Pre-embedded sprue system

A technology of pre-embedding and pouring cups, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of low utilization rate of molten steel, high production cost, and low production quality, and achieve weight reduction, quality assurance, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

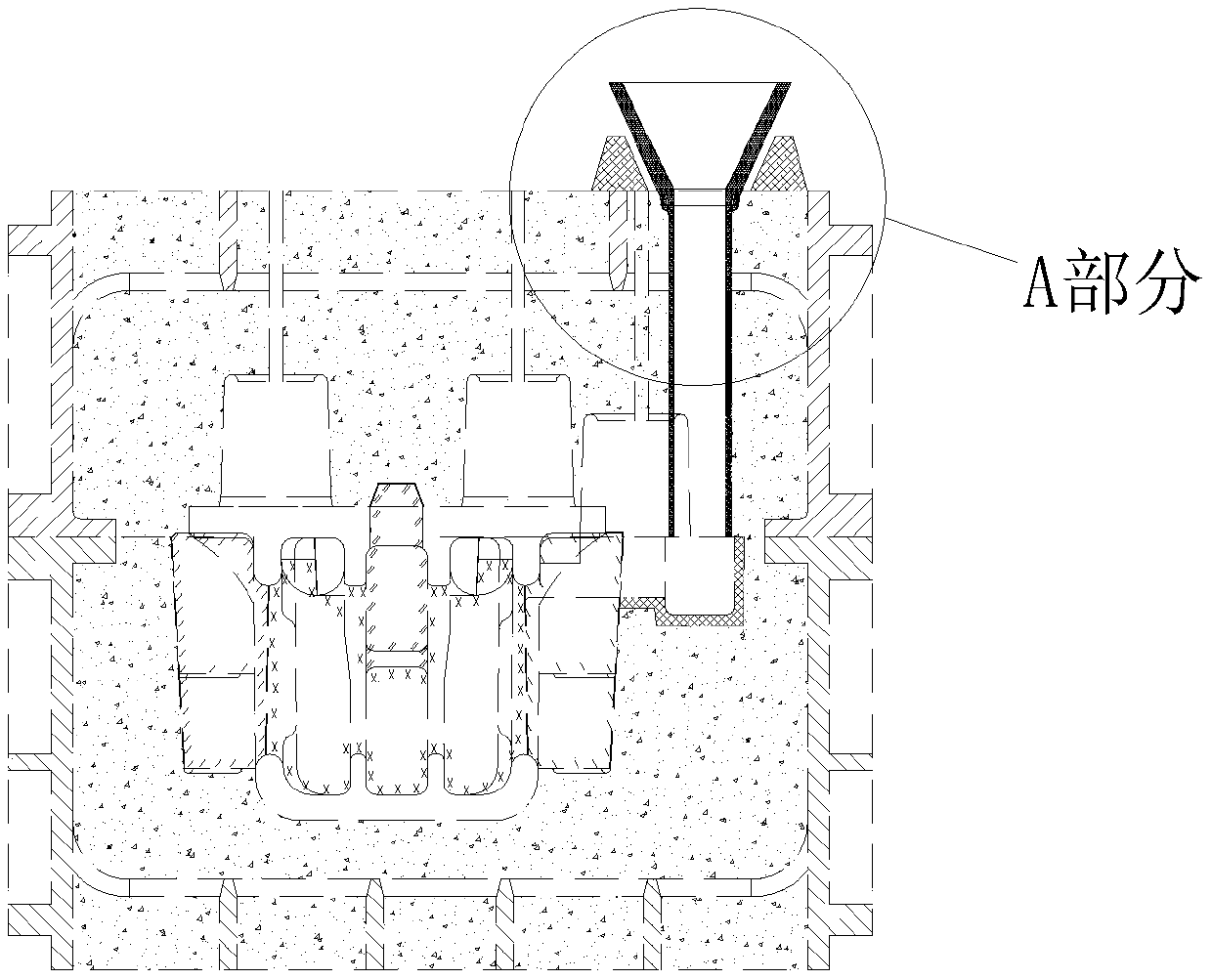

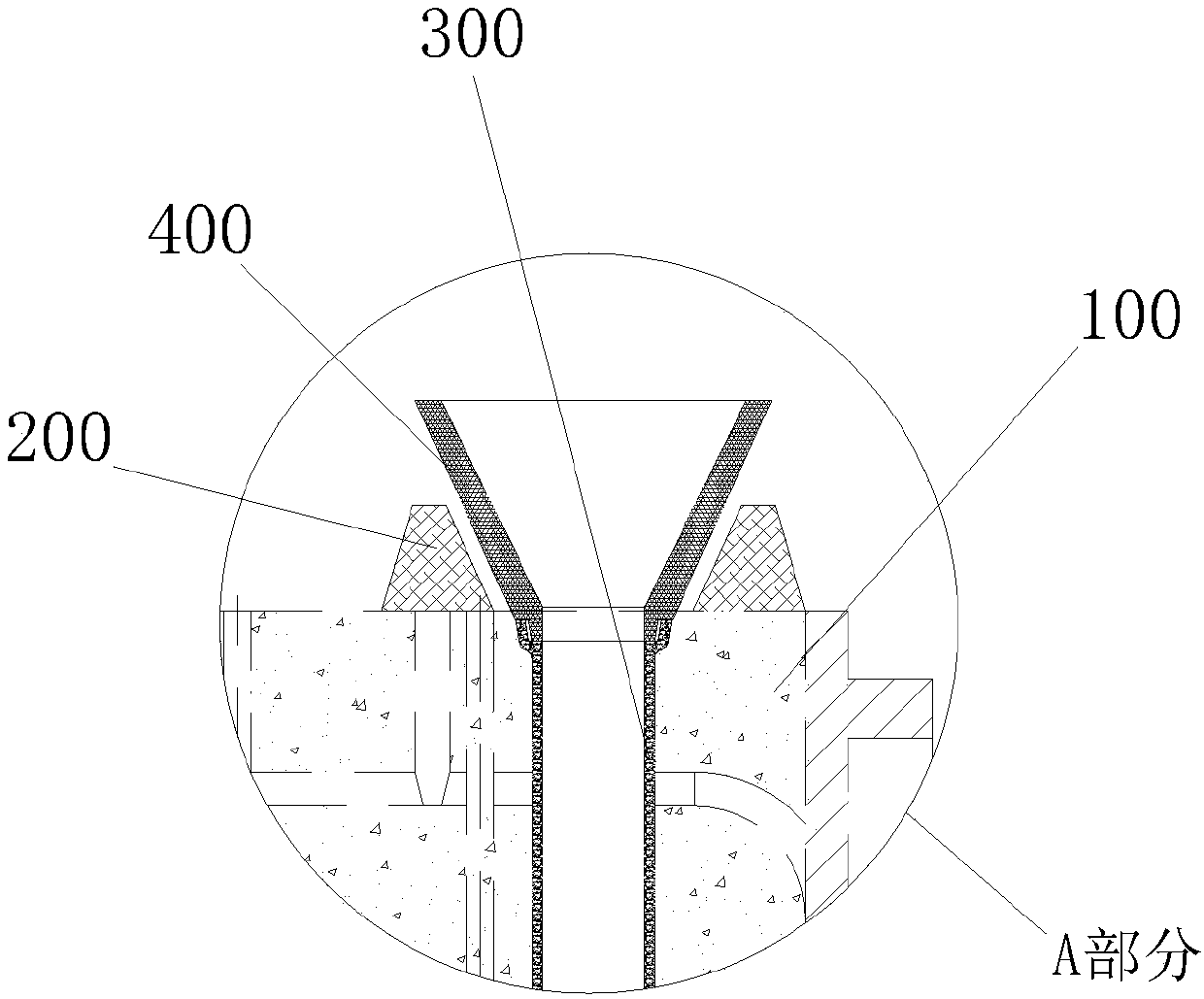

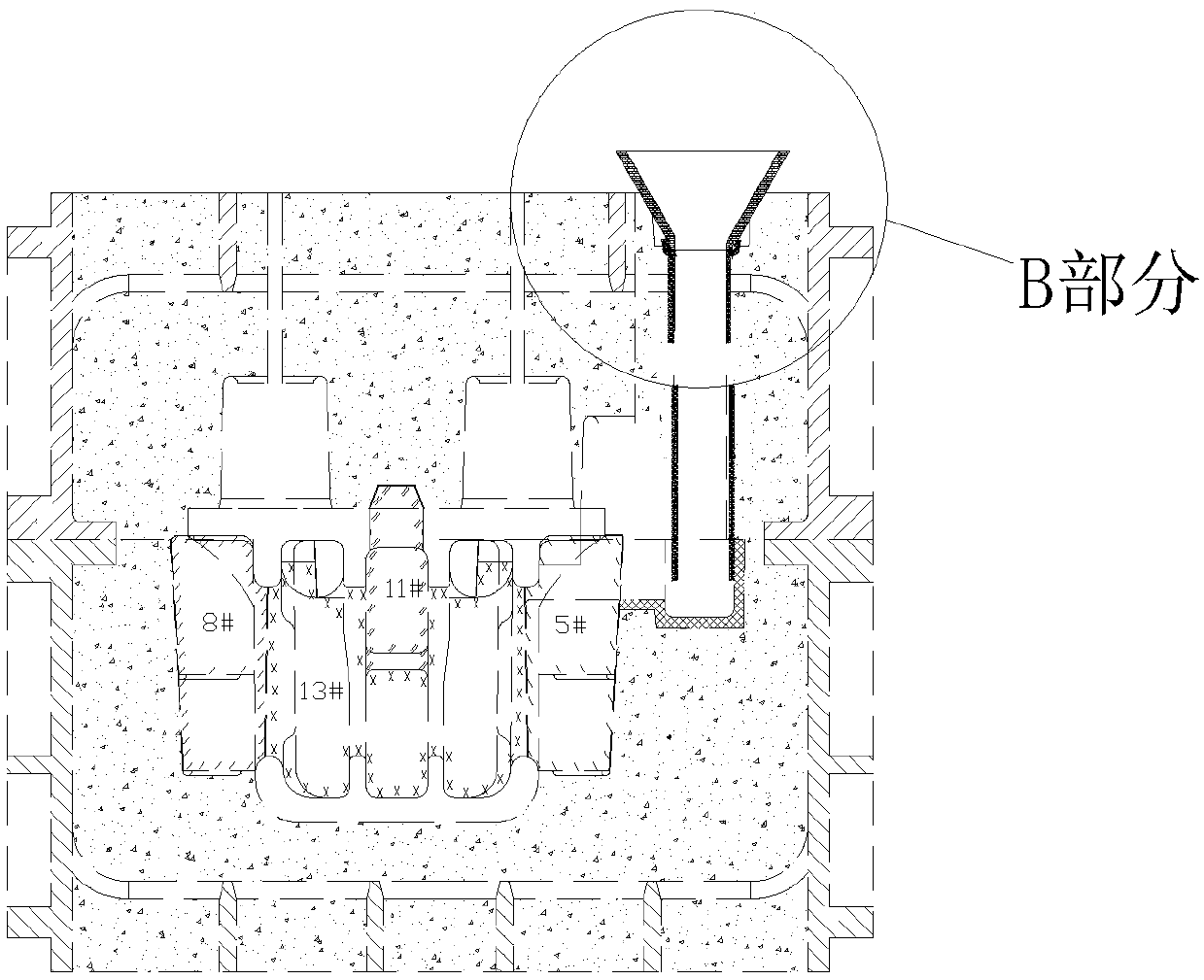

[0024] combine image 3 and Figure 4 As shown, a pre-embedded gate system includes a sand box 1, a casting pottery tube 2 in the sand box 1 and a sprue cup 3, and a receiving groove 4 is opened on the sand box 1 at the port of the pouring pottery tube 2, Described receiving groove 4 is made up of upper and lower two parts, and its upper part is the conical shape of upper wide and lower narrow, and its lower part is cylindrical shape, and sprue cup 3 is placed in receiving groove 4, and the upper part of receiving groove 4 The minimum diameter is greater than the minimum diameter of the sprue cup 3 and smaller than the maximum diameter of the sprue cup 3, and the maximum diameter of the upper part of the receiving groove 4 is also greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com