Illumination assembly for dental and medical applications

a technology for illumination assemblies and dental and medical applications, applied in the direction of lighting support devices, spectales/goggles, optical radiation measurement, etc., can solve the problems of increasing the difficulty of viewing the patient or workpiece, the interior of such holes generally cannot be viewed without direct illumination, and the prior art devices fail to fully or partially include, etc., to achieve automatic illumination of the area the user is viewing, and the effect of reducing the weight of the illumination assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

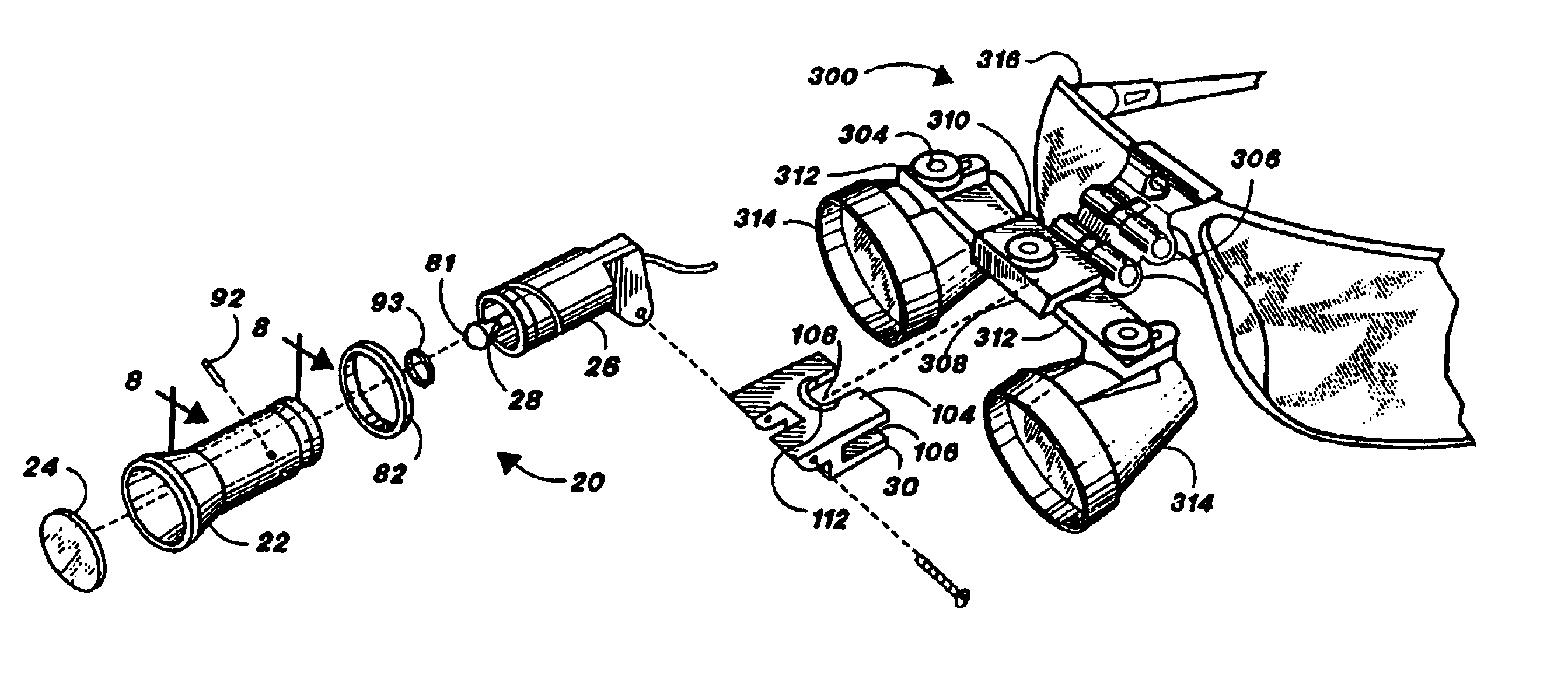

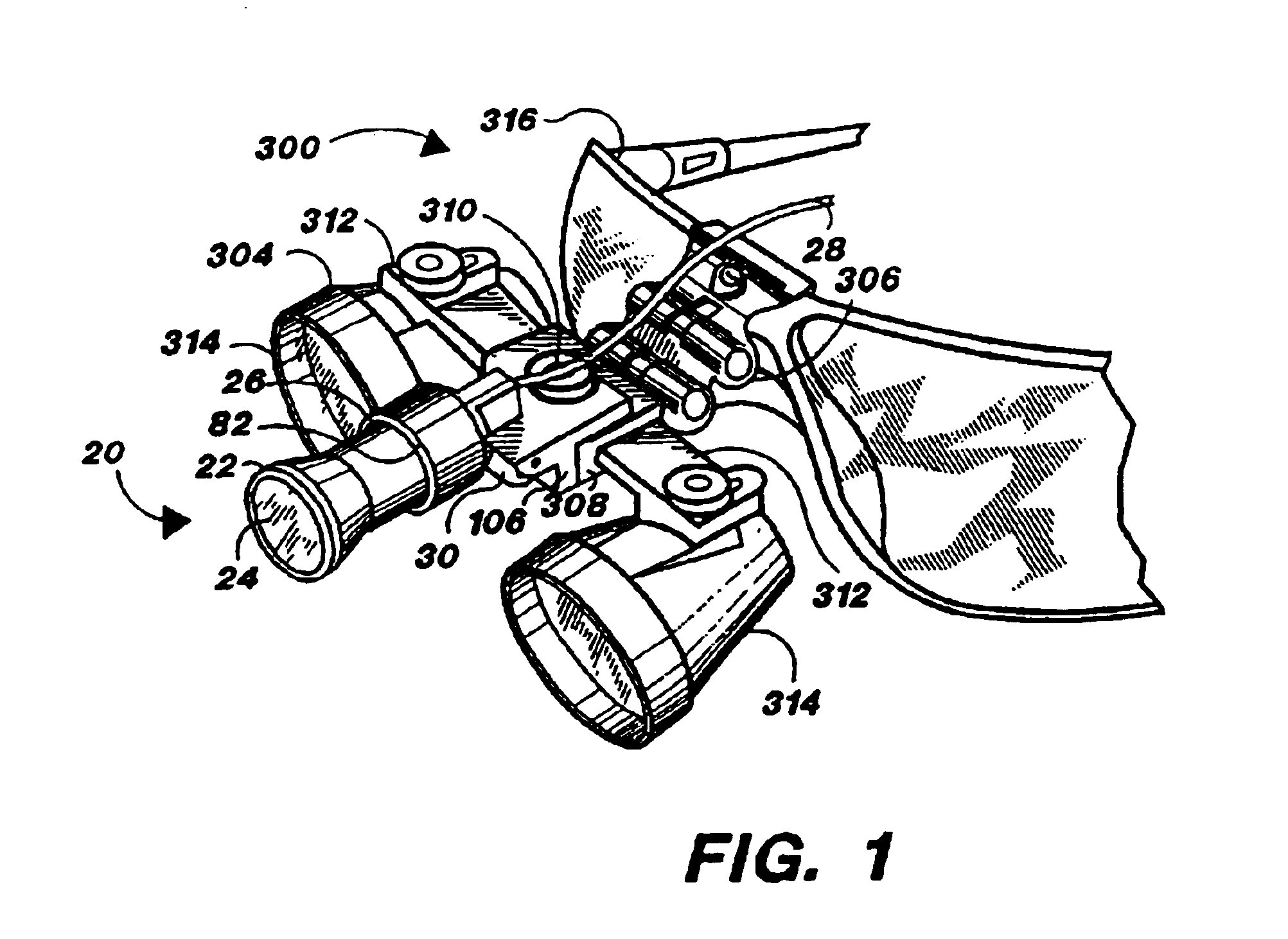

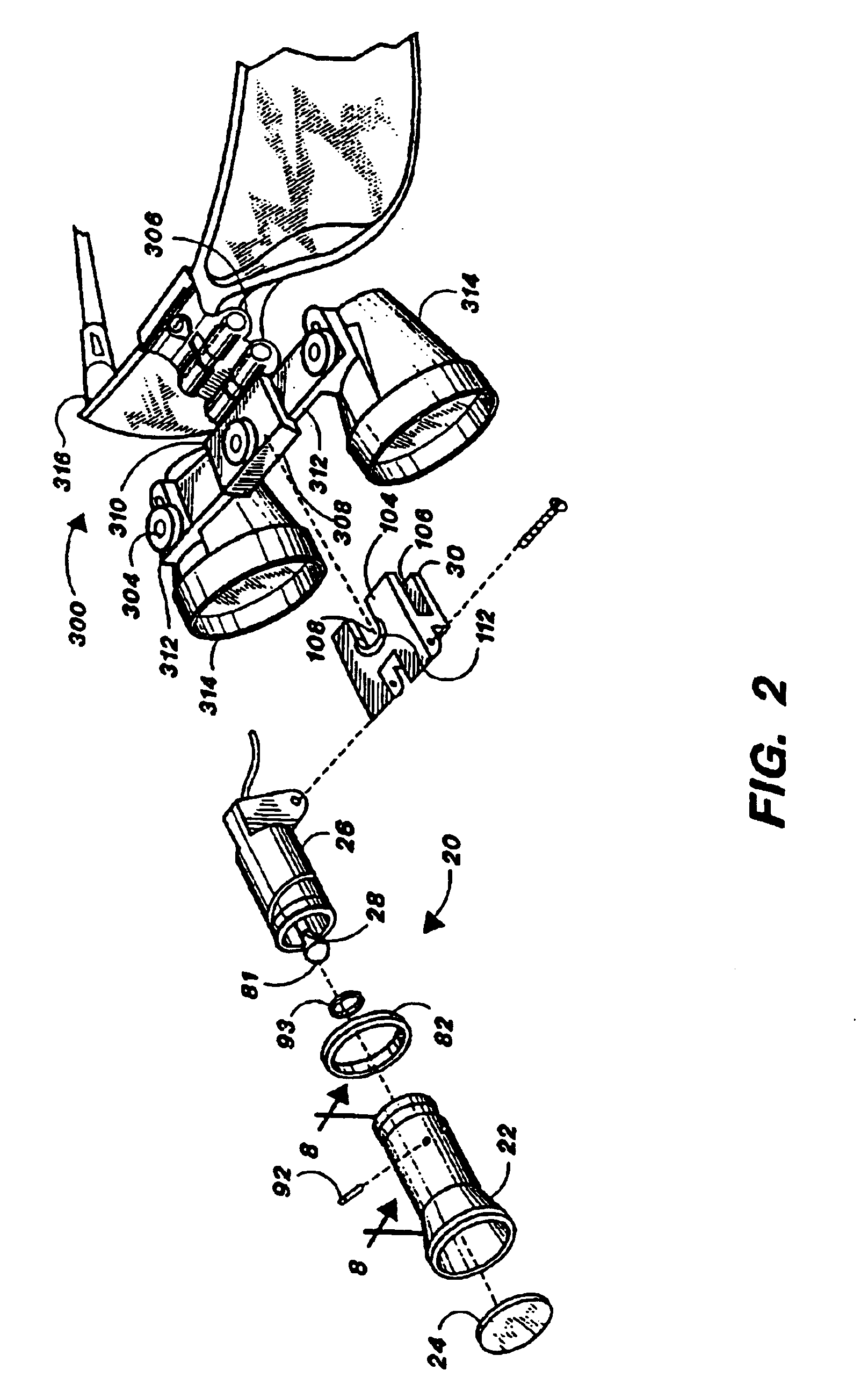

[0042]In the drawings, wherein the same or similar features are designated throughout with the same reference numeral, the illumination assembly of the present invention is shown at 20 in FIGS. 1-3. The illumination assembly 20 has five main components: a housing 22 which contains an optical element 24, a housing base 26 engaged to the housing 22 and wherein a light guide 28 enters, and a clip 30 which provides attachment means for removably attaching the housing base 26 to the user's head or headgear. Throughout this specification, when reference is made to attachment of the illumination assembly 20 to the user's head to headgear, this is understood to include attachment to implements mounted on the user's head such as eyeglasses and goggles, face shields and masks, and headbands and helmets, as well as similar implements. It is further understood to include attachment to accessory implements such as lenses, loupes, and binoculars mounted on the aforementioned implements. Each of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com