Attaching device and method with material belt positioned through strip material small holes in sleeving mode

A bonding device and tape technology, applied in packaging, labeling machines, transportation and packaging, etc., can solve the problems of lower product yield, low production efficiency, and difficult to effectively guarantee the stability of product accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the application and the features in the embodiments can be combined with each other. The following further describes the application in detail with reference to the drawings and specific embodiments.

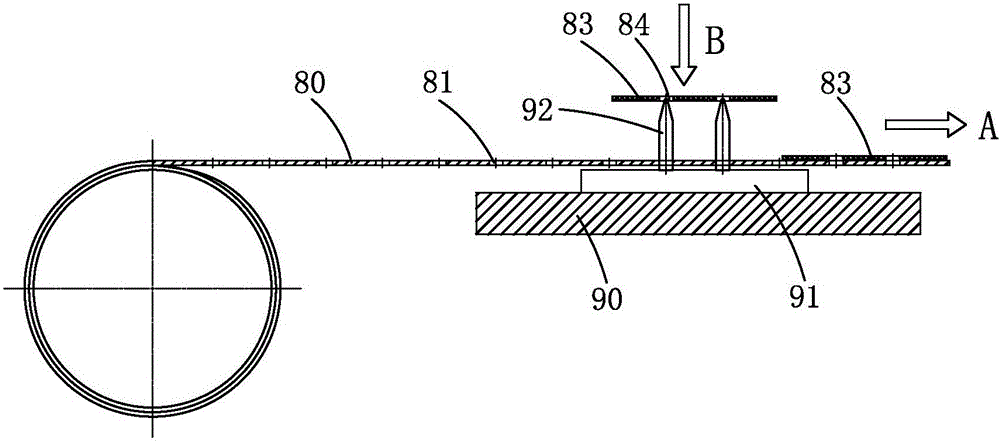

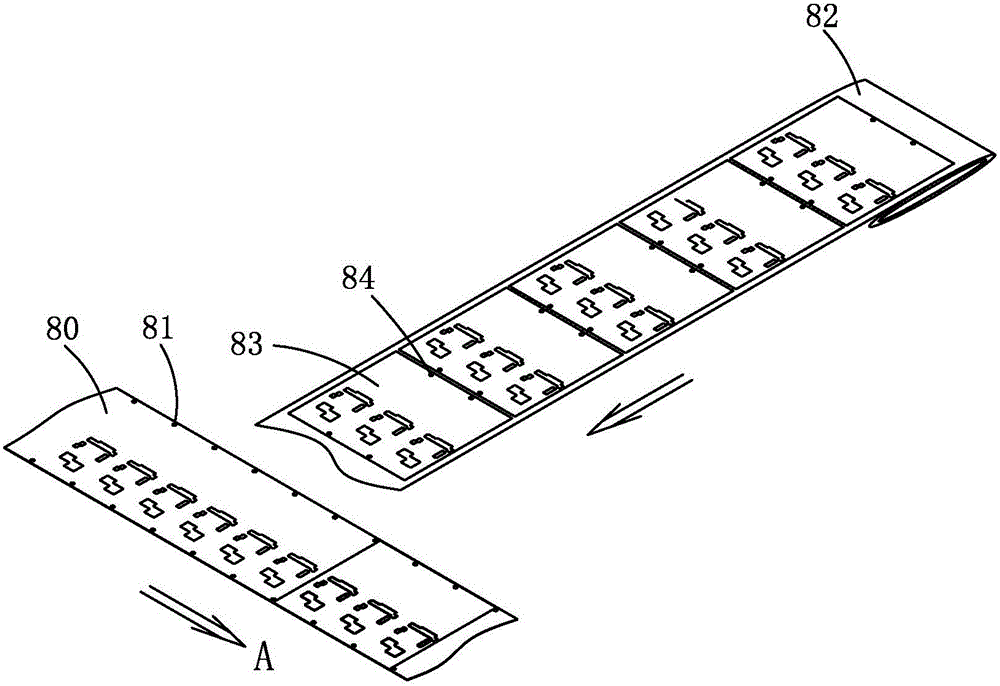

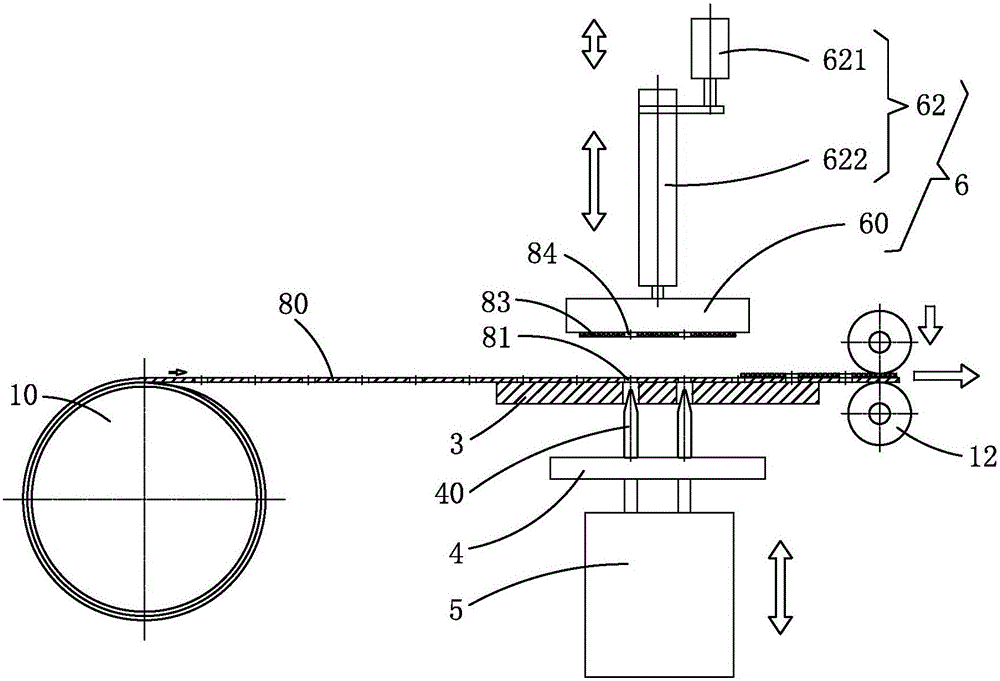

[0026] Such as Figure 2 to Figure 6 As shown, the present invention provides a device for attaching a tape to a small hole of a sheet, including a product tape supply mechanism (not numbered in the figure) for supplying a product tape 80 to be labeled, and for supplying a label tape The label material tape supply mechanism (not shown in the figure), the laminating platform 3, the fixture board 4 located below the laminating platform 3 and the top surface with the positioning pin 40, the lifting mechanism 5 that drives the fixture board 4 up and down, and the Labeling and labeling mechanism 6 for picking up and attaching labels.

[0027] The product strip supply mechanism includes a tray assembly 10 for l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com