Robot for concrete horizontal springback detection

A concrete and robotic technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of low connection reliability, ineffective and stable provision of rebound instruments, etc., to achieve reliable support, reduce height dimensions, and safety detection The effect of homework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

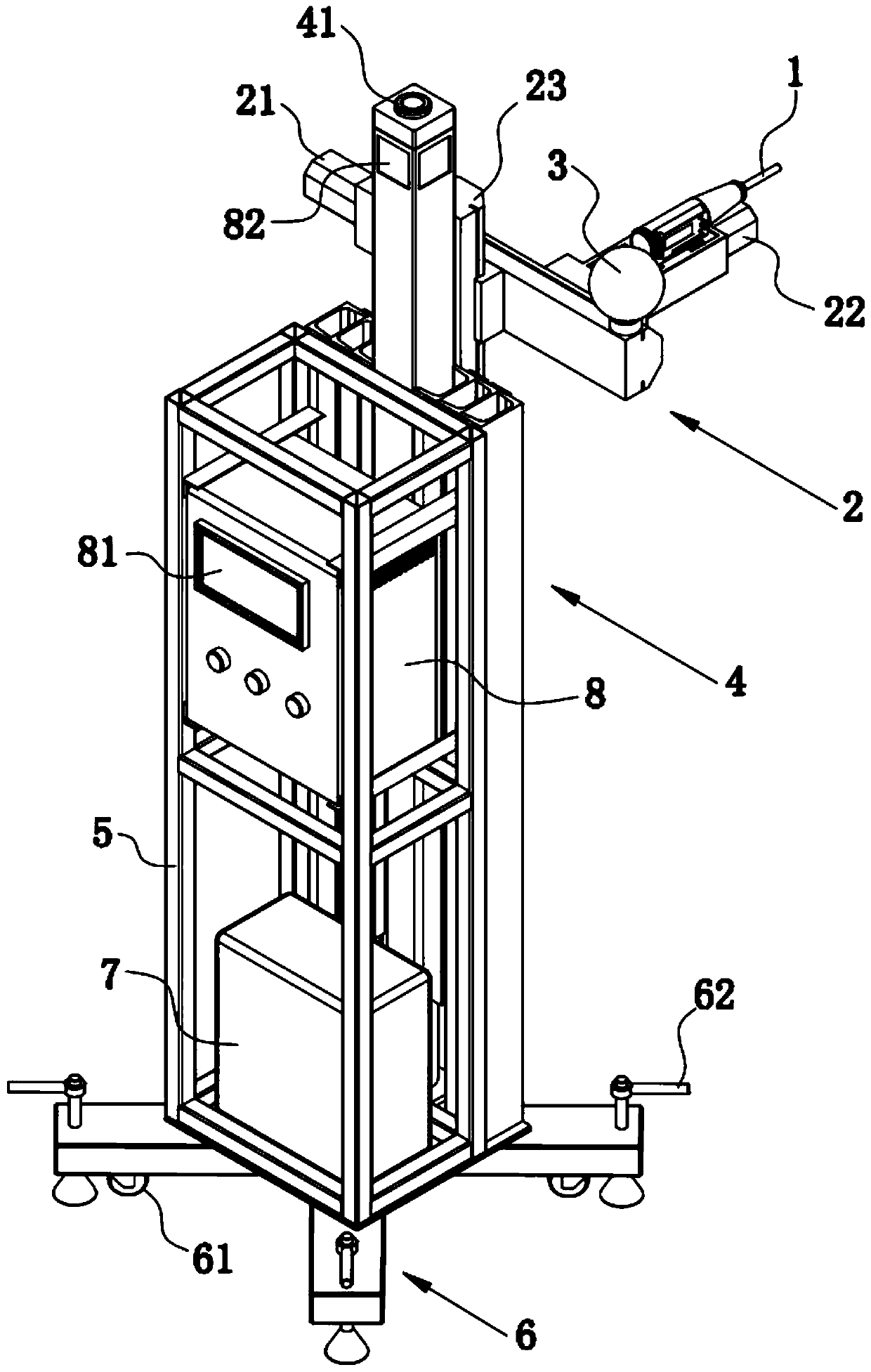

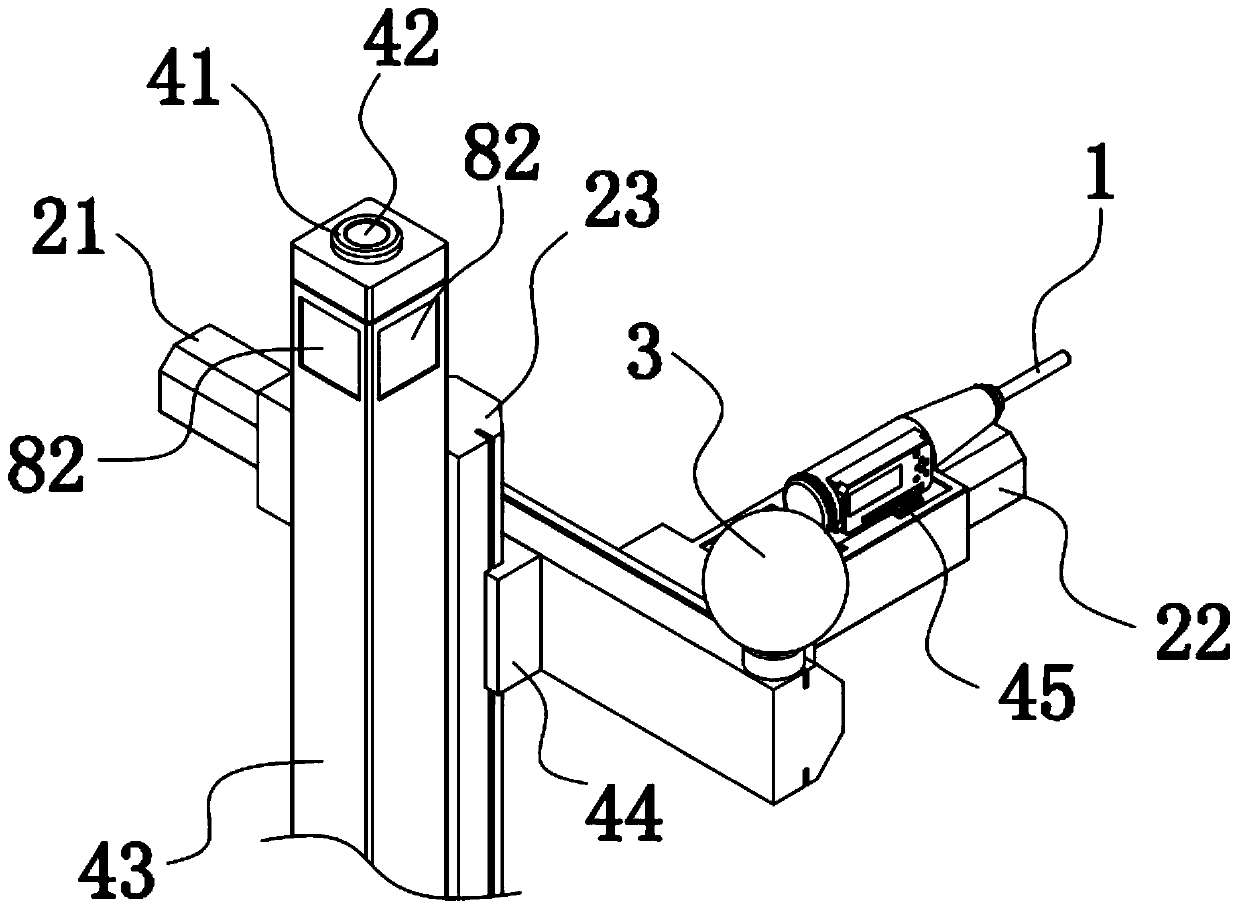

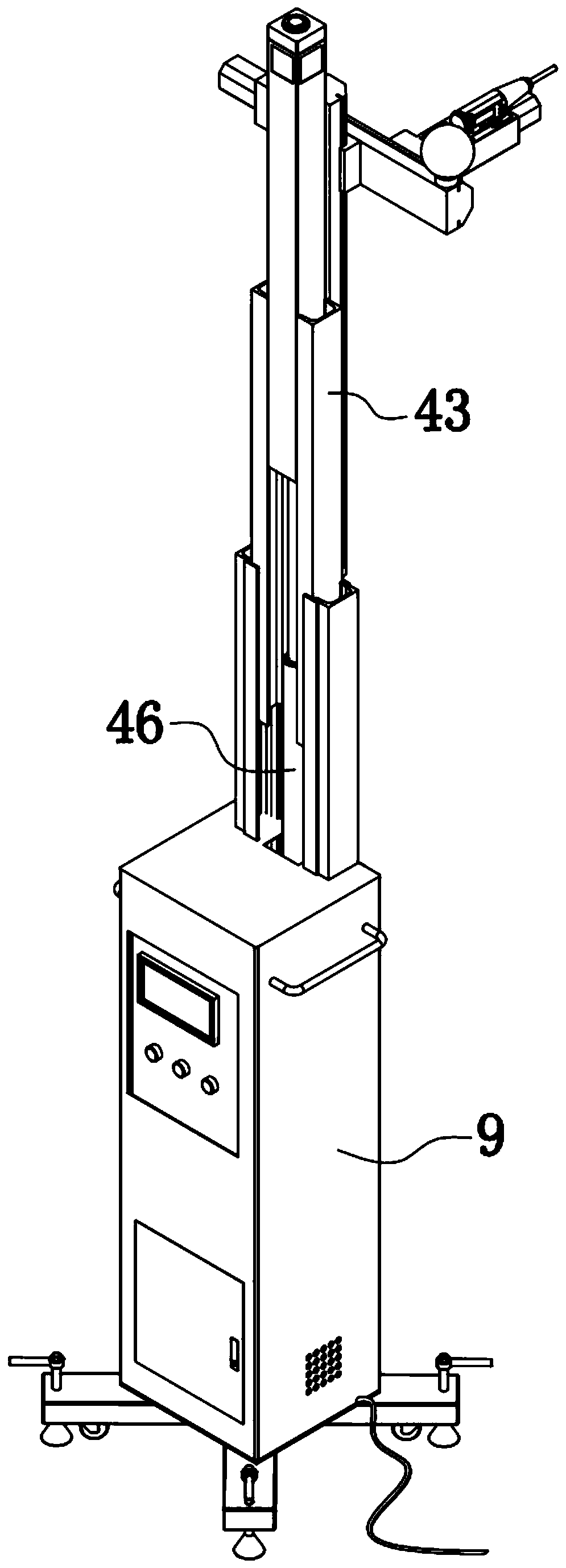

[0035] In order to achieve the purpose of the present invention, a kind of robot that is used for concrete horizontal springback detection comprises: lifting mechanism, has vertical reciprocating linear degree of freedom; Three-dimensional moving mechanism 2, is fixed on the top of lifting mechanism, and three-dimensional moving mechanism 2 includes The vertically connected x-direction linear module 21, y-direction linear module 22, and z-direction linear module 23; the detection mechanism includes a digital display rebound hammer 1 fixed parallel to the y-direction linear module 22, and a digital display rebound hammer 1 It has the freedom of movement along the three rectangular coordinate axes of x, y, and z; the lifting mechanism also includes a supporting mechanism, and the top of the lifting mechanism is a vertically telescopic nesting column 43, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com