Full-automatic LCD glass surface mounting machine

A chip mounter and glass sheet technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of high production cost, glass substrate damage, low degree of automation, etc., and achieve safe and reliable equipment operation, less lamination defects, The effect of high bonding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

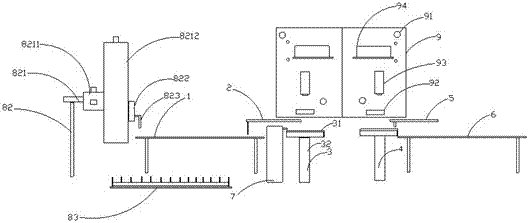

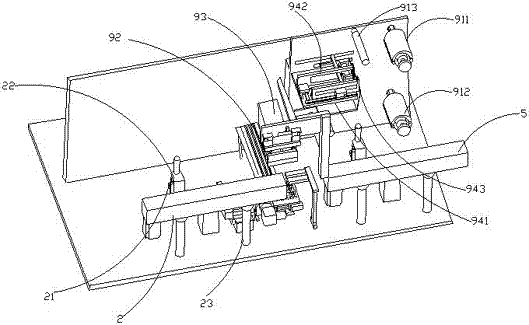

[0044] Such as Figure 1~6 As shown, this embodiment provides a fully automatic LCD glass placement machine, which is equipped with a servo motor and PLC to realize the intelligence of the placement machine, and includes a feeding device 8, a first conveyor belt 1, and a glass feeding device in sequence according to the order in which the glass sheets pass through. 2. The first placement platform 3, the first placement machine, the second placement platform 4, the second placement machine 9, the transfer adsorption device 5 and the second conveyor belt 6;

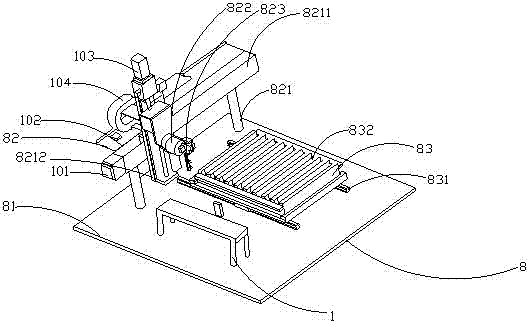

[0045] Feeding device 8 comprises base 81, feeding frame 82 and groove frame 83, and feeding frame 82 and groove frame 83 are all fixed on the base 81; Feeding frame 82 is used for sending the glass sheet in groove frame 83 to the first On the conveyor belt 1, the loading rack 82 includes a frame 821, a feeding suction rod 822 and a feeding suction nozzle 823. The feeding suction rod 822 is connected to the feeding suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com