TiCl4 refining continuous vitriol alum removing process

A technology of equipment and distillation kettle, applied in the direction of titanium halide, etc., can solve the problems of blockage of heat exchanger and low production cost, and achieve the effect of reducing labor level, simple operation and excellent product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

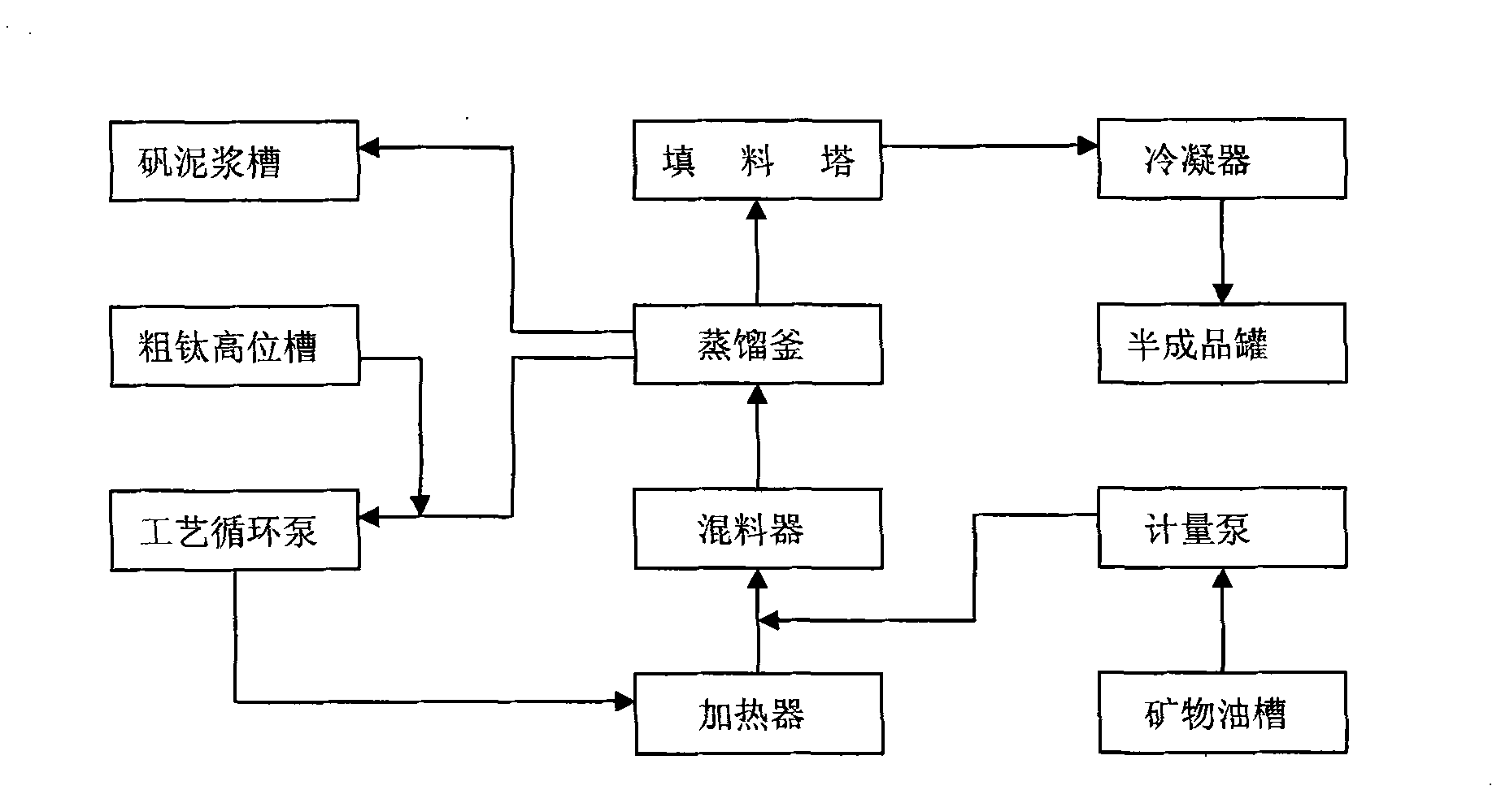

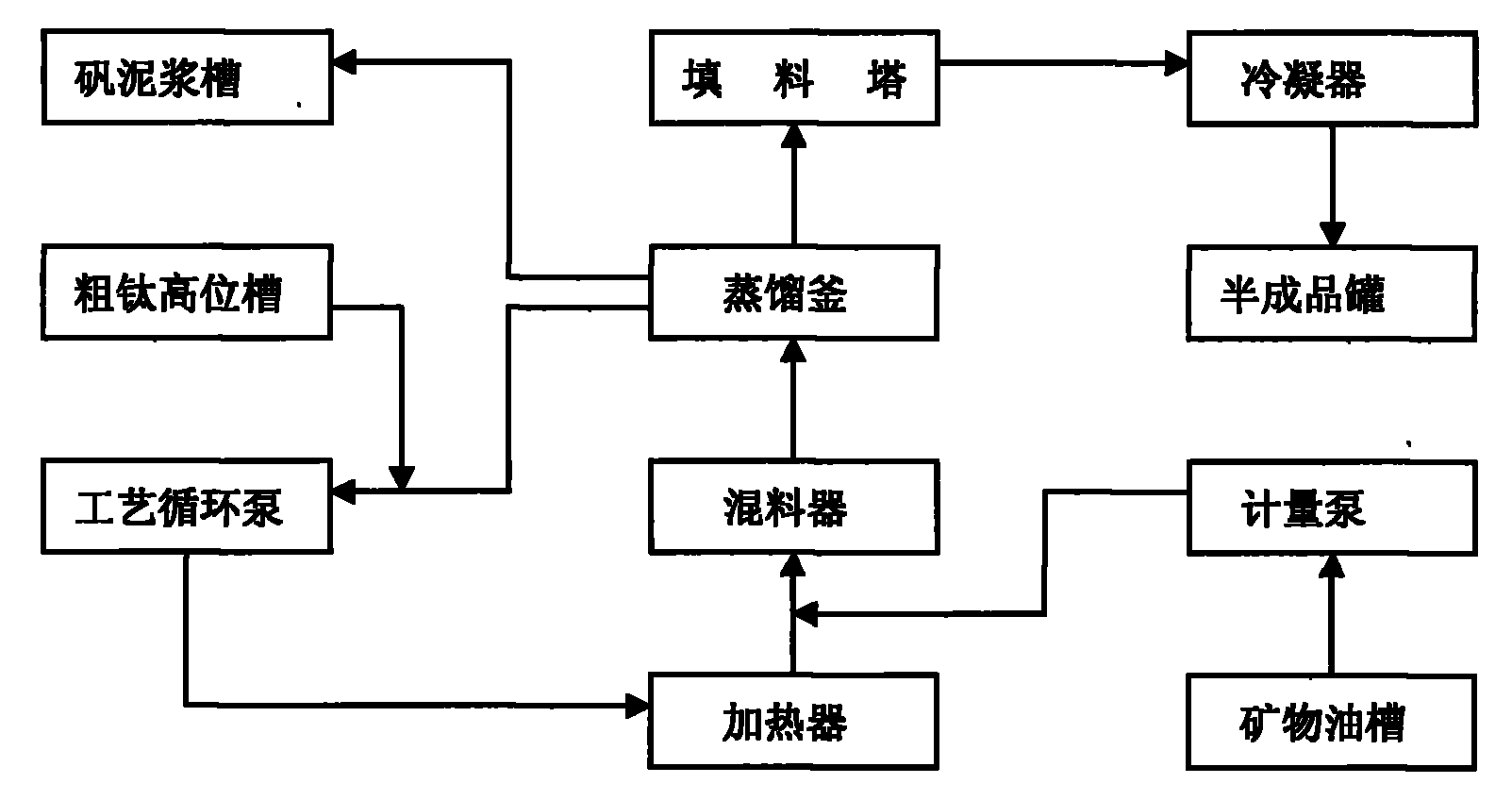

[0017] As shown in Figure 1, the TiCl4 refined and de-aluminum special equipment is composed of a crude titanium high-level tank, a circulation pump, a heat exchanger, a mixer, a distillation kettle, an alum slurry tank, a packed tower, a condenser, a semi-finished product tank, a mineral oil tank, The metering pump is composed of a circulation pump, heat exchanger, mixer and distillation kettle to form a circulation system. The mineral oil tank is connected to the inlet of the mixer through the metering pump, the gas phase outlet of the distillation kettle is connected to the inlet of the packed tower, and the condenser is connected to the packed tower. Between the tank and the semi-finished product tank, the inlet of the alum slurry tank is connected with the bottom outlet of the distillation still.

Embodiment 2

[0019] Taking crude TiCl4 with a production capacity requirement of 3.5 tons / hour as an example, the crude TiCl4 is pumped into the high-level tank of crude titanium, and the high-level tank of crude titanium supplies materials to the circulation system composed of distillation kettle, circulating pump, heat exchanger and mixer. until the system is full. Start the circulation pump to circulate the material, start the heat exchanger to heat the material to 145 ° C; according to the mass ratio of mineral oil to crude TiCl4 1.6:1000, add the mineral oil from the mineral oil tank to the inlet of the mixer after metering by the metering pump, so that the mineral The oil and the impurity VOCl3 in TiCl4 fully contact and react at a temperature close to the boiling point of TiCl4 to generate high boiling point substances. The supplemented crude TiCl4 enters the circulation system from the crude titanium head tank through the inlet of the circulation pump, and the supplemented mineral ...

Embodiment 3

[0021] Taking crude TiCl4 with a production capacity requirement of 1.0 tons / hour as an example, put the crude TiCl4 into the high-level tank, and feed the crude titanium high-level tank to the circulation system composed of distillation kettle, circulation pump, heat exchanger and mixer until the system is full. until. Start the circulation pump to circulate the material, start the heat exchanger to heat the material to 137 ° C; according to the mass ratio of mineral oil to crude TiCl4 1.2:1000, add the mineral oil from the mineral oil tank to the inlet of the mixer after metering by the metering pump, so that the mineral The oil and the impurity VOCl3 in TiCl4 fully contact and react at a temperature higher than the boiling point of TiCl4 to generate high boiling point substances. The supplemented crude TiCl4 enters the circulation system from the crude titanium head tank through the inlet of the circulation pump, and the supplemented mineral oil enters the mixer through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com