Preparation of nano-cerium oxide composite abrasive grain polishing solution

A technology of nano-cerium oxide and composite abrasive grains, which is applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of fast polishing speed, polishing scratches, and many scratches, so as to improve surface quality, improve surface quality, reduce The effect of surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment one: the polishing liquid preparation process and steps in this embodiment are as follows:

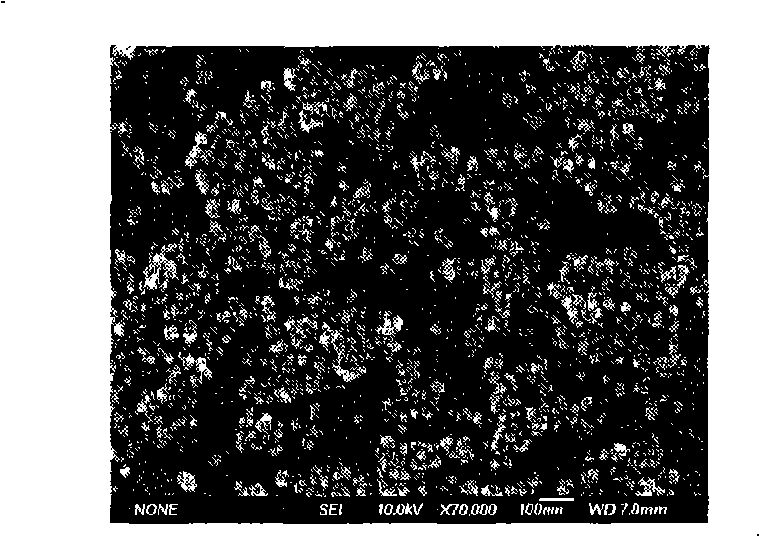

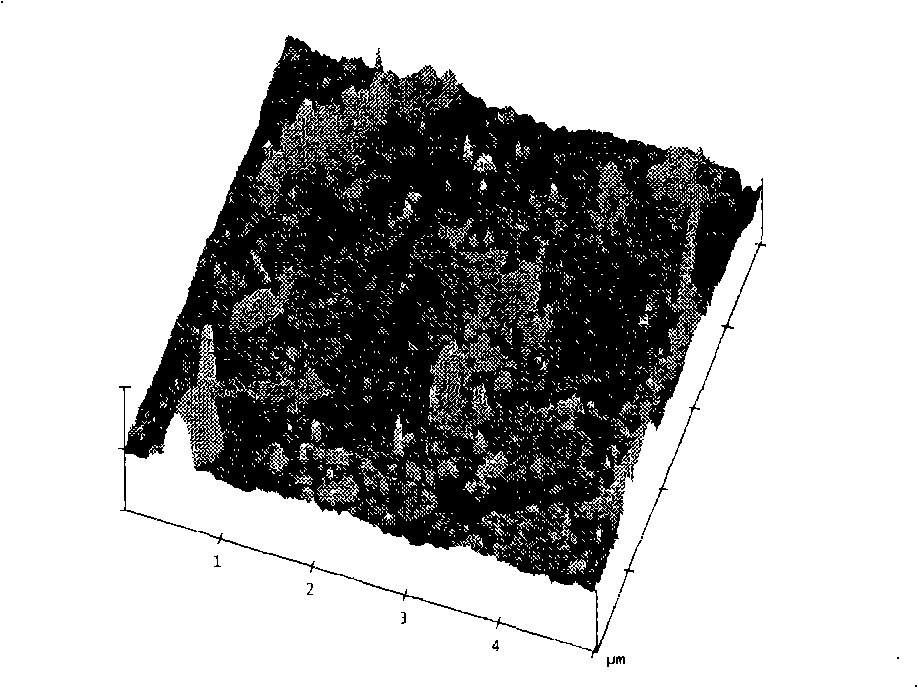

[0014] (1) Preparation of cerium oxide composite abrasive grains: prepared by homogeneous precipitation method, weighing 5 grams of SiO with a particle size of 30nm 2 Inorganic abrasive particles are dispersed into 100ml of water, followed by adding 10ml of CO(NH 2 ) 2 solution and 10ml concentration of 0.3mol / L (NH 4 )2Ce(NO 3 ) 6 Solution: Pour the prepared mixed solution into a three-necked flask, heat to 100°C with a jacketed thermostat, stir with an electric stirrer, and heat to reflux under stirring for 7 hours. After the reaction was completed and cooled to room temperature, the obtained precipitate was separated by a centrifuge and washed three times with deionized water; then dried in a constant temperature drying oven at 80°C, and then ground to obtain a light yellow powder, namely Nano silicon oxide particles as the core, SiO with cerium oxide as the s...

Embodiment 2

[0016] Embodiment two: the polishing liquid preparation process and steps in this embodiment are as follows:

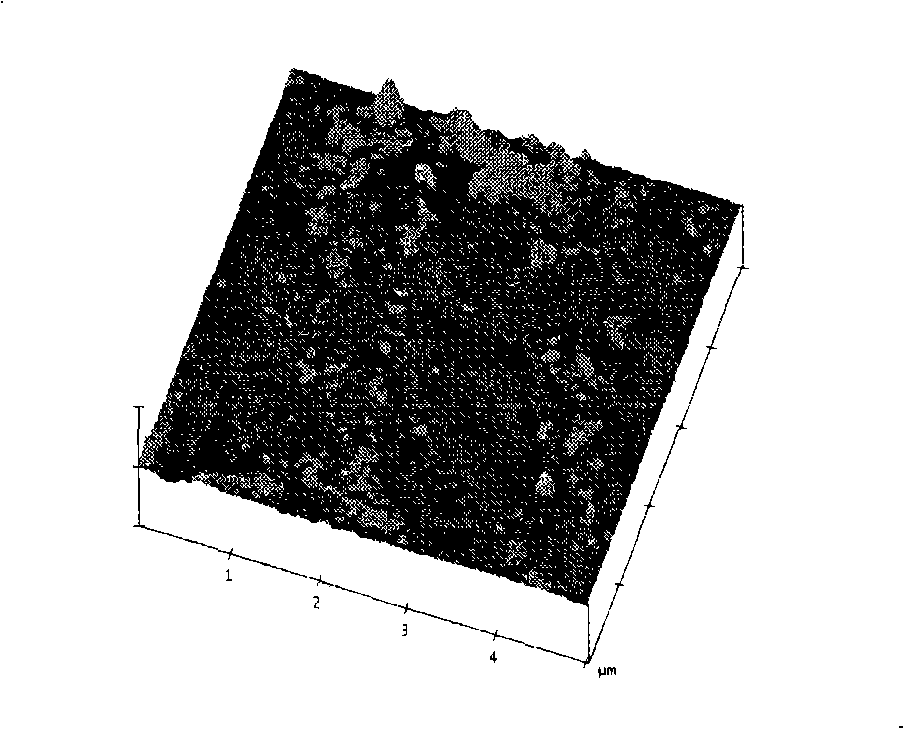

[0017] (1) Preparation of cerium oxide composite abrasive grains: the above-mentioned SiO 2 / CeO 2 Add the composite abrasive particles into water, and the weight ratio of the composite abrasive to water is 4%; then add 1% of the dispersant sodium hexametaphosphate, and stir with a mechanical mixer to make the dispersion even; further disperse the above mixed solution with a ball mill, Make a uniform dispersion liquid; then add oxidant hydrogen peroxide 2%, corrosion inhibitor benzotriazole 0.1%, lubricant phosphate 0.1%; the addition of the above substances is based on water 100% as a reference, this is nano SiO 2 / CeO 2 Composite abrasive polishing fluid.

[0018] For comparison, the commercially available CeO 2 The polishing liquid was prepared from the polishing powder as a comparative example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com