Thermoplastic gasket in individual protection helmet and manufacturing method of thermoplastic gasket

A production method and thermoplastic technology, applied in helmets, helmet caps, hat products, etc., can solve the problems of pilots wearing stability and comfort, offset of pad position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

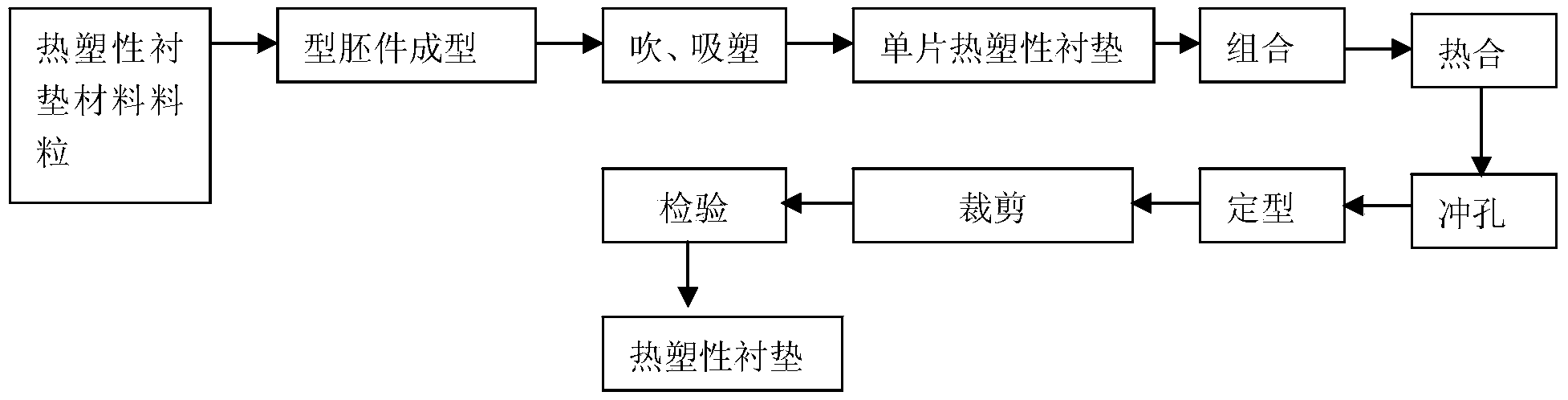

[0021] The manufacturing method of the inner thermoplastic liner of the personal protective helmet of the present invention comprises the following steps:

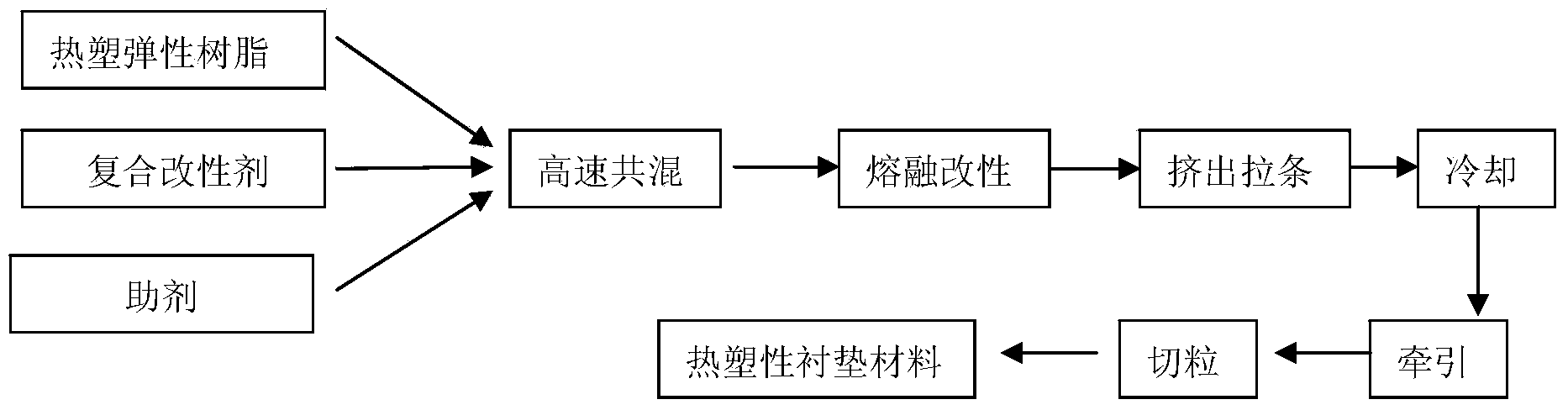

[0022] S1. Using thermoplastic elastic resin as the basic material, adding acrylic acid copolymer composite modifier and inorganic nanoparticle additives, using a high-shear twin-screw extruder to perform high-speed blending and melt modification of the three, and extruding Strands, and then the rods are cooled, drawn, pelletized, and finally thermoplastic gasket materials are obtained, such as figure 1 shown.

[0023] Since the working temperature range of the thermoplastic gasket is -55°C to 70°C, the temperature range is large, and the thermoplastic elastic resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com