Pump-driving-free micro-fluidic chip manufacturing method based on three-dimensional printing and product

A microfluidic chip and three-dimensional printing technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve problems such as high production costs, achieve simple and fast processing, and facilitate industrialized large-scale production , the effect of convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Embodiment: Taking the manufacture of a quincunx-shaped microfluidic chip and the detection of nitrite as examples, the manufacturing process mentioned in the present invention is further described.

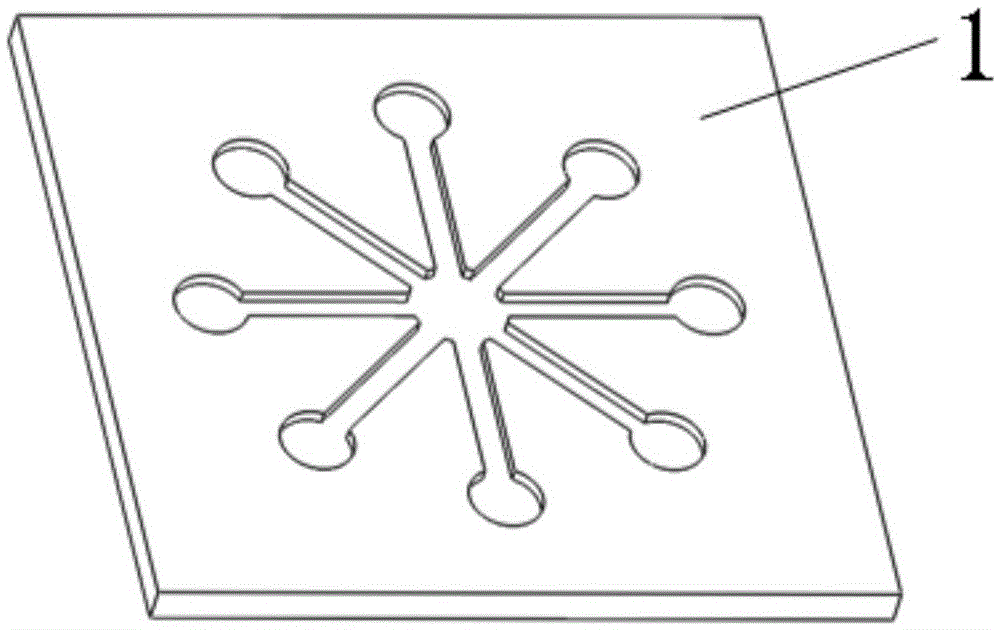

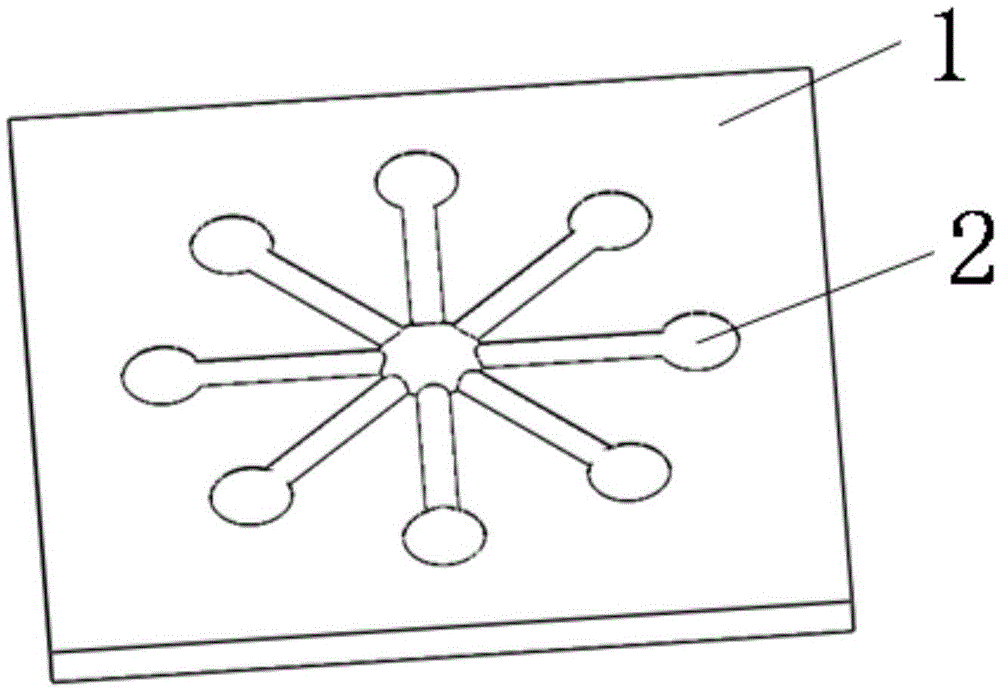

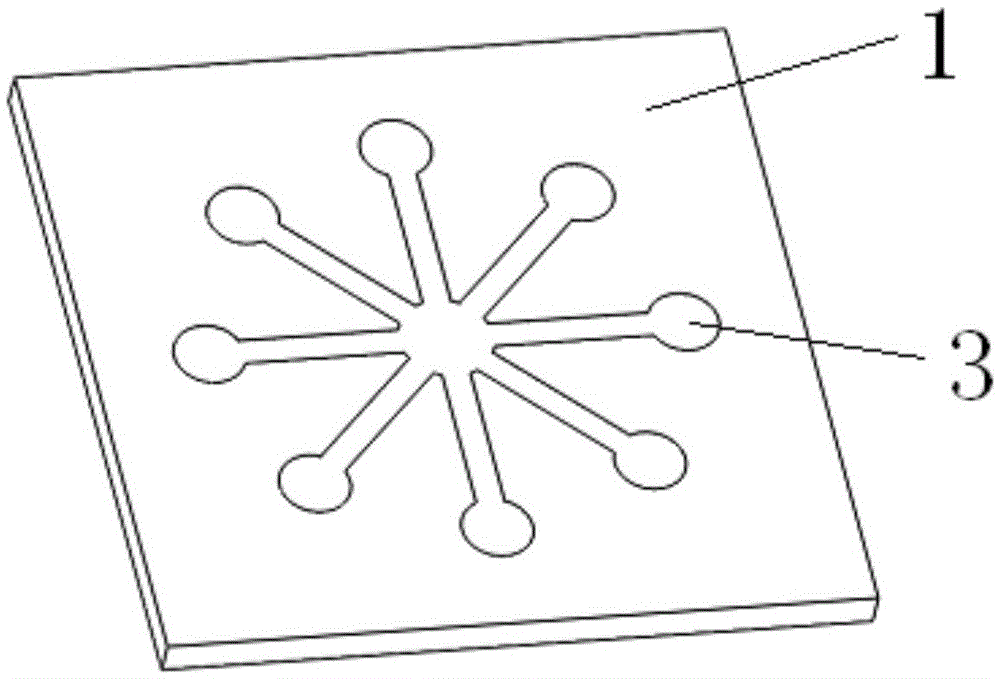

[0055] figure 1 The three-dimensional model of the designed quincunx-shaped microfluidic chip substrate 1 is shown, and the three-dimensional model file is generated as an STL format file, and the obtained STL format file is imported into the three-dimensional printing software, and the printing parameter filling rate is set to 60. Connect to the computer, start the FDM three-dimensional printer, control the FDM three-dimensional printer to work through the computer, and start the printing process of the microfluidic chip substrate 1. Existing printing materials can be selected, such as polylactic acid (PLA), acrylonitrile-butadiene-styrene copolymer (ABS), etc., and polylactic acid is selected in this embodiment. After the printing is completed, the PLA microfluidic chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com