Peanut seed sheller

A technology for shelling machines and peanut seeds, applied in threshing equipment, seed and rhizome treatment, agricultural machinery and implements, etc., can solve problems such as stagnation, time-consuming and laborious, damage to drums and curved sieves, and achieve large differences in shape and size , avoid distinguishing burdens, prevent mixed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0027] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the description in the manual and the drawings. The specific connection methods of each part adopt the mature bolts, rivets and welding in the prior art. Conventional methods such as, pasting, etc. will not be detailed here.

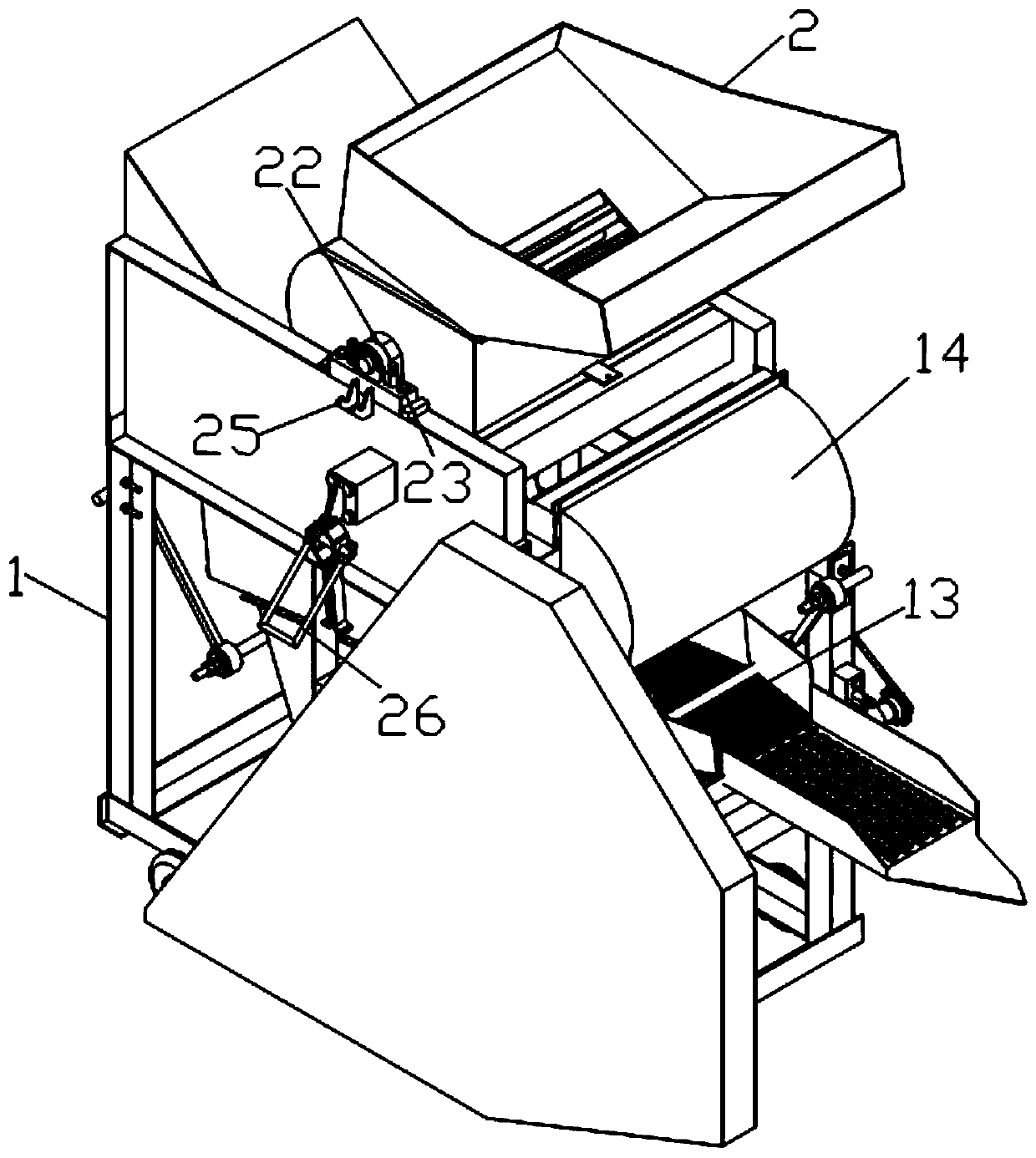

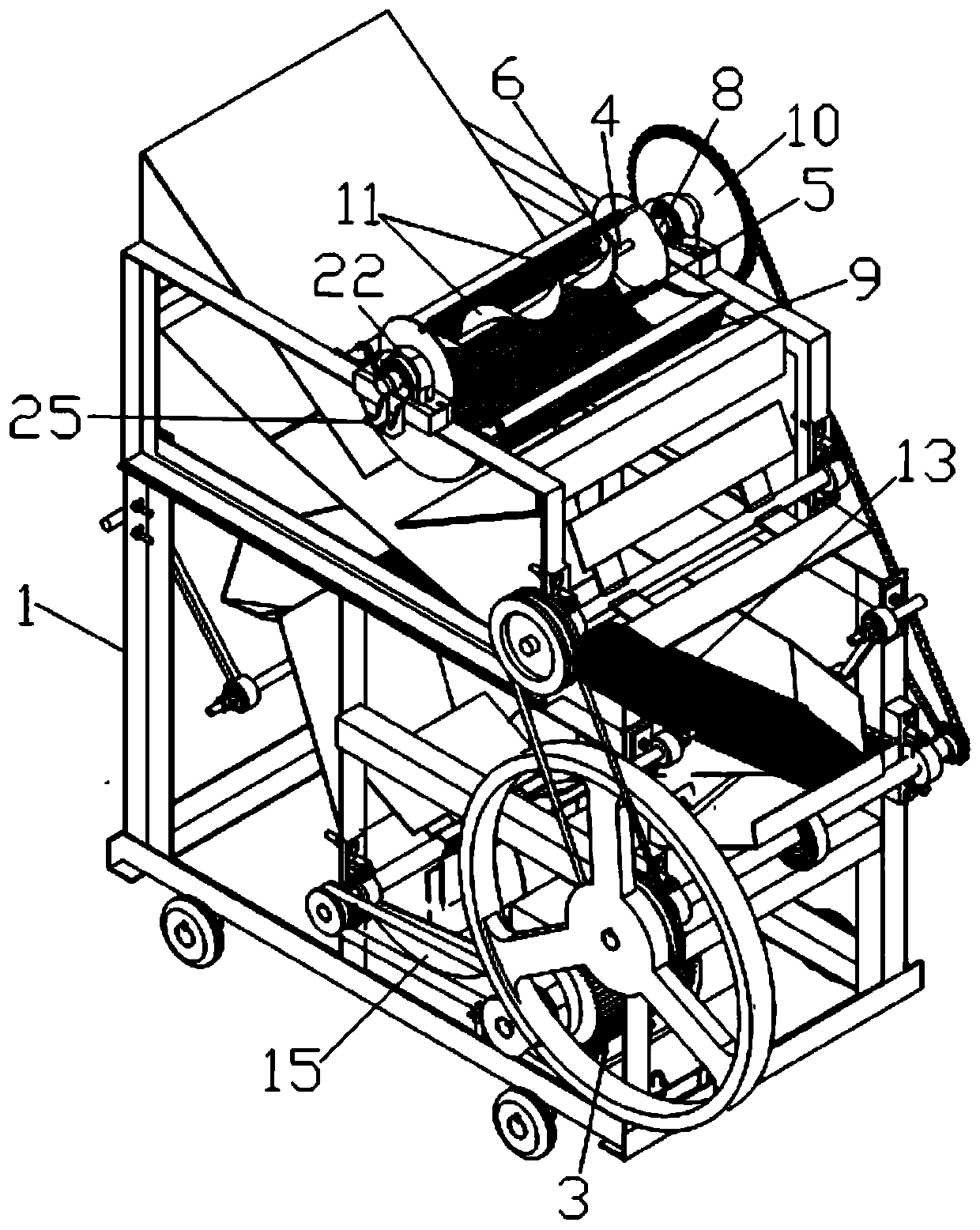

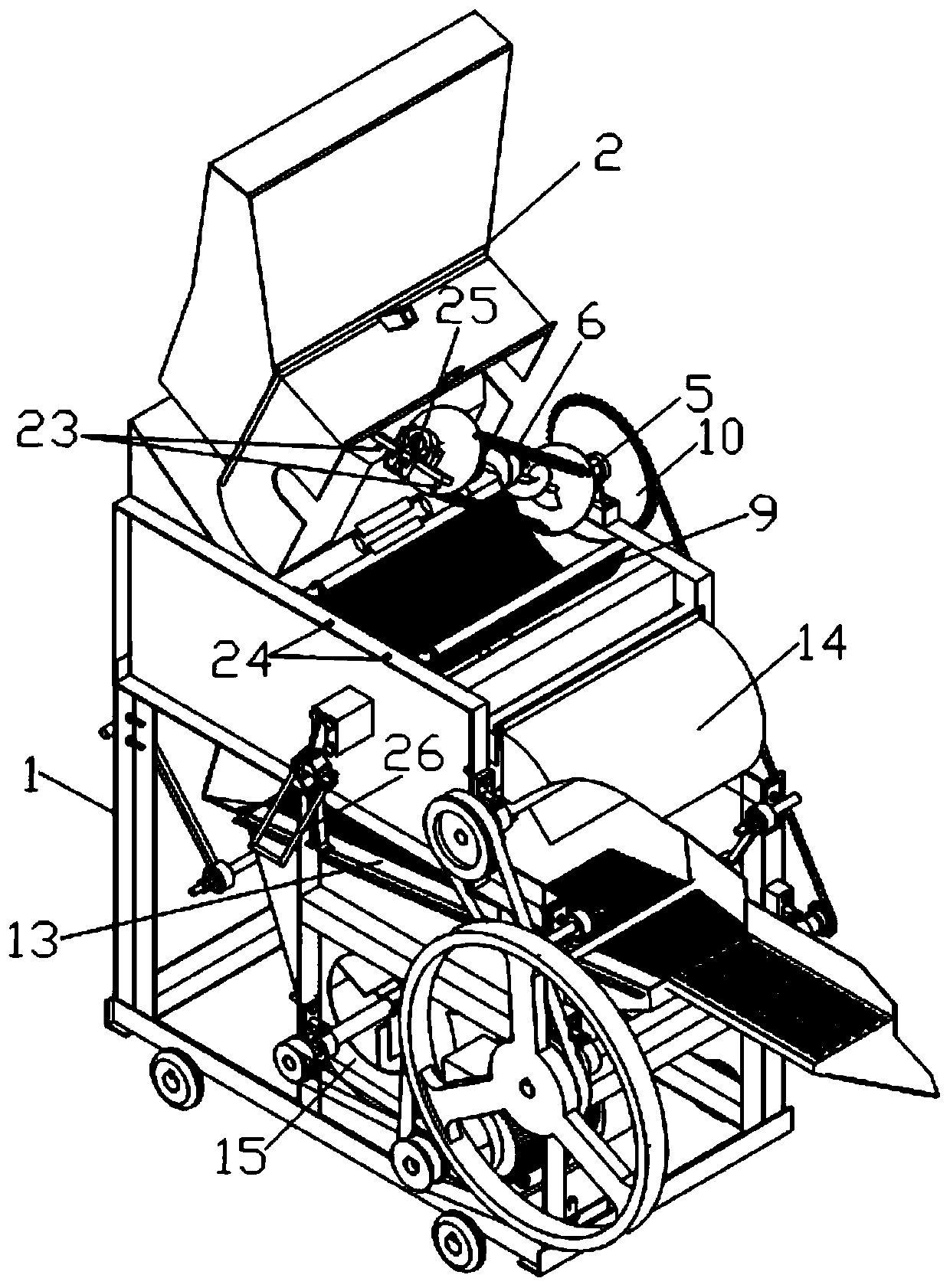

[0028] by Figure 1~7 As can be seen from the illustrated embodiment, this embodiment includes a frame 1 and a hopper 2 arranged on the frame 1, a peanut shelling device, a winnowing and separating device for husks, a driving motor 3 and a transmission device;

[0029] The outer wall of the hopper 2 is hinged with the frame 1;

[0030] The peanut shelling device is arranged under the hopper 2 through the frame 1, which includes a shelling structure, a turning structure and a peanut pod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com