Clamping deformation resistant jig for machining large-diameter elbow

A mechanical processing, large-diameter technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of thin-walled elbow deformation, excessive clamping or pressing force, etc., to control deformation, ensure The effect of machining precision and rich resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

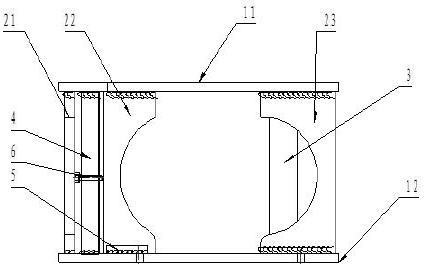

[0030] The clamping and deformation-resistant elbow machining fixture of the present invention performs clamping and positioning of large-diameter elbows by combining clamping blocks.

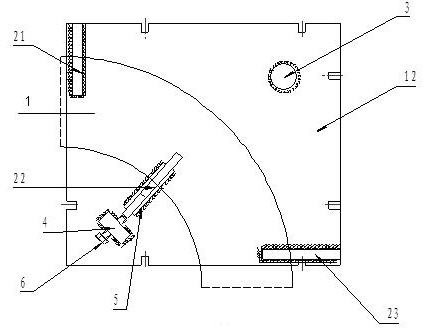

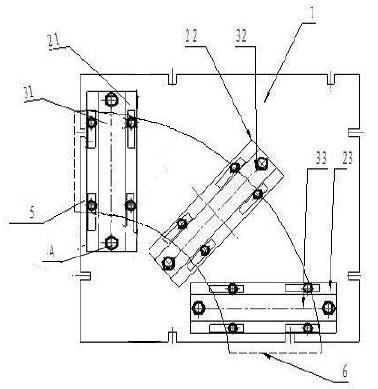

[0031] Such as Figure 2a and Figure 2b As shown, a 90° large-diameter elbow anti-clamping deformation machining fixture includes a clamping base plate 1, three combined clamping blocks with the same shape and distributed at an angle of 45° on the clamping base plate 1, and 6 upper , The lower clamping block connecting bolt 4, 12 locking bolts 5 that fix the combined clamping block and play a role of sliding guide.

[0032] Such as image 3 As shown, the clamping base plate 1 is connected to the processing platform of the milling and boring machine. Twelve threaded holes are processed on the clamping base plate 1 corresponding to the corresponding positions of the combined clamping blocks for locking bolts 5 to fix the combined clamping blocks.

[0033] see Figure 2b and Figure 4a , F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com