Curtain wall installation structure and installation method

A technology for installing structures and curtain walls, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of easy failure of sealant, easy to fall off, and reduced safety performance, so as to achieve the improvement of installation firmness and stability, and improve stability Enhanced performance, safety, and installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

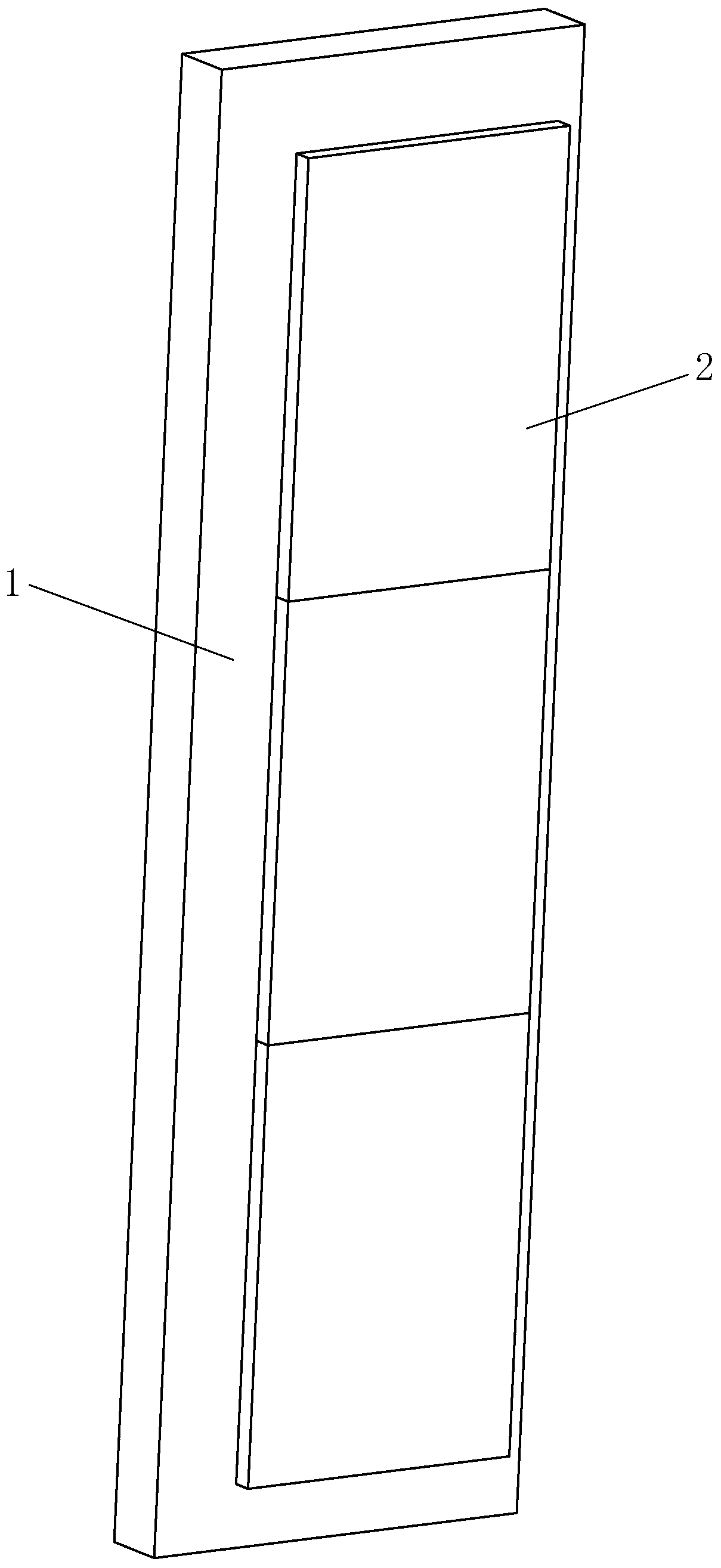

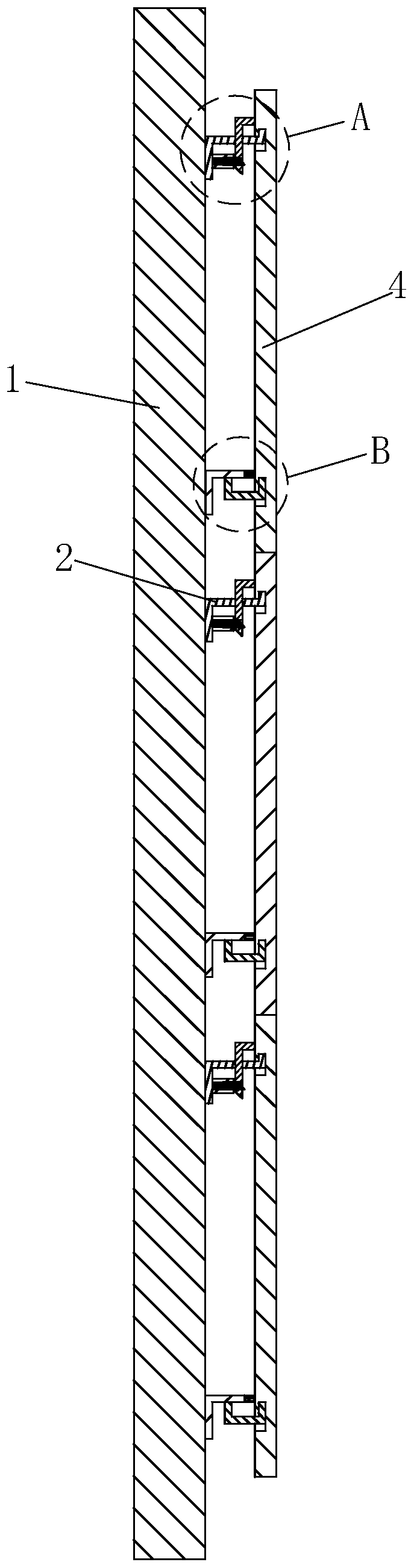

[0041] A curtain wall installation structure that combines figure 1 with figure 2 , Including the wall 1, the outer surface of the wall 1 is fixedly provided with a plurality of angle steels 2, each of the four angle steels 2 is a group, and the four angle steels 2 of each group are distributed in a parallelogram pattern, of course, The rectangular distribution is the best. The side of the angle steel 2 away from the wall 1 is fixedly provided with a curtain wall panel 4, and each curtain wall panel 4 corresponds to each group of four angle steels 2, so that the angle steel 2 and the curtain wall panel 4 form a multi-point fixation to improve the curtain wall panel 4 The installation stability of the curtain wall panel 4 greatly improves the safety after installation.

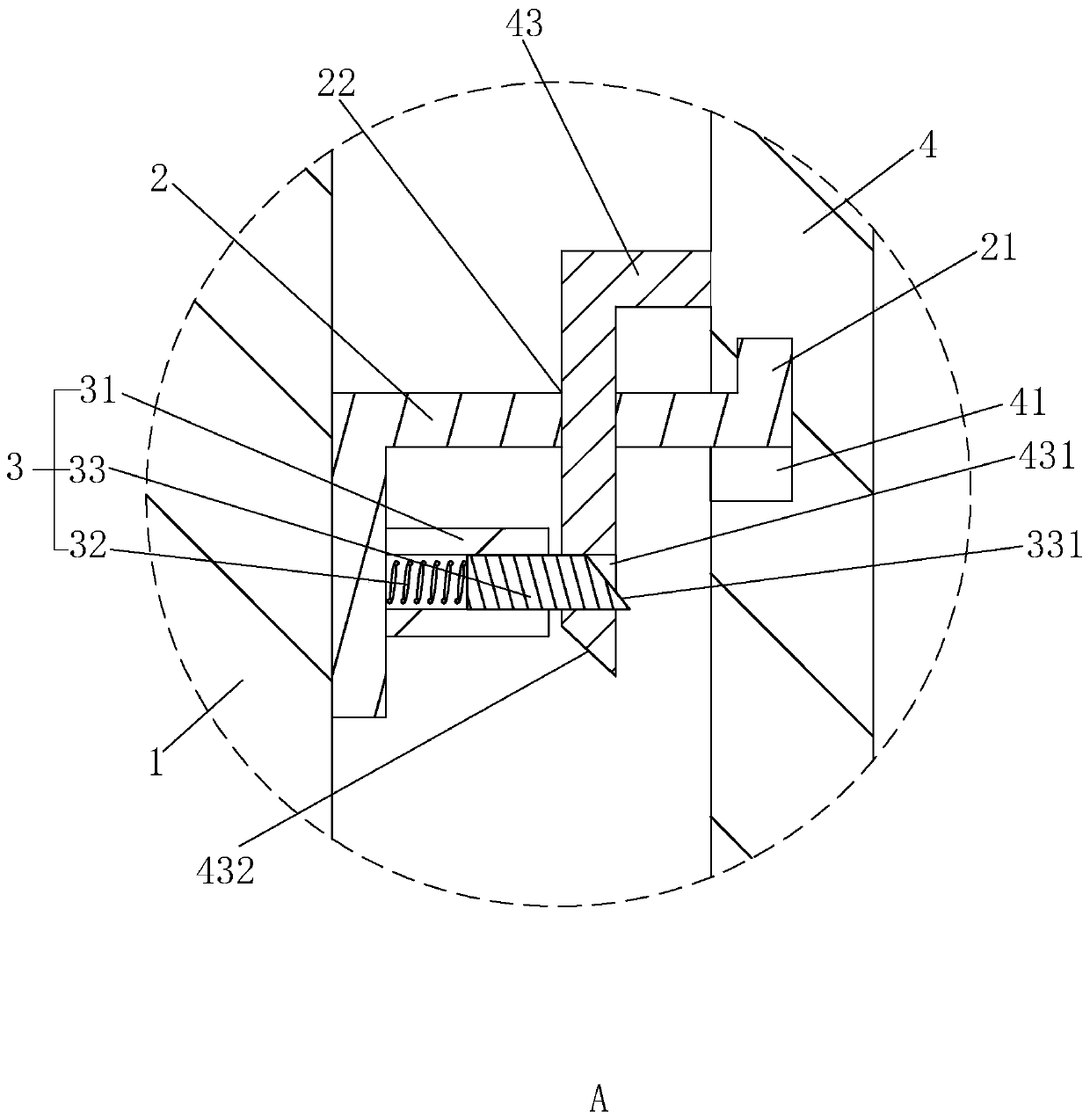

[0042] Combine image 3 with Figure 4 , The surface of the curtain wall panel 4 facing the wall 1 is provided with two sets of L-shaped hook grooves 41 and two sets of auxiliary L grooves 42. The two sets of L-s...

Embodiment 2

[0049] A curtain wall installation structure described in embodiment 1, and its installation method includes the following steps:

[0050] S1. The inner side of the angle steel 2 is welded and fixed to the locking spring 32, the end of the locking spring 32 is welded and fixed to the locking bar 33, and the sliding cylinder 31 is sleeved on the outer side of the locking spring 32 and the locking bar 33, and the sliding cylinder 31 and the angle steel 2 are welded and fixed, and the upper surface of part of the angle steel 2 is submitted to open a limit groove 24 and install the compression assembly 5 in the limit groove 24;

[0051] S2, install the angle steel 2, and use bolts to fix the angle steel 2 on the surface of the wall 1 at a predetermined distance and position;

[0052] S3. Install the curtain wall panel 4, so that the hook 21 is inserted into the L-shaped hook groove 41, the C-shaped hook 23 is inserted into the auxiliary L groove 42, and the L-shaped insert 43 is inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com