Damping and shock insulating bidirectional spherical support

A ball bearing and shock isolation technology, which is applied in the direction of shockproof, bridge parts, building components, etc., can solve the problems of irreparable, self-recovery, shock-absorbing and shock-isolation bearings weakening the kinetic energy in the horizontal direction, etc., so as to reduce hard impact , Improve the effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

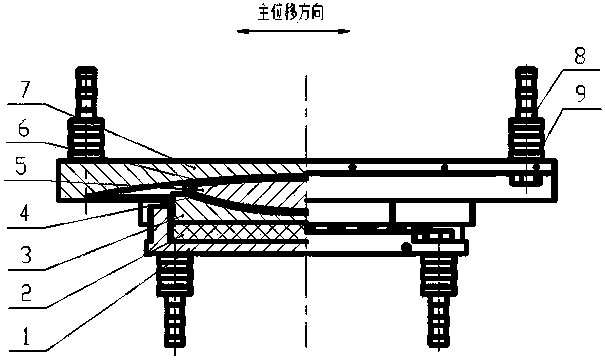

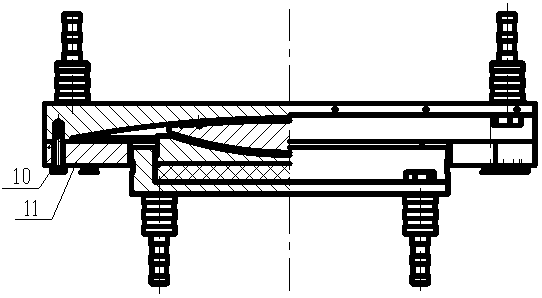

[0027] combine figure 1 and figure 2 As shown, the present invention fixes the upper support plate 7 on the bridge and fixes the lower support plate 1 on the pier by pre-embedding the anchor bolt 8 and the sleeve 9 .

[0028] Under normal working conditions, or when the earthquake does not reach a certain intensity, under the restriction of the guide plate, the upper and lower bearing plates of the bearing will slide relative to each other along the principal displacement direction. At this time, the support takes place as follows: the shock-absorbing rubber plate 2 is compressed or unstressed according to the change of the vertical bearing capacity, reducing the hard impact between the support parts; the spherical crown liner 5 is opposite to the upper support plate 7 Doing pendulum motion, the shock-absorbing slide 6 is attached to the spherical crown liner, and sliding friction occurs with the upper support plate, absorbing the kinetic energy of the support, and dissipati...

Embodiment 2

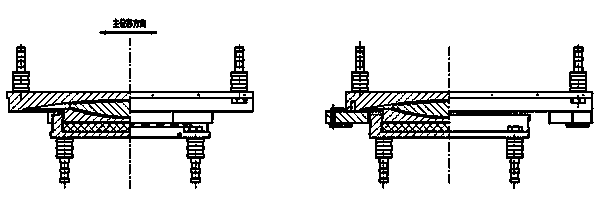

[0031] How Bidirectional and Fixed Bearings Work Bidirectional and fixed bearings work similarly to unidirectional bearings. In normal working condition, when the upper and lower bearing plates of the bidirectional bearing are in normal working condition, the upper and lower bearing plates of the bidirectional bearing can slide relative to each other along the main displacement direction and the non-main displacement direction, that is, the displacement in the main displacement direction is relatively small. big.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com