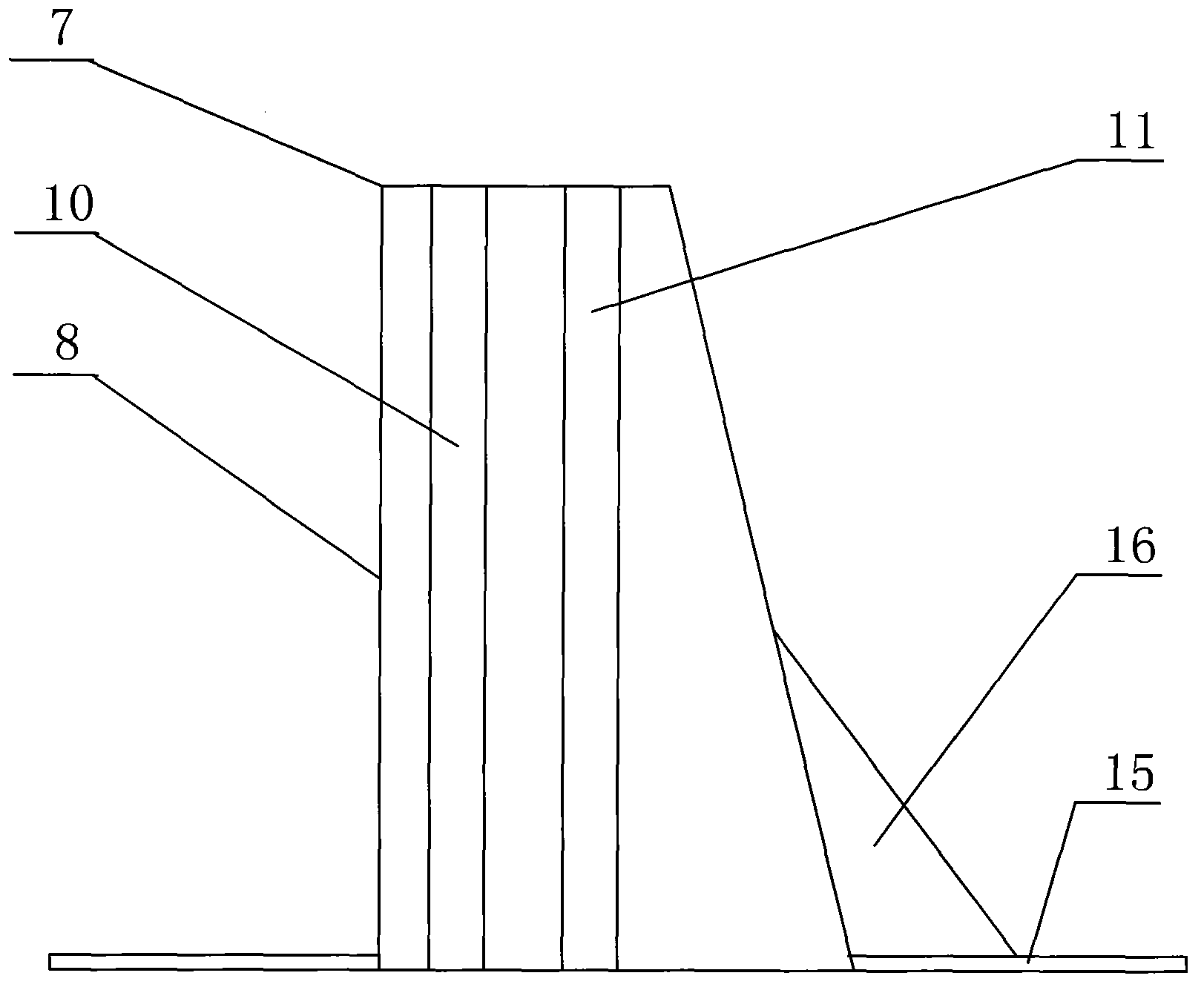

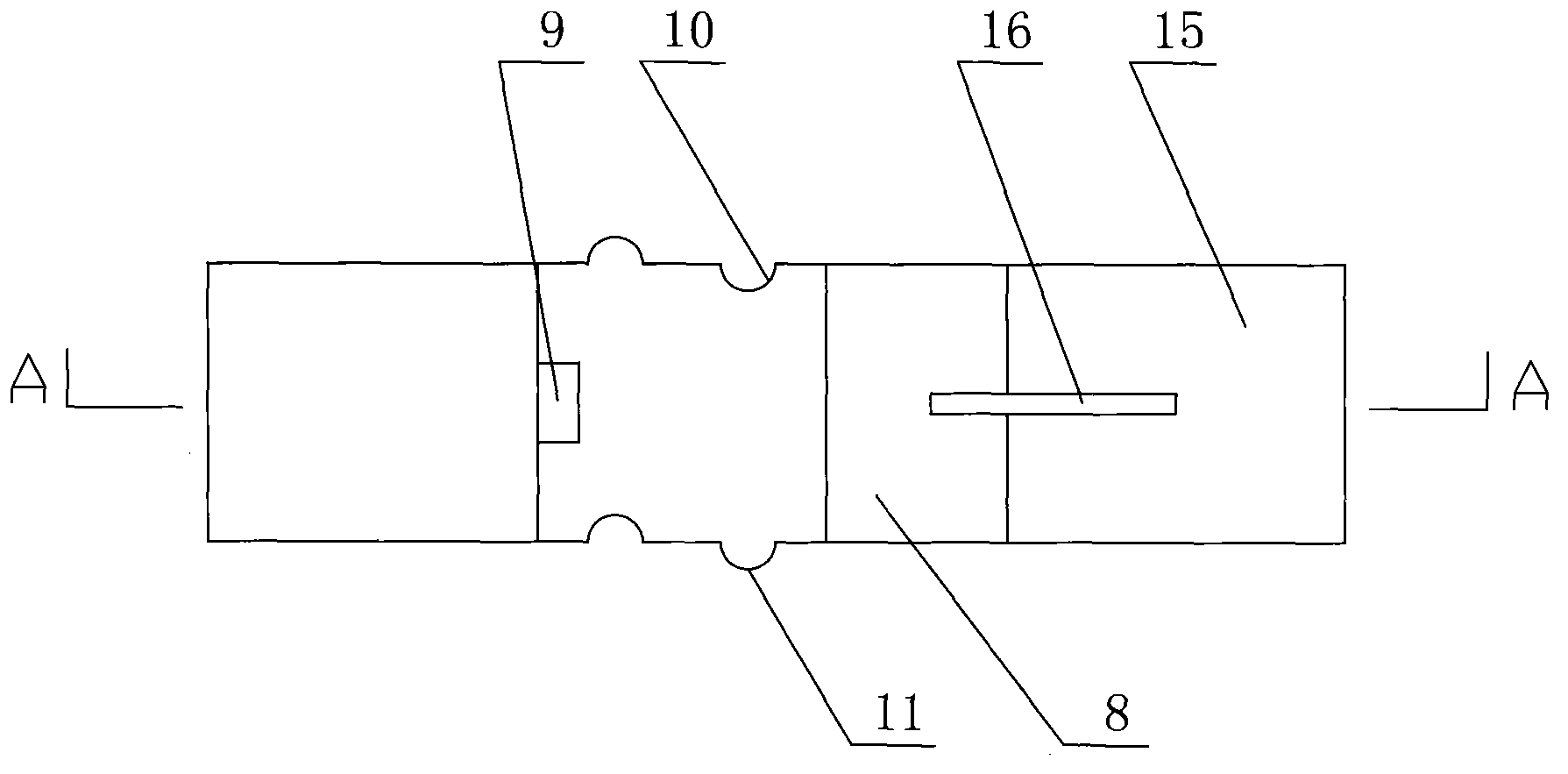

Quick-mounting combined type greenhouse

InactiveCN103299860AHigh speedImprove storm resistanceClimate change adaptationGreenhouse cultivationGreenhouseStructural engineering

The invention discloses a quick-mounting combined type greenhouse which comprises a back wall, corner walls, gable walls, arched girders and lighting boards, wherein the gable walls are arranged on two sides of the back wall, the top surfaces of the gable walls are arched surfaces raising gradually from one end to the other end, the two ends of the back wall are fixedly connected with the back wall through the corner walls, a plurality of arched girders are arranged between the two gable walls in an alternative manner, the upper ends of the arched girders are fixedly connected with the top of the back wall, the lower ends of the arched girders are embedded into the foundation, one lighting board is arranged between every two adjacent arched girders, the two side edges of each lighting board are inserted into the two adjacent arched girders, and one lighting board is arranged between one arched girder and one gable wall. The quick-mounting combined type greenhouse provided by the invention has the advantages that the greenhouse is quick-mounting, detachable and movable, has overall stability and strong weatherliness, and is good in heat preservation effect, low in building cost, and long in service life.

Owner:那顺套格套

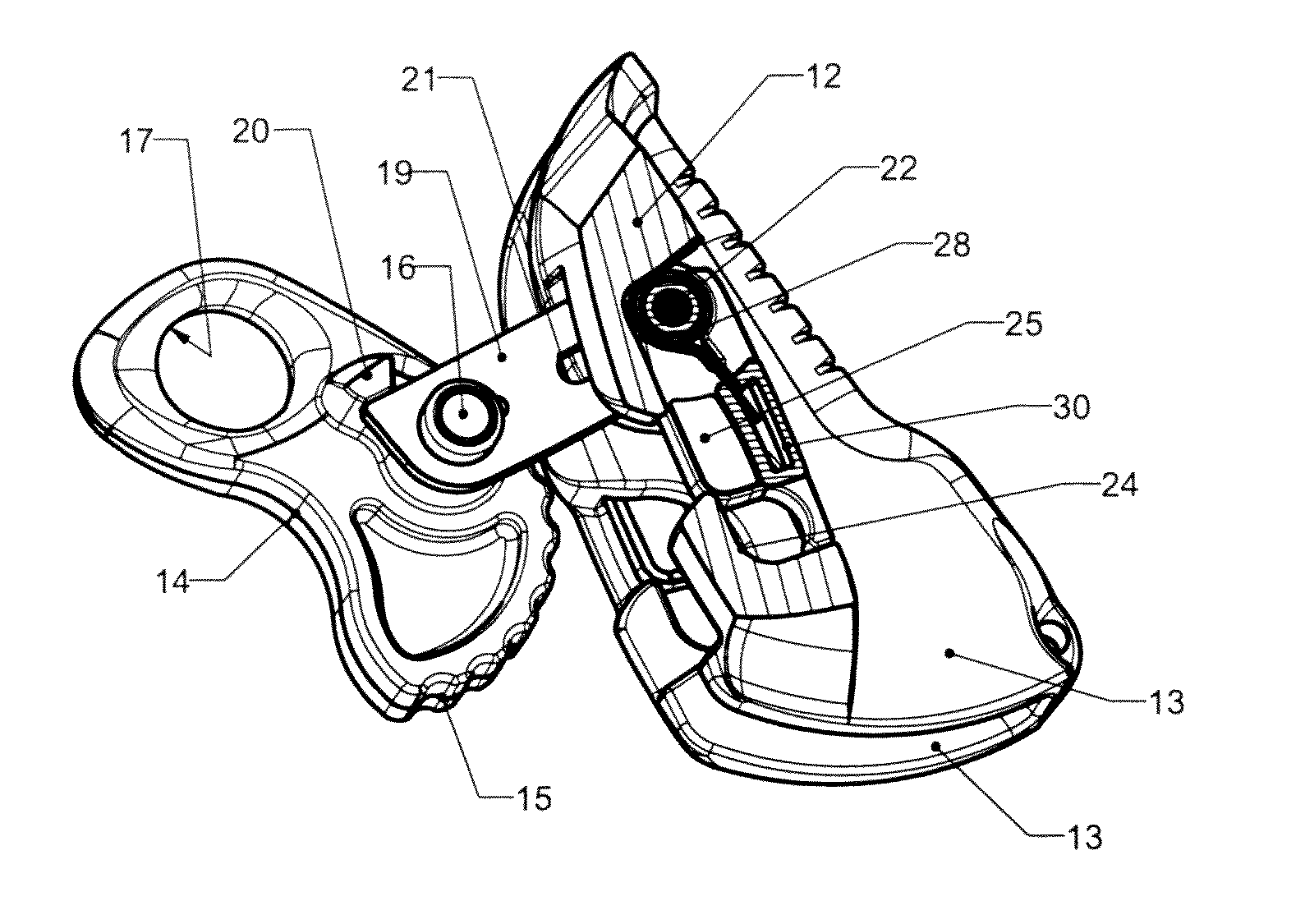

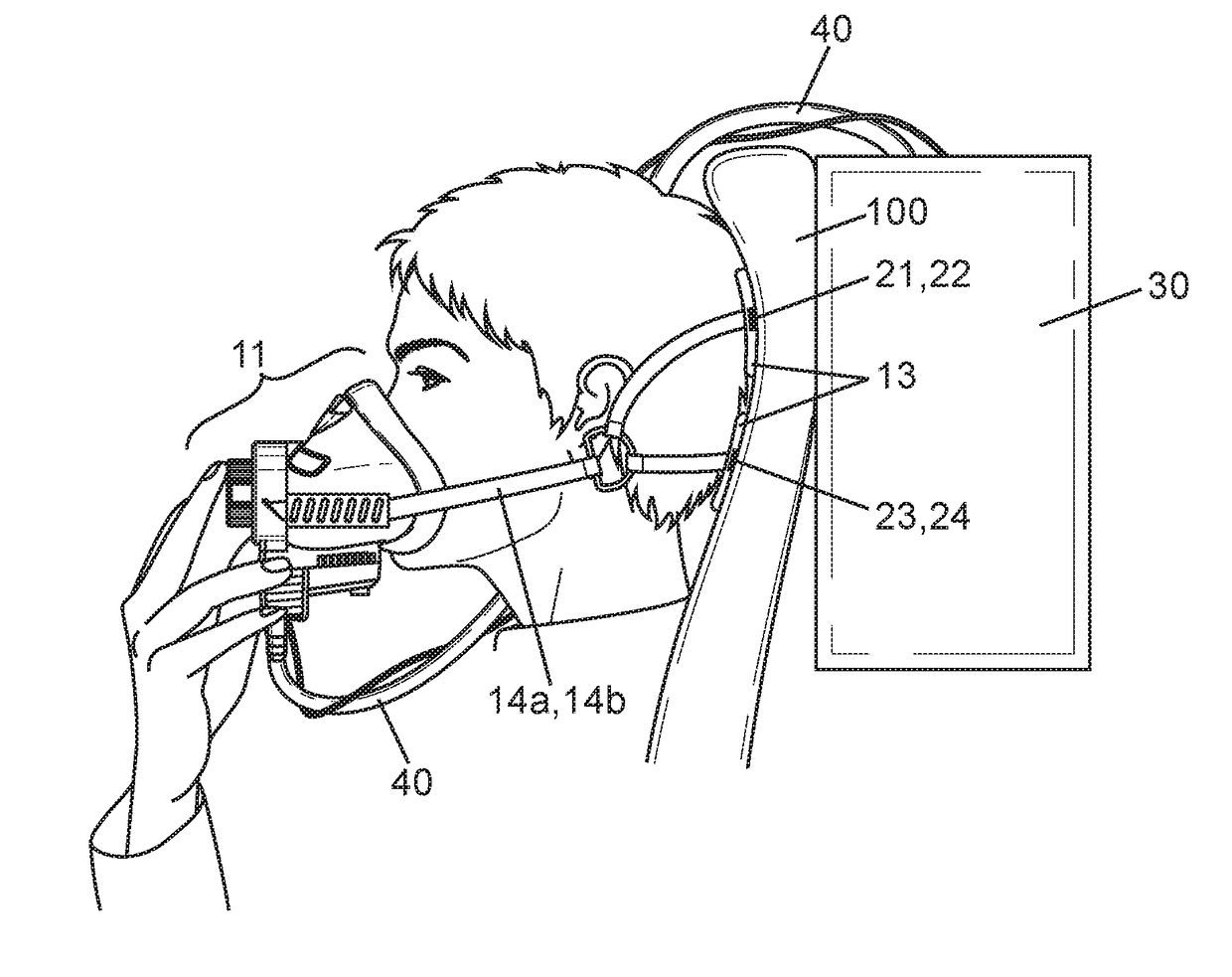

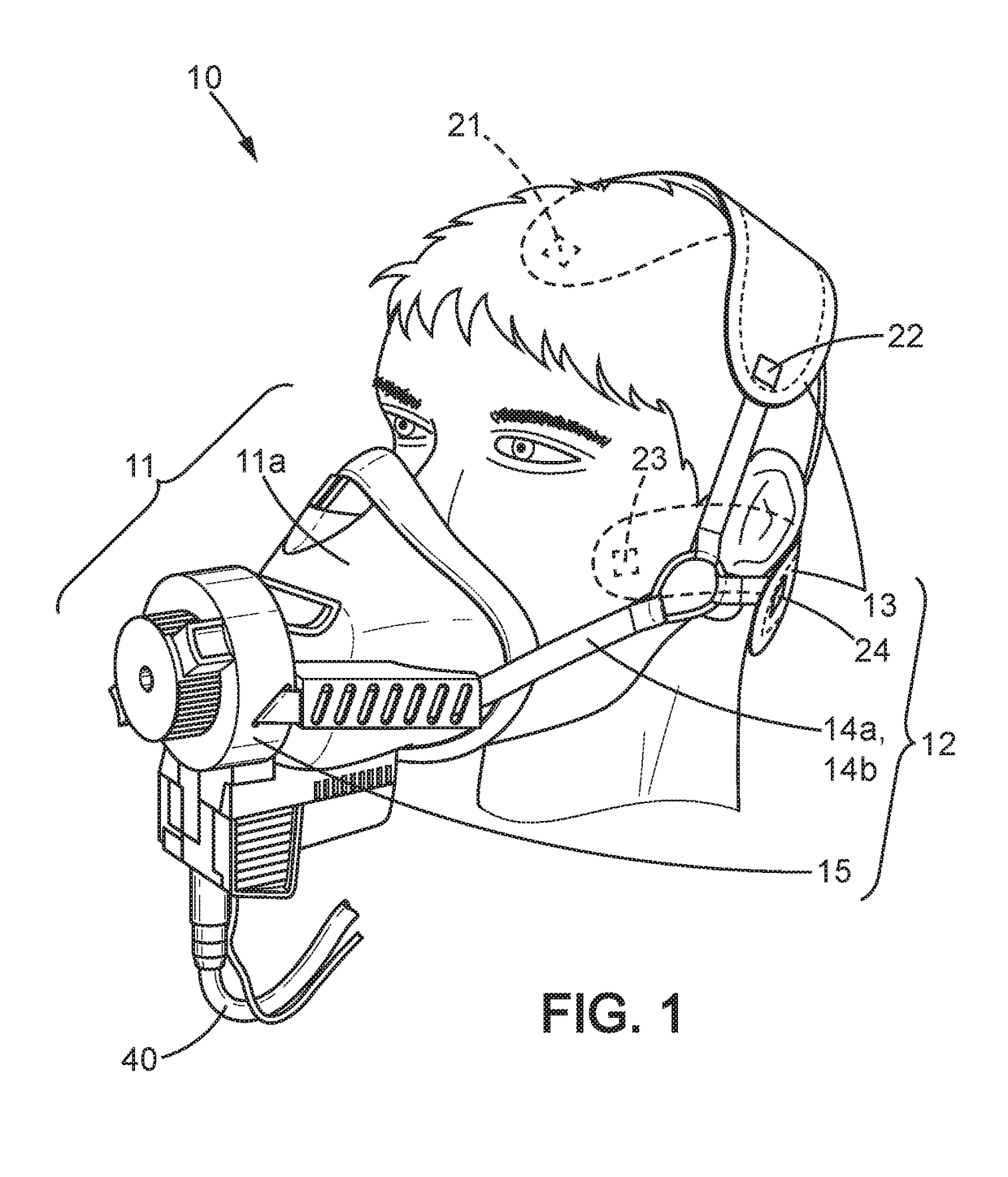

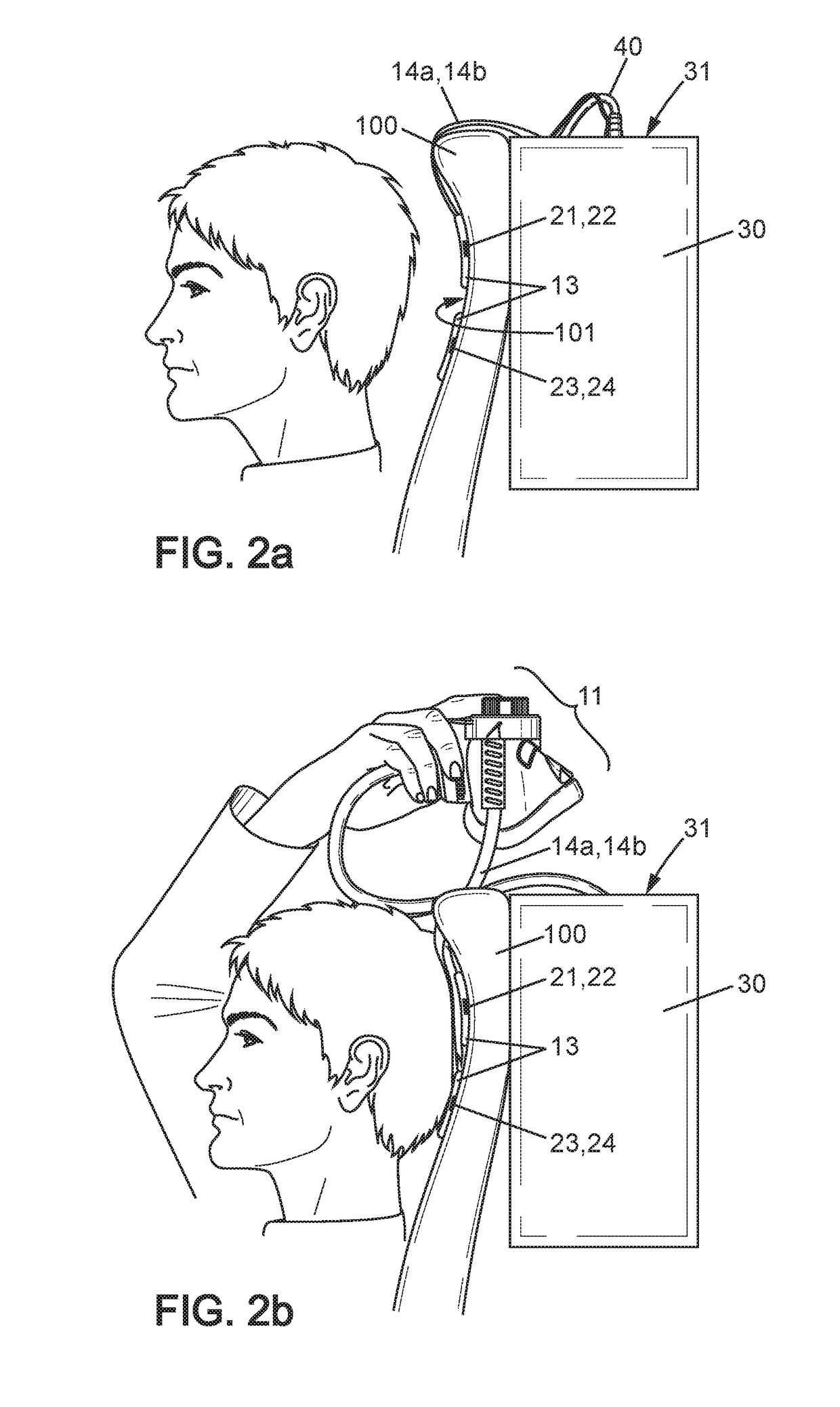

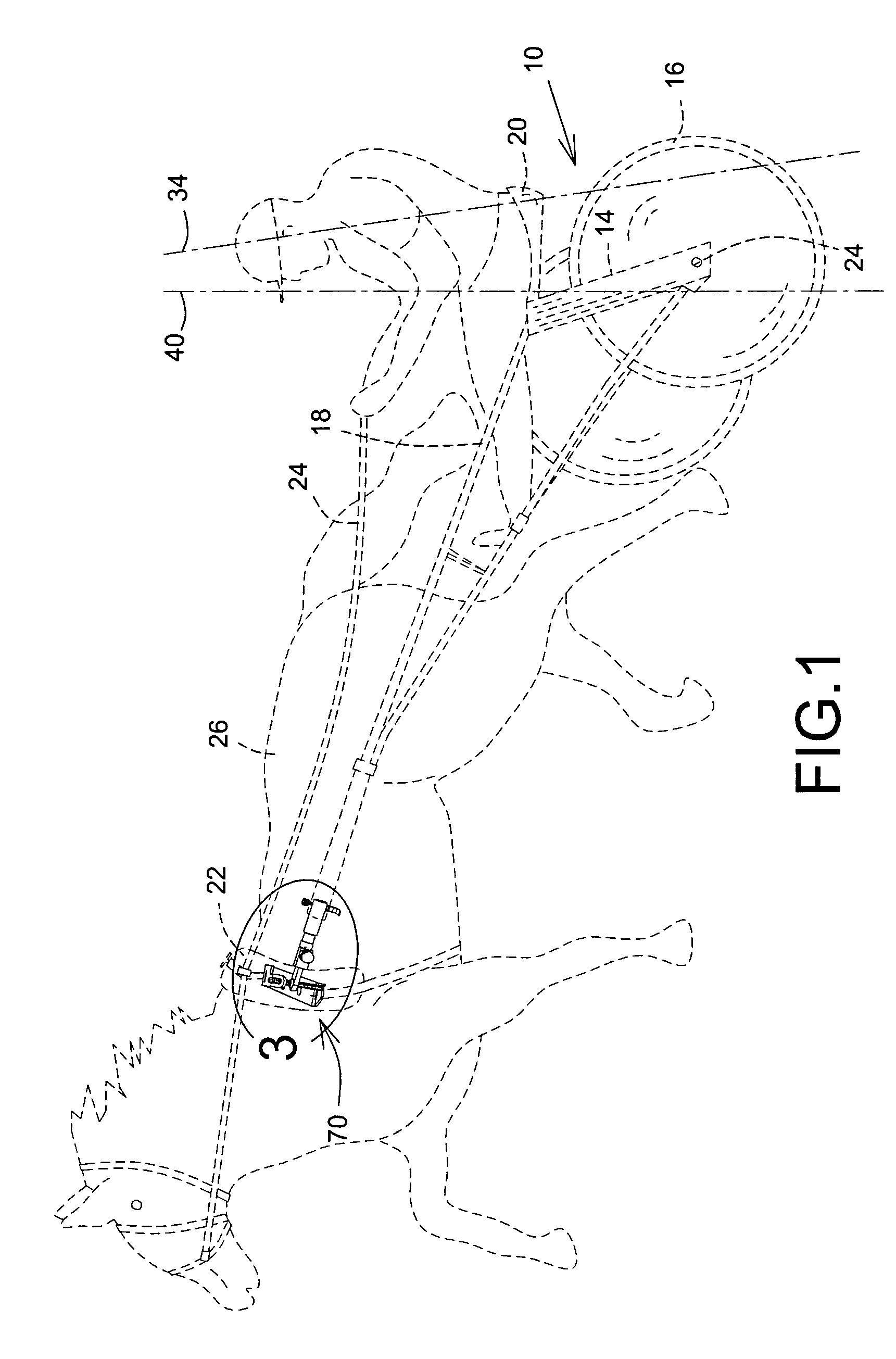

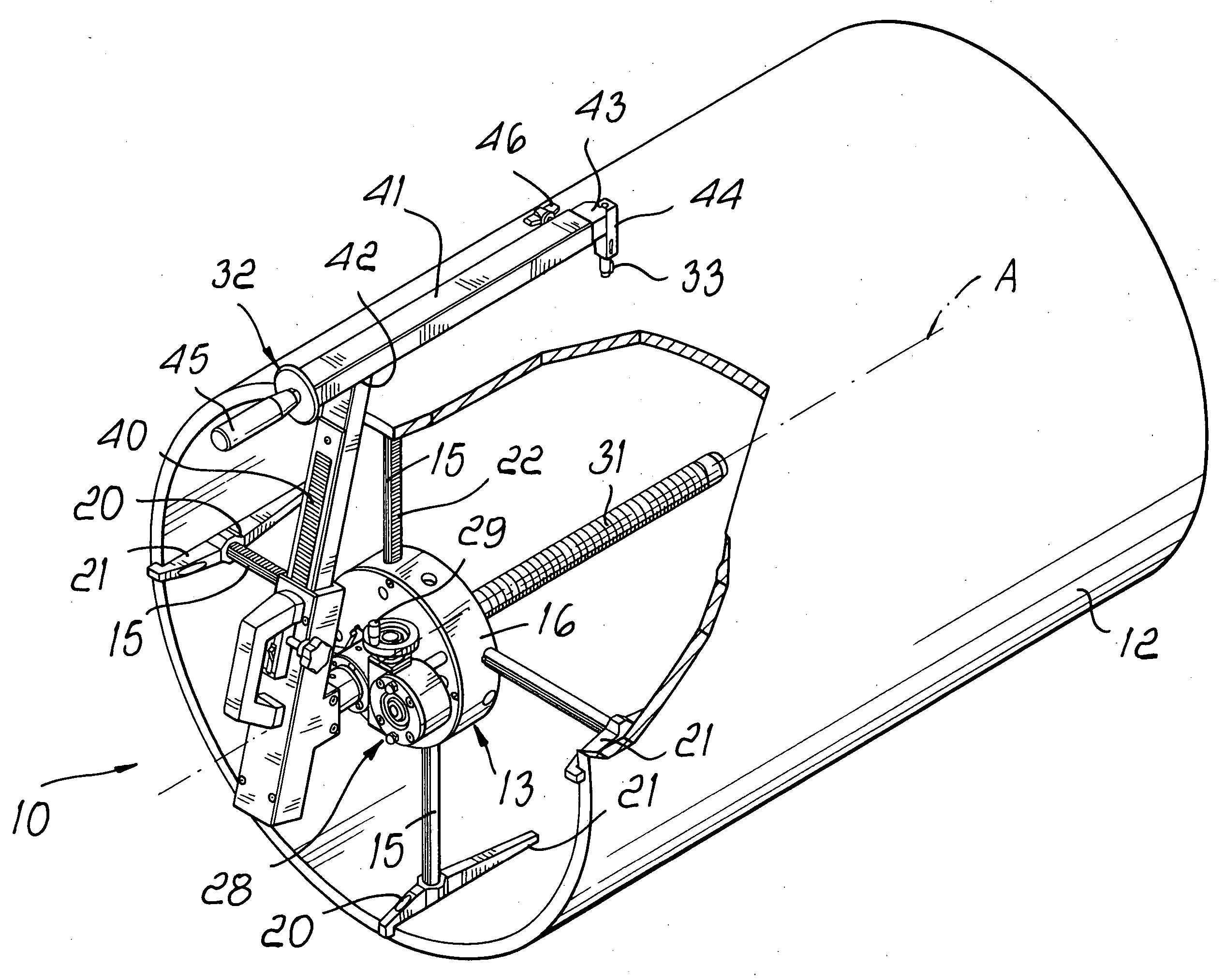

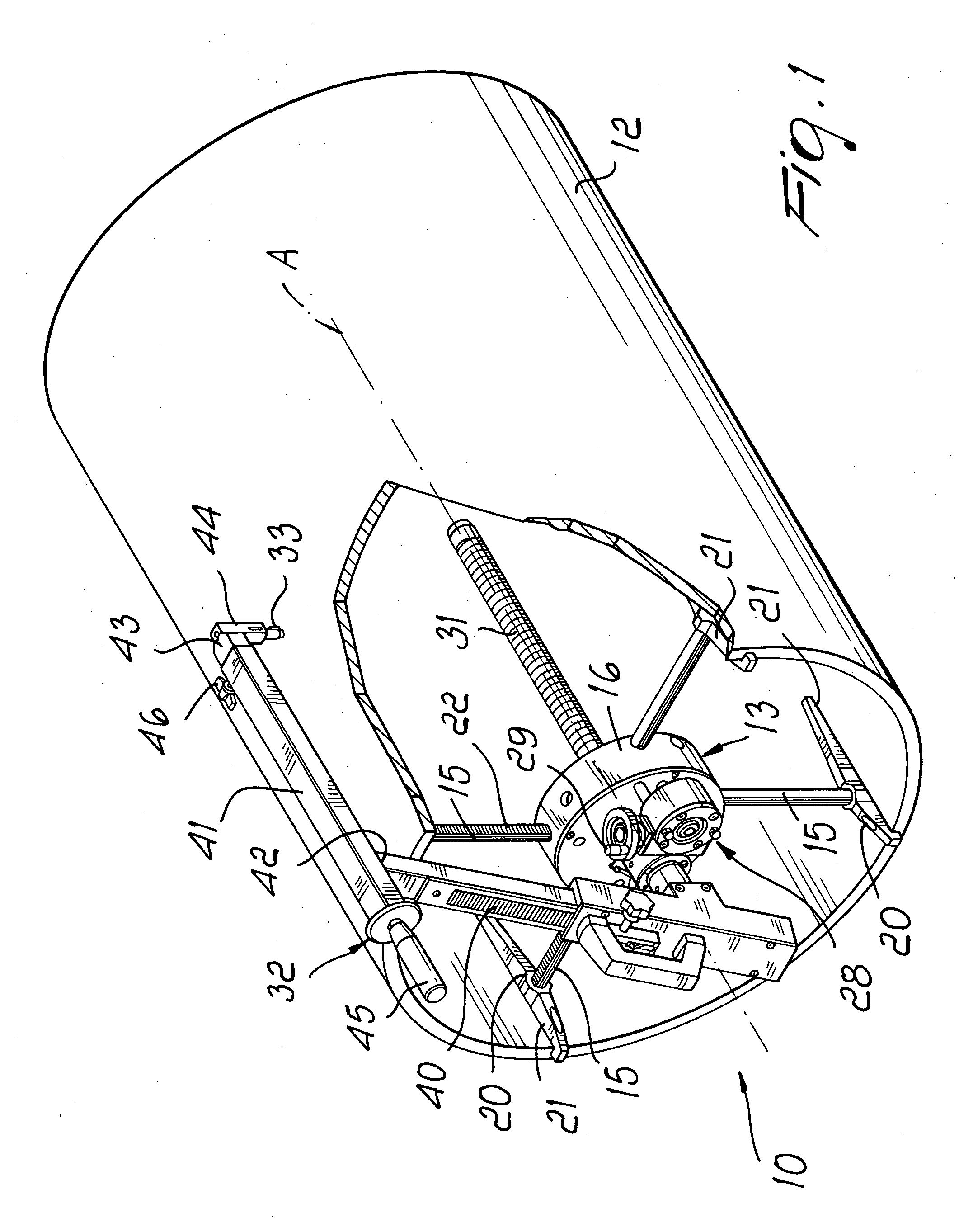

Breathing system and seat for aircraft crew member or passenger

ActiveUS20170136269A1Easy to operateAvoid reverse motionRespiratory device storageBreathing masksEmbedded systemAirplane

A breathing system for an aircraft crew member or passenger comprises a face-fitting device (11), storage means added to a seat headrest (100) for retaining the face-fitting device in a storage position apart from the head, and a back portion (13) for retaining the face-fitting device on the user's head when the breathing system is used. The back portion is retained on the headrest by removable fixing means (21-24) when the face-fitting device is in the storage position, and said removable fixing means are released upon tightening the face-fitting device on the user's head.

Owner:SAFRAN AEROTECHNICS

Method for preparing individual integrally implantable auricular cartilage support by fast veneer gluing

ActiveCN103040545ANatural colorIncrease temperatureProsthesisTwo-dimensional graphAuricular cartilage

The invention relates to a method for preparing an individual integrally implantable auricular cartilage support by fast veneer gluing. An auricle reconstructed by an existing method is greatly different from an original ear in appearance or color, and wearing effects are affected. The method includes the steps: firstly, acquiring a slab image of the appearance of a reference auricle and extracting a cartilage contour; secondly, acquiring a three-dimensional solid model of an auricular cartilage; thirdly, additionally arranging a support capable of stably fitting a skeleton and ensuring a correct angle of a repaired auricle; fourthly, additionally arranging a drainage duct; fifthly, layering the acquired three-dimensional solid model to obtain two-dimensional graphs of layers and inputting the two-dimensional graphs to a fast forming machine; and finally, performing layered accumulation or layer-by-layer cutting by the fast forming machine to obtain the auricular cartilage support. The artificial auricular cartilage support prepared by the method is subcutaneously implanted, so that the vivid auricle symmetric to a healthy auricle can be obtained.

Owner:HANGZHOU DIANZI UNIV

Double pulley device for use for Tyrolean traversing on a rope or cable

A double pulley device comprises a pair of sheaves arranged in line inside a reverse U-shaped metal support flange-plate, each sheave being mounted rotating free on a fixed spindle of the flange-plate. At least one orifice for the passage of a snap-hook, is situated between the two spindles of the sheaves, so that the fixing point of the snap-hook is positioned above the point of contact of the sheaves with the cable. One of the wings of the flange-plate is arranged to enable the mobile finger of the snap-hook to be opened when the double pulley device is fitted onto the cable.

Owner:ZEDEL CORP

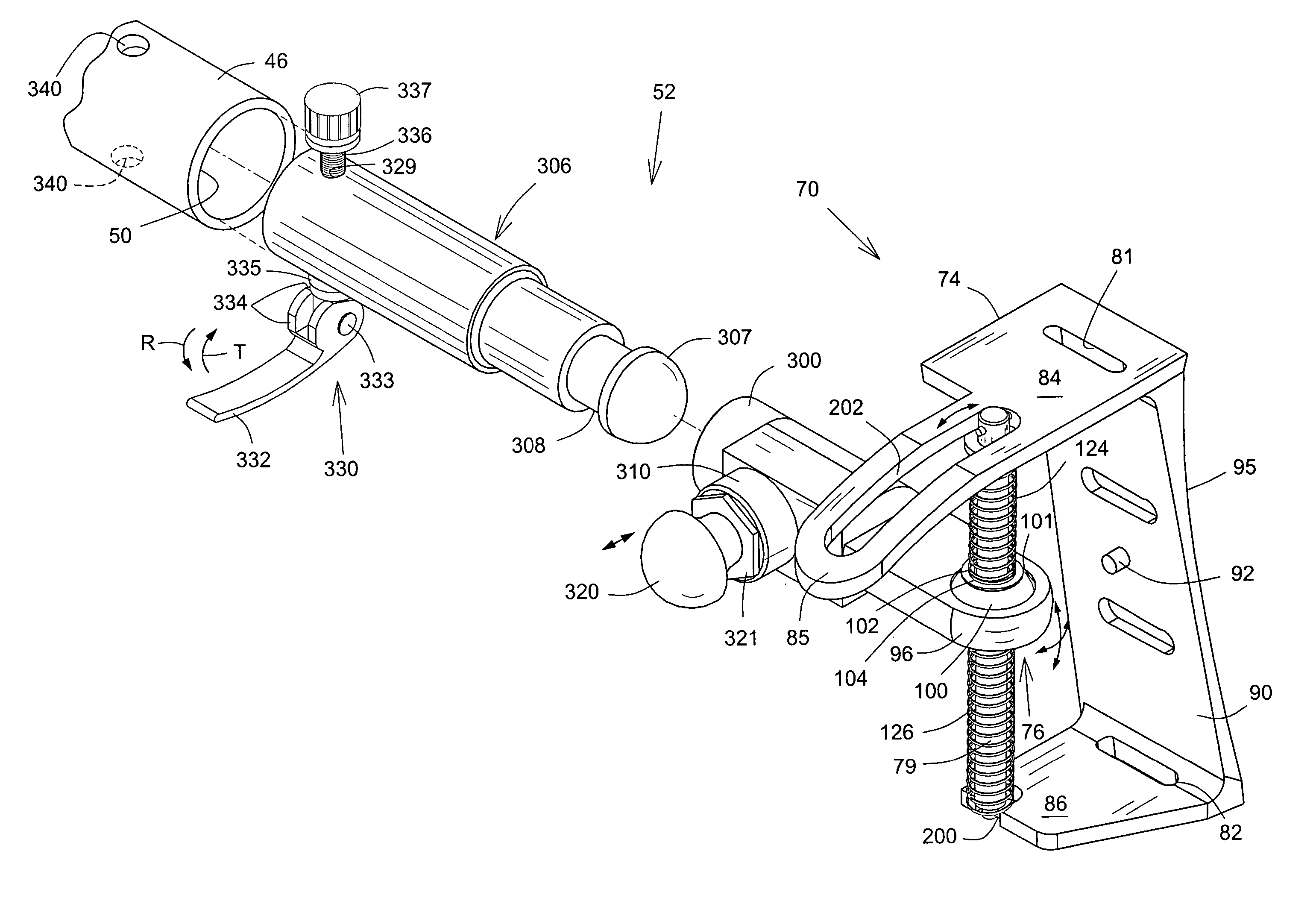

Sulky shaft connector device

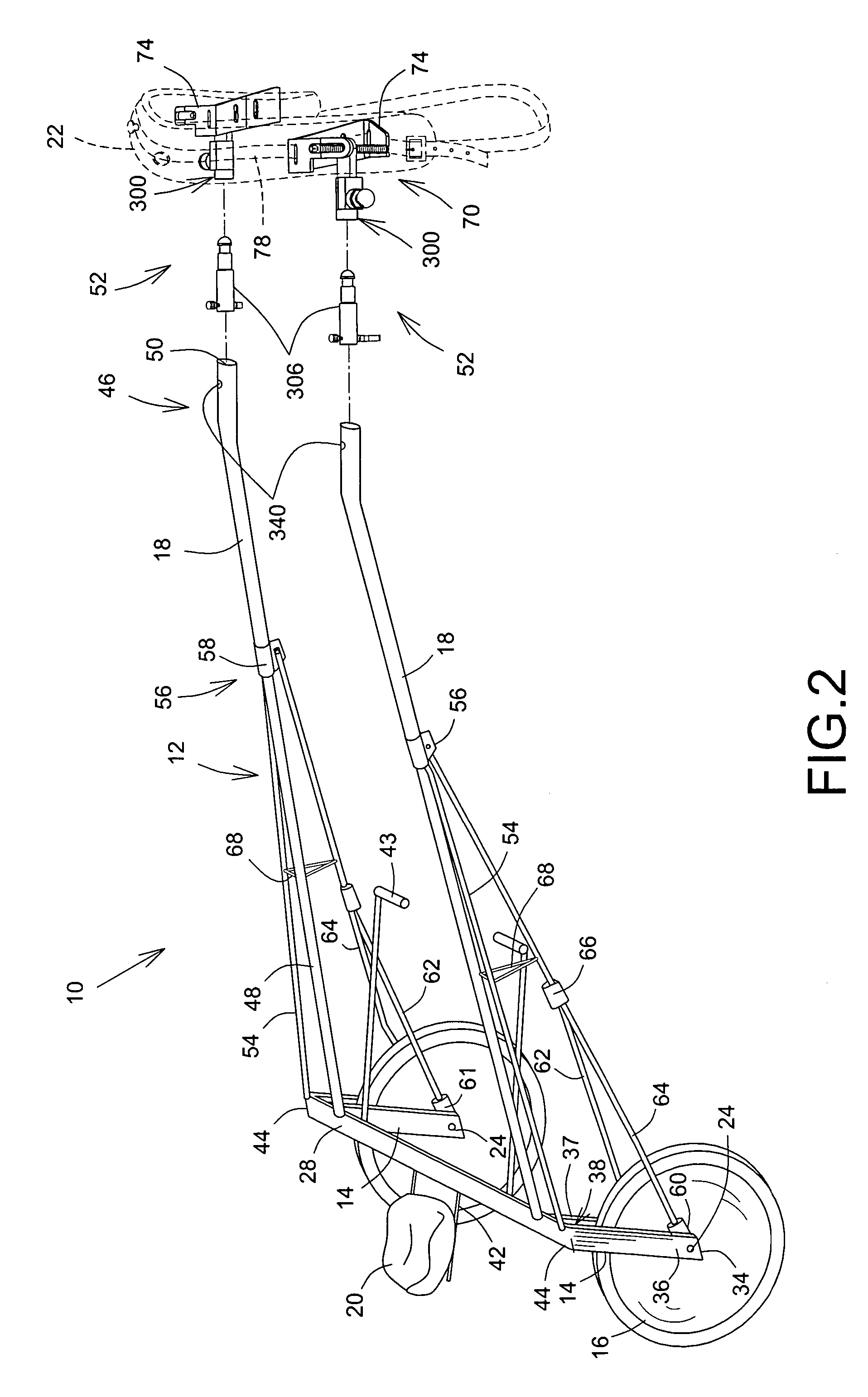

InactiveUS7487980B2Fit fastEasy to disassembleCarriage/perambulator with single axisDraught assembliesEngineeringBall joint

A sulky shaft connector device includes a swivel ball joint arrangement whereby the sulky shaft is allowed relative damped vertical movement with respect to the harness. A sulky shaft connector member, removably connected to the sulky shaft, forming part of the device also provides for quick and releasable engagement between the sulky shaft and the sulky shaft connector device.

Owner:GODDARD RON +3

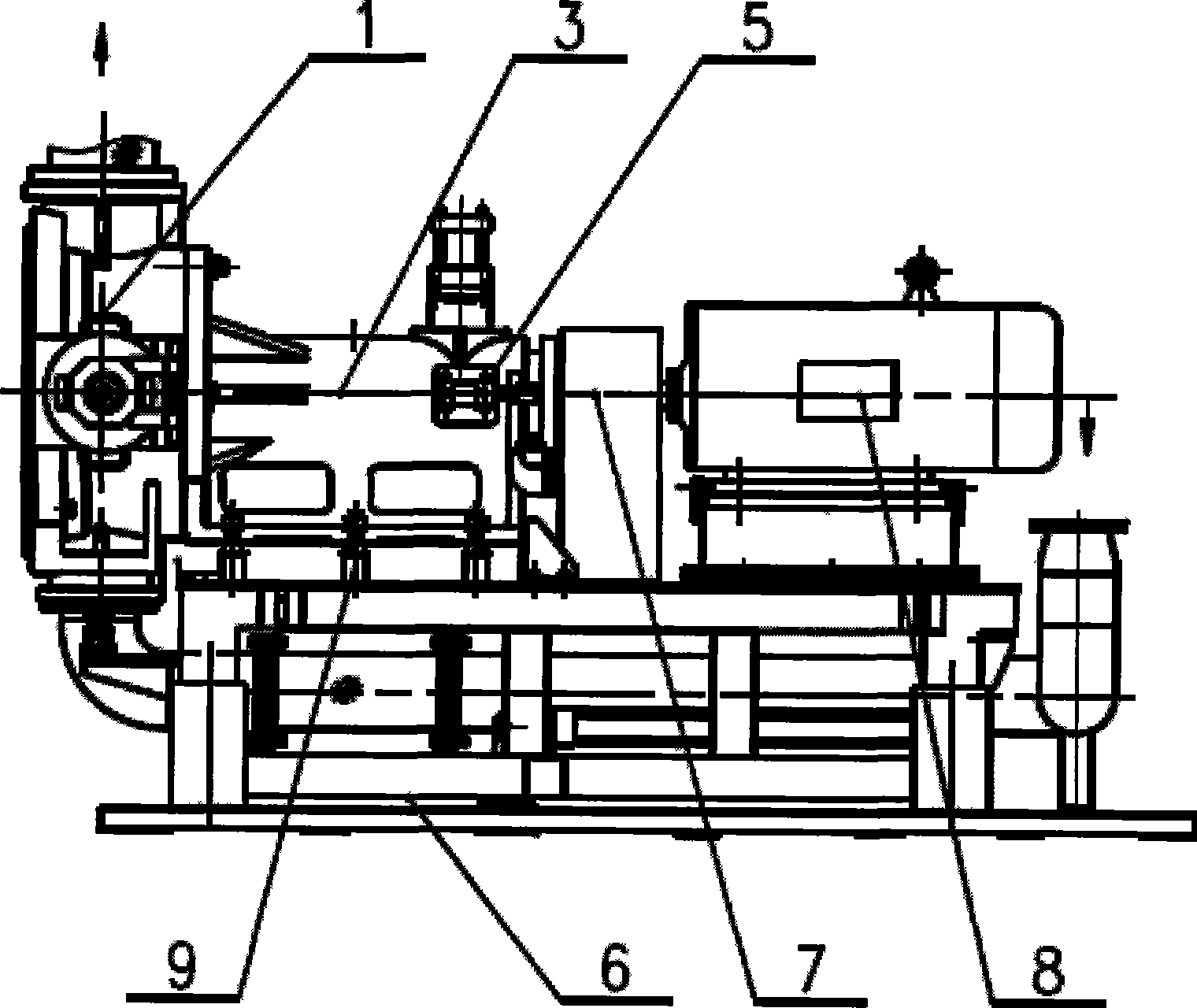

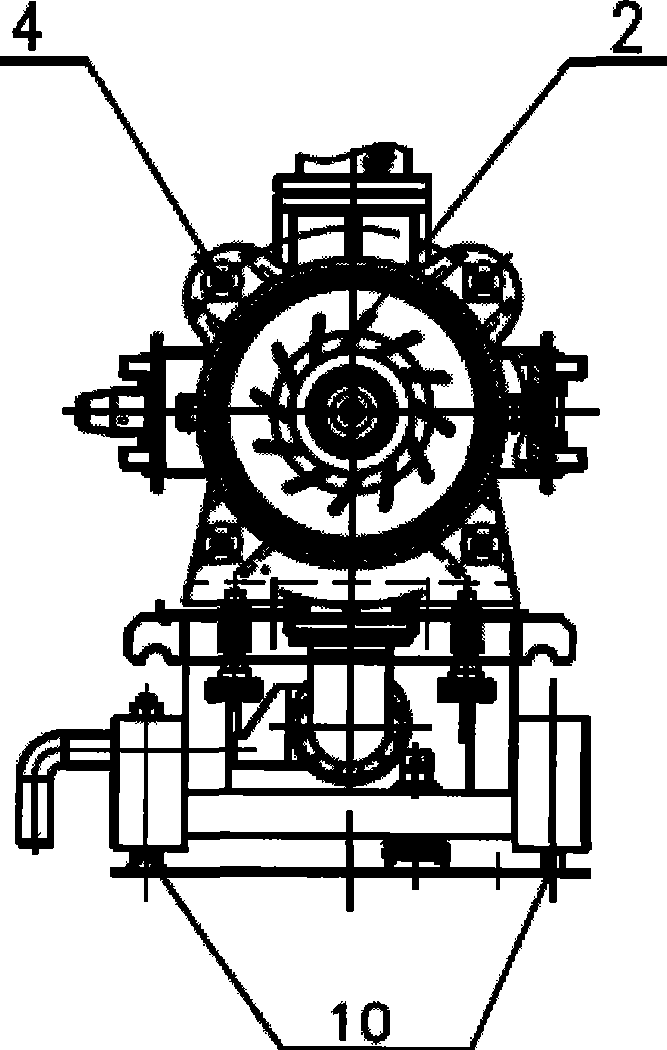

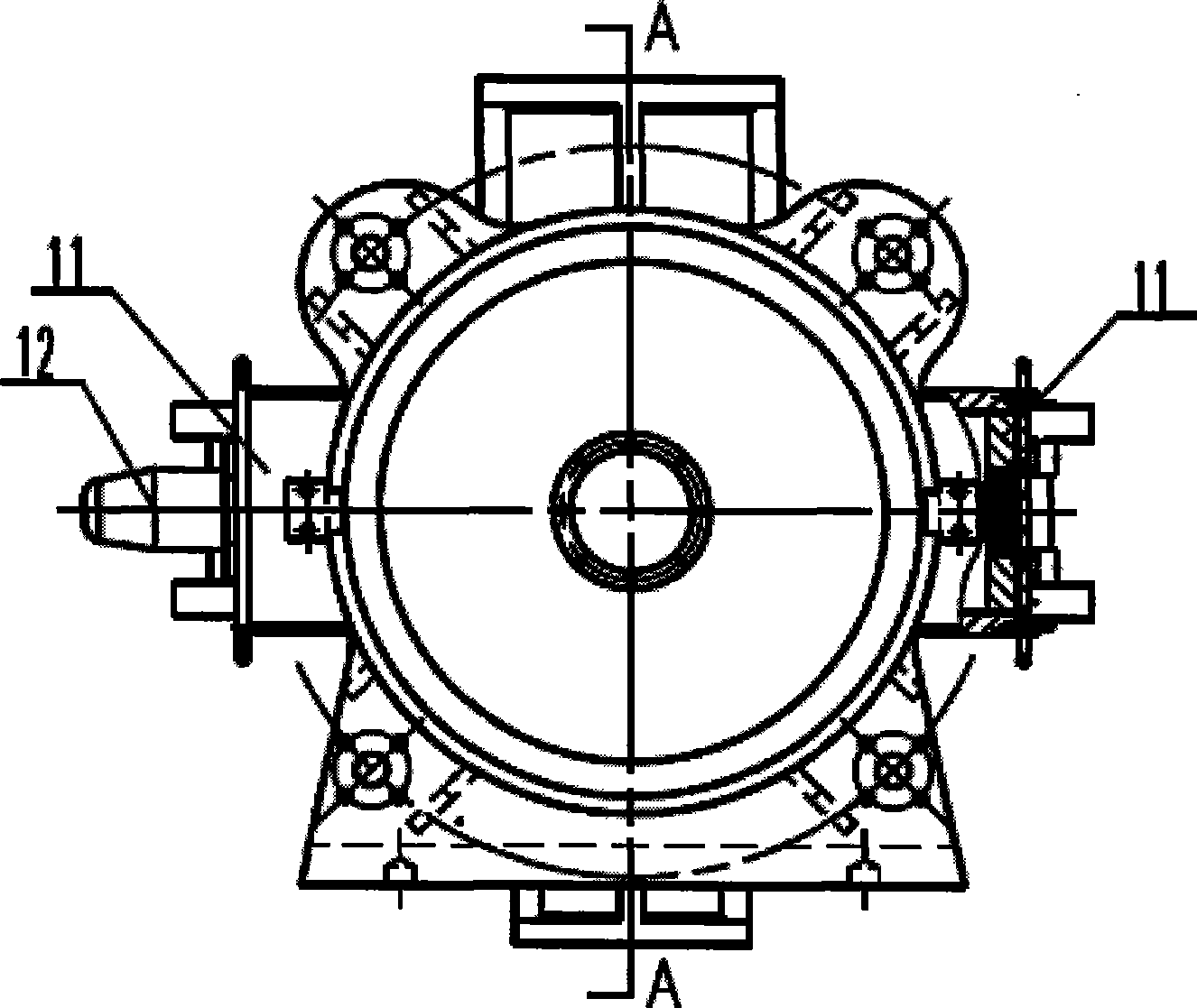

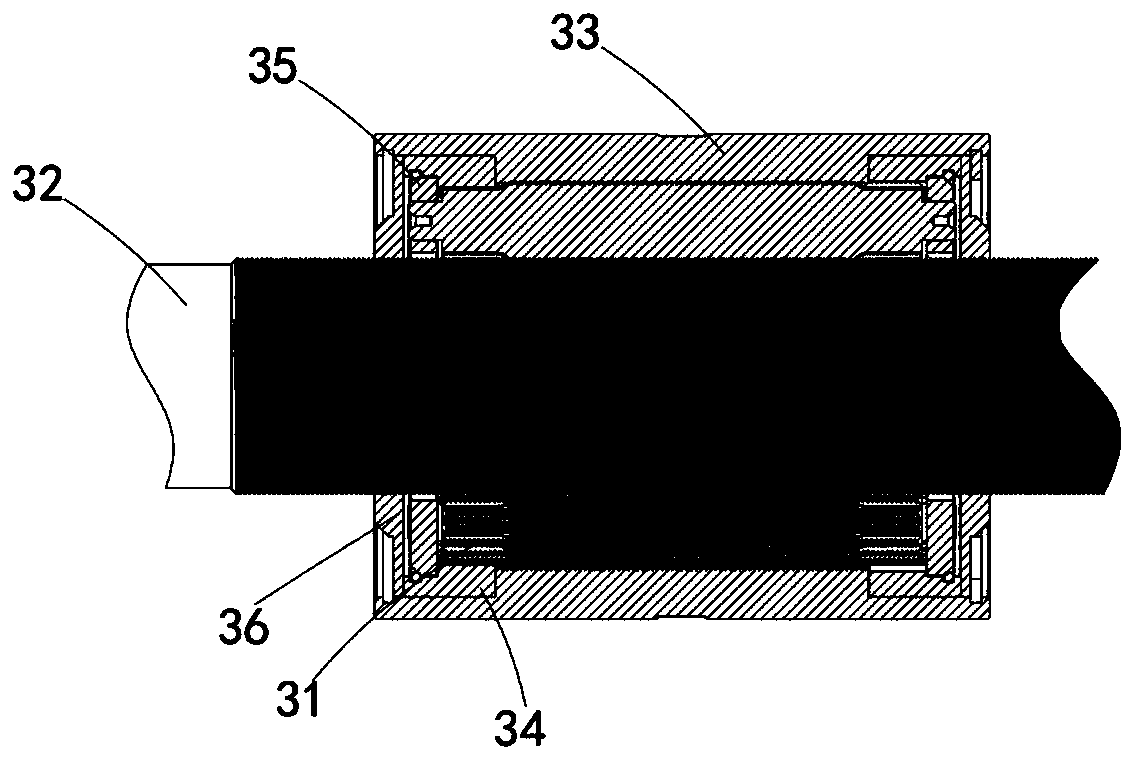

Underwater pelleting device of machine unit for compounding, squeezing and prilling

The invention relates to a mixing extrusion pelleting machine set. An underwater pelleting device of the mixing extrusion pelleting machine set is provided with a machine head template and a pelleting cutter head, wherein the machine head template is arranged on the wall surface of a hot water chamber and sealed, the cutter head is arranged in the hot water chamber through the end of a cutter shaft, a driving motor is in driving connection with the cutter shaft through a coupling, the cutter shaft is arranged in a bearing box and driven by a piston rod of a cylinder, the bearing box is arranged on a trolley bracket, trolley wheels are placed on a guide rail, and the cylinder drives a trolley to move along the guide rail so as to combine and separate the pelleting cutter head and the temperate. The mixing extrusion pelleting machine set rotates at high speed close to a discharge template in the water chamber filled with deionized water during operation, so as to finish pelleting. Cut particles are conveyed to a downstream device along with cooling water. The machine set is safe, is favorable for prolonging service life of the template and a pelleting cutter, and controls a system with simple and easy operation.

Owner:大连橡胶塑料机械有限公司

Nucleated pearl lamella conditioning fluid and application thereof

InactiveCN103283661AHigh activityAvoid infectionClimate change adaptationPisciculture and aquariaWound healingCell division

The invention relates to nucleated pearl lamella conditioning fluid in the technical field of pearl culture and application of the nucleated pearl lamella conditioning fluid. The conditioning fluid comprises the following constituents, by mass-to-volume concentration percentage, 1-5% of acid red, 0.01-5% of chondroitin, 0.1-5% of mafenide, 0.1-5% of taurine, 0.75% of sodium chloride, 0.1-5% of hyriopsis cumingii polysaccharide, and 0.05-3% of vitronectin, and allowance being water. The invention further relates to the application of the nucleated pearl lamella conditioning fluid in the pearl culture. The nucleated pearl lamella conditioning fluid can strengthen cell viability, prevent cell infection, and accelerate cell division and wound healing. When the nucleated pearl lamella conditioning fluid is applied to culture pearls, the death rate of the pearls is obviously reduced, and the rate of remaining nucleuses is obviously improved. Meanwhile, lamellas can be rapidly attached to lamella insertion shells, and the lamella insertion shells can rapidly proliferate to grow into pearl sacs. The nucleated pearl lamella conditioning fluid is simple in method, easy to achieve, wide in application range and remarkable in effect, is used for cultivating nucleated pearls by fresh water pearl mussels, and has wide application prospects.

Owner:ZHEJIANG SHANXIAHU PEARL GROUP CO LTD

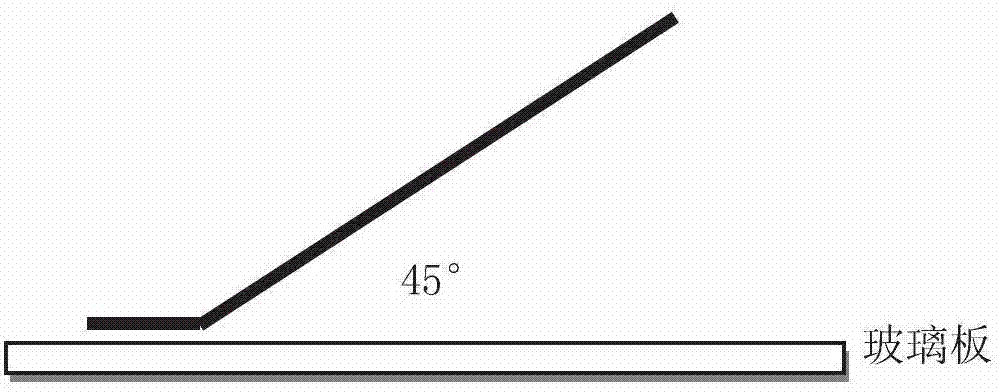

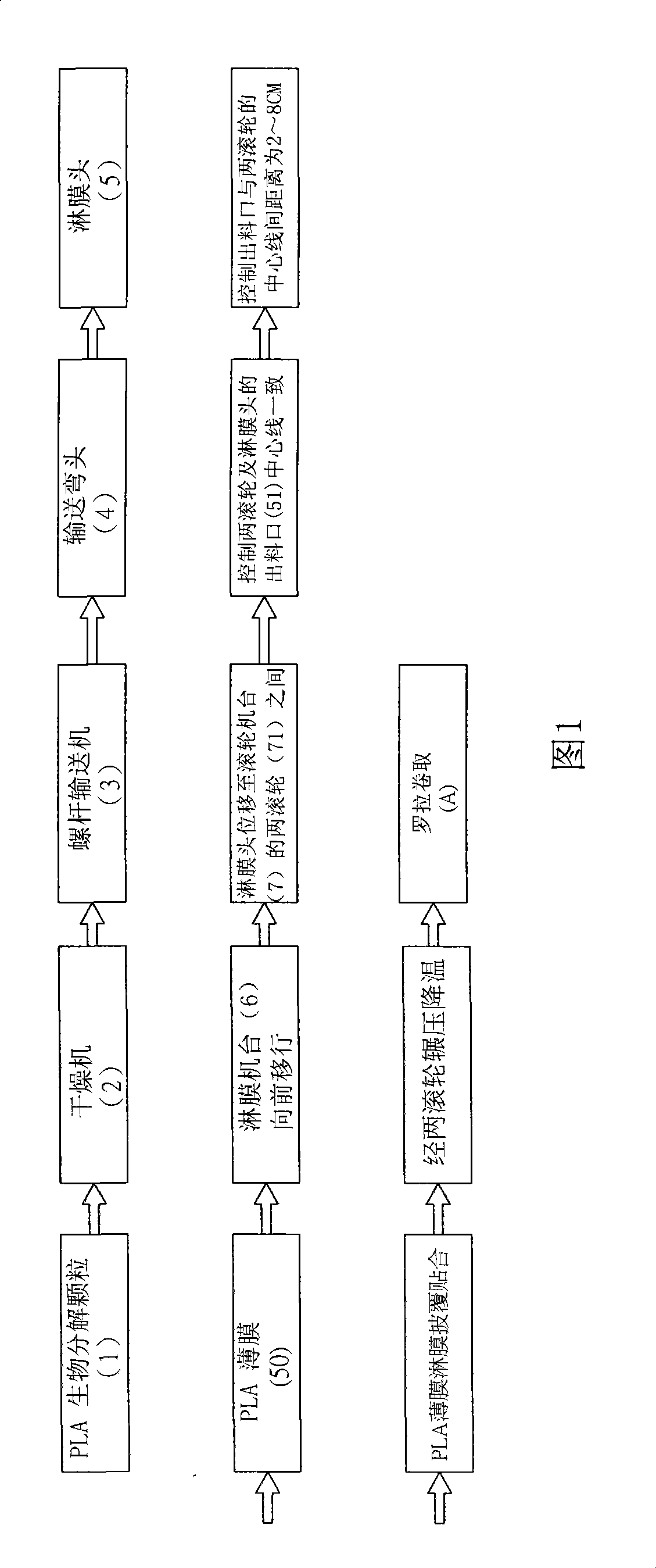

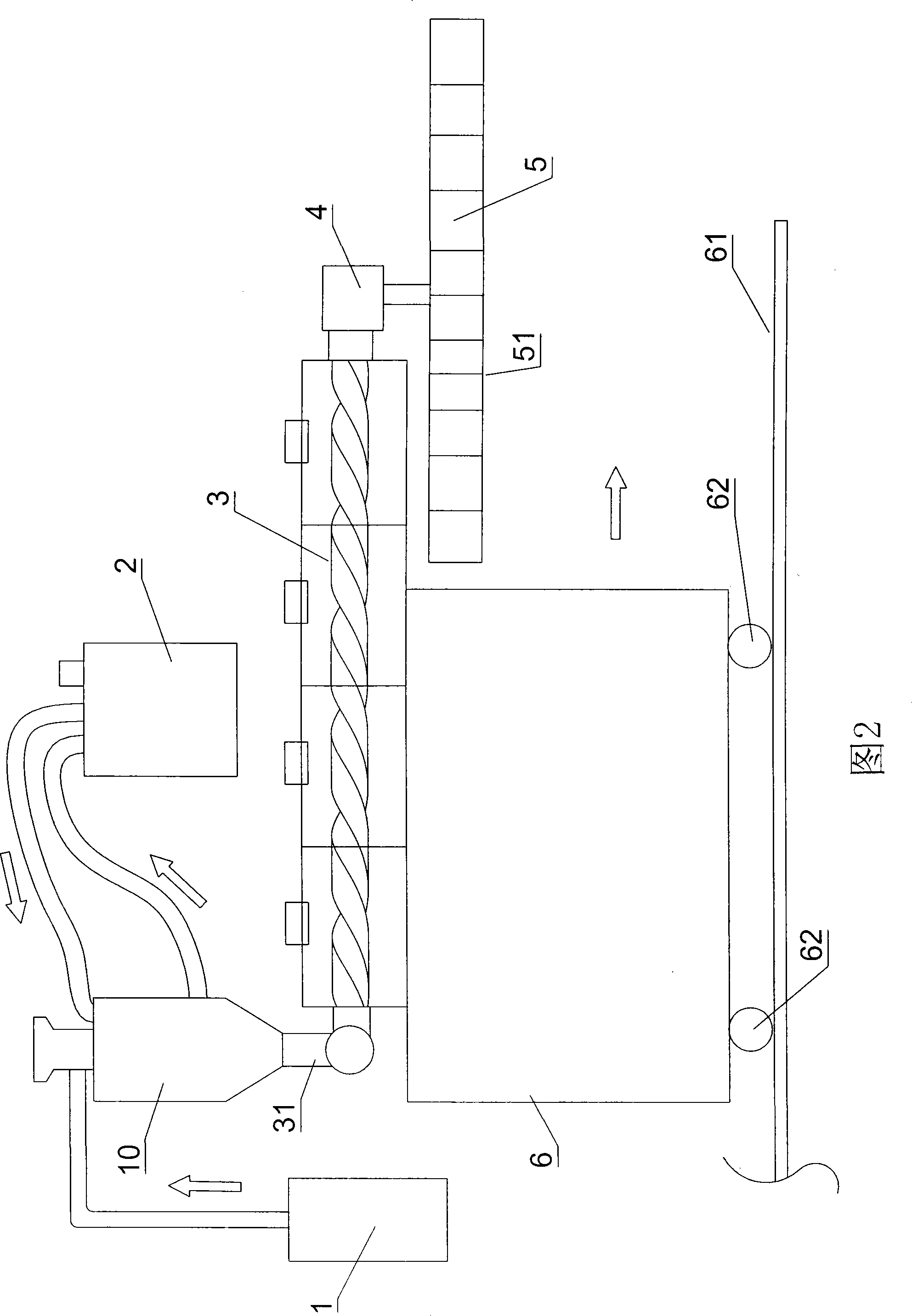

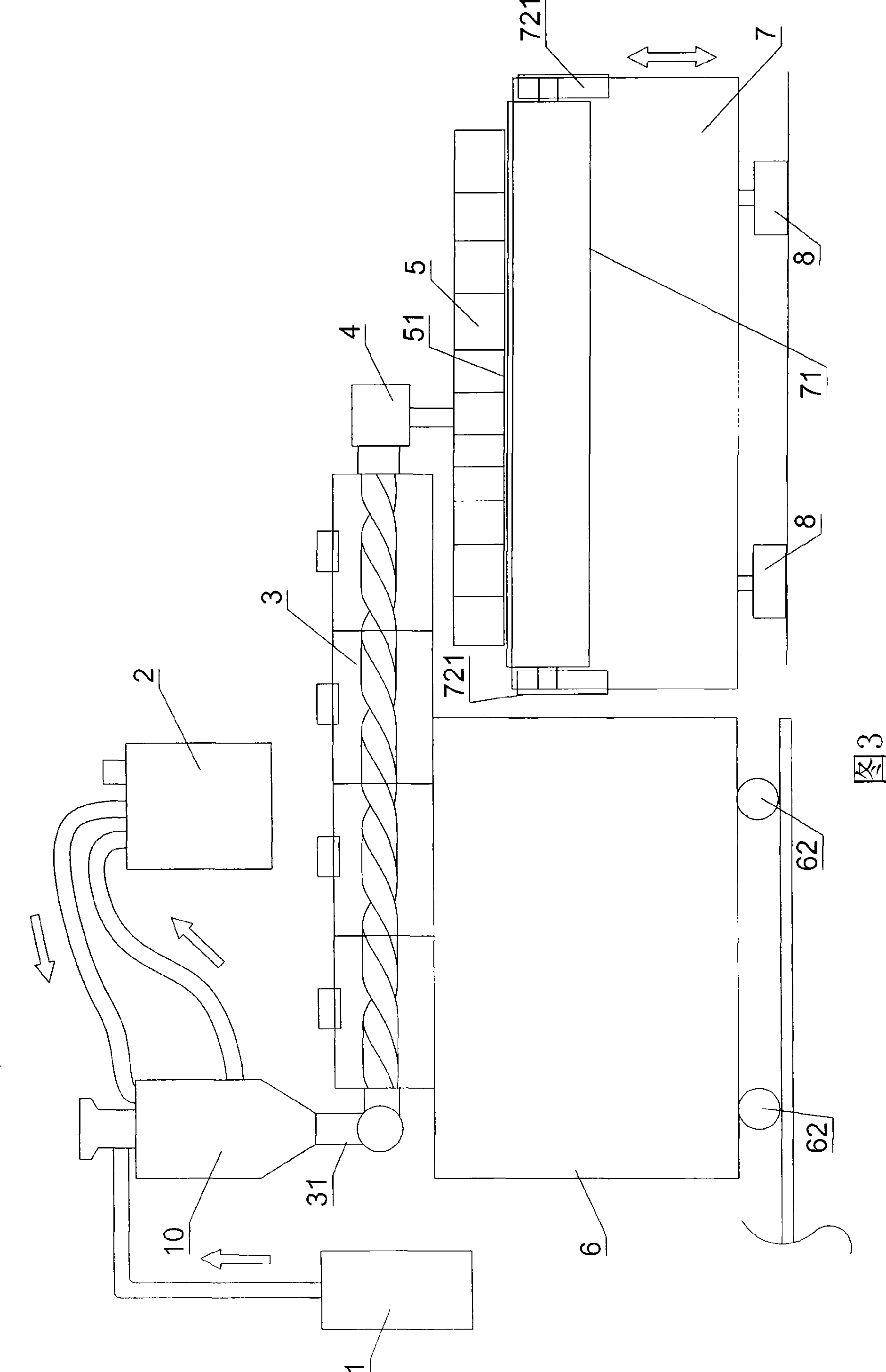

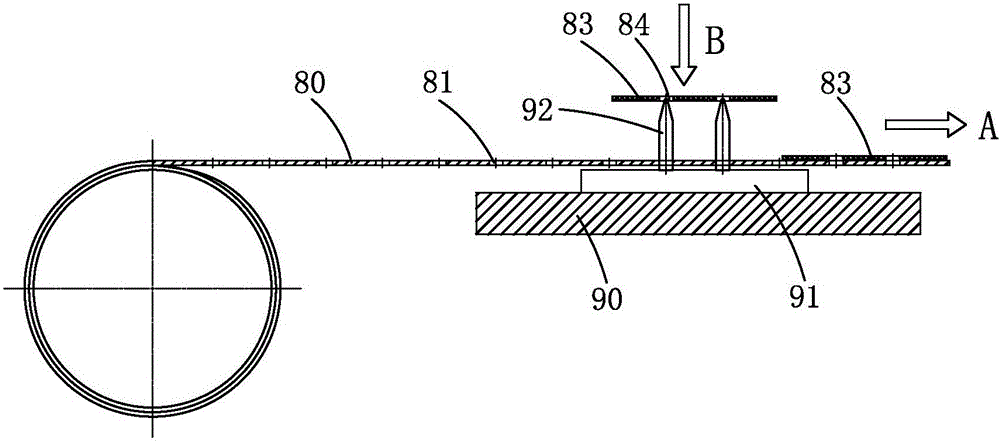

Production method and equipment of drench film coated by PLA biological decomposition material

InactiveCN101457502AEasy and quick fitLow costMechanical working/deformationSpecial paperWater contentDecomposition

The invention relates to a method for preparing a polylactic acid (PLA) biodegradable material for lamination and coating, as well as a device thereof. The proposal of the invention is as follows: the PLA biodegradable particles are dried by a drier until the water content reaches a certain standard; the PLA biodegradable particles are heated and melted by a screw conveyor and put into a lamination header by a delivery elbow simultaneously to extrude out a membrane; the lamination machine is pushed to a certain position and the lamination header is located between two rollers of a rolling machine; the displacement of the lamination header left-to-right is controlled by a transverse oil pressure cylinder so as to locate the lamination header at the central position of the two rollers; simultaneously the rolling machine is controlled to lift up and down so as to lift a lamination point between the two rollers to a predetermined distance from a material outlet of the lamination header, therefore, the membrane is laminated or coated on the ground paper or a thin wood paper board to finish quick adhesion more easily so as to provide a paper-made container and achieve the environment-friendly effect of natural degradation.

Owner:宏基淋膜纸业有限公司

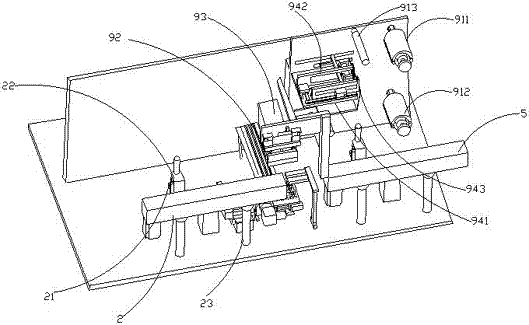

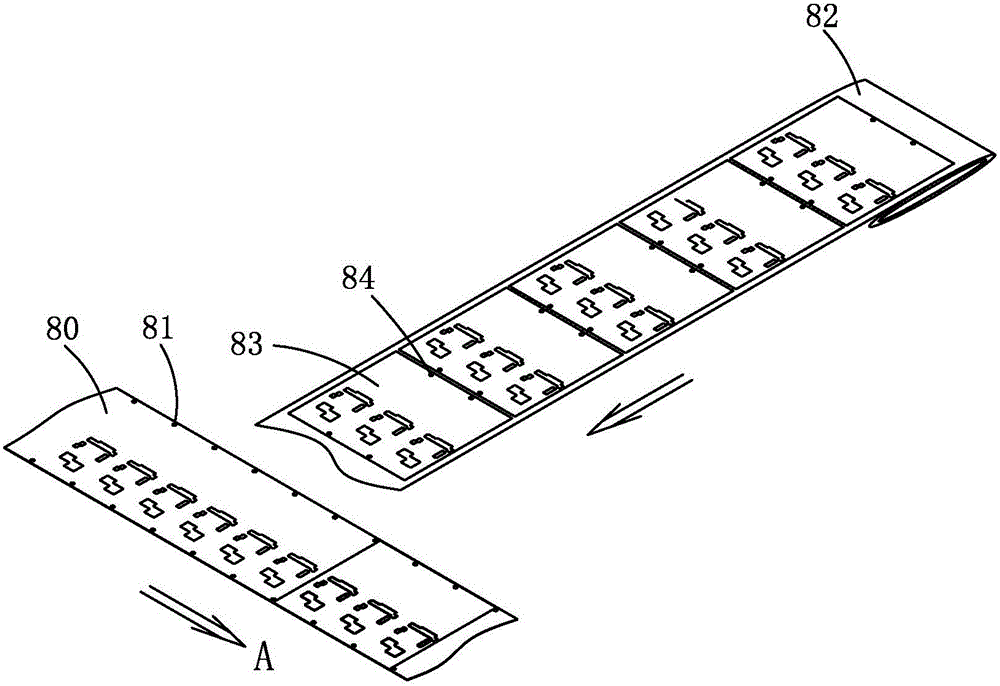

Attaching device and method with material belt positioned through strip material small holes in sleeving mode

The invention provides an attaching device and method with a material belt positioned through strip material small holes in a sleeving mode. The attaching device comprises a product material belt supply mechanism, a label material belt supply mechanism, an attaching platform, a jig plate, a lifting mechanism and a label suction and attaching mechanism, wherein the jig plate is located below the attaching platform, positioning needles are arranged on the top surface of the jig plate, and the lifting mechanism drives the jig plate to ascend and descend. The product material belt supply mechanism comprises a material disc assembly, a material pulling drum and a servo motor driving the material pulling drum to rotate. The attaching platform is provided with a plurality of through holes used for positioning, and the positioning needles right face the through holes in the attaching platform. The label suction and attaching mechanism comprises a label suction plate connected with a vacuum generating device and a displacement assembly driving a label suction head to move. The attaching method includes a feeding step, a positioning step, an attaching step and a resetting step. The material pulling drum automatically pulls a product material belt to achieve material supply, then the label suction and attaching mechanism achieves the operation of automatically sucking and attaching labels, the automation degree is high, and the labels can be attached to the product material belt rapidly and accurately.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

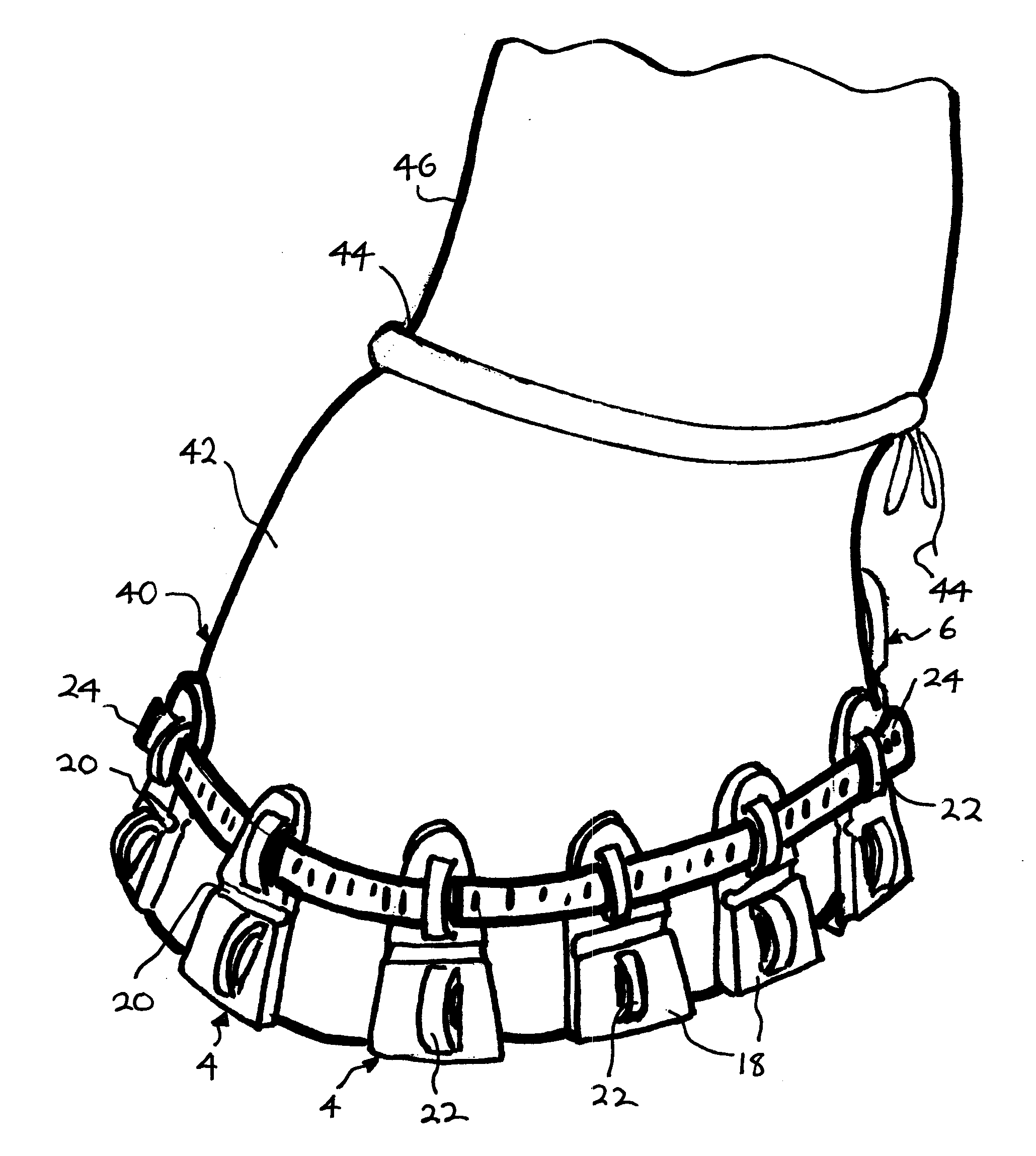

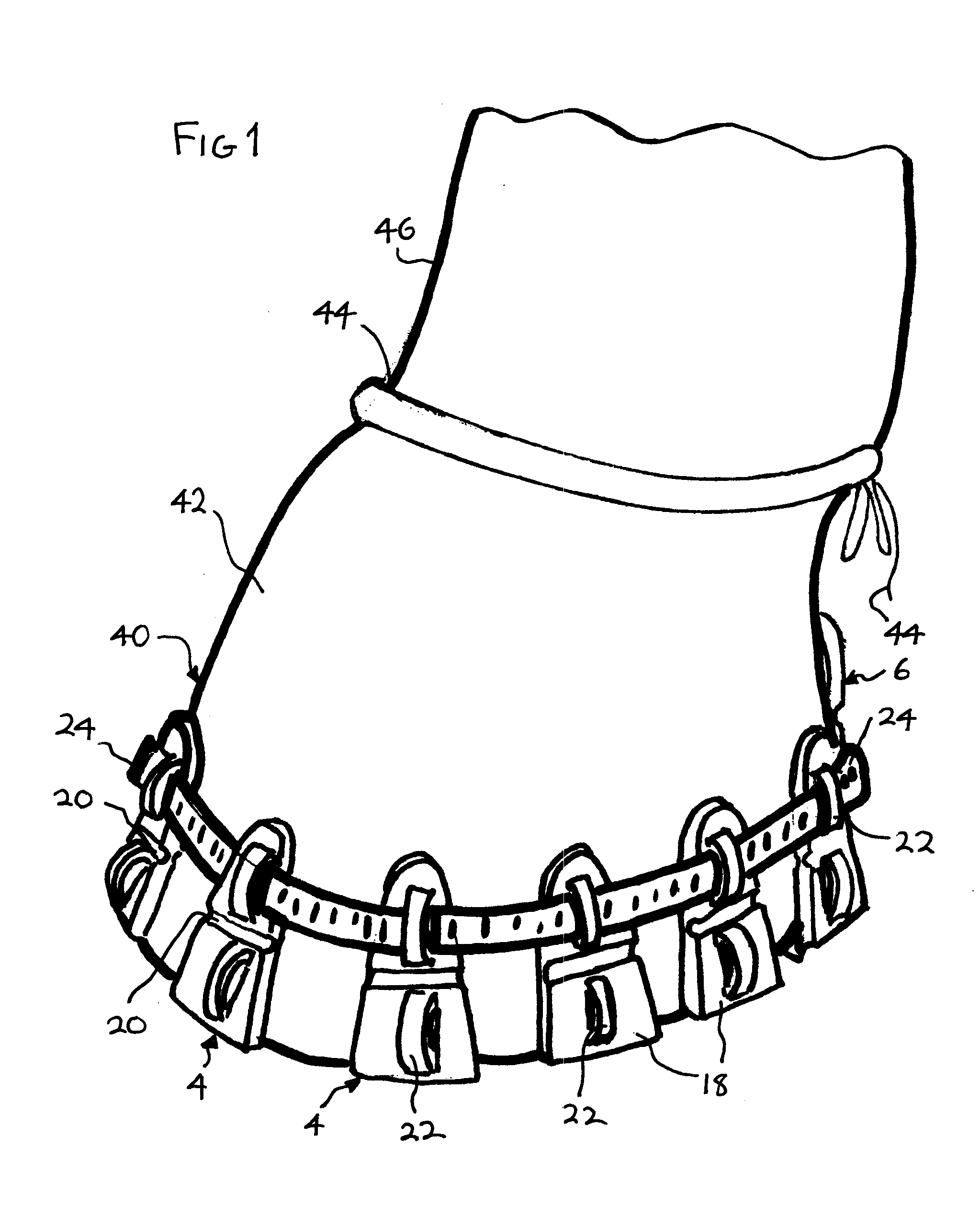

Animal Overshoes

Owner:BUCHANAN NIGEL ALEXANDER

Uniform spraying device for curved-surface plate

The invention belongs to the technical field of spraying equipment, and particularly relates to a uniform spraying device for a curved-surface plate. The uniform spraying device comprises a support part, a suspension part, a spraying mechanism and a rubber guide rail. According to the uniform spraying device for the curved-surface plate, a piston rod of a support cylinder drives the curved-surface plate to move upwards, so that a curved surface matched with the curved-surface plate is formed on the bottom surface of the rubber guide rail, after the matched curved surface is formed, a piston rod of a tensioning cylinder tensions a tension rope, a metal sheet is enabled to be attached to a rubber sheet, the rubber sheet is tightly attached to a hanger rod, the friction force between the rubber sheet and the hanger rod is increased, the hanger rod is locked, the lower end of the hanger rod is connected with the rubber guide rail, the bottom surface of the rubber guide rail is matched with the surface of the curved-surface plate accordingly, after the hanger rod is locked, the piston rod of the support cylinder drives the curved-surface plate to move downwards, the distance between the curved-surface plate and the spraying mechanism is the spraying distance, the vertical distances between the spraying mechanism and all the positions of the curved-surface plate are equal in the spraying process, then uniform spraying of the curved-surface plate is achieved, and the spraying quality is improved.

Owner:SHAOYANG VICTOR HYDRAULICS

Automatic foam sticking machine and processing technology adopting same

InactiveCN105172304ASimple structureEasy to useLaminationLamination apparatusEngineeringMechanical engineering

The invention relates to an automatic foam sticking machine which comprises a rack, a control device, a first loading rack and a second loading rack, wherein a first material feeding mechanism is arranged on the first loading rack and comprises a first baseplate, a first material laying plate, a first driving mechanism and a second driving mechanism, a first sunken part is arranged on the first material laying plate, and at least one second material feeding mechanism layer is arranged on the second loading rack; a material taking mechanism capable of moving horizontally is arranged on the rack, a needle plate capable of moving vertically and a material bearing plate are arranged on the material taking mechanism, a plurality of needles are arranged on the needle plate, a second sunken part is arranged on the material bearing plate, and the first sunken part and the second sunken part correspond in the vertical direction; an electrical heating mechanism is arranged on the rack; based on input parameters or instructions, the control device controls the sticking machine to work. The invention further relates to a processing technology adopting the automatic foam sticking machine. The automatic foam sticking machine and the processing technology adopting the same have the benefits that loading is convenient and safe, and the sticking accuracy is high.

Owner:JIANGSU BVM INTELLIGENT TECH

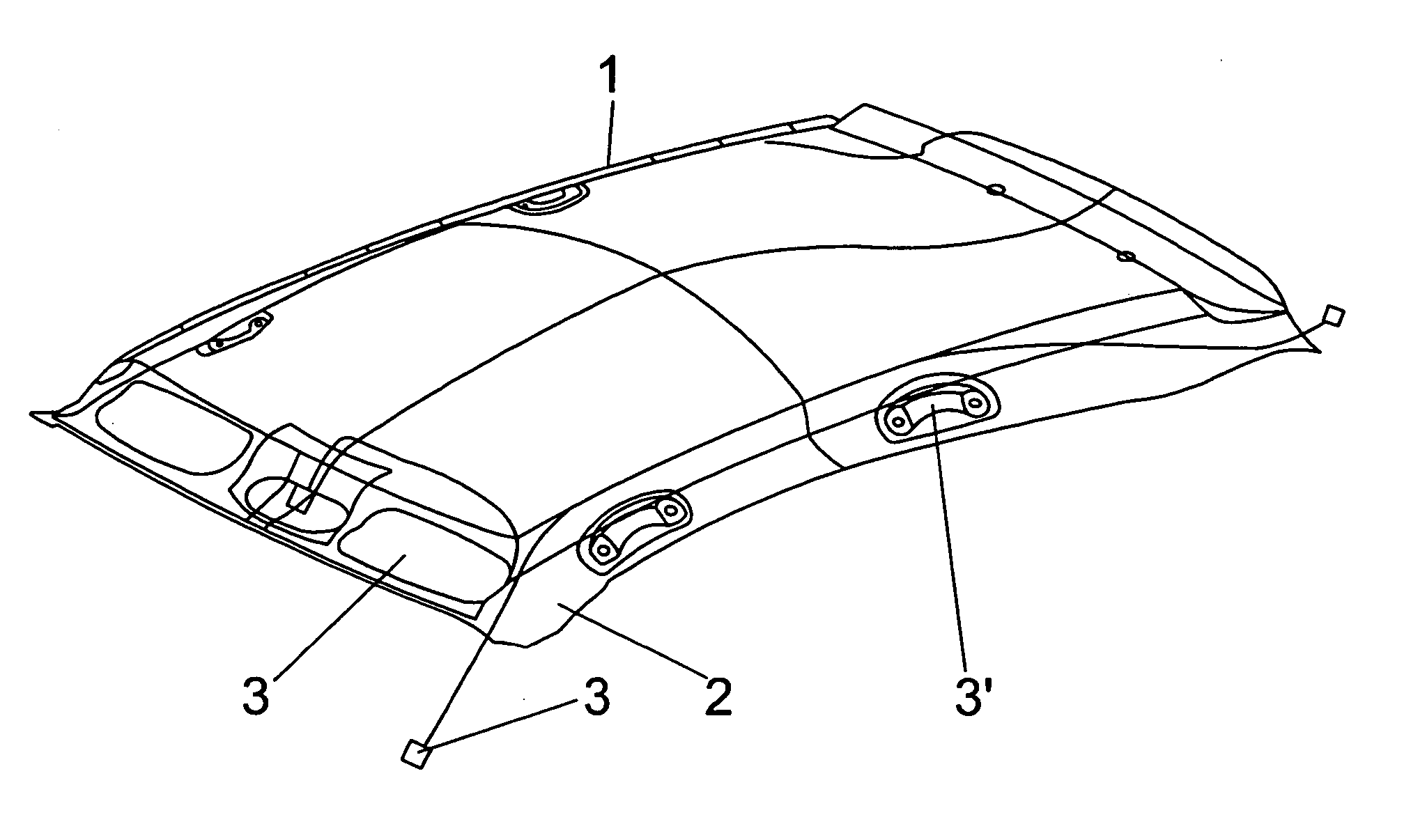

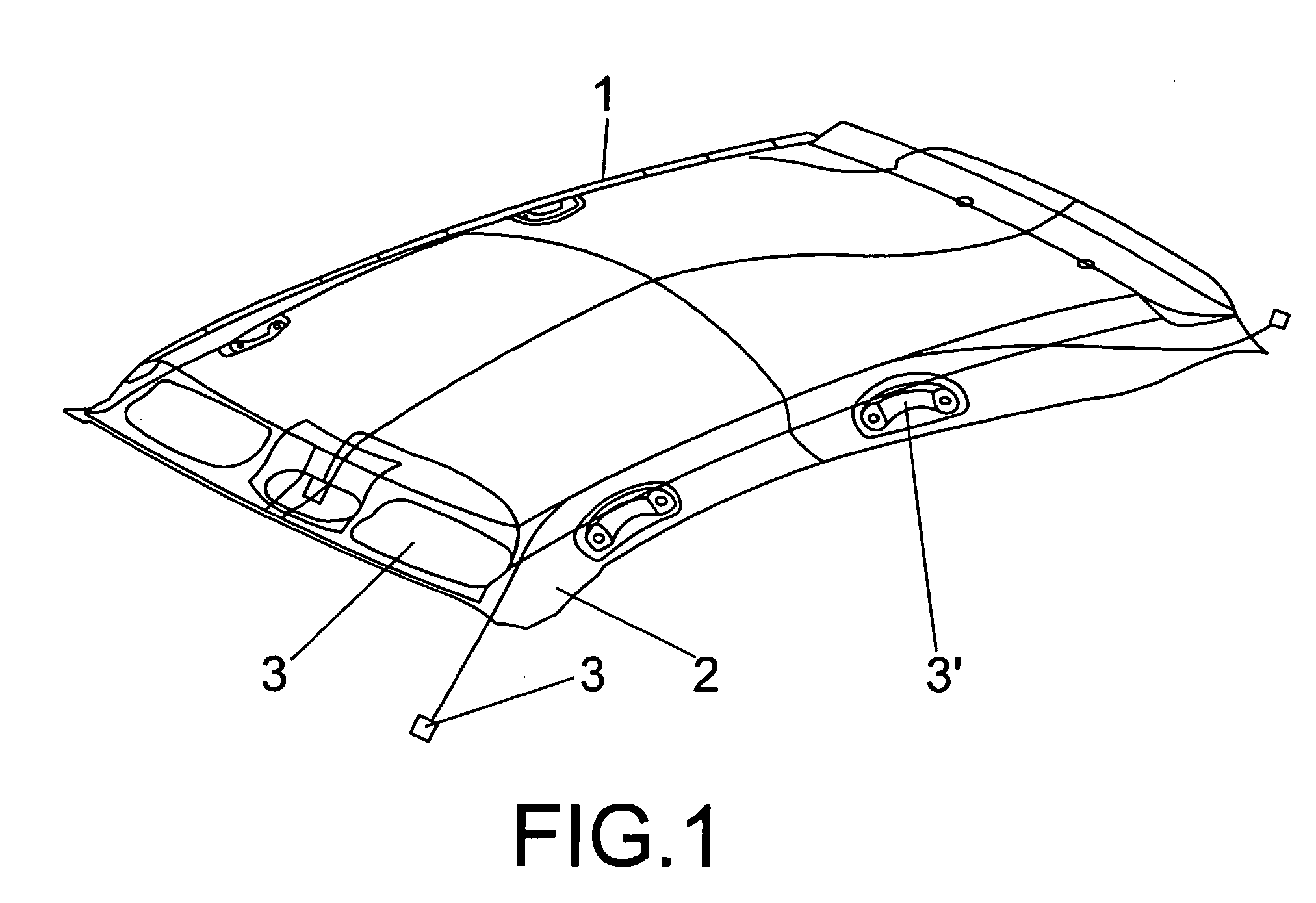

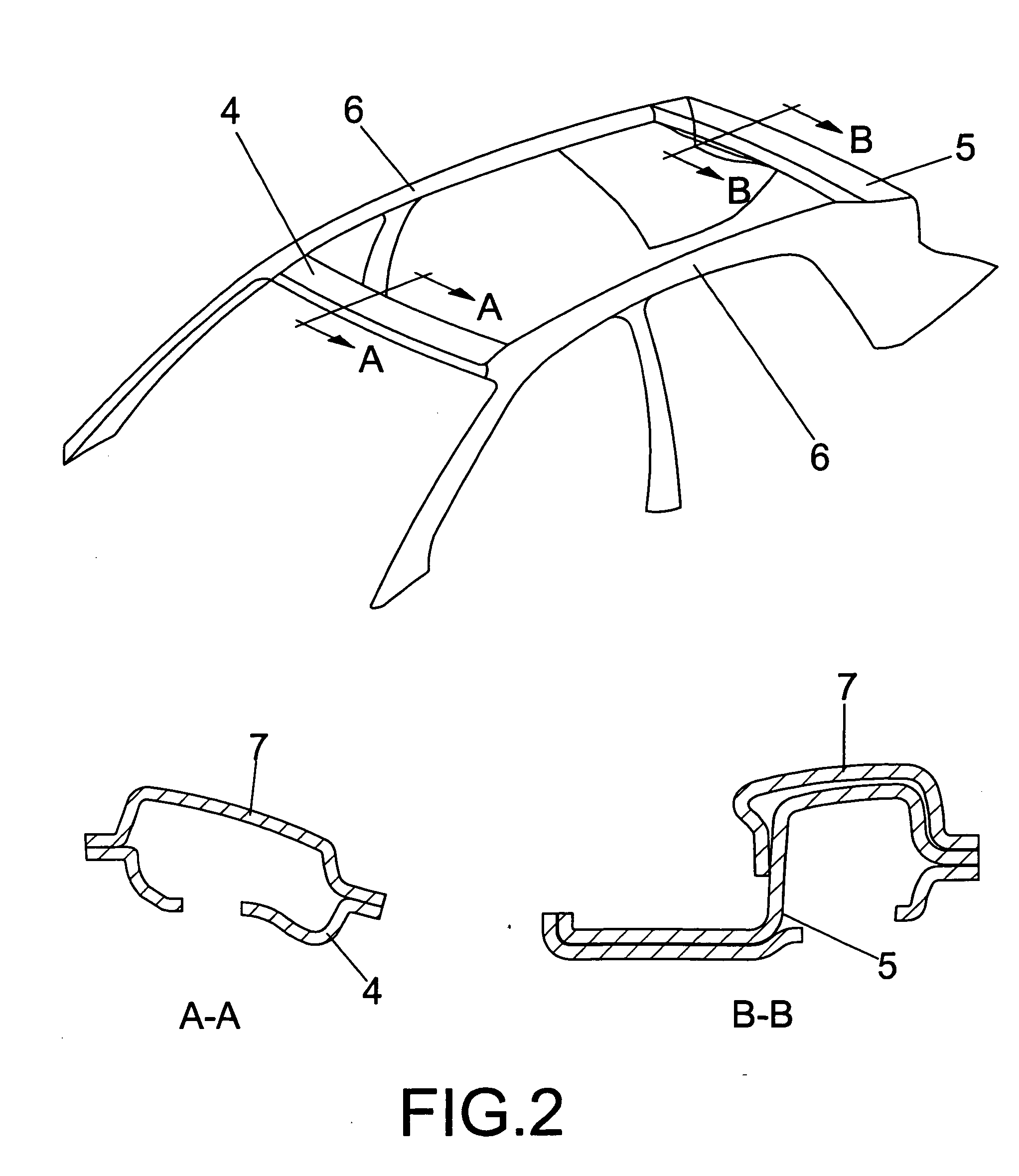

Vehicle roof module

This roof module is designed for installation on a vehicle body in which an opening of approximately the same dimensions as the roof has been made and it is composed of the original roof panel (1), with its end finish, a complete conventional interior trim (2), usually of larger dimensions than the afore-mentioned panel, as well as pre-installed interior accessories (3) and (3′). At its front and rear edges the roof panel (1) is provided with dished recesses (10) which engage underneath the front (4) and rear (5) body cross members, covering it at least, the cross members (4) and (5) being closed at the top with a panel (7) that covers them and provides the form and finish matching the exterior of the vehicle. The roof panel (1) has perimeter steps (11) and (13) that each match up positionally with respective peripheral shoulders (9) provided both on the front (4) and rear (5) cross members, as well as on the side rails (6) of the body, forming between them a contact surface through which the roof module is joined to the body by adhesive.

Owner:GRP ANTOLIN ING SA

Apparatus for preparing the welding region on the outer surface of plastic pipes

InactiveUS20050077008A1More flexibleEasy to slidePipe elementsPipe connection arrangementsGear systemEngineering

An apparatus for preparing the welding region on the outer surface of plastic pipes, comprising elements for anchoring to a pipe; a threaded pivot being coupled to the anchoring elements to perform a longitudinal, rotary and translational motion; supporting elements for a tool being jointly coupled to the threaded pivot, that can be arranged so as to interfere with, and remove material from, the outer surface of the pipe. The anchoring elements comprise a central body with longitudinal sliding guides thereon for rod-like elements, which protrude partially from the central body, do not intersect each other, and support at ends feet for resting against the inner surface of the pipe. Respective racks are provided longitudinally on the rod-like elements and are kinematically connected to a common actuation gear system.

Owner:RITMO SRL

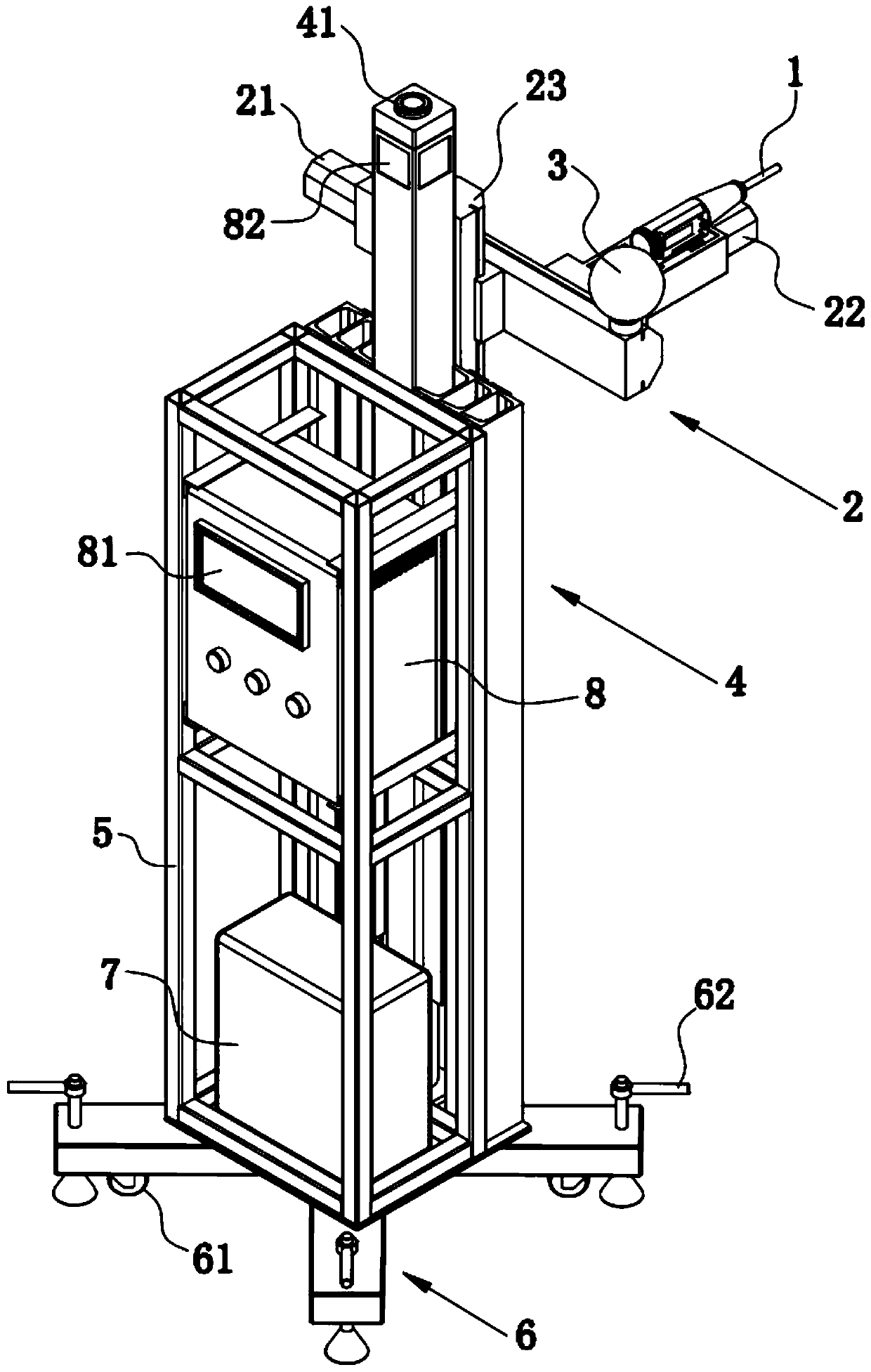

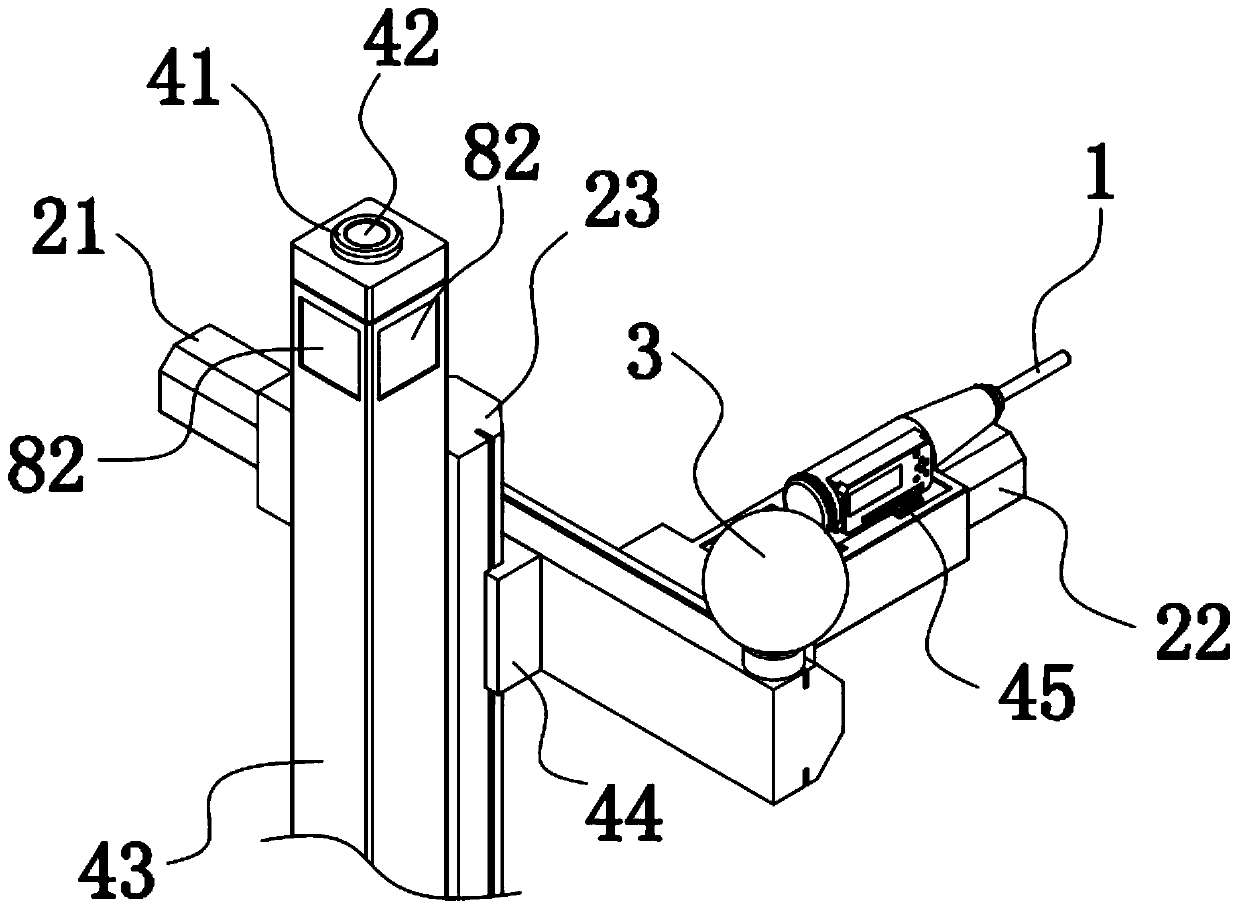

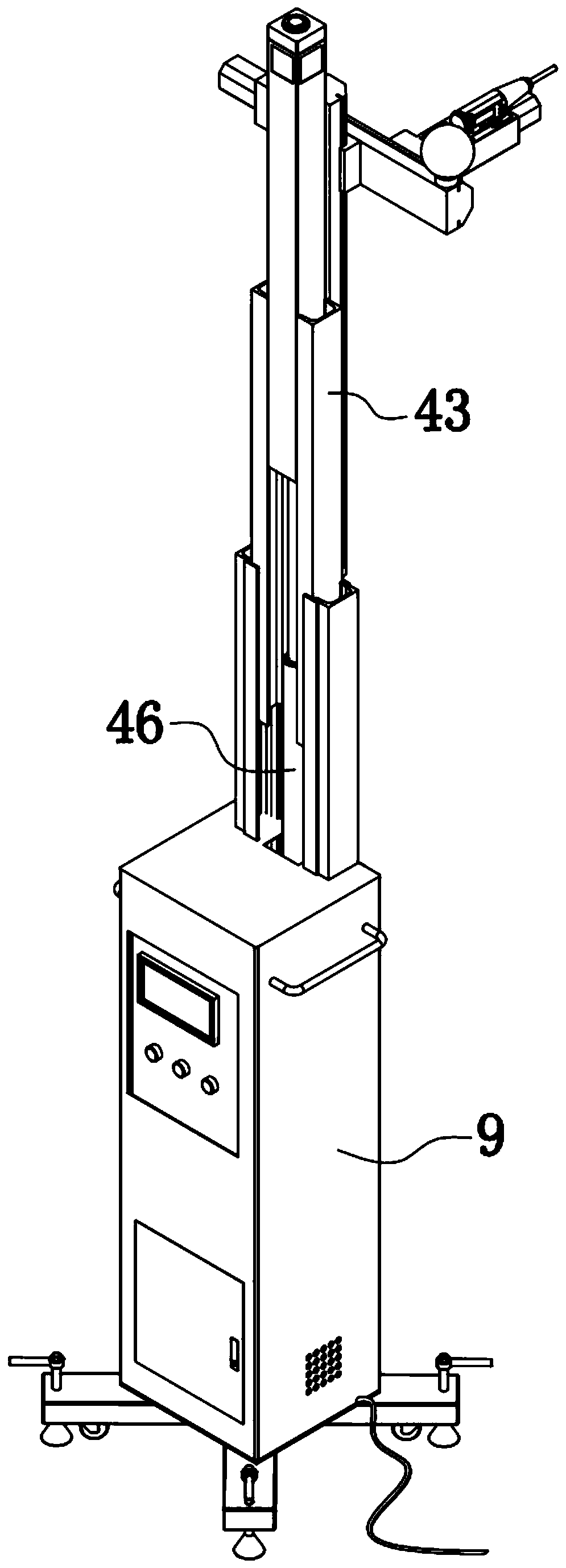

Robot for concrete horizontal springback detection

PendingCN111157381AStable detection operationEfficient detection operationsInvestigating material hardnessRectangular coordinatesControl engineering

The invention discloses a robot for concrete horizontal springback detection. The robot comprises a lifting mechanism with a vertical reciprocating linear degree of freedom; a three-dimensional movingmechanism which is fixed to the top of the lifting mechanism and comprises an x-direction linear module, a y-direction linear module and a z-direction linear module which are perpendicularly connected with one another; and a detection mechanism which comprises a digital display resiliometer fixed in parallel with the y-direction linear module and has moving degrees of freedom along x, y and z rectangular coordinate axis directions. The lifting mechanism further comprises a supporting mechanism, the top of the lifting mechanism is provided with a vertically-telescopic nesting column, the z-direction linear module and the nesting column are fixed in parallel, the digital display resiliometer faces the horizontal direction and deviates from the position where the nesting column is located, and the supporting mechanism comprises a rubber gasket located at the top of the nesting column. Stable support can be provided during the rebound test of the side facade of the building, the robot isstabilized by means of the friction force of the lower surface of the building and the detection efficiency is improved.

Owner:苏州桐济建仪机电科技有限公司

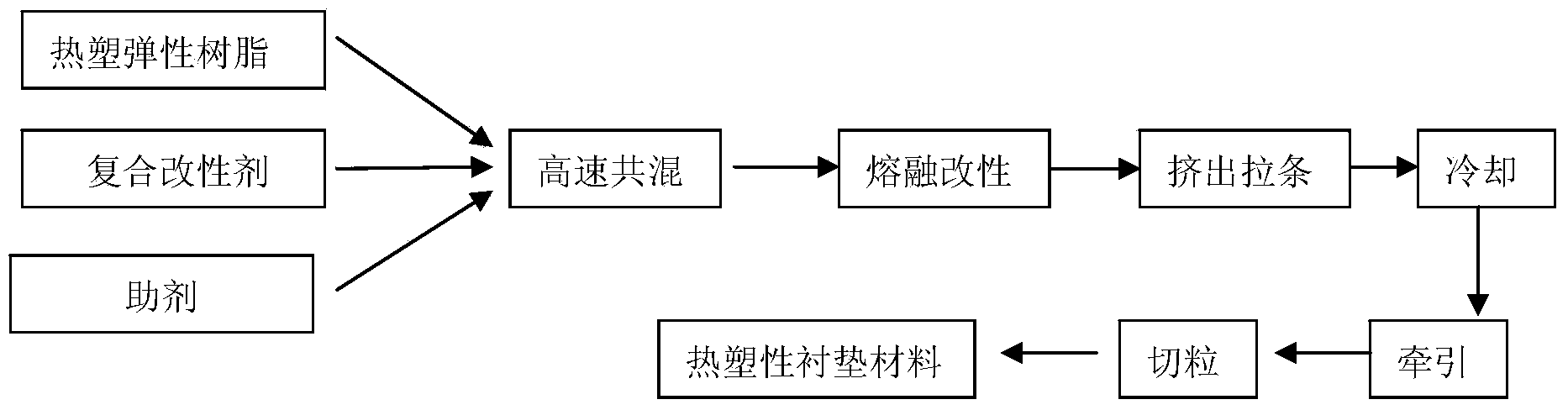

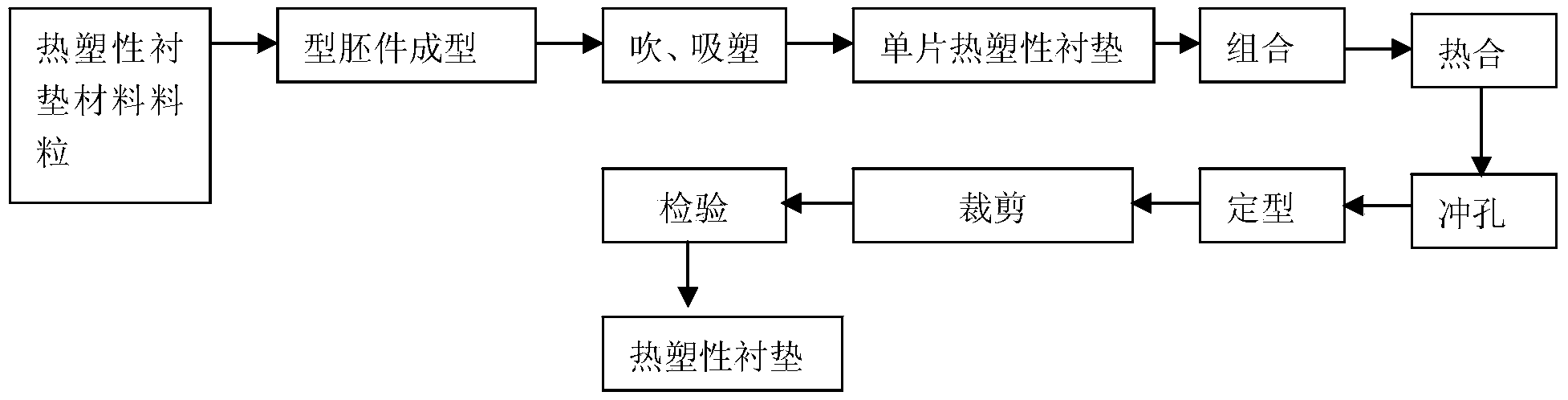

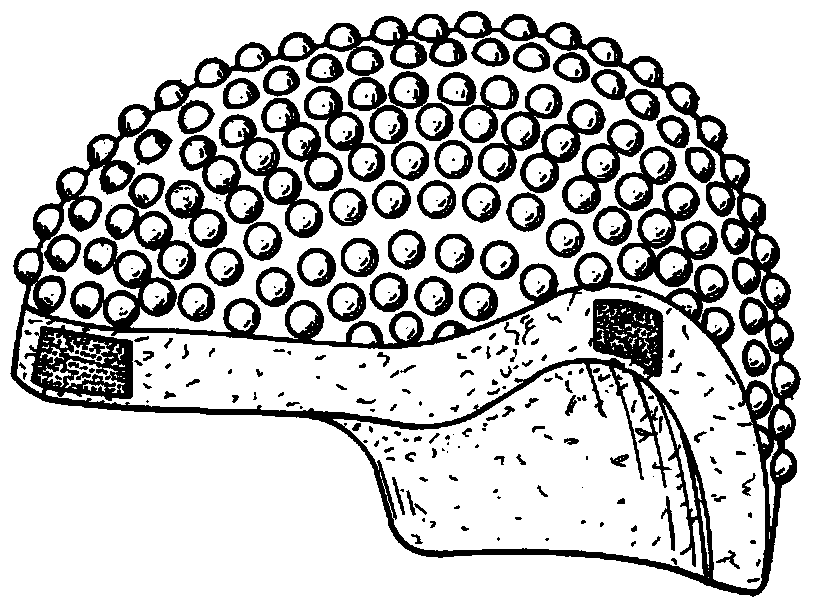

Thermoplastic gasket in individual protection helmet and manufacturing method of thermoplastic gasket

The invention relates to a thermoplastic gasket in an individual protection helmet and a manufacturing method of the thermoplastic gasket. The manufacturing method comprises the following steps: S1, taking thermoplastic elastic resin as a basic material and adding an acrylic copolymer compound modifier and an inorganic nanoparticle aid so as to obtain a thermoplastic gasket material; S2, performing injection molding on the thermoplastic gasket material to form a material, softening the material in a drying box, pressing the material in a pressing mould into single billets, and blistering the billets to form single thermoplastic gaskets; S3, stacking the plurality of single thermoplastic gaskets to form a multi-layer thermoplastic gasket, heating and softening the multi-layer thermoplastic gasket, putting the multi-layer thermoplastic gasket between a clamp and the head of a wearer, performing thermoplastic forming on the multi-layer thermoplastic gasket according to the shape of the head of the wearer to finally form the thermoplastic gasket. The gasket is manufactured by the method; the manufacturing method is simple, convenient and low in cost, and the gasket can quickly fit the head of the wearer; the layer number of the gasket can be changed at will to meet different head styles, and the gasket cannot move when being worn.

Owner:AEROSPACE LIFE SUPPORT IND LTD

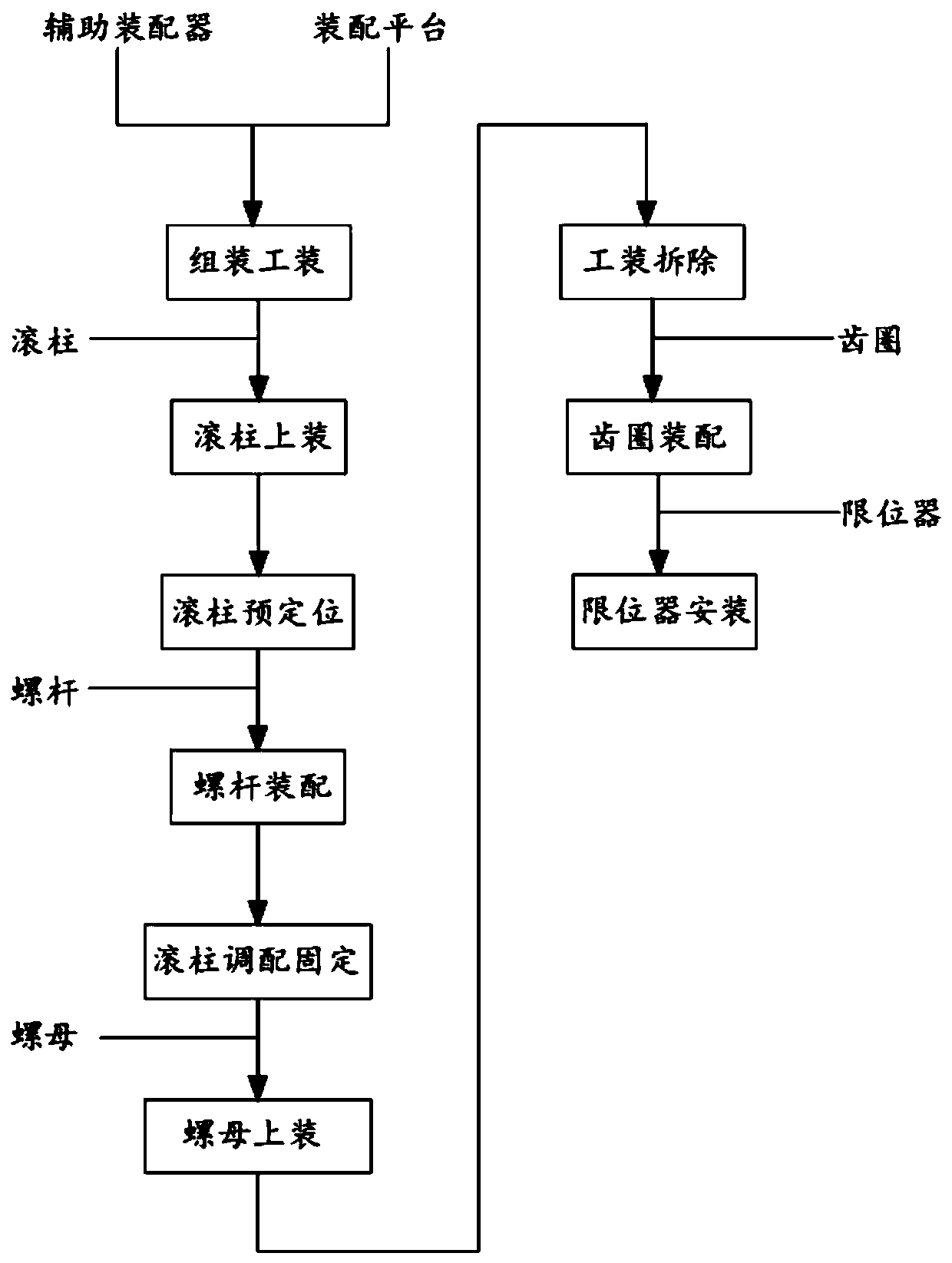

Closed roller lead screw mechanism assembling method

ActiveCN111015157AQuick assemblyAssembly precisionAssembly machinesMetal working apparatusRoller screwScrew thread

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD

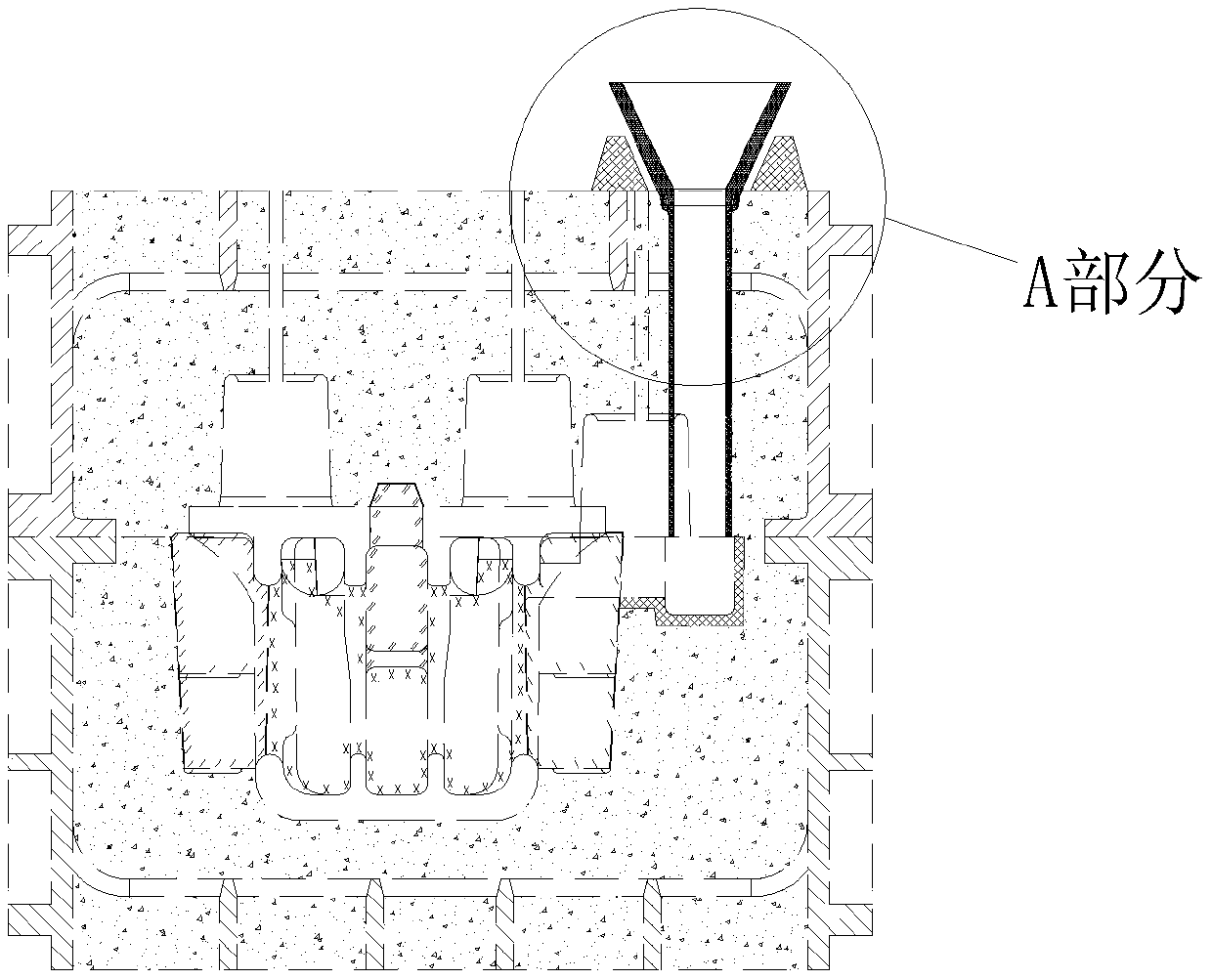

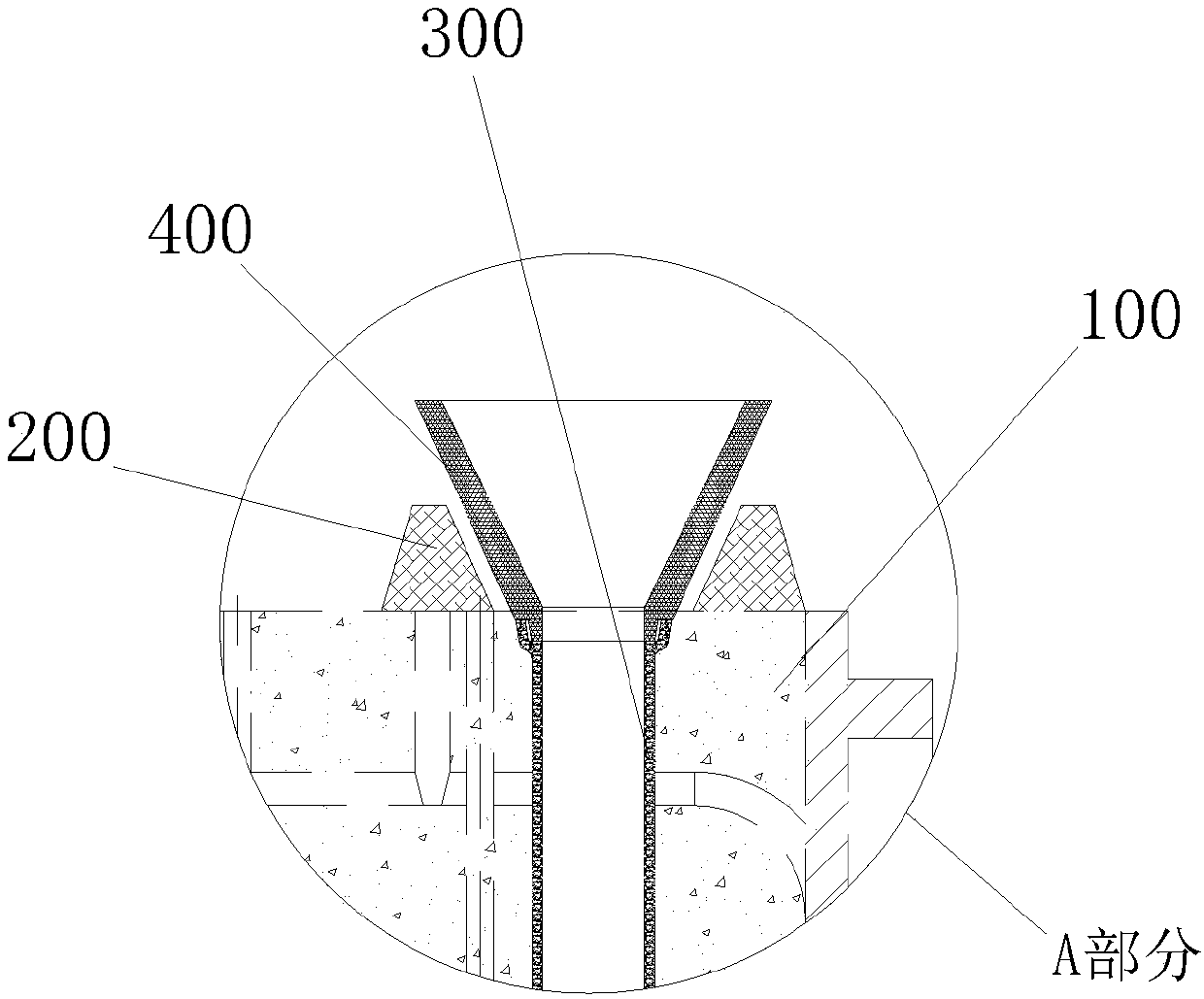

Pre-embedded sprue system

InactiveCN107866527AFit fastSolve the phenomenon of running steelFoundry mouldsFoundry coresMaximum diameterEngineering

The invention discloses a pre-embedded sprue system which comprises a sand box, a pouring earthenware pipe and a sprue cup, wherein an accommodating groove is formed in the sand box and is composed ofan upper part and a lower part; the upper part takes the shape of a circular truncated cone with a wider upper part and a narrower lower part; the lower part is cylindrical; the sprue cup is placed in the accommodating groove; the minimum diameter of the upper part of the accommodating groove is greater than the minimum diameter of the sprue cup and is less than the maximum diameter of the spruecup; and the maximum diameter of the upper part of the accommodating groove is greater than the minimum diameter of the sprue cup and is less than the maximum diameter of the sprue cup. The pre-embedded sprue system has the following advantages: the design of the accommodating groove ensures that the sprue cup can fit and is fastened and does not incline during pouring, so that the phenomenon about steel loss at the cup bottom is completely eliminated, and the accommodating groove meets the complicated site using condition and is durable and unlikely to deform; a sand collecting groove can collect floating sand during the working process of an external die, so that the purity of molten steel is ensured; the pouring earthenware pipe positions the sprue cup; and the production cost is reduced, the weight of an entire system is reduced, and the on-site operation is portable and simple.

Owner:CRRC YANGTZE TONGLING CO LTD

Clickable cable trays

ActiveUS20200266614A1Improve stabilityFit fastPipe supportsElectrical apparatusCable trayElectric cables

Owner:VERGOKAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com