Anti-static self-exhaust protection adhesive tape and preparation method thereof

A protective tape, self-exhaust technology, applied in adhesives, film/sheet adhesives, coatings, etc., to achieve stable anti-static, good anti-static effect, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

[0029] The experimental methods in the following examples are conventional methods unless otherwise specified. The materials used in the following examples are all commercially available products unless otherwise specified.

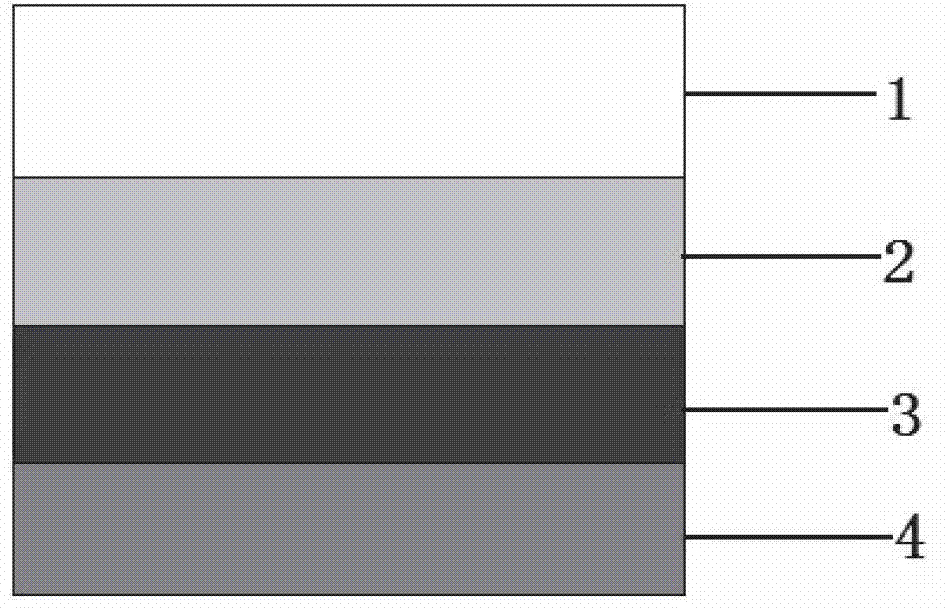

[0030] The preparation method of the antistatic self-exhausting protective adhesive tape of the embodiment of the present invention 1 to 4 is as follows:

[0031] 1) Preheat the substrate 1 with hot air to remove the moisture adsorbed on the surface of the substrate 1;

[0032] 2) Use an ion air gun on the surface of the substrate 1 to remove the static electricity carried on the surface of the substrate 1;

[0033] 3) Use a silica gel roller to remove dust and foreign matter adsorbed on the...

PUM

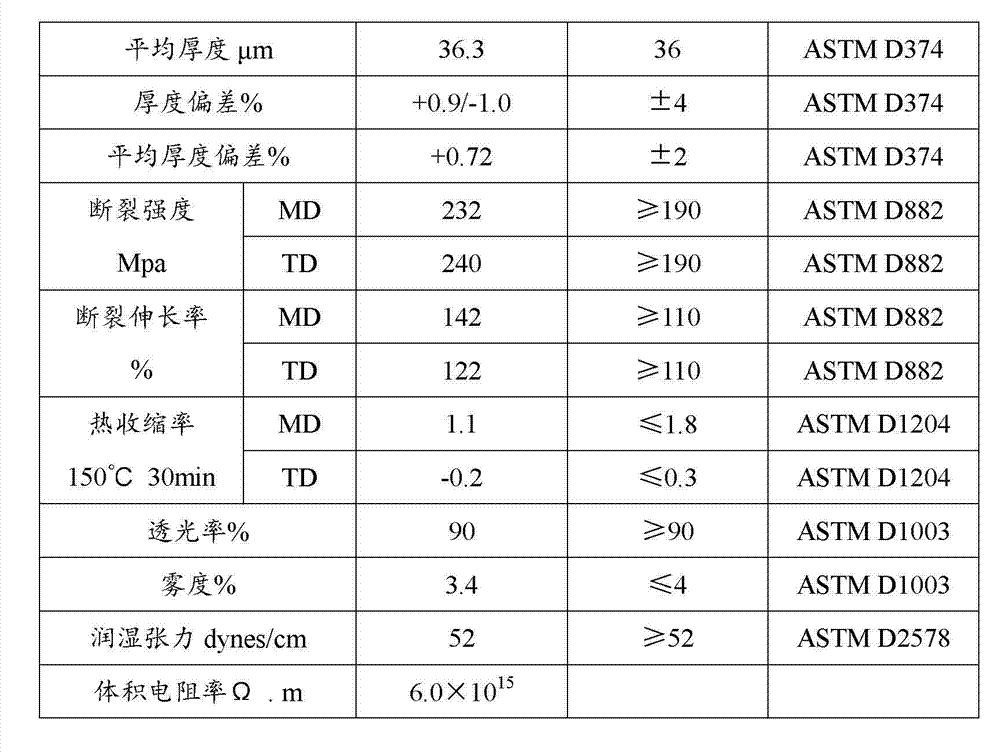

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com