Truss type formwork support for suspended cast-in-place plate and using method thereof

A truss-type, cast-in-place slab technology, which is applied to formwork/formwork/work frames, scaffolding supported by building structures, and on-site preparation of building components, which can solve the problem of limited construction speed, impact on construction progress, and large amount of materials To improve construction safety, reduce installation difficulty, and simplify construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0026] Example.

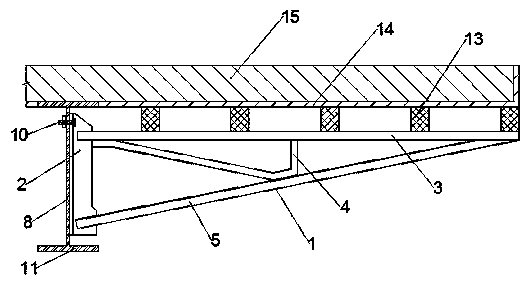

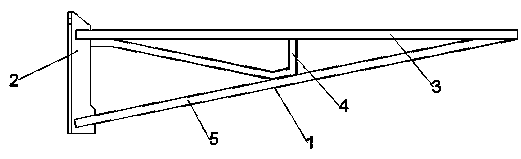

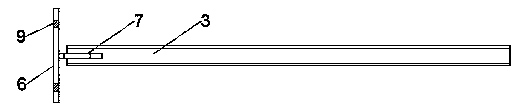

[0027] see Figure 1 to Figure 6 , the truss-type formwork support for cantilevered cast-in-place slabs according to the embodiment of the present invention includes truss chords 1 and quick-release connectors 2 .

[0028] The truss chord 1 of this embodiment includes an upper chord 3, a web 4 and a lower chord 5 fixed to each other. The upper chord 3, the web 4 and the lower chord 5 are all made of square steel pipes with high strength. The lower chord The right end of 5 is an inclined plane, which is welded with the right end of the upper chord 3 to form an acute angle. The web 4 is located between the upper chord 3 and the lower chord 5. The web 4 is bent into three sections. The two ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com