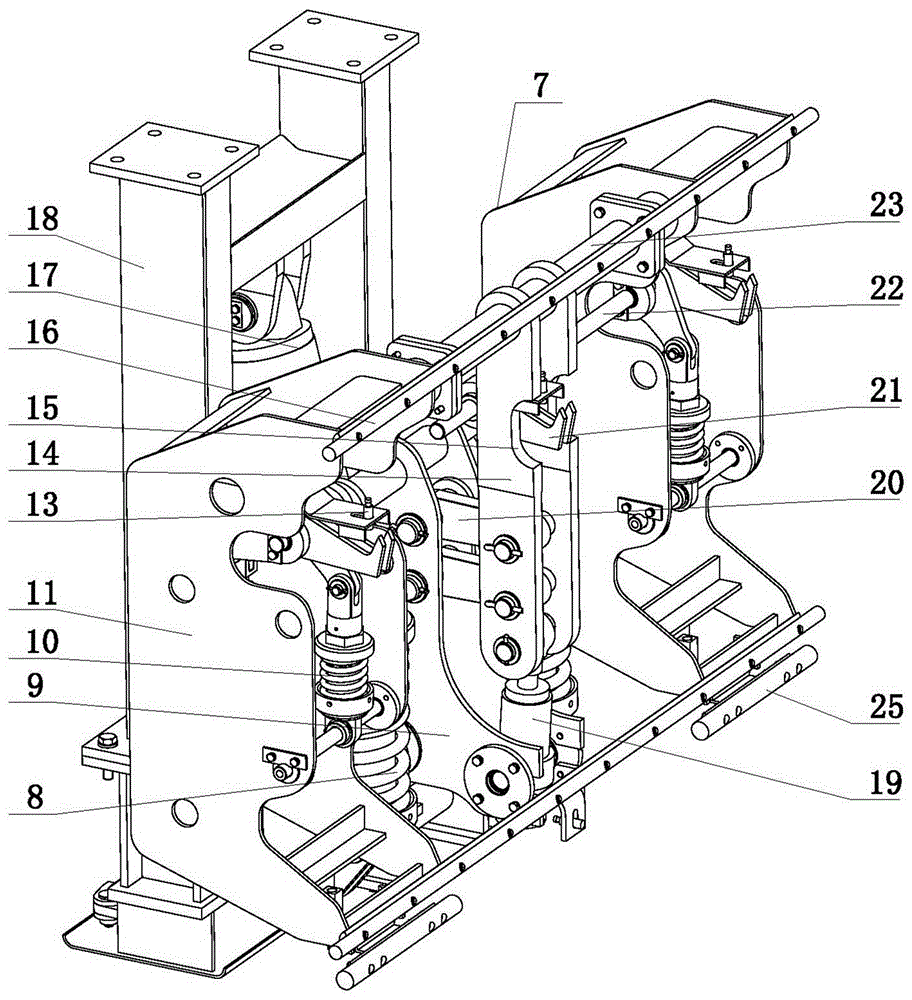

Clamp device for opening electrolytic cell cover plate

A fixture device and electrolytic cell technology, applied in the field of metallurgical machinery, can solve the problems of increasing electrolytic aluminum production time, increasing the number of employees, increasing labor costs, etc., and achieving the effects of reducing labor intensity, improving production efficiency, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

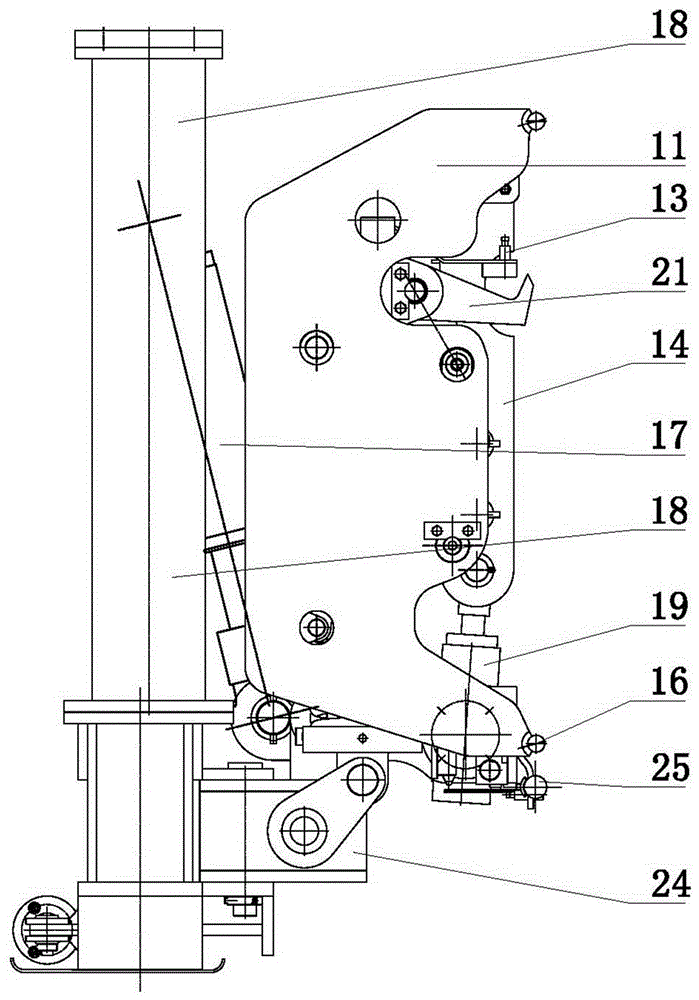

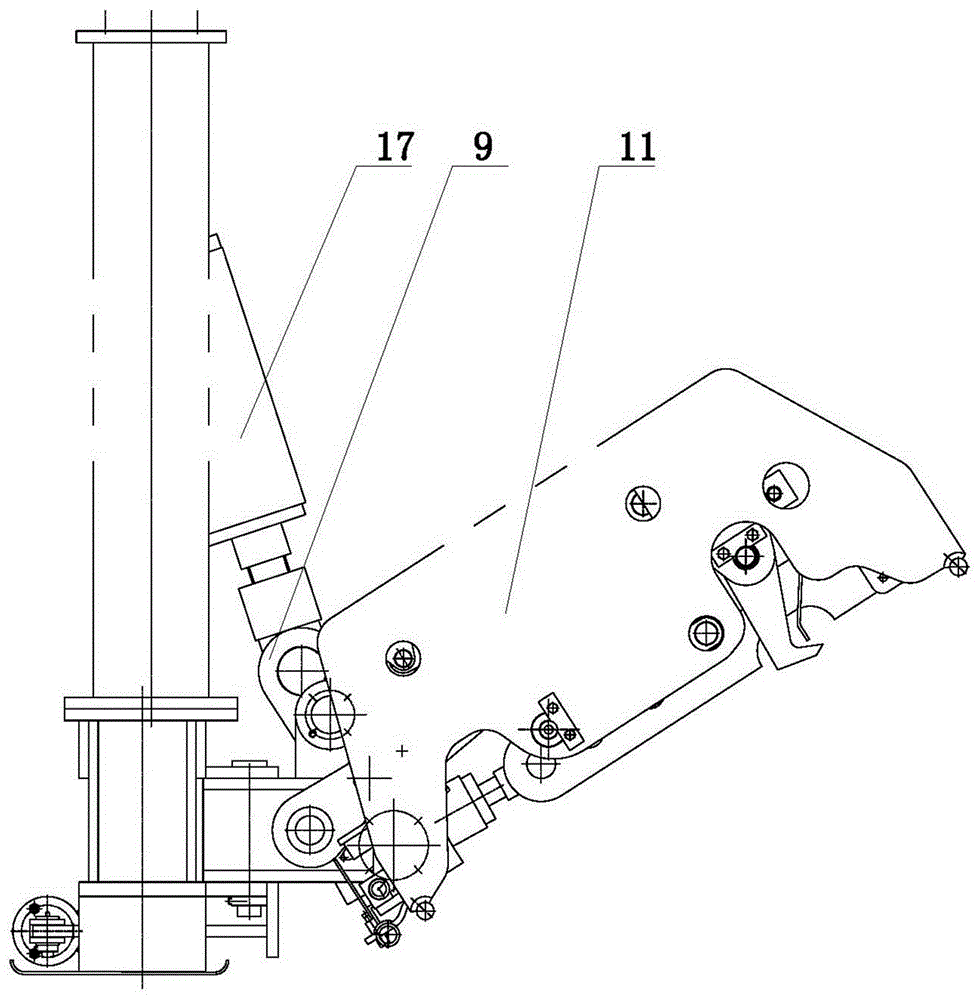

[0021] The present invention includes a clamp fixing frame 18, on which a clamp body 7 is arranged, and is characterized in that: the lower end of the clamp fixing frame 18 is hingedly provided with a swing adjustment seat 24, and the clamp body 7 includes a The opening and closing drive device 17, the end of the opening and closing drive device 17 is hinged with one end of the bottom of a special-shaped frame 9, the middle position of the bottom of the special-shaped frame 9 is hinged with the swing adjustment seat 24, and the other end of the bottom of the special-shaped frame 9 is hinged. Mobile driving device 19; Mobile driving device 19 links to each other with the lower end of a moving frame 14; A connecting rod 20 is hingedly arranged between the middle part of the moving frame 14 and the middle part of the special-shaped plate; A supporting spring device 8 is arranged between the horizontal shaft 28 and the swing adjustment seat 24; the upper end of the moving frame 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com