Electric vehicle battery mounting structure and electric vehicle

An electric vehicle battery and installation structure technology, applied in the electric vehicle field, can solve the problems of easy loosening of the connection, affect the battery, increase the cost, etc., and achieve the effects of reducing the pulling, improving the sealing effect, and being less prone to skew.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

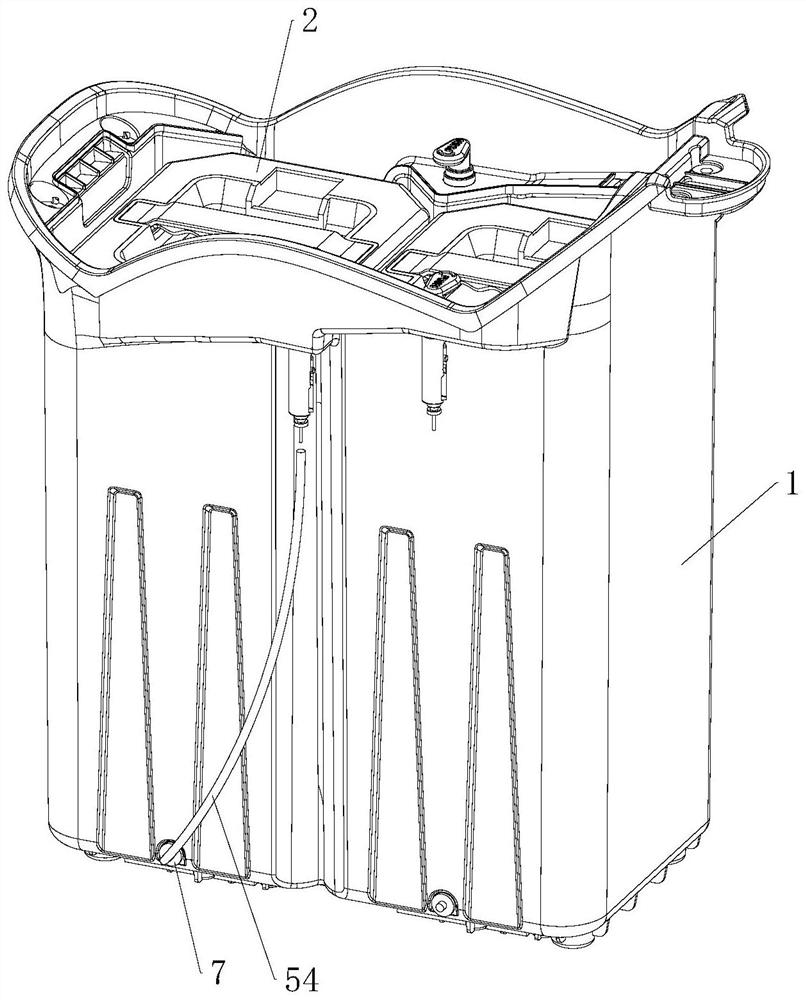

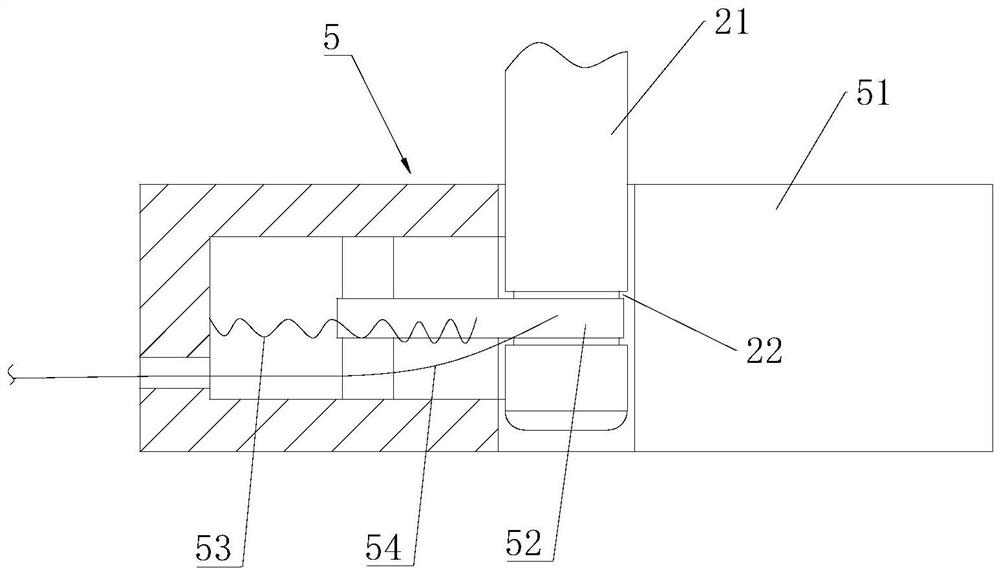

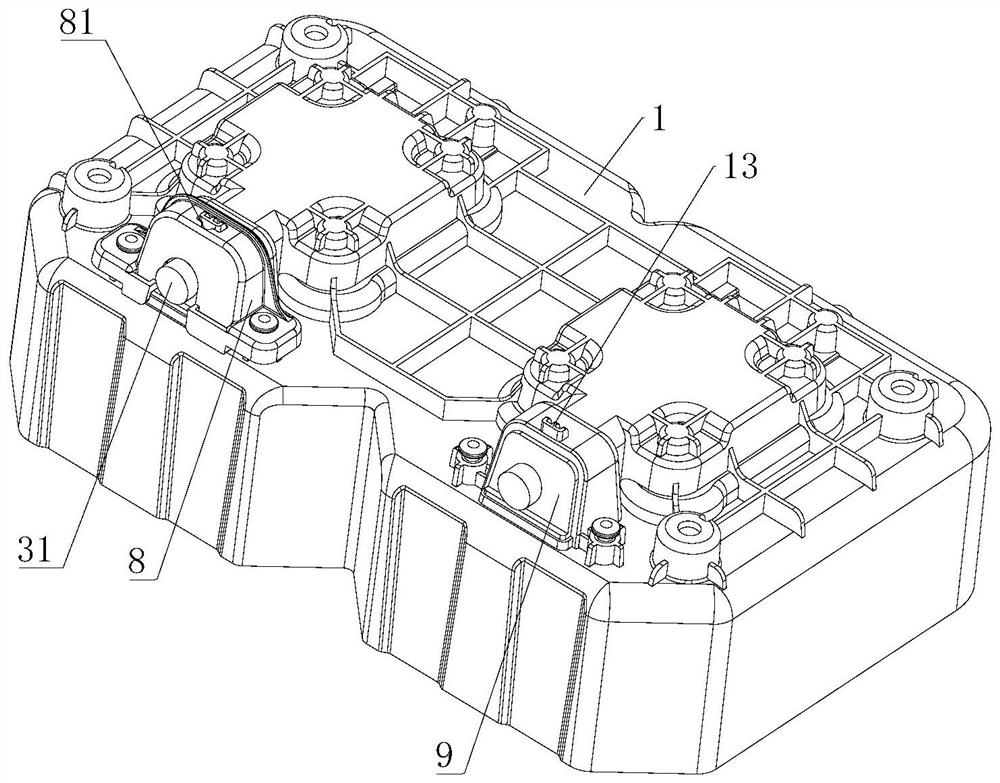

[0034] like figure 1 and figure 2 As shown, an electric vehicle battery installation structure includes a seat barrel 1 , a battery 2 and a female seat 3 , and the battery 2 is placed in the seat barrel 1 . One end of the bottom of the battery 2 is vertically protruded downward with a cylinder 21 , and an annular groove 22 is formed on the outer circumference of the cylinder 21 . The bottom of the seat barrel 1 is located below the cylinder 21 and is provided with a battery lock 5. The battery lock 5 includes a lock plate 51, a lock hook 52, a spring 53 and a lock wire 54. The lock plate 51 is fixed on the bottom of the seat barrel 1. The lock plate 51 There is a lock hole for the cylinder 21 to pass through, the lock plate 51 is provided with a receiving groove, a pin shaft is vertically arranged in the receiving groove, the lock hook 52 is horizontally rotated and arranged on the pin shaft, and the lock hook 52 is away from the end of the pin shaft. It is suspended, and t...

Embodiment 2

[0038] An electric vehicle, including the battery installation structure in Embodiment 1.

[0039] In summary,

[0040] First, the main wire harness 31 of the female seat 3 is inserted into the central hole of the middle partition plate 41 and passed out from the through hole, so that the main wire harness 31 and the joint 32 are located under the middle partition plate 41, and the connecting plate 34 of the fixing member is located in the middle partition plate 41. The top of the plate 41 is fixed on the middle partition plate 41, each spring is placed, and each countersunk head bolt 42 is inserted into the four corners of the middle partition plate 41 and into the spring, fixed with the nut 44, and the locking sleeve 8 is installed. Then, when the battery 2 is placed in the seat barrel 1, the cylinder 21 is embedded in the lock hole, the cylinder 21 contacts the suspended end of the lock hook 52 and squeezes the suspended end into the channel, and the spring 53 is compressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com