Chip suction drill

A chip and drill bit technology, which is applied in the direction of drill repair, drill accessories, drilling/drilling equipment, etc., can solve the problems of not being able to obtain chip attraction, not being able to suck chips smoothly, and difficult air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

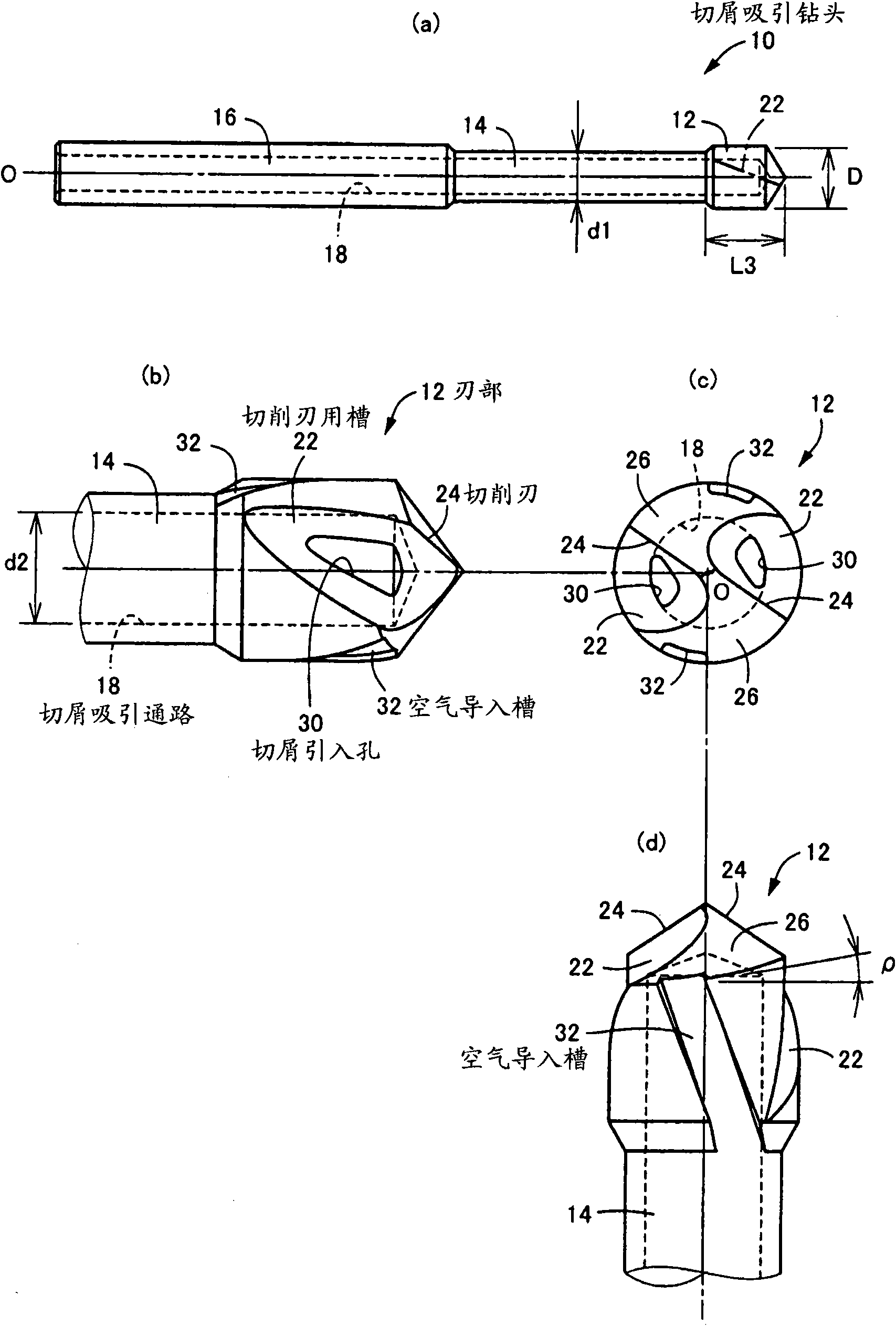

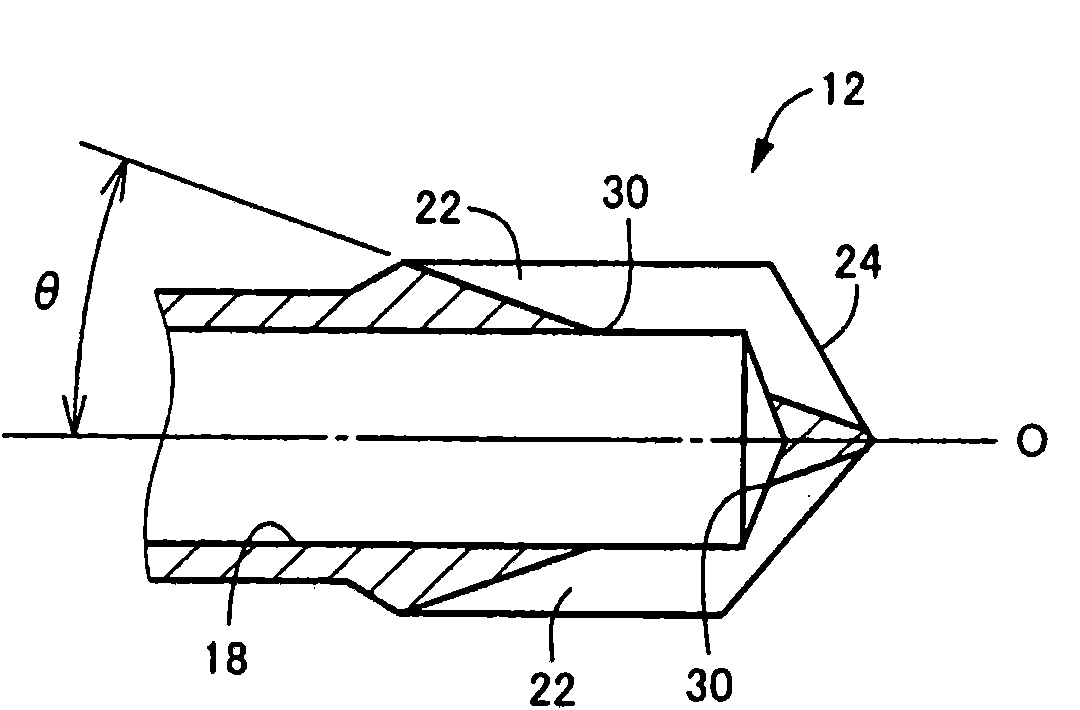

[0047] figure 1 It is a diagram showing a chip suction drill 10 as an embodiment of the present invention, (a) is a schematic front view seen from a direction perpendicular to the axis O, and (b) is a cutting edge portion 12 at the tip (c) is an end view viewed from the right side of (b), that is, viewed from the front end side, (d) is an illustration viewed from the bottom of (c), which is the same as (b) ) compared to that seen when viewed from a direction that is 90° out of phase around the axis O. The chip attracting drill 10 is made of cemented carbide, and at the same time, it is continuously and integrally equipped on the axis O: a cutting edge 12 having the same diameter as the drill diameter D, which is smaller than the cutting edge 12 and has a certain diameter. The head 14 of d1, and the drill shank 16 having the same diameter size as the cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com