Patents

Literature

71results about How to "Reduce hard impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

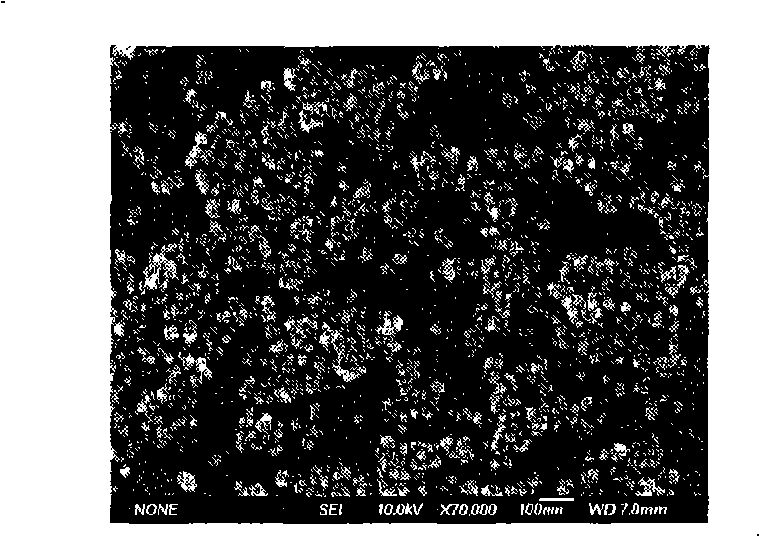

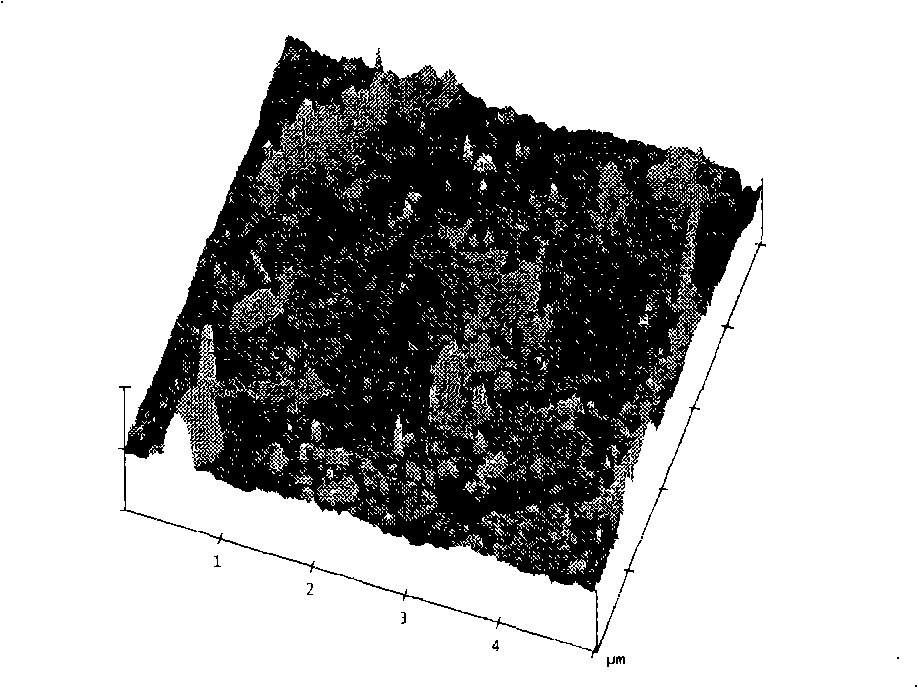

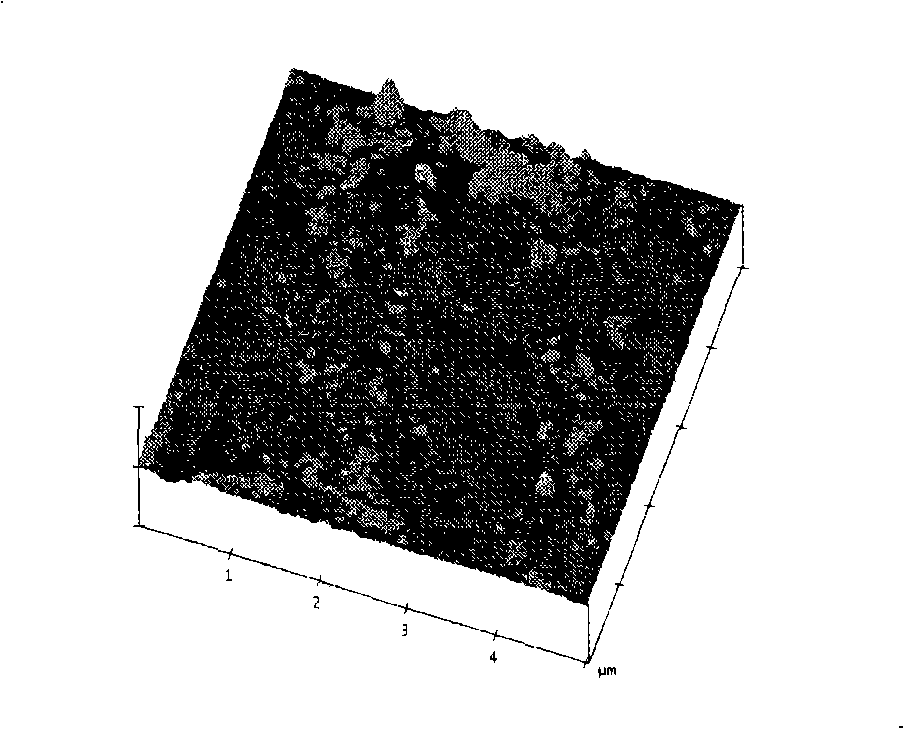

Preparation of nano-cerium oxide composite abrasive grain polishing solution

InactiveCN101302404AGood dispersionReduce surface damagePolishing compositions with abrasivesSmooth surfaceCerium oxide

The invention discloses a method for preparing nano cerium oxide composite abrasive particle polishing solution. The method is characterized by taking inorganic abrasive particles as the inner core and a cerium oxide coating as the shell to form the nano cerium oxide composite abrasive particle polishing solution with a core / shell structure, and belongs to the high-precision polishing material preparation technique technical field. The preparation process of the polishing solution is as follows: firstly, the nano cerium oxide composite abrasive particles are prepared by the homogeneous precipitation method; secondly, the polishing solution is prepared through the cerium oxide composite abrasive particles. During the preparation process of the polishing solution, the weight percent of the cerium oxide composite abrasive particles and water is between 2 and 10 percent, and 0.5 to 2 percent of dispersant is added; after further ultrasonic dispersion or ball milling dispersion of mixture, uniform dispersion liquid is formed; and the nano cerium oxide composite abrasive particle polishing solution is obtained after addition of 0.5 to 5 percent of oxidant, 0.05 to 0.1 percent of corrosion inhibitor and 0.05 to 0.1 percent of lubricant (the addition of various materials takes 100 percent of water as the reference basis). The polishing solution is represented by low surface roughness and scratch level, and then an ultra-smooth surface is obtained.

Owner:SHANGHAI UNIV

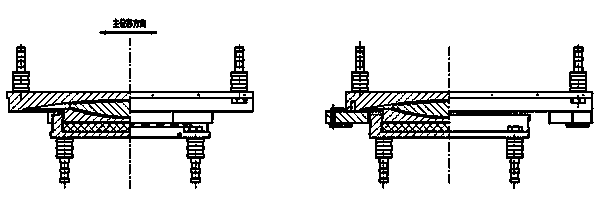

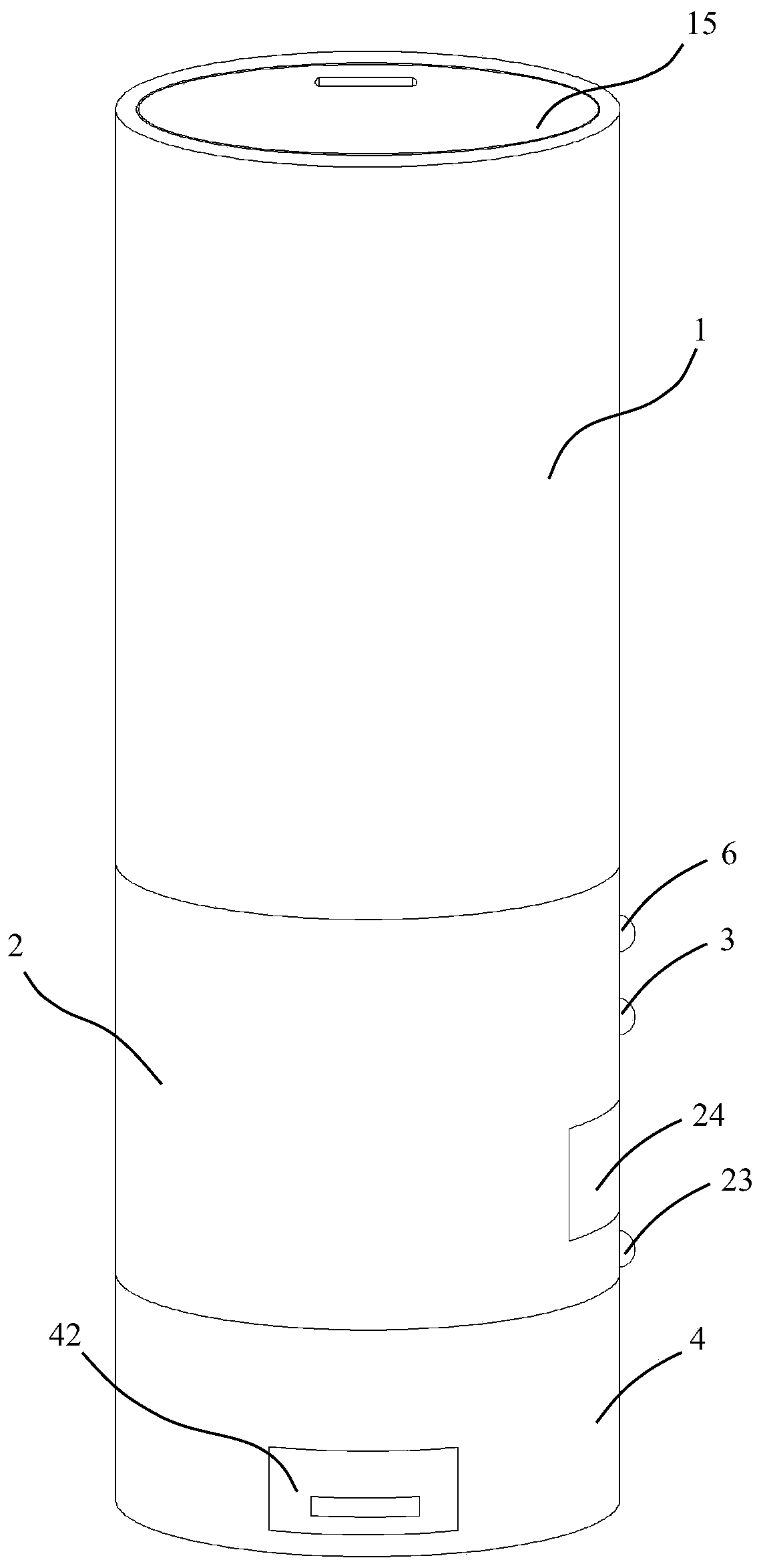

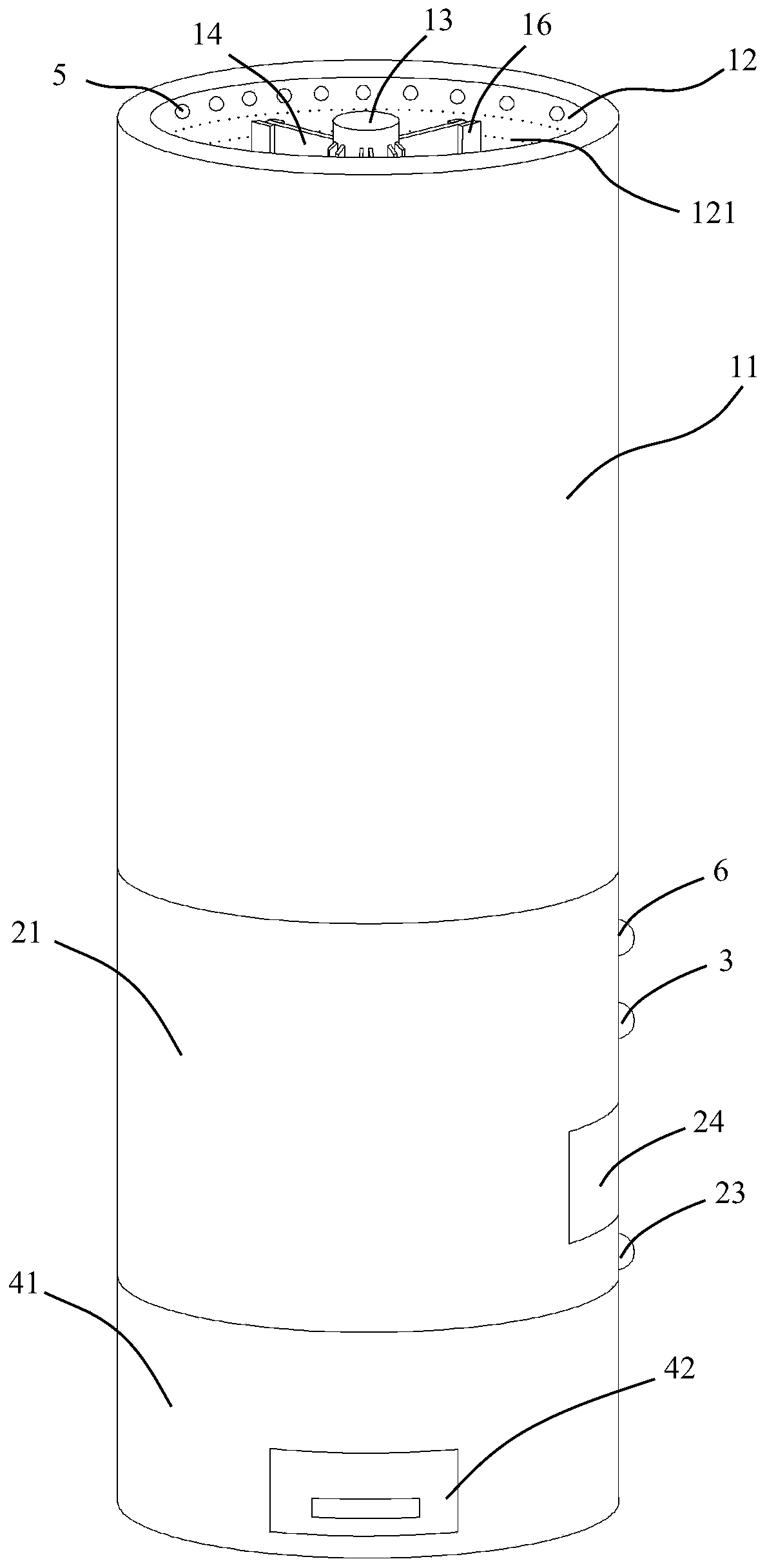

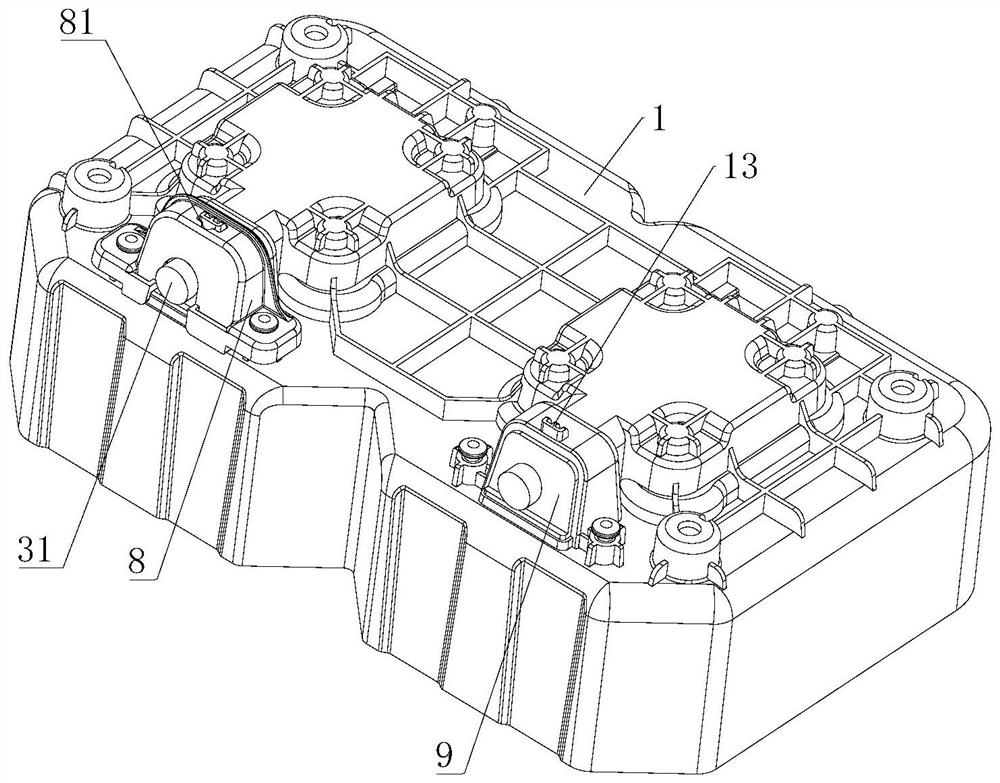

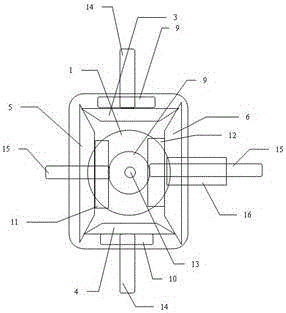

Stainless steel circular thin plate origin forming mechanism

The invention discloses a stainless steel circular thin plate origin forming machine. The stainless steel circular thin plate origin forming machine comprises a rack, wherein an upper supporting frame is fixedly arranged on the top surface of a top plate of the rack; a stamping oil cylinder is fixedly arranged on the middle part of the top surface of the top plate of the upper supporting frame; a pushing rod of the stamping oil cylinder passes through the top plate of the upper supporting frame and is fixedly equipped with an upper supporting plate; an upper mould is fixedly arranged on the middle of the bottom surface of the upper connecting plate; a plurality of stamping convex points are uniformly distributed on the bottom surface of the upper mould; the top surface of the middle part of the top plate of the rack is fixedly equipped with a lower supporting block; a main groove is formed in the middle part of the top surface of the lower supporting block; a mounting block is in plug bush in the main groove; a plurality of buffer springs are fixedly arranged on the bottom surface of the mounting block; the lower ends of the buffer springs are fixedly arranged on the bottom surface of the main groove; and an upper ring-shaped plate is fixedly connected to the top surfaces of the lower supporting blocks through bolts, and resists against the side part of the top surface of the mounting block. According to the stainless steel circular thin plate origin forming machine disclosed by the invention, hard collision between an upper mould and a lower mould can be reduced, so that the stainless steel circular thin plate origin forming machine is prevented from being damaged, and the service life of the stainless steel circular thin plate origin forming machine is prolonged; and meanwhile, the stainless steel circular thin plate origin forming machine is not easily adhered on the lower mould, and is quick in de-molding.

Owner:江门市德高实业有限公司

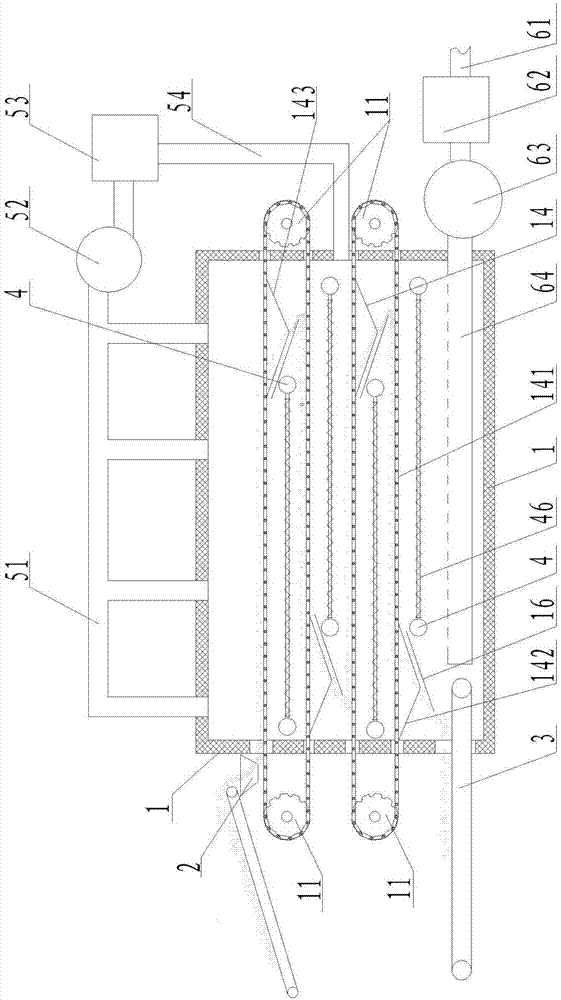

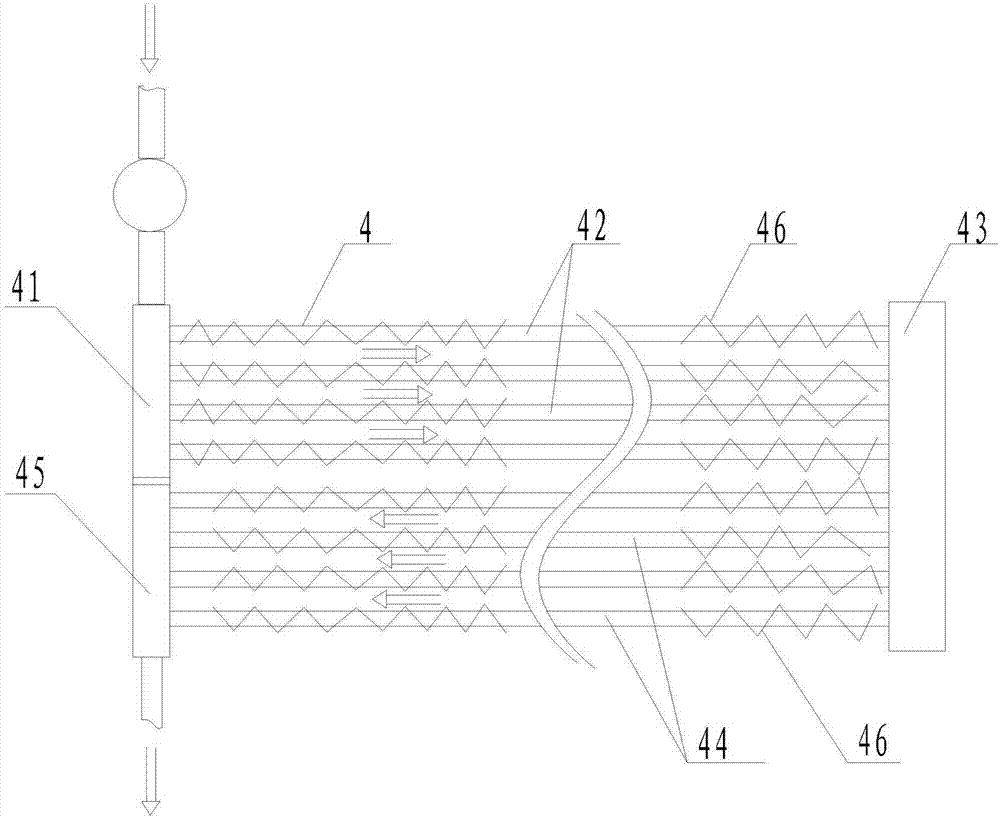

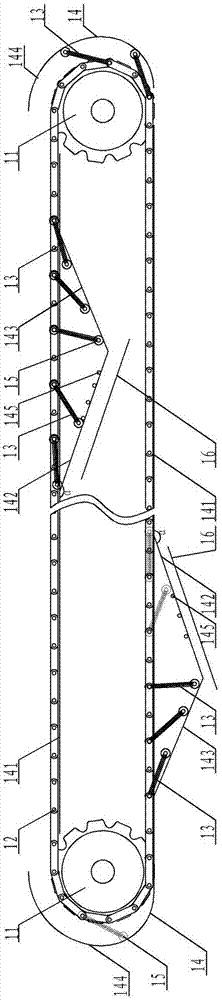

Horizontal type coal briquette drying machine

ActiveCN104748532ADry fastReduce energy consumptionDrying gas arrangementsDrying solid materialsCoal briquetteGrating

The invention relates to a horizontal type coal briquette drying machine. The horizontal type coal briquette drying machine comprises a drying cavity, a chain plate conveying mechanism arranged in the drying cavity, a feed hopper arranged on the top of the drying cavity, a discharging conveying belt arranged on one side of the bottom of the drying cavity, a heating system, an air circulating device and a tail gas recovery device. Coal briquettes make reciprocating motion in the chain plate conveying mechanism and fall layer by layer until the coal briquettes are dried by the discharging conveying belt and are conveyed out of the drying machine. The air circulating device separates water vapor and then conveys dry hot air back into the drying cavity, and the surfaces of the coal briquettes can be dried more quickly; furthermore, the tail gas recovery device leads flue waste gas of an oil furnace into the drying cavity so that waste heat utilization can further be increased, and the energy consumption of the entire drying finance is greatly lowered; in particular, a rigid grating plate can be guided by a guide rail to carry and dump the coal briquettes, the moving mode of the rigid grating plate is simple, in this way, the structure of the guide rail is made simple, the material falling section falls down slowly, the coal briquettes roll down evenly, the hard collision of the grating plate and other equipment is relieved, and the service life of the equipment is prolonged.

Owner:石家庄市矿区丰旺机械有限公司

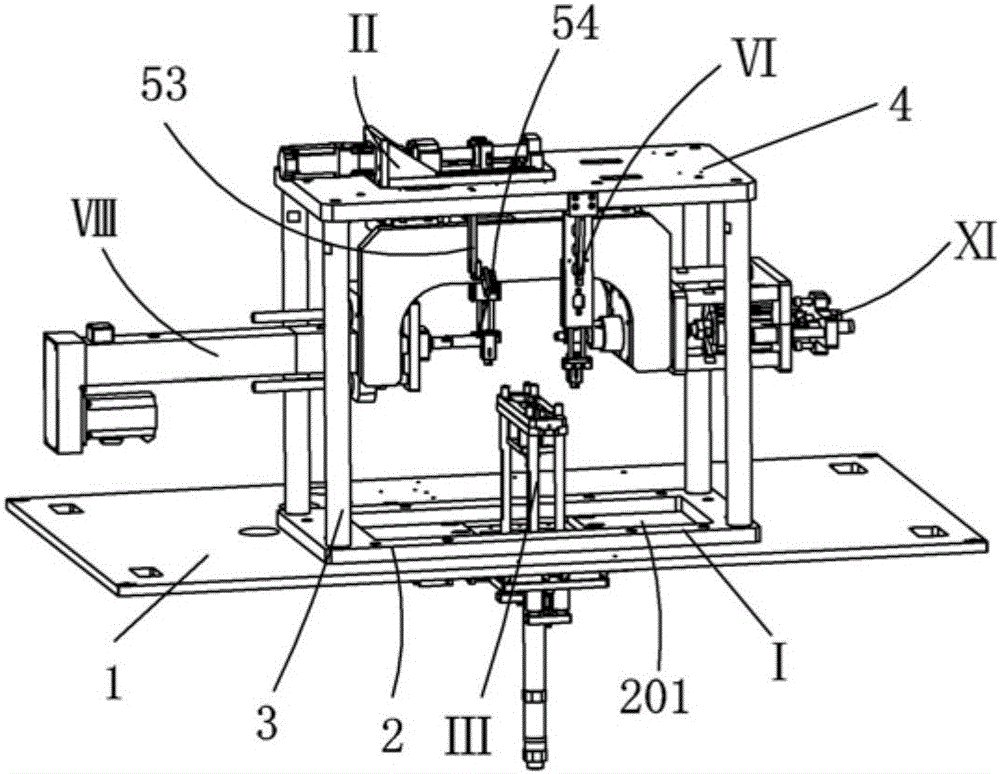

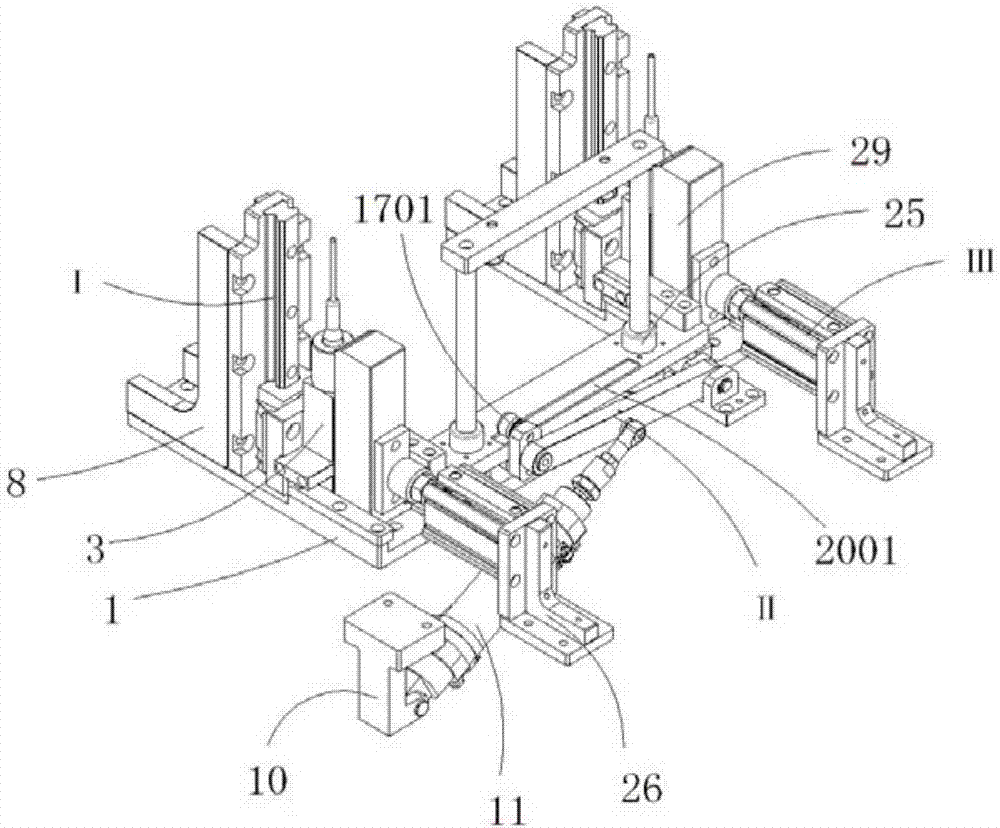

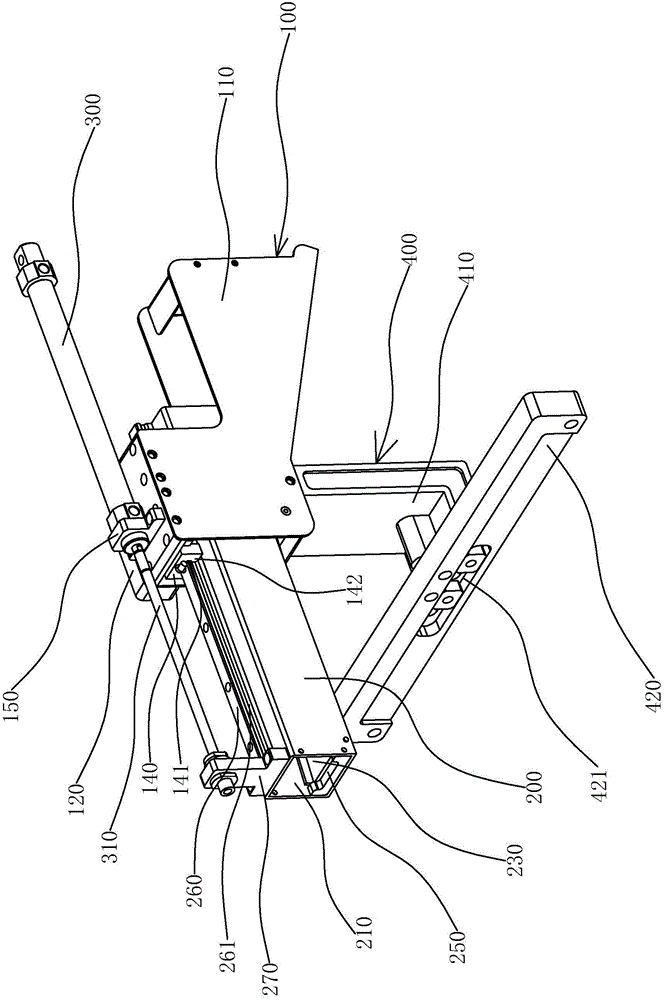

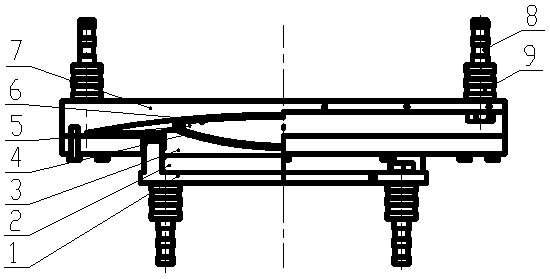

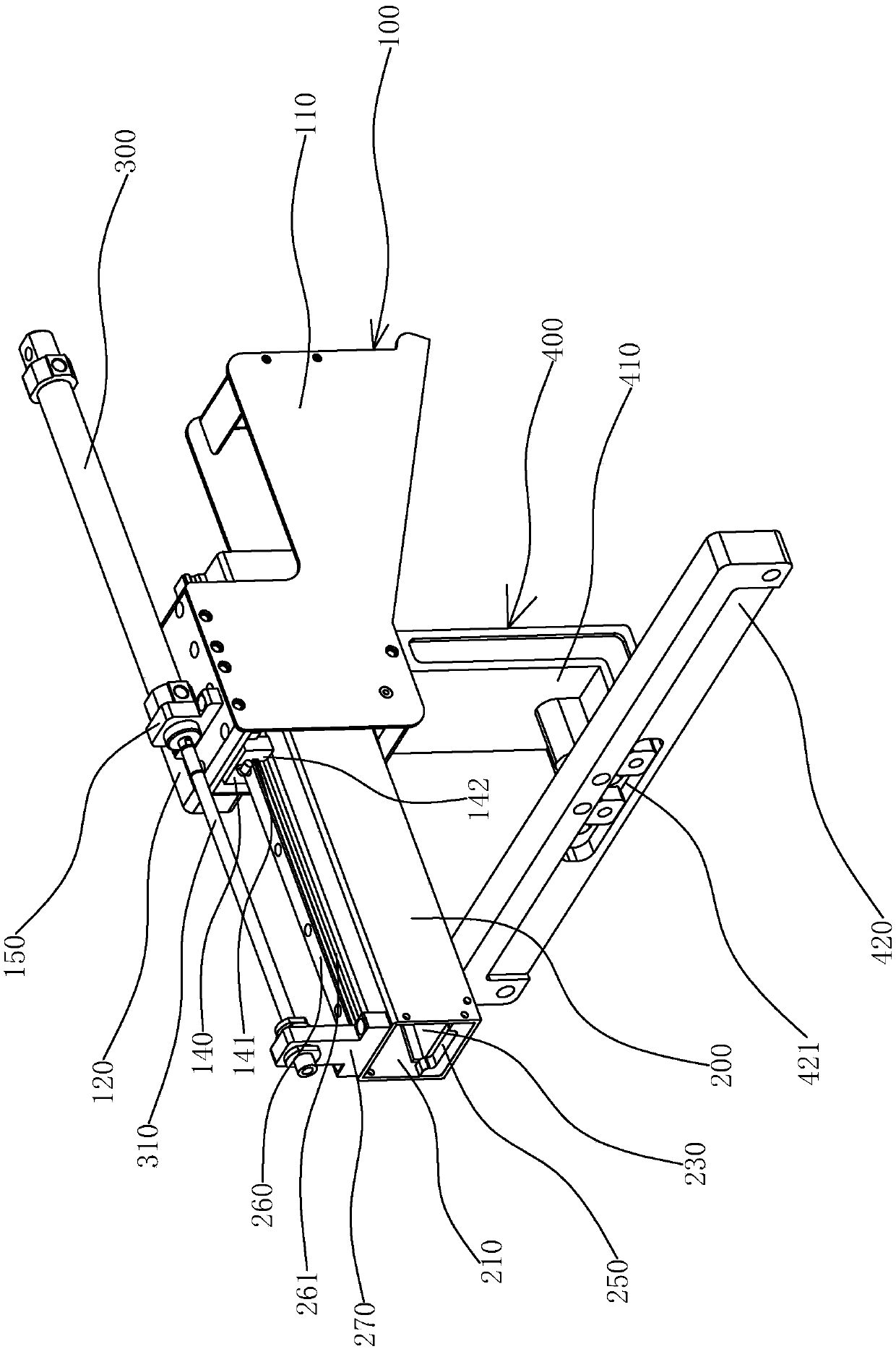

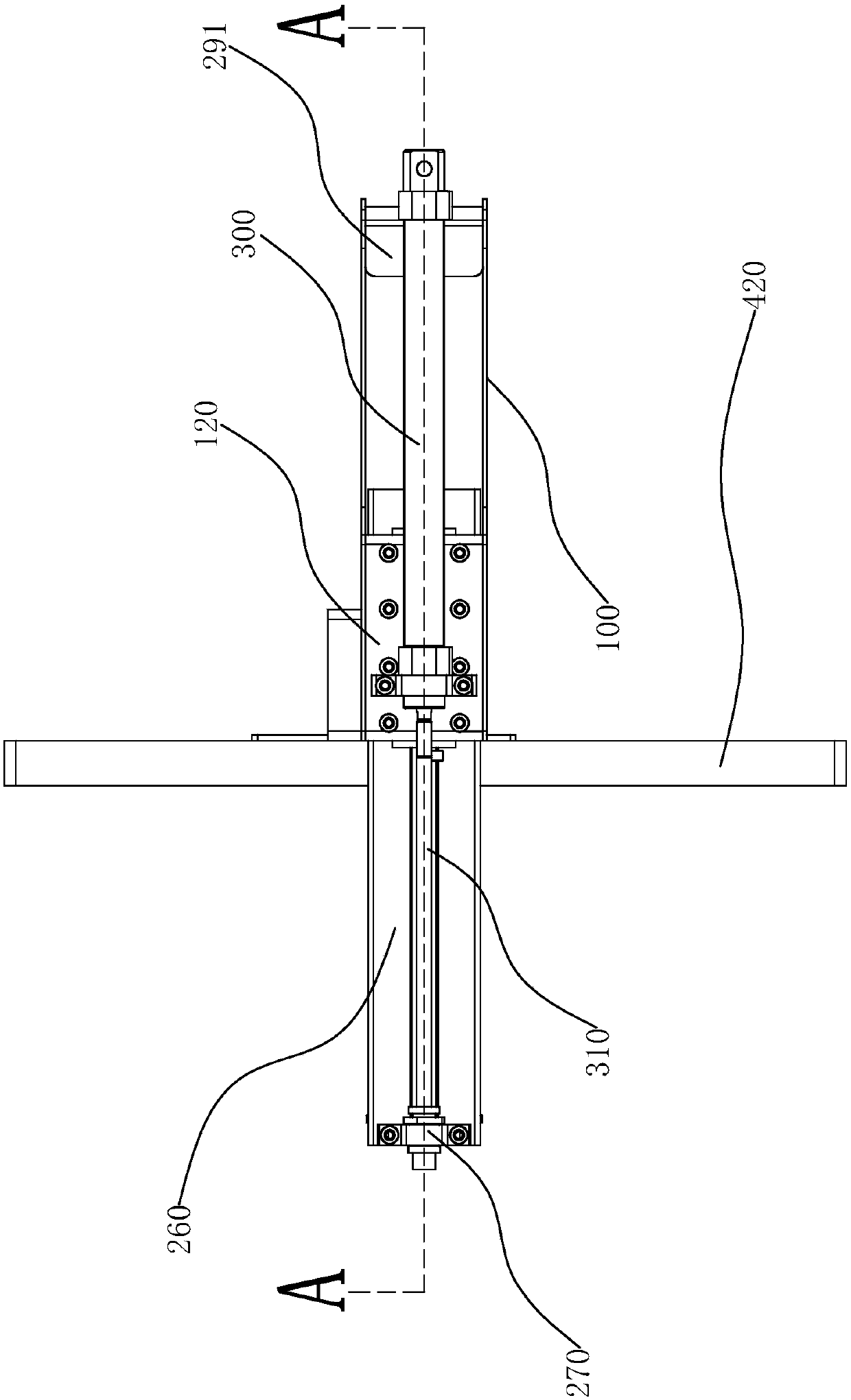

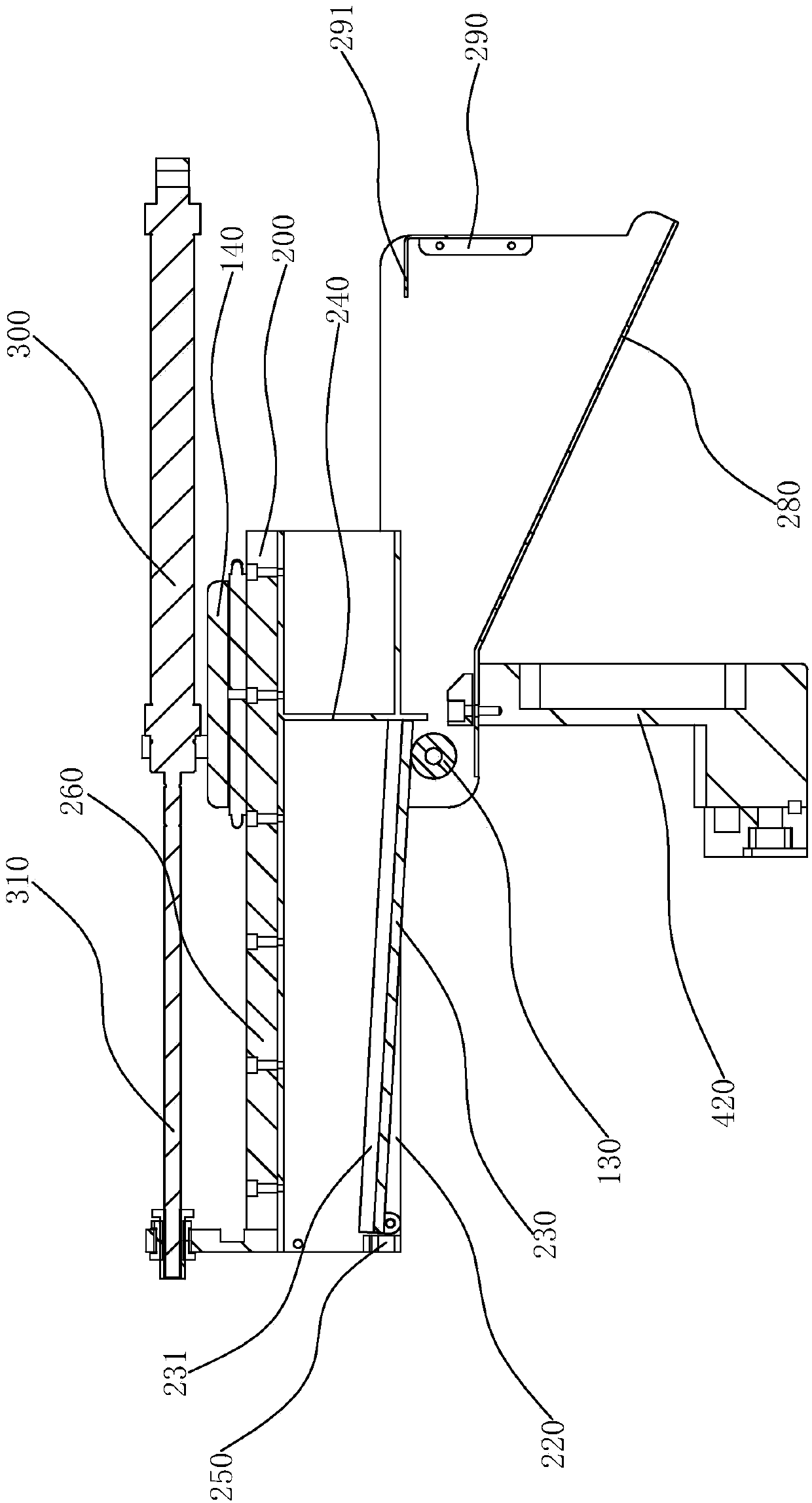

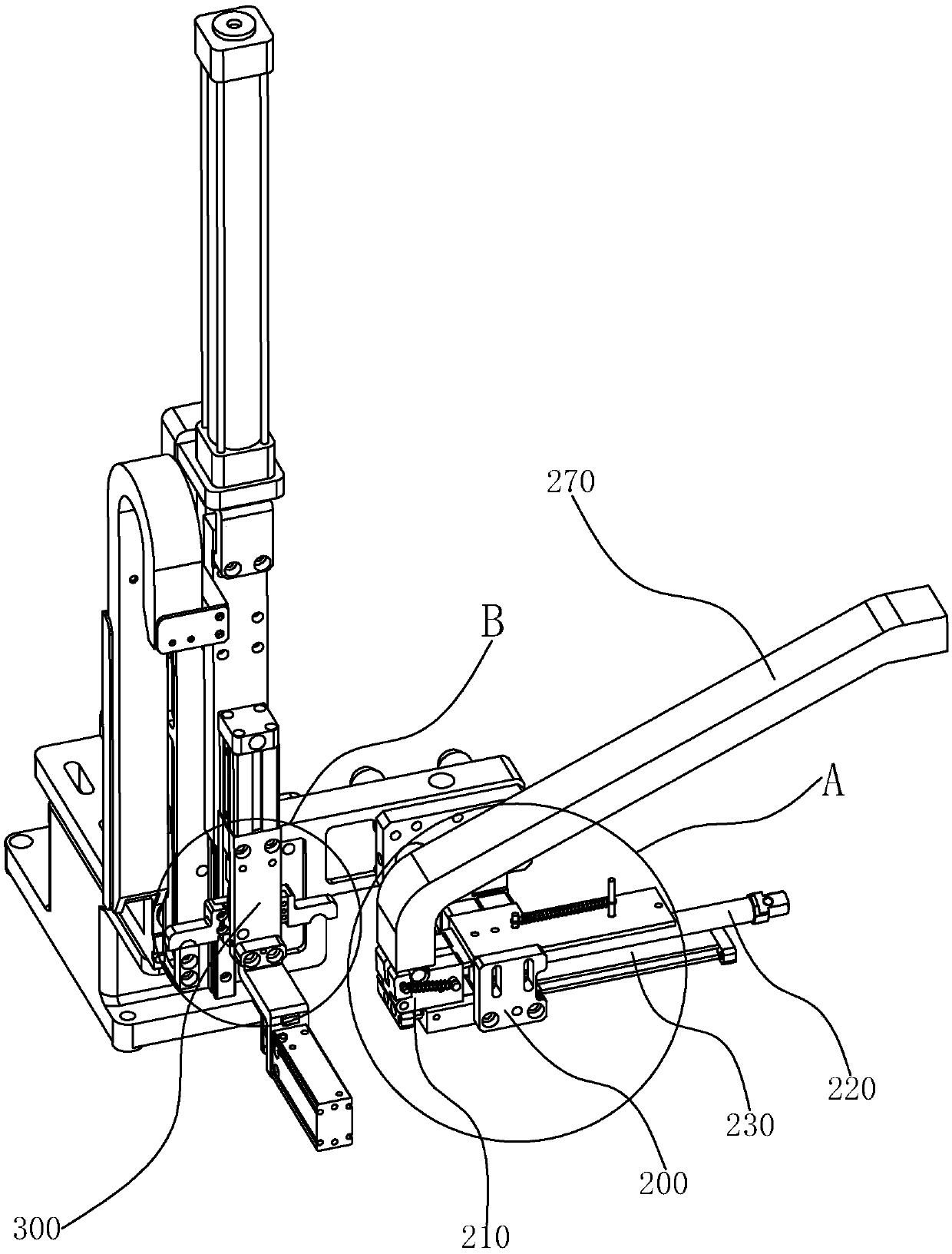

Bushing pressing mechanism

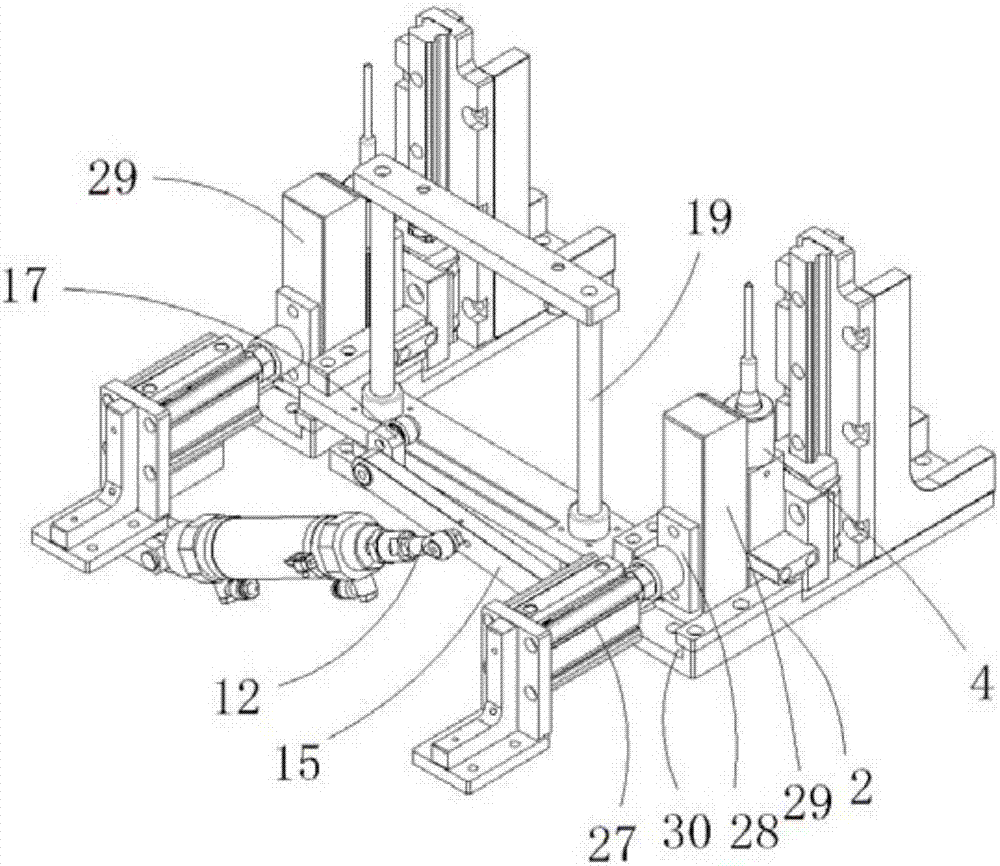

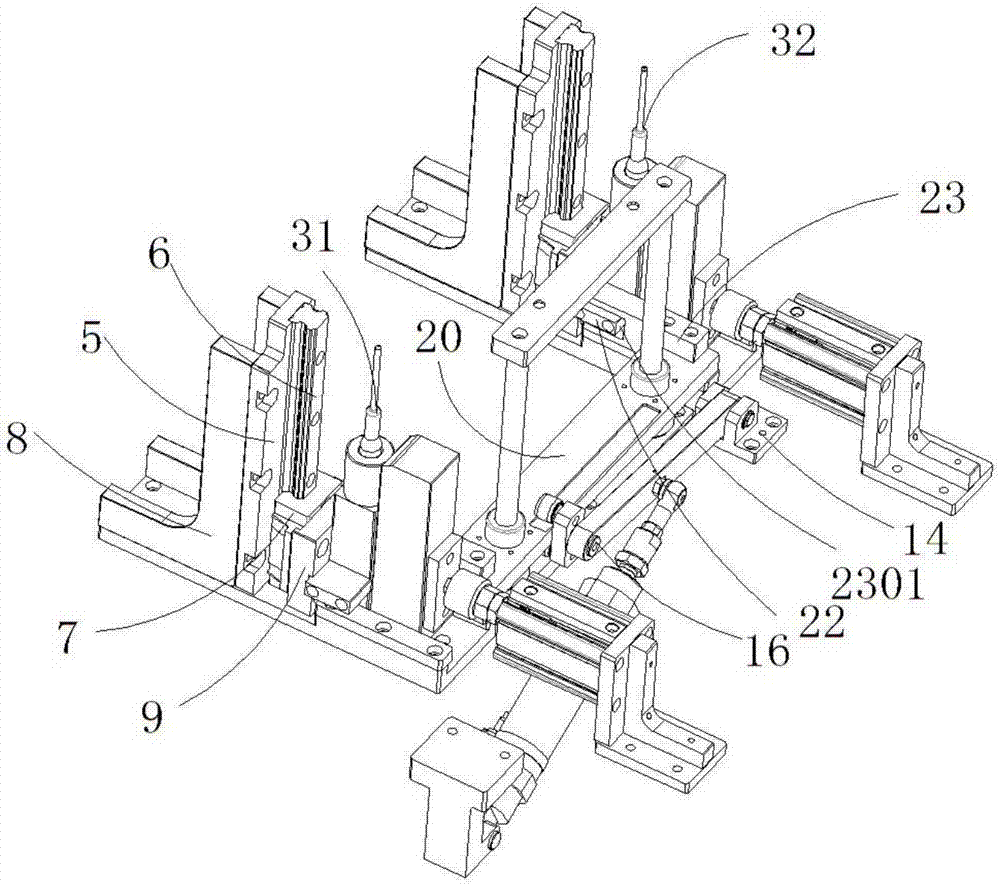

ActiveCN105690073AEnsure stabilityFrom shockMetal working apparatusEngineeringMechanical engineering

The invention relates to a bushing pressing mechanism which comprises a bottom plate and a fixed component; a drive component is mounted on a top plate of the fixed component; a positioning buffer component is mounted on the bottom plate, a bearing seat of the positioning buffer component is positioned between the bottom plate and the top plate, and a product is positioned on the bearing seat; two groups of pressing components capable of pressing the bearing seat are respectively mounted on the front side and the rear side of the top plate; the bottom of a movable connecting block of the drive component is connected with a mounting frame through a connecting base; a first pressing component capable of pressing a bushing into the left side of the product is mounted at the left part of the mounting frame; a second pressing component capable of pressing a bushing into the right side of the product is mounted at the right part of the mounting frame; a sensor capable of detecting whether the bushings are at pressing positions on the two sides of the product or not is mounted at the bottom of the top plate through a sensor fixing seat; the drive component drives the second pressing component to press the brushing on the right side to a preset position, then the second pressing component is taken as a right side support, the first pressing component presses the bushing on the left side in place, and finally the bushing on the right side is pressed in place.

Owner:BOZHON PRECISION IND TECH CO LTD

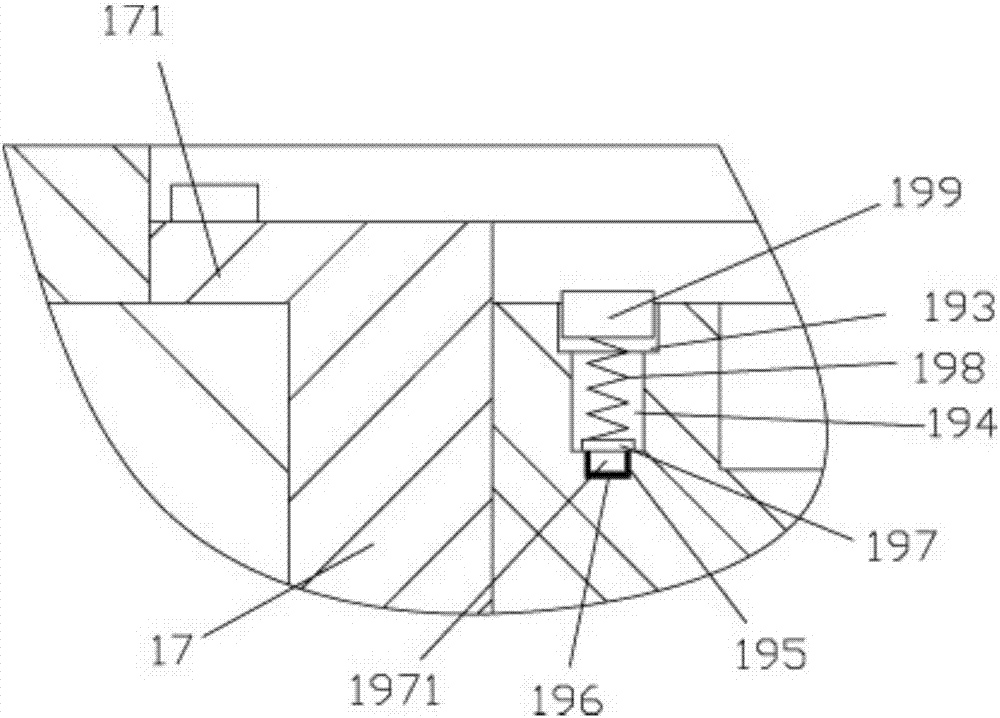

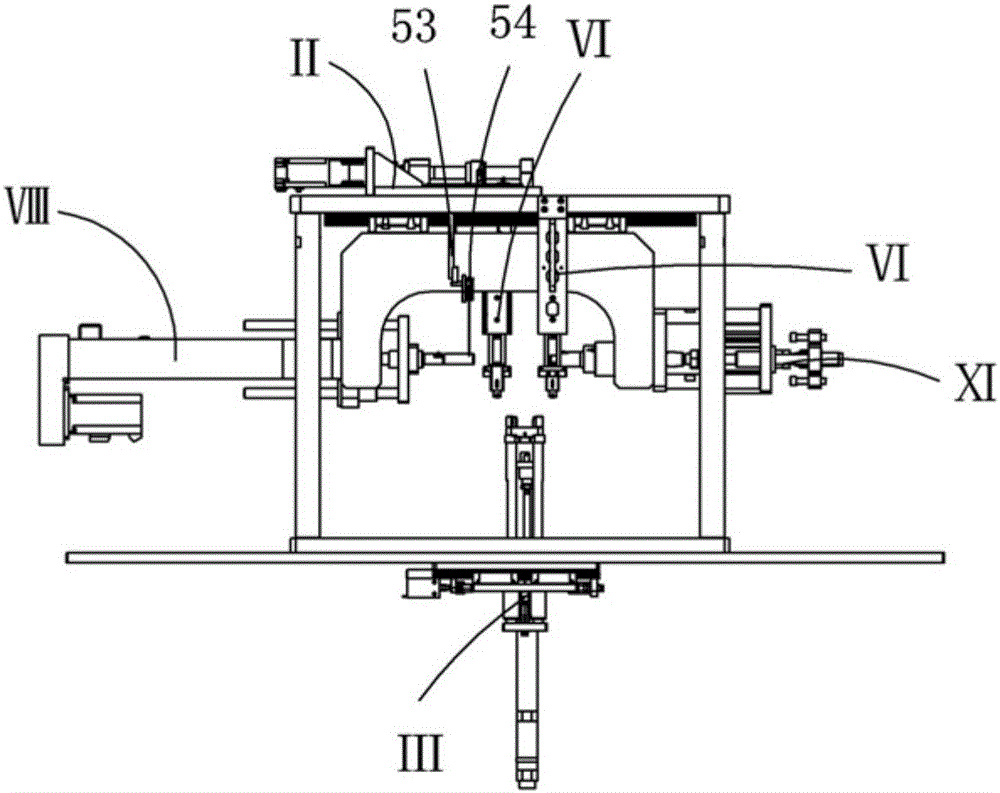

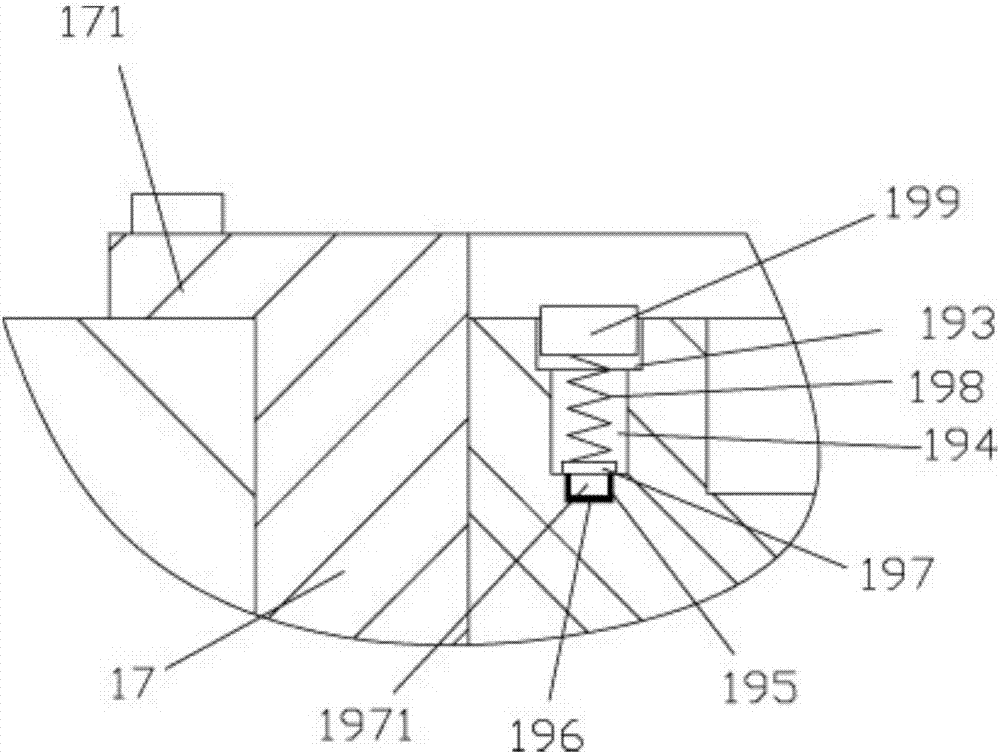

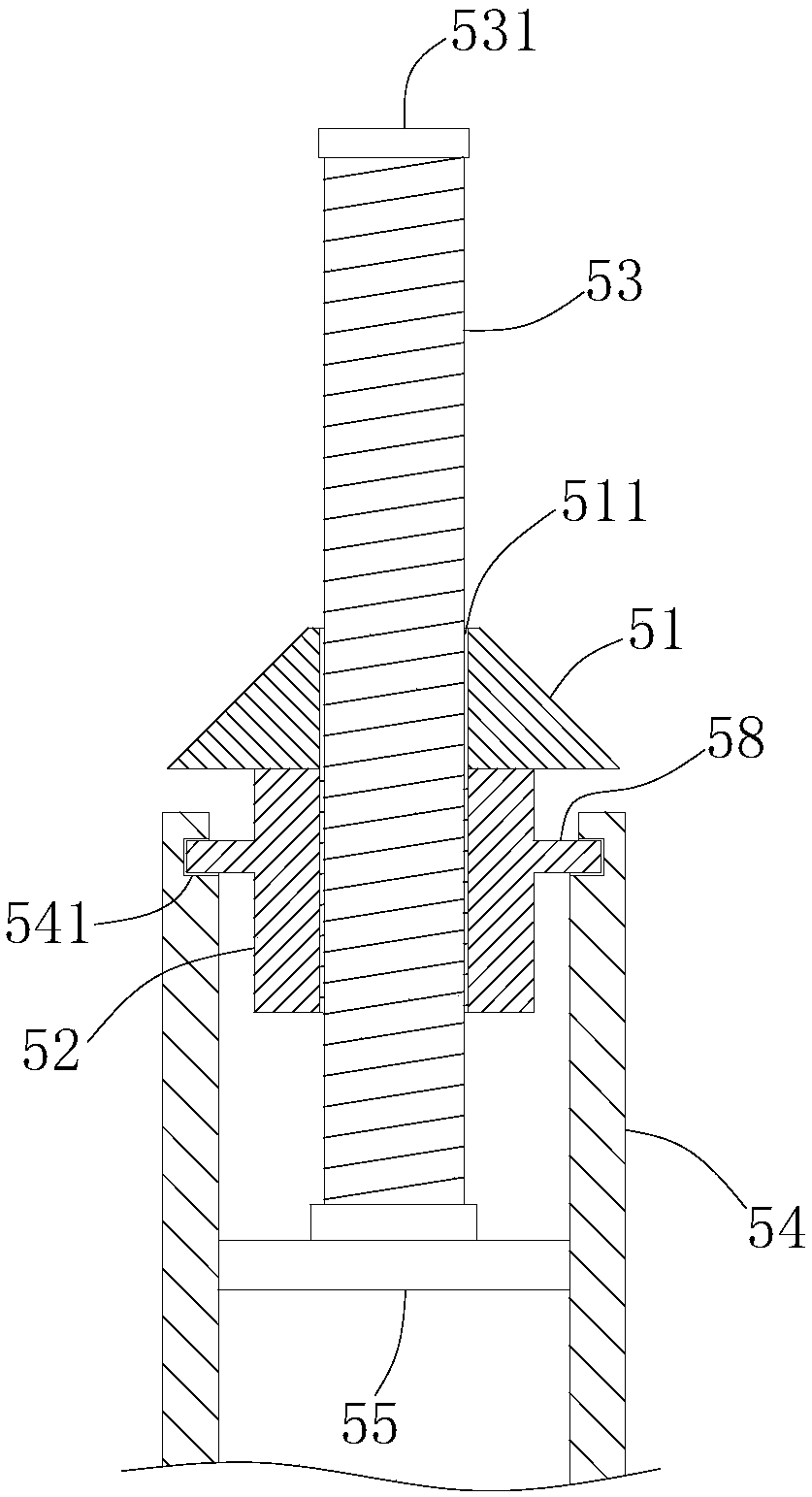

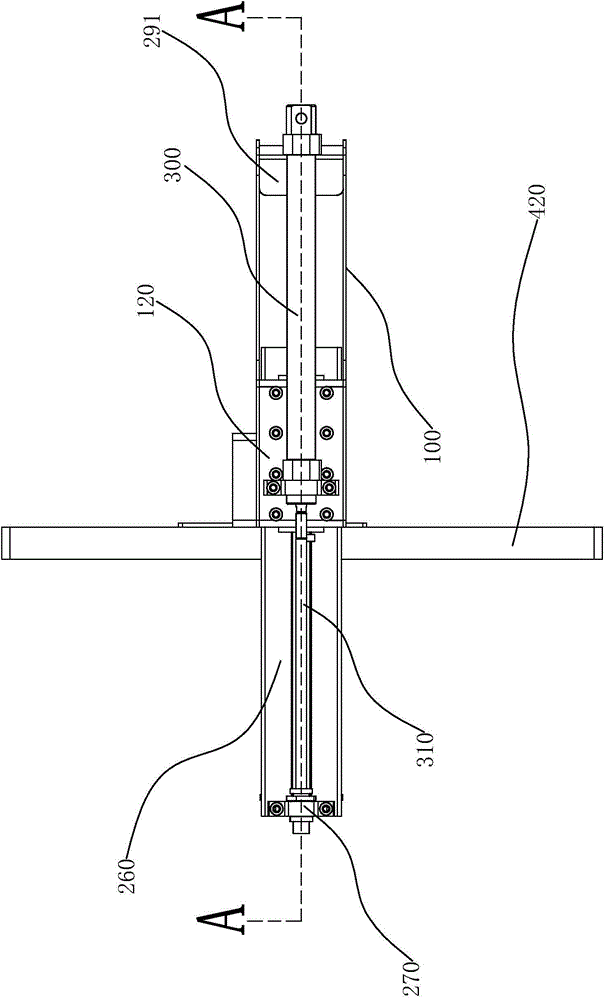

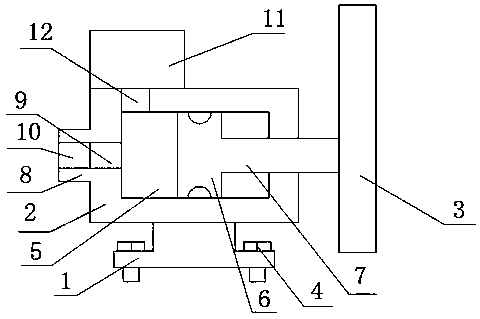

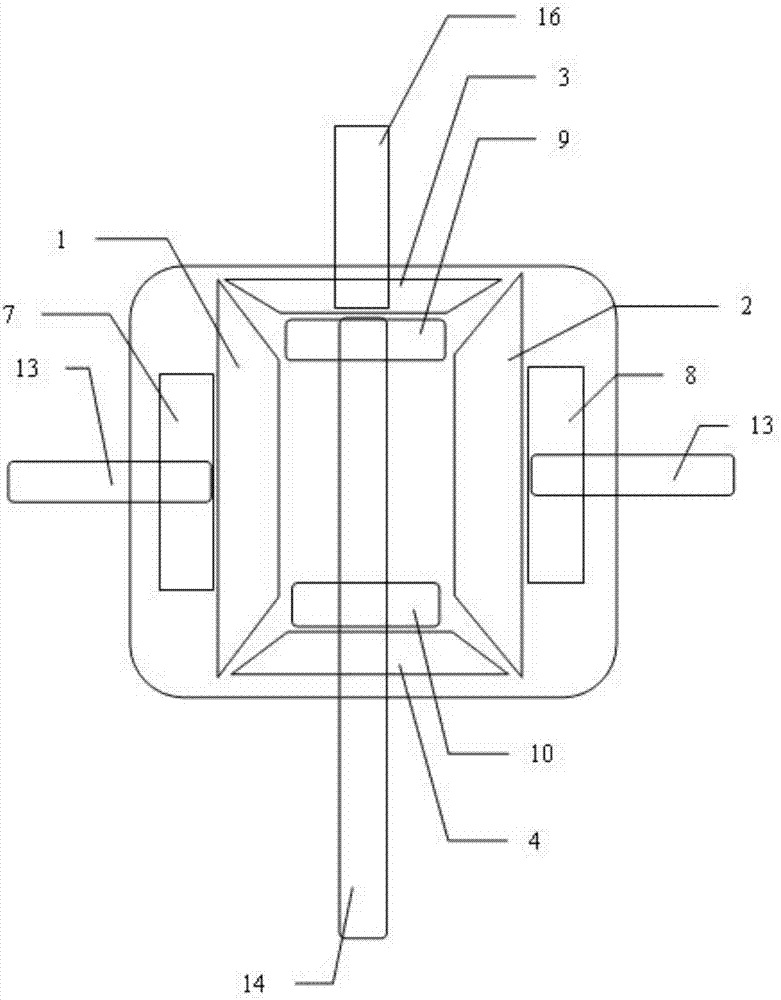

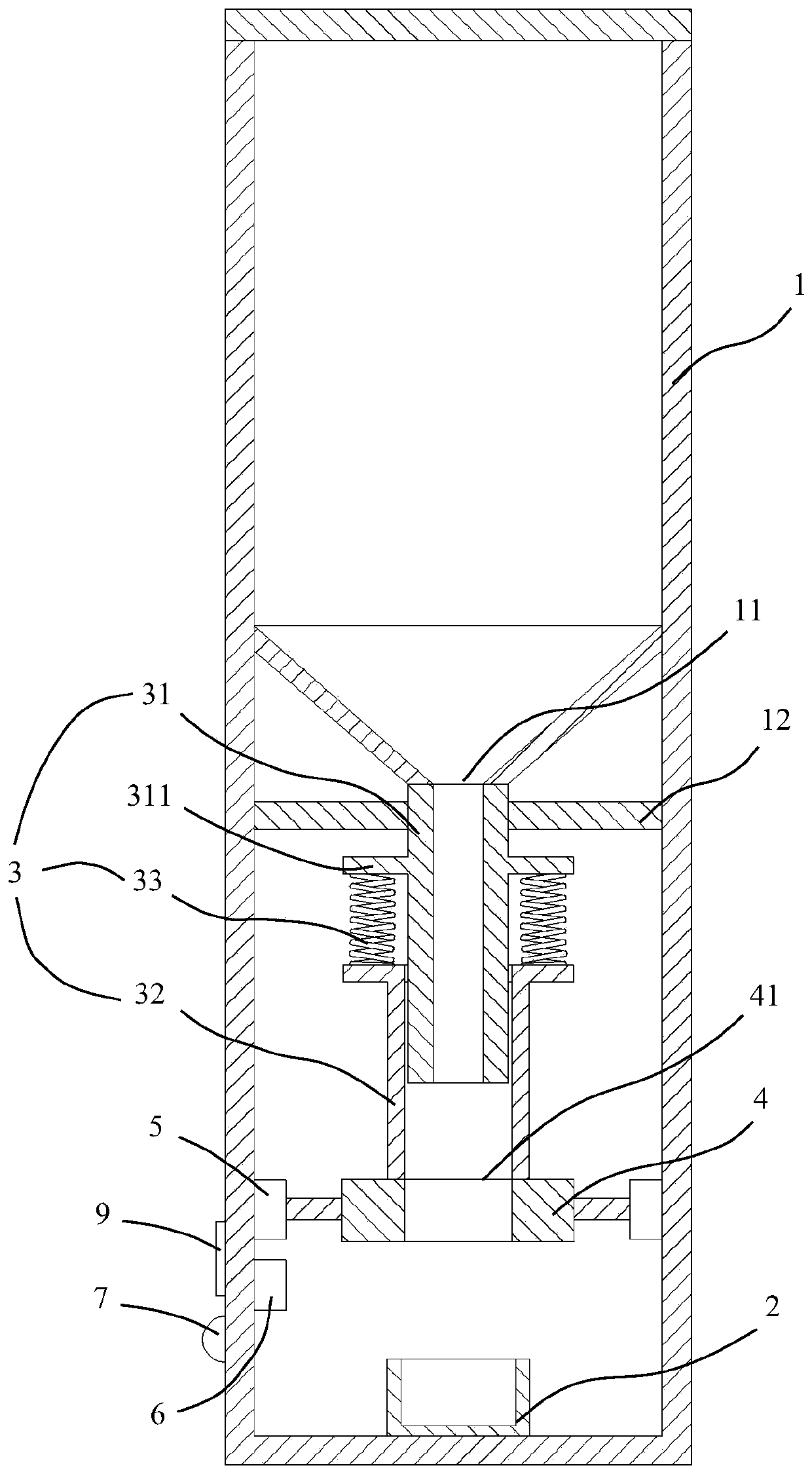

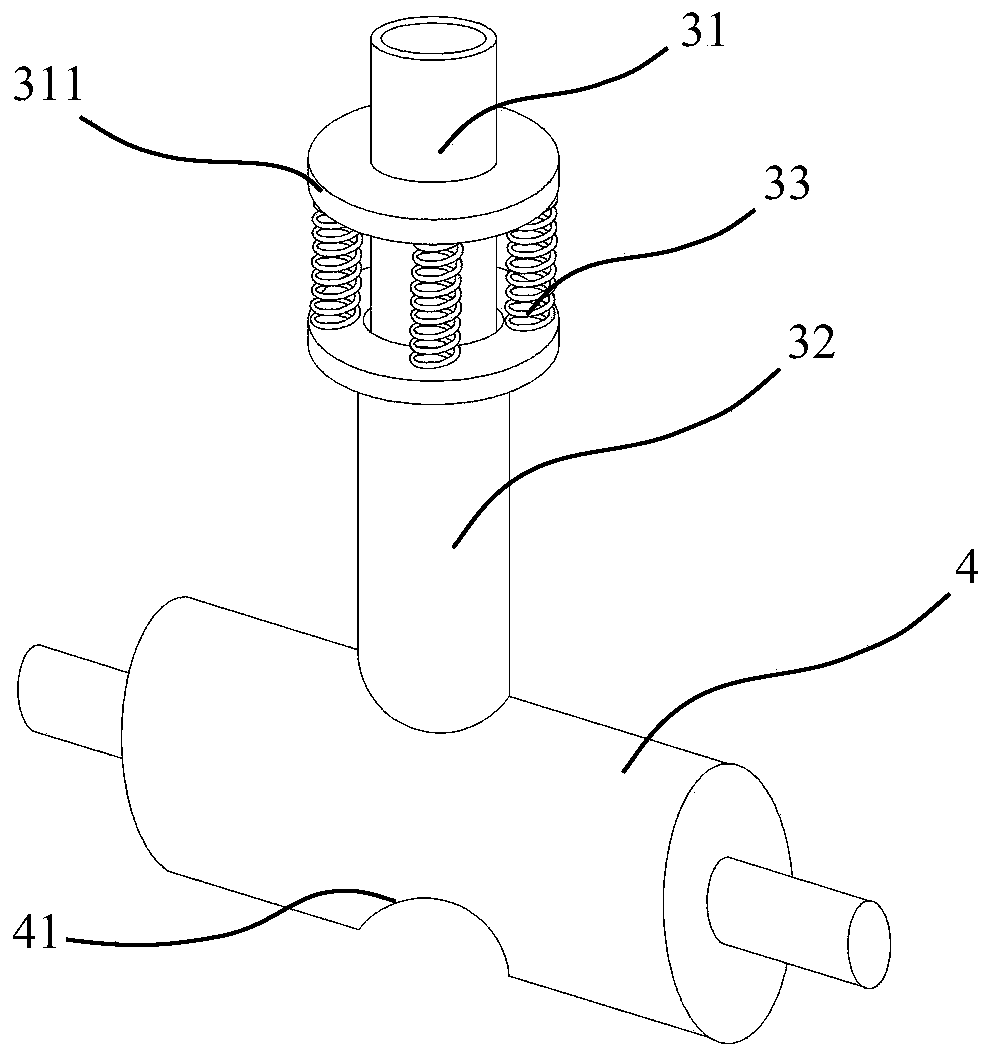

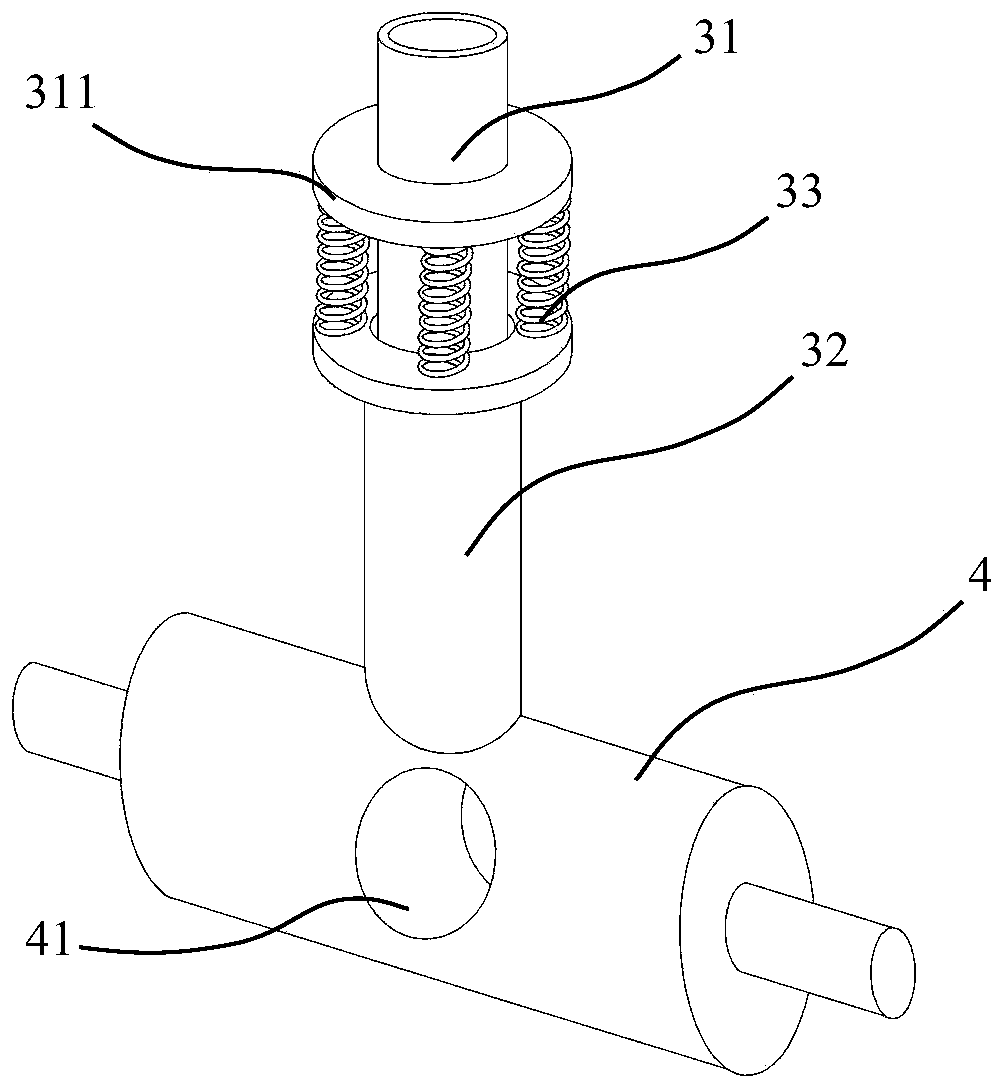

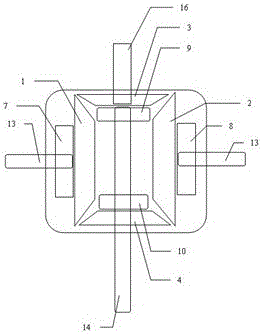

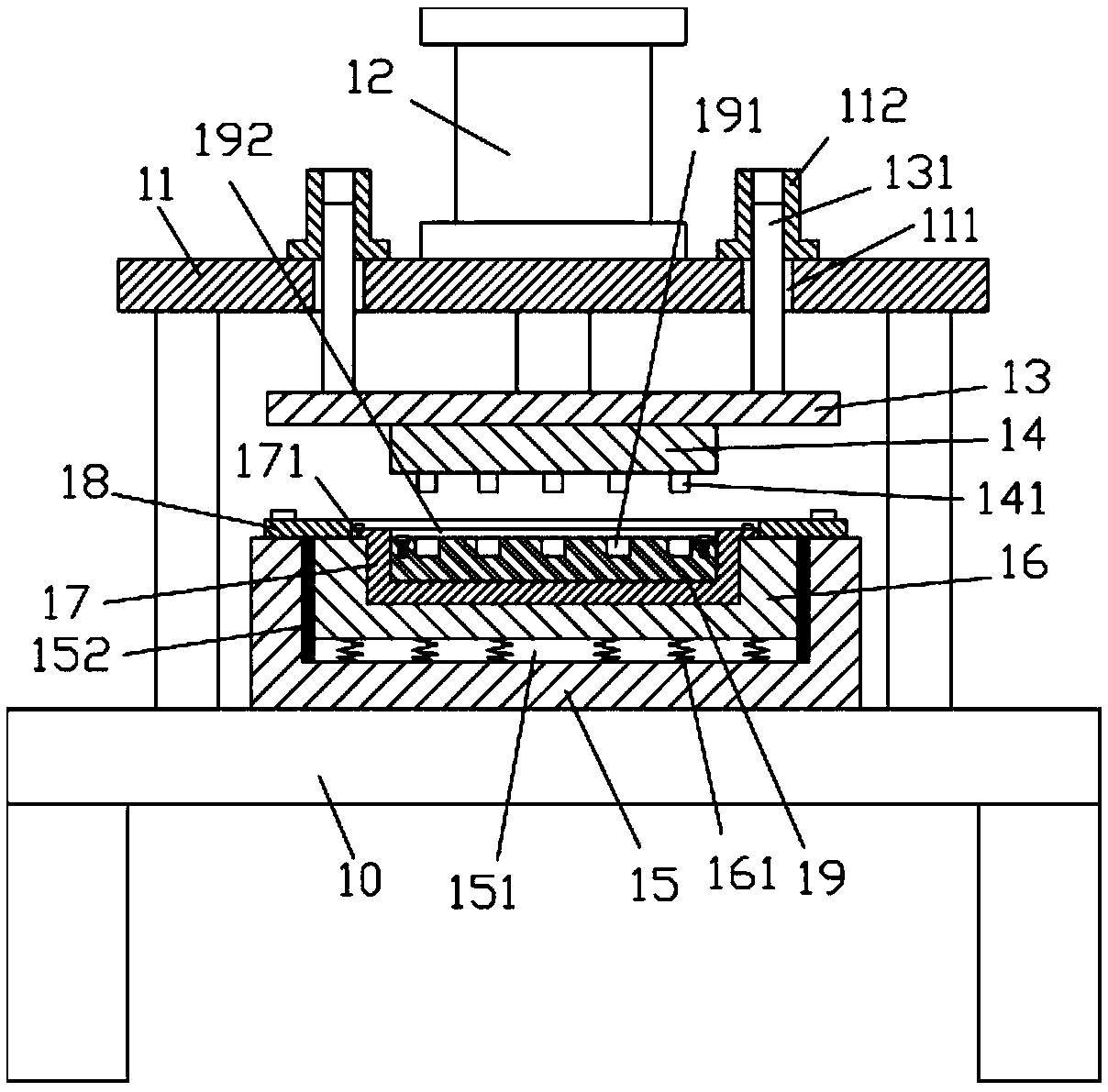

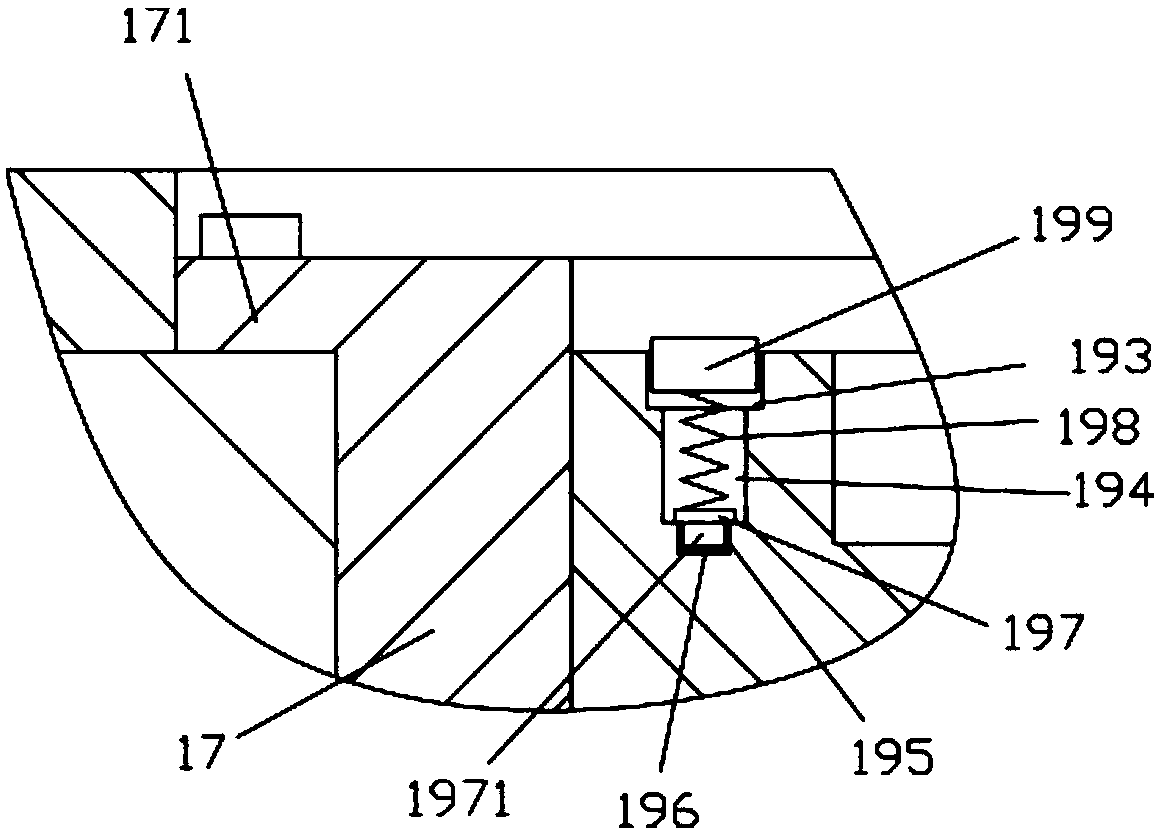

Orignal forming mechanism, capable of realizing quick demolding, for stainless steel circular thin plate

ActiveCN107243537AReduce hard impactNot easy to stickShaping toolsShaping safety devicesPunchingEngineering

The invention discloses an origin forming mechanism, capable of realizing quick demolding, for a stainless steel circular thin plate. The origin forming mechanism comprises a rack. An upper support frame is fixed on the top surface of a top plate of the rack. A punching cylinder is fixed in the middle of the top surface of a top plate of the upper support frame. A push rod of the punching cylinder passes through the top plate of the upper support frame, and is fixed on an upper connecting plate. An upper mold is fixed in the middle of the bottom surface of the upper connecting plate. A plurality of convex punching points are uniformly distributed on the bottom surface of the upper mold. A lower support block is fixed on the top surface of the middle of the top plate of the rack. A main groove is formed in the middle of the top surface of the lower support block. A mounting spacing block is inserted into, sleeved by and clamped in the main groove. The outer side wall of the top of the mounting spacing block is provided with an extending edge. The extending edge is fixedly connected onto the top surface of the lower support block by means of a bolt. The origin forming mechanism has the advantages that hard collision between the upper mold and a lower mold can be reduced, damage of the upper mold and the lower mold is reduced, the service life is prolonged, and in addition, a stainless steel circular thin plate is not easily adhered to the upper die or the lower die, so that demolding is quick.

Owner:NANJING GAODA STAINLESS STEEL

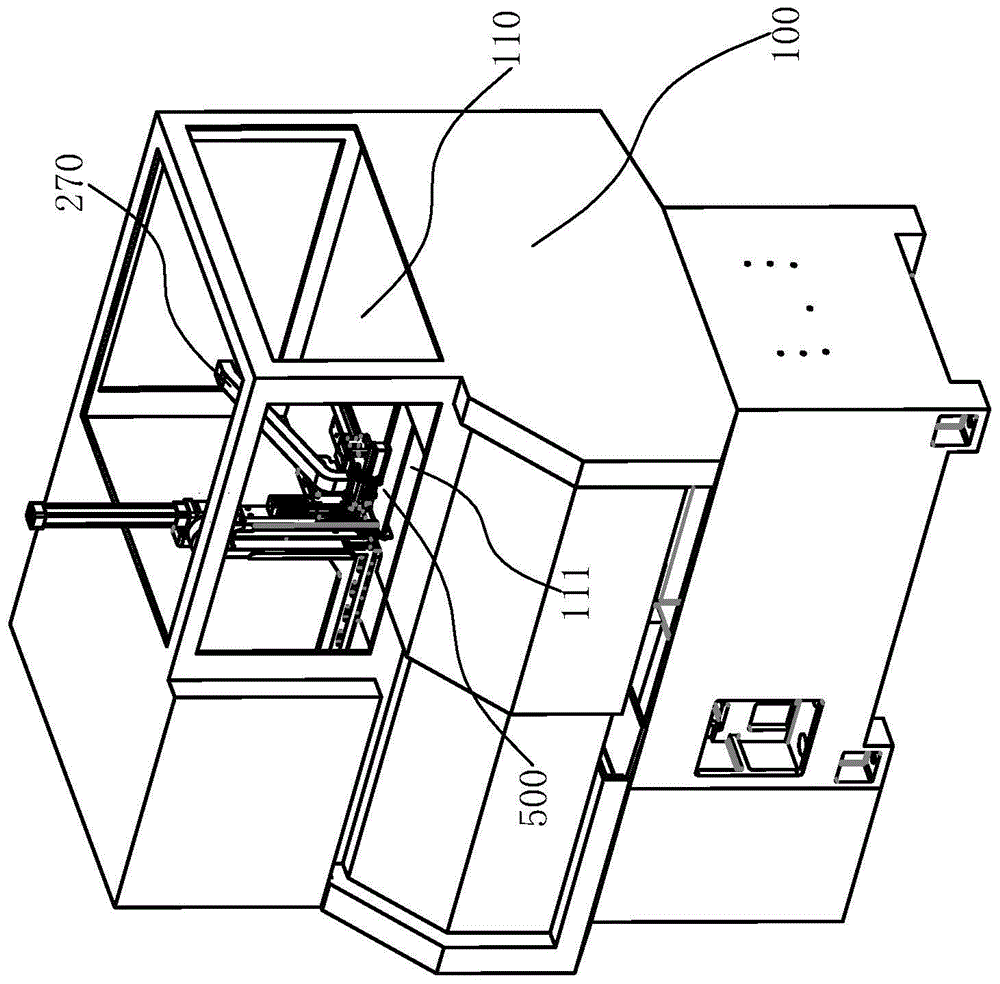

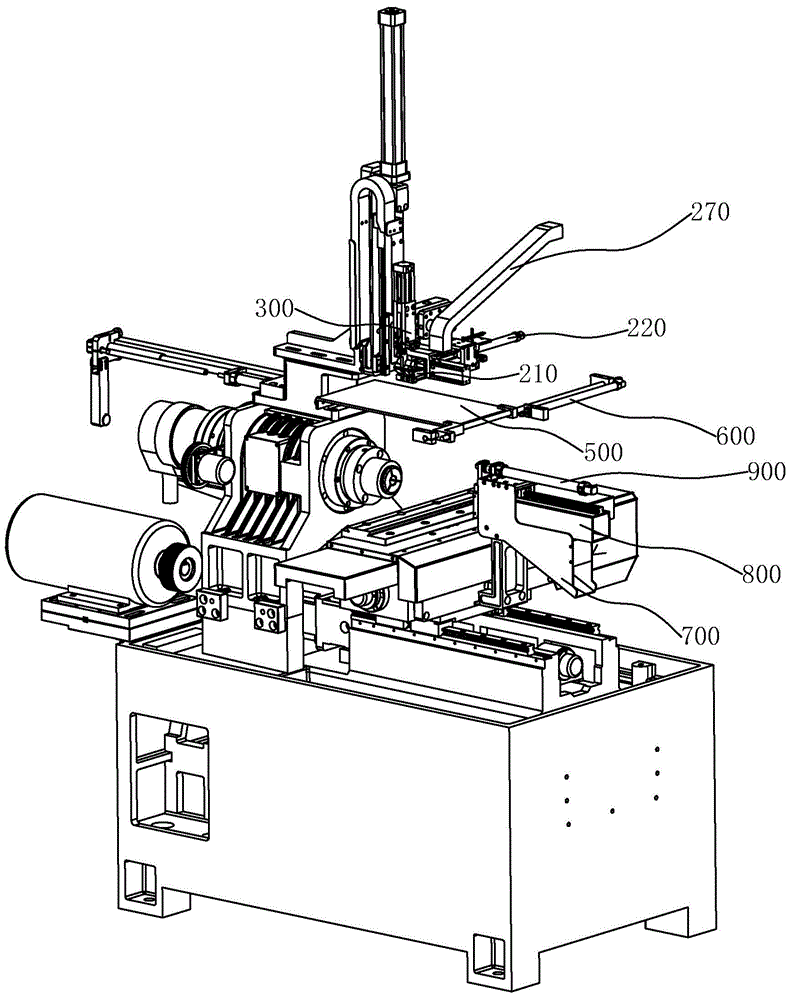

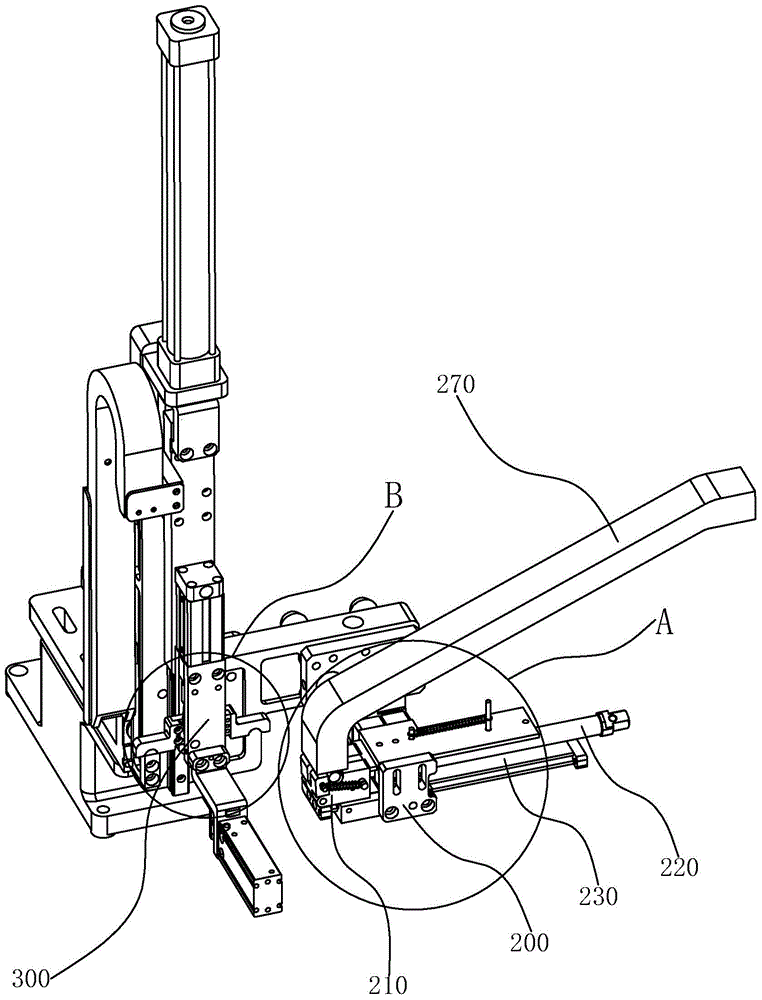

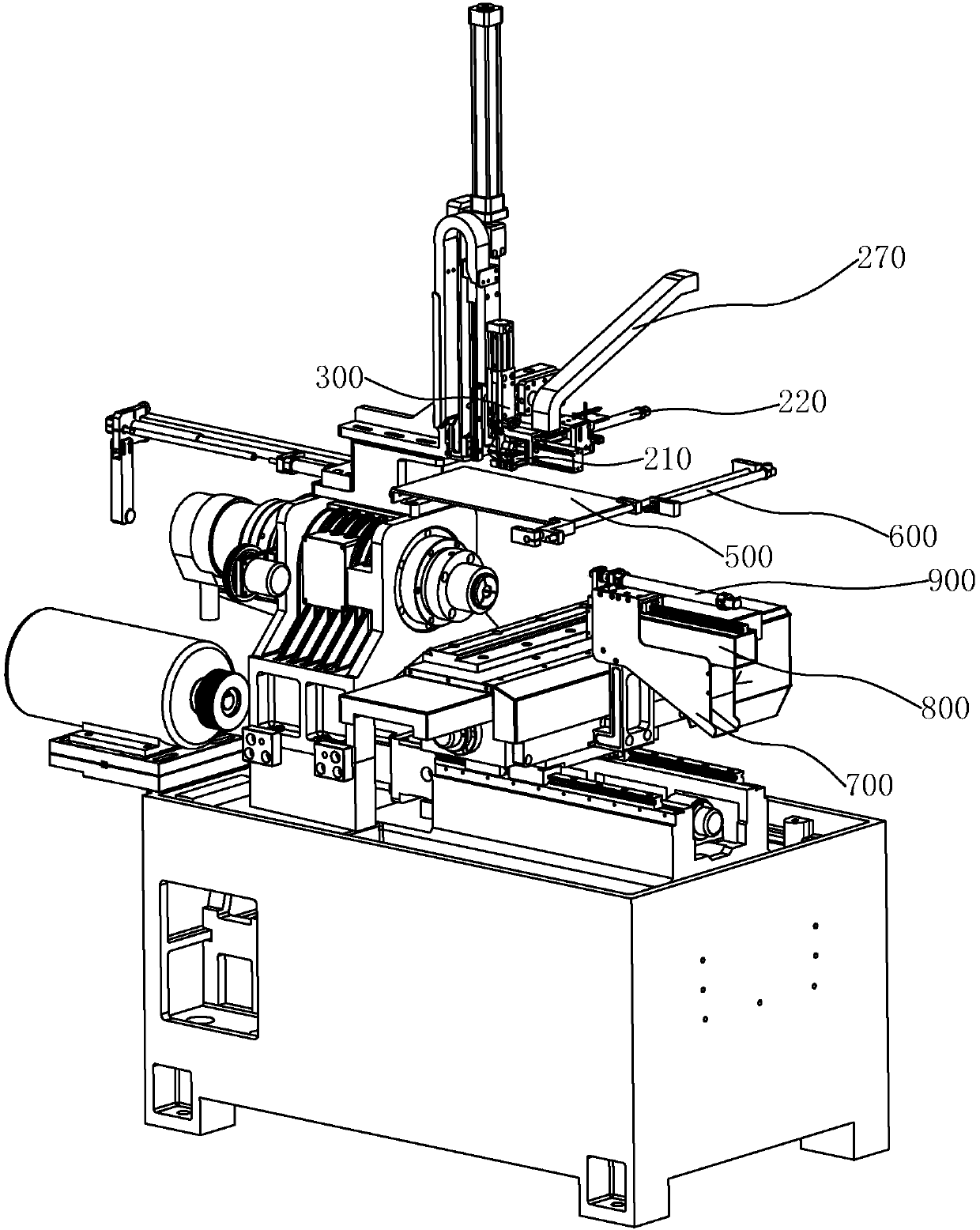

Pneumatic manipulator processing equipment

ActiveCN104057105AShort tripSave feeding timeAuxillary equipmentMetal working apparatusEngineeringHolding tank

The invention provides pneumatic manipulator processing equipment and belongs to the technical field of automatic lathes; the technical problems that a pneumatic manipulator in a traditional lathe is long in stroke, workpieces are easy to damage during material receiving and discharging, and chippings and water spots generated by processing are easy to splash to a feeding end are solved by the pneumatic manipulator processing equipment provided by the invention. The pneumatic manipulator processing equipment is arranged on a rack, and comprises a feeding device, a protection device and a material receiving device, wherein the feeding device is provided with a permanent seat and a feeding assembly; the protection device is provided with a guide rod and a protection plate; the material receiving device is provided with a feed cover frame and a feed pipe; a holding tank is formed in the feeding assembly, and moreover, when the feeding assembly moves, the workpieces can be shifted from the holding tank; the rack is provided with a processing end and a feeding end; the protection device can be moved to a position between the processing end and the feeding end, and the processing end and the feeding end are separated; a notch is formed in the bottom part of the feed pipe, and a material receiving plate hinged to the feed pipe is arranged in the notch; a rolling shaft is arranged in the feed cover frame, and the rear end of the material receiving plate is put on the rolling shaft. The stroke of the pneumatic manipulator is shortened, the safety and the cleanness of the feeding end are protected, and the damage to the workpieces is smaller.

Owner:宁波宫铁智能科技有限公司

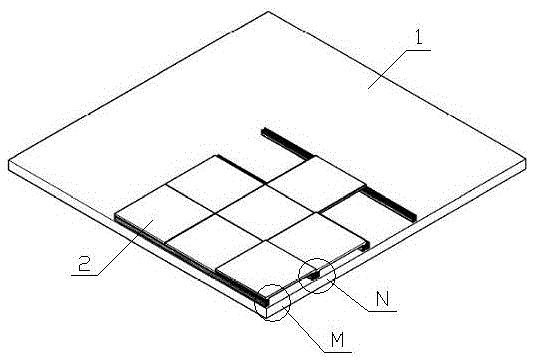

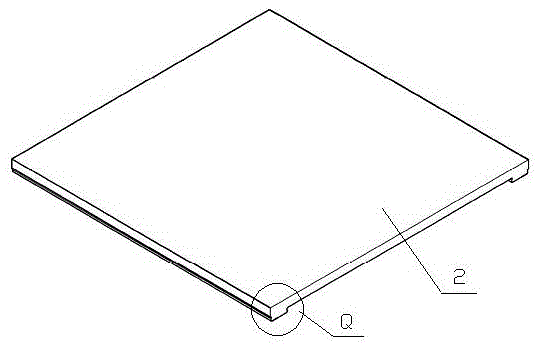

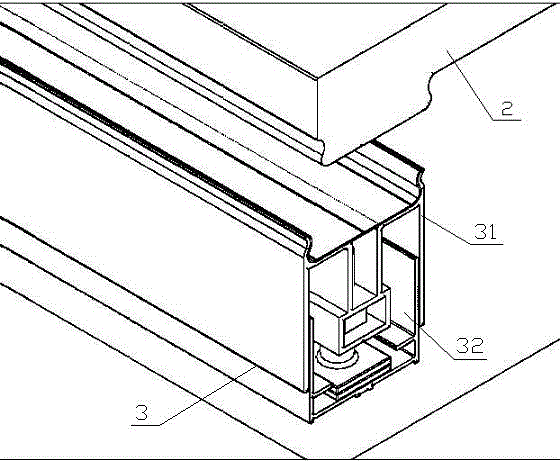

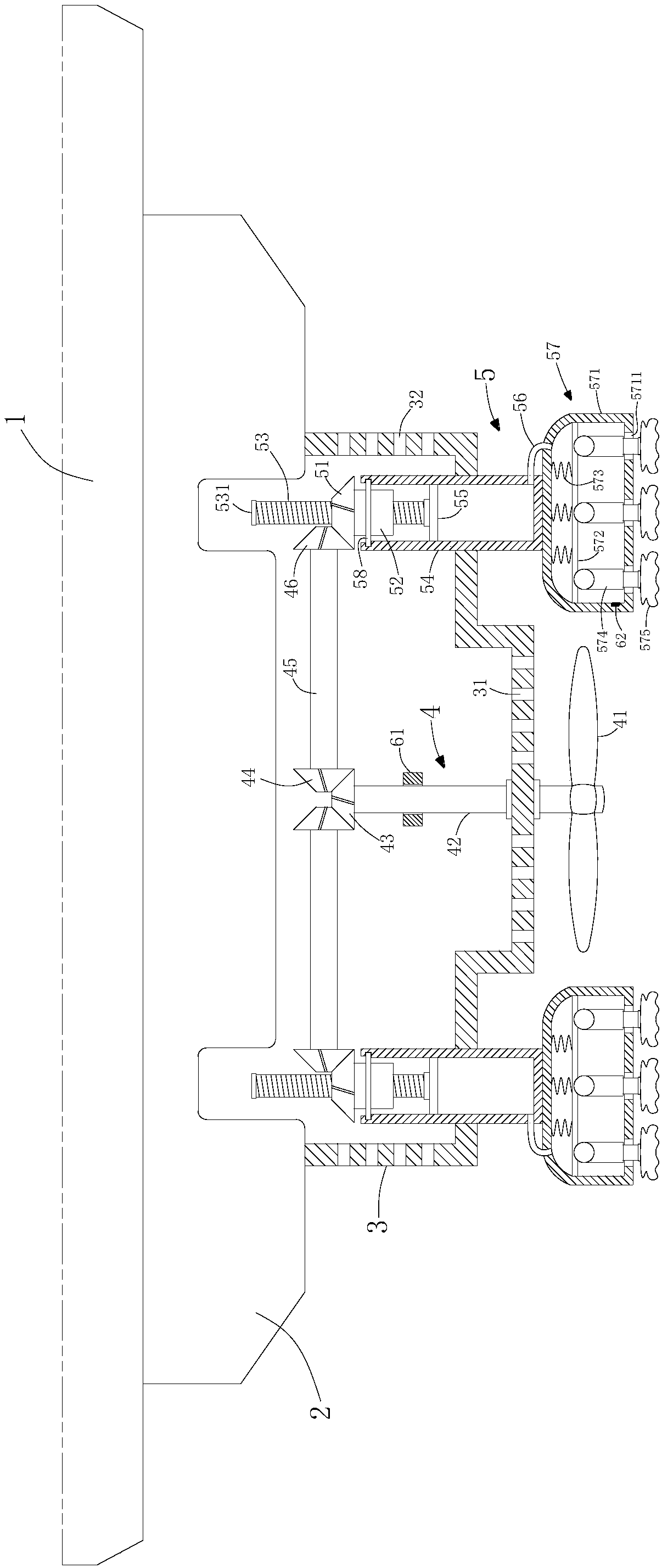

Ground aerial structure capable of being leveled

ActiveCN105587097AStable supportStable structureFlooring insulationsFalse floorsEconomic benefitsStructural engineering

The invention relates to a ground aerial structure capable of being leveled on flooring in a building. The structure solves the problems that workloads are large, the period is long, pollution exists and the weight of the building is increased. The structure is characterized in that a plurality of support beams are arranged on a ground foundation, and tile positioning grooves are formed in the tops of the support beams; each support beam comprises a supporting cross beam located at the bottom, and a buckle cross beam buckled to the upper portion of each supporting cross beam; a nut seat frame is arranged in each buckle cross beam, and each buckle cross beam and the corresponding supporting cross beam are connected through an adjusting screw. Supporting force is strong, the structure is sable, buckling between tiles and the buckle cross beams is more compact, and collision sound between hard objects is avoided. Detachment is facilitated, use of cement mortar is reduced, the environment is beautified, workloads are reduced, cost is reduced, operation is convenient, resources are saved, the structure can be installed without special skills, the structure can be detached and repeatedly used, all the parts are industrially produced, and economic benefits are improved.

Owner:ZHEJIANG YASHA DECORATION

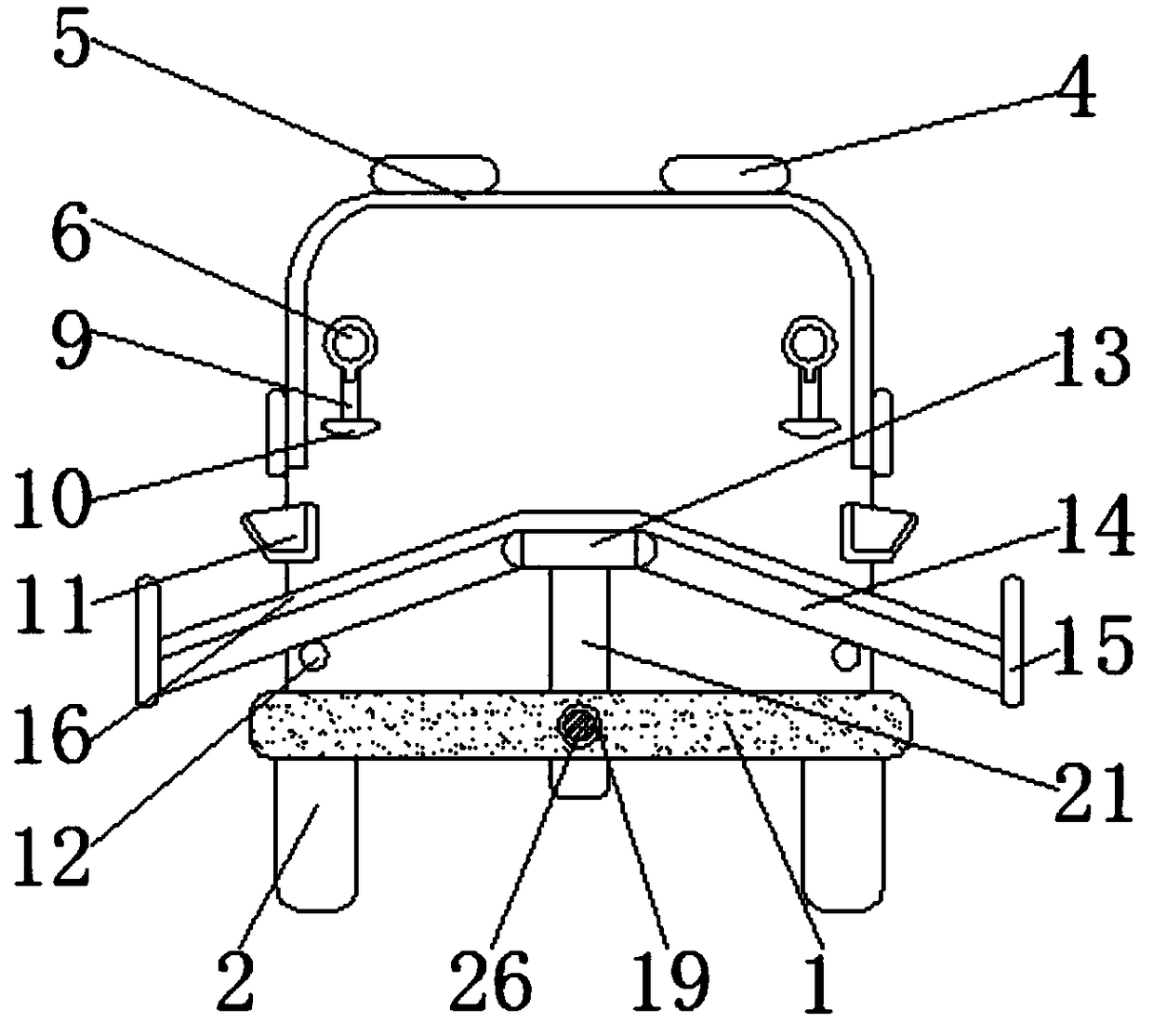

Unmanned aerial vehicle and buffering device used for landing of unmanned aerial vehicle

The invention relates to the field of unmanned aerial vehicles and discloses a buffering device used for landing of an unmanned aerial vehicle and the unmanned aerial vehicle provided with the buffering device. The buffering device used for landing of the unmanned aerial vehicle comprises an upper shell used for being fixedly connected with the bottom of an unmanned aerial vehicle body, a lower shell fixed to the lower portion of the upper shell, a power component and a buffering component which are fixedly arranged relative to the lower shell. When the unmanned aerial vehicle lands, the powercomponent depends on upstream airflow with the motion direction opposite to that of the unmanned aerial vehicle to supply power so as to drive the buffering component to enter in a buffering state. When the unmanned aerial vehicle lands, the upstream airflow can supply power to the power component, the power component can drive the buffering component to enter in the buffering state through the power, so that impact on the vehicle body in the landing process is reduced, and the vehicle body is protected.

Owner:浙江海贝思机械有限公司

Damping and shock insulating bidirectional spherical support

InactiveCN104088368AHigh temperature resistanceIncrease coefficient of frictionBridge structural detailsShock proofingSlide plateEngineering

The invention discloses a damping and shock insulating bidirectional spherical support which comprises a lower support plate, an upper support plate, anchor bolts and sleeves, wherein a damping rubber plate, a spherical concave liner plate, a spherical surface sliding plate, a spherical crown liner plate and a damping sliding plate are further sequentially arranged from bottom to top between the lower support plate and the upper support plate; the damping sliding plate and the spherical surface sliding plate are respectively adhered to the upper and lower sides of the spherical crown liner plate; guide plates and shearing bolts are arranged at the left and right ends of both the upper support plate and the lower support plate; the guide plates are fixed on the upper support plate and the lower support plate through the shearing bolts. Due to adoption of the damping rubber plate on the lower support plate, the vertical kinetic energy of a bridge is converted into potential energy and heat energy of the bridge itself in earthquake, then the impact of components of the support is alleviated; as the guide plates are fixed on the upper support plate through the shearing bolts, after the earthquake, the support can be recovered by self; if the shearing bolts are cut off, the support can be recovered to a normal use state by only replacing the shearing bolts and resetting the guide plates.

Owner:CHENGDU XINZHU ZHUANBO ENVIRONMENTAL PROTECTION TECH

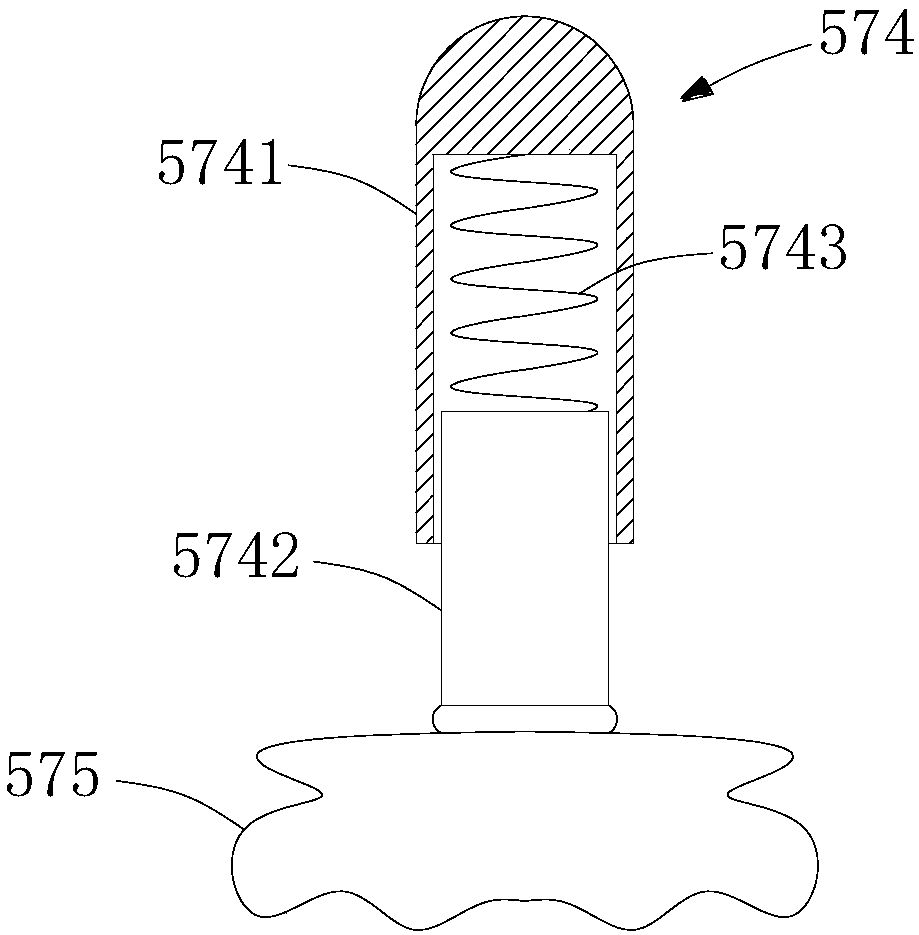

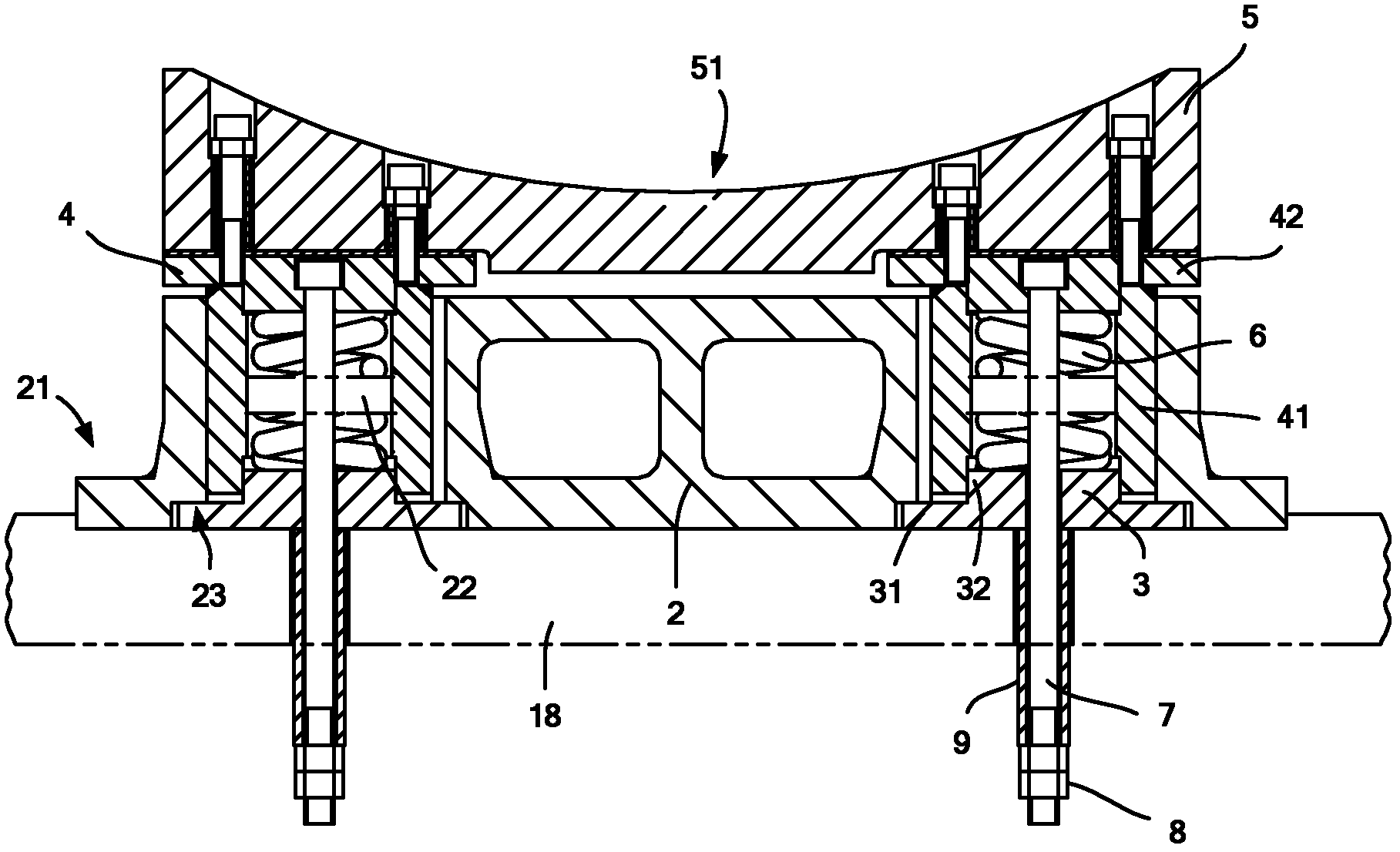

Elastic floating support device for drawing and extending roller die of drawing and extending hydraulic press

The invention discloses an elastic floating support device for a drawing and extending roller die of a drawing and extending hydraulic press. The elastic floating support device comprises a base seat, a spring seat, a support plate and a guide cylinder, wherein the base seat is fixedly installed on a front beam base plate of the drawing and extending hydraulic press, and a guide through hole is arranged on the pedestal; the spring seat is fixedly installed on the front beam base plate and is located in the guide through hole; the upper end surface of the support plate is a cambered surface matched with a shell of the drawing and extending roller die; and the guide cylinder is sheathed in the guide through hole, the upper end surface is fixedly connected with the support plate, the lower end is in sliding fit with the spring seat, and a spring is pretightened between the guide cylinder and the spring seat. In the invention, the guide cylinder and the spring seat are in sliding fit, the guide cylinder is connected with the support plate for supporting the drawing and extending roller die, and the pretightened spring is installed in the guide cylinder. When the drawing and extending roller die undergoes impacts and vibrations during working, the support plate can buffer the impacts and vibrations of the drawing and extending roller die through the guide cylinder and the support plate in sliding fit with the fixedly installed spring seat and via buffering and resetting of the spring in the guide cylinder.

Owner:TAIYUAN HEAVY IND

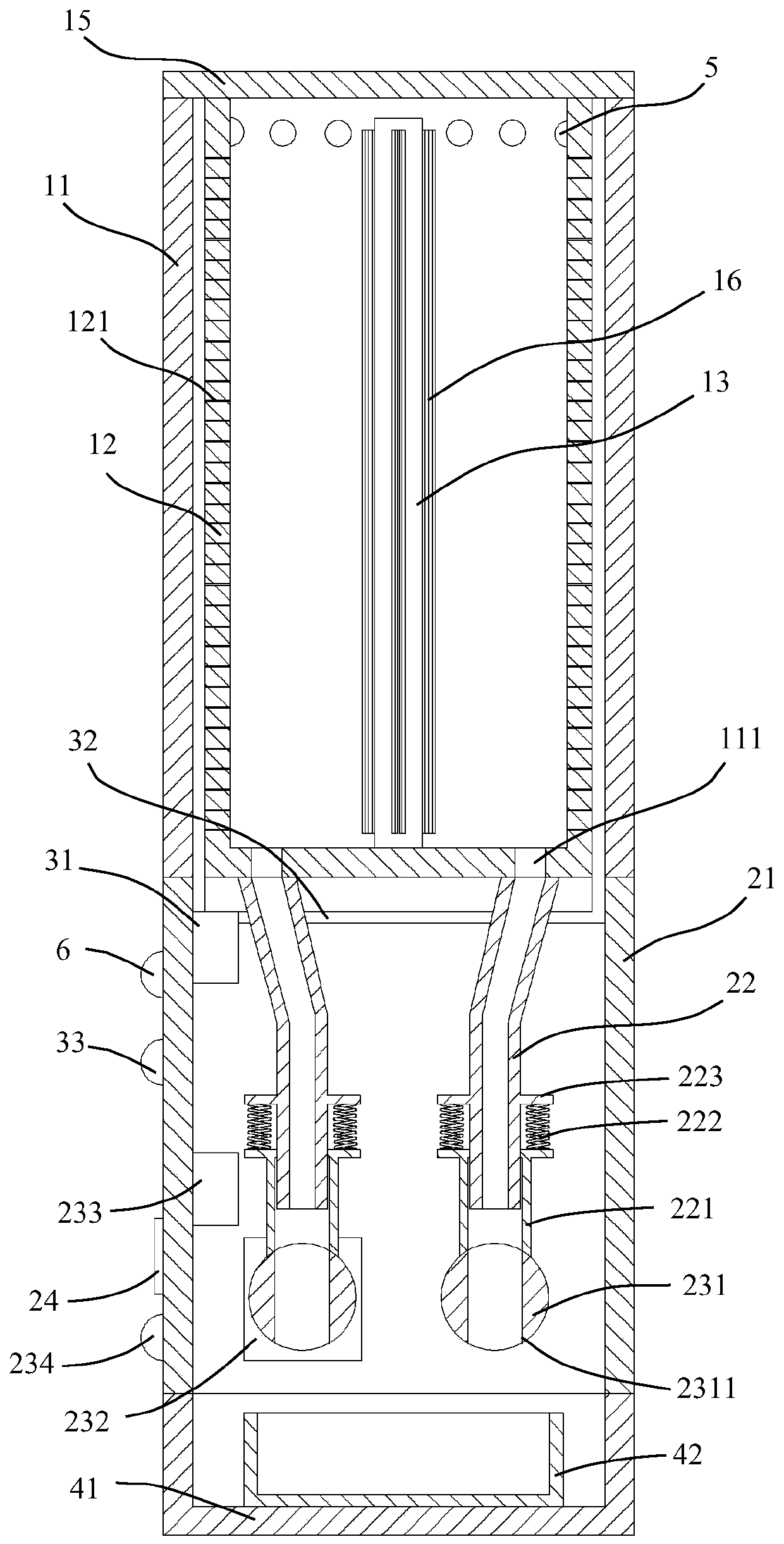

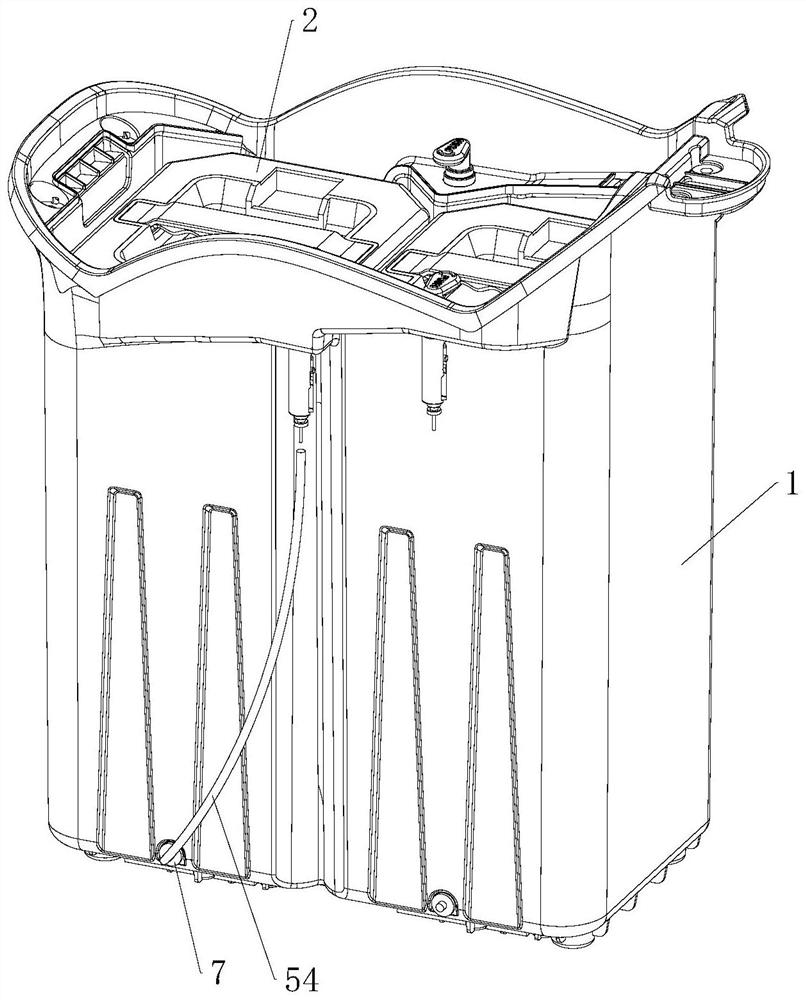

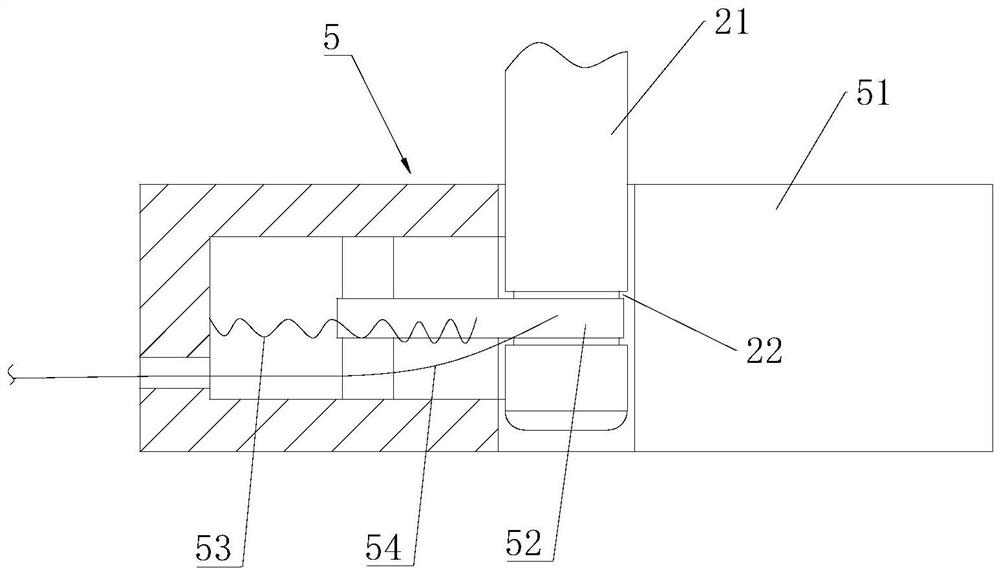

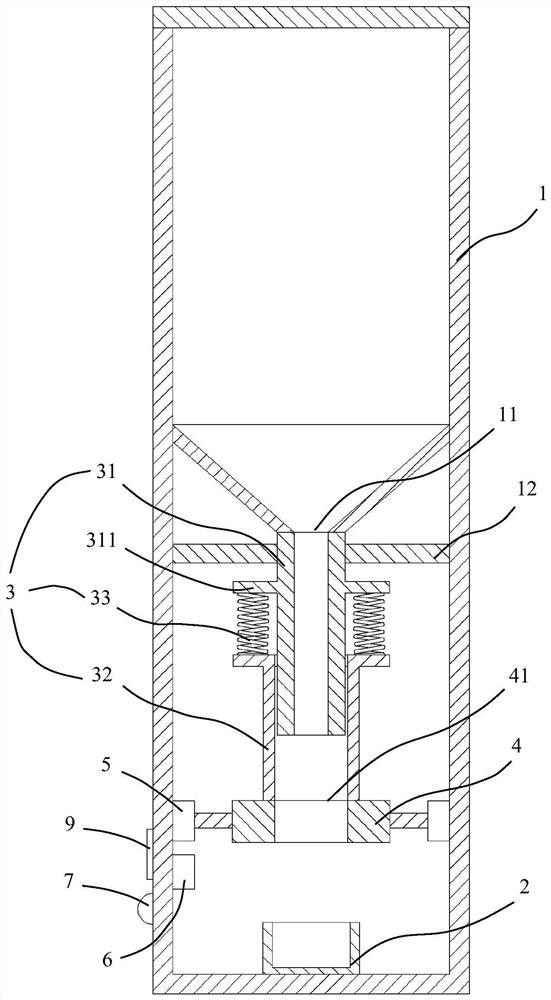

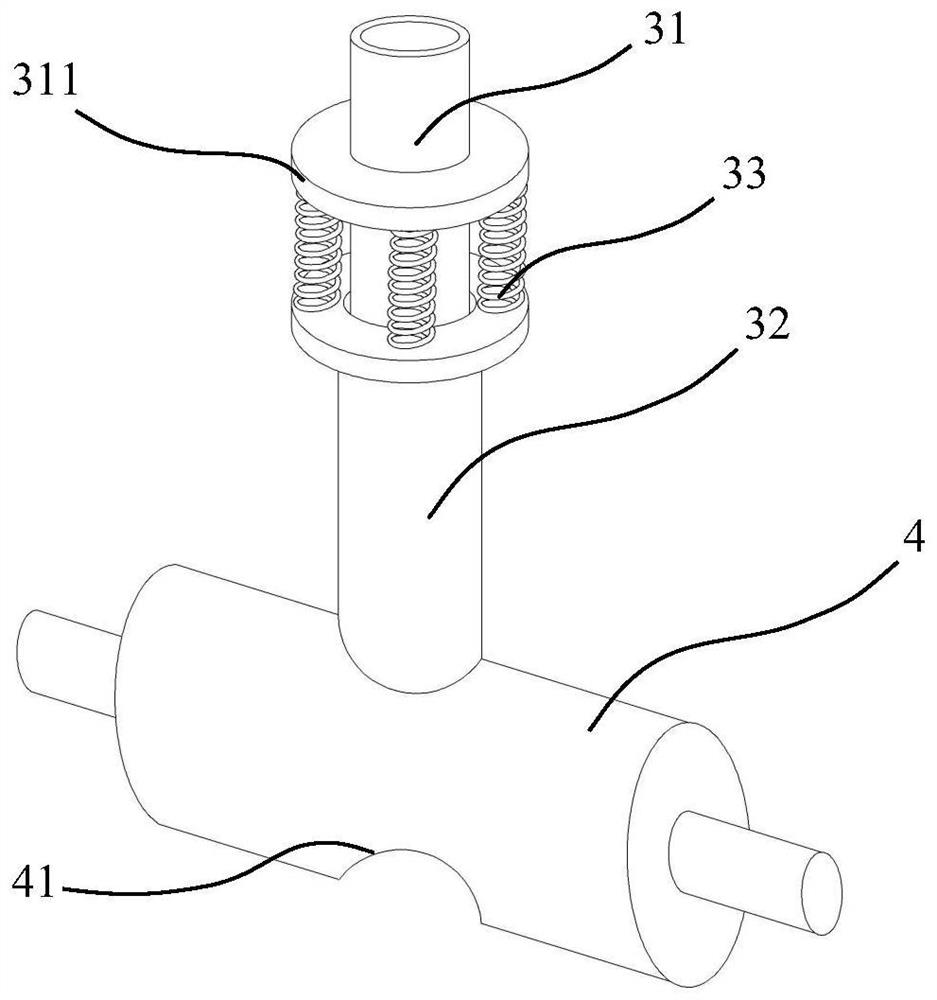

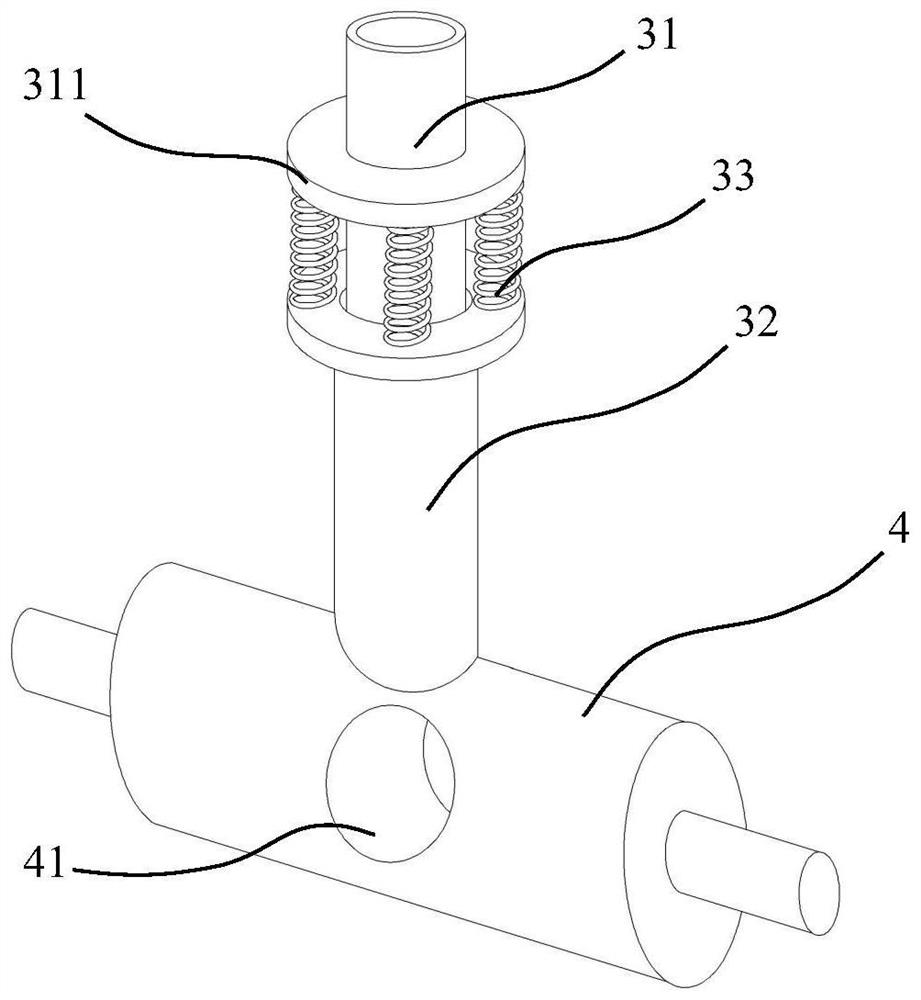

Intelligent rice storage barrel

ActiveCN110606262ARealize automatic rice outputFree adjustment of storage capacityLinings/internal coatingsContainers preventing decayAir pumpEngineering

The invention discloses an intelligent rice storage barrel comprising a rice storage part, a control part, an air supply part and a rice discharge part. The rice storage part comprises an outer barrel, an inner barrel, a stand column, insertion plates and a cover body. The control part comprises an enclosing plate, rice discharge pipes and an electronic control assembly. The air supply part comprises an air pump and an air pipe. The rice discharge part comprises a bottom box and a drawing box. According to the intelligent rice storage barrel, by regulating the insertion plates, the volume-adjustable multi-rice-bin function is achieved, various different types of grain can be stored in the rice storage barrel at the same time, and meanwhile, the storage capacity for the various types of grain can be freely regulated according to requirements; meanwhile, by means of control of the air supply part, ventilation treatment can be conducted on the inner portion, and the moisture prevention and insect prevention effects are good; and by means of control of the electronic control assembly, automatic rice discharge can be achieved for the different types of grain, the automation degree and the intellectualization degree are high, and use is convenient.

Owner:ZHEJIANG NORMAL UNIVERSITY

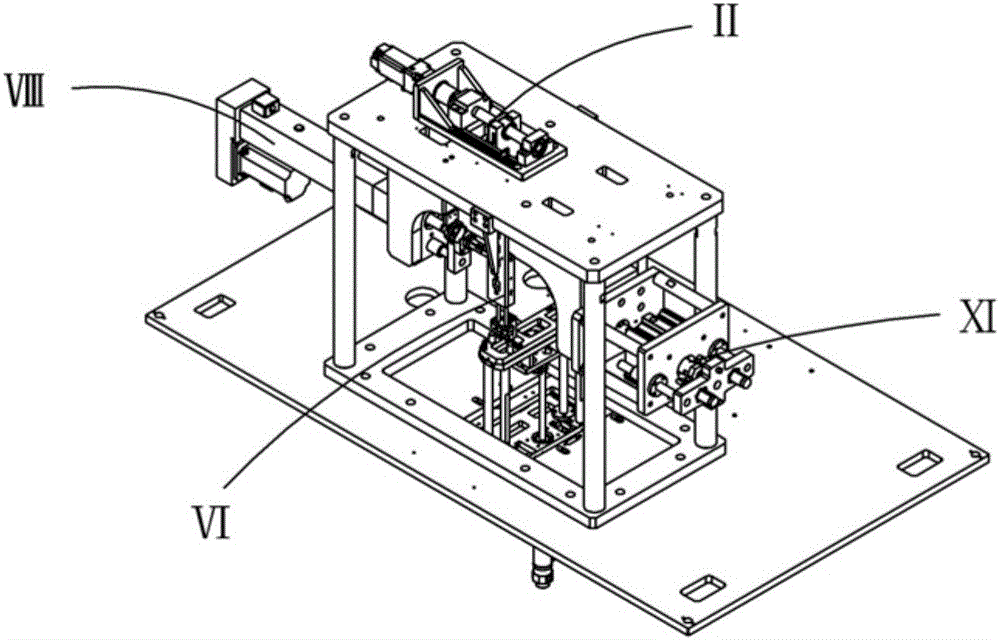

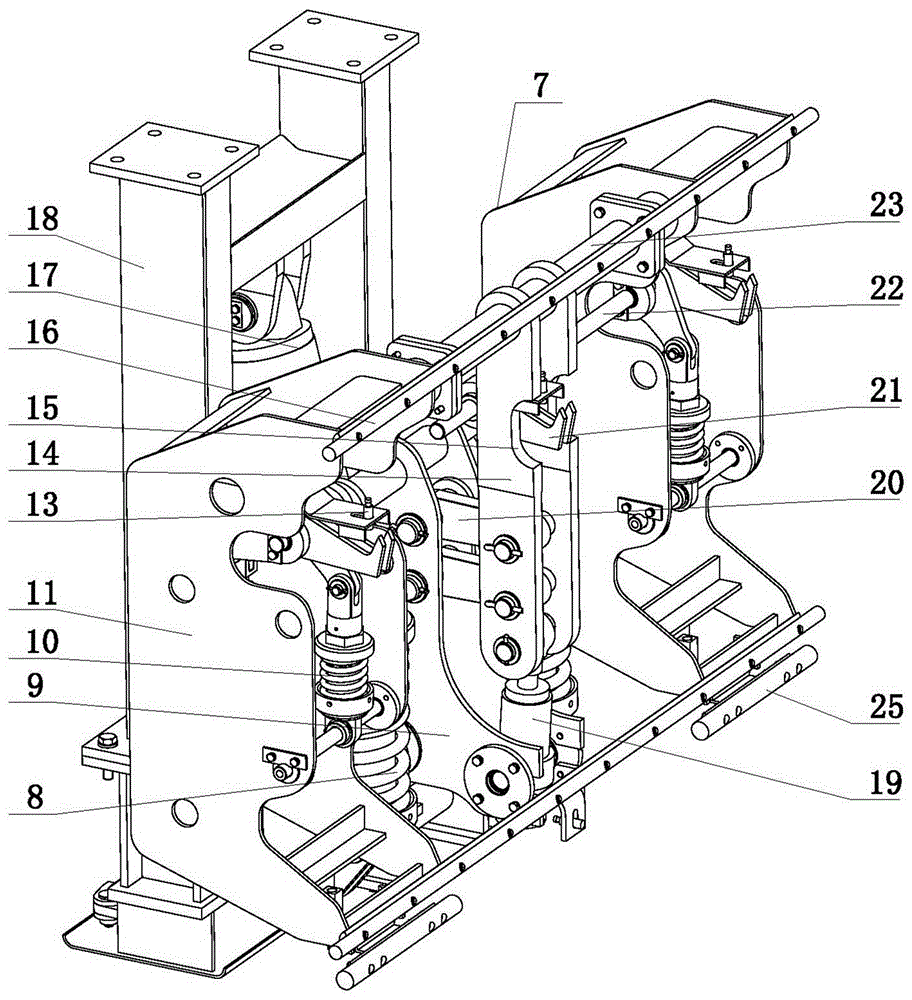

Double-stroke achieved jacking mechanism provided with connecting rod jacking device and pushing devices

ActiveCN107187857AEfficient and coherent movementCompact structureMetal working apparatusConveyor partsSoftware engineeringOblique angle

The invention relates to a double-stroke achieved jacking mechanism provided with a connecting rod jacking device and pushing devices. The connecting rod jacking device drives a left buoyancy needle installation base and a right buoyancy needle installation base to move upwards and is limited through limiting buffering screws, after limiting is carried out, the two sets of pushing devices synchronously drive corresponding pushing blocks to move along corresponding longitudinal sliding grooves, the oblique angle a on the rear side of the upper portion of each pushing block is in contact transition with the oblique angle b of the front side of the upper portion of the left buoyancy needle installation base and the right buoyancy needle installation base, as gaps exist between clamping blocks and groove holes of the clamping blocks, the left buoyancy needle installation base and the right buoyancy needle installation base continue to be pushed to ascend, the upper plane of each pushing block makes full contact with the lower plane of the left buoyancy needle installation base and the lower plane of the right buoyancy needle installation base, and then the riveting working procedure is carried out. The double-stroke achieved jacking mechanism solves the problems that under the situation that the space is limited, a conventional air cylinder mechanism cannot meet a gasket feeding height requirement and a jacking height requirement of a riveted 67 mm rivet at the same time, and space saving and efficient coherent actions are achieved by arranging the synchronous pushing devices.

Owner:BOZHON PRECISION IND TECH CO LTD

Partition-type farmhouse for breeding local chickens

The invention discloses a partition-type farmhouse for breeding local chickens. The partition-type farmhouse for breeding the local chickens comprises a baseplate, supporting legs are fixedly connected to the lower surface of the baseplate, and supporting plates are fixedly connected to the two sides of the upper surface of the baseplate; the outer walls of the two supporting plates are fixedly connected with the two sides of a connection plate respectively, a separation net is fixedly connected to the inner wall of the connection plate, and the two side faces of the separation net are fixedlyconnected with the opposite faces of the two supporting plates respectively; water pipes are fixedly inserted and connected into the two supporting plates. Through toothed grooves of the surfaces ofa hand wheel and a rotation rod, a movable ring conveniently rotates, a first toothed block is used for conveniently moving a thread rod for control in the up-down direction, the function of controlling a movable plate to move up and down is achieved, the angles of movable rods and a supporting net are conveniently adjusted, eggs clamped to the supporting net are conveniently moved, the function of sufficiently collecting the eggs is achieved, the rolling speed of the eggs can be controlled, and the eggs are not easily broken.

Owner:CHENXI XIANGLINBAO ECOLOGICAL POULTRY IND

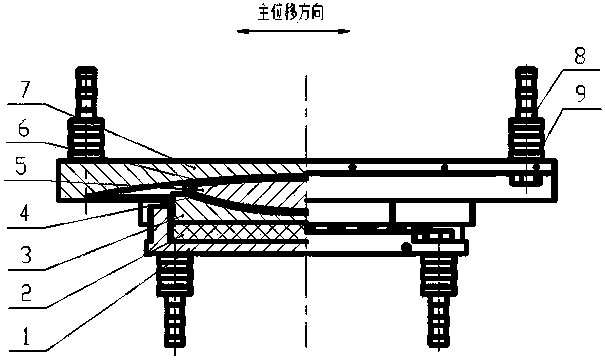

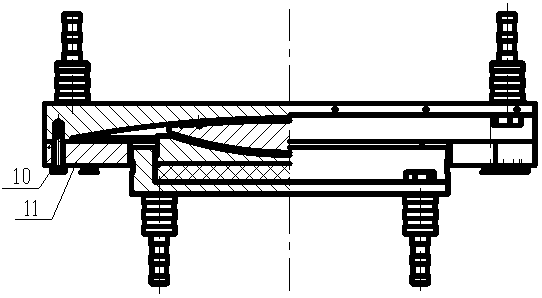

Pneumatic manipulator material receiving device

The invention provides a pneumatic manipulator material receiving device and belongs to the technical field of automatic lathes; the technical problems that workpieces are easy to damage during the material receiving process of a traditional material receiving device, and the material receiving performance of the traditional material receiving device is poorer are solved by the pneumatic manipulator material receiving device provided by the invention. The pneumatic manipulator material receiving device is arranged on a rack, and comprises a feed cover frame and a feed pipe, wherein the front part and the rear part of the feed cover frame are through; the feed pipe is arranged in the feed cover frame and can move in the feed cover frame; the top part of the feed pipe is connected with the feed cover frame; a notch is formed in the bottom part of the feed pipe, and a material receiving plate of which one end is hinged to the feed pipe is arranged in the notch, wherein the material receiving plate and the feed pipe can be opened and closed; a rolling shaft is arranged in the feed cover frame, and the material receiving plate is put on the rolling shaft; when the feed pipe moves on the feed cover frame, the material receiving plate moves on the rolling shaft, and the material receiving plate and the feed pipe are opened or closed. The pneumatic manipulator material receiving device provided by the invention has the beneficial effects during the falling process of the workpieces, the inertia of the workpieces is smaller, so that the impact between the workpieces is reduced; the friction between the workpieces and the material receiving plate is smaller, so that abrasion to the material receiving plate and the workpieces is smaller, and the service life of the material receiving plate is prolonged.

Owner:宁波宫铁智能科技有限公司

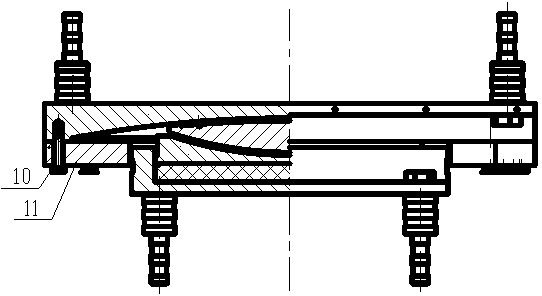

Electric vehicle battery mounting structure and electric vehicle

ActiveCN114537567AReduce pullingReduce connectivityCycle batteriesVehicular energy storageElectric-vehicle batteryElectrical battery

The electric vehicle battery mounting structure comprises a seat cask, a battery and a female seat, the battery is placed in the seat cask, the female seat comprises a connector integrally connected with a main wire harness and a fixing part arranged at the upper end of the connector, the lower end of the seat cask is concaved downwards to form a groove, a floating structure is arranged in the groove, and the floating structure is arranged in the groove. The fixing piece is fixed on the floating structure, and the connector is located below the floating structure; the lower end of the battery is provided with a male head inserted into the upper portion of the fixing piece. The floating structure drives the connector to synchronously float up and down along with the bumping of the battery, so that the connector is always in plugging connection with the male connector, and the phenomenon of loose connection or short circuit is reduced; meanwhile, the pulling of the main wire harness can be reduced.

Owner:台铃科技(江苏)股份有限公司

Damping and shock insulating spherical fixing support

InactiveCN104088222AHigh coefficient of frictionIncrease coefficient of frictionBridge structural detailsShock proofingSlide plateEngineering

The invention discloses a damping and shock insulating spherical fixing support which comprises a lower support plate, an upper support plate, anchor bolts, sleeves as well as guide plates and shearing bolts, wherein a damping rubber plate, a spherical concave liner plate, a spherical surface sliding plate, a spherical crown liner plate and a damping sliding plate are further sequentially arranged from bottom to top between the lower support plate and the upper support plate; the damping sliding plate and the spherical surface sliding plate are respectively adhered to the upper and lower sides of the spherical crown liner plate; four sets of guide plates and shearing bolts are provided; the guide plates are fixed at the front, rear, left and right ends of the upper support plate through the shearing bolts. Due to adoption of the damping rubber plate on the lower support plate, the vertical kinetic energy of a bridge is converted into potential energy and heat energy of the bridge itself in earthquake, and then the impact of components of the support is alleviated; as the guide plates are fixed on the upper support plate through the shearing bolts, if the shearing bolts are cut off, the support can be recovered to a normal use state by only replacing the shearing bolts and resetting the guide plates.

Owner:CHENGDU XINZHU ZHUANBO ENVIRONMENTAL PROTECTION TECH

Impact mitigation traffic guardrail device

ActiveCN108086200AReduce hard impactAvoid damageRoadway safety arrangementsRolloverImpact mitigation

Disclosed is an impact mitigation traffic guardrail device. A plurality of through holes are formed in a base, and bolts, screws and other objects can be fixed on a plane; the interior of a protectiondevice is provided with a force-resilient space, and a sealed type force-receiving mechanism is installed inside the force-resilient space; one end of the force-resilient space is provided with a force-receiving medium inlet and outlet which is the same structure with the force-resilient space, and a force-receiving medium access hole and a sealing switch which are connected with the outside andthe force-resilient space are disposed inside the force-receiving medium inlet and outlet; and a medium discharge mechanism which is the same structure with the force-resilient space is disposed abovethe force-resilient space. According to the impact mitigation traffic guardrail device, the protection device can be used for reducing the hard impact between a vehicle and a guardrail, and under theaction of the protection device, the guardrail can obtain a certain amount of resilient space, so as to reduce the damage of the hard impact in a traffic accident to the vehicle and people in the vehicle; and meanwhile, the certain amount of resilient space can reduce the chance of vehicle rollover under the hard impact and maximize the safety of personnel.

Owner:徐州科聚利鑫机械设备制造有限公司

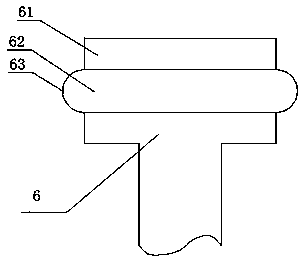

Material receiving device

InactiveCN109940443AExtended service lifeAvoid damageMetal working apparatusEngineeringMechanical engineering

The invention provides a material receiving device and belongs to the technical field of automatic lathes. The material receiving device solves the technical problems that when an existing material receiving device is used in the material receiving process, a workpiece is easy to damage, and the material receiving performance of the existing material receiving device is poor. The material receiving device is installed on a machine frame and comprises a material cover frame and a material pipe, wherein the material cover frame is arranged in a front-and-back communicating mode, and the materialpipe is arranged in the material cover frame and can move in the material cover frame. The top of the material pipe is connected with the material cover frame. A notch is formed in the bottom of thematerial pipe. A material receiving plate is arranged in the notch, wherein one end of the material receiving plate is hinged to the material pipe and can be opened or closed together with the material pipe. A roller shaft is arranged in the material cover frame, and the material receiving plate is arranged on the roller shaft. When the material pipe moves on the material cover frame, the materialreceiving plate moves on the roller shaft, and the material receiving plate and the material pipe are enabled to be opened or closed. The material receiving device has the beneficial effects that inthe falling process of workpieces, the inertia of the workpieces is small, the impact between the workpieces is reduced, the friction between the workpieces and the material receiving plate is small,the abrasion of the material receiving plate and workpieces is small, and the service life of the material receiving plate is prolonged.

Owner:王芳

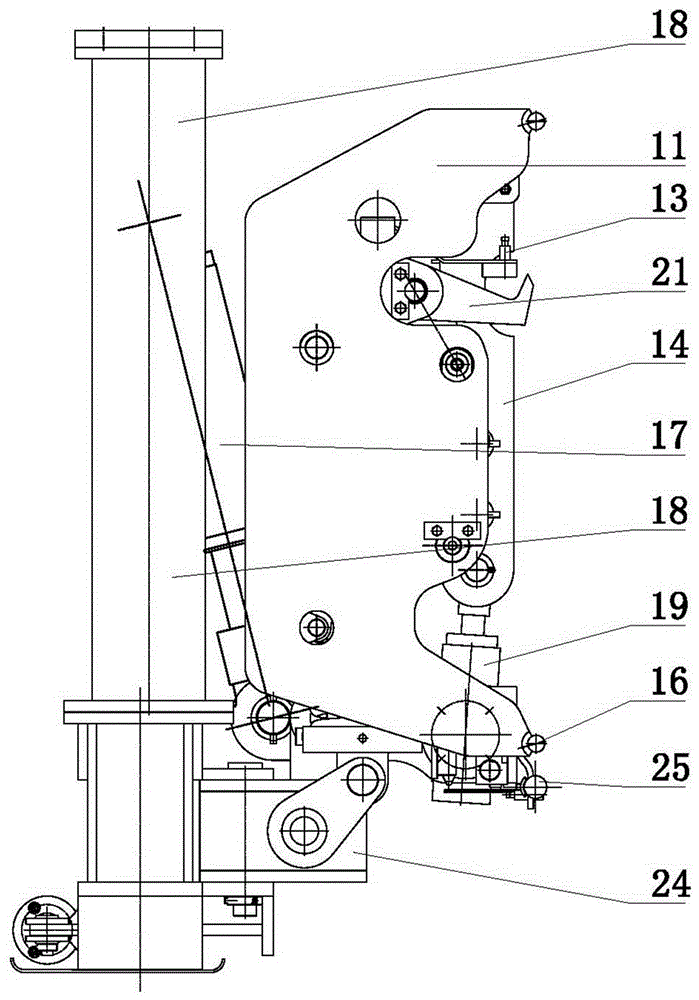

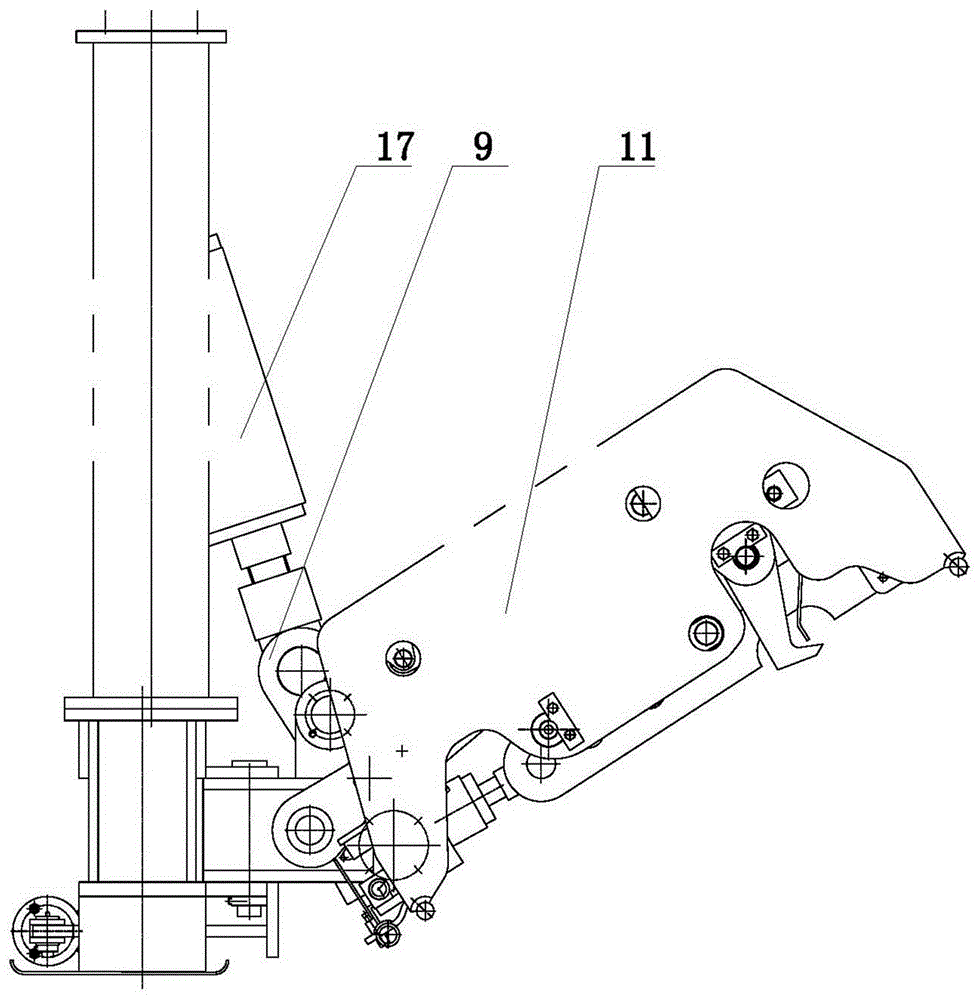

Clamp device for opening electrolytic cell cover plate

The invention discloses a clamp device for opening an electrolytic cell cover plate, and belongs to the technical field of metallurgical machinery, and particularly relates to a cell cover plate gripping device. The invention provides the clamp device for opening the electrolytic cell cover plate, and the clamp device does not need manual operation, is convenient to use, and is high in efficiency. The clamp device comprises a clamp fixed mount, wherein a clamp body is arranged on the clamp fixed mount. The clamp device is characterized in that the lower end of the clamp fixed mount is hinged with a swing regulating base; the clamp body comprises an opening-closing drive device connected to the clamp fixed mount, wherein the end part of the opening-closing drive device is hinged with one end of the lower part of a specially-shaped frame; the middle position of the lower part of the specially-shaped frame is hinged with the swing regulating base; and the other end of the lower part of the specially-shaped frame is hinged with a moving drive device.

Owner:NFC (SHENYANG) METALLURGICAL MACHINERY CO LTD

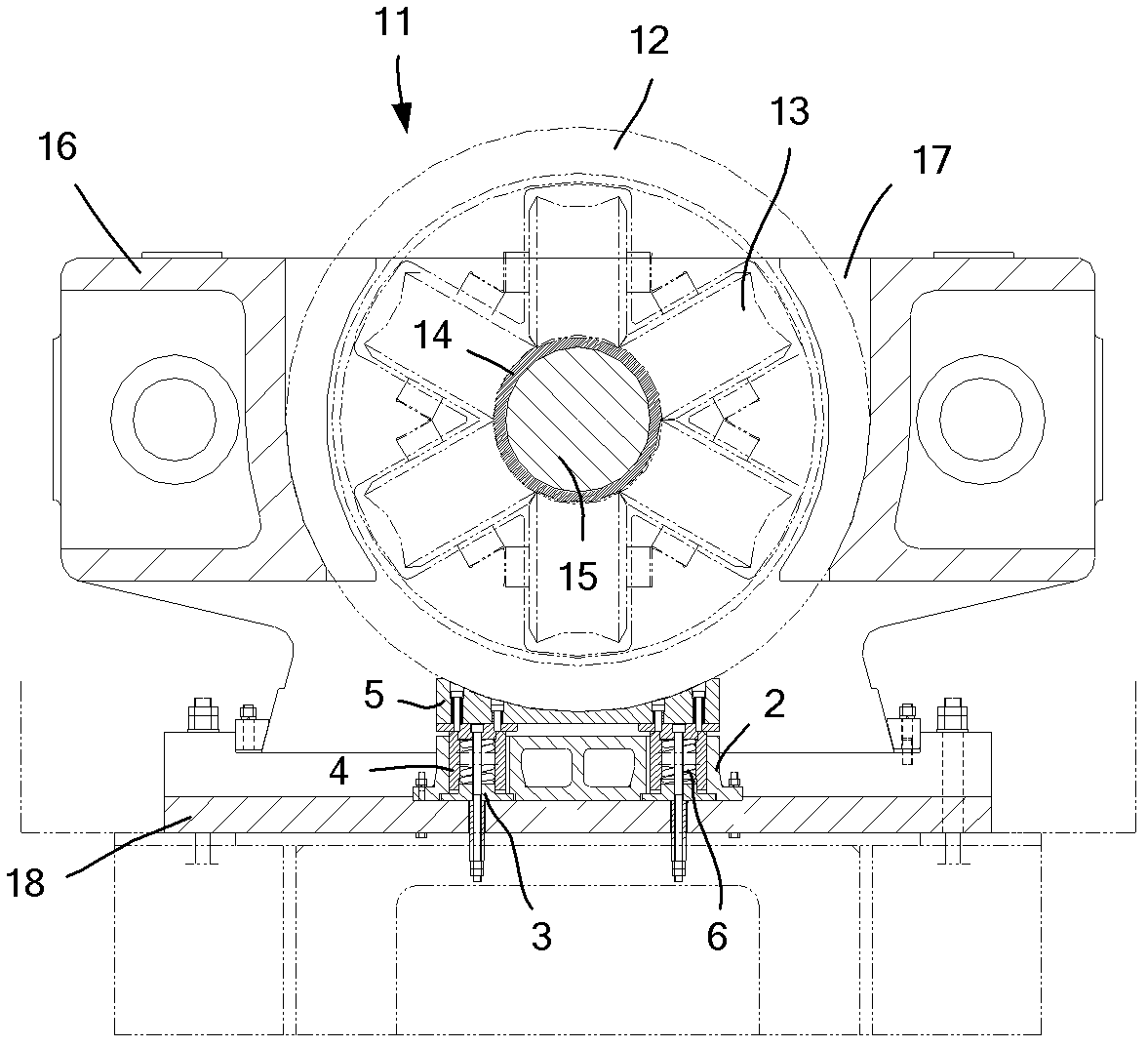

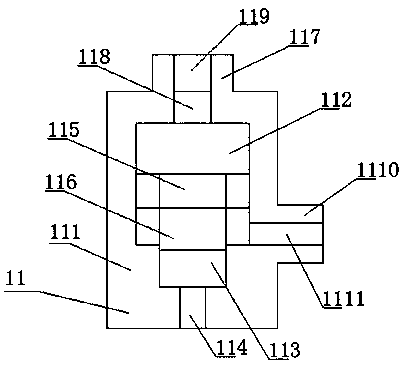

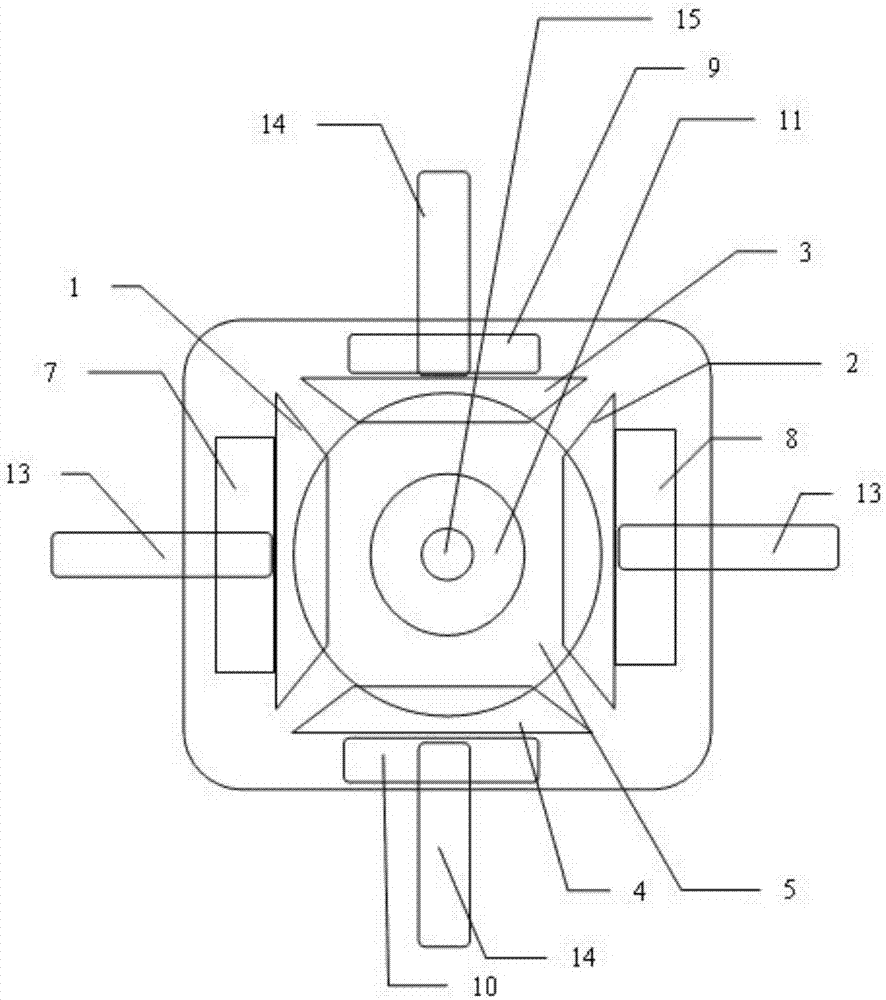

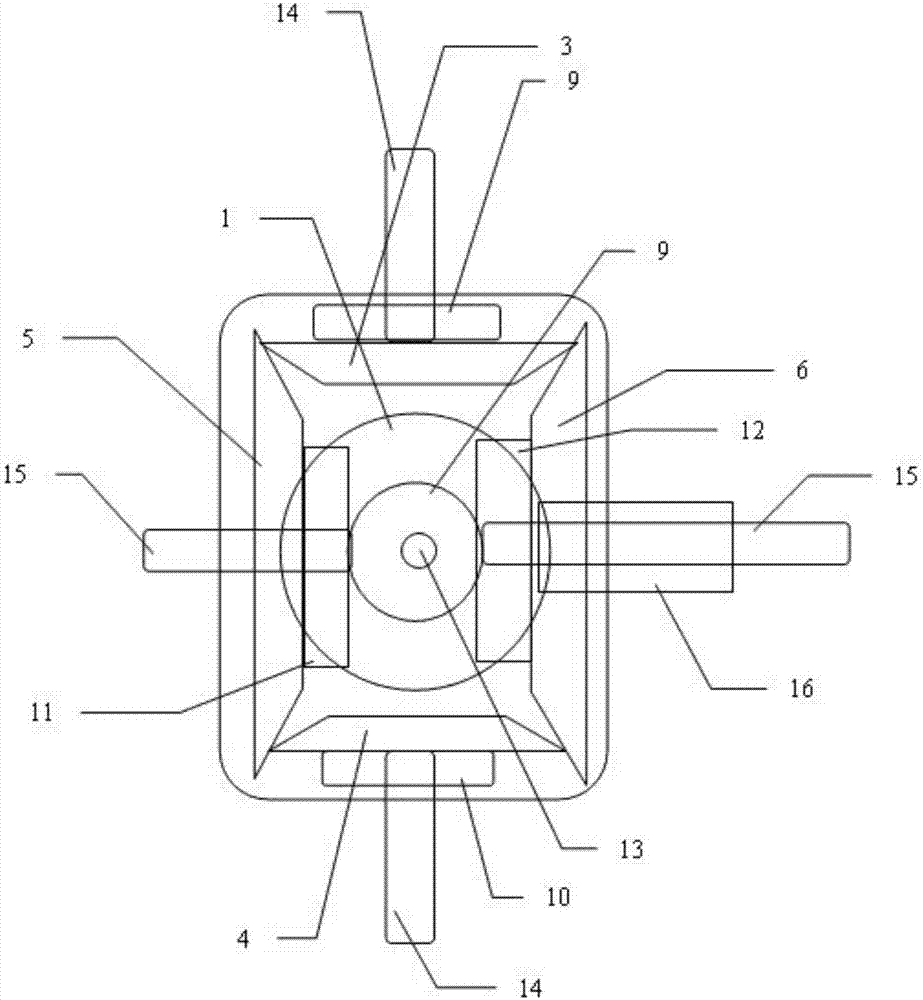

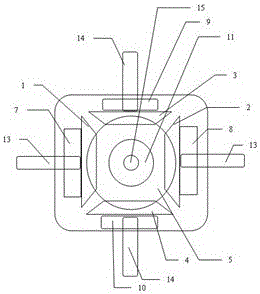

Unidirectional conversion device and power system provided with same

ActiveCN107250536AExtended service lifeLow costMachines/enginesEngine componentsEngineeringPower load

Disclosed is a unidirectional conversion device (22). The unidirectional conversion device (22) comprises a power output part and power selected from at least one of a first swinging input shaft (13) for receiving front and rear swinging power, a second swinging input shaft (14) for receiving left and right swinging power and a third swinging input shaft (15) for receiving horizontal swinging power. Further disclosed is a power system including the unidirectional conversion device; the power system comprises one or more unidirectional conversion devices (22); the plurality of unidirectional conversion devices (22) are combined as a whole by means of sharing the swinging input shafts; the unidirectional conversion devices are connected to one or more swinging devices and / or are arranged on the swinging devices; and the power output part is connected to a power load. The unidirectional conversion device and the power system provided with the device can absorb swinging power from different directions simultaneously and have advantages such as high conversion efficiency, high stability, and wide range of applicability.

Owner:吴钦发

Quantitative rice discharging device of intelligent rice storage bucket

The invention discloses a quantitative rice discharging device of an intelligent rice storage bucket. The quantitative rice discharging device of the intelligent rice storage bucket in the invention comprises a rice outlet pipe, a rotating shaft, a stepping motor, a controller, an electric button and a power supply; the rice outlet pipe is vertically arranged; furthermore, the top of the rice outlet pipe is communicated with a rice outlet; two ends of the rotating shaft are rotatably connected with the side wall of a rice bin; furthermore, the shaft body of the rotating shaft is fit to the edge of the pipe mouth at the bottom of the rice outlet pipe; a radial through hole is formed in the shaft body of the rotating shaft; the through hole is communicated with the rice outlet pipe; the stepping motor is fixed on the inner wall of the rice bin; furthermore, the power output shaft is connected with one end of the rotating shaft; the controller is fixed on the inner wall of the rice bin, and electrically connected with the stepping motor; the electric button is arranged on the outer wall of the rice bin, and electrically connected with the controller; and the power supply is respectively connected with the stepping motor and the controller electrically. According to the quantitative rice discharging device of the intelligent rice storage bucket in the invention, rotation of the rotating shaft is controlled, so that closing and opening of the rice outlet pipe are realized; the rice outlet amount can be controlled by controlling the starting time; operation is simple; the controleffect is good; the rice discharging amount can be precisely measured; and starting is convenient.

Owner:ZHEJIANG NORMAL UNIVERSITY

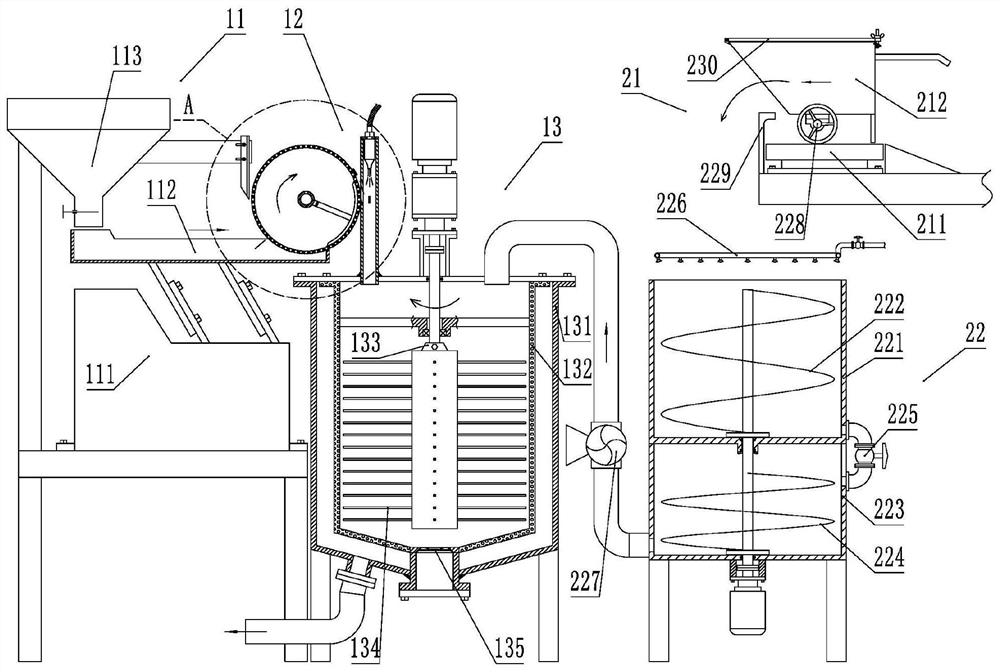

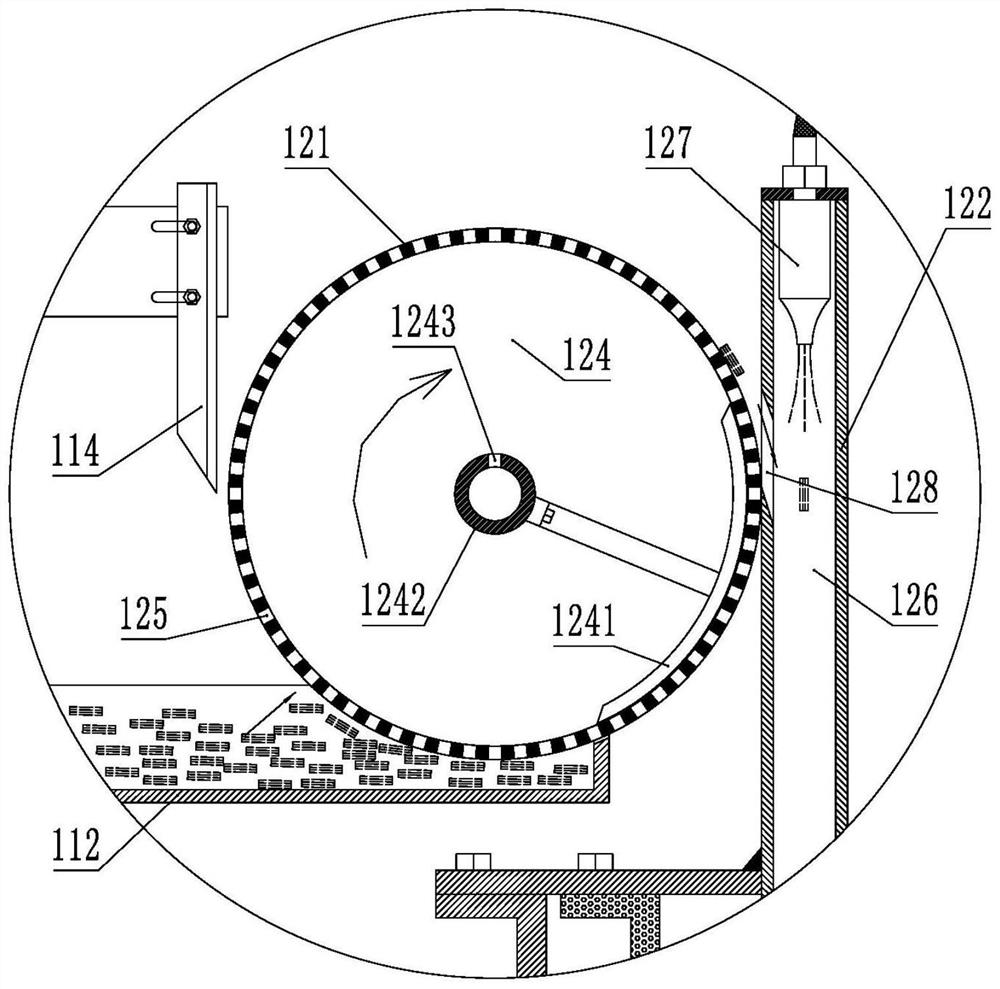

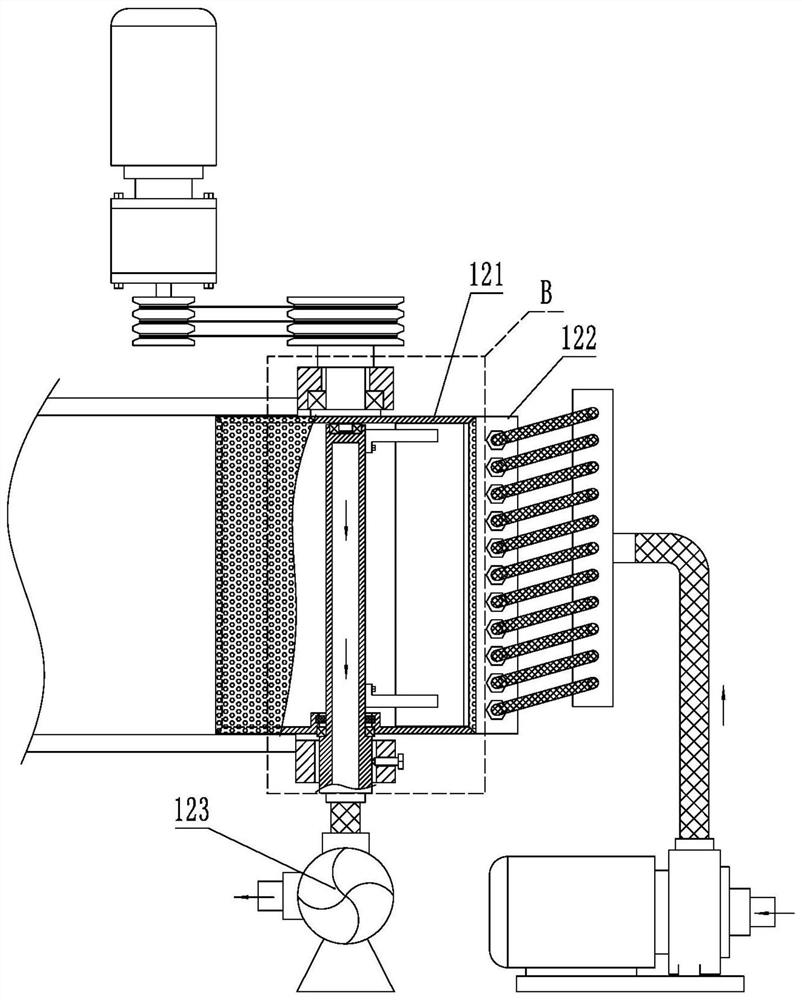

Mica production equipment with leftover material recovery treatment

ActiveCN112064403AGuaranteed aspect ratioReduce formationMixing methodsTransportation and packagingPapermakingProcess engineering

The invention provides mica production equipment with leftover material recovery treatment, and relates to the technical field of mica papermaking. The mica production equipment comprises a vibrationfeeding device, a stripping and crushing device, a flexible impact pulping device, a weighing and feeding device and a secondary stirring device. The vibration feeding device comprises a vibrator, a feeding disc and a feeding hopper. The stripping and crushing device comprises a roller and a stripping shell; a negative-pressure cavity is formed in the roller, and a negative-pressure air suction port is formed in the outer circle of the roller; and a stripping cavity and a pressure water nozzle are arranged in the stripping shell in the tangential direction of the outer circle of the roller, and a long and narrow feeding port is formed in the side of the stripping shell. The flexible impact pulping device comprises an outer pulping barrel, an inner pulping filtering barrel and a rotating shaft, and a flexible strip is arranged on the rotating shaft. The weighing and feeding device is used for weighing and feeding. The second-stage stirring device comprises an upper-layer stirring barreland a lower-layer stirring barrel, and slurry the bottom of the lower-layer stirring barrel is conveyed to the inner pulping filtering barrel through a slurry pump. The invention aims to obtain slurry of high-grade mica fines and recycle leftover materials of mica paper for pulping.

Owner:平江县惠源云母制品有限公司

Unidirectional conversion device and power system comprising same

InactiveCN105952599AExtended service lifeHigh mechanical conversion efficiency of energy harvestingMachines/enginesEngine componentsNatural disasterFlywheel

The invention discloses a unidirectional conversion device and a power system comprising the same. According to the unidirectional conversion device, the problems that the recycling efficiency of irregular power sources is low, the structure is complex, the cost is high, and the natural disaster resistance ability is poor in the prior art are mainly solved. The unidirectional conversion device is characterized in that the unidirectional conversion device is provided with a plurality of swing input shafts and combined with overrun clutches and gears to convert swing power sources coming from the different directions into kinetic energy which unidirectionally rotates at the constant speed in a mechanical transmission mode under the action of inertia fly wheels, and accordingly unidirectional stable and rotary power is produced and drives power loading parts to work.

Owner:吴钦发

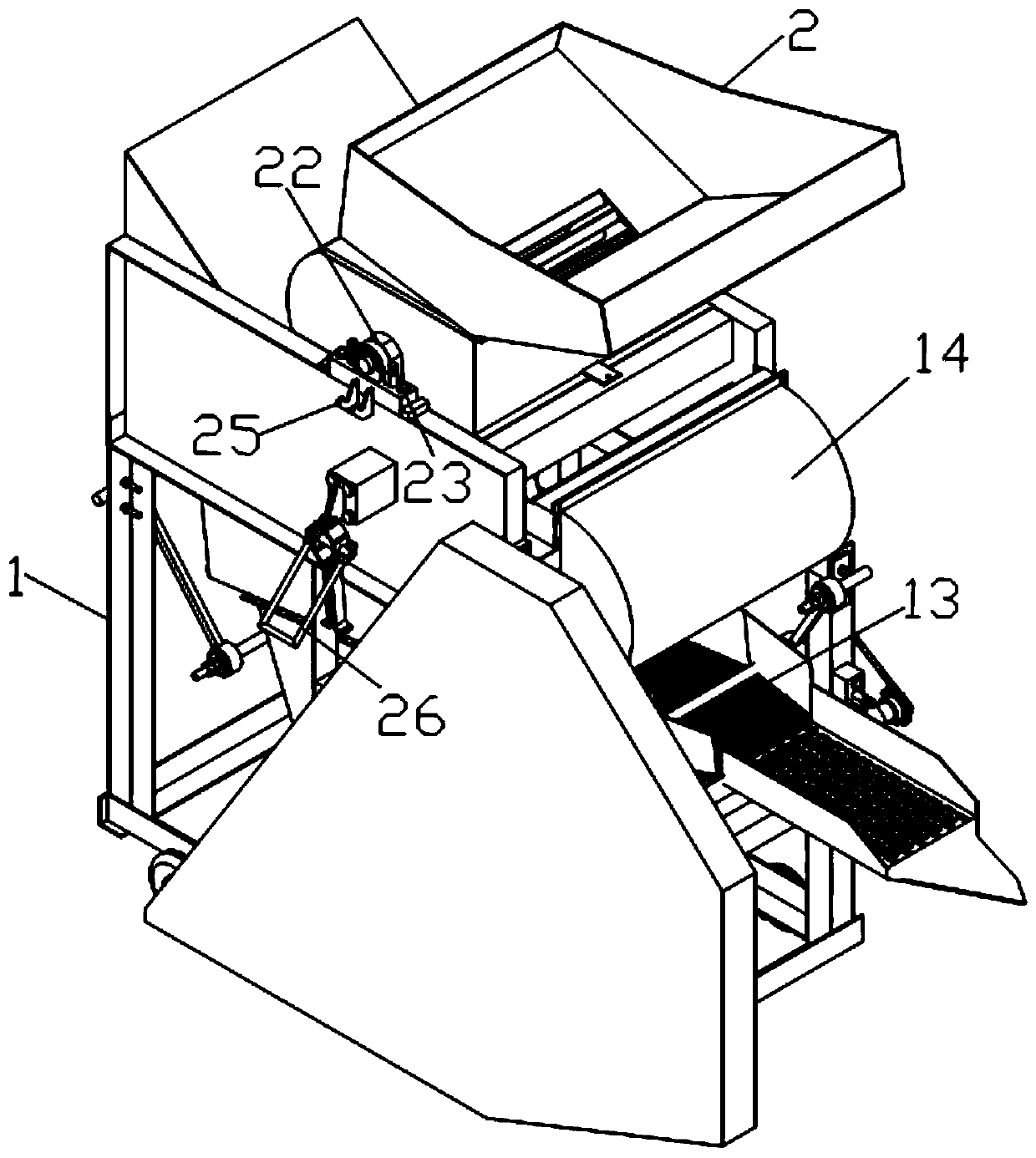

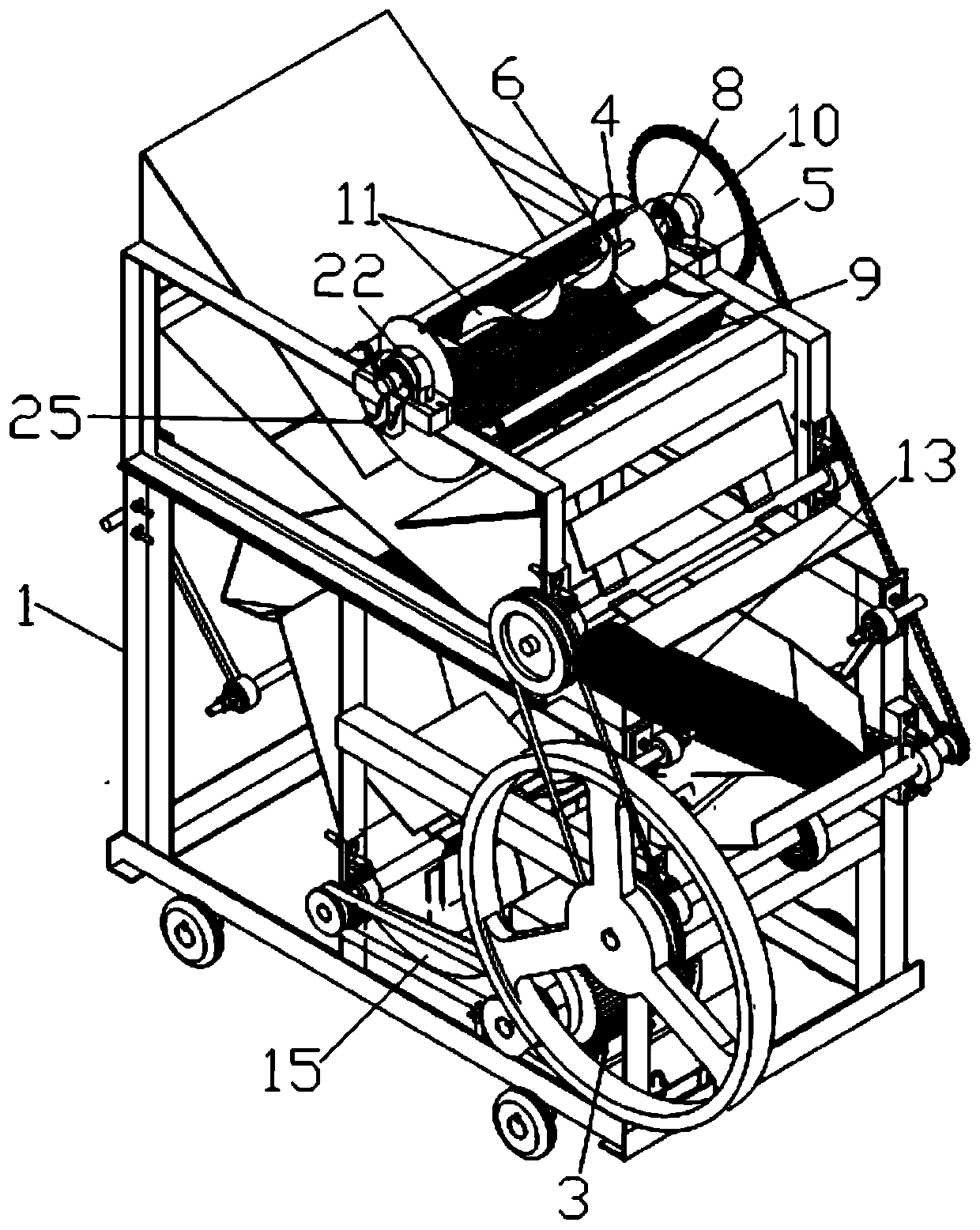

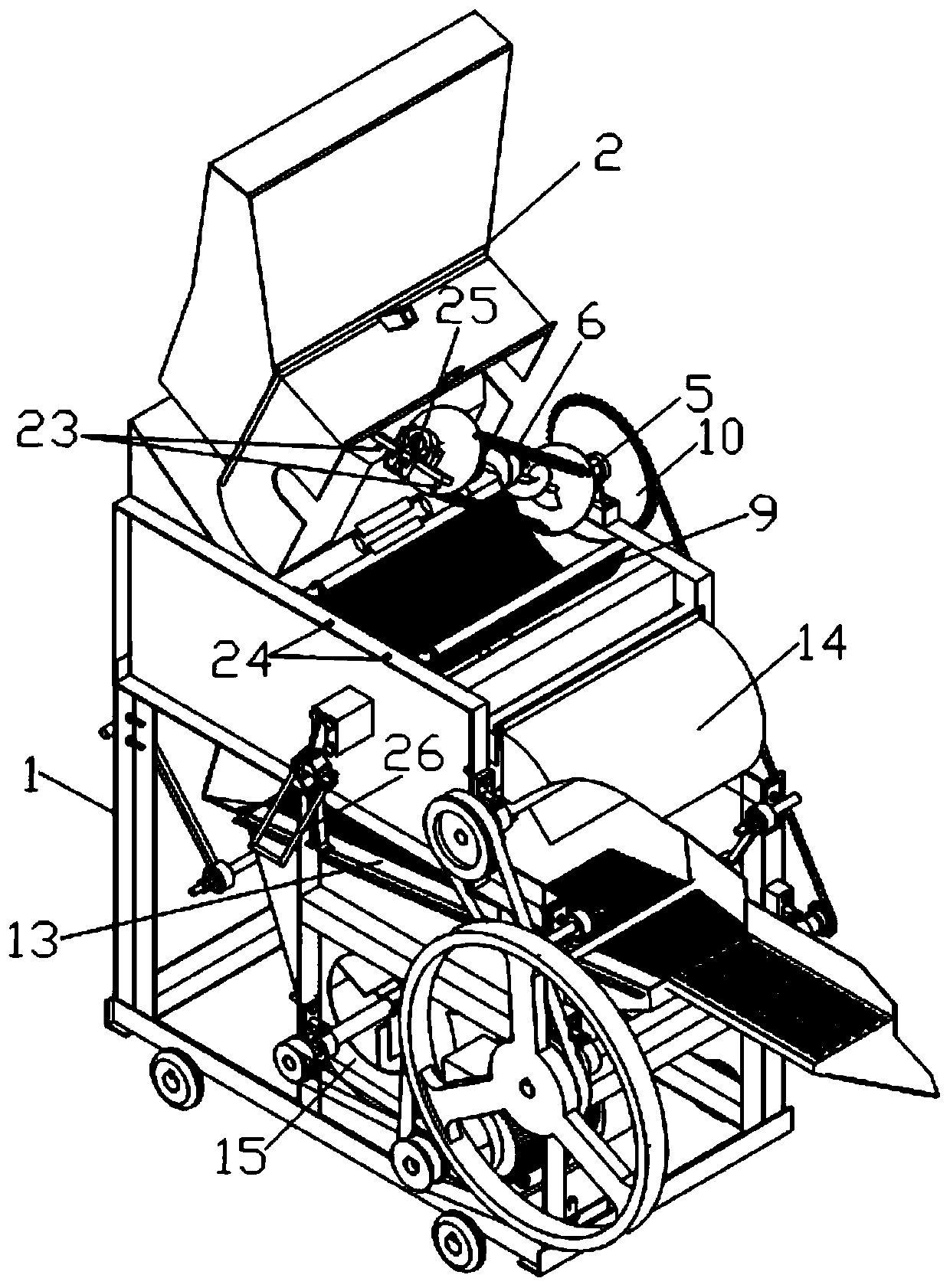

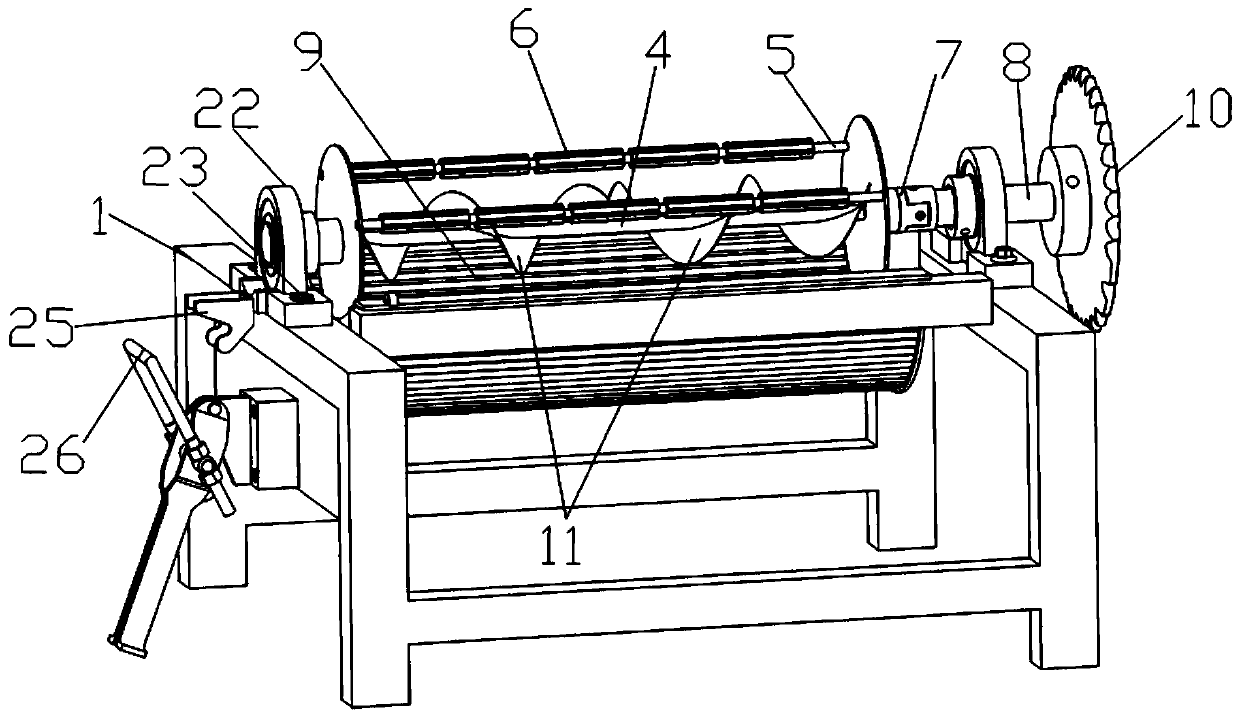

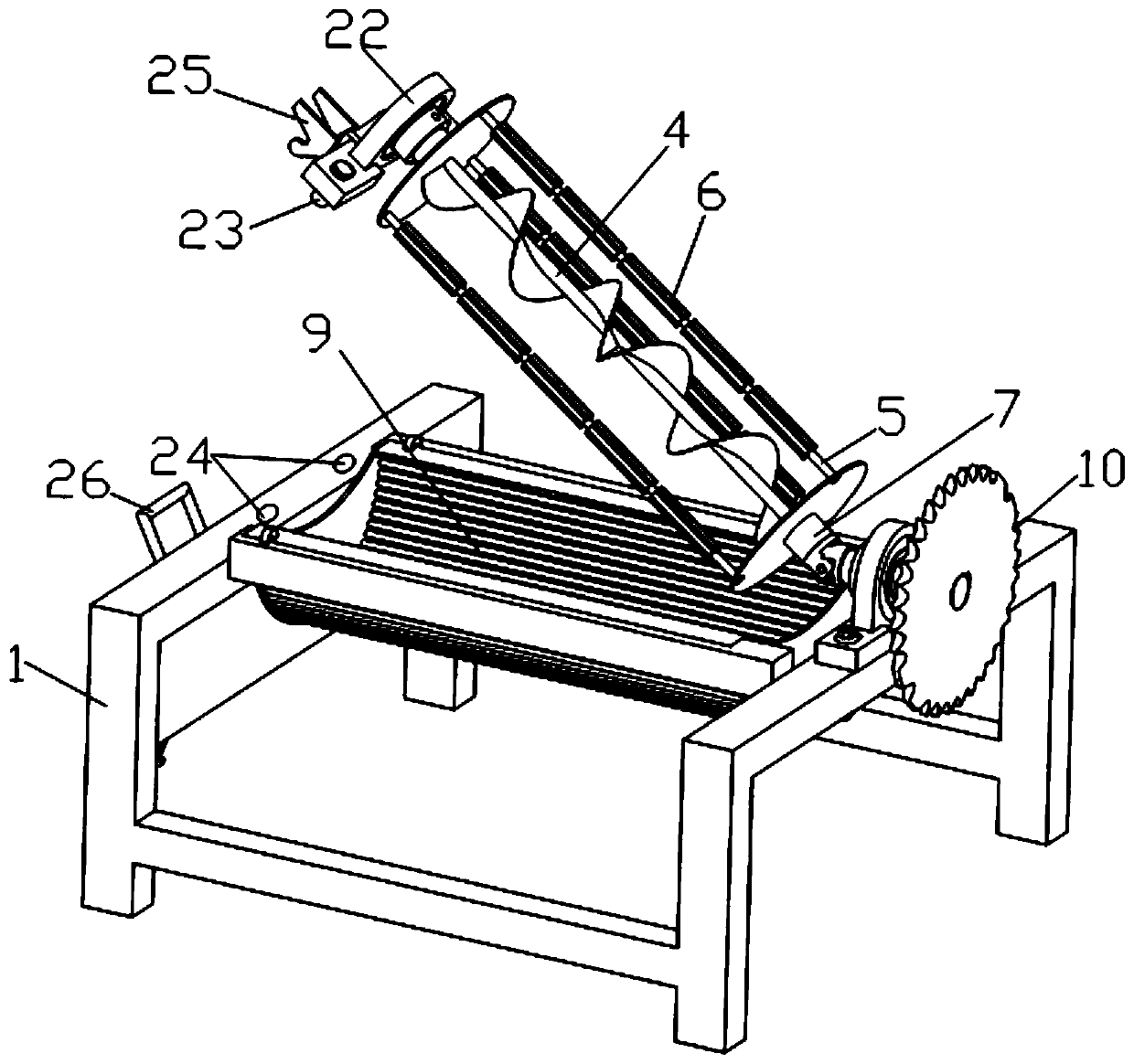

Peanut seed sheller

PendingCN111183799AIncrease the burden of differentiationRich varietySievingGas current separationAgricultural engineeringEngineering

The invention discloses a peanut seed sheller, and belongs to the technical field of peanut seed shellers. The peanut seed sheller comprises a rack, a feed hopper which is arranged on the rack, a peanut shelling device, a kernel / shell winnowing and separation device, a driving motor and a transmission device; the outer wall of the feed hopper is hinged with the rack; the peanut shelling device isarranged below the feed hopper through the rack and comprises a shelling structure, a replication structure and a peanut shell / kernel uniform distribution structure; the shelling structure comprises aroller and an arc-shaped screen body; the roller comprises a roller shaft and a plurality of rubbing columns; each rubbing column comprises a column core and a nylon sleeve; the inner holes of the nylon sleeves are connected with the column cores in a sliding matching manner; a plurality of grooves are radially formed in the column surfaces of the nylon sleeves; the grooves are uniformly arrangedalong the circumferences of the column surfaces of the nylon sleeves; and the replication structure comprises a cross joint type universal coupling and a short shaft which is connected with the crossjoint type universal coupling end to end. The peanut seed sheller has the advantages of being convenient to clean the sundries of arc-shaped screens, causing less damages to the peanut seed kernels and the skins of the peanut seed kernels in the shelling process, and being high in efficiency of obtaining high-quality peanut seeds.

Owner:HEBEI AGRICULTURAL UNIV. +1

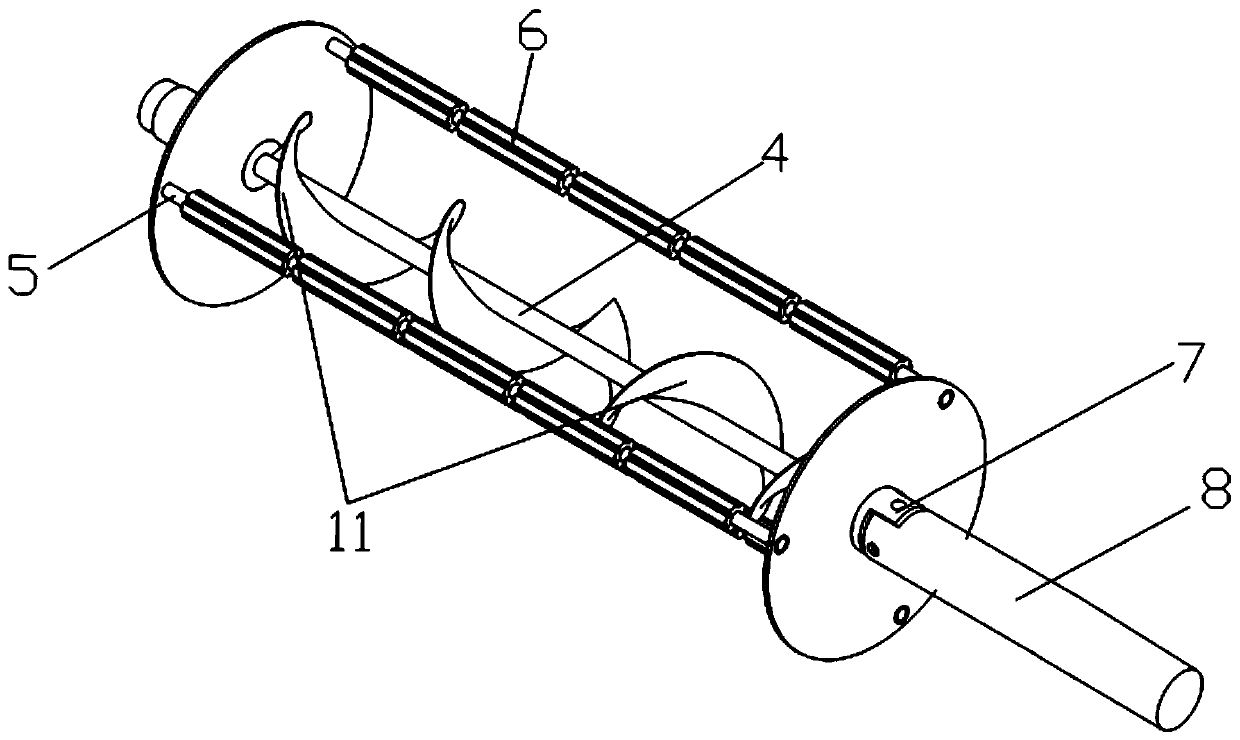

Peanut shelling device for peanut seed shelling machine

PendingCN111183798AIncrease the burden of differentiationRich varietyGas current separationSeed and root treatmentSpiral bladeAgricultural engineering

The invention discloses a peanut shelling device for a peanut seed shelling machine, and belongs to the technical field of peanut shelling machines. The peanut shelling device includes a shelling structure, a turning structure and an uniform distribution structure of peanut pods. The shelling structure includes a roller and an arc-shaped sieve body. The roller includes a roller shaft and a plurality of rubbing columns, each rubbing column includes a column core and a nylon sleeve. The inner hole of the nylon sleeve is slidably connected with the column core, and a plurality of grooves are provided radially on the cylindrical surface of the nylon sleeve, and each groove is evenly distributed along the circumferential direction of the cylindrical surface of the nylon sleeve. The turning structure includes a cross shaft universal coupling and a short shaft connected from end to end. The uniform distribution structure of peanut pods includes two spiral blades symmetrically arranged on theroller shaft. The rotation direction of the two spiral blades causes the peanut pods to be pushed from the middle to both ends, and the pitch of the two spiral blades gradually increases from the inner end to the outer end. The device has the advantages of being convenient for cleaning the debris of the arc-sieve, thereby causing less damage to the peanut seed kernel and the peanut seed red coat during the shelling process and obtaining high-quality peanut seeds with high efficiency.

Owner:HEBEI AGRICULTURAL UNIV. +1

A quantitative rice loading device for an intelligent rice storage bucket

ActiveCN110419968BAchieve closureAccurate measurementKitchen equipmentElectric machineAgricultural engineering

The invention discloses a quantitative rice discharging device of an intelligent rice storage bucket. The quantitative rice discharging device of the intelligent rice storage bucket in the invention comprises a rice outlet pipe, a rotating shaft, a stepping motor, a controller, an electric button and a power supply; the rice outlet pipe is vertically arranged; furthermore, the top of the rice outlet pipe is communicated with a rice outlet; two ends of the rotating shaft are rotatably connected with the side wall of a rice bin; furthermore, the shaft body of the rotating shaft is fit to the edge of the pipe mouth at the bottom of the rice outlet pipe; a radial through hole is formed in the shaft body of the rotating shaft; the through hole is communicated with the rice outlet pipe; the stepping motor is fixed on the inner wall of the rice bin; furthermore, the power output shaft is connected with one end of the rotating shaft; the controller is fixed on the inner wall of the rice bin, and electrically connected with the stepping motor; the electric button is arranged on the outer wall of the rice bin, and electrically connected with the controller; and the power supply is respectively connected with the stepping motor and the controller electrically. According to the quantitative rice discharging device of the intelligent rice storage bucket in the invention, rotation of the rotating shaft is controlled, so that closing and opening of the rice outlet pipe are realized; the rice outlet amount can be controlled by controlling the starting time; operation is simple; the controleffect is good; the rice discharging amount can be precisely measured; and starting is convenient.

Owner:ZHEJIANG NORMAL UNIVERSITY

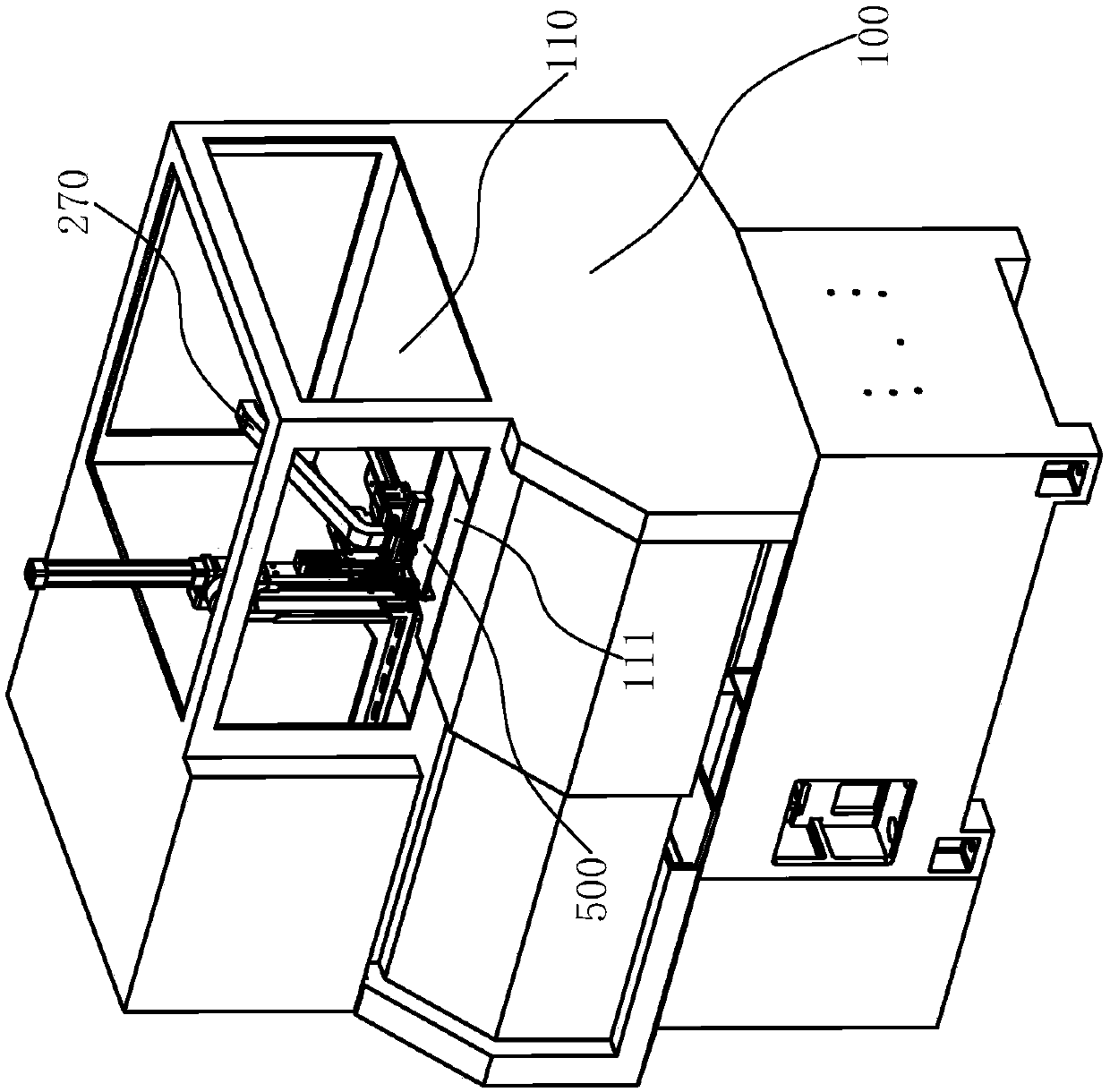

Pneumatic machining equipment

InactiveCN109940440AShort tripSave feeding timeMetal working apparatusMaintainance and safety accessoriesManipulatorMachining

The invention provides pneumatic machining equipment, belongs to the technical field of automatic lathes, and solves the technical problems of long travel of a pneumatic manipulator, easy damage of workpieces during receiving and unloading and easy splashing of chips and water generated during machining to a feeding end in a traditional lathe. The pneumatic machining equipment is mounted on a frame, and comprises a feeding device with a fixed base and a feeding module, a protecting device with a guide rod and a protecting plate, and a receiving device with a cover frame and a material pipe; the feeding module is provided with an accommodating tank; when the feeding module moves, the workpieces can flatly move out of the accommodating tank; the frame is provided with a machining end and a feeding end; the protecting device can move between the machining end and the feeding end to separate the two; a gap is formed in the bottom of the material pipe, and is provided with a receiving platehinged with the material pipe; a rolling shaft is arranged in the cover frame; and the back end of the receiving plate is placed on the rolling shaft. The pneumatic machining equipment shortens the manipulator travel, protects the safety and the cleanness of the feeding end, and is lower in damage of the workpieces.

Owner:王芳

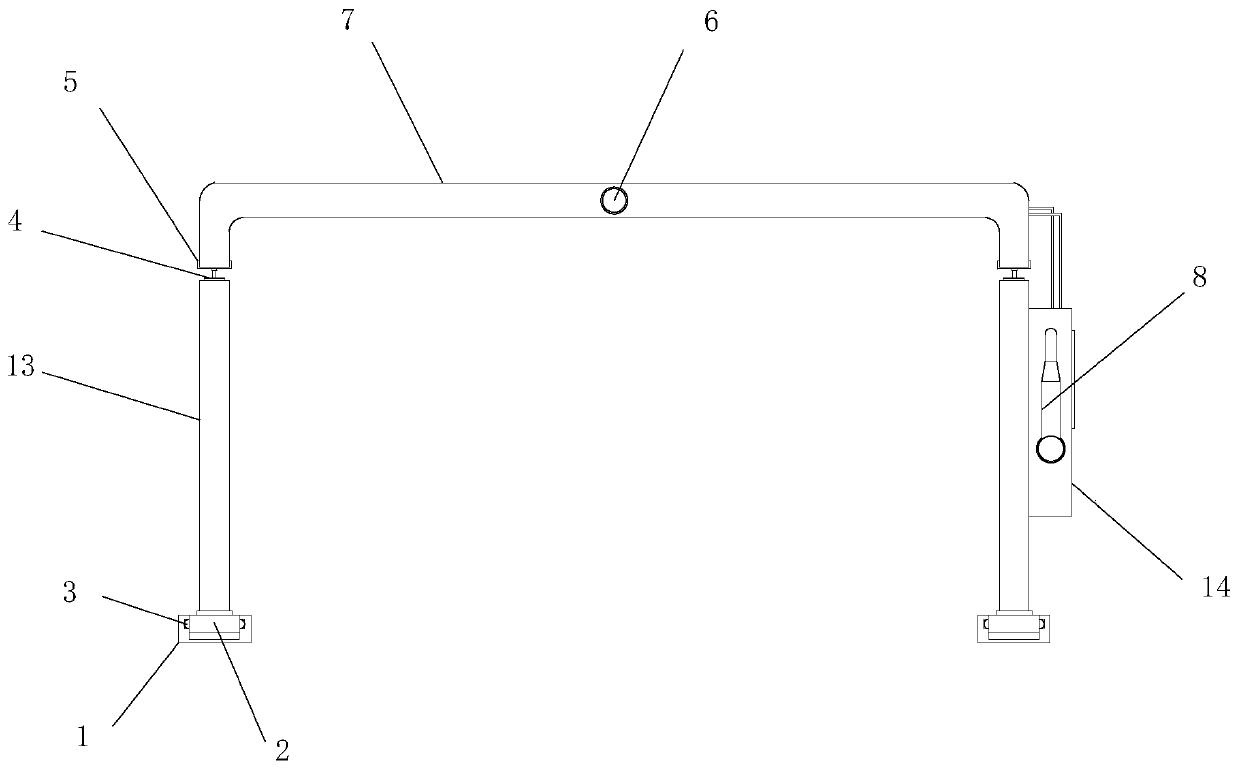

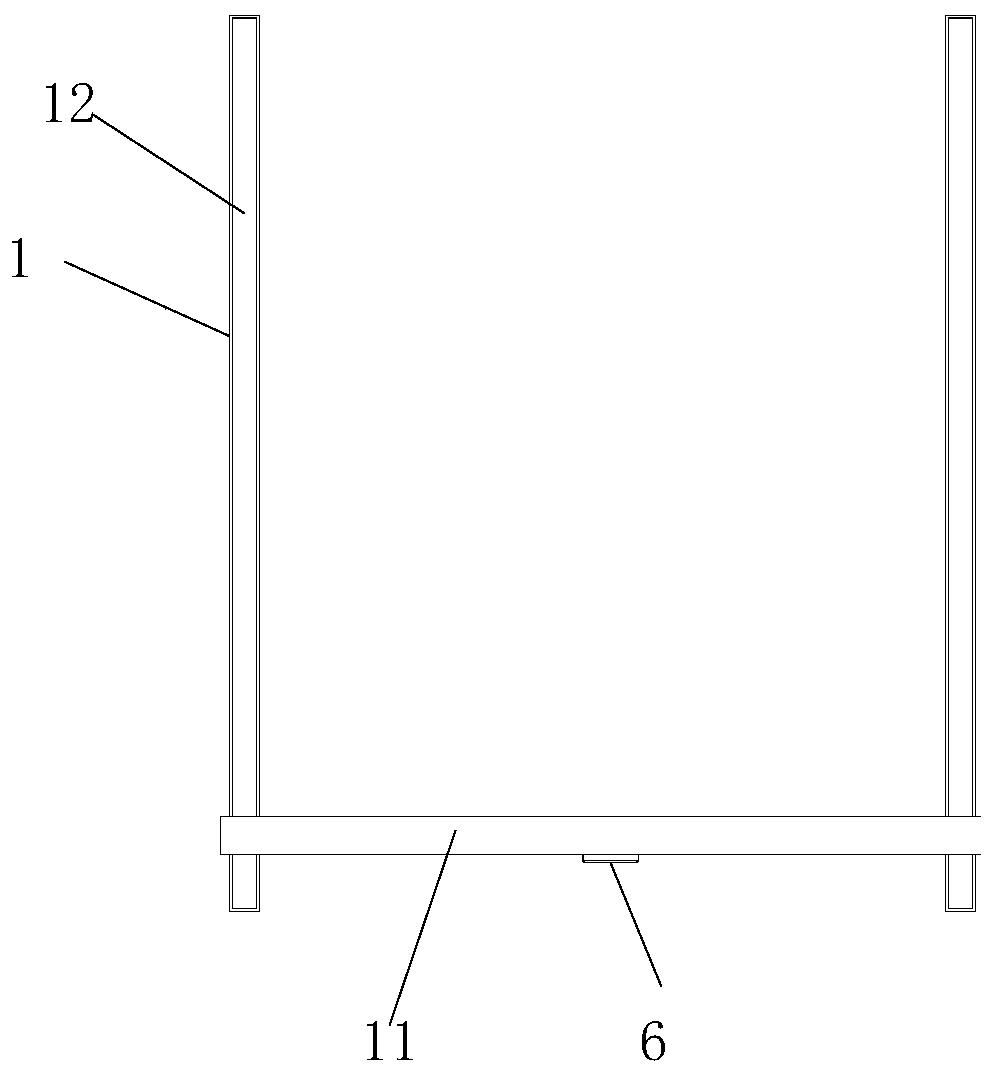

New energy charging system

InactiveCN109941131AExtended service lifeReduced occupancy of the charging areaCharging stationsElectric vehicle charging technologyParking areaNew energy

The invention discloses a new energy charging system. The system comprises more than one charging system arranged in a charging area, wherein each charging system comprises two buried guide rails; theburied guide rails are arranged between two sides respectively to form a parking area; a gantry bracket is slidably arranged in each buried guide rail; the gantry bracket limits the entrance height of a vehicle; a charging main machine is arranged on one side of the gantry bracket; a charging gun is arranged on the charging main machine; a power input end of the charging main machine is connectedto an external power supply through a power line. The system can limit the entrance area of a parking space and prevent a non-charging vehicle from entering the parking space to occupy the charging parking space; meanwhile, the whole gantry bracket can slide, the position of the charging main machine can be adjusted randomly according to the vehicle type, the use is very flexible, the main machine can be effectively prevented from being impacted, the use safety is improved, and a parking line does not need to be carved.

Owner:黄朝勇

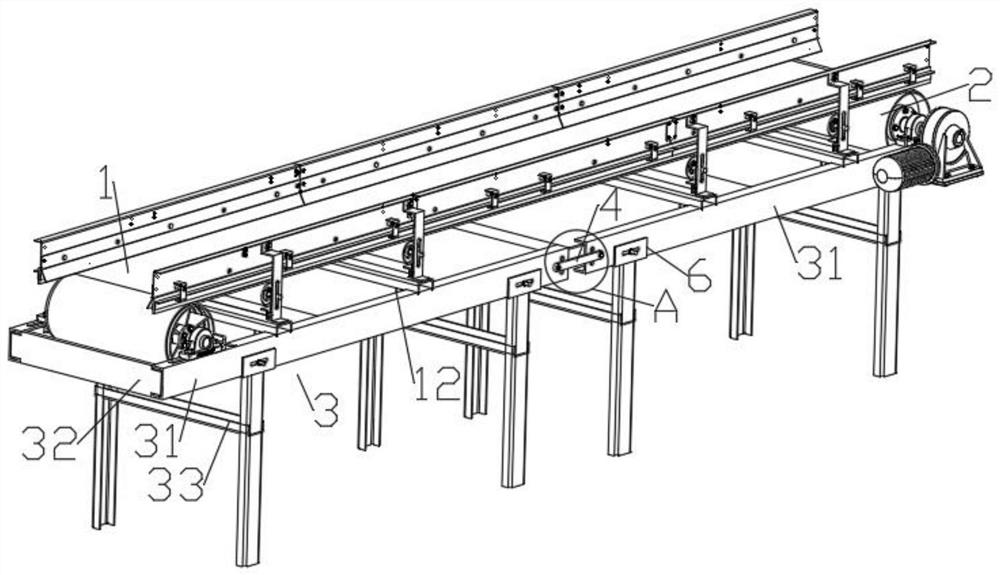

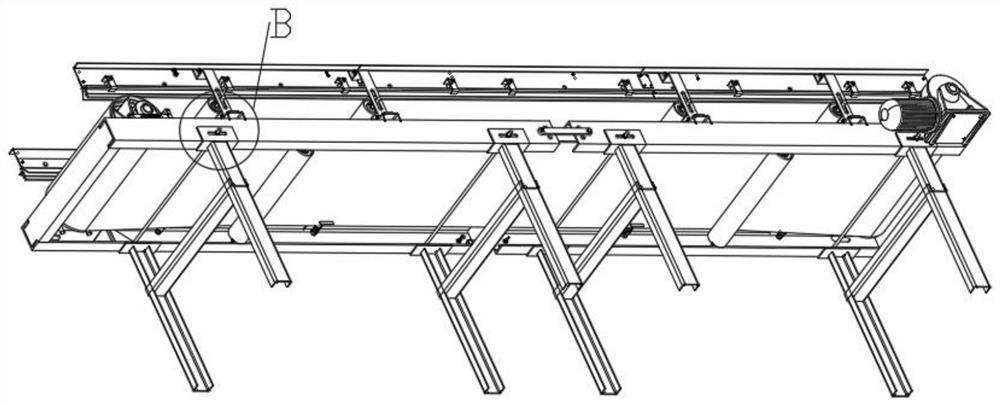

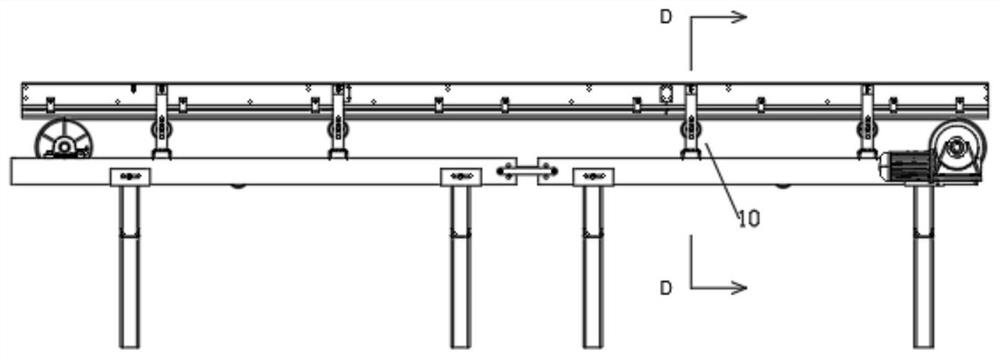

An anti-vibration conveyor belt

ActiveCN111332702BReduce direct damageReduce hard impactConveyorsSupporting framesShaped beamConveyor belt

The invention discloses an anti-seismic conveyor belt, belonging to the technical field of conveying devices, comprising a belt body, a driving roller driving the belt body to rotate, and a bracket supporting the belt body and the driving roller, and the bracket is sequentially connected by several sub-supports Formed, the sub-brackets include two beams, connecting beams and outriggers, adjacent two sub-brackets are spaced apart and connected by a connecting plate, the connecting plate is located on the side of the beam and its two ends pass through the first The rotating shaft is rotatably connected with the beams of the two brackets; the device of the invention can reduce the rigid impact of the bracket on the belt body during an earthquake, thereby reducing the direct damage to the bracket caused by the earthquake and ensuring the normal operation of the belt body conveying on the bracket.

Owner:EAST CHINA JIAOTONG UNIVERSITY

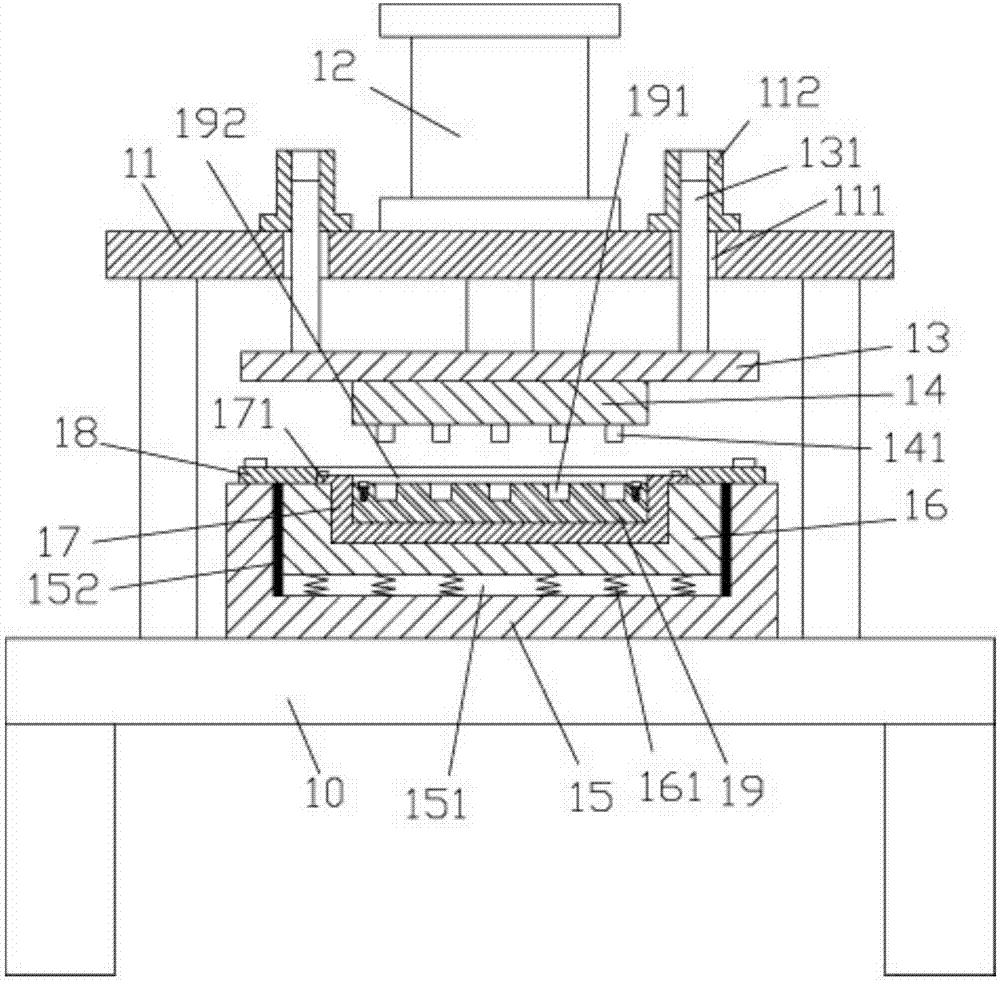

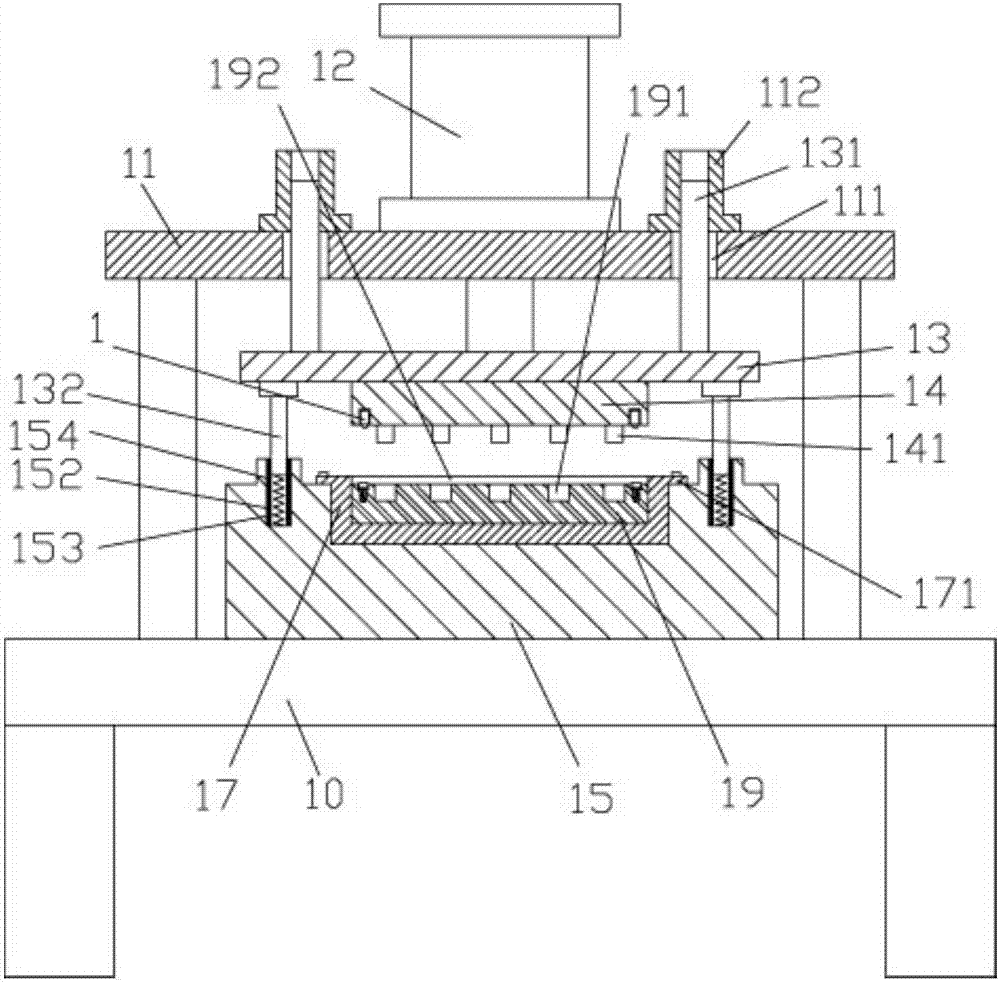

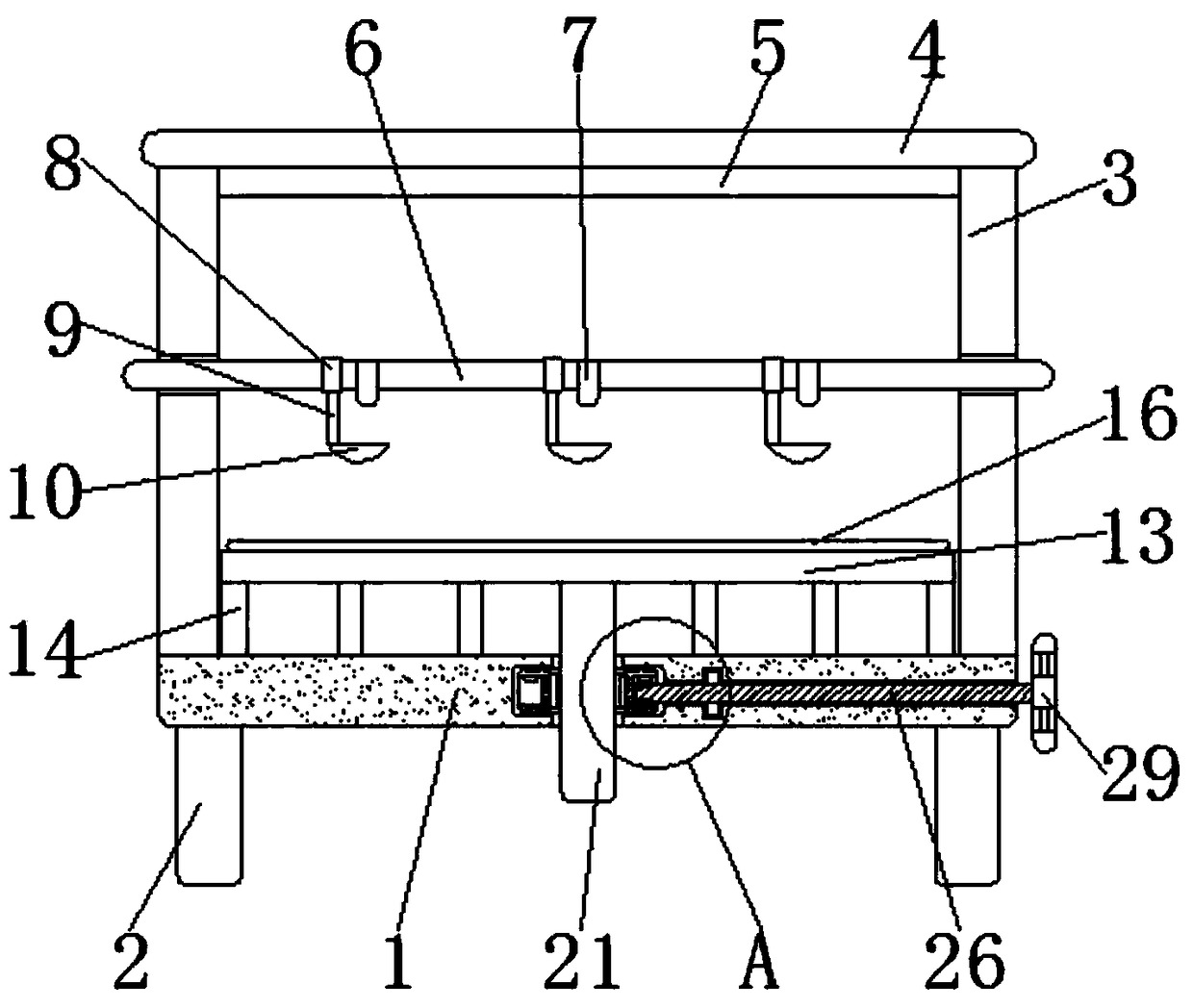

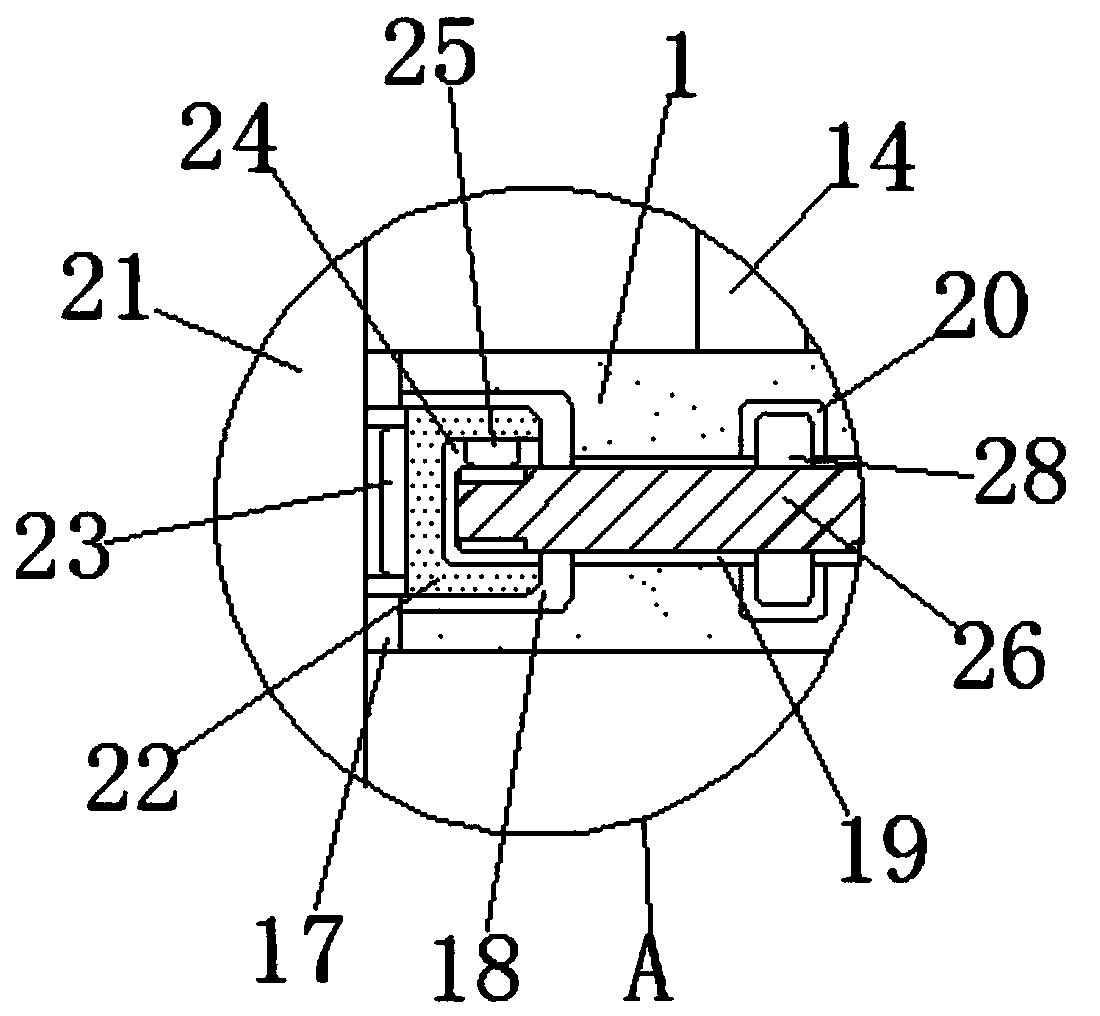

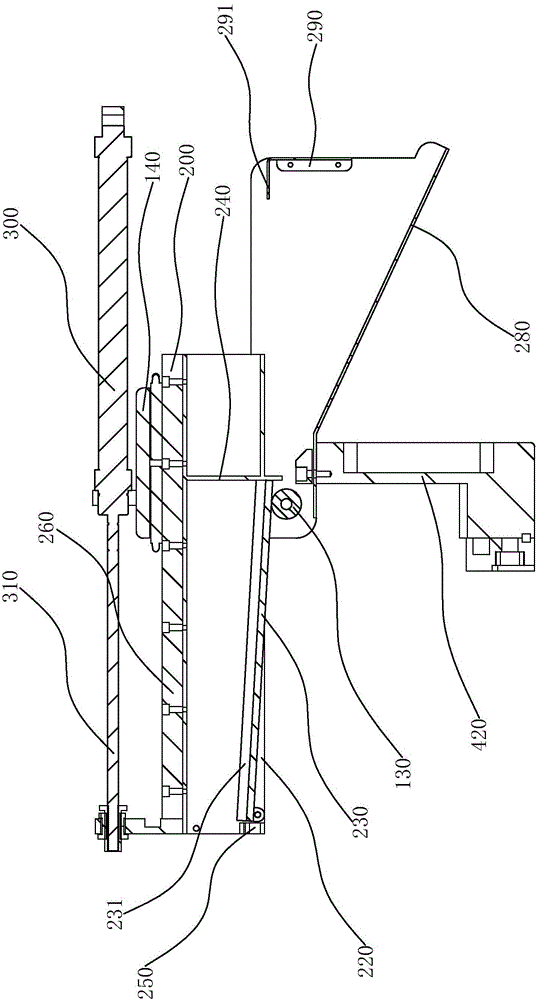

A stainless steel circular thin plate origin forming mechanism

ActiveCN106903223BReduce hard impactAvoid damageShaping toolsEjection devicesMaterials scienceSupport plane

The invention discloses a stainless steel circular thin plate origin forming machine. The stainless steel circular thin plate origin forming machine comprises a rack, wherein an upper supporting frame is fixedly arranged on the top surface of a top plate of the rack; a stamping oil cylinder is fixedly arranged on the middle part of the top surface of the top plate of the upper supporting frame; a pushing rod of the stamping oil cylinder passes through the top plate of the upper supporting frame and is fixedly equipped with an upper supporting plate; an upper mould is fixedly arranged on the middle of the bottom surface of the upper connecting plate; a plurality of stamping convex points are uniformly distributed on the bottom surface of the upper mould; the top surface of the middle part of the top plate of the rack is fixedly equipped with a lower supporting block; a main groove is formed in the middle part of the top surface of the lower supporting block; a mounting block is in plug bush in the main groove; a plurality of buffer springs are fixedly arranged on the bottom surface of the mounting block; the lower ends of the buffer springs are fixedly arranged on the bottom surface of the main groove; and an upper ring-shaped plate is fixedly connected to the top surfaces of the lower supporting blocks through bolts, and resists against the side part of the top surface of the mounting block. According to the stainless steel circular thin plate origin forming machine disclosed by the invention, hard collision between an upper mould and a lower mould can be reduced, so that the stainless steel circular thin plate origin forming machine is prevented from being damaged, and the service life of the stainless steel circular thin plate origin forming machine is prolonged; and meanwhile, the stainless steel circular thin plate origin forming machine is not easily adhered on the lower mould, and is quick in de-molding.

Owner:江门市德高实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com