A damping and vibration-reducing tool rod

A tool holder and damping technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of inability to reduce vibration, complex processing process, and high cost, and reduce vibration and noise , The processing process is simple, the effect of prolonging the life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

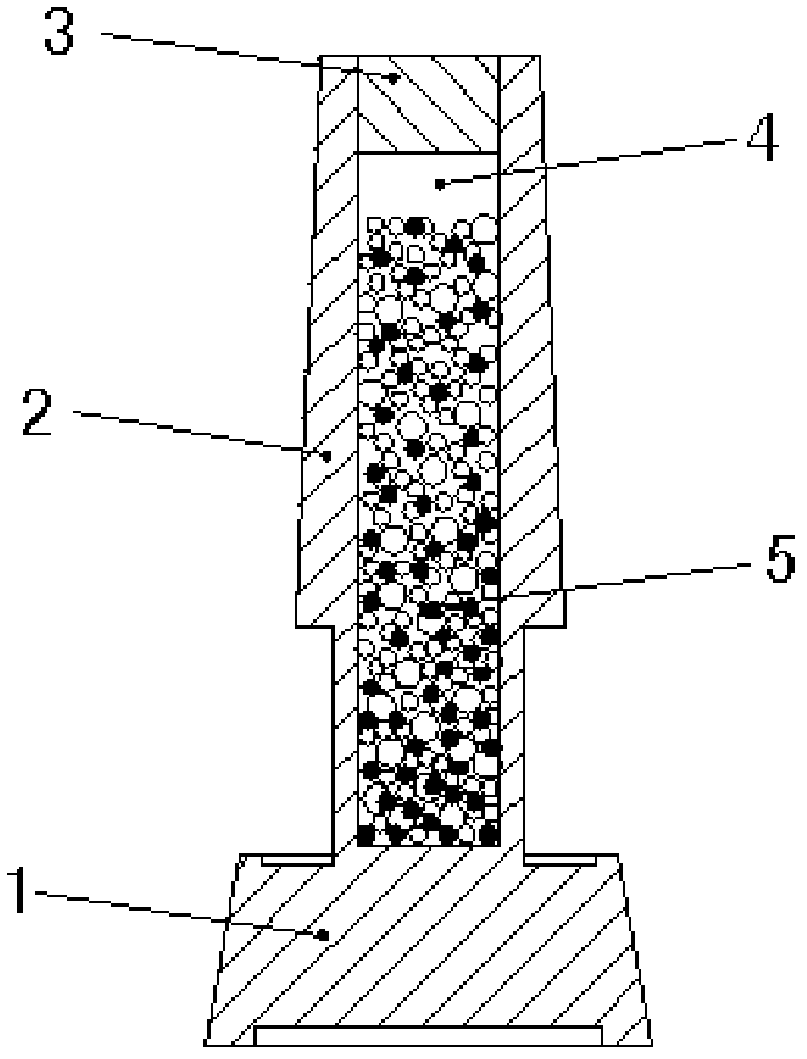

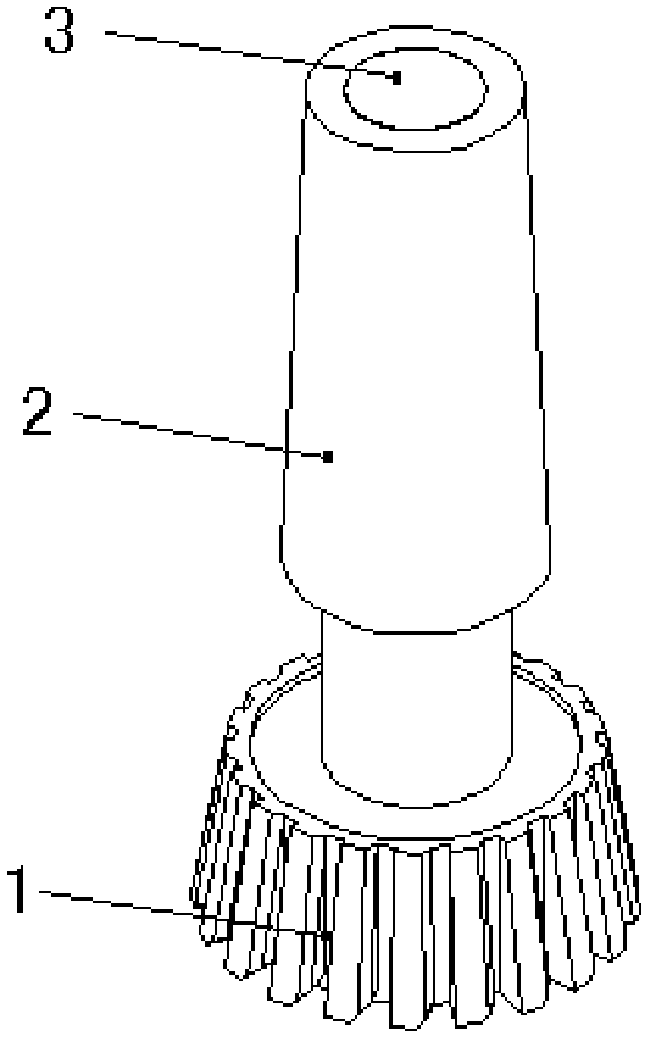

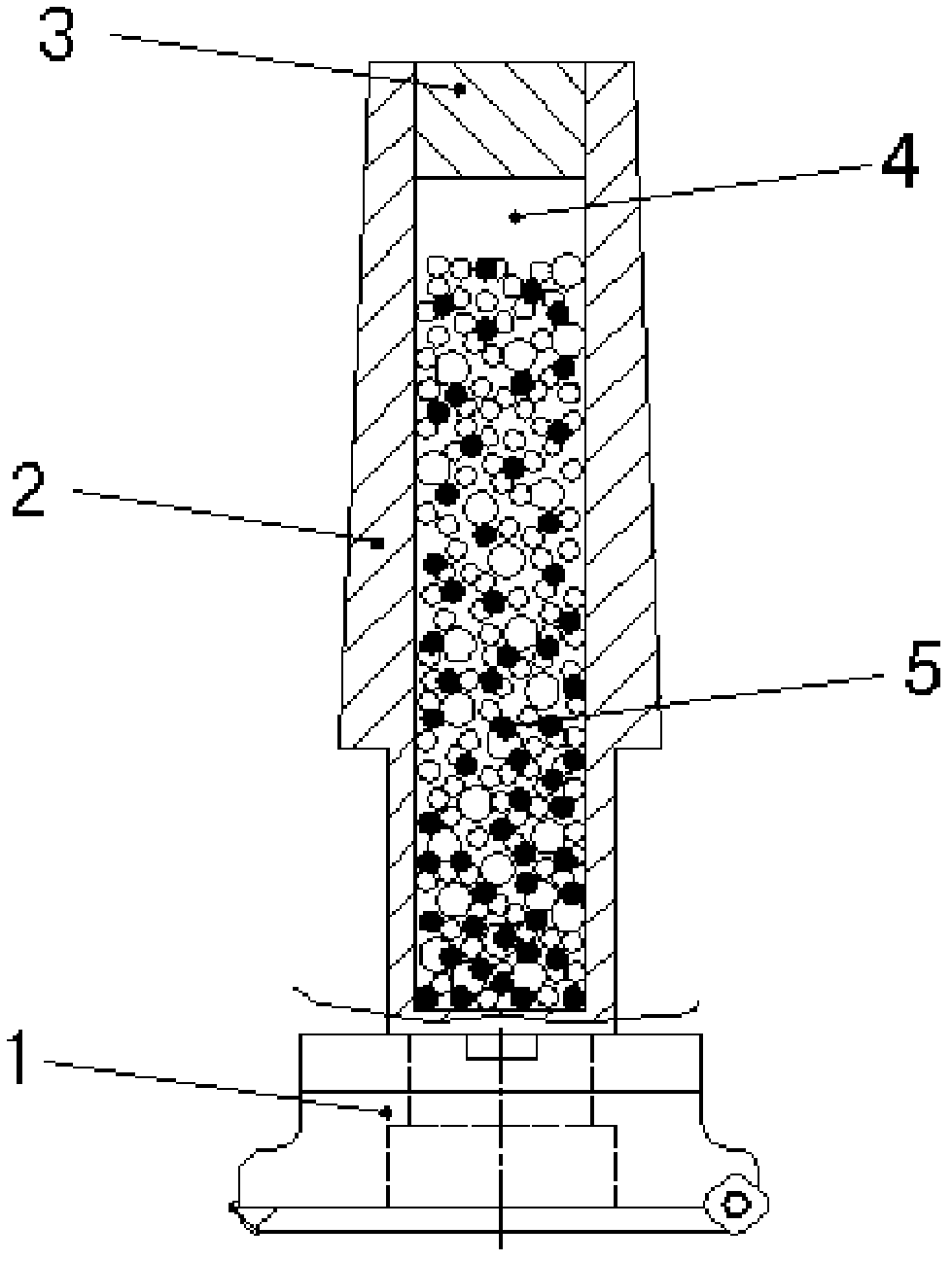

[0034] The particle size ranges from 0.02 mm to 5 mm, and the particle size ranges from 0.02 mm to 5 mm. According to the volume of the cutter bar cavity, take a certain amount of particles according to 80% to 85% % filling rate is filled into the cavity of the milling tool holder; at the same time, 10% to 15% of viscous liquid is filled; according to image 3 The particle damping and vibration-absorbing tool holder is formed after sealing as shown, which is mainly used for vibration and noise reduction of milling cutter tool holders.

Embodiment 2

[0036] Example 2 of a particle damping tool holder: when milling a hollow workpiece of 500mm×500mm×400mm, particles of a composite material with a certain shape with high external vibration damping characteristics and high toughness at the core are used, and the particle size ranges from 0.02 mm to 5 mm, according to the volume of the cavity of the cutter bar, take a certain amount of particles and fill it into the cavity of the milling tool bar at a filling rate of 80% to 85%; at the same time fill with 10% to 15% of viscous liquid; according to image 3 The particle damping and vibration-absorbing tool rod is formed after sealing as shown in the figure. The vibration of the tool rod is very small, and the average vibration displacement (dimensionless) is 37. The surface of the workpiece to be processed is very smooth, such as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com