Mechanical and electrical installation construction method for entrance and exit of long heavy grade of subway

A technology with long ramps and construction methods, applied in cable laying equipment and other directions, can solve the problems of difficult laying of hard cables, high risk of scaffolding platforms, poor practicability of brackets, etc., so as to improve practical maneuverability and reduce tension. The effect of lifting and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In conjunction with the accompanying drawings, the key points of each operation of the construction method of the present invention will be described in detail.

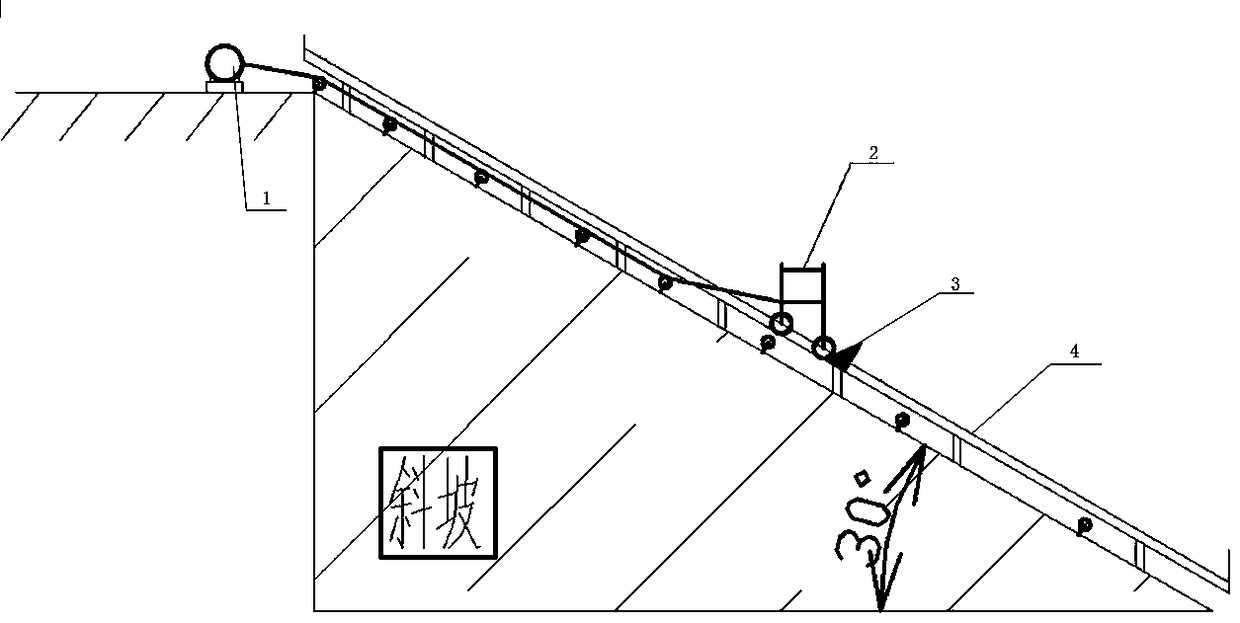

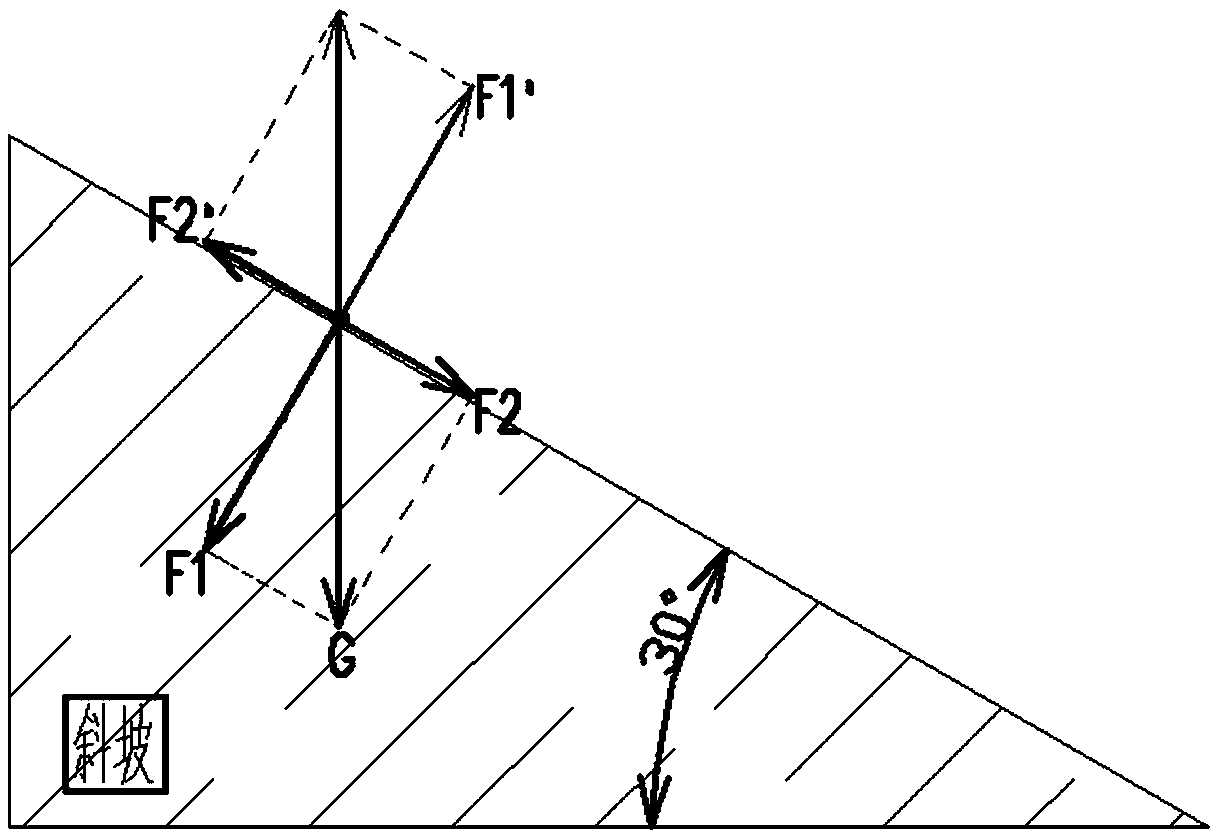

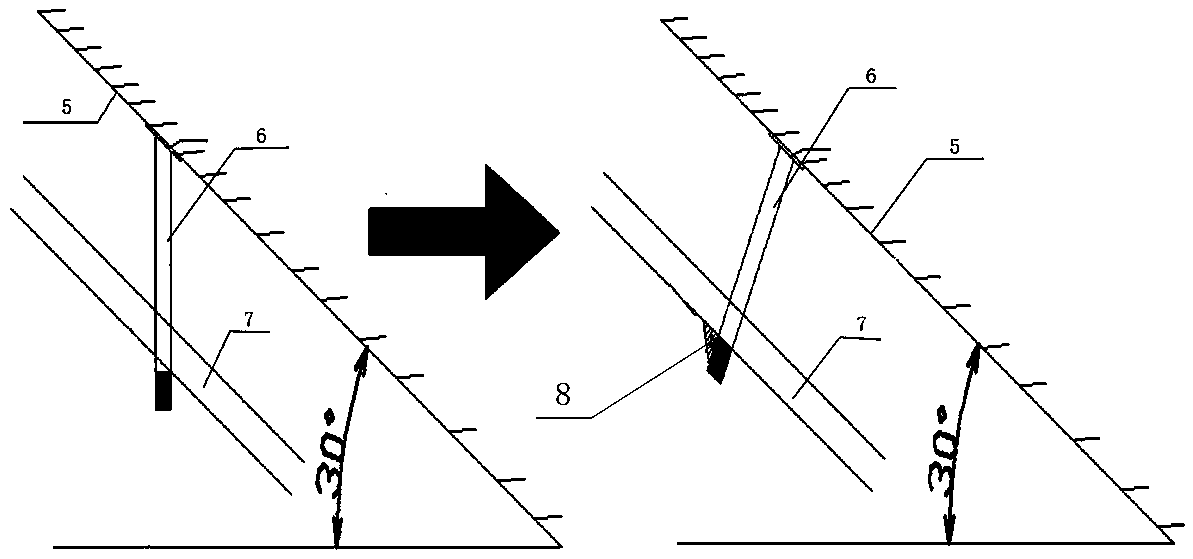

[0029] The principle of train guide rail operation is adopted to solve the problem of inefficient material transportation. Combined with the entrance and exit ramps, the channel steel is used to build the transport guide rail and the transport trolley matching the transport guide rail; the hoist and the rope are used to construct the power system; self-made wedge-shaped magnetic iron shoes are used as the braking system; The equipment, in which the long equipment is directly set with a hook and is pulled up to the construction site along the guide rail by the power system, and the square equipment is transported to the construction site by a transport trolley. Along the entrance and exit of the long ramp of the subway, build a long ramp guide rail material, equipment transportation, and lifting machinery and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com