Automated bucket loading system

A technology of loading system and automatic control system, applied in the field of automatic system, can solve the problems of inconvenient loading, troublesome, bucket dumping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

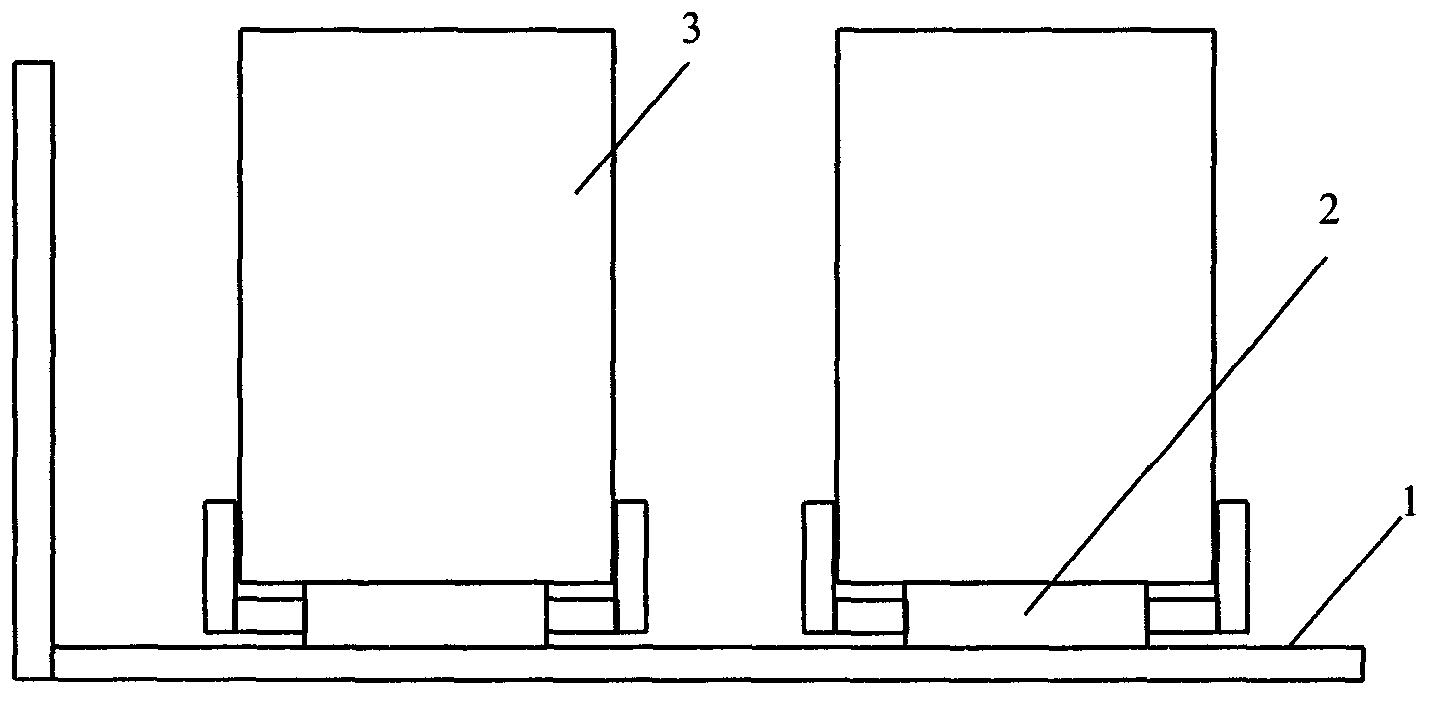

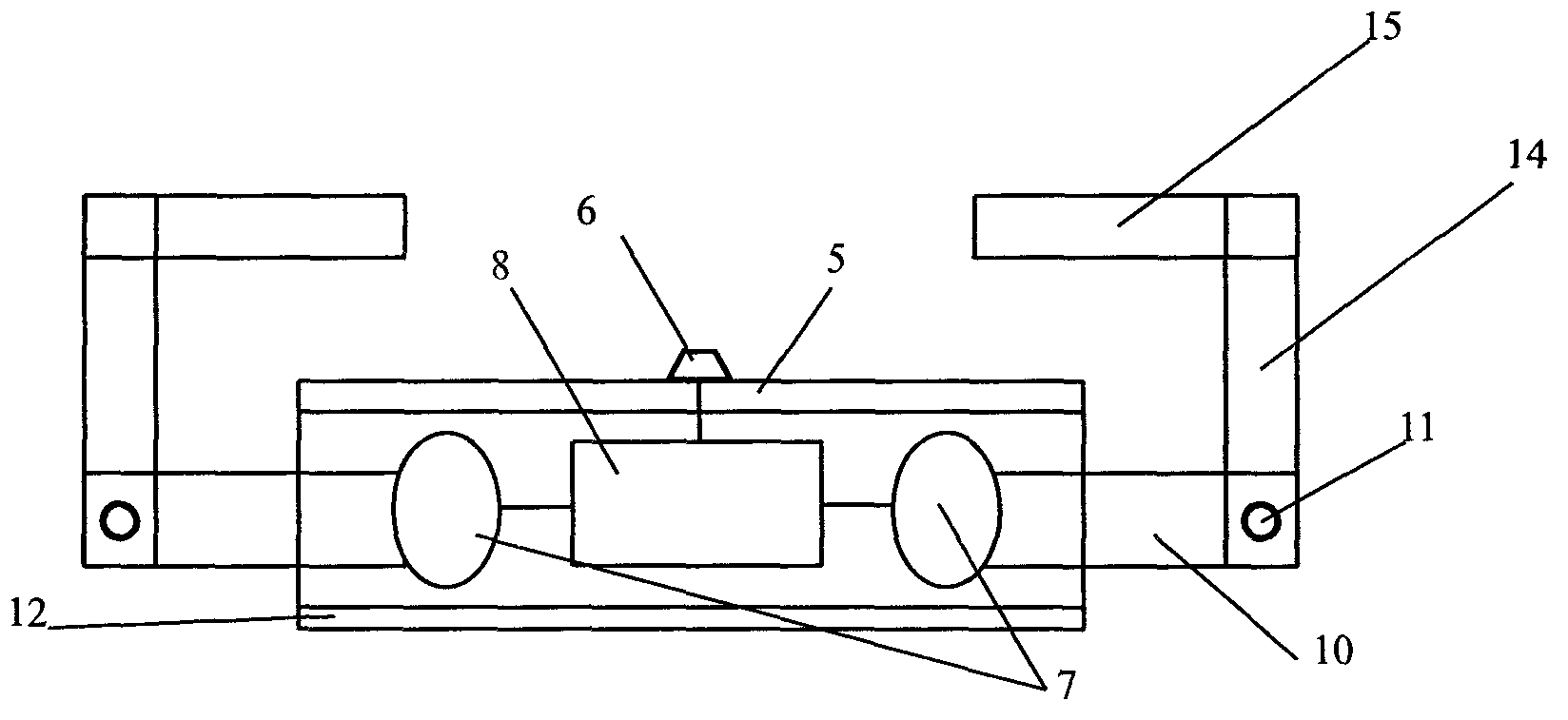

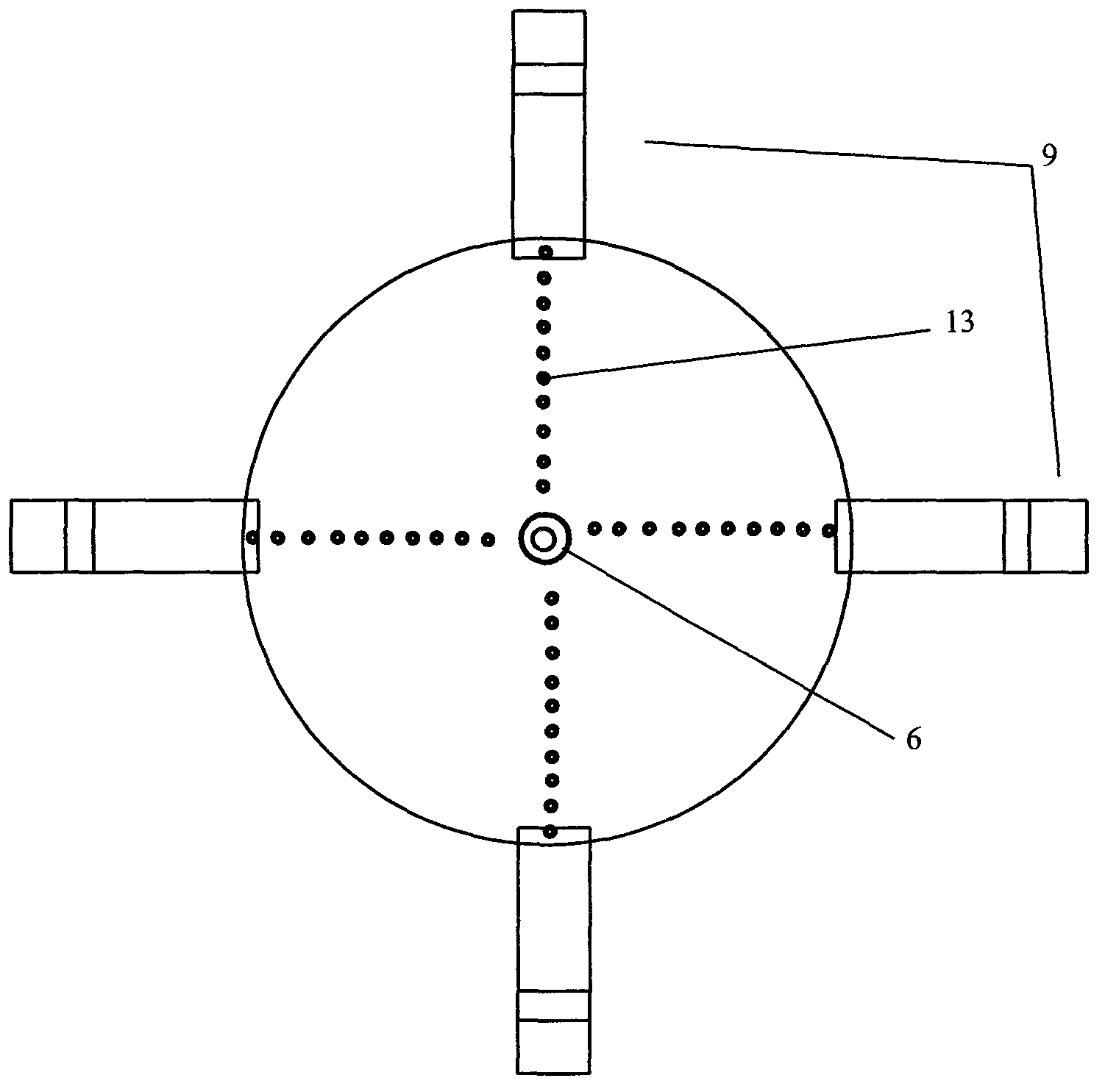

[0015] The automatic barrel loading system 2 includes a base body 4, an induction base platform 5, claws, a push-type start button 6, an internal gear adjustment system 7 of the base, and an automatic control system 8; the base body 4 is a cylinder Shaped platform, the induction platform is a cylindrical platform, located on the upper surface of the base body 4, the diameter of the induction platform is equal to the diameter of the base body 4, and overlapping configuration; the induction platform is arranged by On the upper surface of the base main body 4, a plurality of photosensors 13 and the transparent reinforced resin covered above the photosensors 13 are formed. The center of the base main body 4 has a push-type start button 6, and the push-type start button 6 starts from The middle part of the induction base platform 5 protrudes; the base body 4 has a base internal gear adjustment system 7, and the base internal gear adjustment system 7 is connected with a plurality of ...

specific Embodiment 2

[0019] An automatic barrel loading system 2, the automatic barrel loading system 2 includes a base body 4, an induction base platform 5, claws, a push-type start button 6, an internal gear adjustment system 7 of the base, and an automatic control system 8; The base body 4 is a cylindrical platform, and the induction platform is a cylindrical platform located on the upper surface of the base body 4. The diameter of the induction platform is equal to the diameter of the base body 4 and overlaps Configuration; the induction platform is composed of a plurality of photosensors 13 arranged on the upper surface of the base body 4 and a transparent reinforced resin covered above the photosensors 13, and the center of the base body 4 has a push-type start button 6, The push-type start button 6 protrudes from the middle of the induction base platform 5; the base body 4 has a base internal gear adjustment system 7, and the base internal gear adjustment system 7 is connected with a plurali...

specific Embodiment 3

[0024] The automatic barrel loading system 2 includes a base body 4, an induction base platform 5, claws, a push-type start button 6, an internal gear adjustment system 7 of the base, and an automatic control system 8; the base body 4 is a cylinder Shaped platform, the induction platform is a cylindrical platform, located on the upper surface of the base body 4, the diameter of the induction platform is equal to the diameter of the base body 4, and overlapping configuration; the induction platform is arranged by The upper surface of the base main body 4 is composed of a plurality of pressure sensors and the transparent reinforced resin covered above the pressure sensors. The center of the base main body 4 has a push-type start button 6, and the push-type start button 6 starts from the induction base. The middle part of the seat platform 5 protrudes; the base body 4 has a base internal gear adjustment system 7, and the base internal gear adjustment system 7 is connected with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com