Patents

Literature

191results about How to "Easy and fast processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

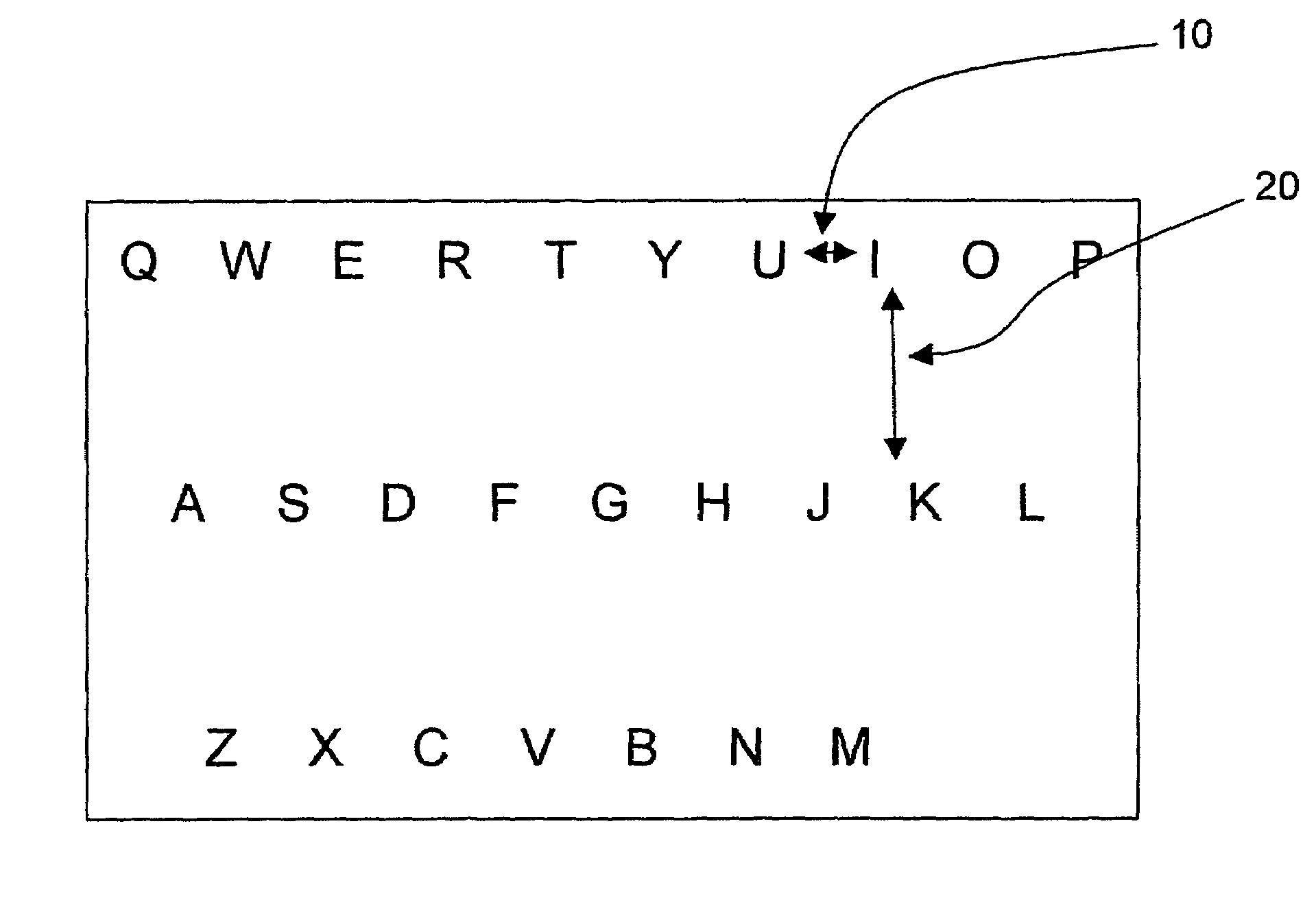

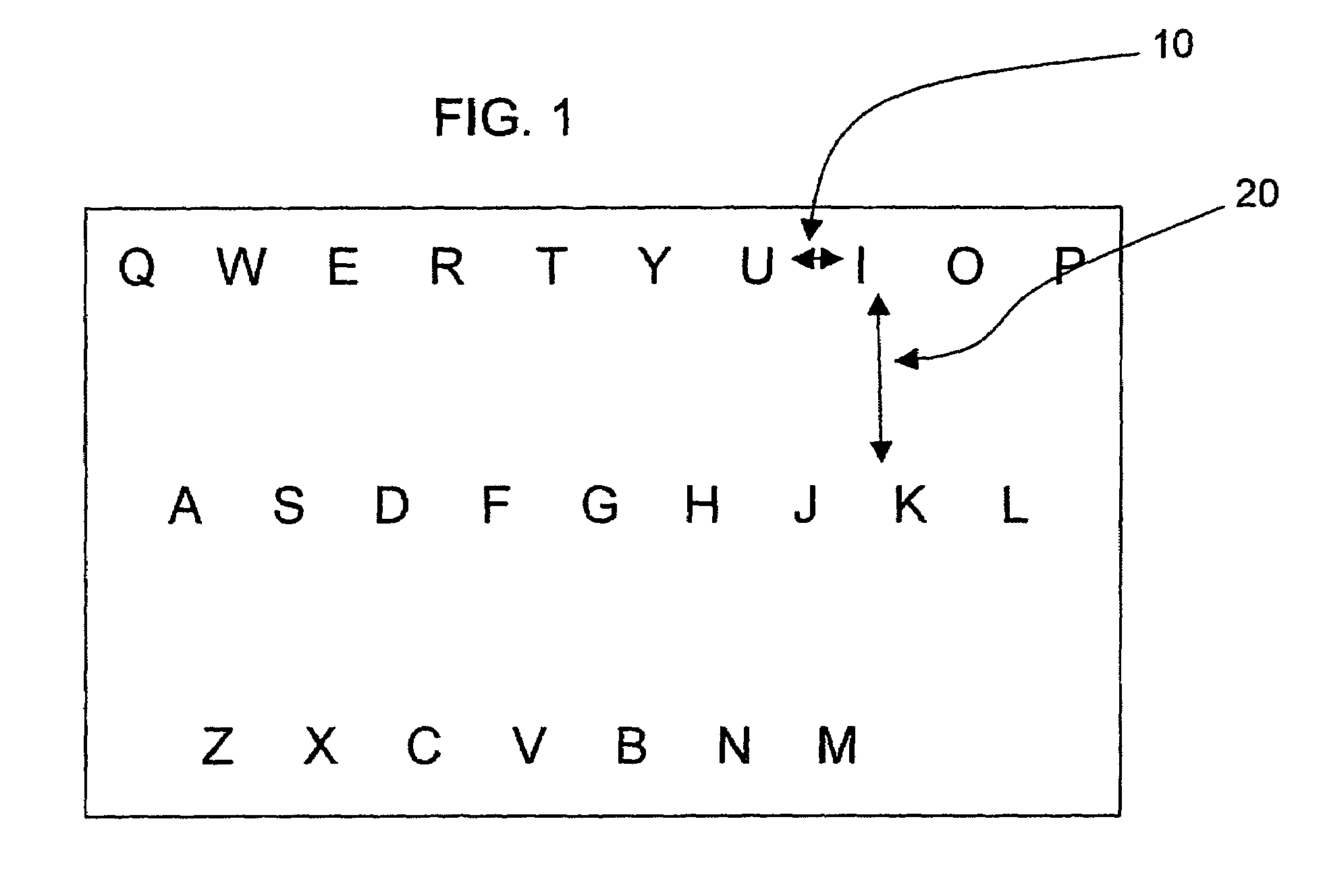

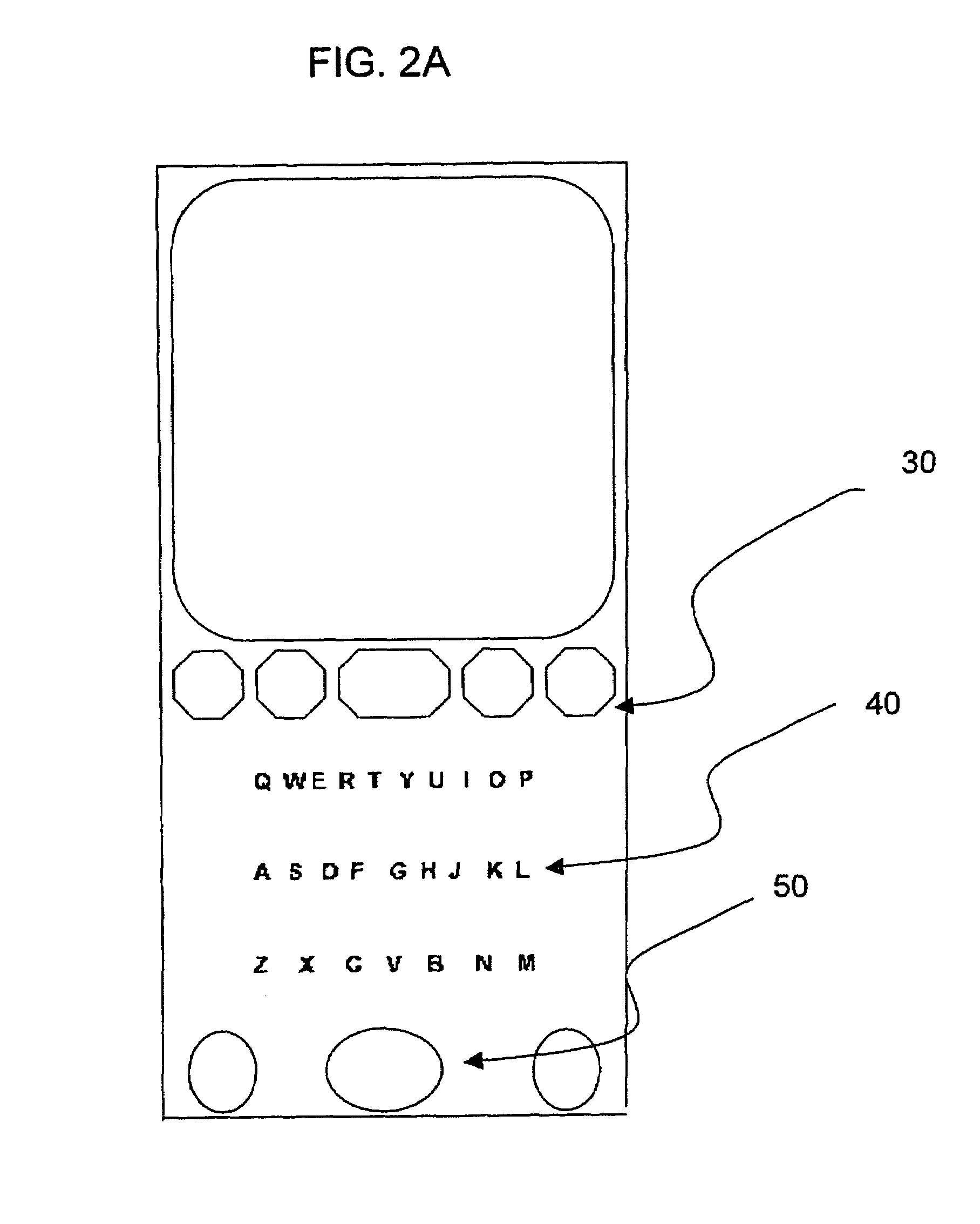

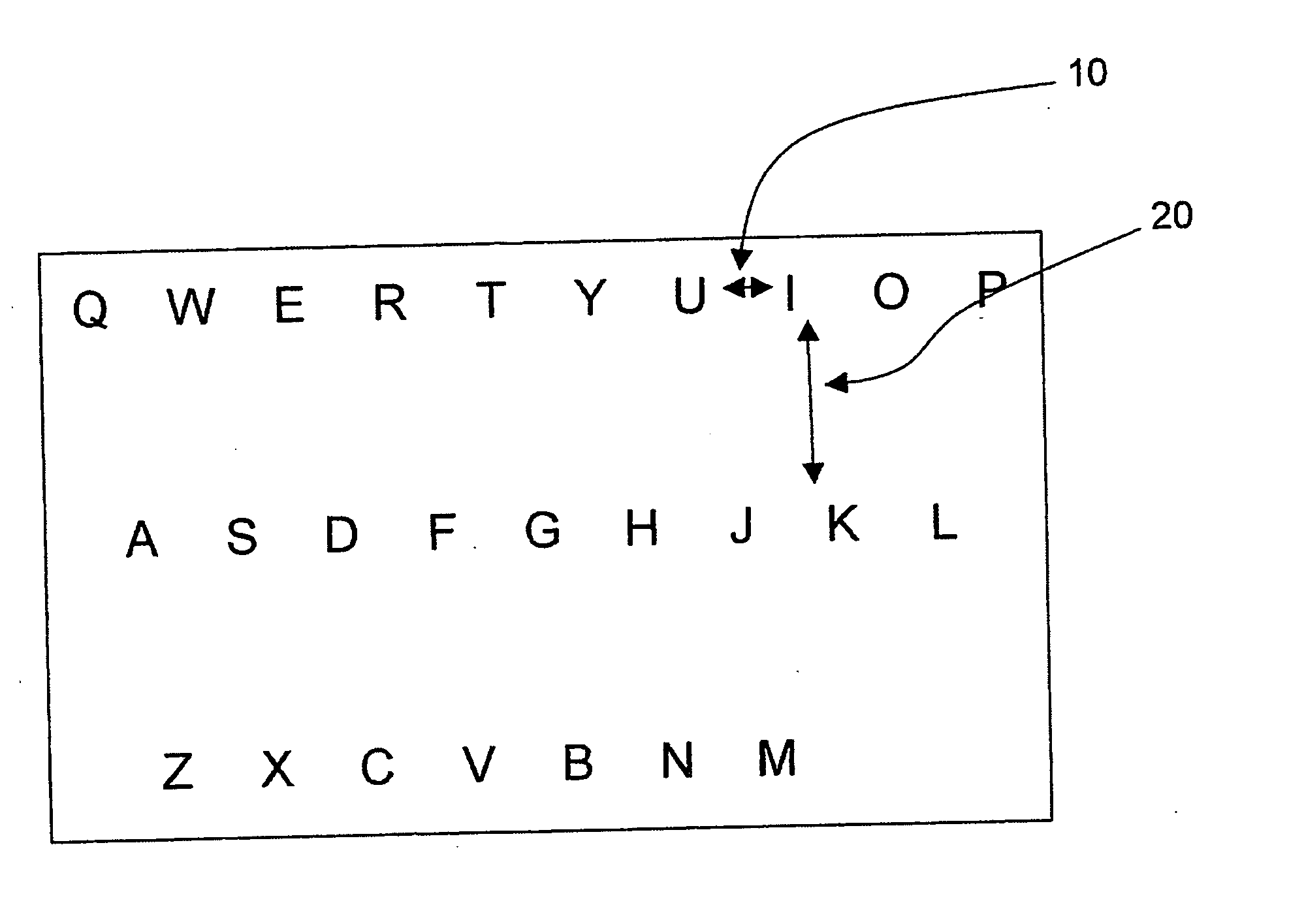

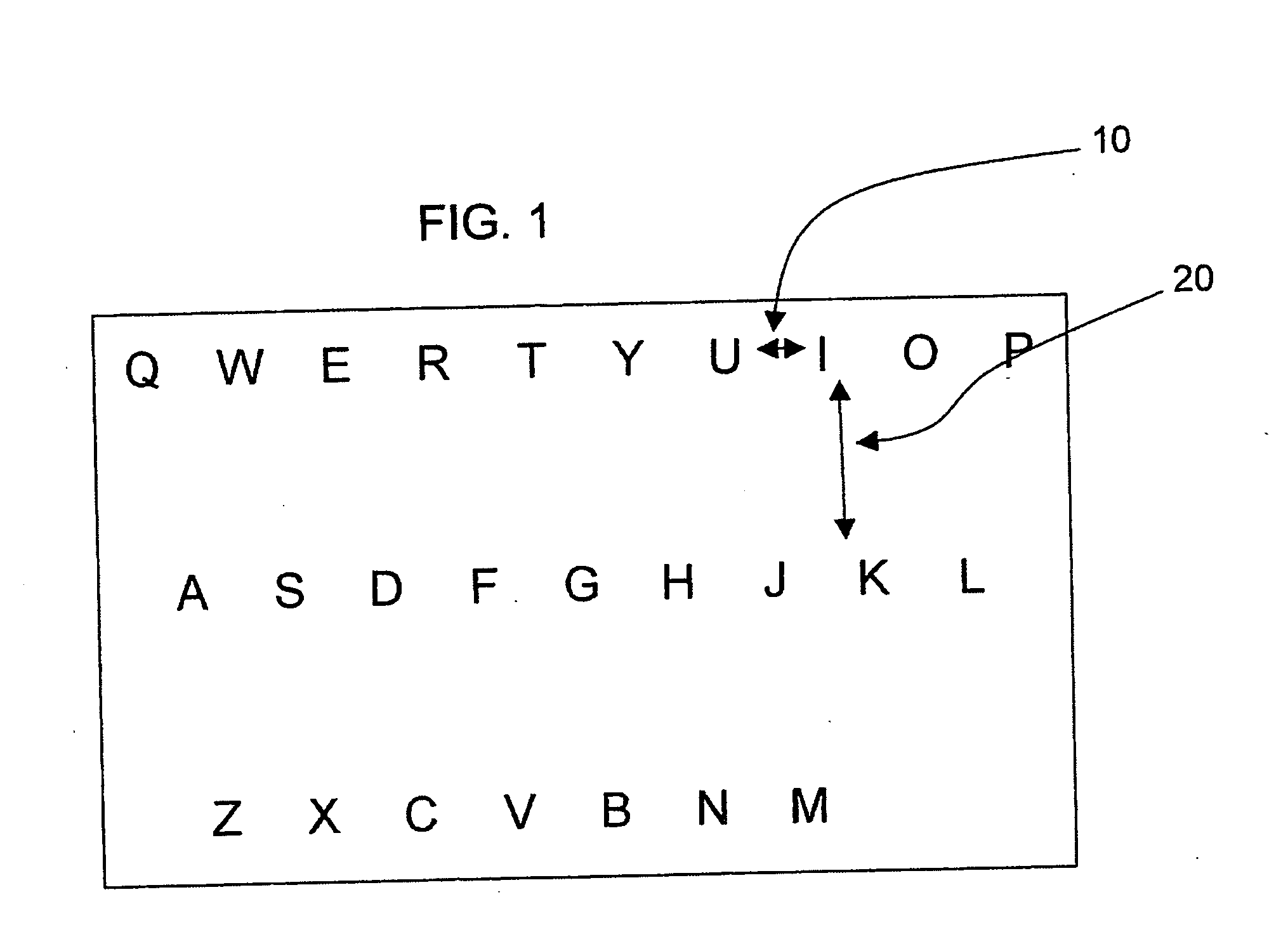

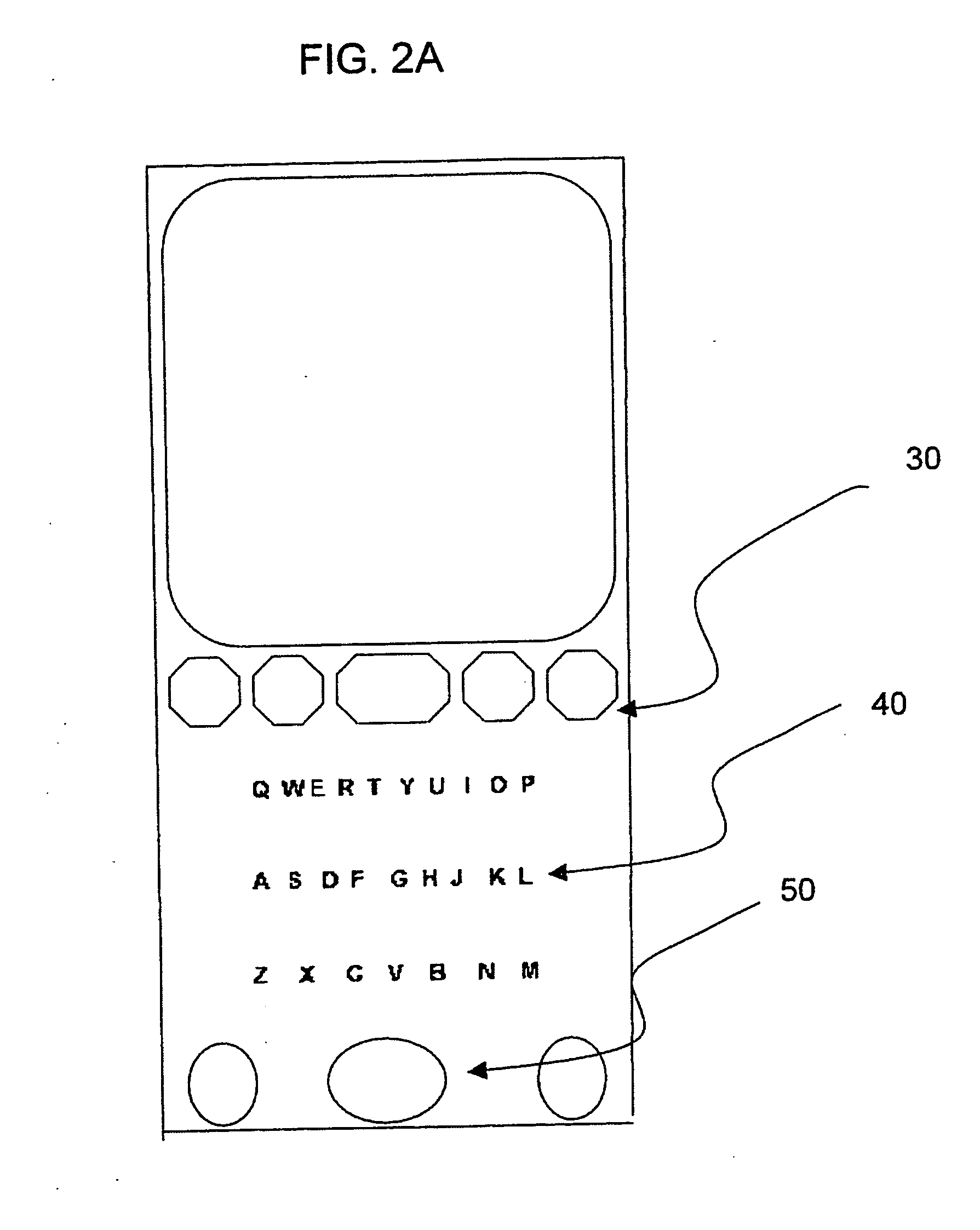

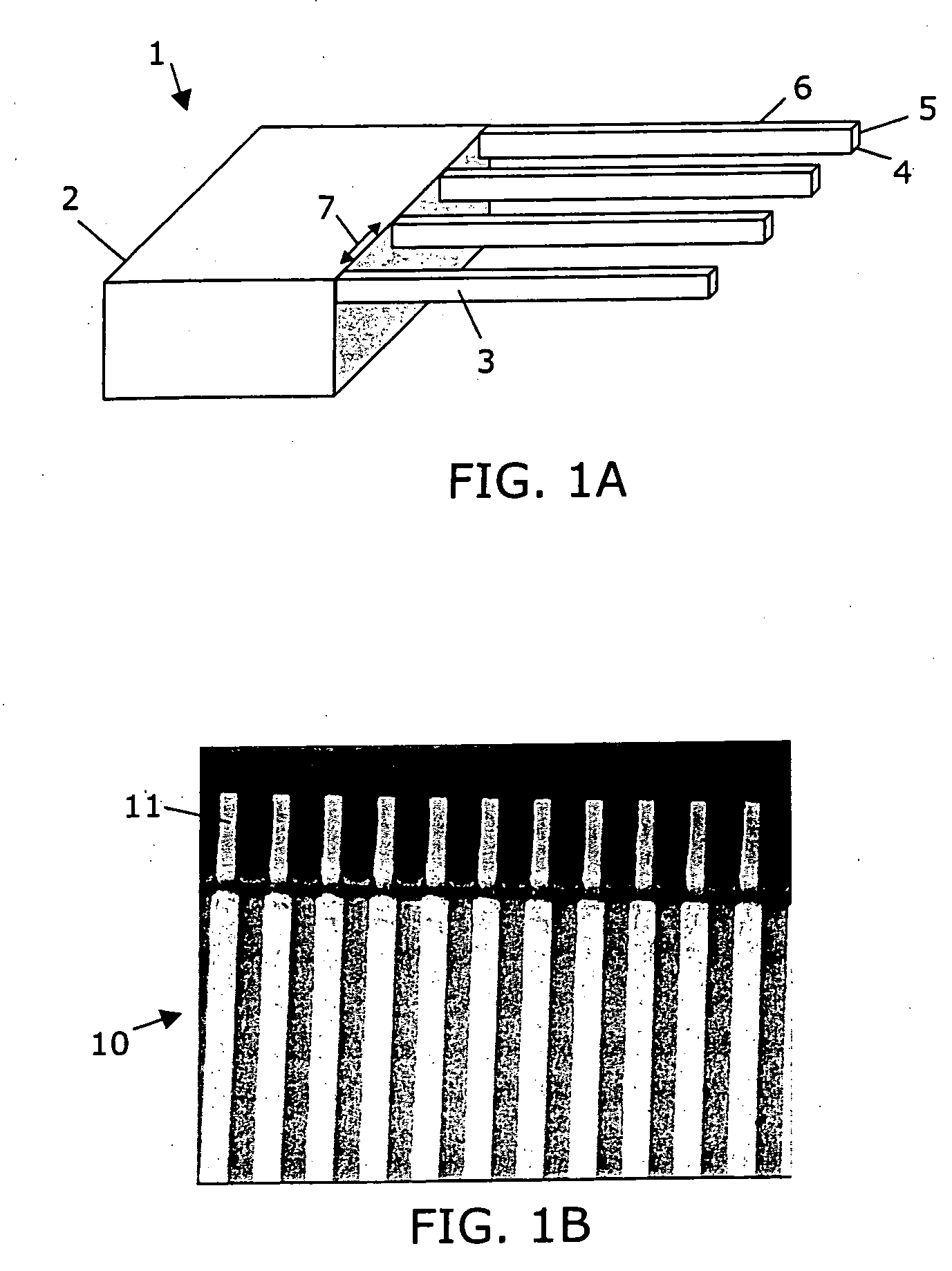

Finger activated reduced keyboard and a method for performing text input

InactiveUS7508324B2Fast and comfortable text inputSmall sizeInput/output for user-computer interactionElectronic switchingText entryArea density

A reduced keyboard apparatus and method for use with small-sized communications and computing devices. Input via the keyboard is performed using fingers or thumbs. The keyboard is characterized by having no discrete boundaries between the included character spaces. The direction and the destination area of a keystroke do not have to be accurate and may correspond to a plurality of included character spaces. Each of the possible characters is provided with a probability value, continuously redefined according to the specific keyboard area activated by the keystroke. The input of a word is defined by a sequence of keystrokes corresponding to the letters of the word. Subsequent to the completion of a keystroke sequence, the apparatus and method determine the identity of the word through a disambiguation process based on area density distribution. The apparatus and method enable fast, natural, and intuitive tapping on small keyboards having character areas much smaller than the user's fingers while at the same time provide highly efficient word determination.

Owner:CERENCE OPERATING CO

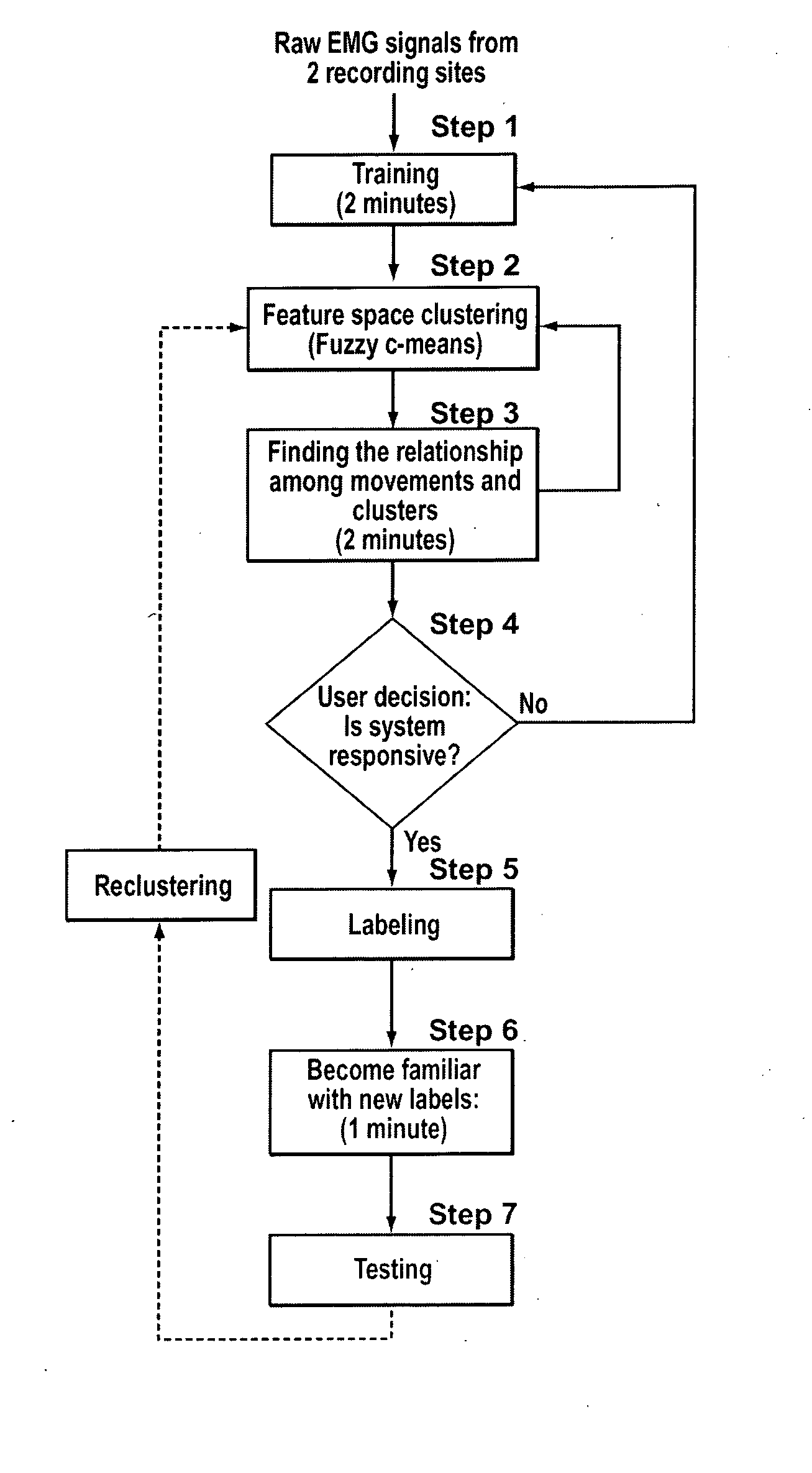

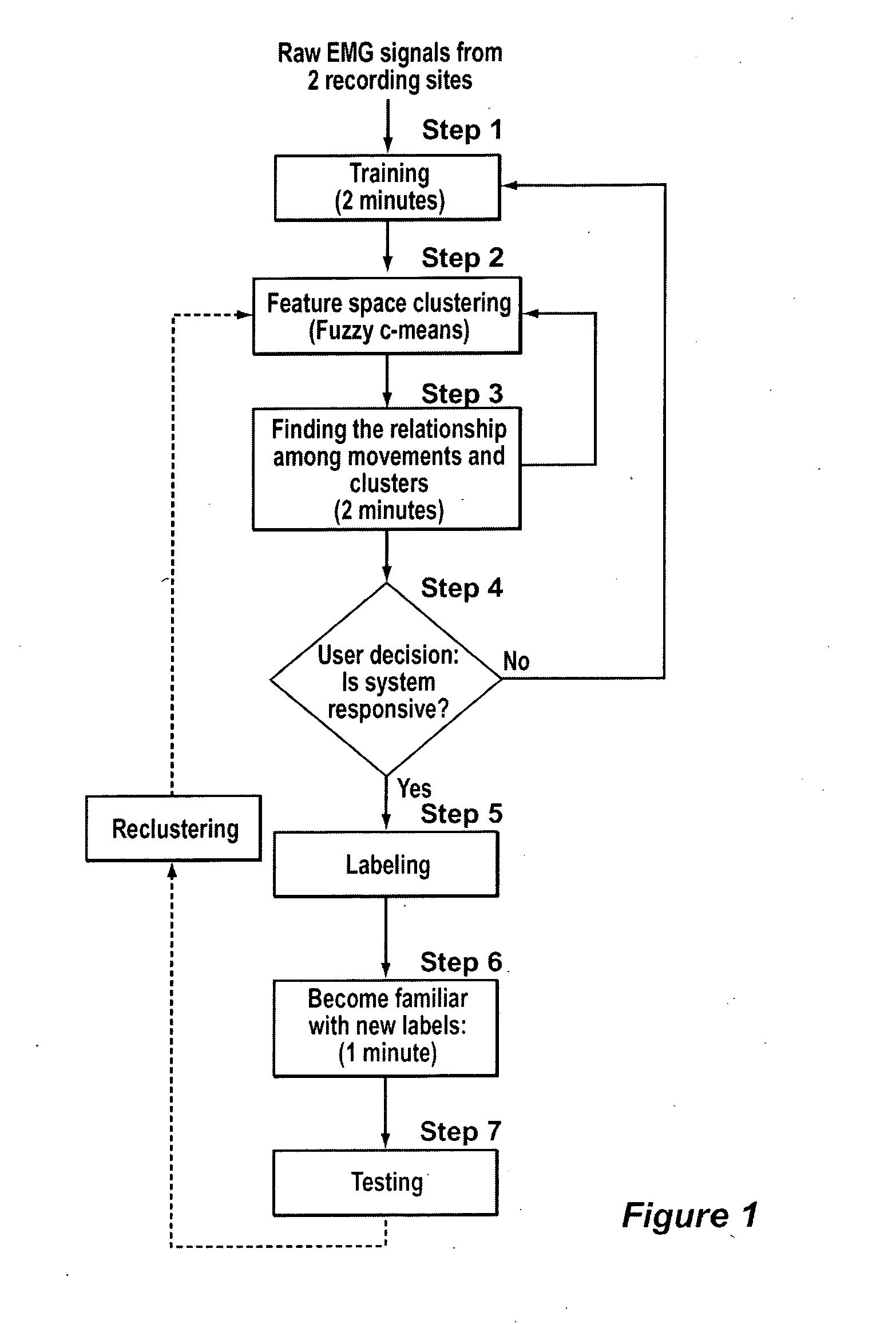

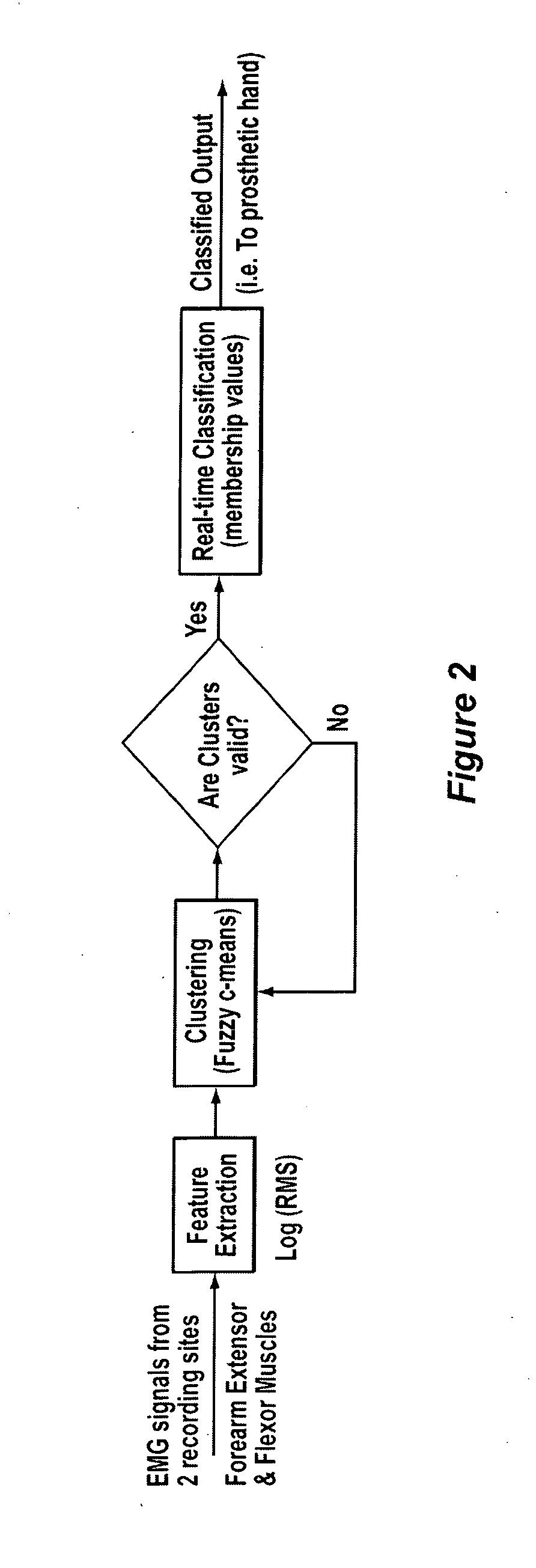

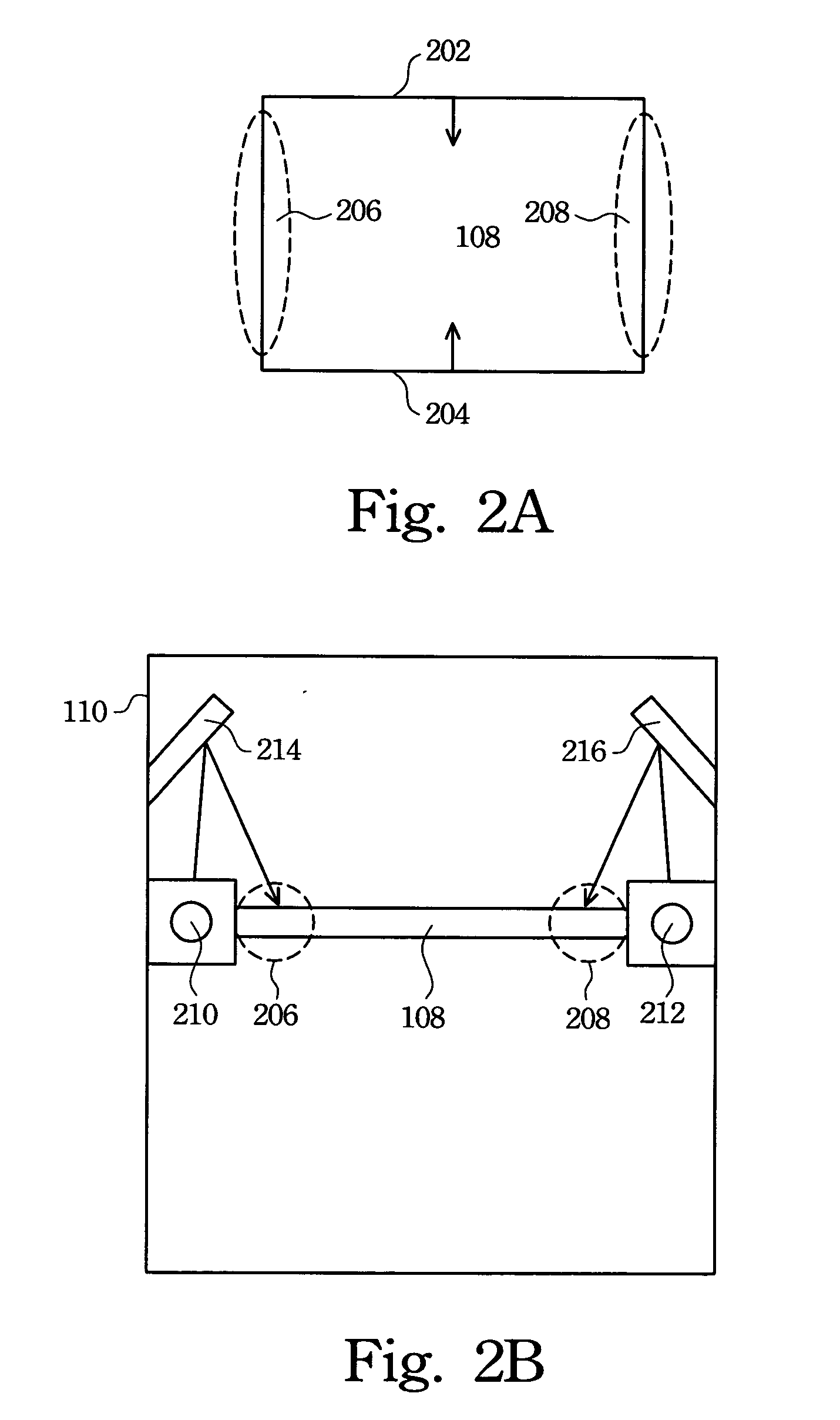

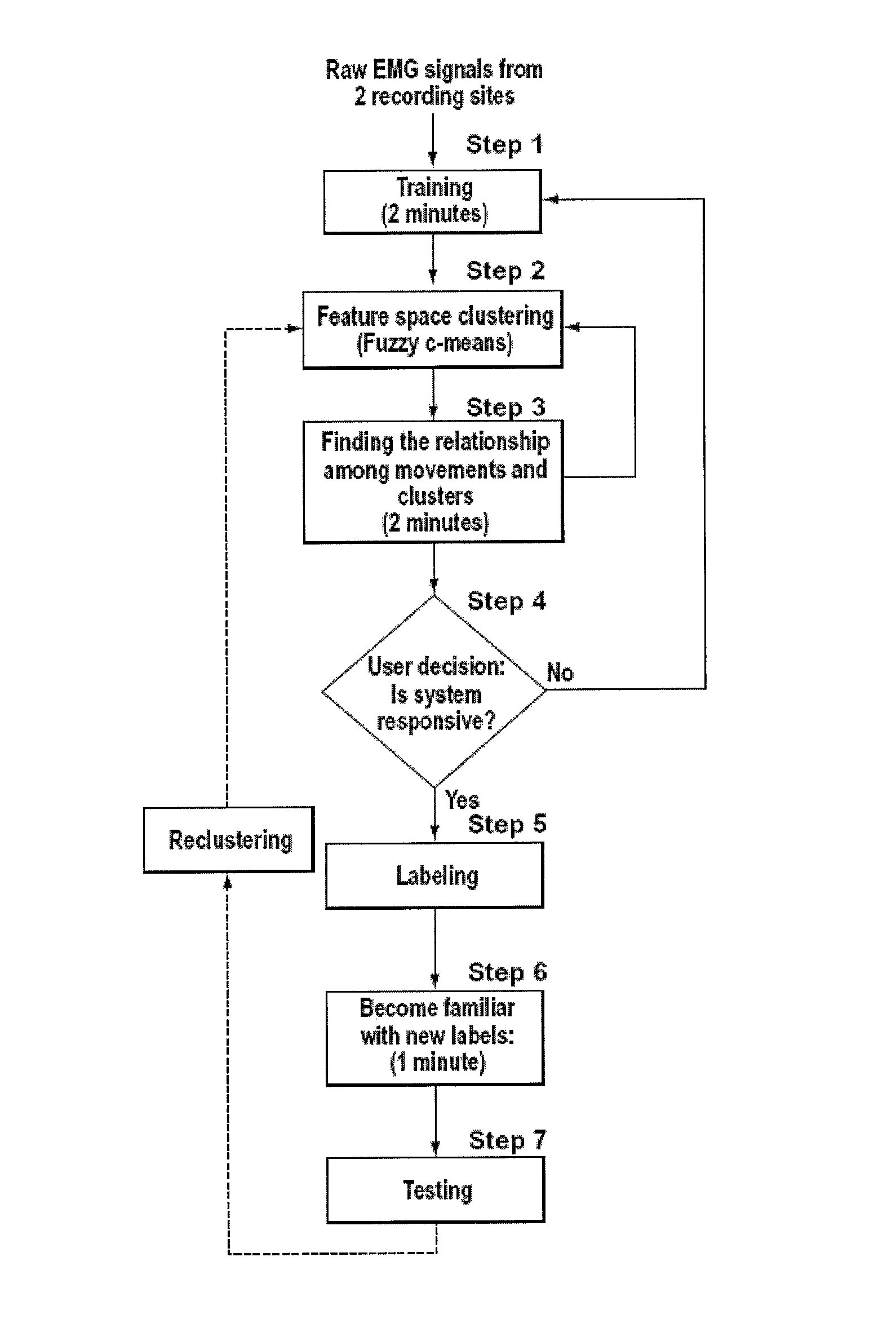

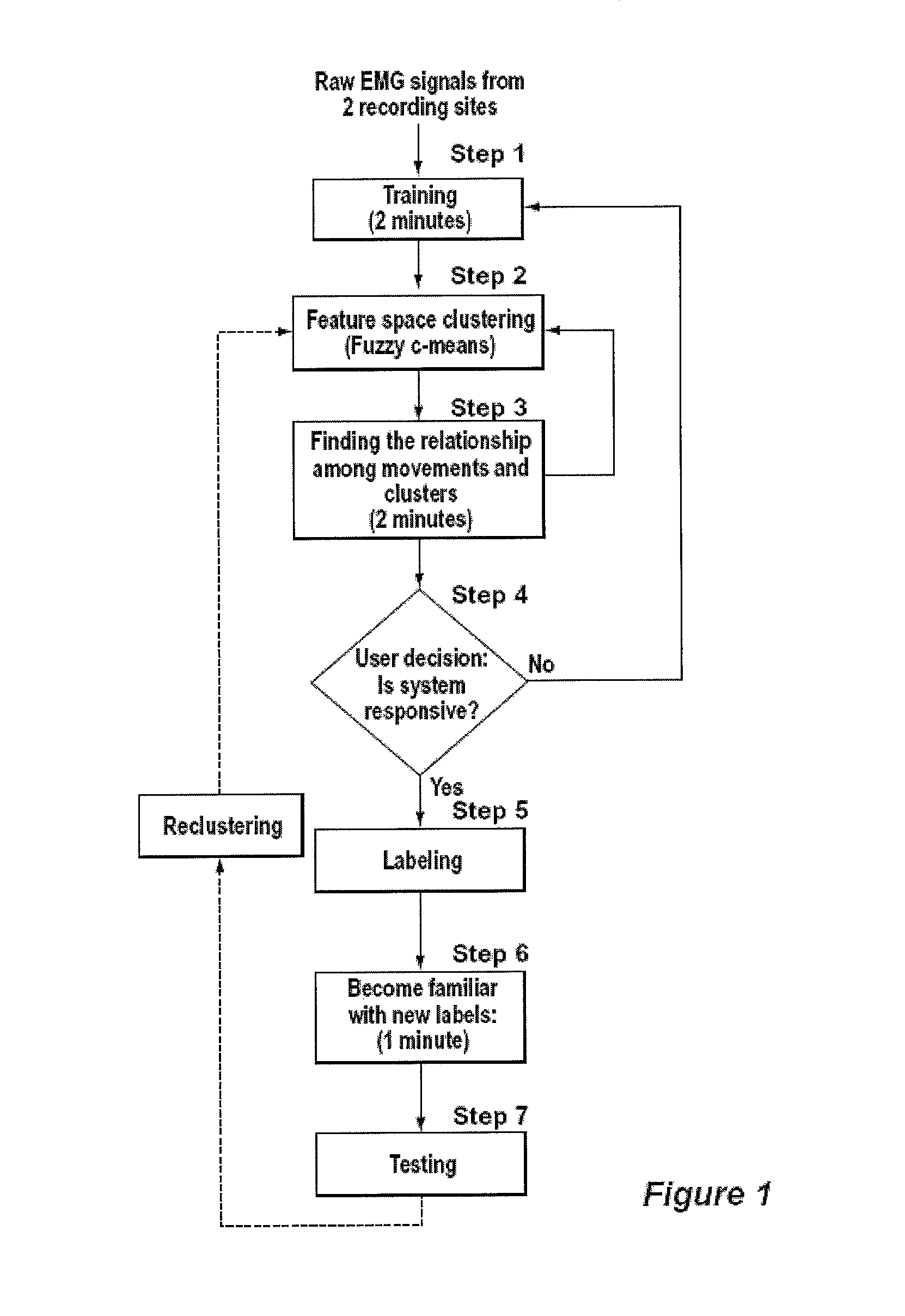

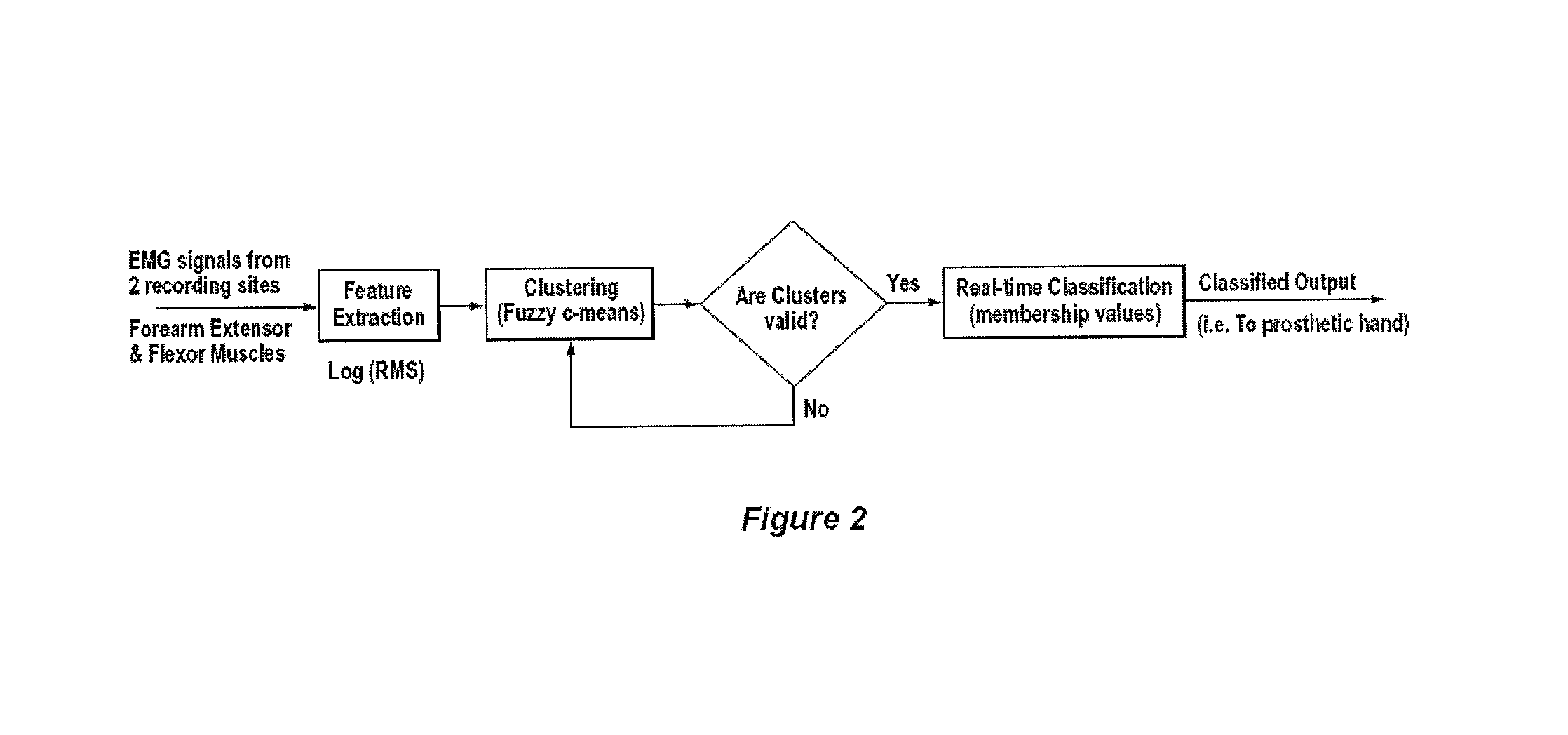

Method, system and apparatus for real-time classification of muscle signals from self-selected intentional movements

InactiveUS20080058668A1Improve abilitiesEasy to operateMedical data miningElectromyographyMuscle contractionSelf training

A new method, system and apparatus is provided that enables muscle signals that correspond to muscle contractions to be mapped to one or more functions of an electronic device such as a prosthetic device or gaming apparatus. Muscle signals are classified in real-time from self-selected intentional movements. A self-training protocol allows users to select and label their own muscle contractions, and is operable to automatically determine the discernible and repeatable muscle signals generated by the user. A visual display means is used to provide visual feedback to users illustrating the responsiveness of the system to muscle signals generated by the user.

Owner:HOLLAND BLOORVIEW KIDS REHABILITATION HOSPITAL

Finger activated reduced keyboard and a method for performing text input

InactiveUS20060028450A1Fast tappingEasy and fast processingInput/output for user-computer interactionElectronic switchingArea densityThumb

A reduced keyboard apparatus and method for use with small-sized communications and computing devices. Input via the keyboard is performed using fingers or thumbs. The keyboard is characterized by having no discrete boundaries between the included character spaces. The direction and the destination area of a keystroke do not have to be accurate and may correspond to a plurality of included character spaces. Each of the possible characters is provided with a probability value, continuously redefined according to the specific keyboard area activated by the keystroke. The input of a word is defined by a sequence of keystrokes corresponding to the letters of the word. Subsequent to the completion of a keystroke sequence, the apparatus and method determine the identity of the word through a disambiguation process based on area density distribution. The apparatus and method enable fast, natural, and intuitive tapping on small keyboards having character areas much smaller than the user's fingers while at the same time provide highly efficient word determination.

Owner:CERENCE OPERATING CO

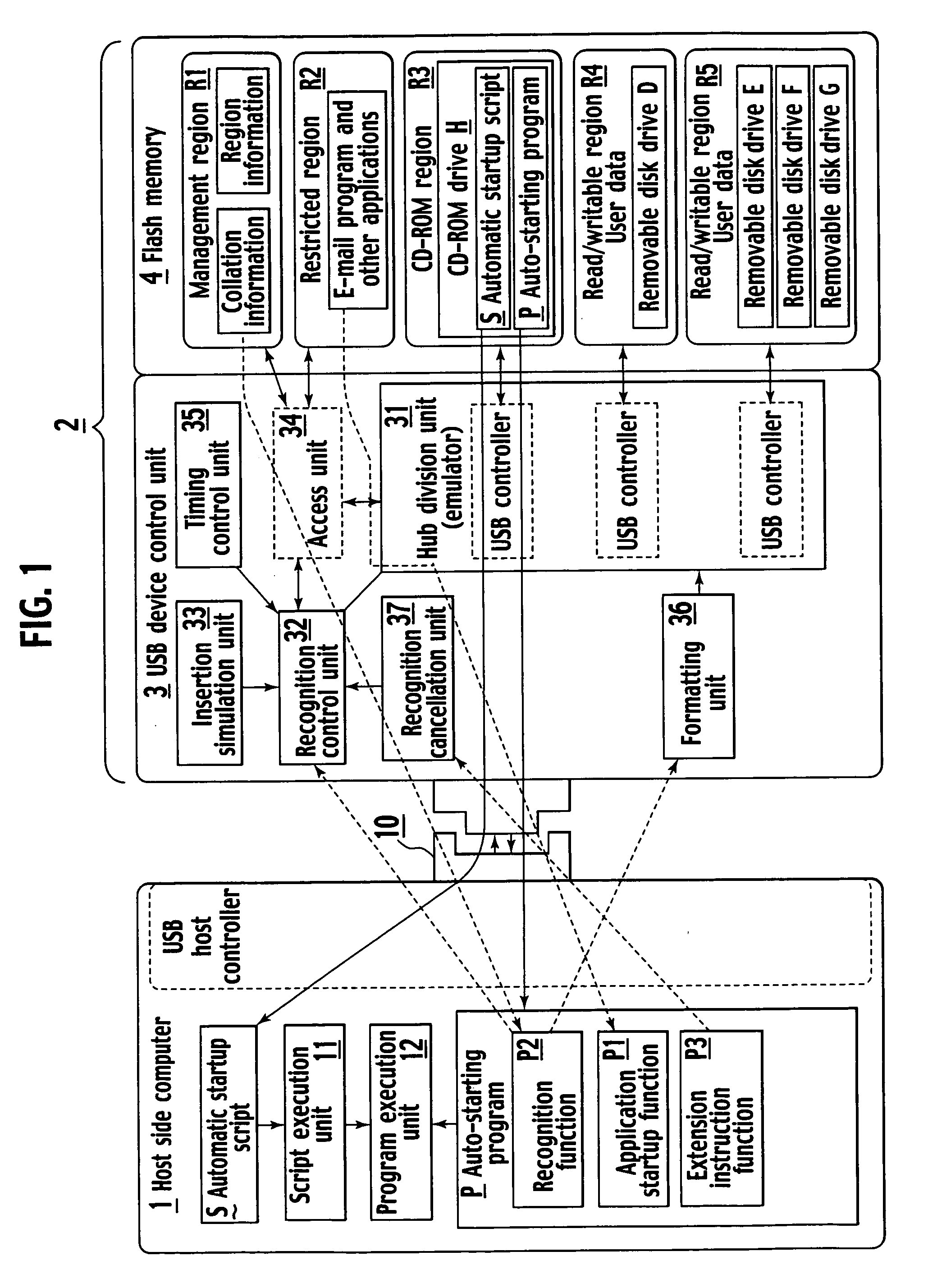

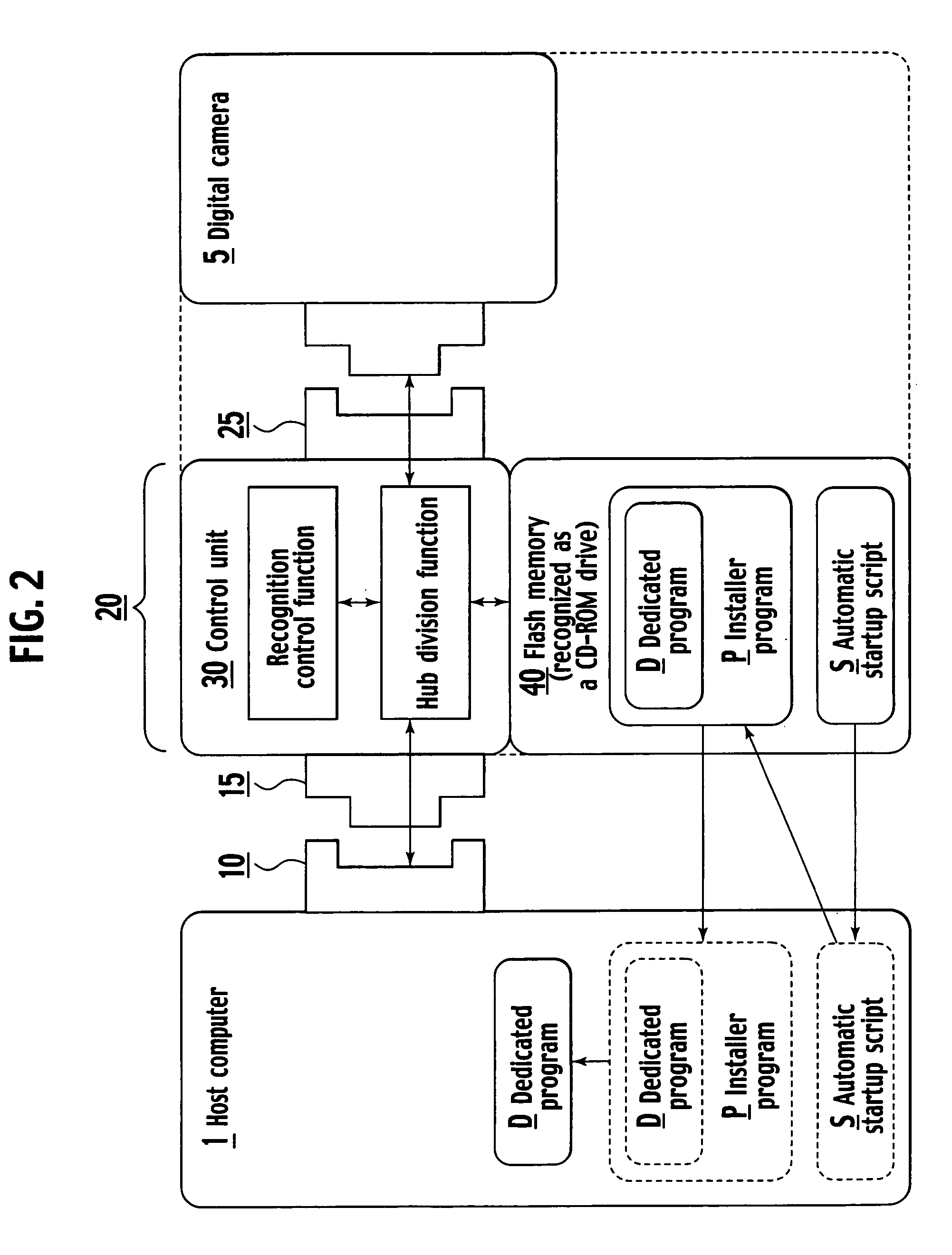

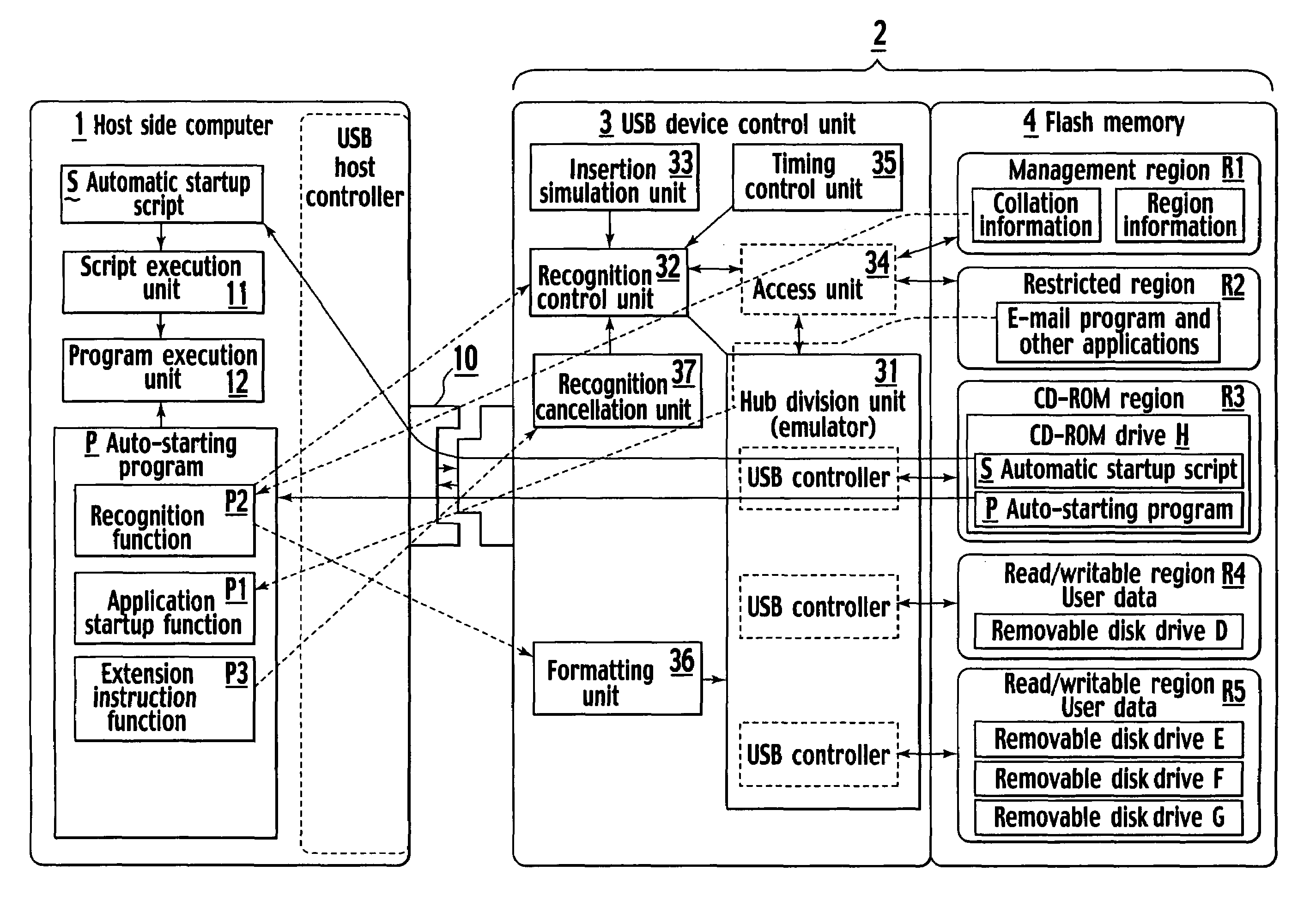

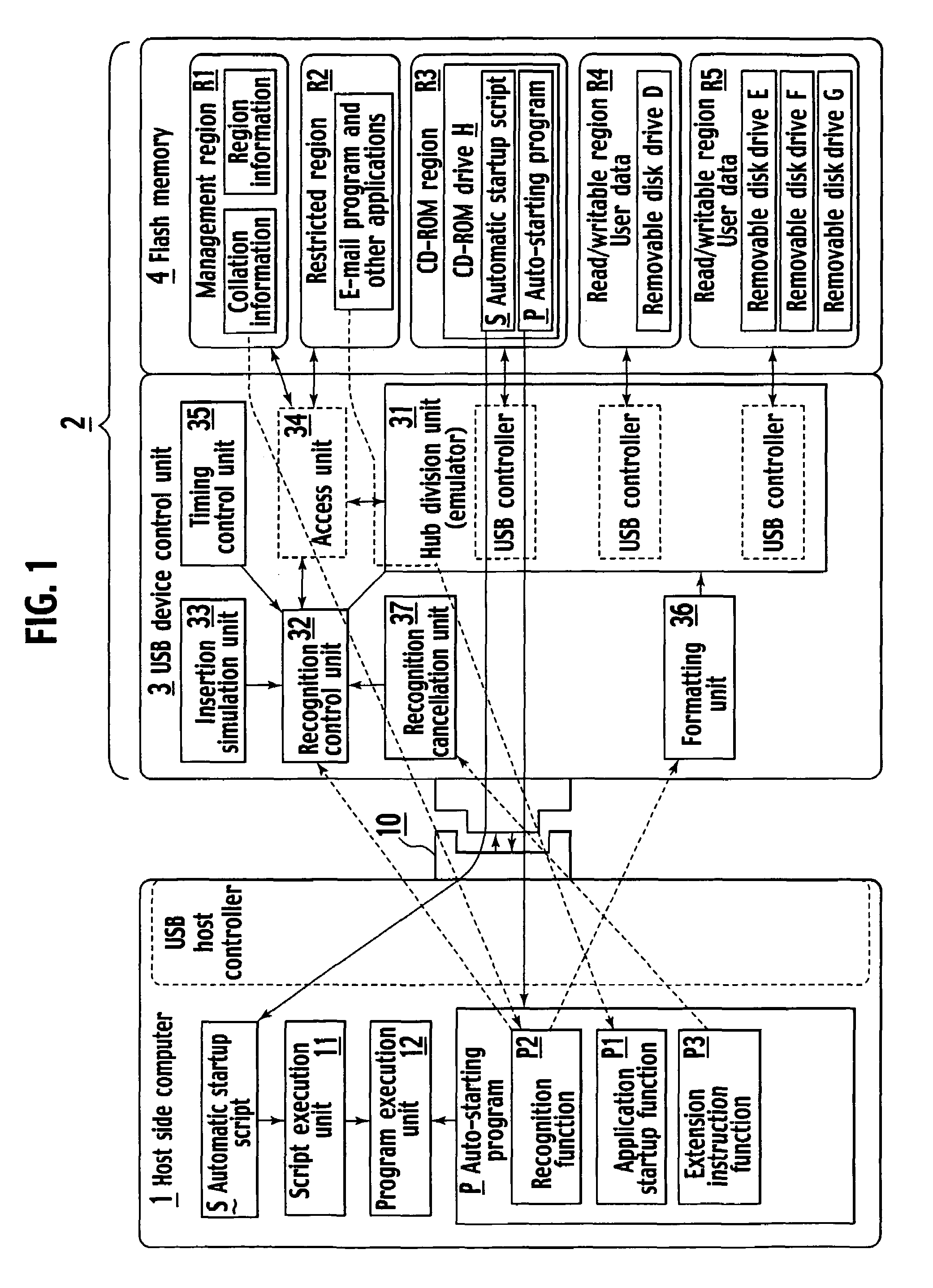

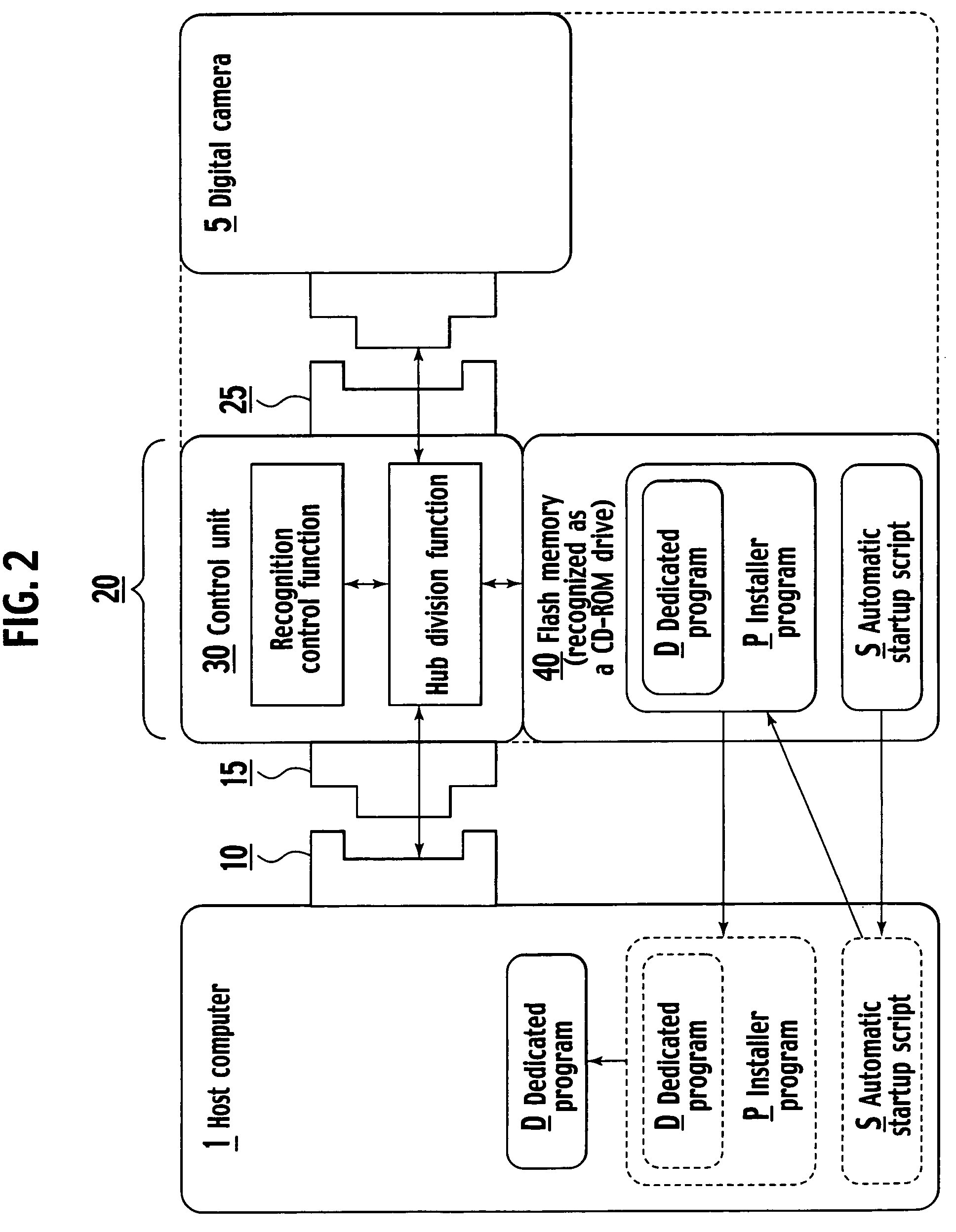

Detachable device, control circuit, control circuit firmware program, information processing method and circuit design pattern in control circuit, and log-in method

InactiveUS20060173980A1Improve convenienceImprove securityDigital computer detailsUnauthorized memory use protectionInformation processingCD-ROM

The present invention provides a highly convenient removable device and a startup method. A hub division unit 31 in a single composite device 2 allocates data exchange with the computer 1 side to a plurality of devices, thereby easily realizing a plurality of functions. When connected to a USB, a recognition control unit 32 returns a signal representing a CD-ROM in a simulated manner in response to inquiry about the type of the device from the host side. When a device is mounted, a desired processing such as a program execution described in the script is automatically performed without installing a resident program for detecting a device mounting in advance in the computer side.

Owner:SASLITE CORP

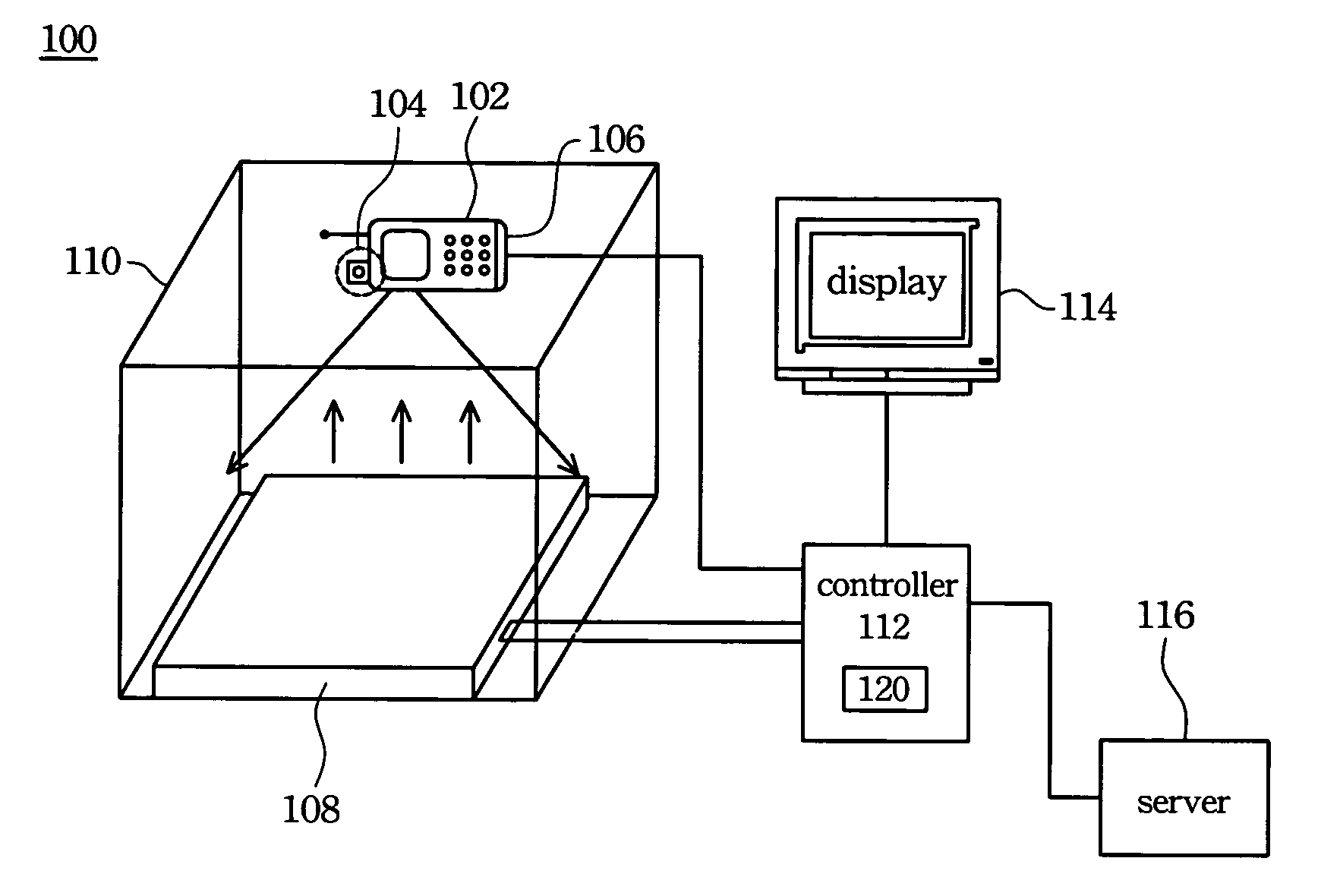

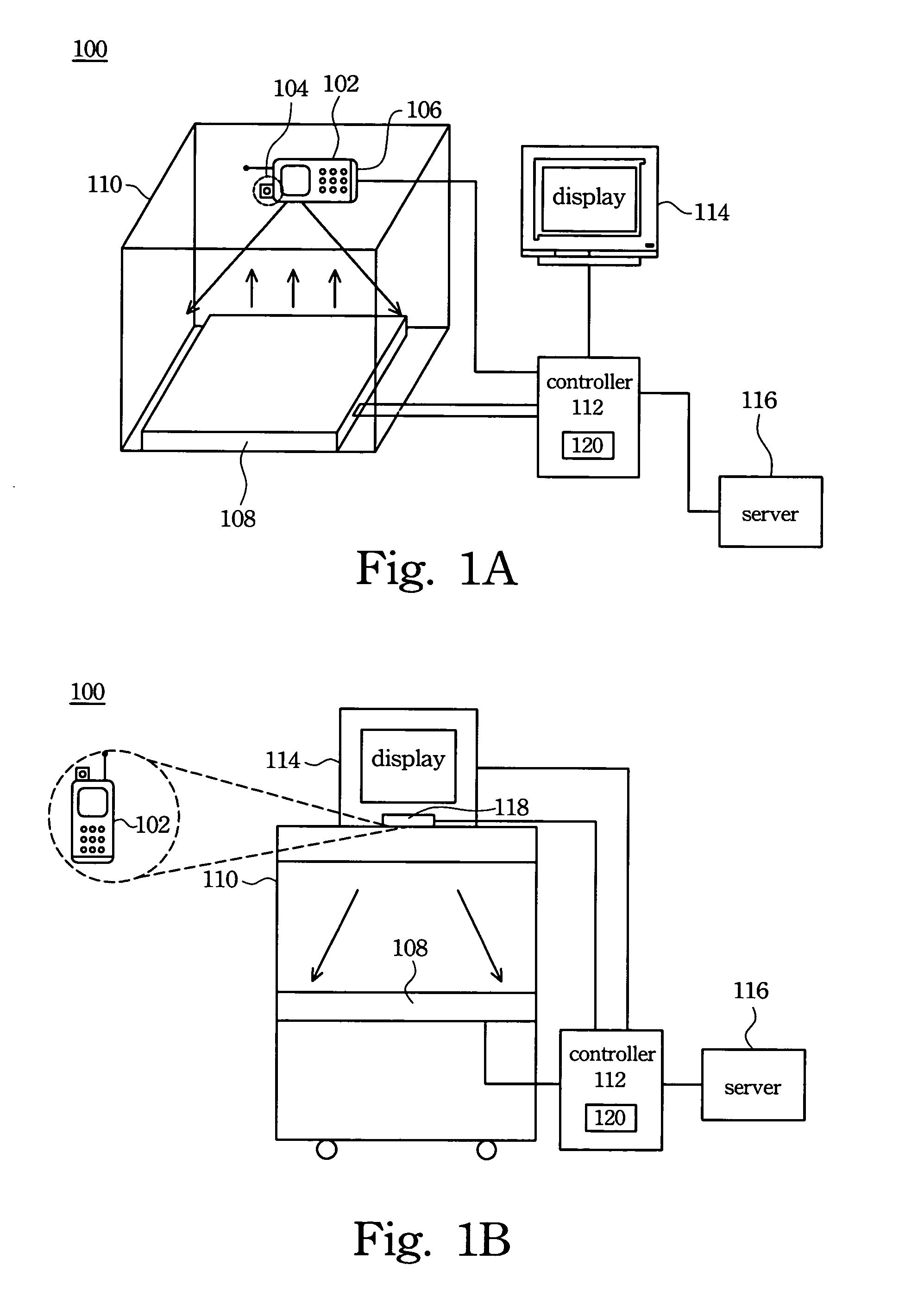

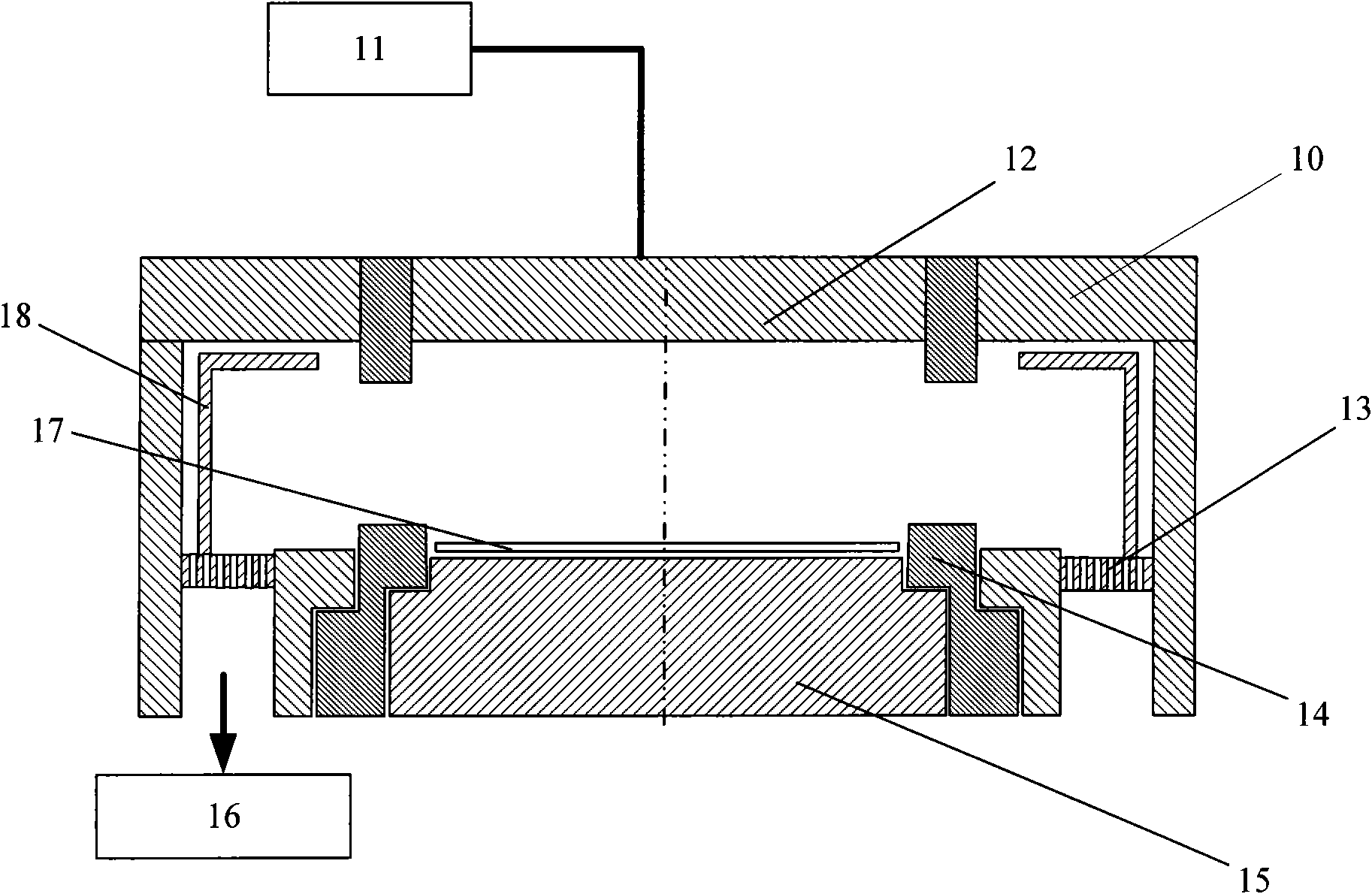

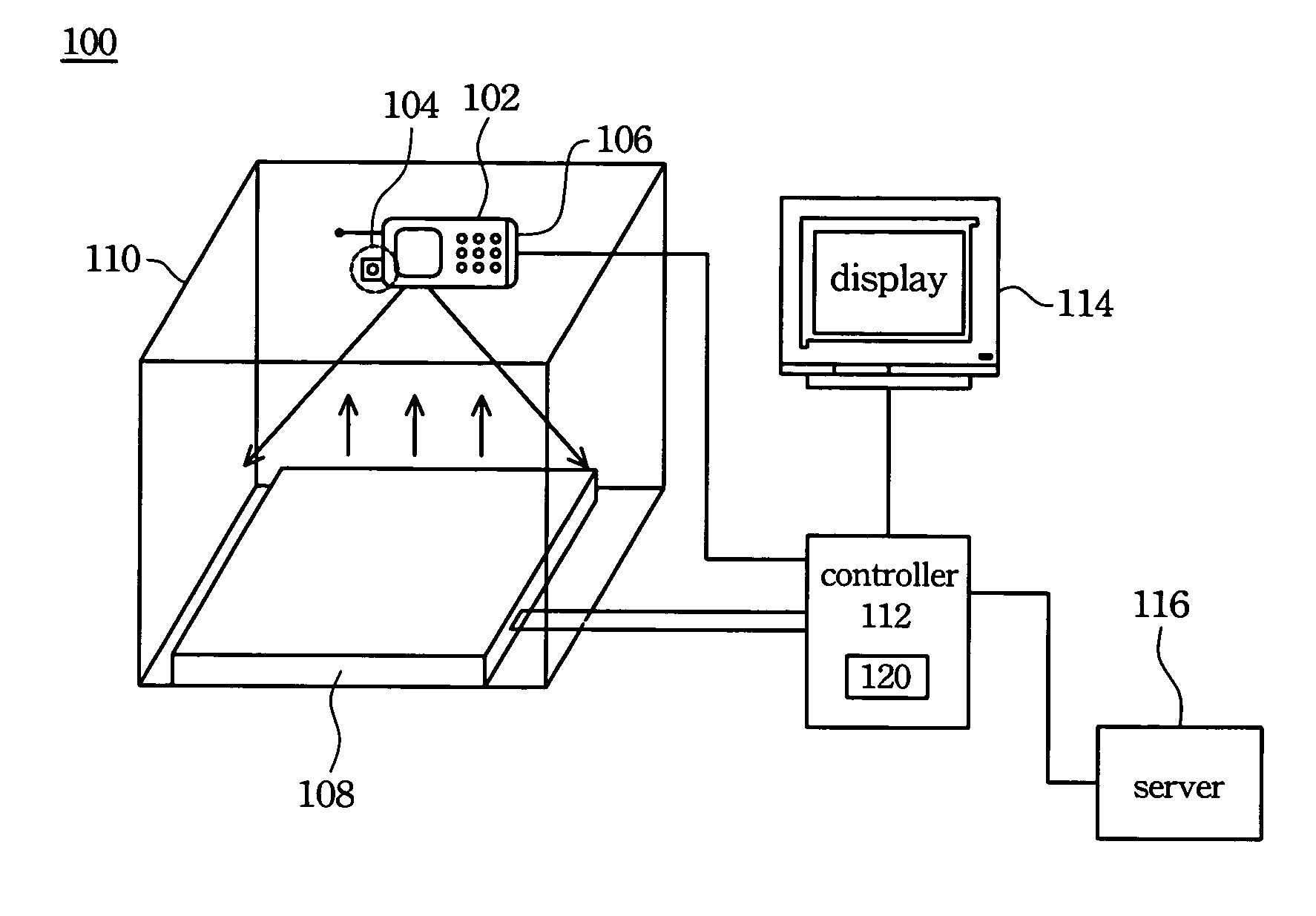

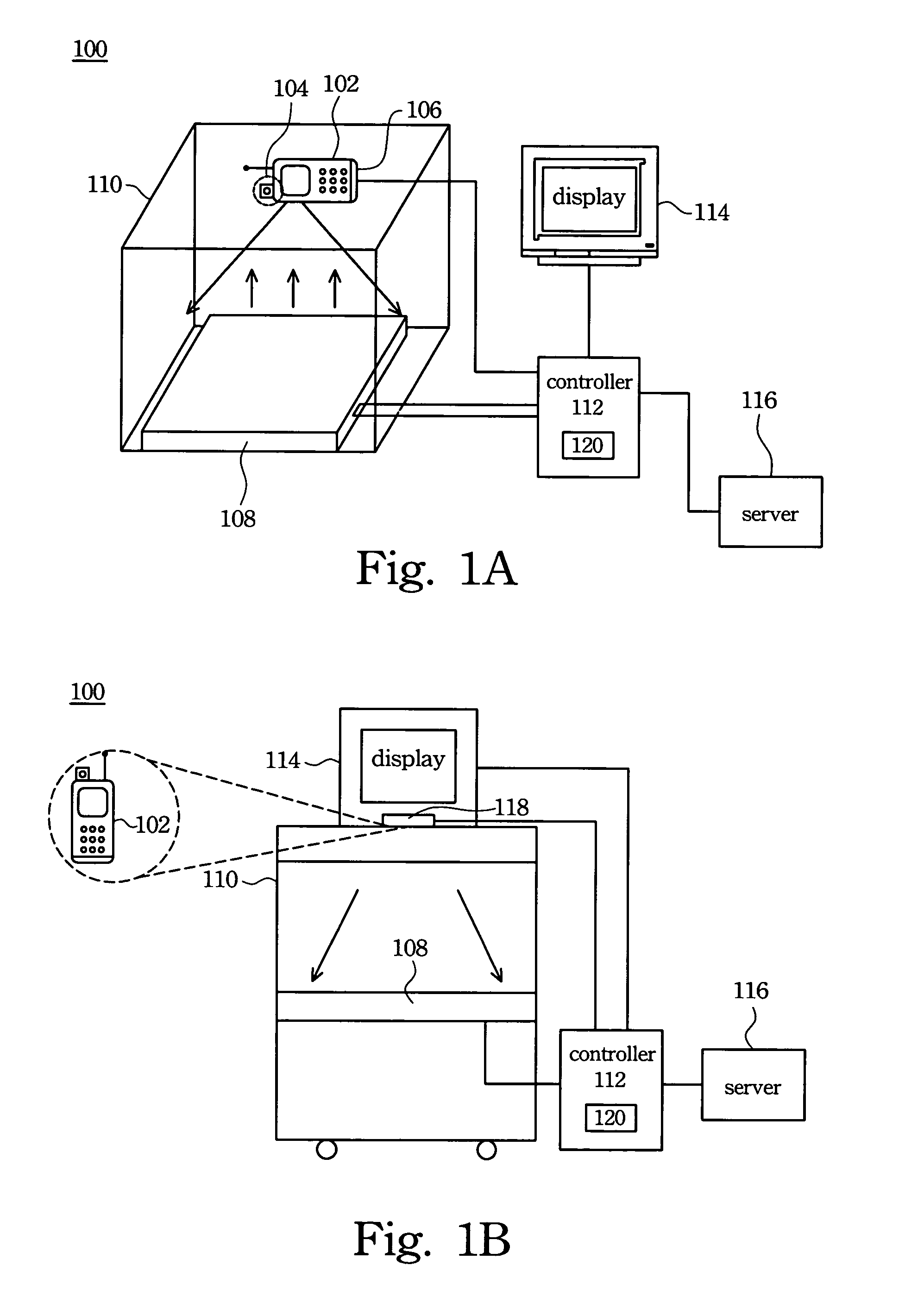

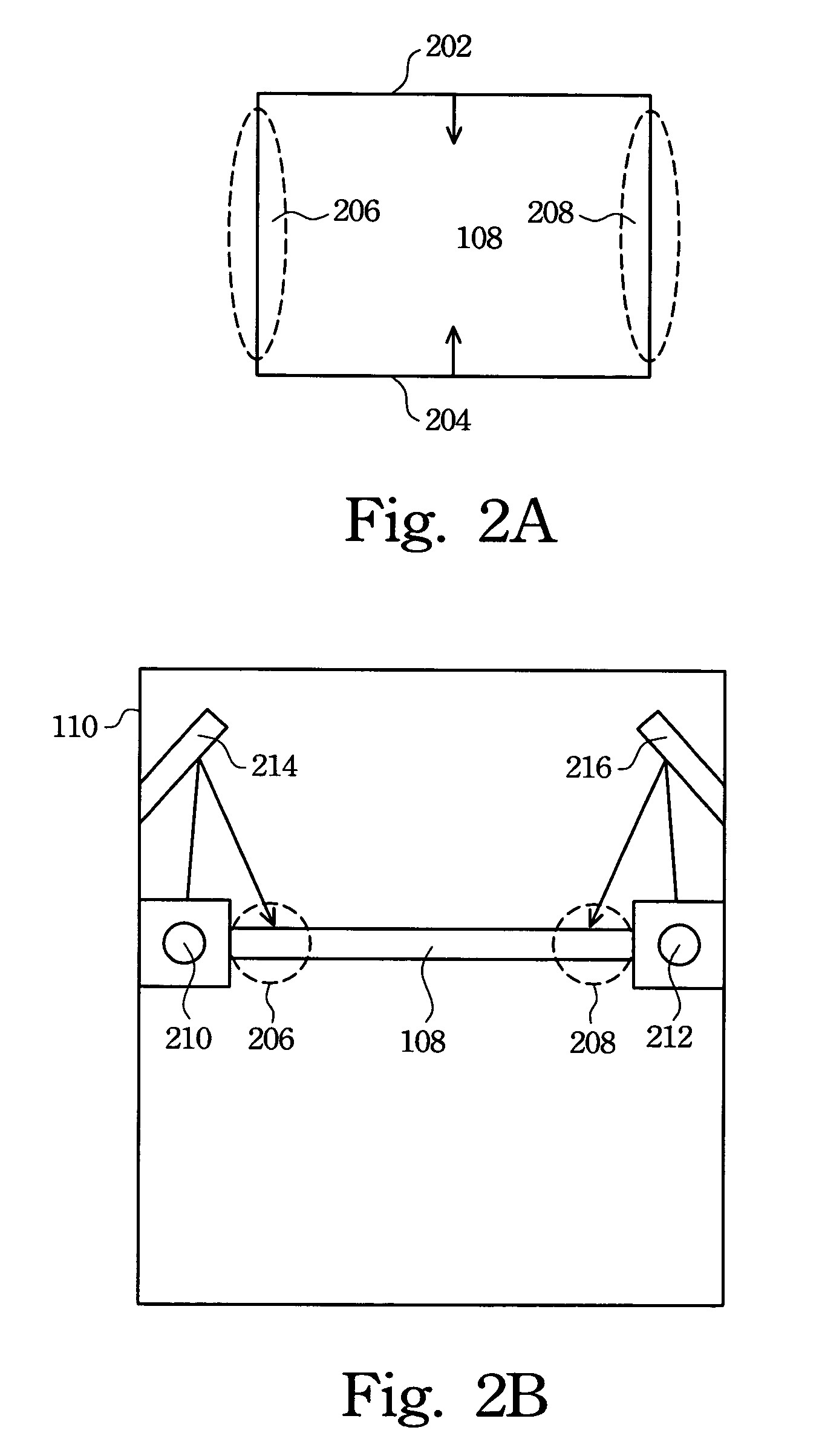

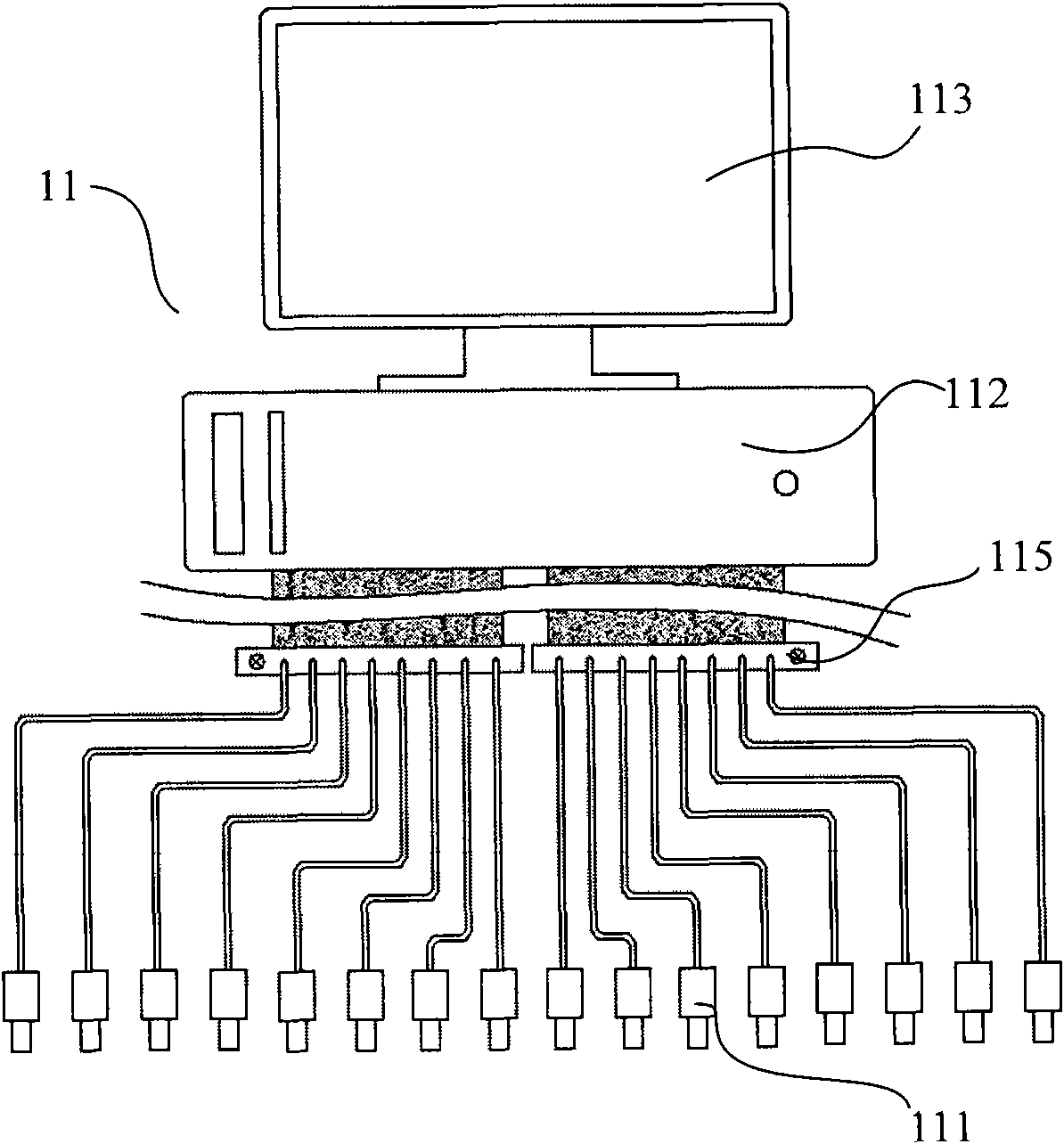

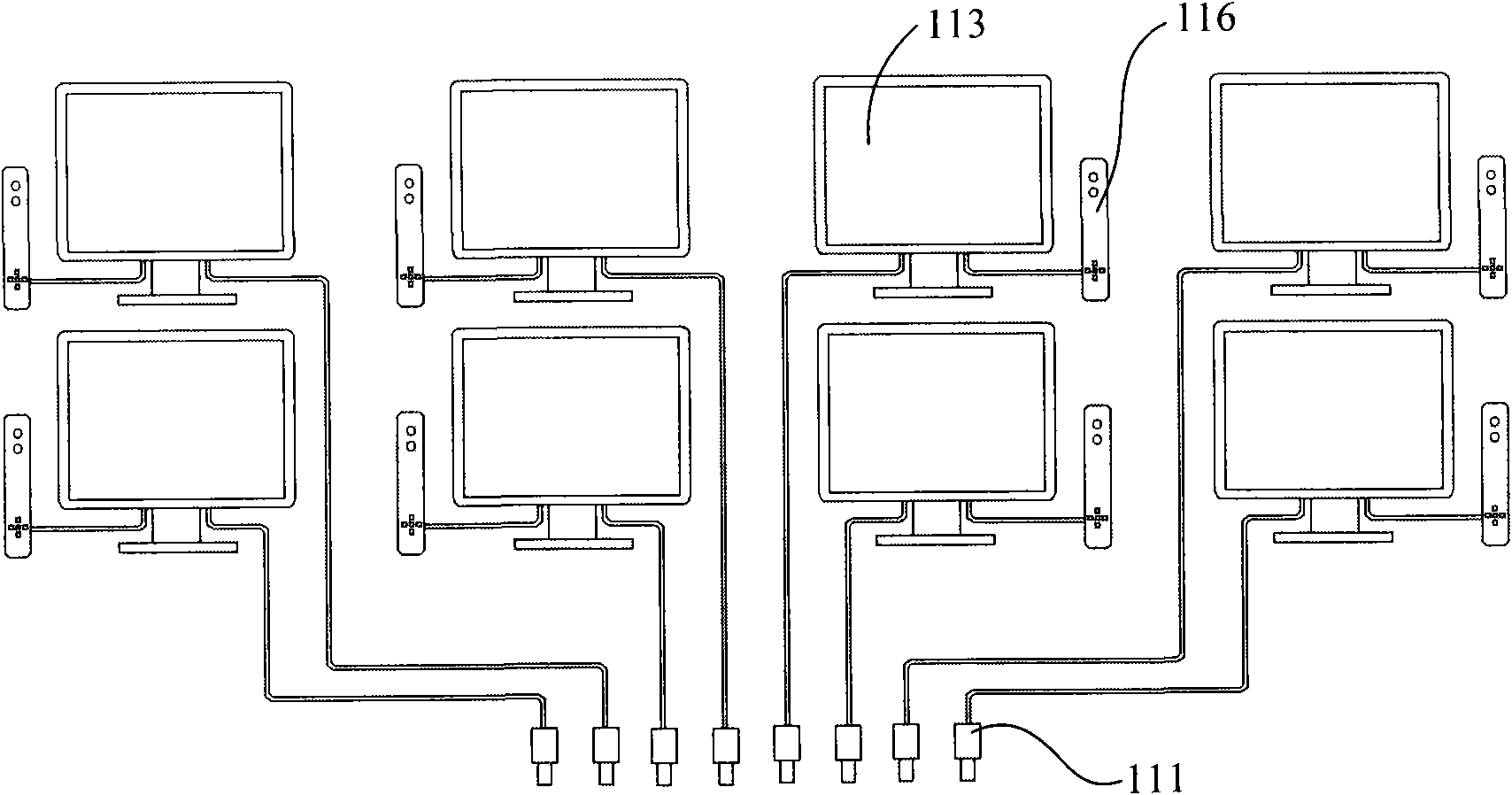

Test system and method for portable electronic apparatus

ActiveUS20050222690A1Easy and fast processingSave powerElectric controllersElectrical measurementsLight sourceComputer hardware

A test system for testing a portable electronic apparatus is described. The test system has at least a display, a platform, and a controller. The controller controls the display to display test images in sequence. The controller commands the portable electronic apparatus, via a test interface, to capture the test images on the display to generate image data. The controller determines whether the image data meet a predetermined test requirement. The test system can further include at least a light source and a reflector. The reflector reflects the light on the display, so that the display reaches a predetermined uniformity of light.

Owner:QUANTA COMPUTER INC

Method, system and apparatus for real-time classification of muscle signals from self-selected intentional movements

InactiveUS8437844B2User training can be minimizedSimple designMedical data miningElectromyographyMuscle contractionSelf training

A new method, system and apparatus is provided that enables muscle signals that correspond to muscle contractions to be mapped to one or more functions of an electronic device such as a prosthetic device or gaming apparatus. Muscle signals are classified in real-time from self-selected intentional movements. A self-training protocol allows users to select and label their own muscle contractions, and is operable to automatically determine the discernible and repeatable muscle signals generated by the user. A visual display means is used to provide visual feedback to users illustrating the responsiveness of the system to muscle signals generated by the user.

Owner:HOLLAND BLOORVIEW KIDS REHABILITATION HOSPITAL

Foamable compositions which comprise isononyl benzoate

InactiveUS20050049341A1High viscosityIncrease shear rateSynthetic resin layered productsAbsorbent padsFloorcoveringPlasticizer

Compositions for producing foamed products which comprise a chlorinated polymer such as PVC and at least one isomeric nonyl benzoate as a plasticizer, the use of these compositions, and products produced therefrom including PVC-containing floorcoverings, synthetic leather, and wallcoverings.

Owner:EVONIK OXENO GMBH (DE)

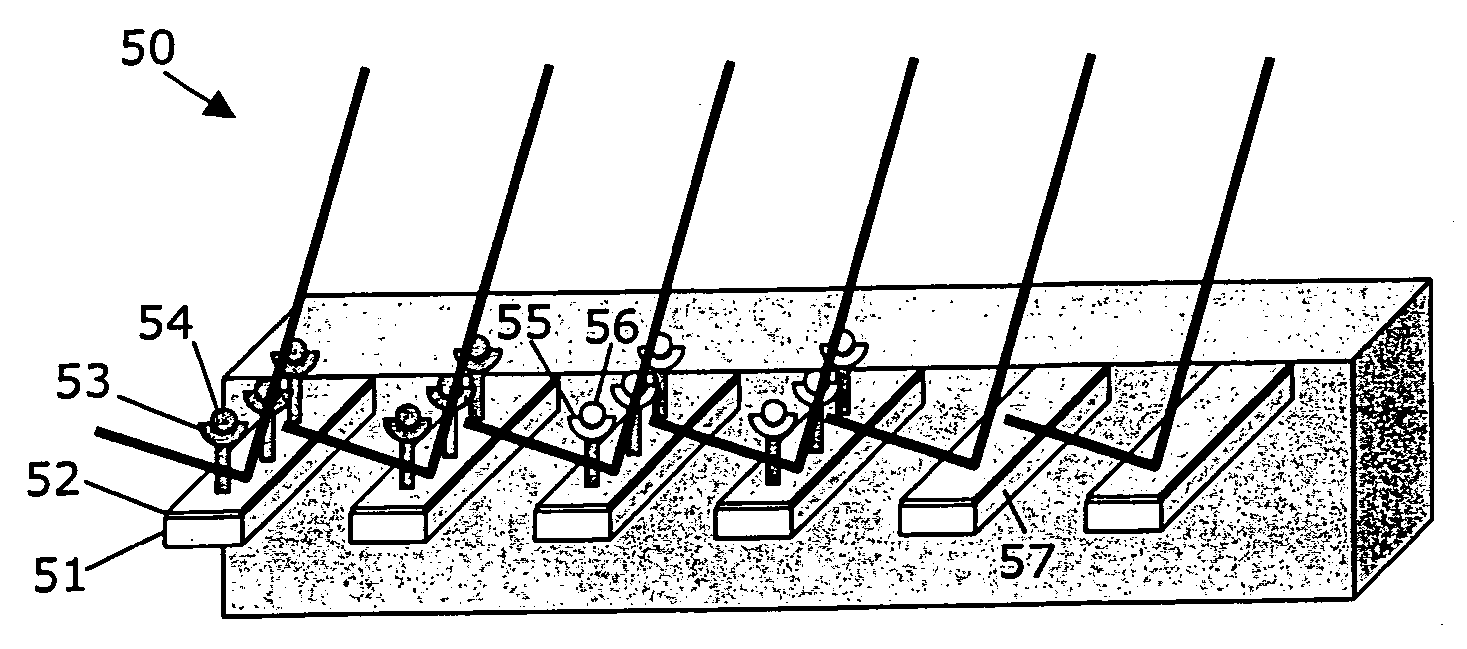

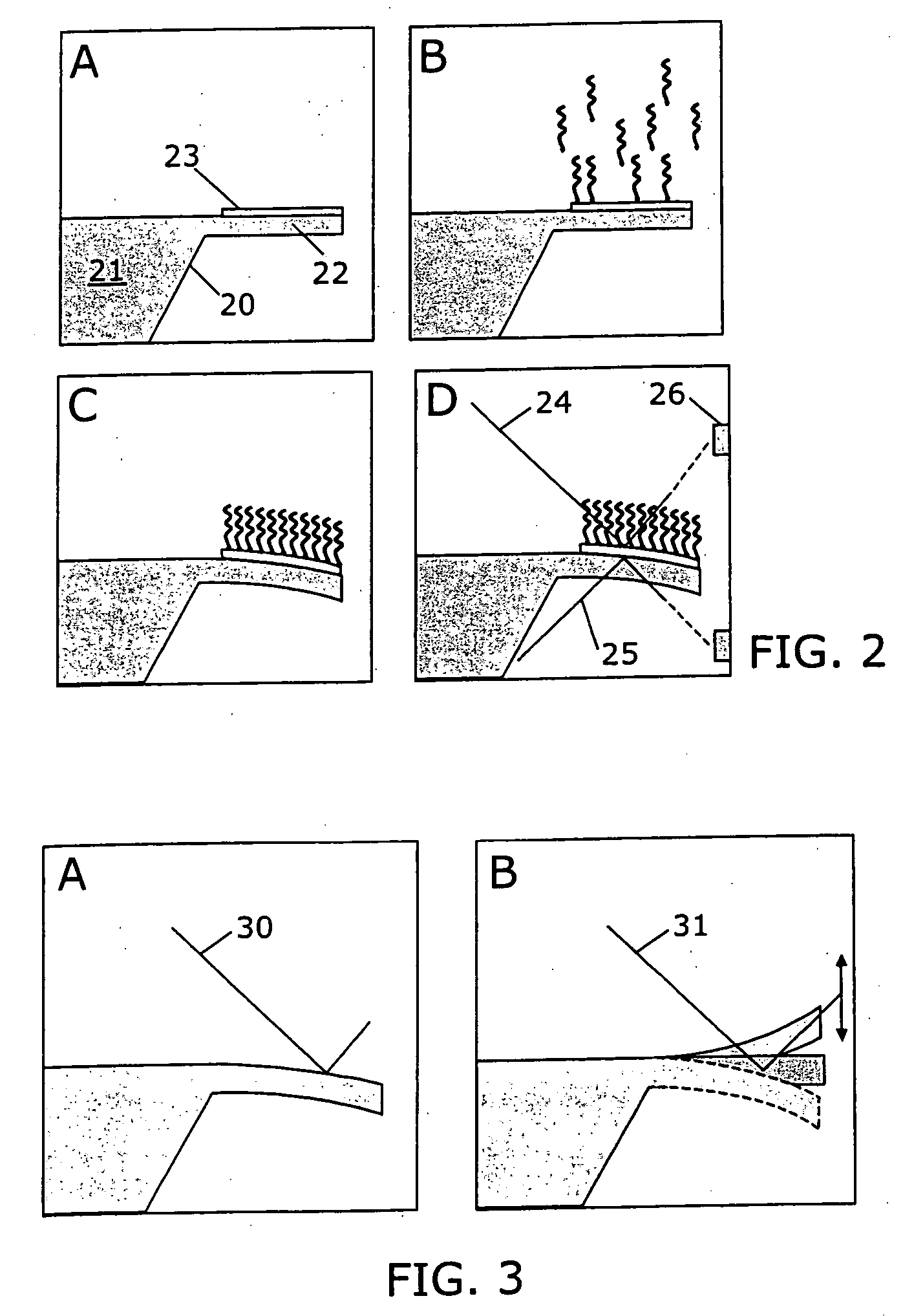

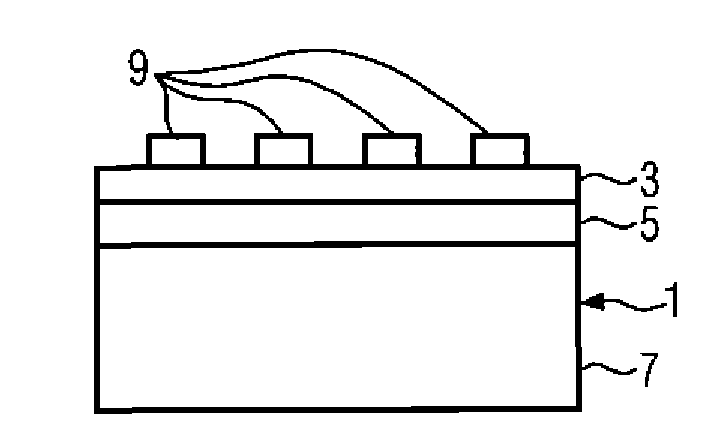

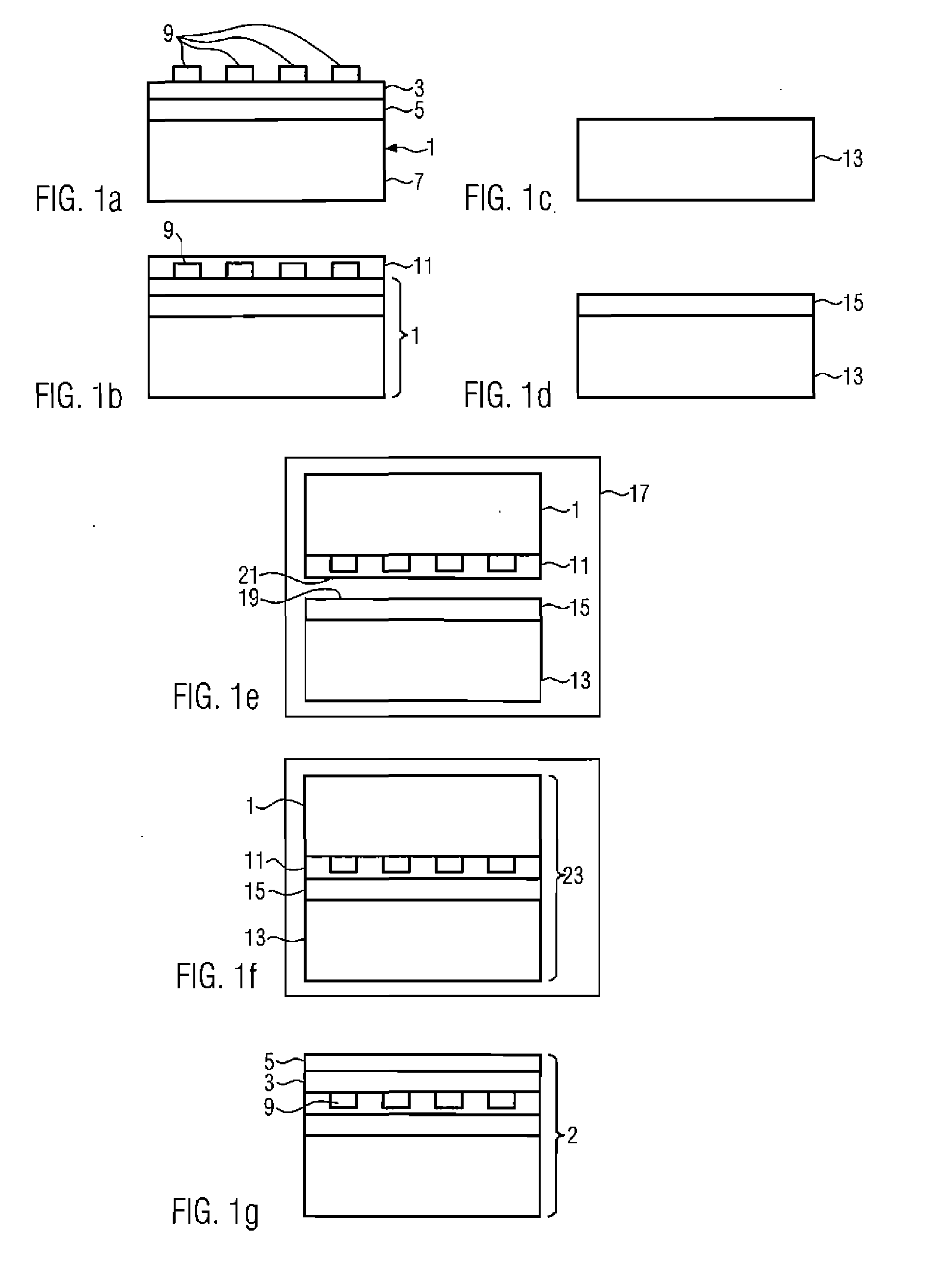

Polymer-based cantilever array with optical readout

InactiveUS20060075803A1Good chemical resistanceEasy and fast processingBioreactor/fermenter combinationsMaterial analysis using sonic/ultrasonic/infrasonic wavesGold layerOptical sensing

A cantilever array for use as a sensor, e.g. a bio / chemical sensor is disclosed. The cantilever array comprises a platform and a multitude of polymer-based cantilevers attached to the platform. Each of the cantilevers is coupled to an optical sensing means adapted to sense deformations of an individual cantilever. The cantilevers may be coated with a first and / or a second layer, the first layer being a metal layer, such as a gold layer, the second layer being a molecular layer capable of functioning as a receptor layer for molecular recognition. Further, two methods of fabricating a cantilever array are disclosed, one being based on photolithography, the other being based on micromoulding.

Owner:DANMARKS TEKNISKE UNIV

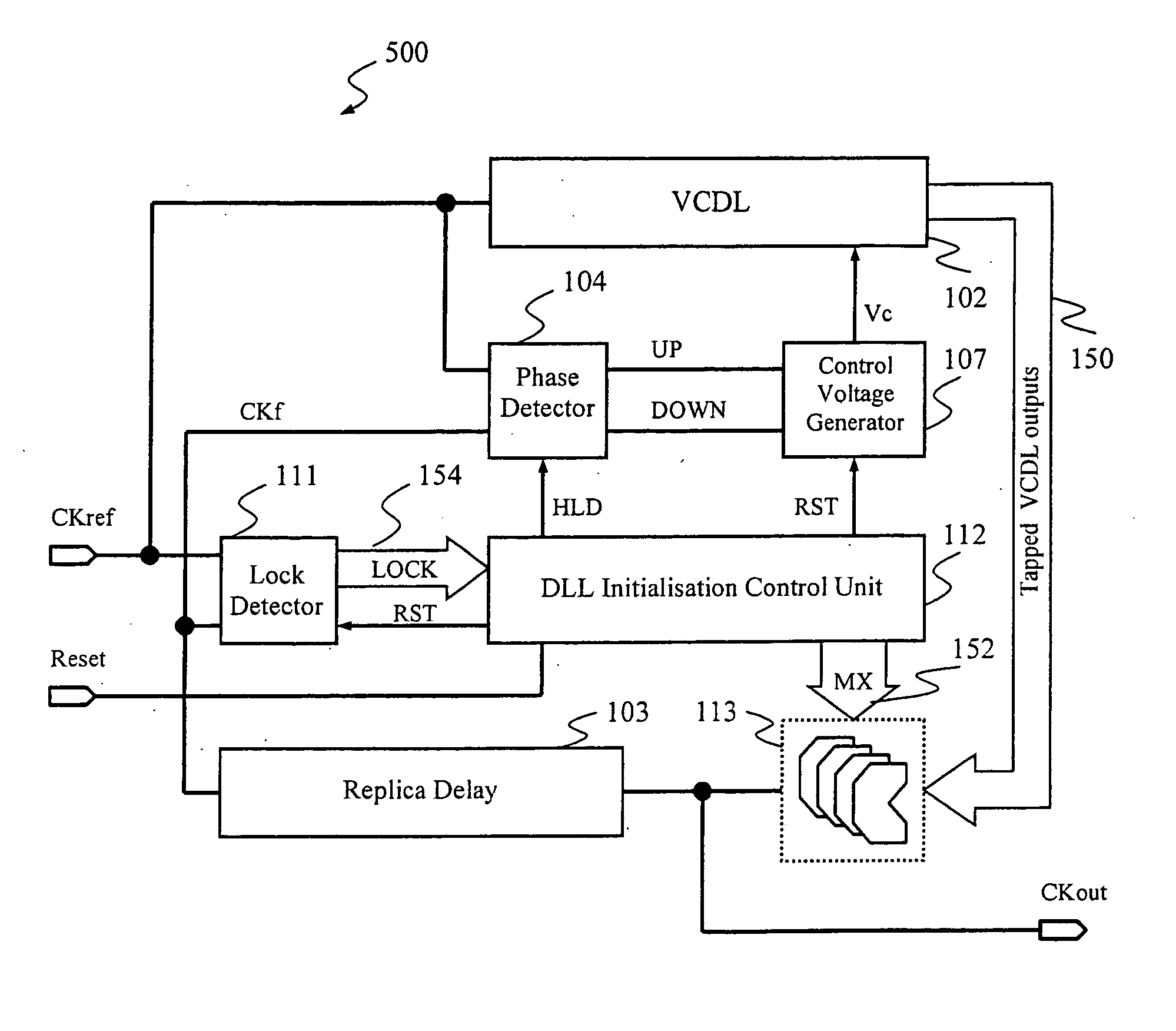

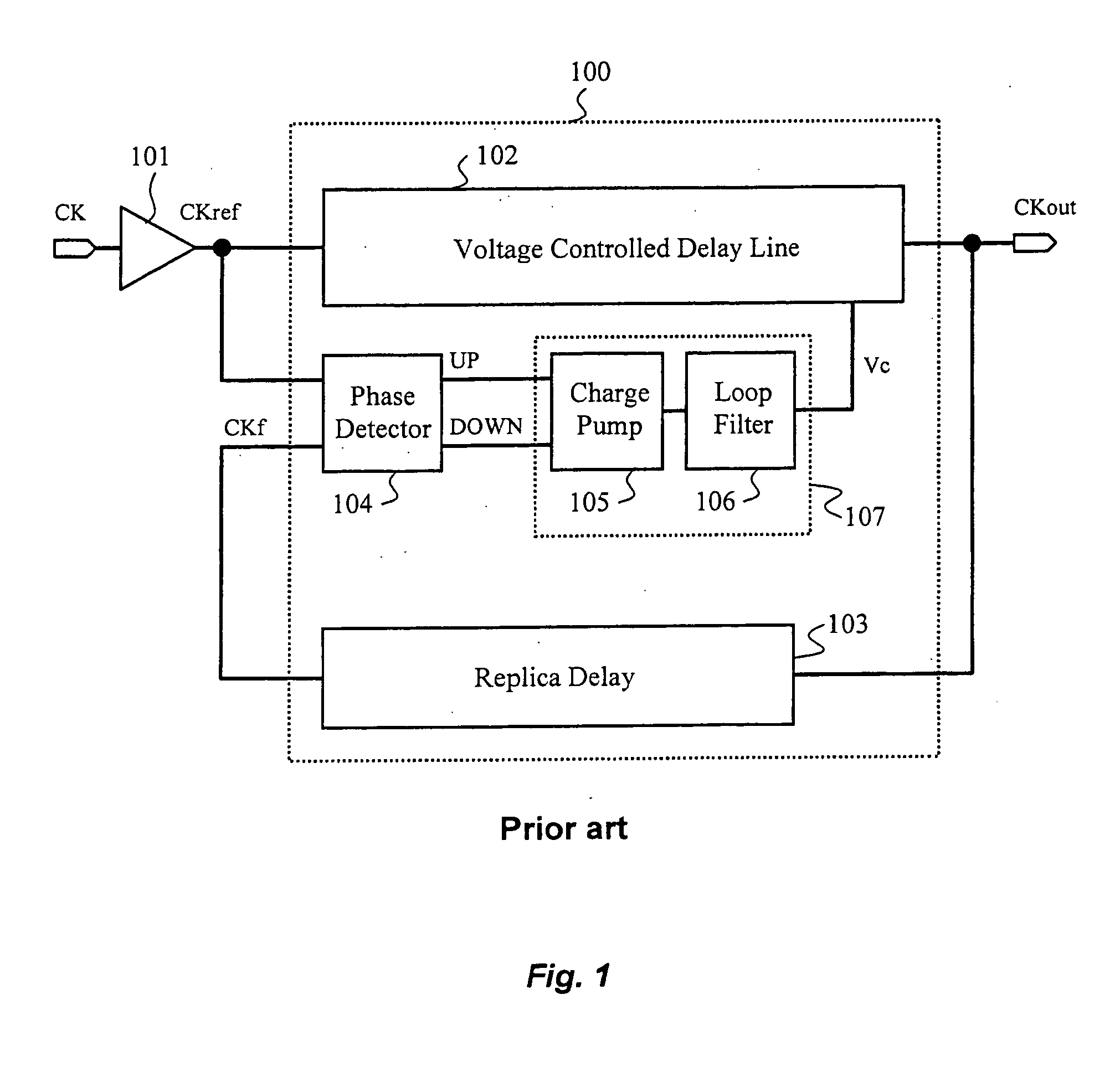

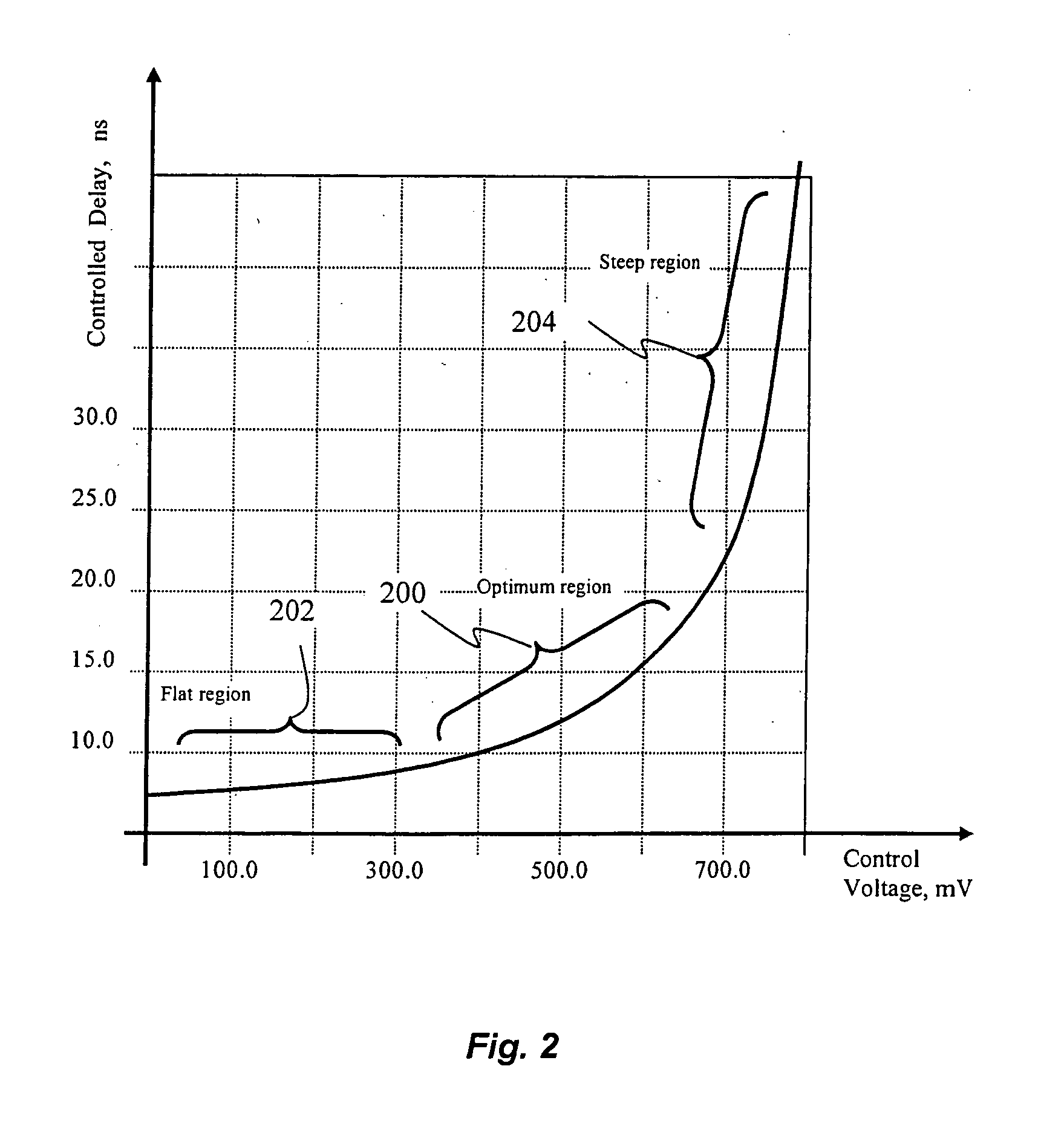

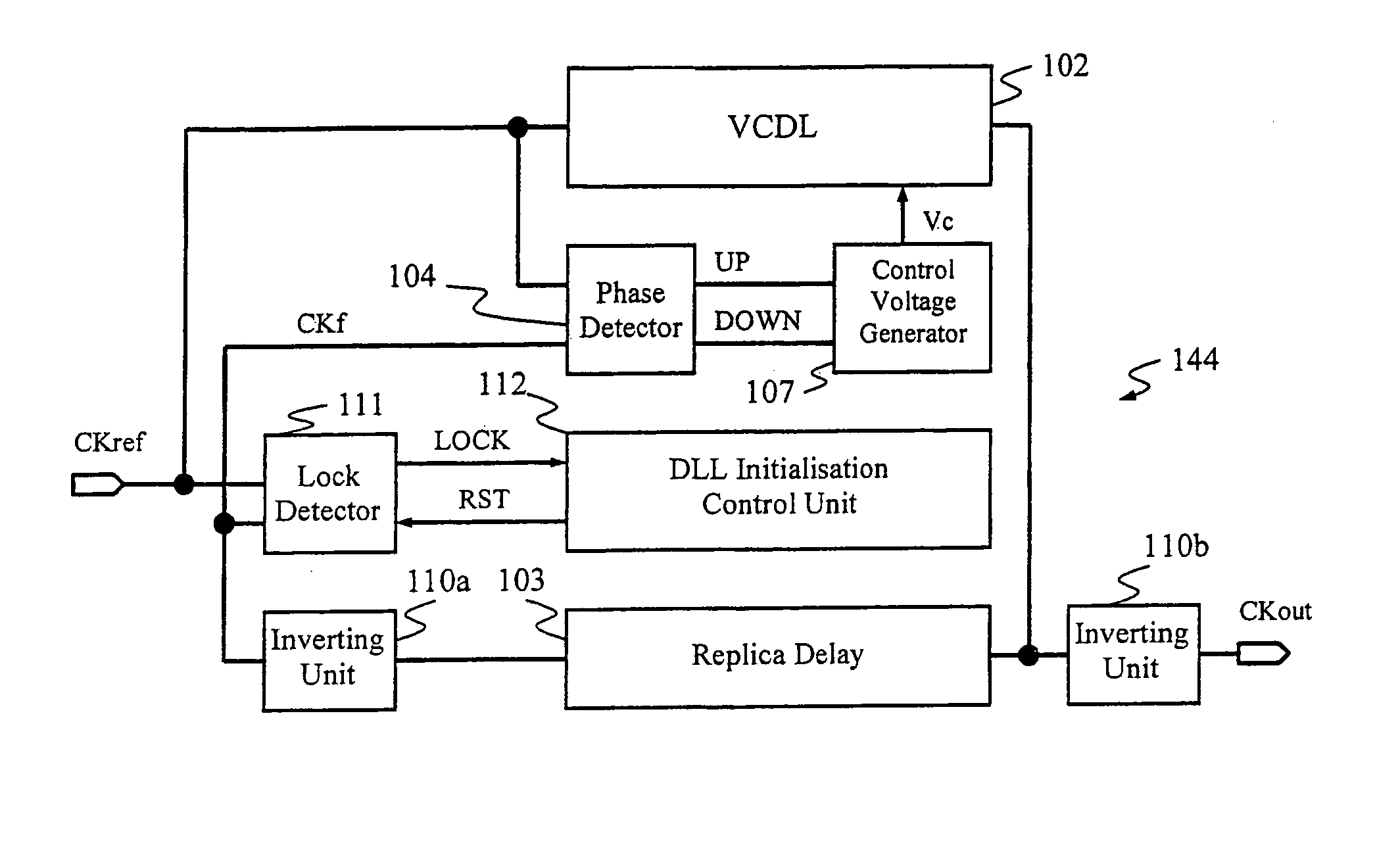

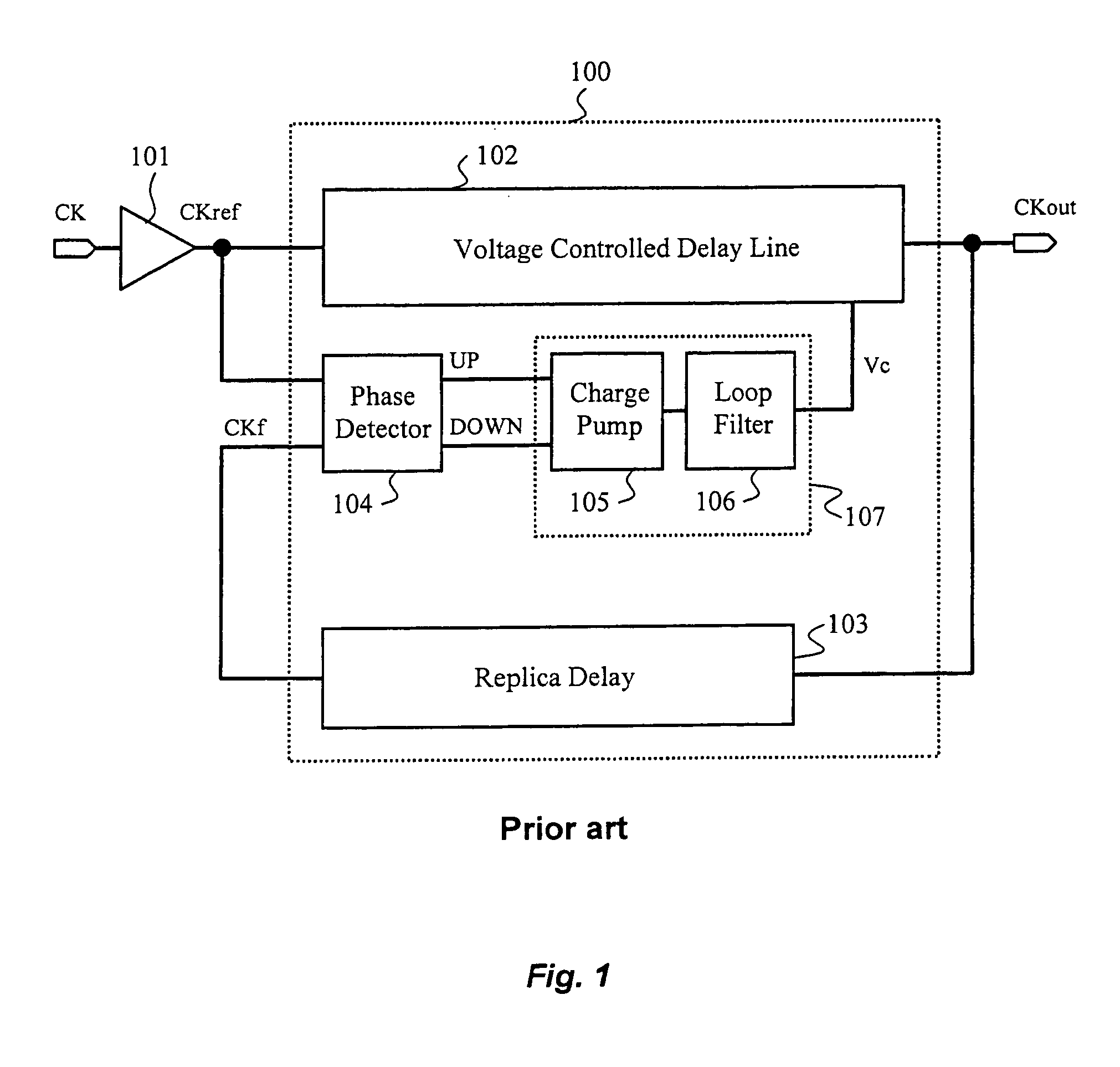

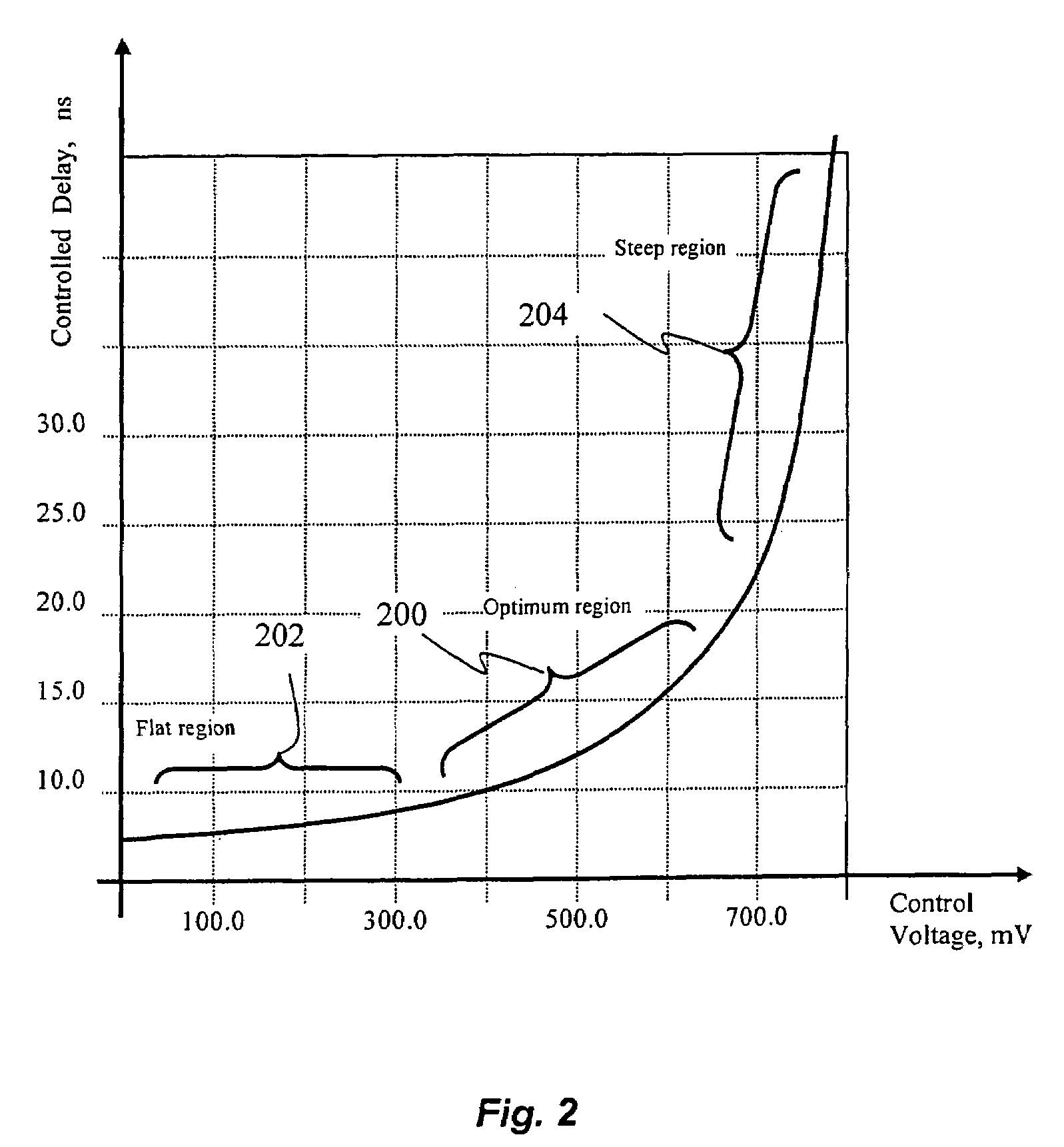

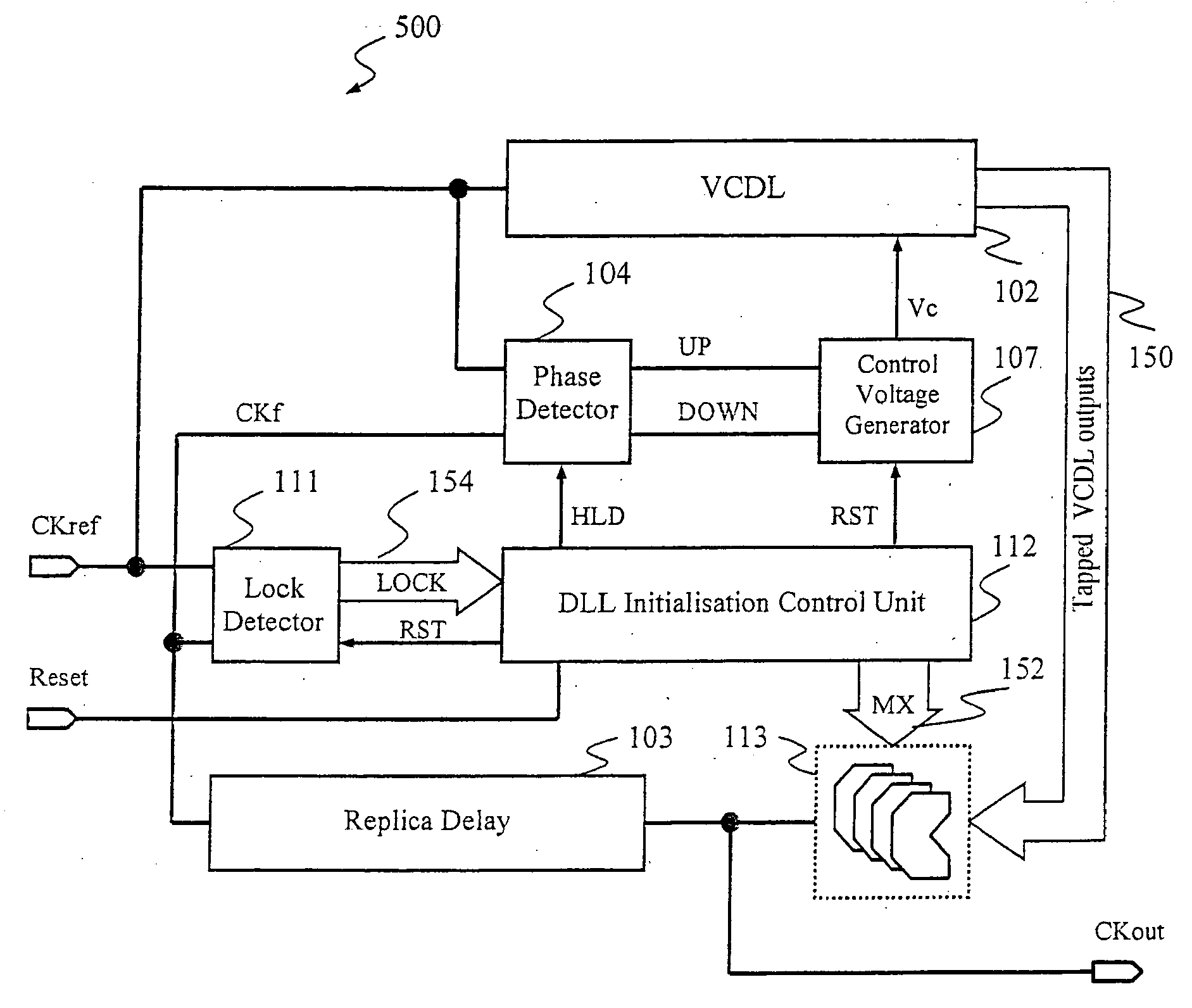

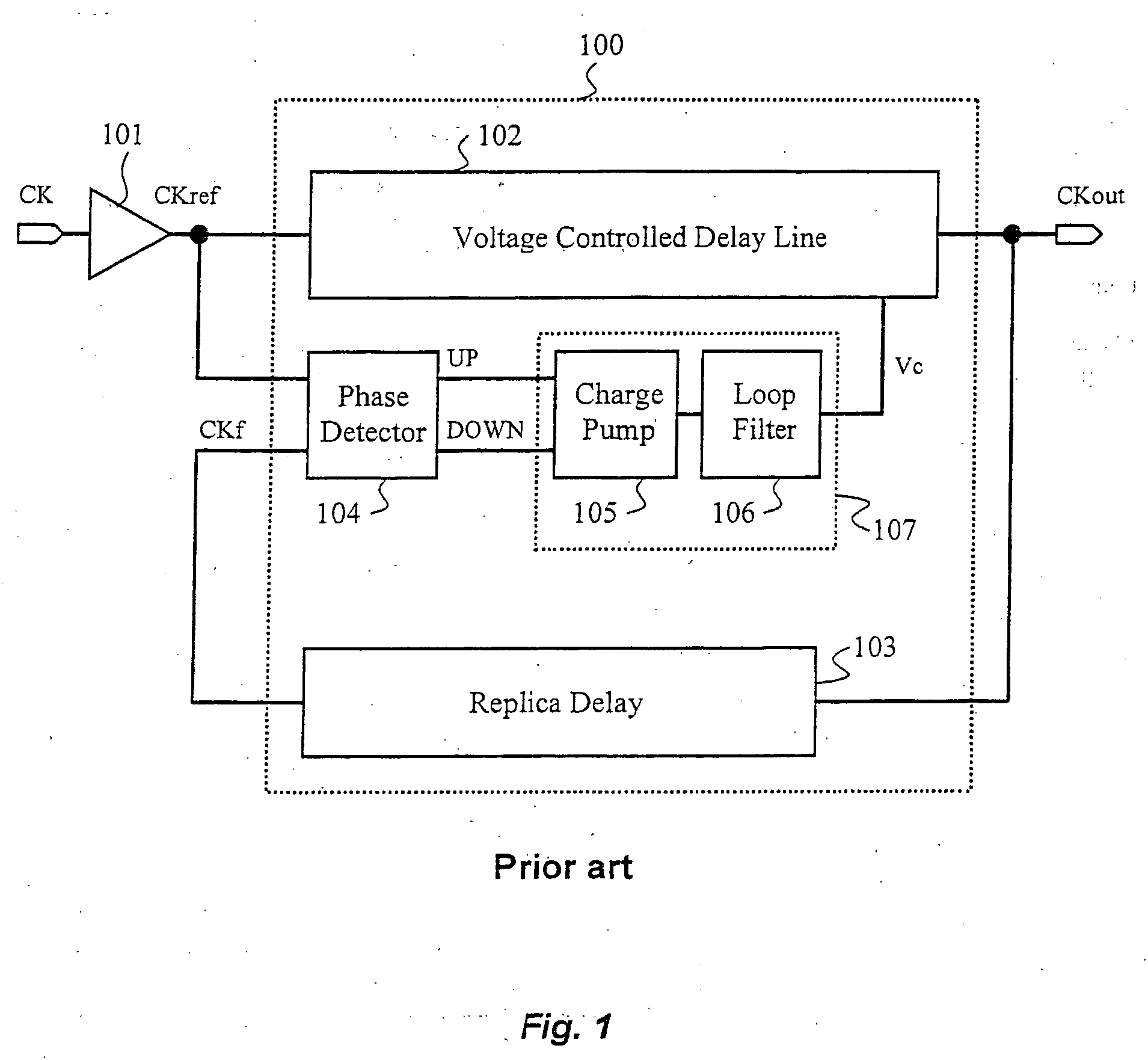

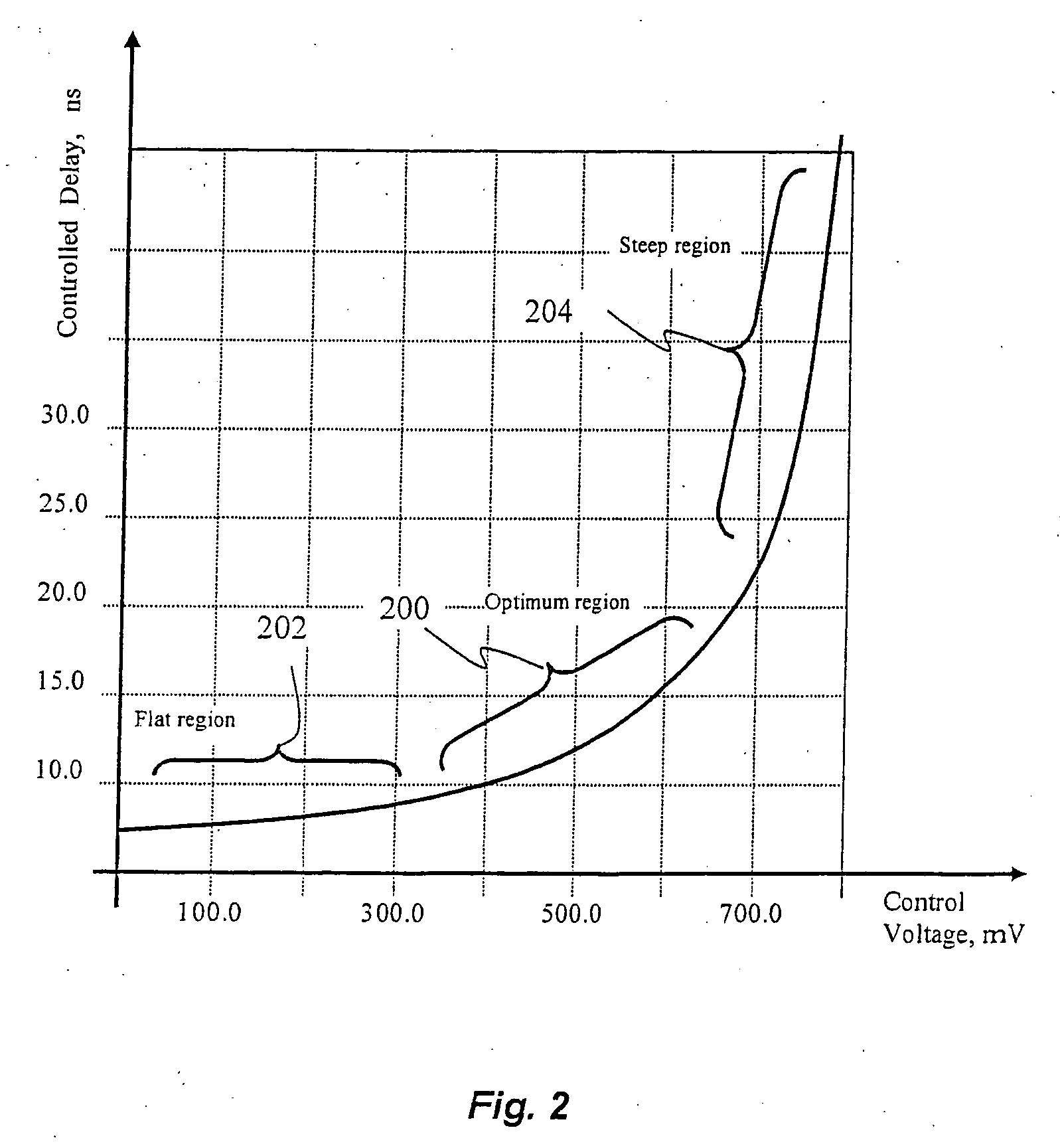

Method and apparatus for initializing a delay locked loop

ActiveUS20060170471A1Steady lockImprove performancePulse automatic controlOperating pointDelay-locked loop

A delay locked loop includes initialization circuitry that ensures that a DLL is initialized to an operating point that is not to close to either end of a delay vs. control voltage characteristic. The initialization circuitry forces the DLL to initially search for a lock point starting from an initial delay, the delay is varied in one direction, forcing the DLL to skip the first lock point. The initialization circuitry only allows the DLL to vary the delay of the voltage controlled delay loop in the one direction from the initial delay until the operating point is reached.

Owner:CONVERSANT INTPROP MANAGEMENT INC

Method and apparatus for initializing a delay locked loop

ActiveUS7190201B2Improve performanceMinimize the numberPulse automatic controlOperating pointDelay-locked loop

A delay locked loop includes initialization circuitry that ensures that a DLL is initialized to an operating point that is not to close to either end of a delay vs. control voltage characteristic. The initialization circuitry forces the DLL to initially search for a lock point starting from an initial delay, the delay is varied in one direction, forcing the DLL to skip the first lock point. The initialization circuitry only allows the DLL to vary the delay of the voltage controlled delay loop in the one direction from the initial delay until the operating point is reached.

Owner:MOSAID TECH

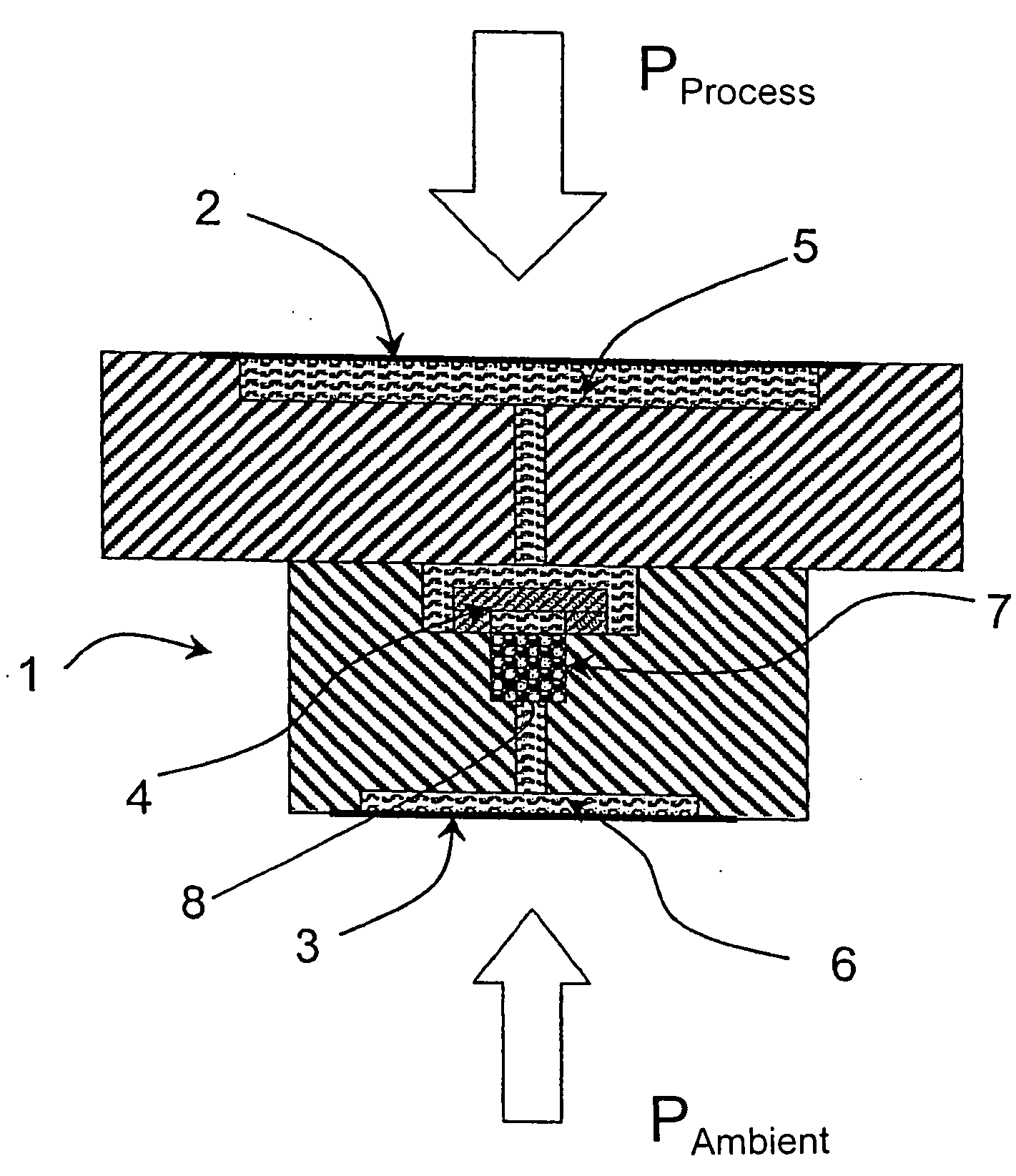

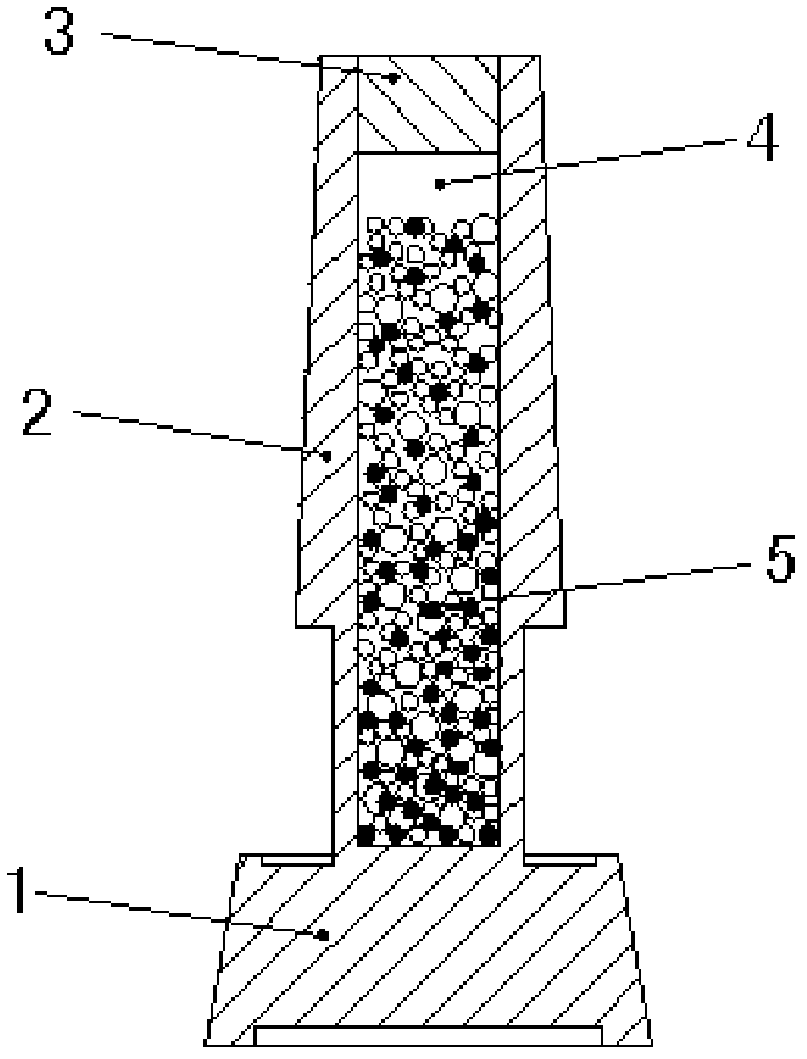

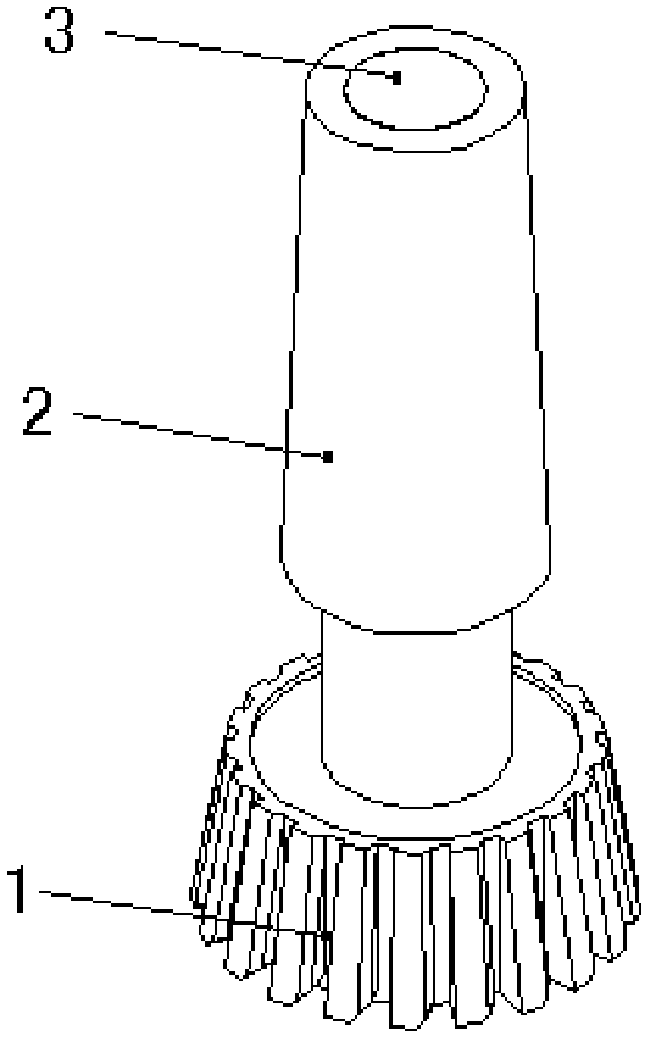

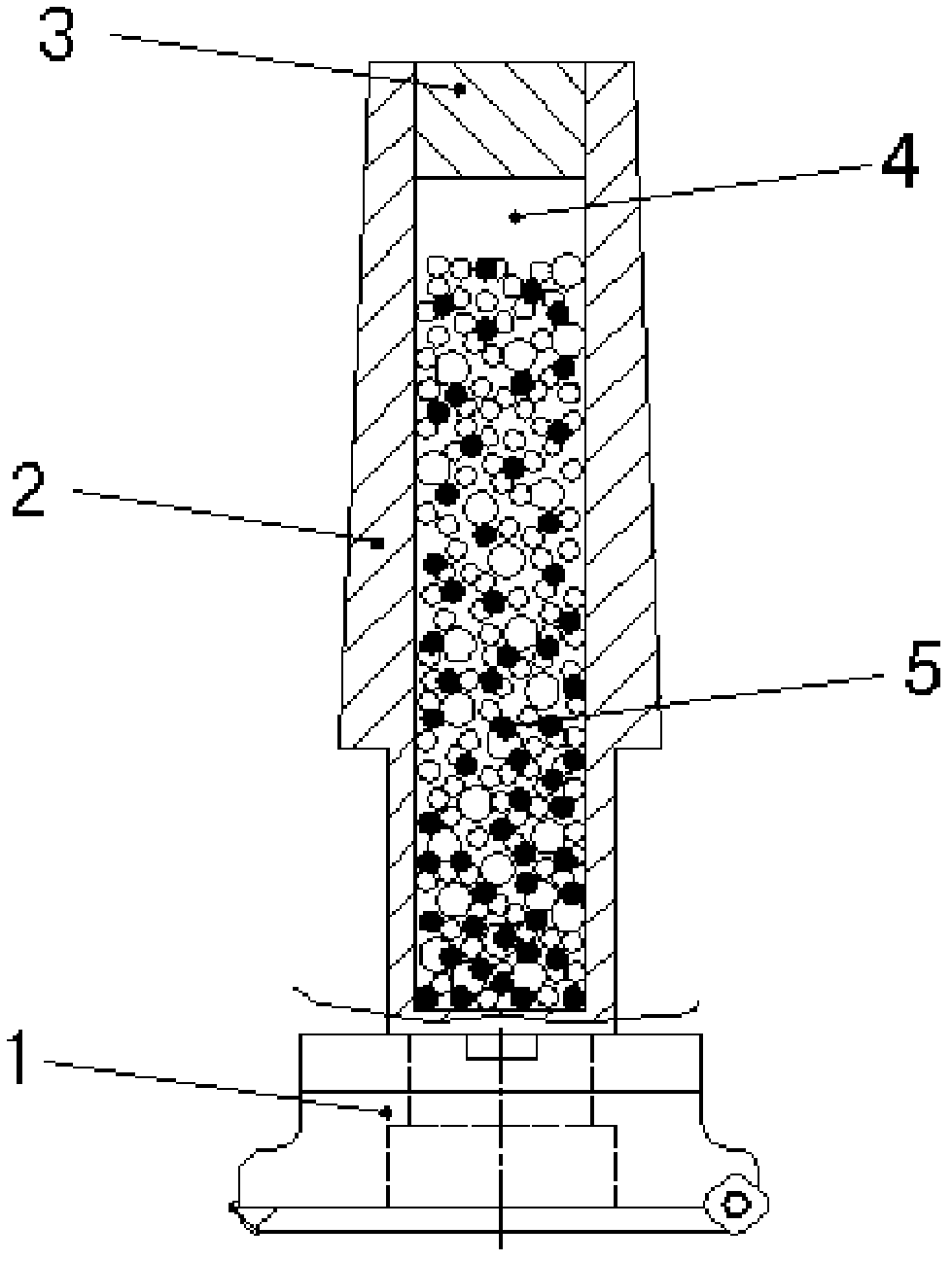

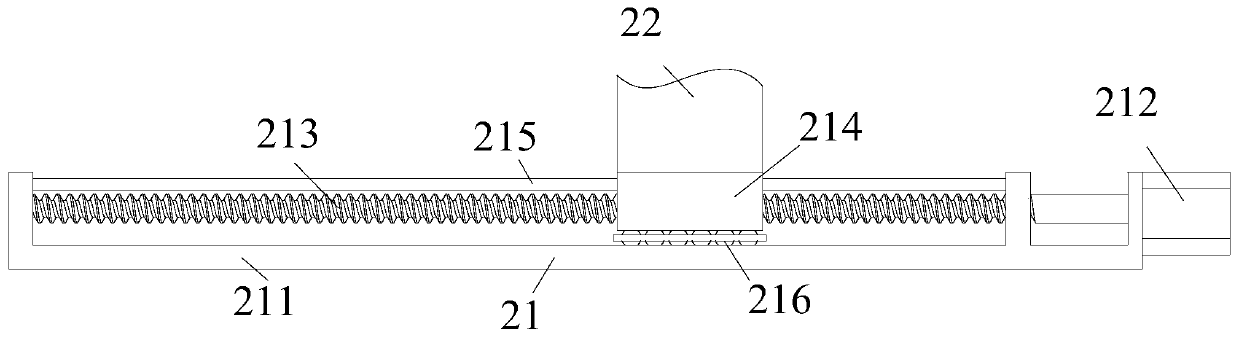

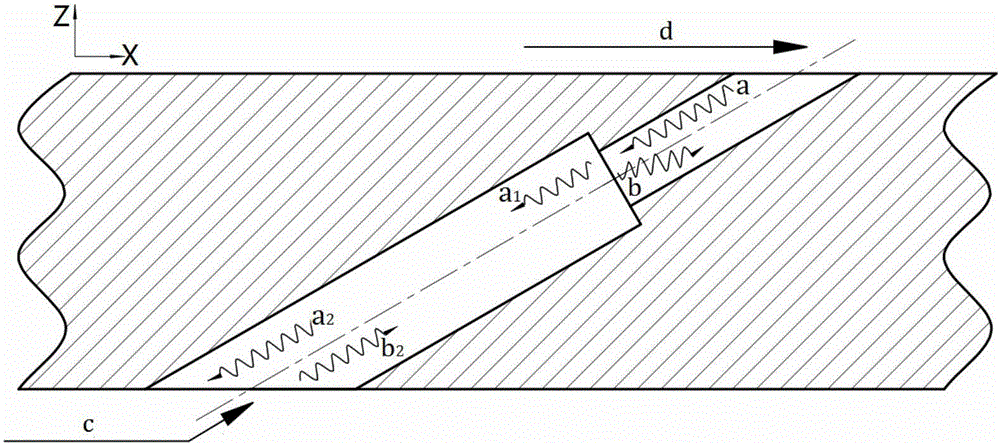

A damping and vibration-reducing tool rod

InactiveCN102275086ALow costLarge aspect ratioMaintainance and safety accessoriesEngineeringMachining process

The invention relates to a damping and vibration reduction cutter rod. The knife rod includes: a knife handle (2) and a cutter head (1) arranged at the lower end of the knife handle (2), and a cylindrical cavity (4) is coaxially arranged in the knife handle (2). Damping particles (5) are sealed and filled in the cylindrical cavity (4). The present invention has the advantages that: 1) the anti-vibration cutter of the particle damping and vibration-reduction system is used in the vibration-damping cutter bar, which can realize a large length-to-diameter ratio at a relatively low cost, making the processing process simpler and more efficient. high. 2) The vibration-damping tool holder of the present invention can improve the machining precision of the tool and prolong the life of the tool. 3) At the same time, in mechanical processing, the use of vibration-damping tools can improve the quality of surface processing and greatly improve work efficiency, especially in boring tools, using this vibration-damping tool bar to bore and cut deep holes, improve the quality of the inner surface and speed up boring Cutting speed will help a lot.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +3

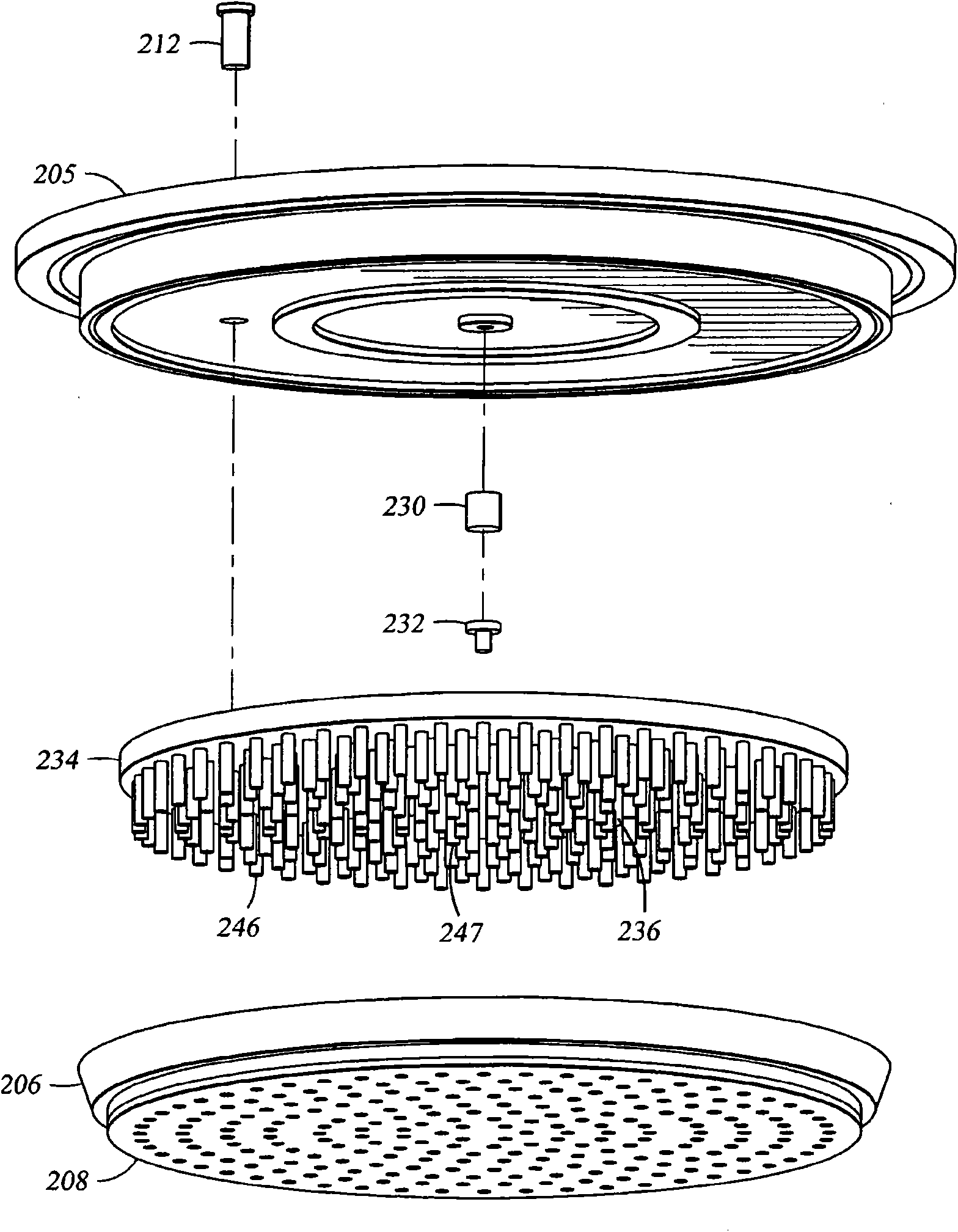

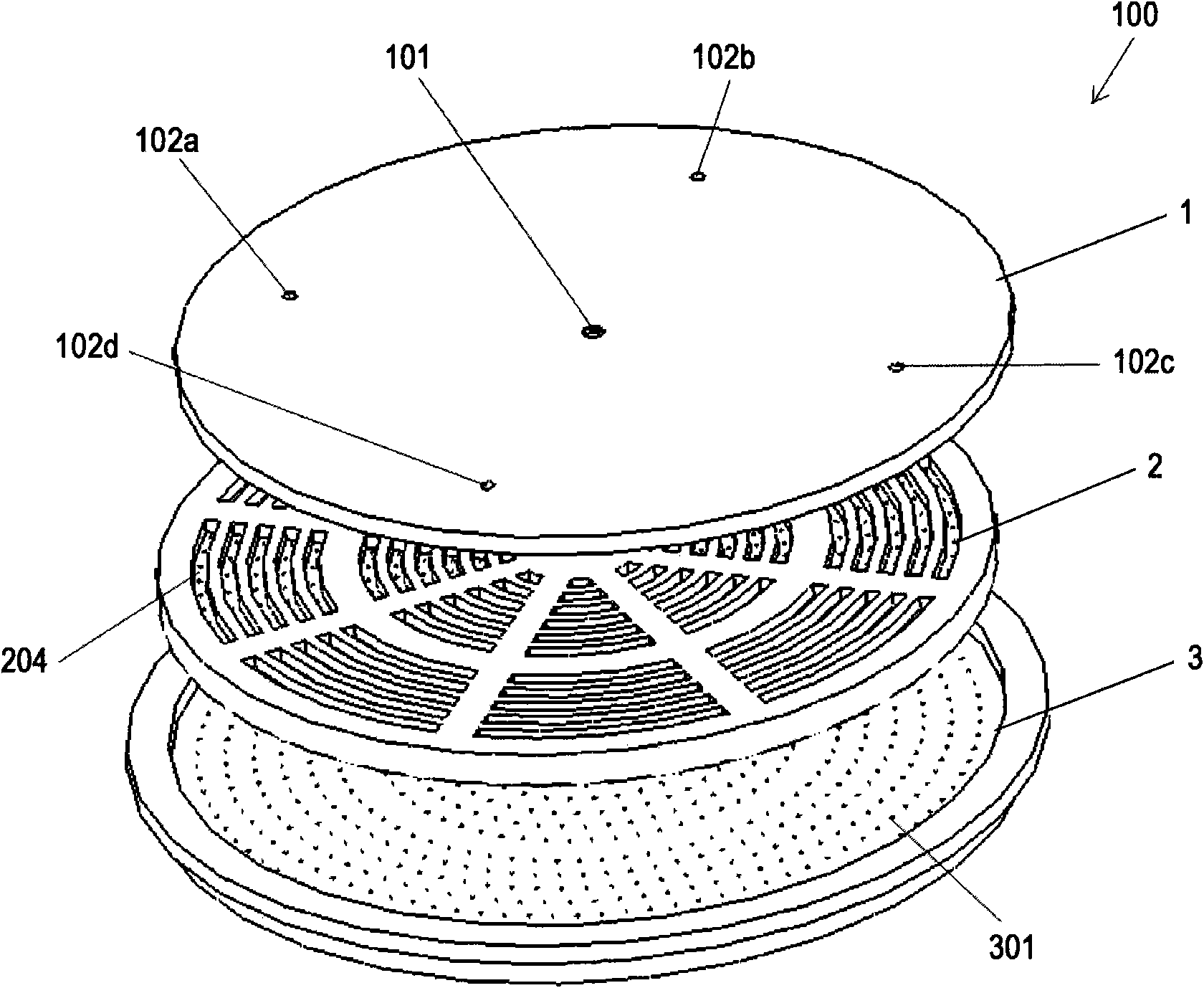

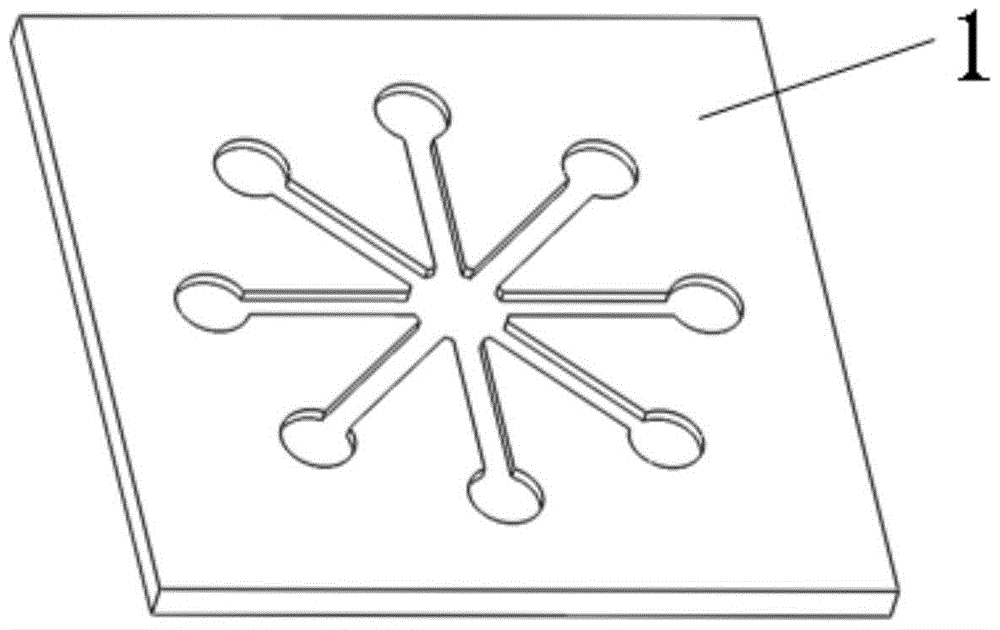

Gas distributor and semiconductor processing equipment applying same

ActiveCN101556904AEasy to processSimple and fast processingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

The invention discloses a gas distributor comprising a supporting plate, a spoiler and a spray header electrode which are sequentially cascaded from top to bottom. The back of the supporting plate is provided with a first supporting table and supporting plate flow guide bosses, and a supporting plate groove is disposed between every two adjacent supporting plate flow guide bosses. The front face of the spoiler is provided with a second supporting table and spoiler grooves, and a spoiler flow guide boss is disposed between every two adjacent spoiler grooves; the width and the depth of the grooves are both larger than those of the corresponding flow guide bosses so that the flow guide bosses can be embedded into the corresponding grooves and when the first supporting table is in contact with the second supporting table, and a certain gap is remained between the flow guide bosses and the corresponding grooves so as to transfer and distribute gas. In addition, the invention also discloses semiconductor processing equipment applying the gas distributor. The gas distributor and the semiconductor processing equipment not only can relatively evenly distribute gas inside a reaction chamber, but also have the advantages of convenient processing, no easy damage, and the like.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

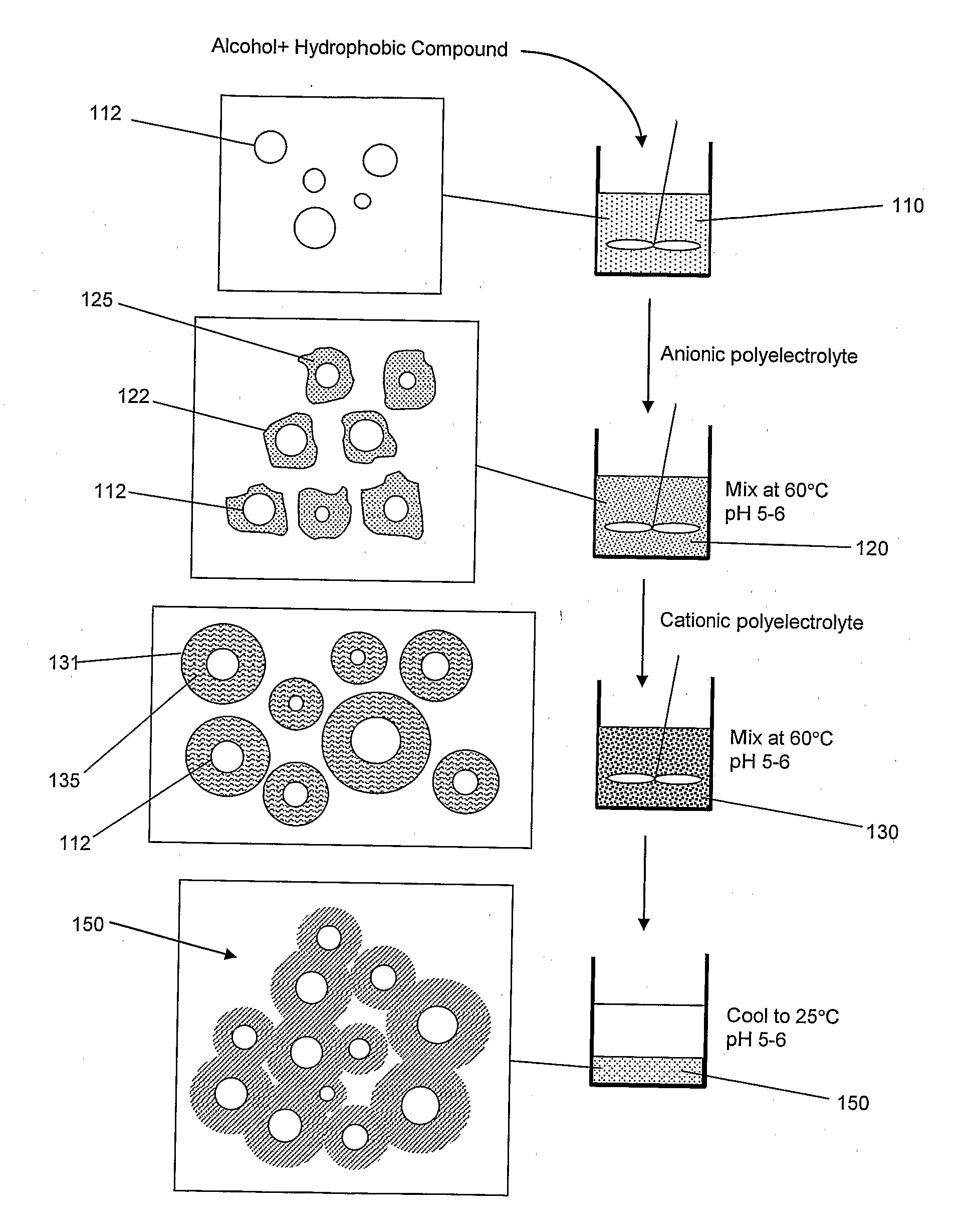

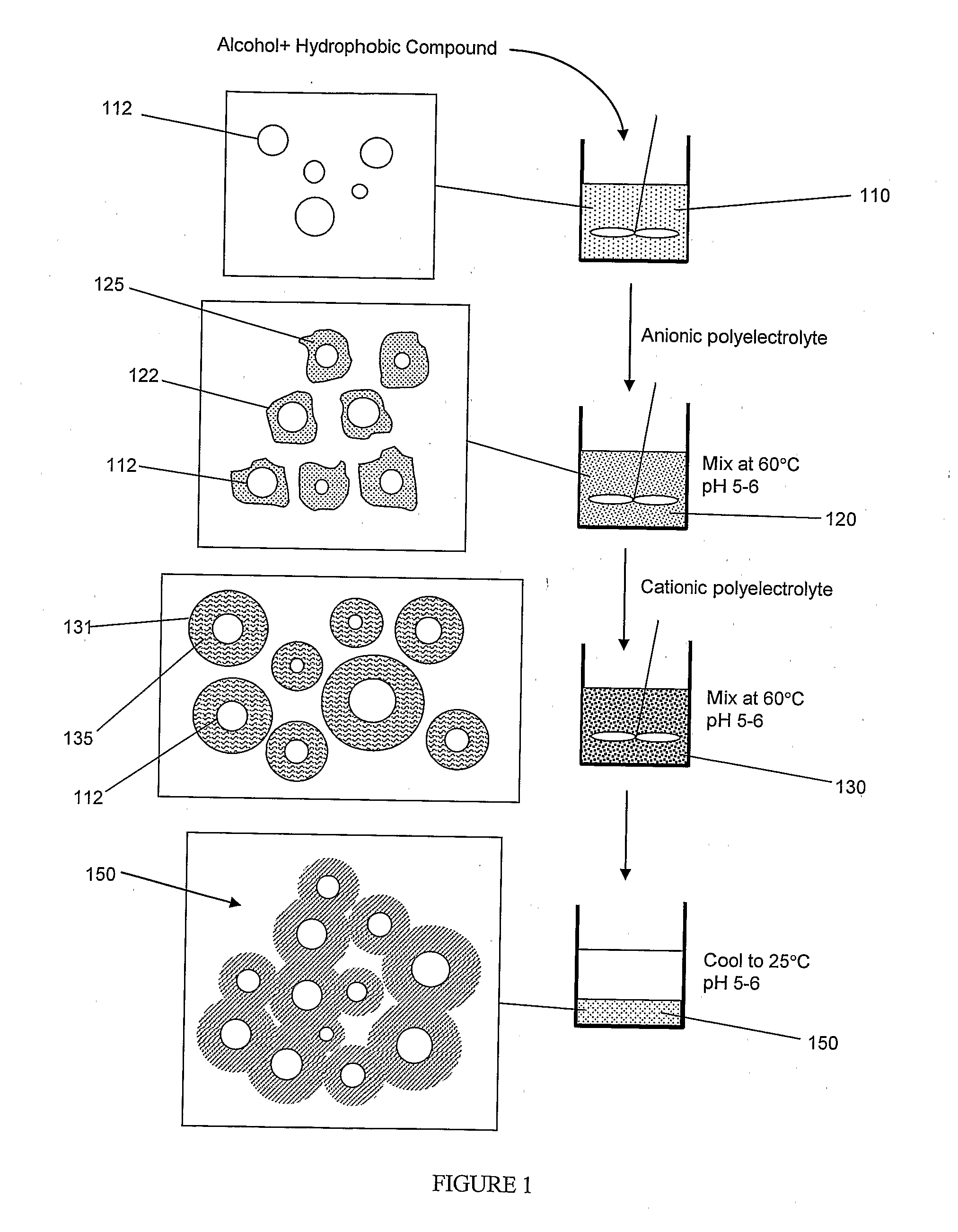

Method for Nanoencapsulation

ActiveUS20100303913A1Increase bioavailabilityReduce preparation costBiocidePowder deliveryCationic polyelectrolytesOrganic solvent

Methods of nanoencapsulation are described herein. Embodiments of the method utilize the coacervation of a cationic polyelectrolyte with an anionic polyelectrolyte to form a novel capsular matrix. In particular, the novel methods may be used to encapsulate a suspension of a hydrophobic material such as a carotenoid. The disclosed methods do not require lengthy pH adjustments nor do they require the use of any toxic crosslinking agents. In one embodiment, a method of encapsulation comprises dispersing a hydrophobic compound in an organic solvent to form a solution. The method also comprises admixing an anionic polyelectrolyte and a cationic polyelectrolyte with the suspension to form a mixture. In addition, the method comprises quiescently cooling the mixture so as to cause self-crosslinking of a capsular matrix encapsulating the hydrophobic particles.

Owner:RICE UNIV

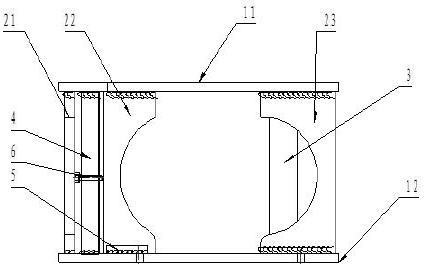

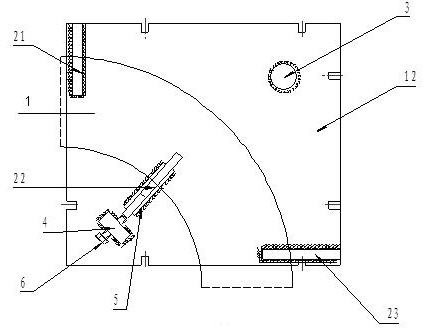

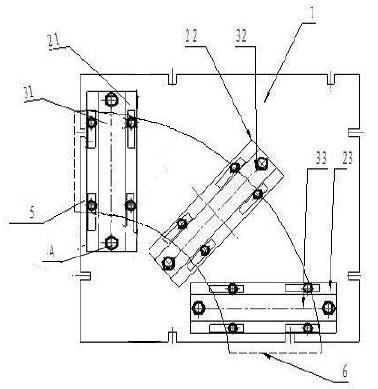

Clamping deformation resistant jig for machining large-diameter elbow

InactiveCN102139457AGuaranteed machining accuracyAbundant resourcesPositioning apparatusMetal-working holdersThin walledEngineering

The invention discloses a clamping deformation resistant jig for machining a large-diameter elbow. Three combined clamping blocks are arranged on a clamping base plate, each combined clamping block consists of an upper clamping block, a lower clamping block, a base plate and connecting bolts, inner sides of the upper clamping blocks and the lower clamping blocks are provided with circular arc-shaped gaps and form a circle consistent with the outer circumference of an elbow to be machined after closed, the upper clamping blocks and the lower clamping blocks are connected and fastened by the connecting bolts, and the base plates are arranged at the bottoms of the lower clamping blocks and are provided with chutes. Lock bolts pass through the chutes on the base plates of the combined clamping blocks and fix the combined clamping blocks on the clamping base plate after being fastened. In the invention, the large-diameter elbow is clamped by adopting a way of directly clamping a pipe blank in a surface-contact manner, thus the elbow does not generate a radial compaction force in the clamping process and is not easy to generate the radial forced deformation and the torsional moment; in addition, the clamping deformation resistant jig disclosed by the invention is applied to machining of a large-diameter thin-wall elbow machine, thereby ensuring the machining precision of the elbow.

Owner:扬州华宇管件有限公司

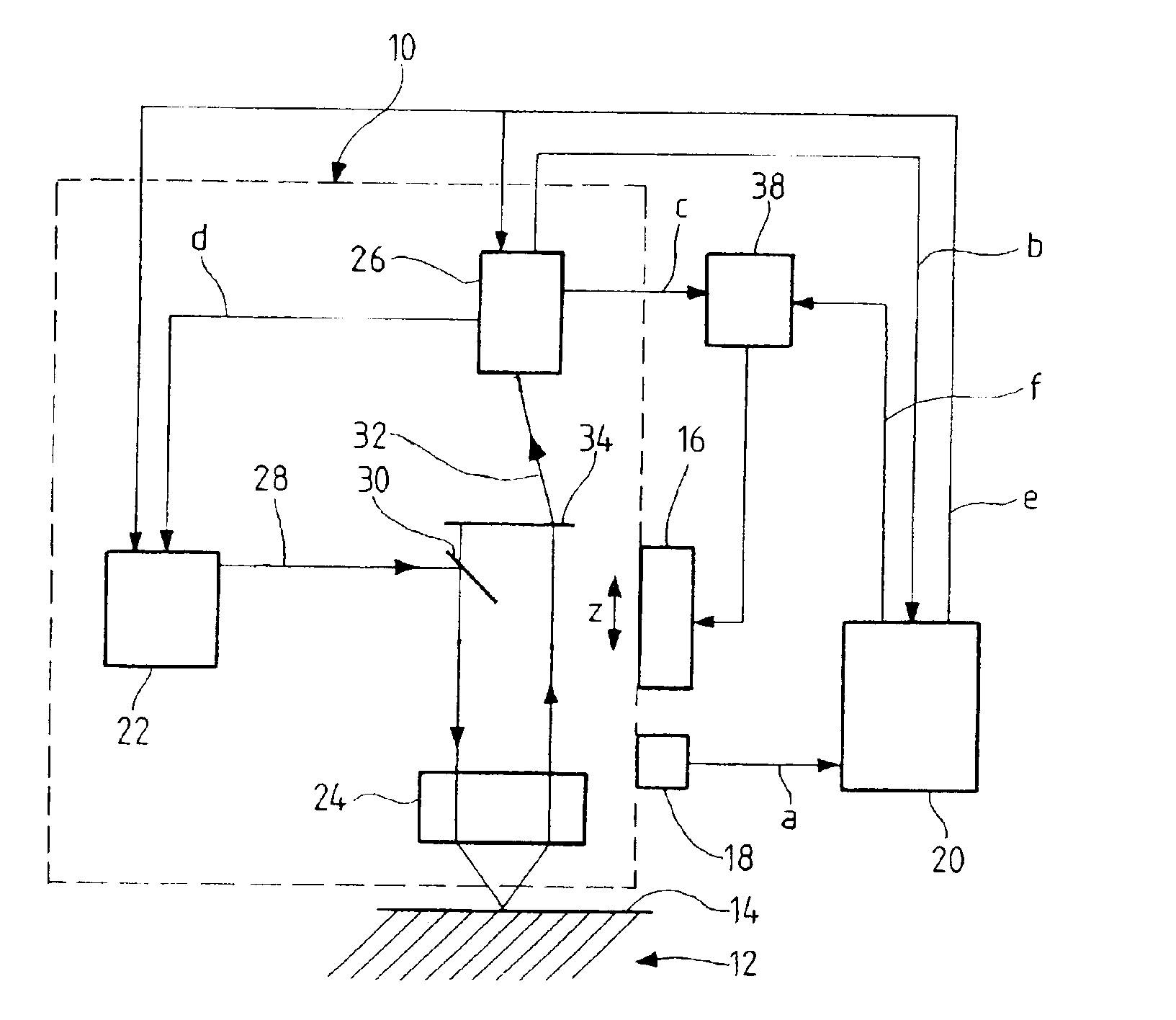

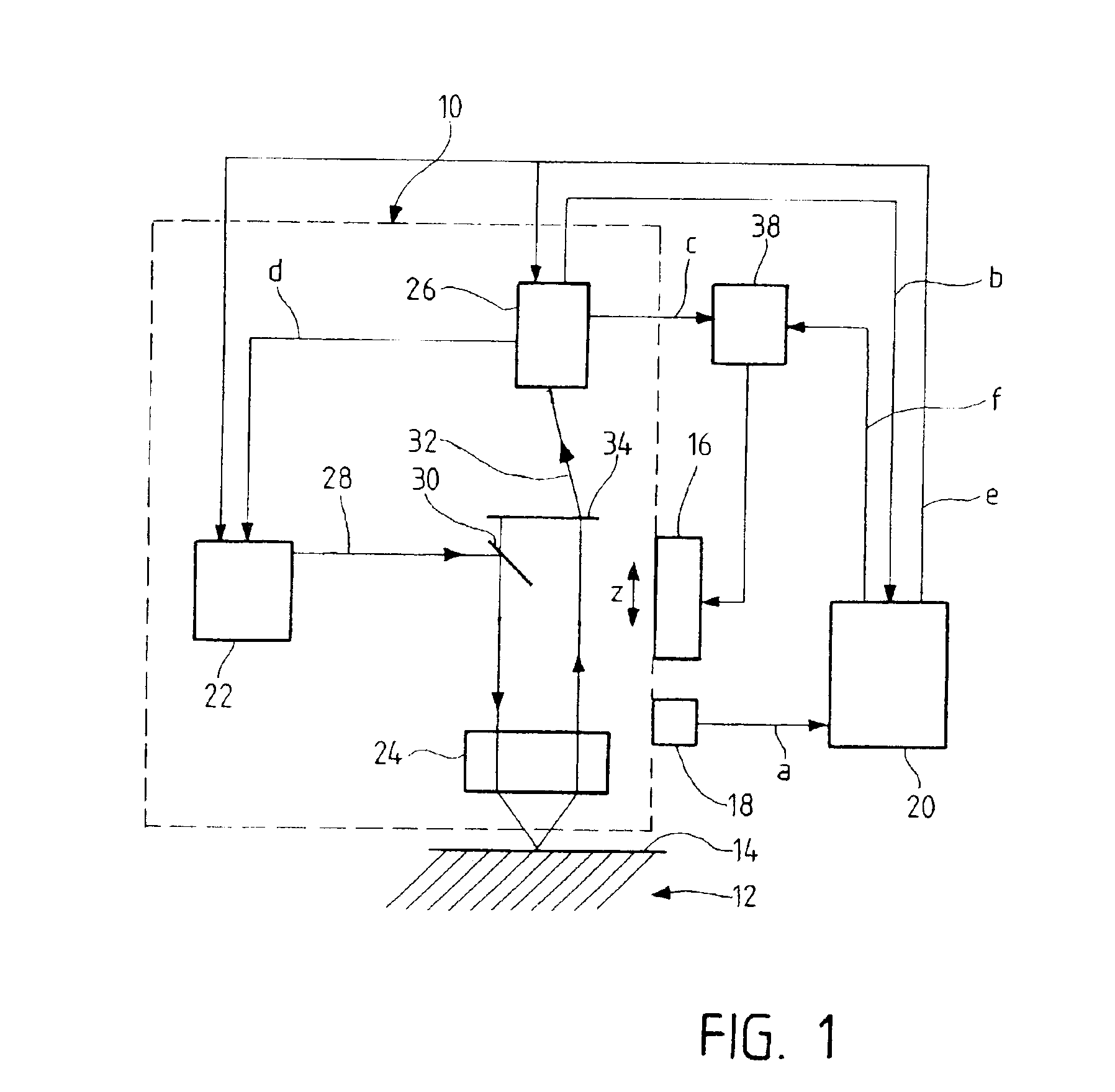

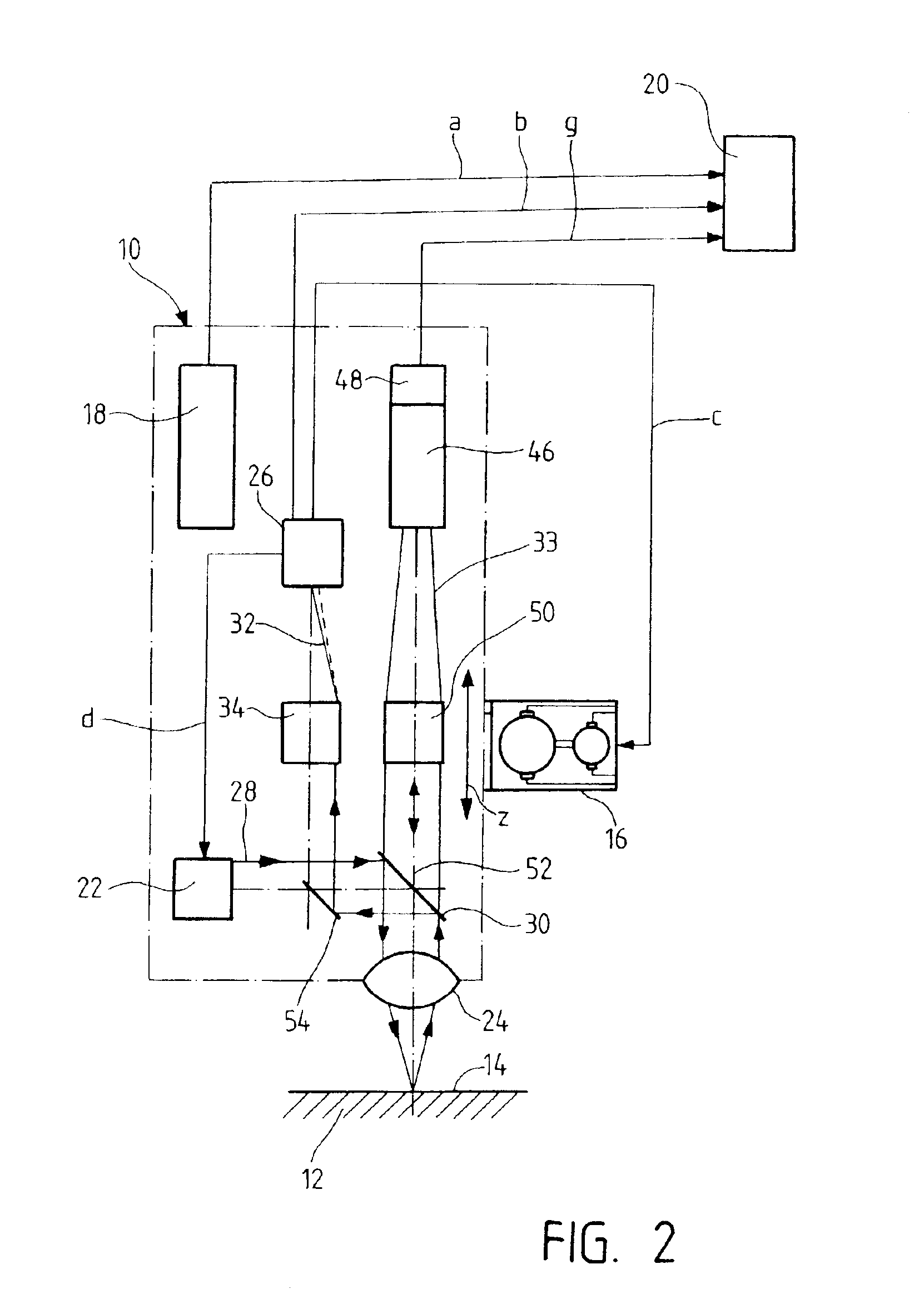

Apparatus for measuring a measurement object

InactiveUS6927863B2Solve the slow scanning speedReduced measurement timeUsing optical meansMechanical measuring arrangementsMeasurement deviceMeasurement point

An apparatus for contactlessly measuring a measurement object is proposed, which has an optical sensor, the optical sensor having an optical probe having a light source and a measurement objective for directing a light beam onto a measurement object and a receiver device for detecting a light beam reflected from the measurement object and generating a corresponding measurement signal; an advancing apparatus for altering the distance between the optical sensor and the measurement object in a first coordinate direction in a manner dependent on the measurement signal generated by the receiver device; and an evaluation unit for determining the coordinates of the measurement point on the measurement object. In order to avoid or at least reduce a so-called contouring error that occurs in conventional measurement apparatuses, the receiver device has a position-sensitive receiver which generates an evaluatable measurement signal within a programmable measurement window; the advancing apparatus sets the distance between the optical sensor and the measurement object in such a way that the receiver of the receiver device receives the light beam reflected from the measurement object within the measurement window; and the evaluation unit determines the coordinates of the measurement point on the measurement object from the position of the optical sensor and the measurement signal generated by the receiver device.

Owner:WERTH MESSTECHN

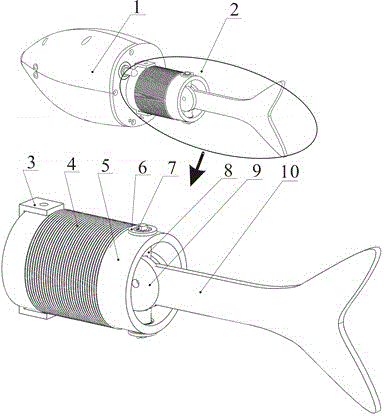

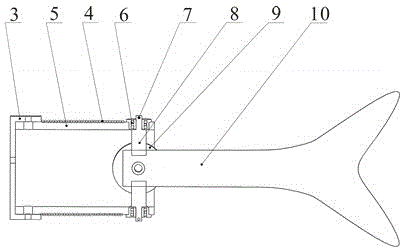

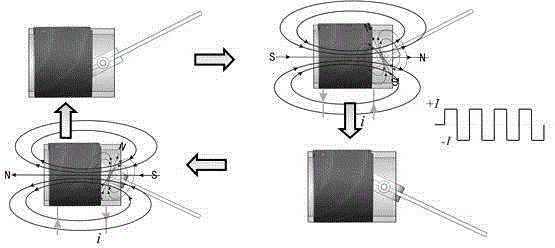

Low-energy-consumption magnetomotive propelling mechanism of bionic robot fish

InactiveCN103950525ASimple structureReduce volumePropulsive elements of non-rotary typeTransmission with non-mechanical gearingElectromagnetic inductionMagnet

The invention discloses a low-energy-consumption magnetomotive propelling mechanism of a bionic robot fish. The low-energy-consumption magnetomotive propelling mechanism comprises a body, i.e. a magnetomotive tail fin, wherein the magnetomotive tail fin comprises a U-shaped connecting frame, a magnetic induction coil, a strong-magnetic swinger and a crescent flexible tail fin; the magnetic induction coil is formed by winding silk-covered wires on a PVC (Poly Vinyl Chloride) bobbin; the strong-magnetic swinger is arranged on the central position of a rotary shaft in a pull-in manner by adopting two round strong-magnetic permanent magnets; the two ends of the rotary shaft are arranged on two small bearings; the tail end of the rotary shaft locks inner races of the small bearings by a clamping pin; the U-shaped connecting frame connects a fish body and the crescent flexible tail fin which consists of a tail handle and a fin surface. The low-energy-consumption magnetomotive propelling mechanism disclosed by the invention has the advantages that the structure is simple, the volume is small, and the processing is convenient; the insulating and waterproof performances are good; any waterproof protection is not needed, so that the complexity of the mechanism is greatly reduced; the electromagnetic induction principle is adopted to realize no-noise driving; the propelling efficiency is high and the working voltage of the magnetomotive propelling mechanism is wider.

Owner:SUZHOU UNIV OF SCI & TECH

Test system and method for portable electronic apparatus

ActiveUS7200497B2Easy and fast processingSave powerElectric controllersStands/trestlesComputer hardwareDisplay device

A test system for testing a portable electronic apparatus is described. The test system has at least a display, a platform, and a controller. The controller controls the display to display test images in sequence. The controller commands the portable electronic apparatus, via a test interface, to capture the test images on the display to generate image data. The controller determines whether the image data meet a predetermined test requirement. The test system can further include at least a light source and a reflector. The reflector reflects the light on the display, so that the display reaches a predetermined uniformity of light.

Owner:QUANTA COMPUTER INC

Method for bonding two substrates

InactiveUS20100155882A1Reduce in quantityFast and easy to carry-outSolid-state devicesSemiconductor/solid-state device manufacturingBiological activationTwo step

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

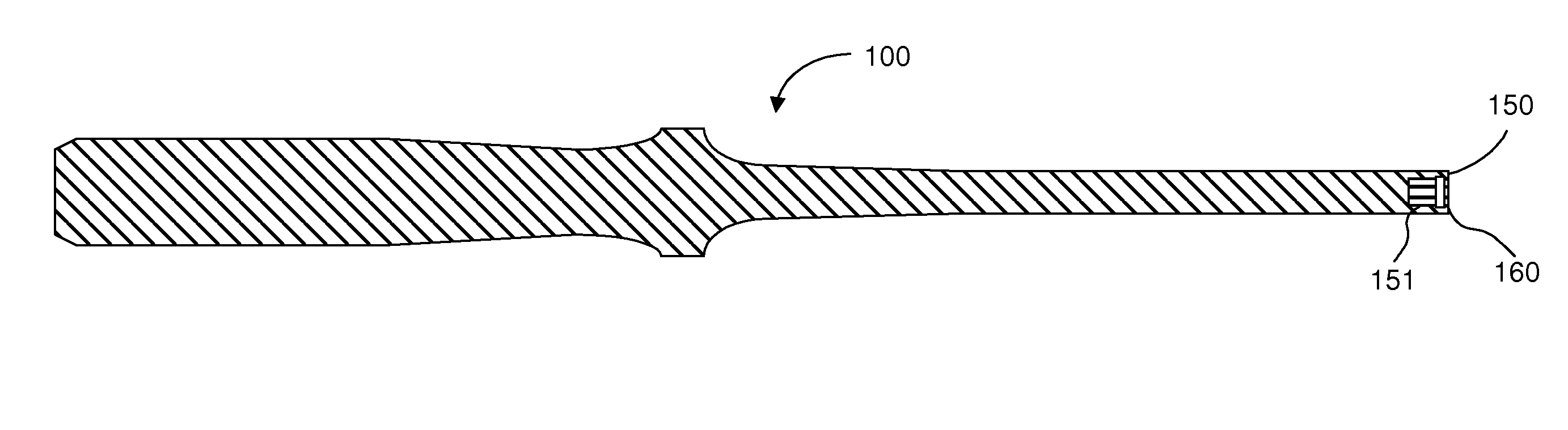

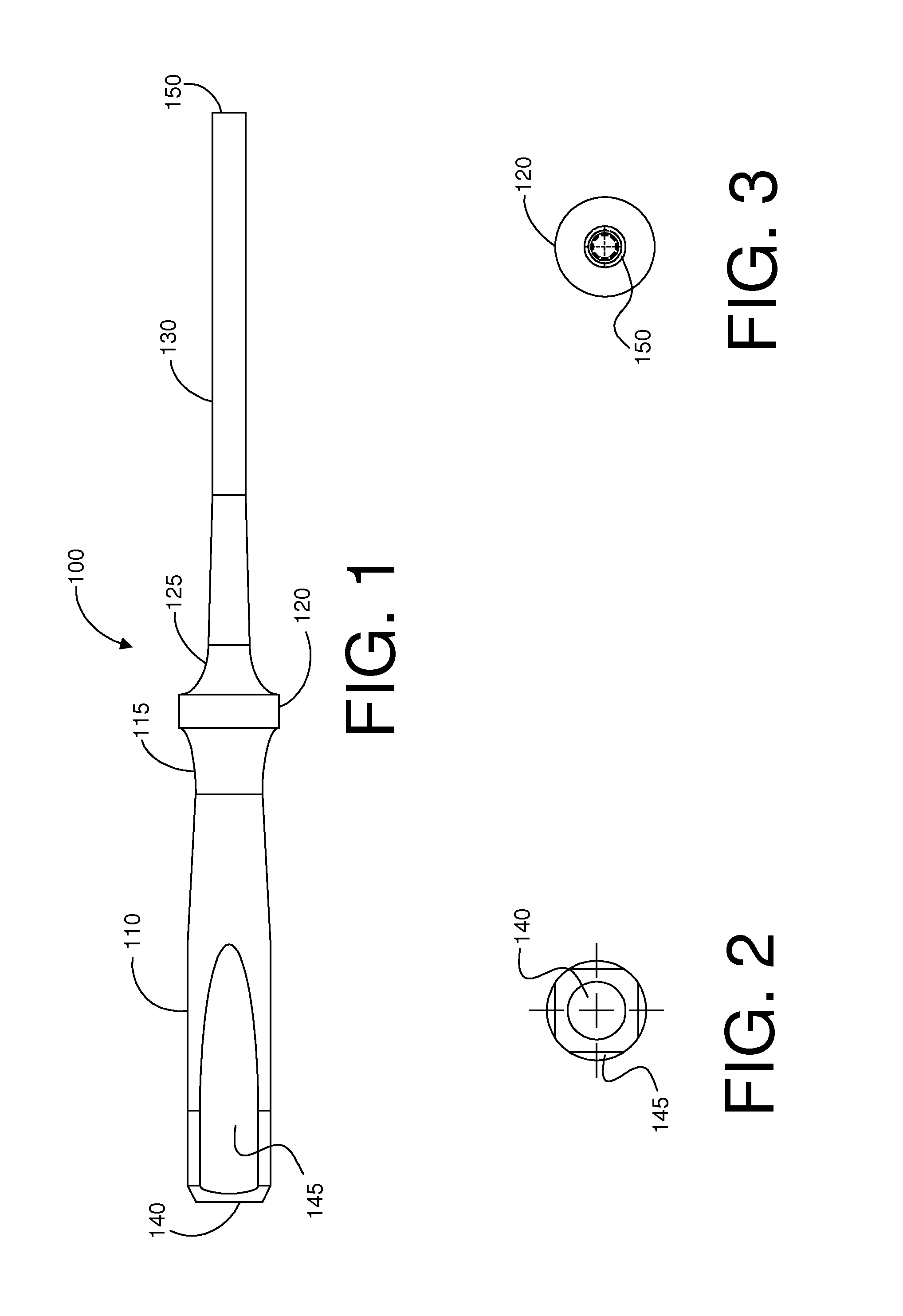

Dental implant driver and carrier removal system

InactiveUS20110143316A1Good tactile feedbackEasy and fast processingDental implantsDental toolsO-ringOsteotomy

The present invention is directed to a tool package for use with bone and / or dental implant systems. The tool package includes of two mating tools. The first tool is designed to engage an implant and carrier assembly and place the implant into the osteotomy. Once the implant is fully seated, the first tool is removed. The second tool is placed over the implant to hold the implant securely in place. The first tool is reintroduced through the second tool to engage and remove the implant carrier. The first tool may function like screwdriver except that the tip is able to mate with and positively engage the octagonal implant carrier head and plastic o-ring catch. The first tool drives the implants into place, and also mates with the second tool to remove the implant carrier.

Owner:DESIGNED DENTAL SYST

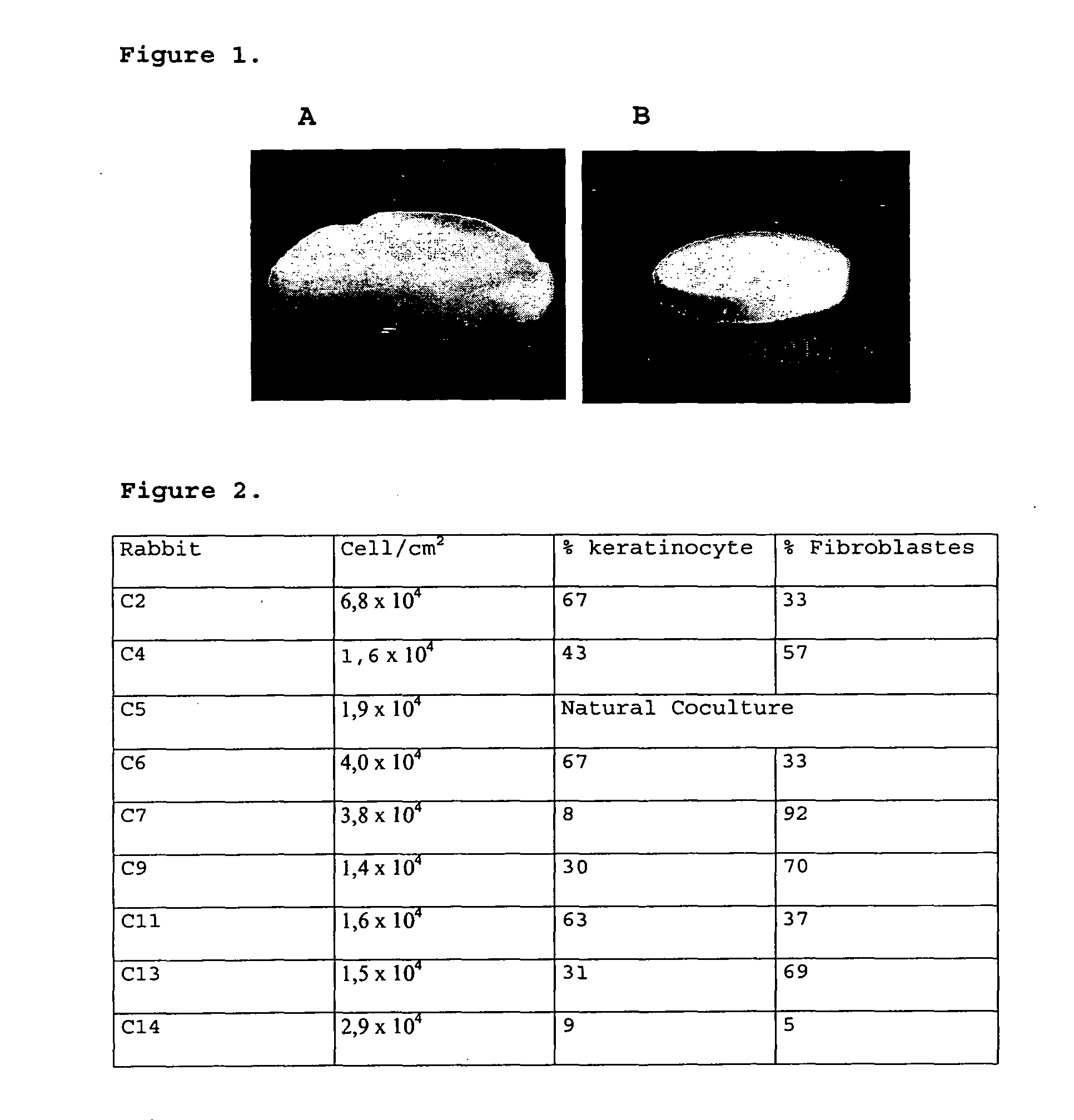

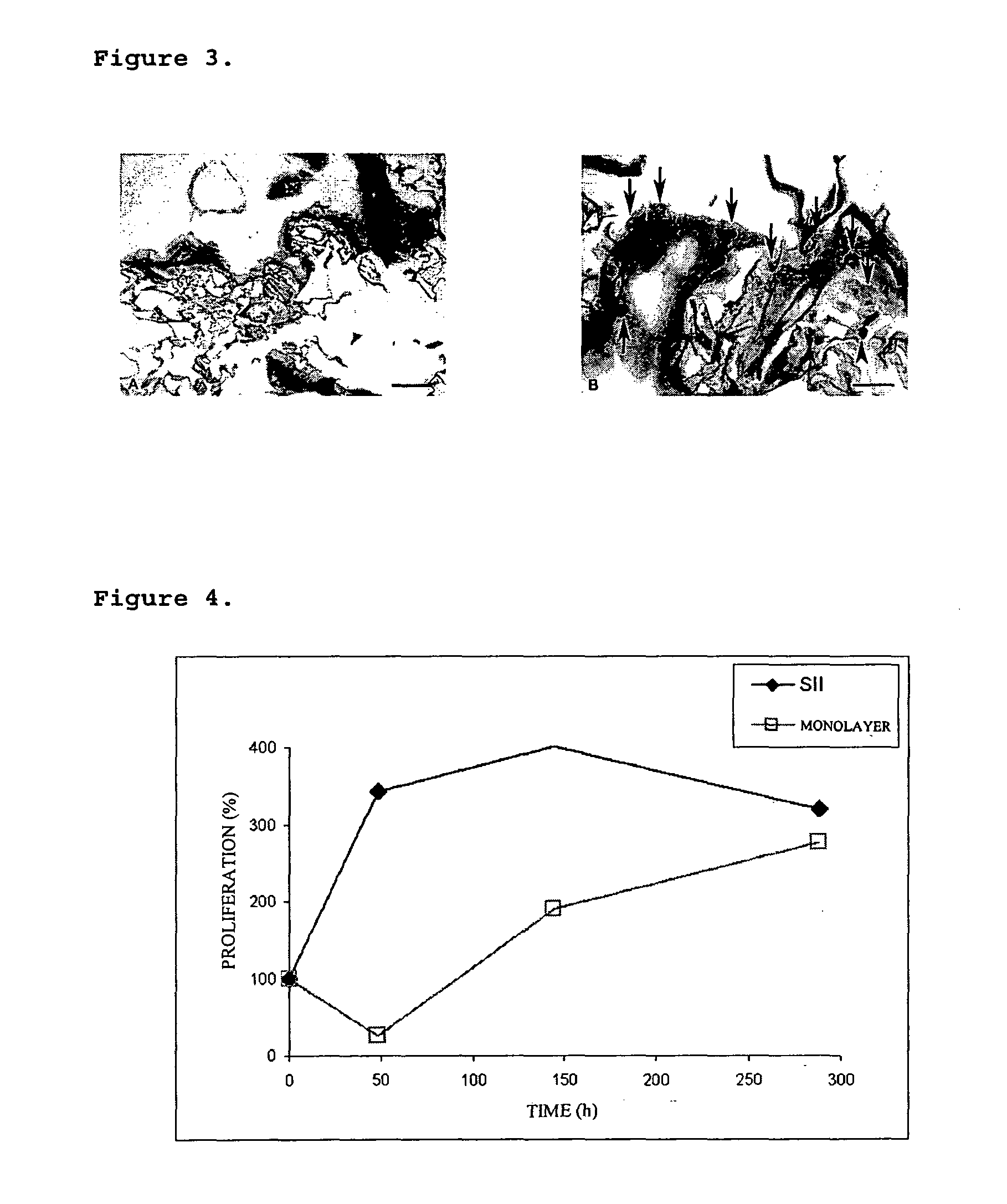

Integrated implant system (IIS) biocompatible, biodegradable and bioactive, comprising a biocompatible sterile porous polymeric matrix and a gel, integrating in situ the tridimensional matrix structure

The present invention refers to an Integrated Implant System constituted as a gel-matrix-cells integrated system, that allows providing implants in a brief time period, for covering a great skin extension to be treated, with a successful acceptance in patients with burns, chronic damage or wound skin, needing of a skin grafting.

Owner:UNIV TECNICA FEDERICO SANTA MARIA +2

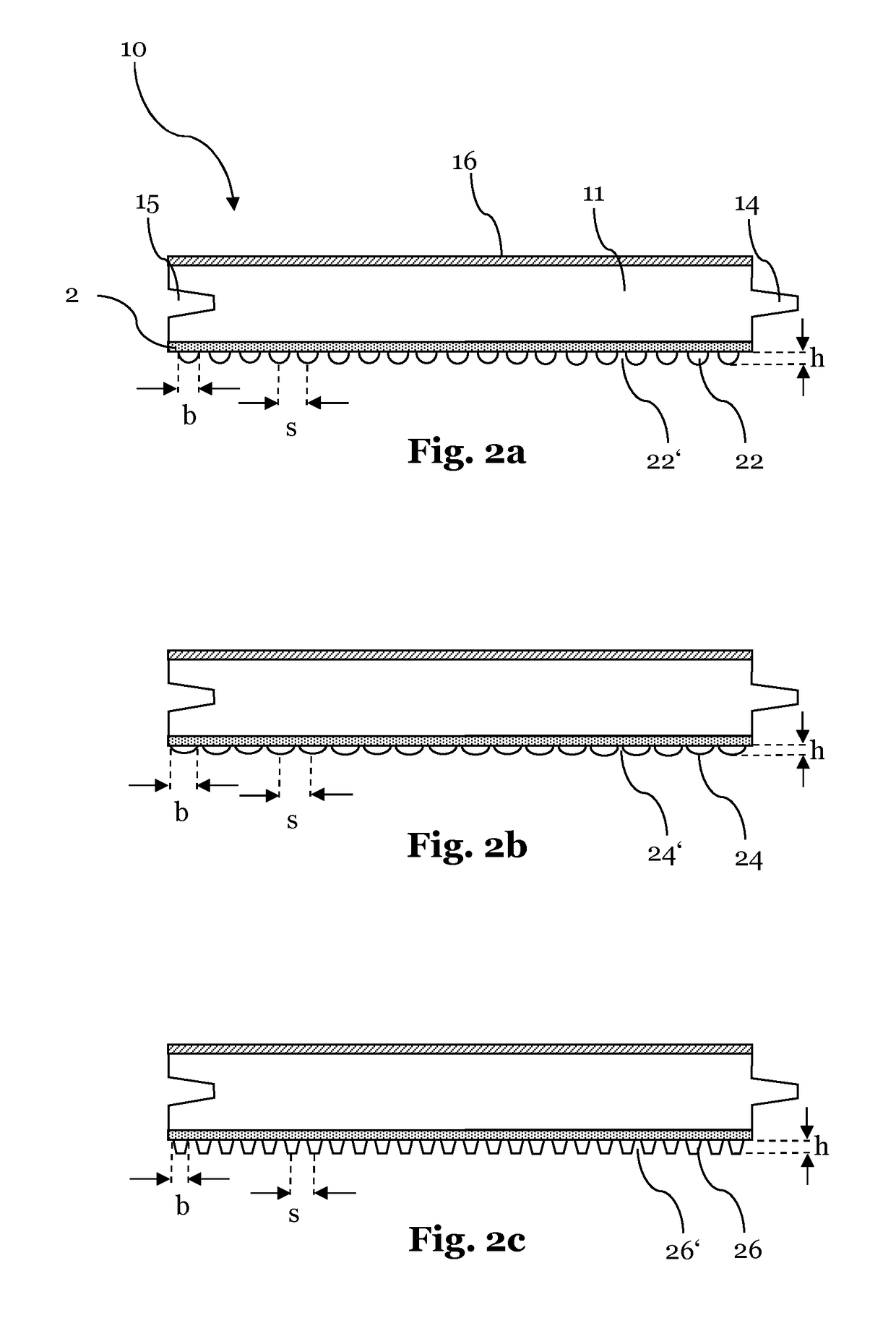

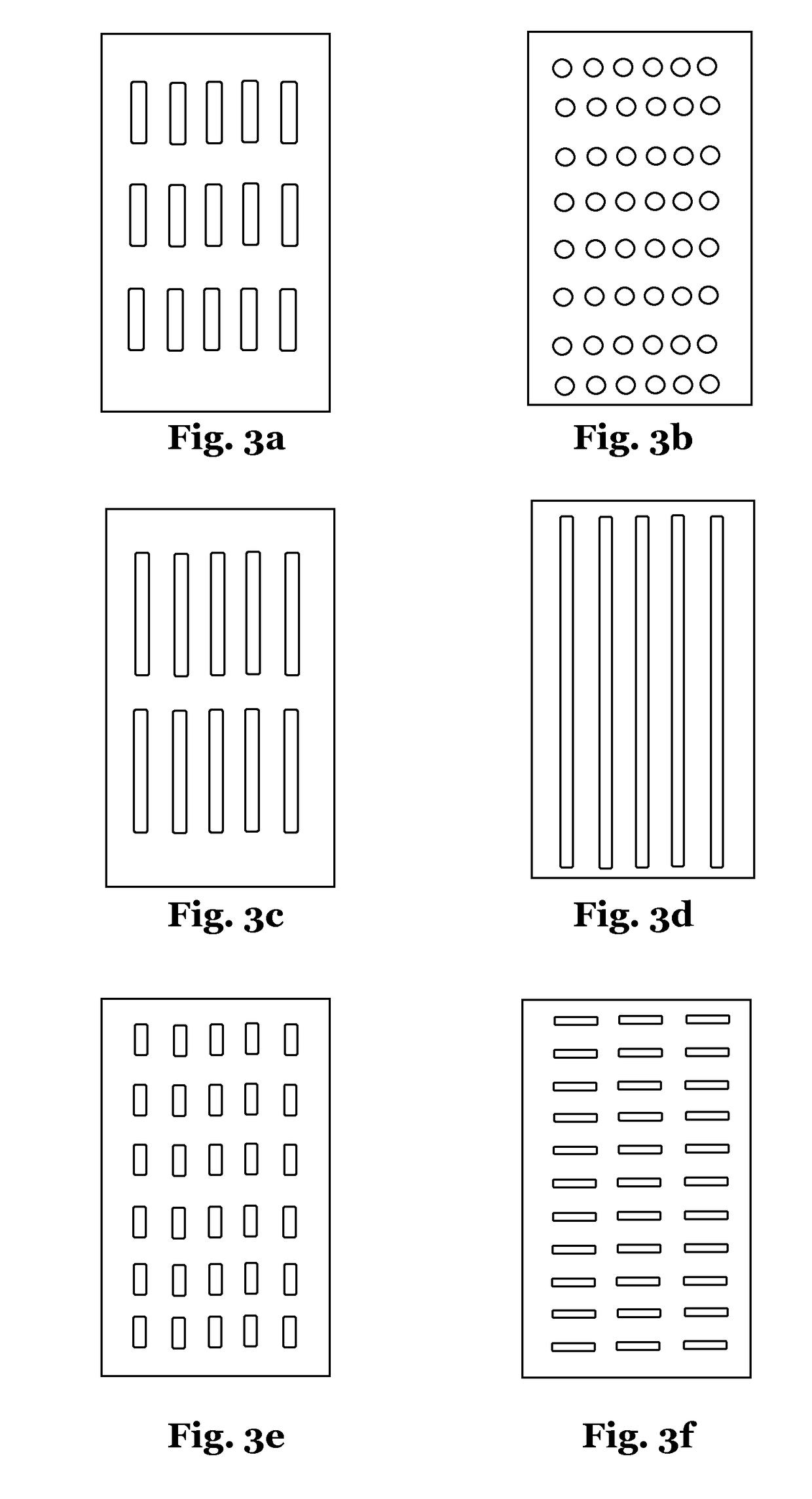

Floor panel having drainage protrusions

ActiveUS20190003189A1Quick installationEasy and fast processingCovering/liningsSynthetic resin layered productsOutdoor areaProtection layer

The present invention relates to a floor panel 10, in particular for the outdoor area or wet areas, with a carrier plate 11 having a front face and rear face, wherein the carrier plate 11 is provided on its front face with a décor and / or protective layer 16. For drainage of liquids and in particular of water, on the rear face of the carrier plate 11 drainage protrusions 22, 24, 26, 32 are applied.

Owner:XYLO TECH AG

Delay locked loop circuit and method

ActiveUS20070120587A1Improve performanceMinimize the numberPulse automatic controlOperating pointDelay-locked loop

A delay locked loop includes initialization circuitry that ensures that a DLL is initialized to an operating point that is not to close to either end of a delay vs. control voltage characteristic. The initialization circuitry forces the DLL to initially search for a lock point starting from an initial delay, the delay is varied in one direction, forcing the DLL to skip the first lock point. The initialization circuitry only allows the DLL to vary the delay of the voltage controlled delay loop in the one direction from the initial delay until the operating point is reached.

Owner:MOSAID TECH

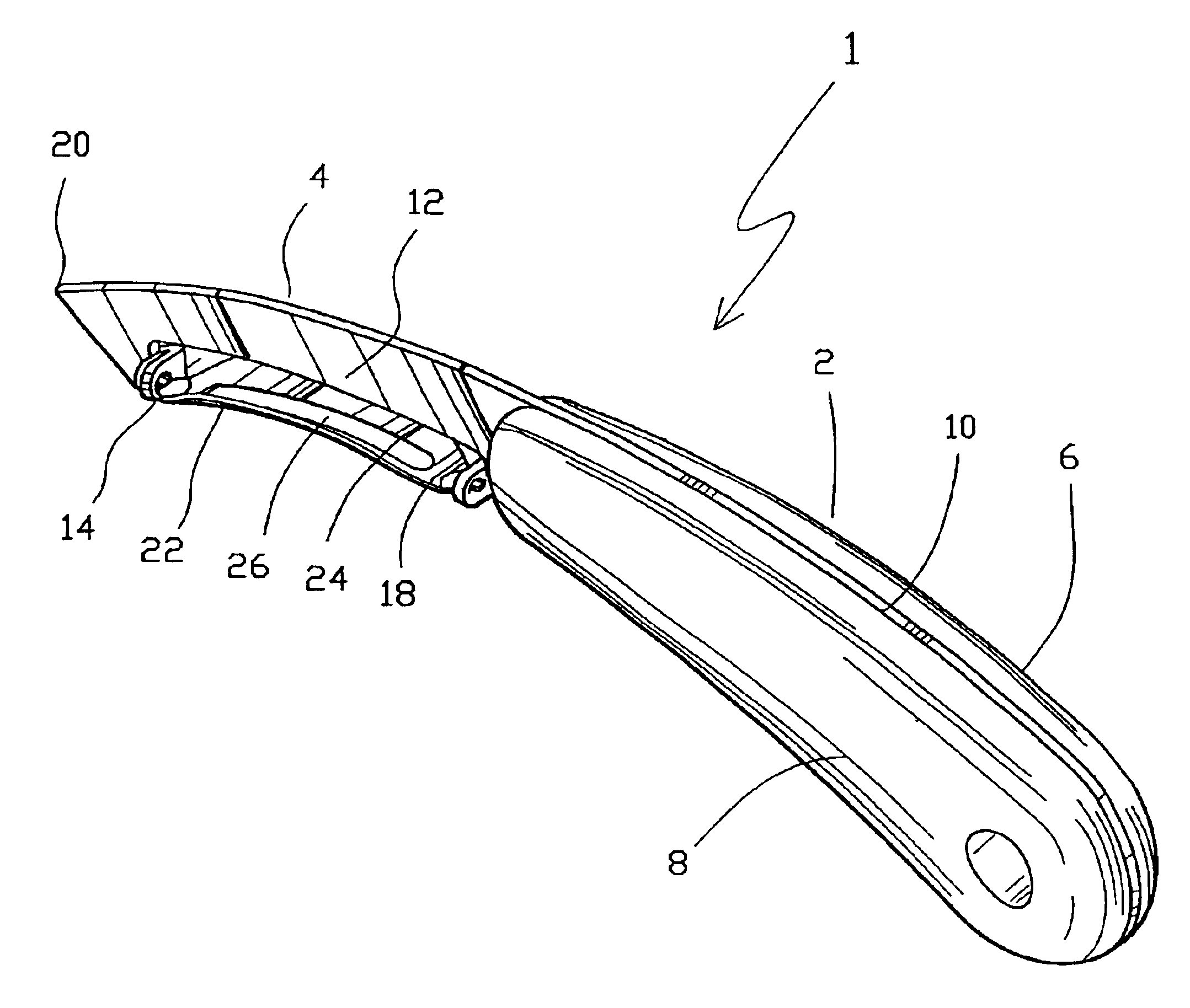

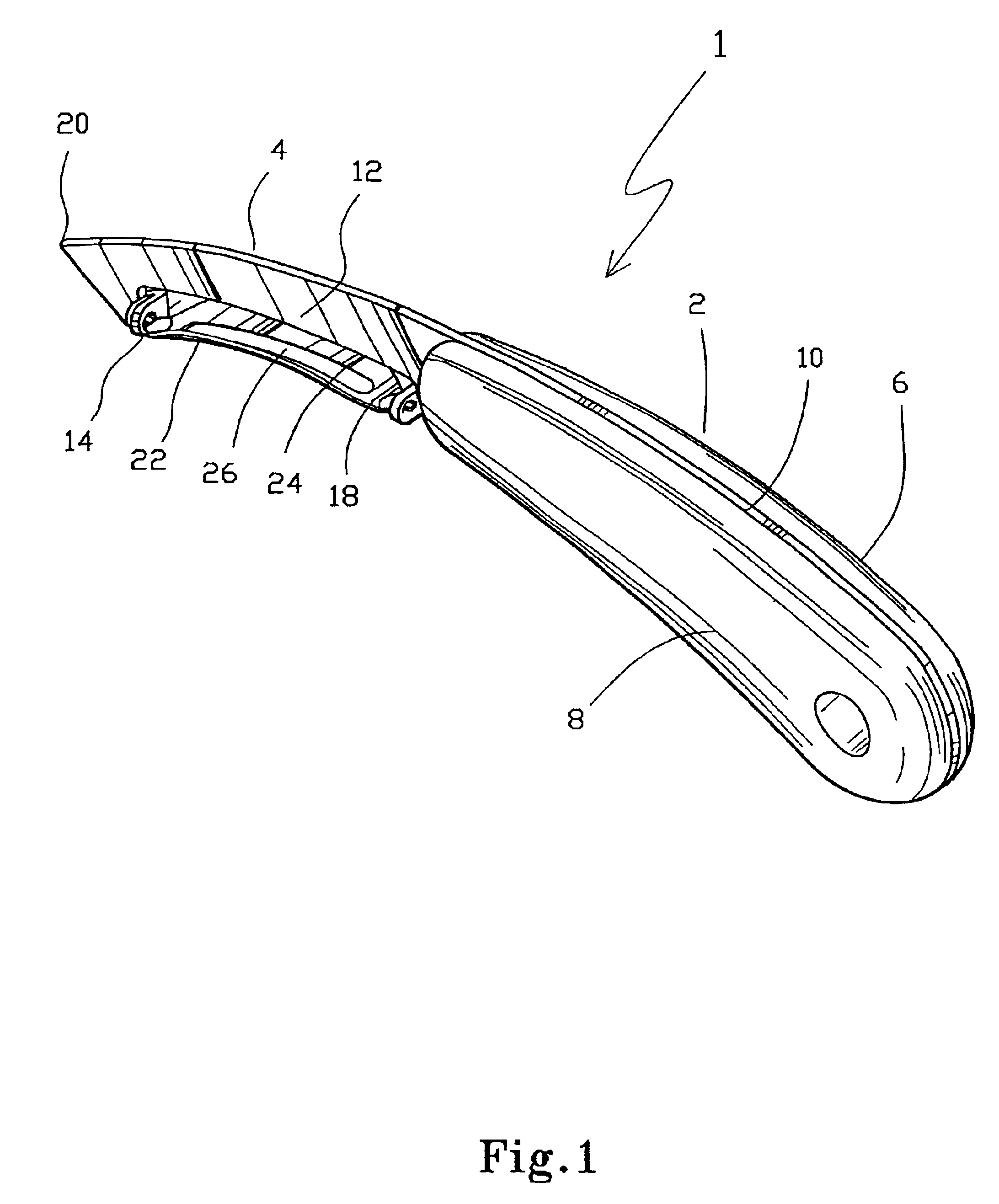

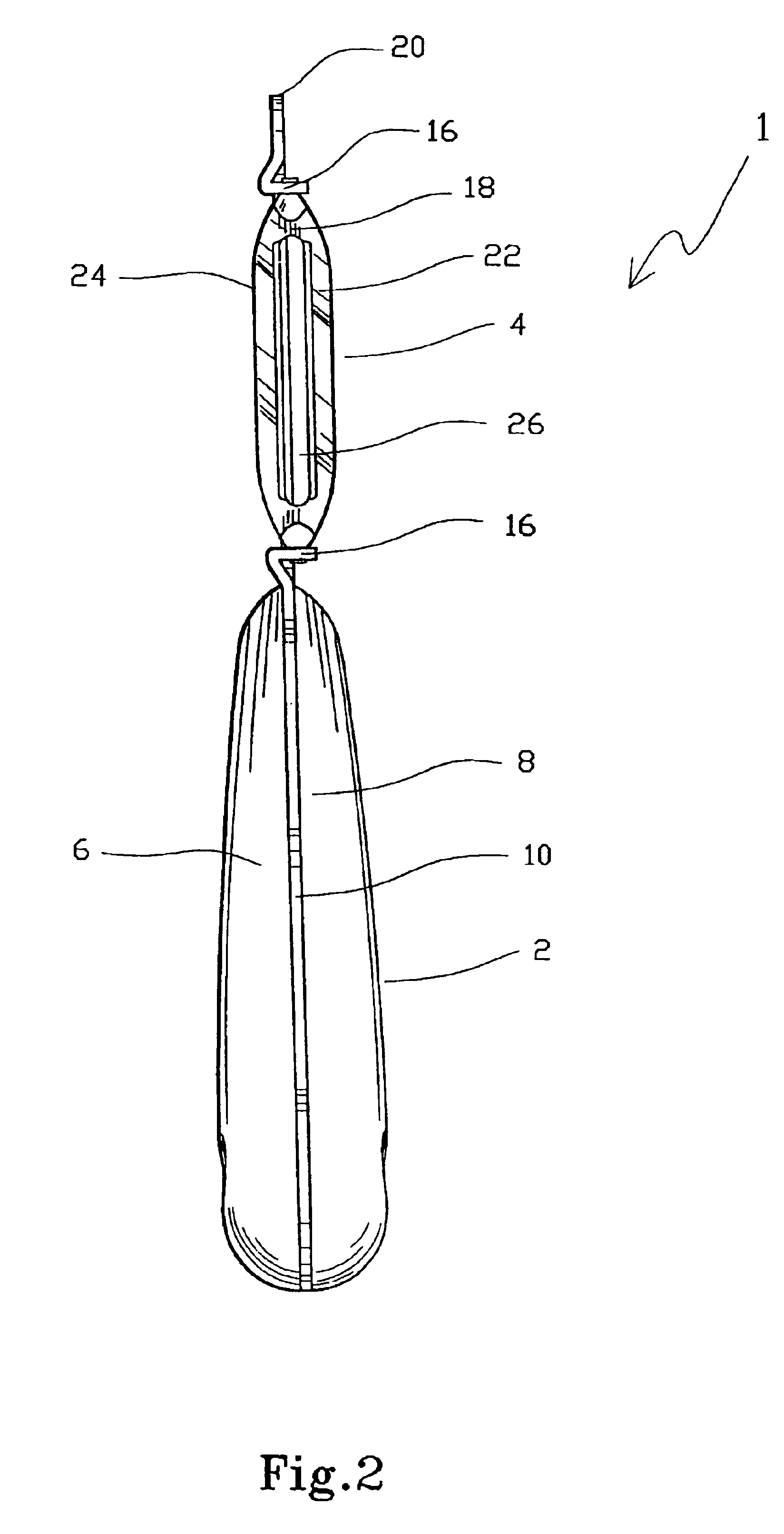

Culinary peeler

InactiveUS6874236B2Effective peelingEasy and fast processingVegetable peelingHand equipmentsKnife bladesBiomedical engineering

A culinary peeler having an elongate blade bent or curved in its lateral dimension having at least one longitudinal opening extending along its length with a sharp cutting region adjacent the opening, wherein the blade is of curved form in its longitudinal direction.

Owner:MAXPAT TRADING & MARKETING FAR EAST LTD

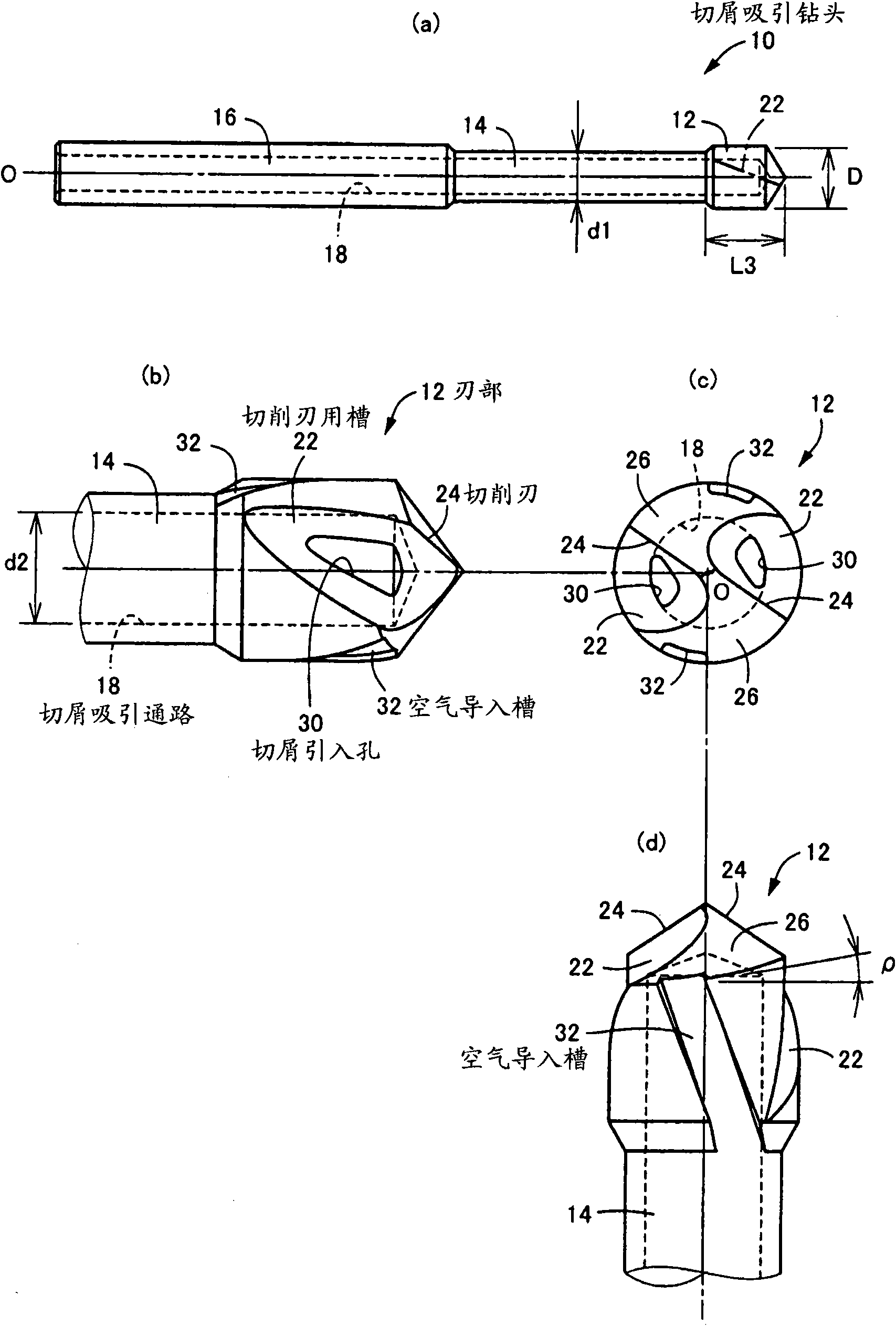

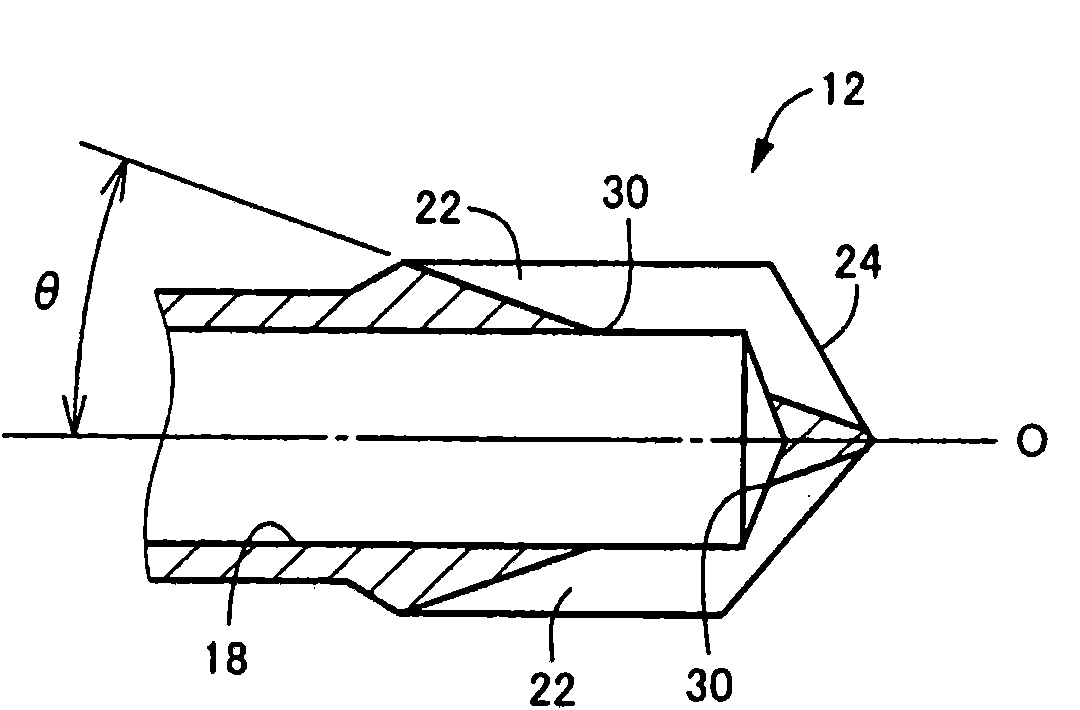

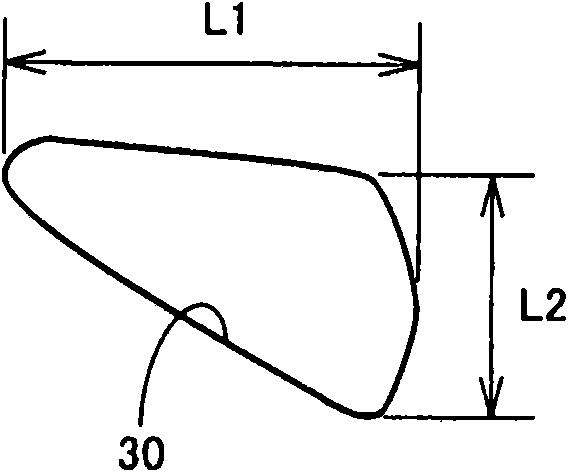

Chip suction drill

ActiveCN101959634AExcellent Chip Attraction PerformanceReduce resistanceTransportation and packagingMetal working apparatusChips intakeHole making

A chip suction drill (10) performs a hole making process to a material to be ground (42) such as a casting using a cutting blade (24). A chip generated is suctioned in a chip suction path (18) from a chip intaking hole (30) formed in a cutting blade groove (22) and ejected to a shank (16) side. In this case, since an air introduction groove (32) is provided in the outer periphery surface of a blade (12), air is excellently introduced into the leading end of a tool at which the chip is generated by the cutting blade (24) and the air introduced into the leading end of the tool upon the suction of air by the chip suction path (18) is excellently suctioned in the chip intaking hole (30) together with the chip. Particularly, since only one chip suction path (18) is provided in the tool, its cross section area can be sufficiently secured and the chip intaking hole (30) can be enlarged along with the enlargement of the chip suction path (18). Thus, the generation of chip packing can be suppressed and excellent chip suction performance can be obtained.

Owner:OSG

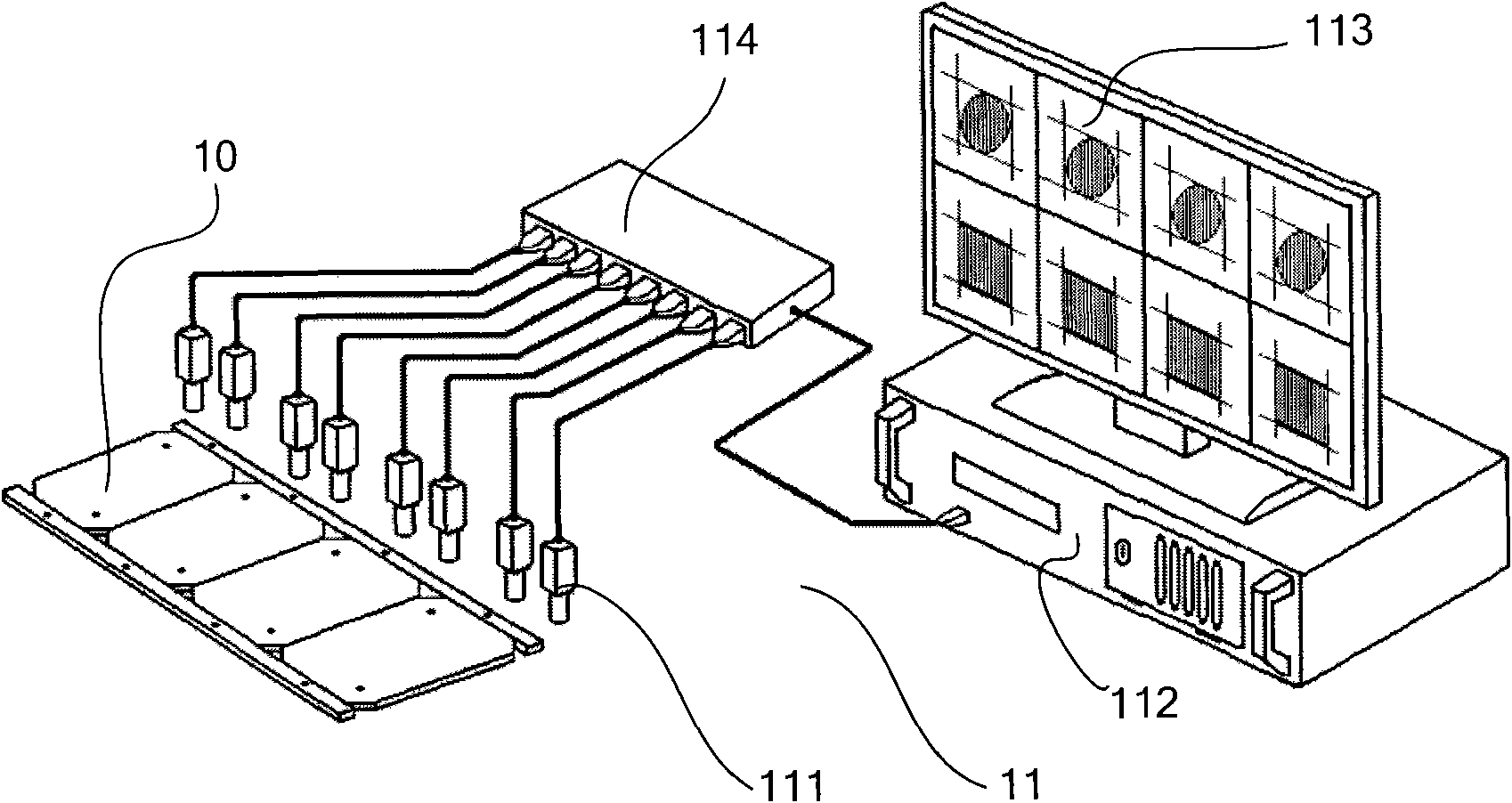

Circuit board framing device and drilling and milling device with image framing

InactiveCN101662928AEasy to observeImproving the accuracy of transplant processingOther manufacturing equipments/toolsElectrical componentsCamera lensComputer science

The invention discloses a circuit board framing device and a drilling and milling device with image framing, comprising a framing device for regulating the position of multiple circuit boards. The framing device comprises a plurality of viewing lens which is arranged for aiming at a plurality of marking points on the multiple circuit boards and retrieving the imaging data of the multiple circuit boards, a processor connected to the viewing lens and arranged for processing the imaging data, a display unit connected to the viewing lens and / or the processor for displaying the imaging data of themultiple circuit boards. The invention respectively observes the marking points on the multiple circuit boards by a plurality of viewing lens and views and compares the imaging data of the multiple circuit boards in the display unit. The microscopic sharp image can be acquired by observing separate marking points with separate viewing lens and the framing precision is high.

Owner:邓智军

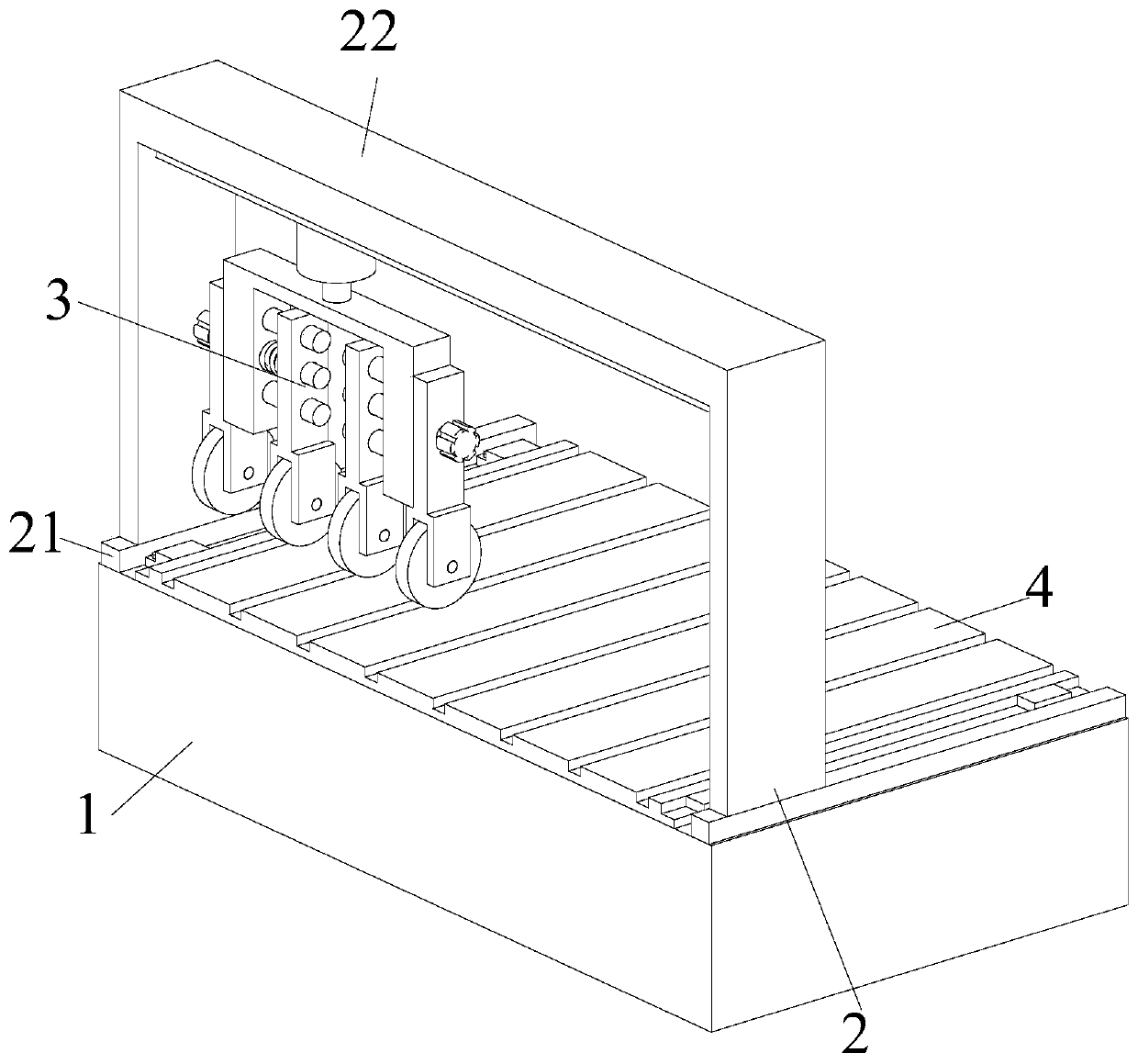

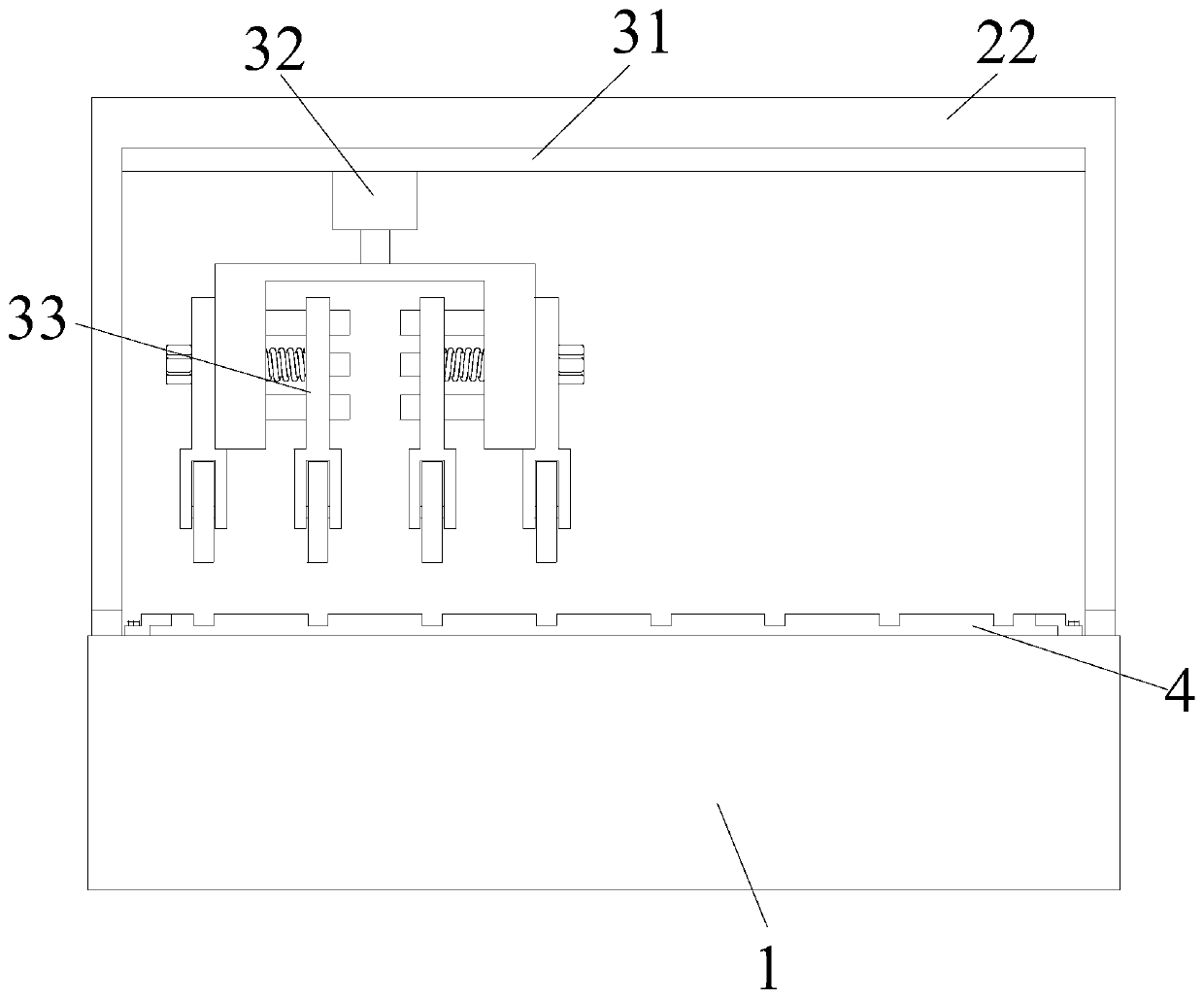

Workpiece surface plastic deformation rolling device and using method thereof

ActiveCN110538910AImprove processing efficiencyAvoid rust-prone situationsShaping toolsSheet steelWave shape

The invention relates to a workpiece surface plastic deformation rolling device and a using method thereof. The device comprises a workbench, a moving device, a rolling device and a lower die plate, the moving device is mounted at the upper end of the workbench, the rolling device is arranged inside the moving device, the lower die plate is mounted at the upper end of the workbench in a threaded connection mode, and the lower die plate is located in the moving device. According to the workpiece surface plastic deformation rolling device and the using method thereof, the problems that when existing color steel tile machining equipment is used for machining a steel plate, the color steel tile only can be formed through rolling of five to six times usually during rolling machining of one color steel tile, the forming process is tedious, the machining efficiency is low, in the case of the existing color steel tile machining equipment, one piece of rolling equipment usually only can be usedfor machining the color steel tile with one wave shape, and the surface of the steel plate is prone to be scratched in the rolling machining process of the color steel tile, so that the surface of the color steel tile is prone to be rusted can be solved.

Owner:TAIZHOU SRUITE IMP &EXP CO LTD

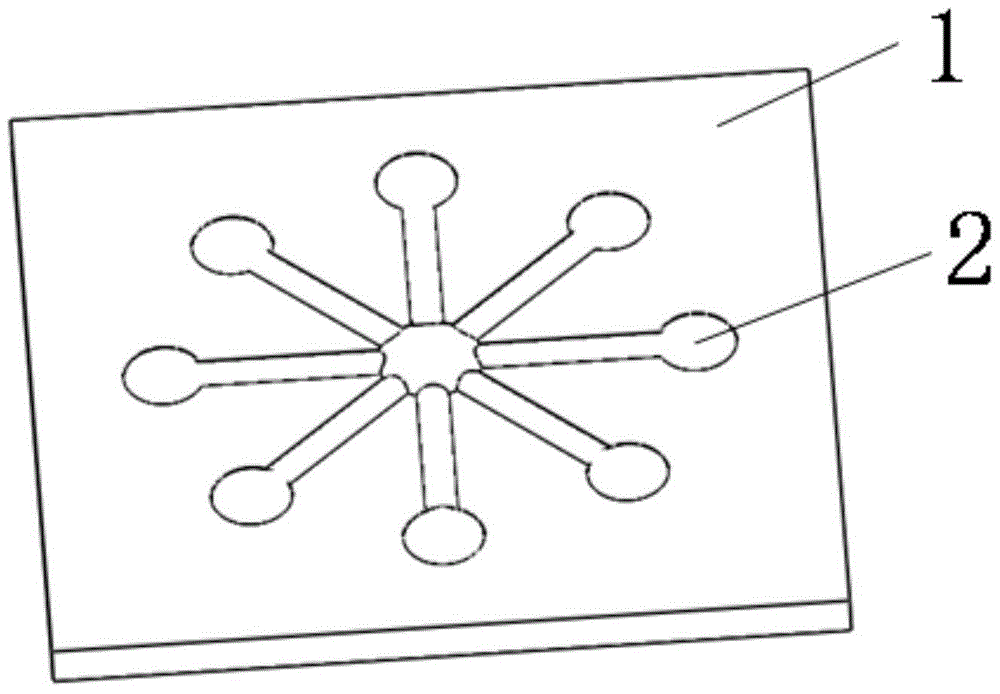

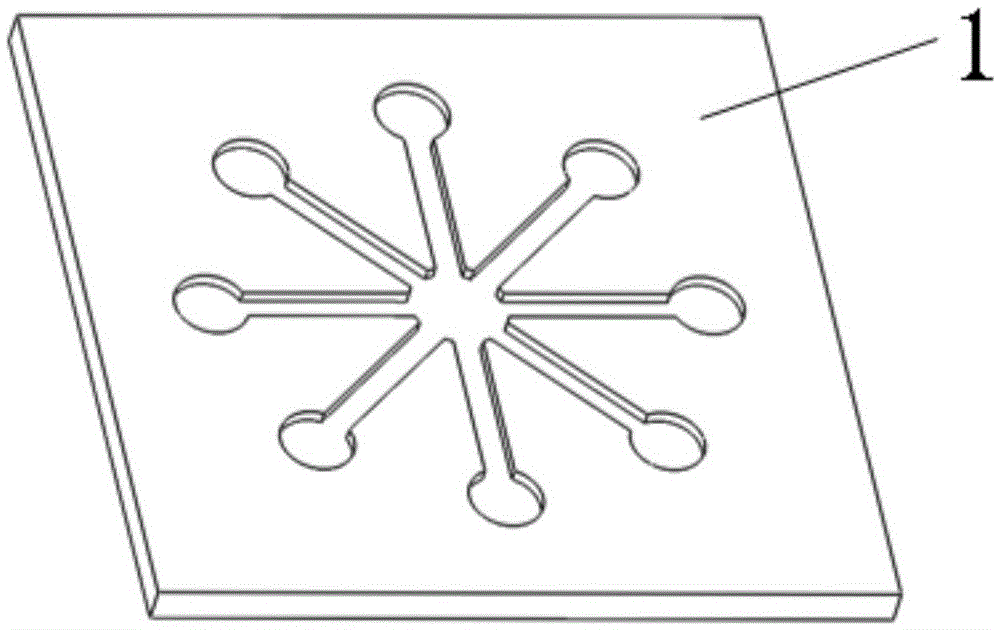

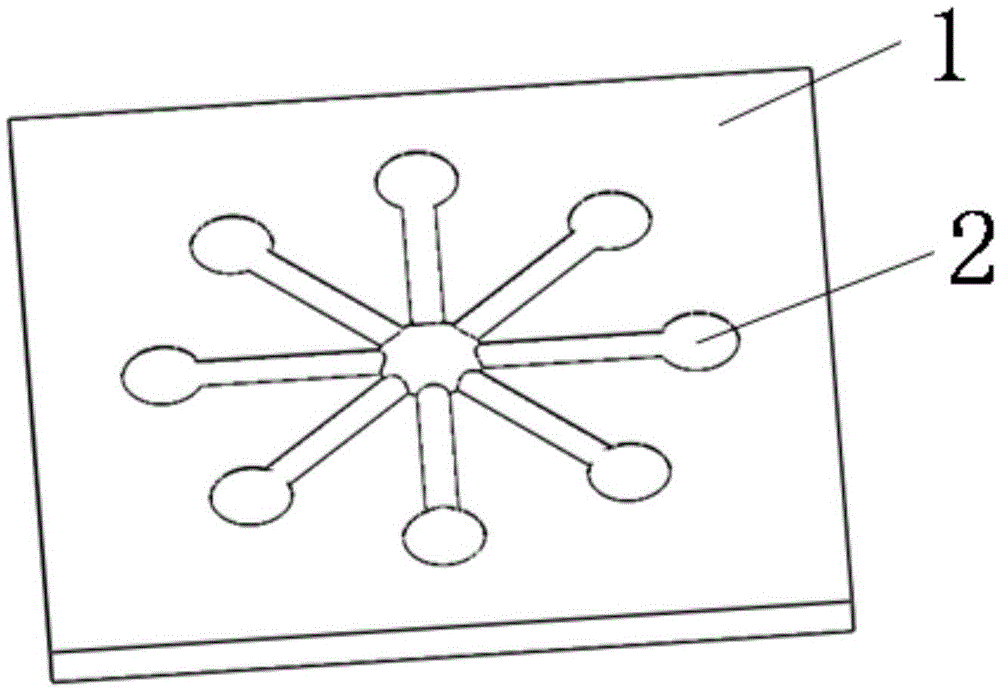

Micro-fluidic chip assembly

ActiveCN105665044AEasy to observeEasy and fast processingLaboratory glasswaresEmbedded systemMicro fluidic

The invention discloses a micro-fluidic chip assembly. The micro-fluidic chip assembly comprises a micro-fluidic chip and a cover plate covering the micro-fluidic chip, wherein a central sample adding port, multiple peripheral sample adding ports surrounding the central sampling adding port as well as runners communicating the multiple peripheral sample adding ports with the central sample adding port are formed in the micro-fluidic chip; through holes corresponding to the central sample adding port and the peripheral sample adding ports are formed in the cover plate; the micro-fluidic chip is in rotation fit with the cover plate, the cover plate is provided with a sample adding station for ensuring all the sample adding ports in the micro-fluidic chip to be correspondingly communicated with the through holes as well as a packaging station for plugging all the peripheral sample adding ports; a shifting piece is arranged between the micro-fluidic chip and the cover plate and used for covering the central sample adding port when the cover plate is located at the packaging station. The micro-fluidic chip assembly is simple in overall structure, convenient to use, capable of switching working states of the micro-fluidic chip only through simple rotation, very convenient to package and open and high in practicability.

Owner:ZHEJIANG UNIV

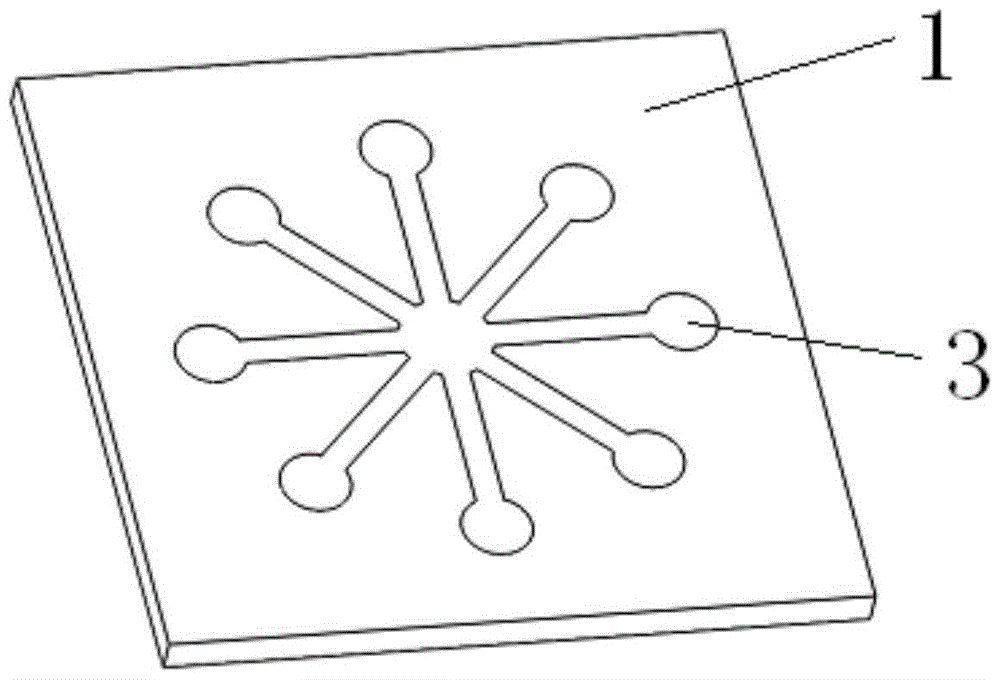

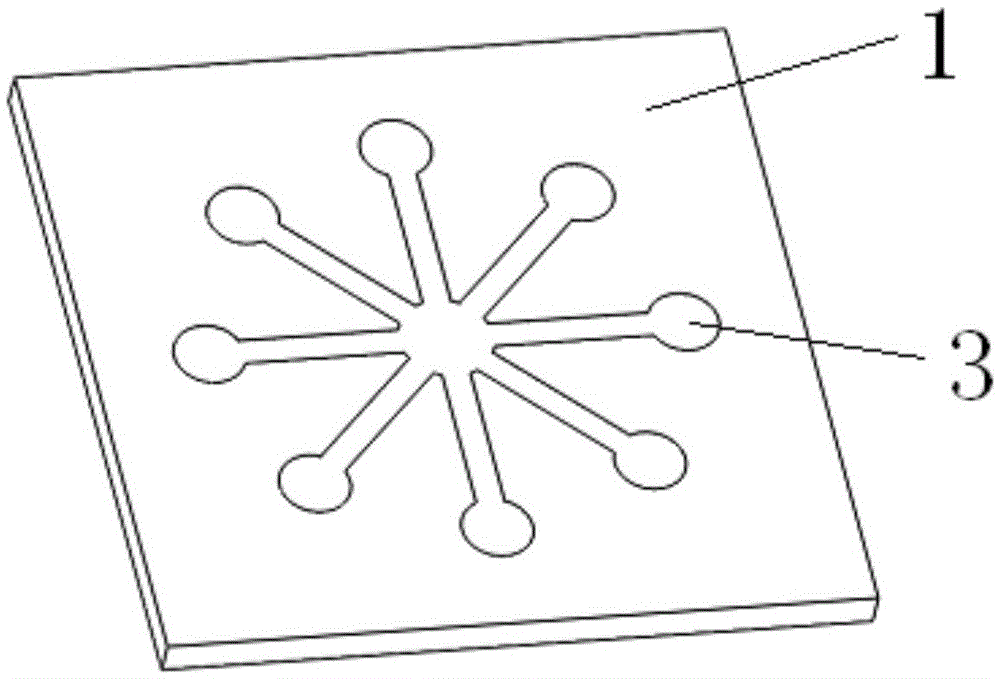

Pump-driving-free micro-fluidic chip manufacturing method based on three-dimensional printing and product

ActiveCN105642377AEasy to observeEasy and fast processingLaboratory glasswaresMachining process3 dimensional printing

The invention discloses a pump-driving-free micro-fluidic chip manufacturing method based on three-dimensional printing. The pump-driving-free micro-fluidic chip manufacturing method comprises the steps that firstly, a three-dimensional model of a micro-fluidic chip substrate with channel grooves is designed; secondly, the micro-fluidic chip substrate with the channel grooves is printed out with printing software of a three-dimensional printer; thirdly, the side, with the channel grooves, of the printed micro-fluidic chip substrate is coated with a layer of a mixture of polydimethylsiloxane and a curing agent, and is dried; fourthly, paste is poured into the channel grooves and dried, and a pump-driving-free micro-fluidic chip based on three-dimensional printing is obtained. According to the pump-driving-free micro-fluidic chip manufacturing method based on three-dimensional printing, the processing process is simple, convenient and fast, the production efficiency is high, and industrial mass production is easy. The micro-fluidic chip prepared through the method can be recycled infinitely, and thus cost is greatly reduced.

Owner:ZHEJIANG UNIV

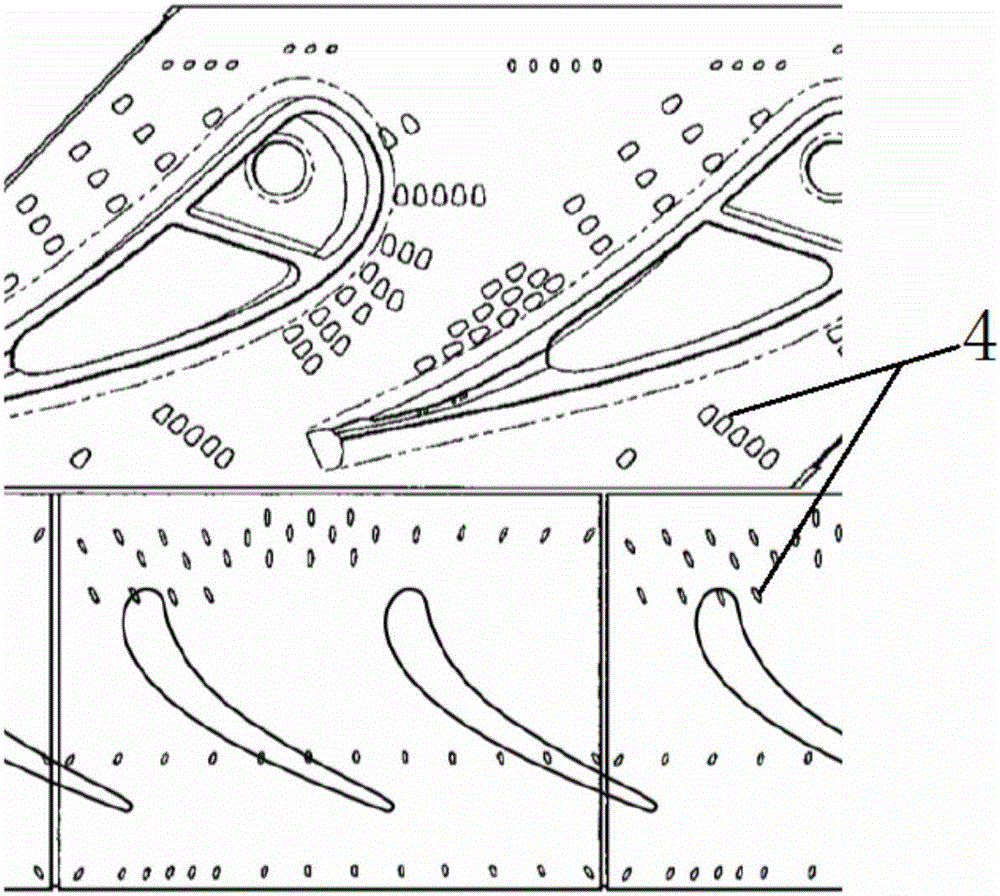

Step-shaped shrinkage air film hole structure

InactiveCN106246238AEasy to FeedbackReduce adverse effectsBlade accessoriesMachines/enginesFeedback effectTurbine blade

The invention discloses a step-type shrinkage film hole structure, which belongs to the technical field of gas turbine blades; by applying a step-type shrinkage transition form to the outlet of a single-aperture cylindrical gas film hole, a thinner straight hole is connected to form a Step-type shrinking film hole structure that stabilizes the outlet flow rate of the film hole. The step-shaped shrinking air film hole can enhance the feedback effect on the acoustic wave effect, and effectively correct the acoustic wave effect carried by the mainstream pressure fluctuation, so as to achieve the purpose of correcting the mass flow rate of the air film hole outlet and preventing backflow. The step-type shrinkage film hole structure has the characteristics of simple and convenient processing and low cost. Effective use of the film hole structure can greatly improve the stability of the film coverage, improve the film cooling efficiency of high-temperature components of the gas turbine, and improve the working reliability and life of the turbine blades and casing.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Removable device and control circuit for allowing a medium insertion

InactiveUS7716384B2Good safety and convenienceReduce riskUnauthorized memory use protectionHardware monitoringDevice typeCD-ROM

Owner:SASLITE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com