Patents

Literature

81results about How to "Save feeding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

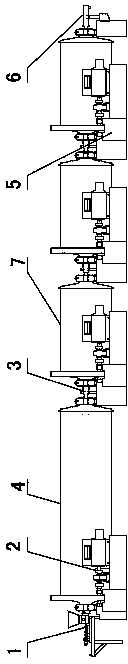

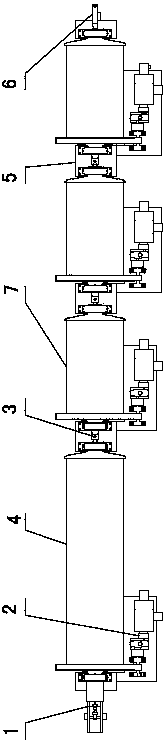

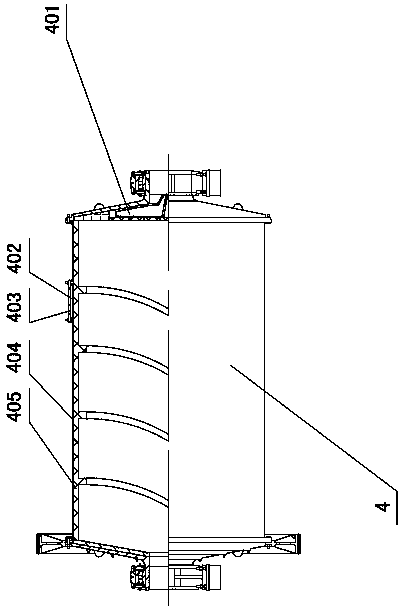

Tandem continuous ball mill and ball milling method

The invention discloses a tandem continuous ball mill and a ball milling method and belongs to the technical field of equipment for producing ceramic products and ball milling technologies. A feeding device (1) is communicated with a feeding end of a first-stage ball milling tank (4), wherein a plurality of second-stage ball milling tanks (7) are connected in series; the length of the first-stage ball milling tank (4) is 1.5-3 times that of one second-stage ball milling tank (7); an inner cavity of the first-stage ball milling tank (4) has a taper of which the diameter is gradually reduced from the feeding end to the discharging end. The tandem continuous ball mill can be used for materials with different sizes; the discharging mode is changed from the traditional overflow into flow extraction; in the ball milling method, materials with different particle sizes are pertinently added; after materials of which the particle sizes are 0.5-15mm are pulped, the pulped materials are directly added in each second-stage ball milling tank (7) through a connecting device (3); after materials of which the particle sizes are 0.1-0.5mm are pulped, the pulped materials are directly added in the tail-end second-stage ball milling tanks (7) through the connecting devices (3), so that the grinding efficiency is greatly improved.

Owner:GUANGDONG EDING IND

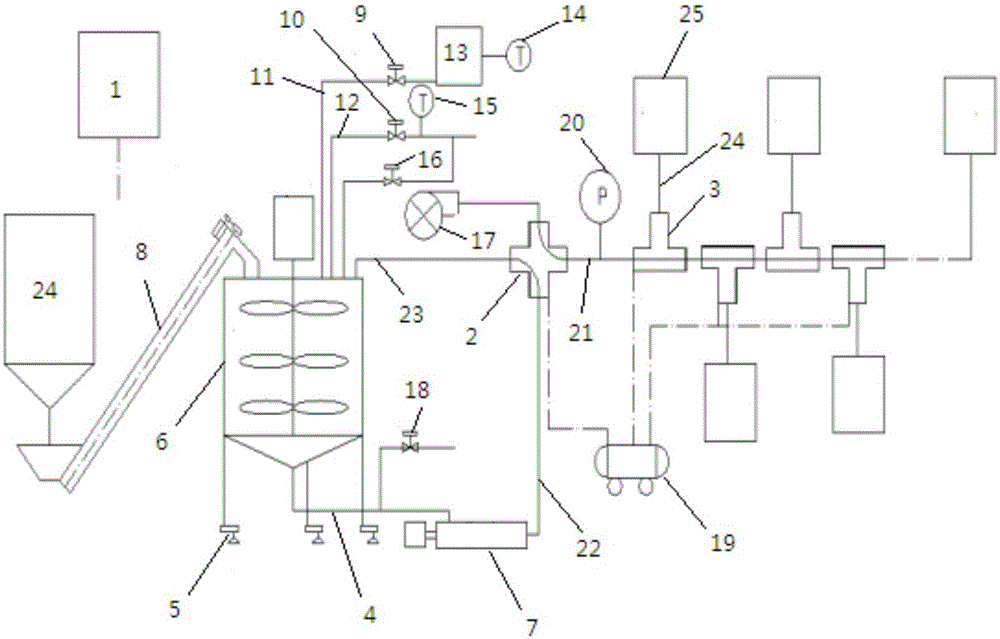

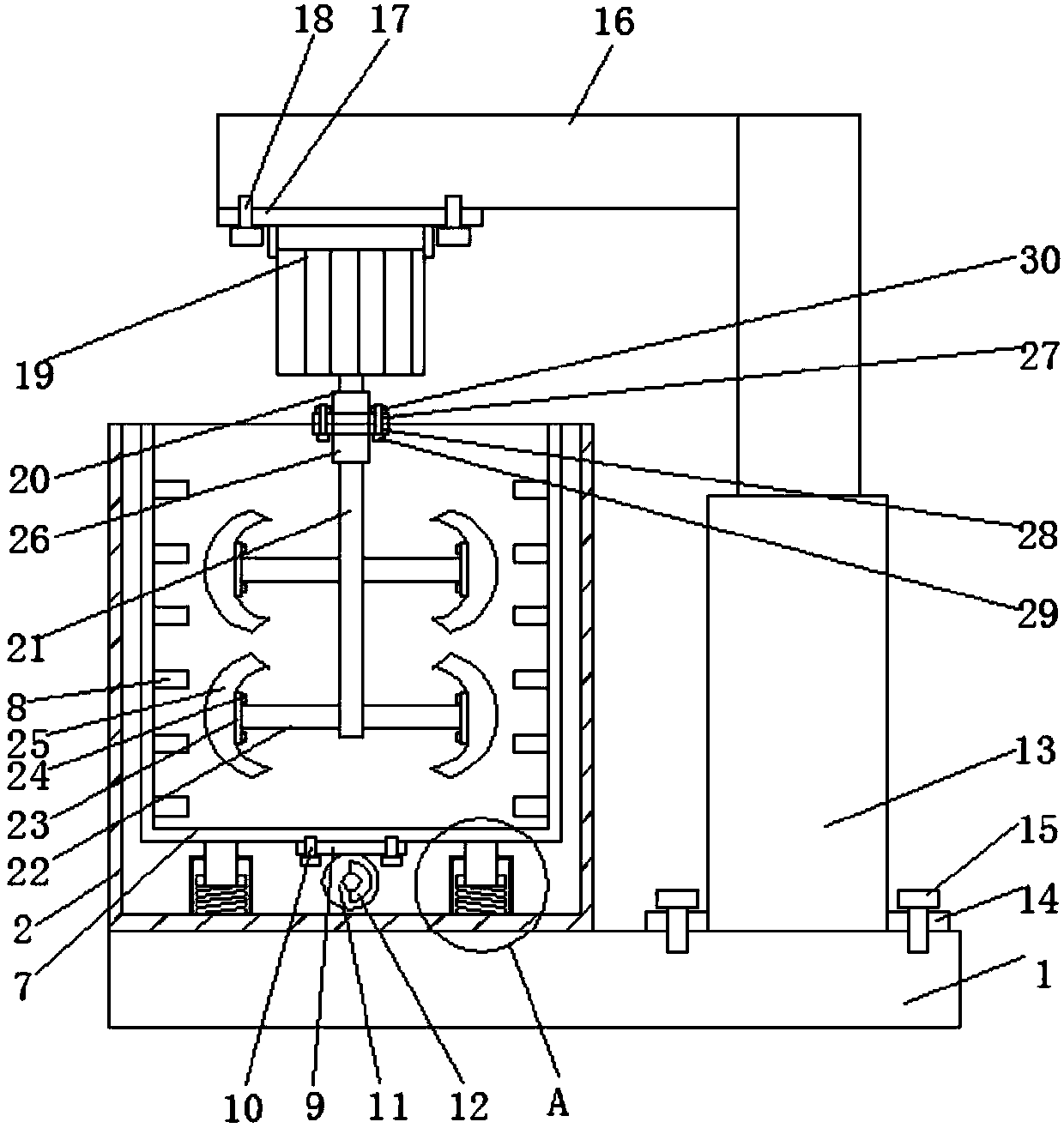

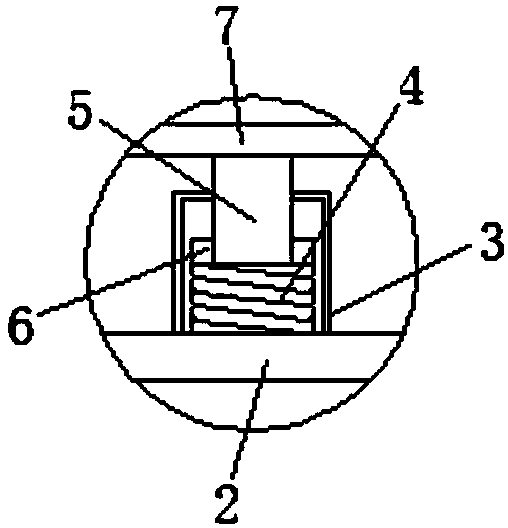

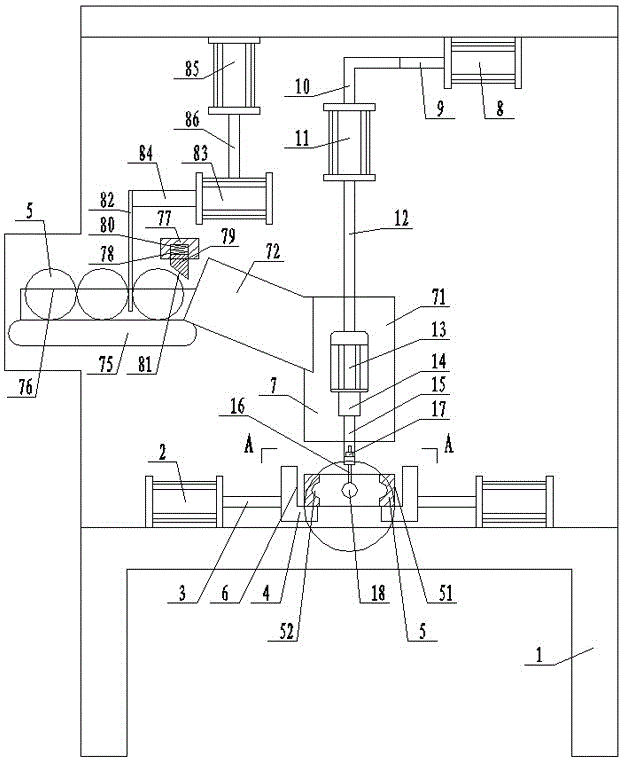

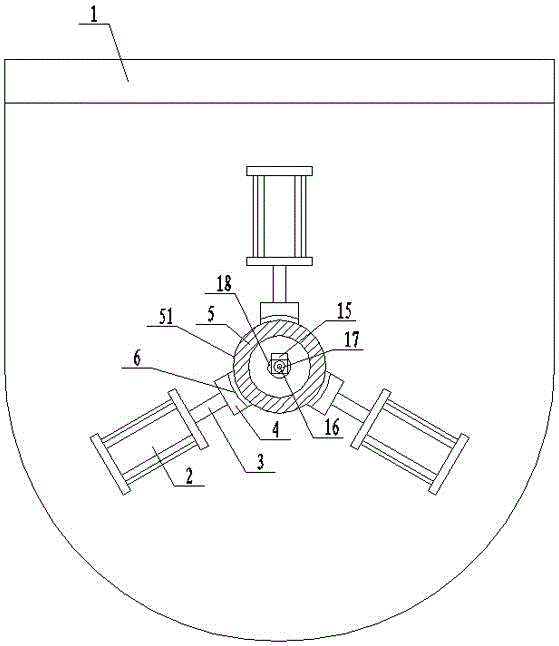

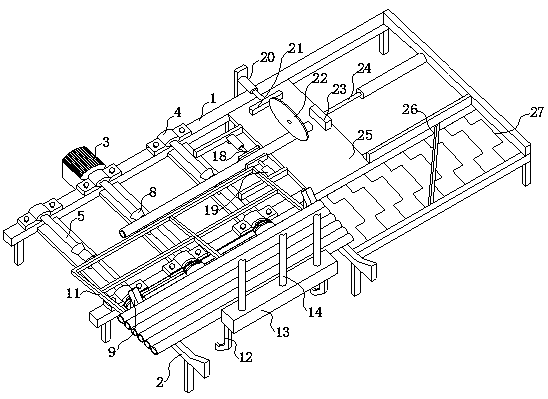

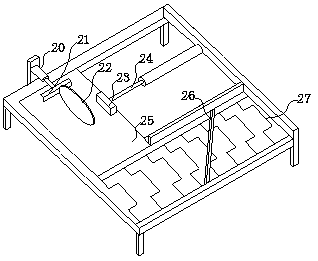

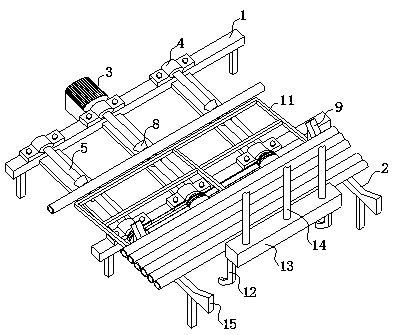

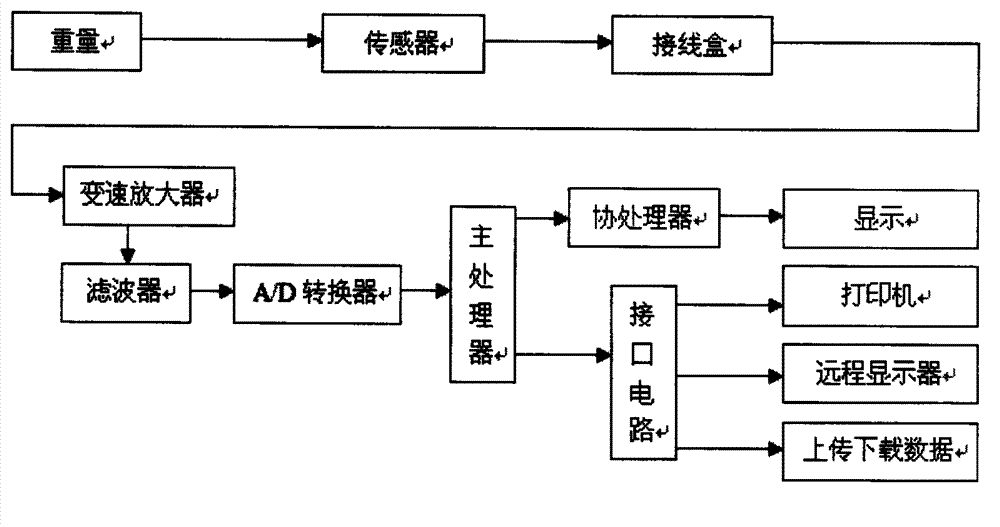

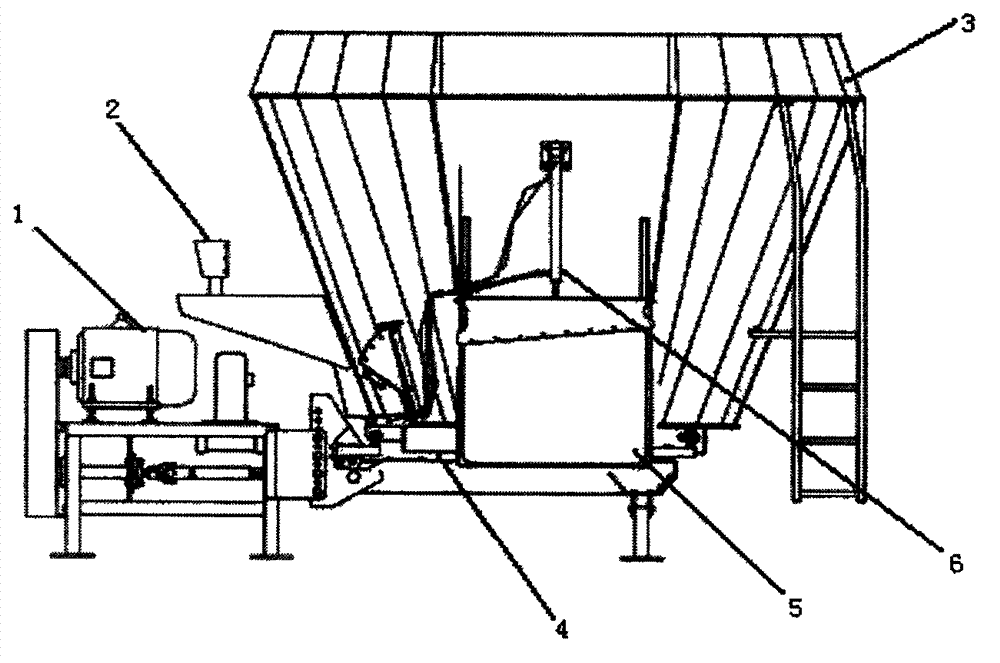

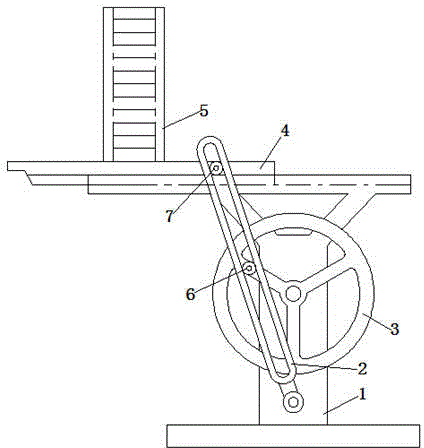

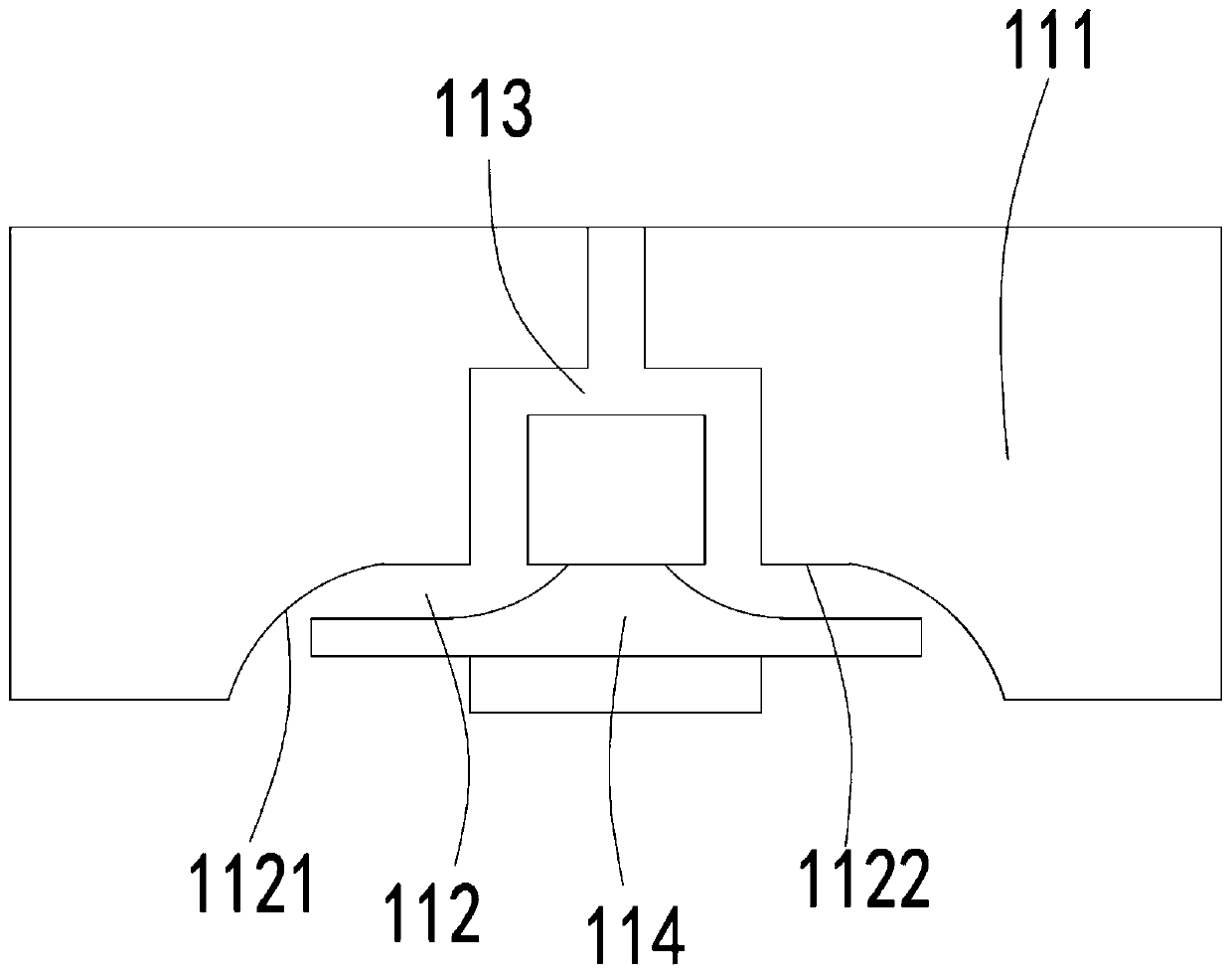

Device and method for feeding pigs with liquid feed

InactiveCN106386550ASave feeding timeHigh degree of automationAnimal feeding devicesEngineeringHigh pressure

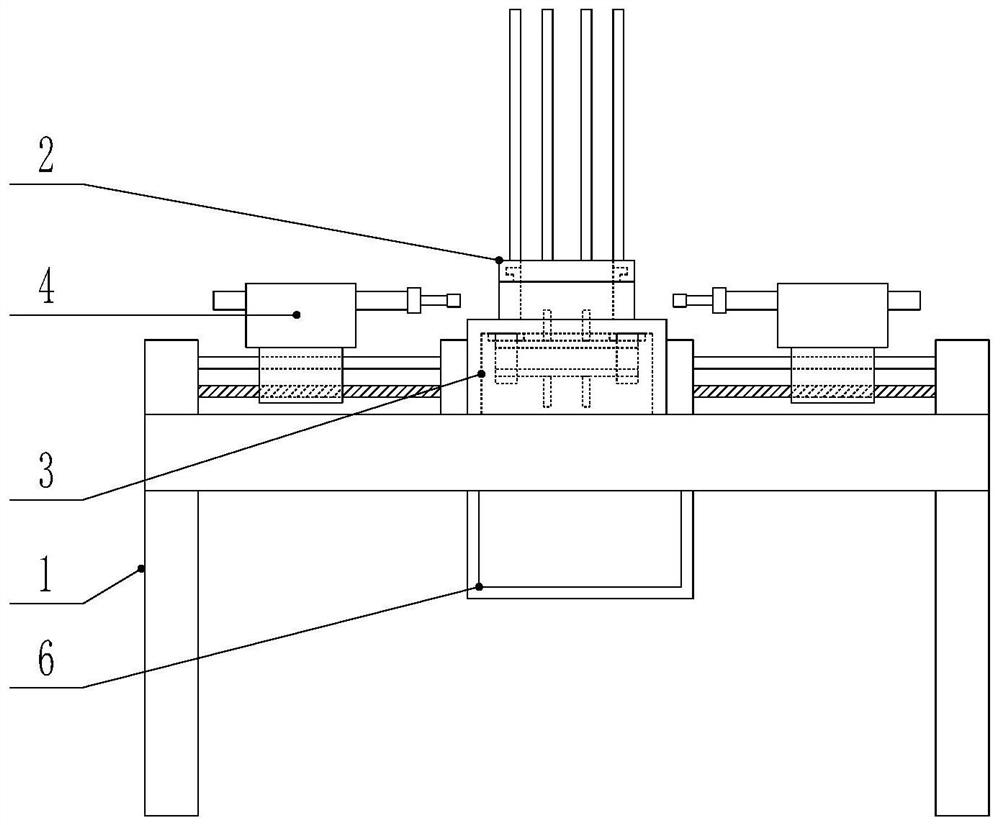

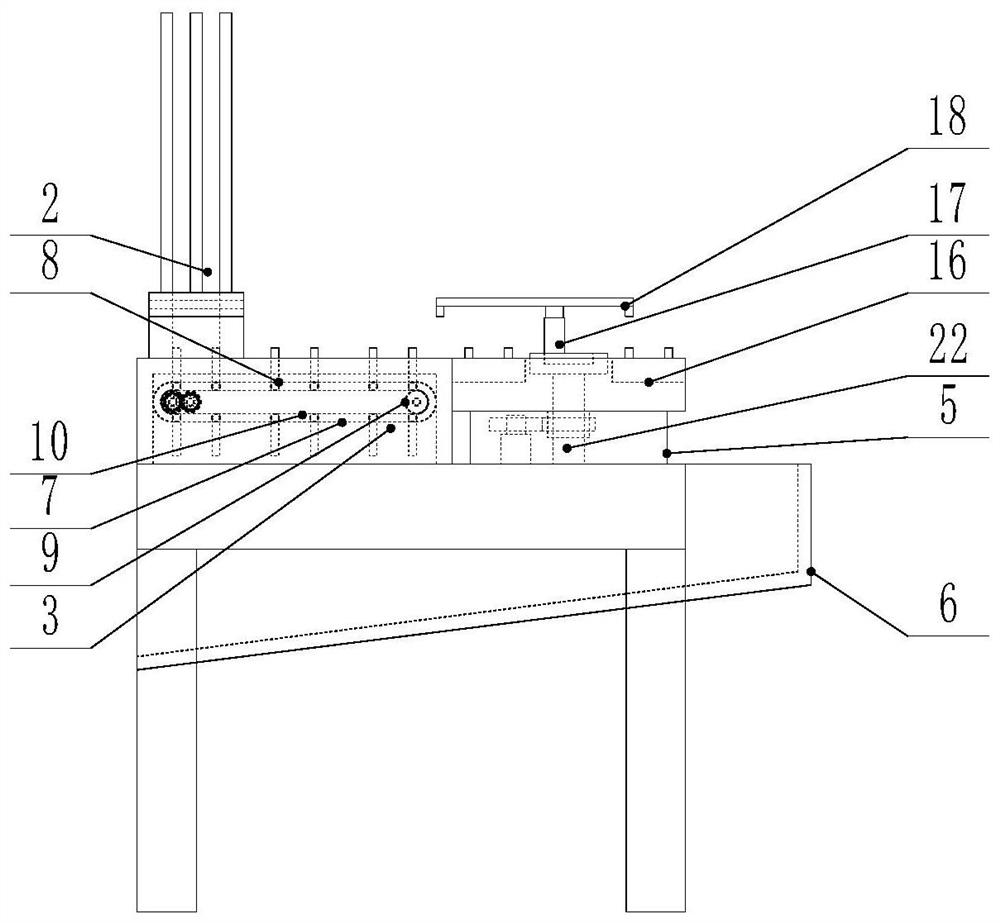

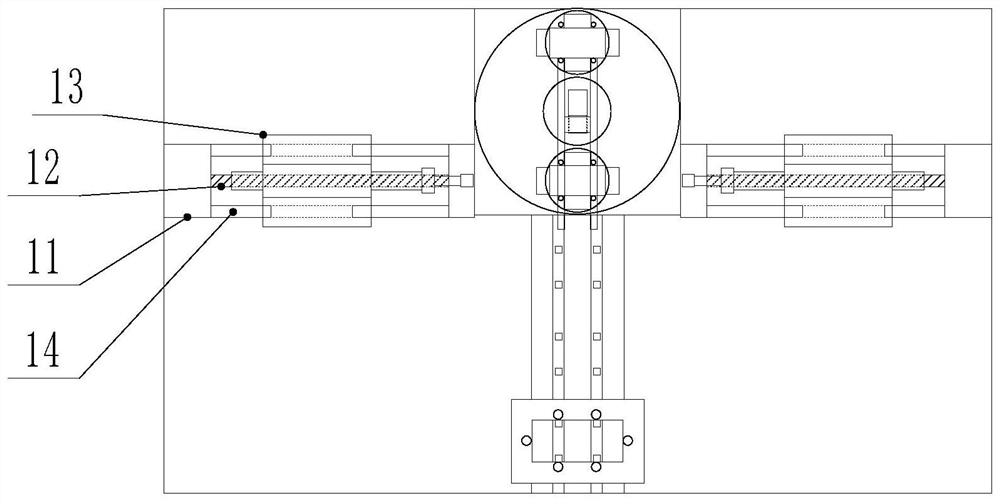

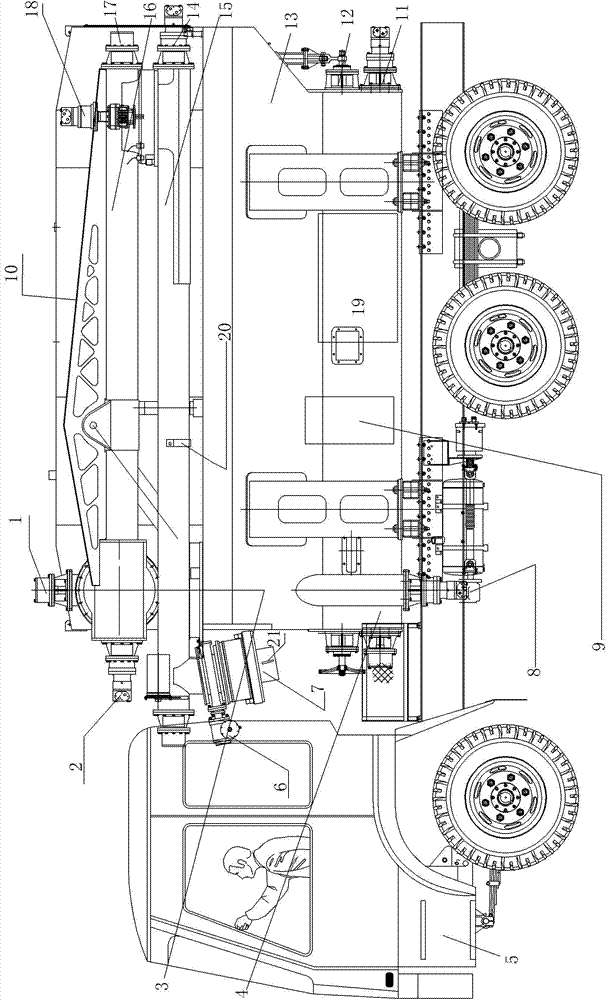

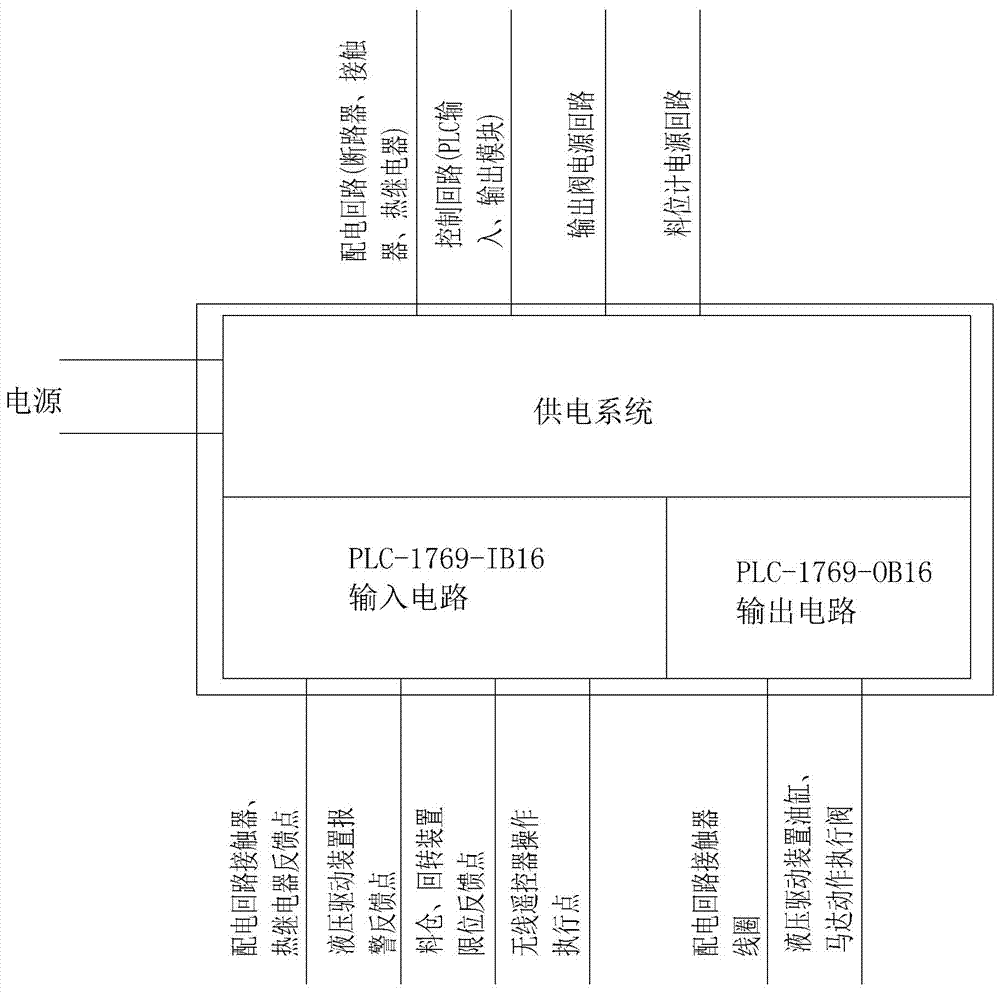

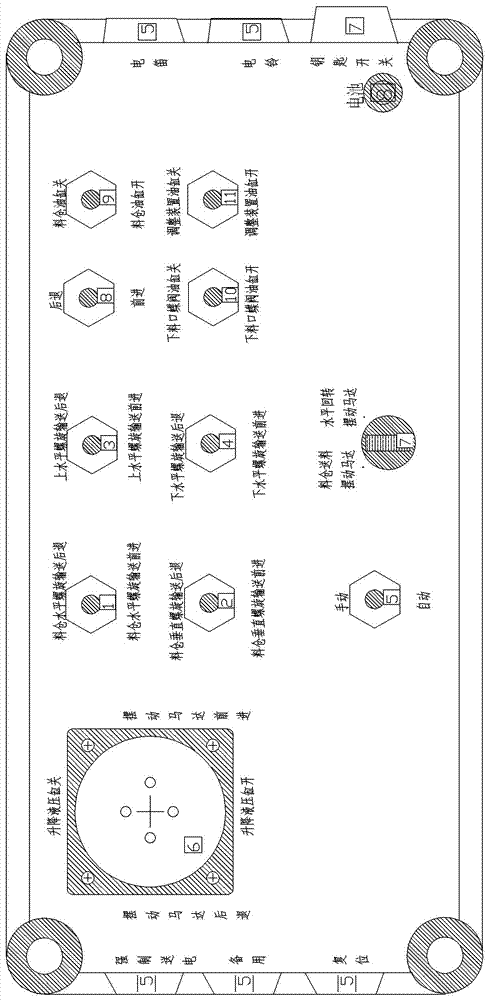

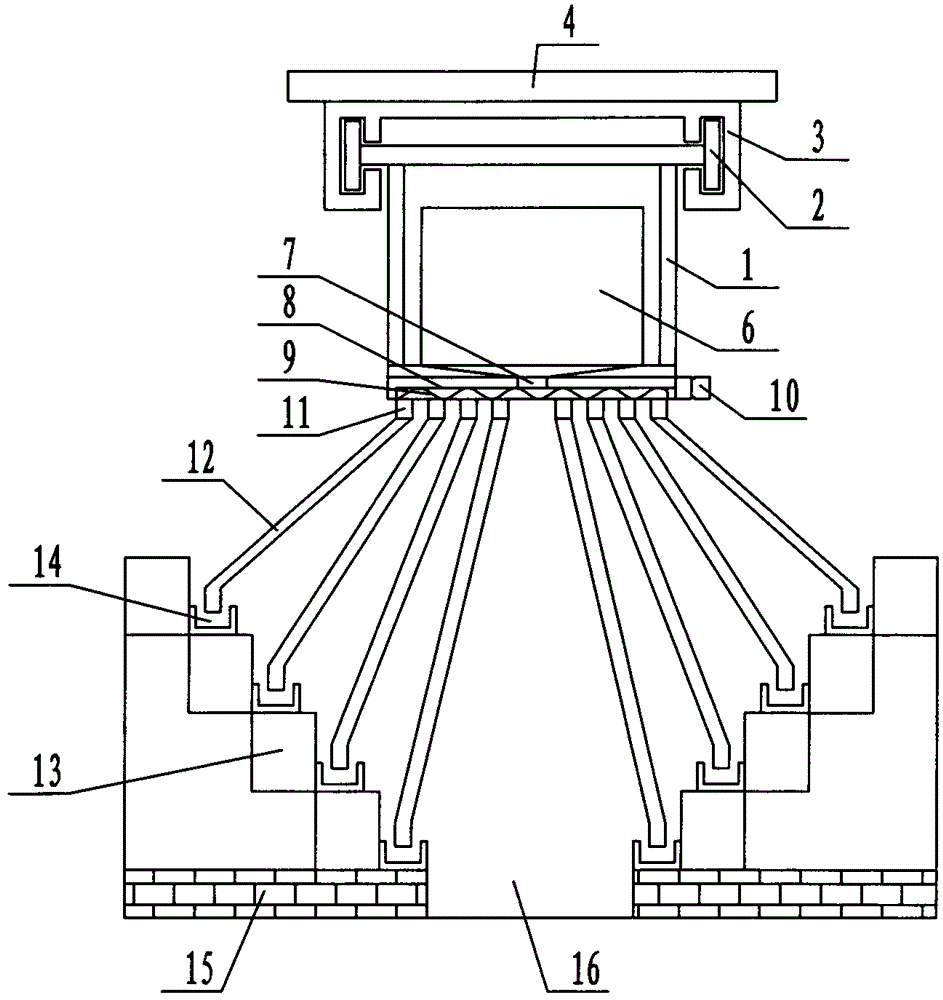

The invention relates to a device and method for feeding pigs with a liquid feed. The feeding device comprises a dry feed feeding device, a water feeding device, a feeding system, a stirring and weighing system and a master control system, wherein the discharging end of the dry feed feeding device and the water inlet end of the water feeding device are connected with a stirring tank, the stirring and weighing system comprises the stirring and a weighing sensor, the feeding system comprises a pushing machine, a high-pressure eddy fan, a feeding pipeline and a four-way feeding valve, the stirring tank is communicated with a feeding port of the pushing machine, a discharging port of the pushing machine is connected with a first port of the four-way feeding valve, a second port of the four-way feeding valve is communicated with a pigsty, a third port of the four-way feeding valve is connected with the high-pressure eddy fan, a four port of the four-way feeding valve is communicated with the stirring tank, and the master control system is in controlling connection with the dry feed feeding device, the water feeding device, the feeding system and the stirring and weighing system. The feeding device can automatically perform liquid-feed feeding, saves labor, can perform accurate feeding and ensure the nutrition demand of pigs, and the problem that labor input for liquid-feed feeding is large, and meeting of the nutrition demand of pigs is not easy to determine.

Owner:李宇晓

Efficient stirring equipment

InactiveCN107649054AEasy to integrateImprove stirring efficiencyShaking/oscillating/vibrating mixersTransportation and packagingArchitectural engineeringVibration motor

The invention provides efficient stirring equipment and relates to the field of machinery. The efficient stirring equipment comprises a fixing base, wherein an outer stirring bucket is fixedly connected with the top of the fixing base; damping casings are fixedly connected with the bottom of the inner wall of the outer stirring bucket; the damping casings are internally provided with damping springs; support jacking rods are fixedly connected with the ends far away from the outer stirring bucket, of the damping springs; the end far away from the damping spring, of each support jacking rod, penetrates through each damping casing and extends outside the damping casing; the end far away from each support spring, of the support jacking rod, is fixedly connected with an inner stirring bucket; stirring blocks are fixedly connected with the inner wall of the inner stirring bucket; a fixing plate is fixedly connected with the bottom of the inner stirring bucket. By adopting the efficient stirring equipment, rotation of an eccentric block is driven by rotation of a vibration motor, then vibration operation is implemented to the inner stirring bucket, combination of materials stirred insidethe inner stirring bucket is effectively accelerated, and the stirring efficiency of the stirring device is improved through vibration of the inner stirring bucket.

Owner:赵顺豪

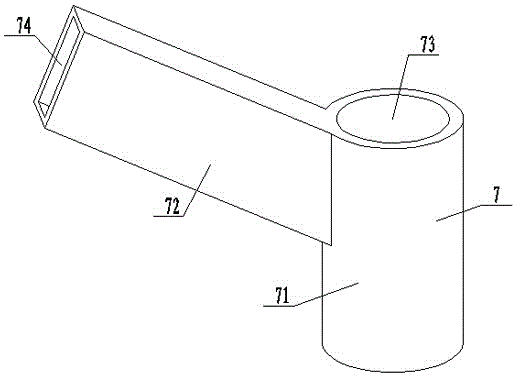

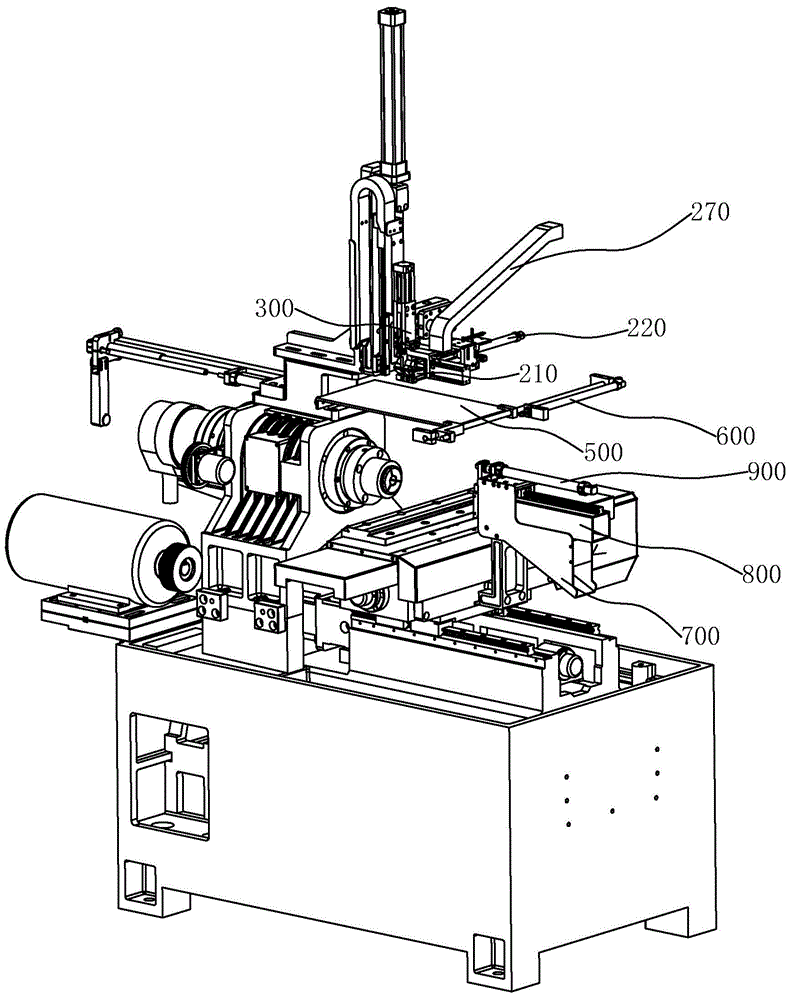

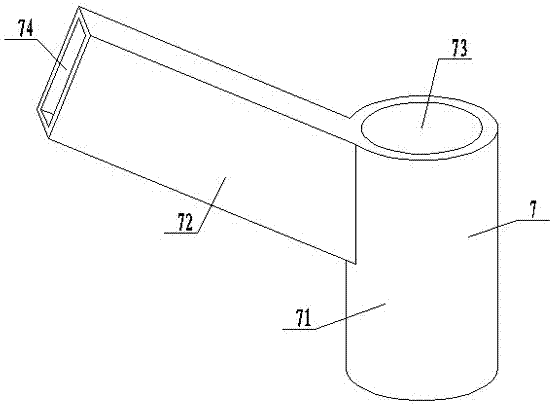

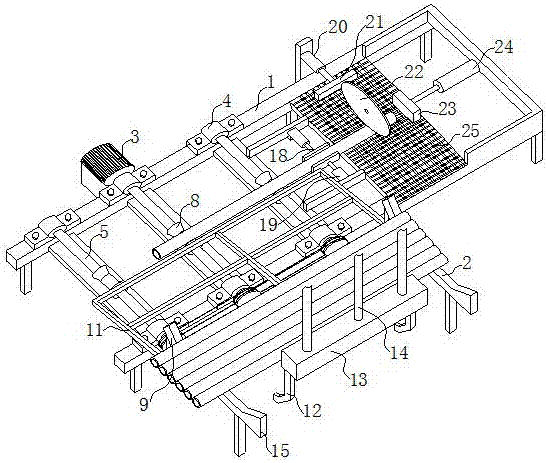

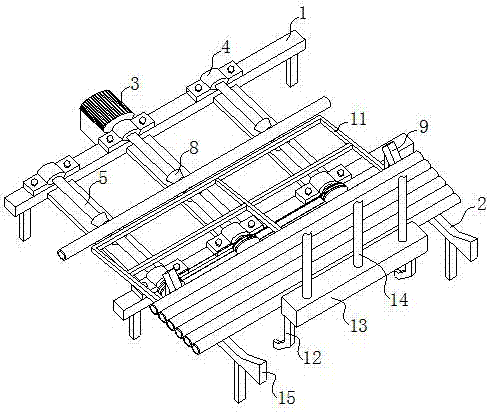

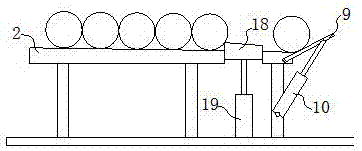

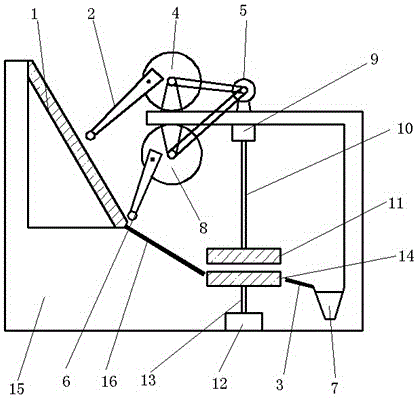

Automatic blanking and grinding all-in-one machine for roller groove of bearing outer ring

InactiveCN106737009AConvenient and unobstructed grindingSimple structureShaftsBearing componentsEngineeringConveyor belt

The invention discloses an automatic blanking and grinding all-in-one machine for a roller groove of a bearing outer ring. The automatic blanking and grinding all-in-one machine comprises a rack, wherein a plurality of clamping cylinders are uniformly arranged on the outer side of the upper end of the rack; an L-shaped clamping block is arranged on a piston rod of each clamping cylinder; an arc-shaped clamping groove matched with an external round surface on the outer side of the bearing outer ring is formed in the inner side of the upper end of an L-shaped clamping block; a bearing outer ring feeding device is arranged at the position, at the upper ends of the L-shaped clamping blocks, on the rack; the bearing outer ring feeding device structurally comprises a round feeding housing arranged in the middle of the rack and a square feeding housing obliquely arranged on one side of the upper end of the round feeding housing; a round feeding channel is arranged in the round feeding housing and penetrates the two ends of the round feeding housing; a square feeding channel communicating with the round feeding channel is arranged in the square feeding housing; and a conveyor belt is arranged at the position, at one side of the square feeding housing, on the rack.

Owner:YANCHENG SANCHUAN BEARING MFG

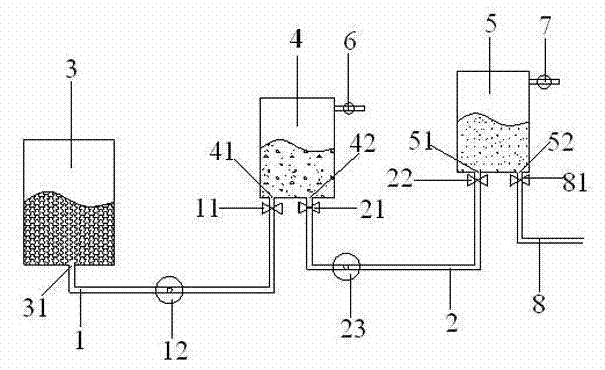

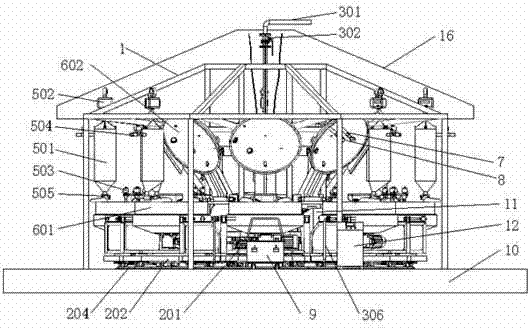

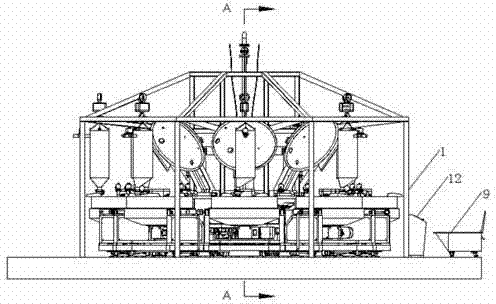

Preparation apparatus and method for lithium ion battery slurry

ActiveCN102824872AWell mixedReduce generationCell electrodesMixing methodsElectrical batteryEngineering

The invention belongs to the technical field of lithium ion batteries and especially relates to a preparation apparatus for lithium ion battery slurry. The apparatus comprises a solvent loading tank and a slurry agitator tank, wherein the slurry agitator tank is connected with a first vacuum pump; the apparatus further comprises a binder premixing tank, wherein the binder premixing tank is connected with a second vacuum pump; a discharge outlet of the solvent loading tank is connected with a feed inlet of the binder premixing tank through a first pipeline, and a discharge outlet of the binder premixing tank is connected with a feed inlet of the slurry agitator tank through a second pipeline. Compared with the prior art, the preparation apparatus provided by the invention has the following advantages: fluids like a solvent and a binder premixed liquid are added from the bottom of a tank to the top of the tank by using vacuum negative pressure, so it is guaranteed that there is only a two-phase interface of a liquid phase and a solid phase, maximum-efficiency mutual infiltration is realized, generation of bubbles in the slurry is reduced, dispersion is promoted, stirring time is shortened and operation is simple, which enables stirring time to be reduced and production efficiency to be improved. Furthermore, the invention also discloses a method of utilizing the apparatus for preparation lithium ion battery slurry.

Owner:DONGGUAN AMPEREX TECH

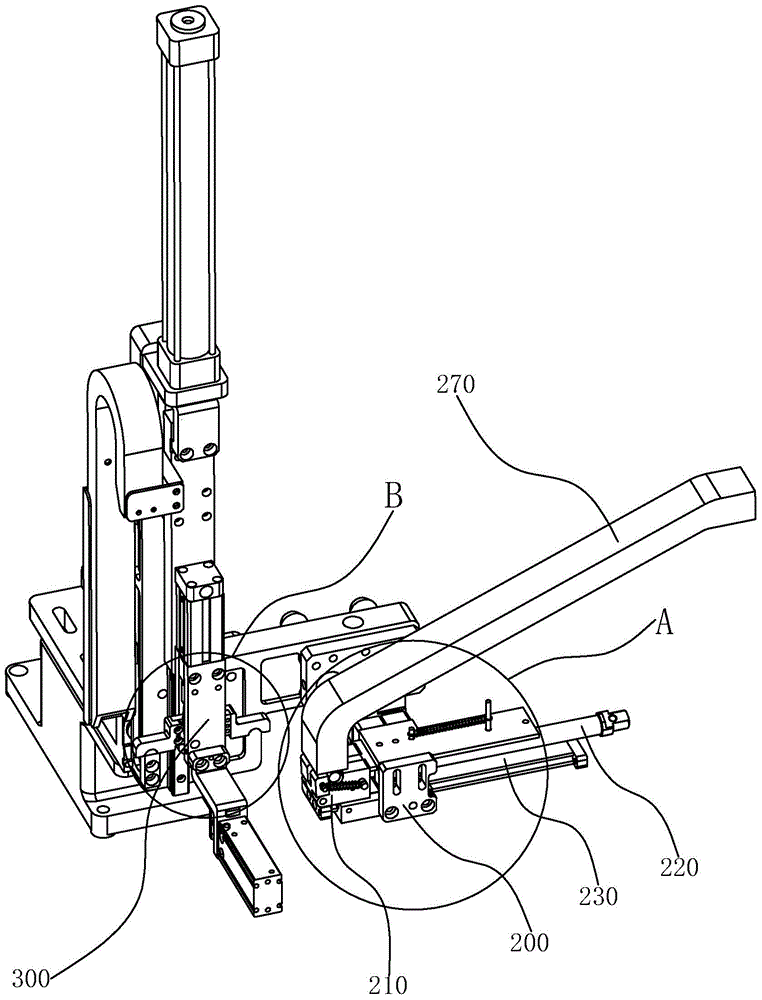

Pneumatic manipulator processing equipment

ActiveCN104057105AShort tripSave feeding timeAuxillary equipmentMetal working apparatusEngineeringHolding tank

The invention provides pneumatic manipulator processing equipment and belongs to the technical field of automatic lathes; the technical problems that a pneumatic manipulator in a traditional lathe is long in stroke, workpieces are easy to damage during material receiving and discharging, and chippings and water spots generated by processing are easy to splash to a feeding end are solved by the pneumatic manipulator processing equipment provided by the invention. The pneumatic manipulator processing equipment is arranged on a rack, and comprises a feeding device, a protection device and a material receiving device, wherein the feeding device is provided with a permanent seat and a feeding assembly; the protection device is provided with a guide rod and a protection plate; the material receiving device is provided with a feed cover frame and a feed pipe; a holding tank is formed in the feeding assembly, and moreover, when the feeding assembly moves, the workpieces can be shifted from the holding tank; the rack is provided with a processing end and a feeding end; the protection device can be moved to a position between the processing end and the feeding end, and the processing end and the feeding end are separated; a notch is formed in the bottom part of the feed pipe, and a material receiving plate hinged to the feed pipe is arranged in the notch; a rolling shaft is arranged in the feed cover frame, and the rear end of the material receiving plate is put on the rolling shaft. The stroke of the pneumatic manipulator is shortened, the safety and the cleanness of the feeding end are protected, and the damage to the workpieces is smaller.

Owner:宁波宫铁智能科技有限公司

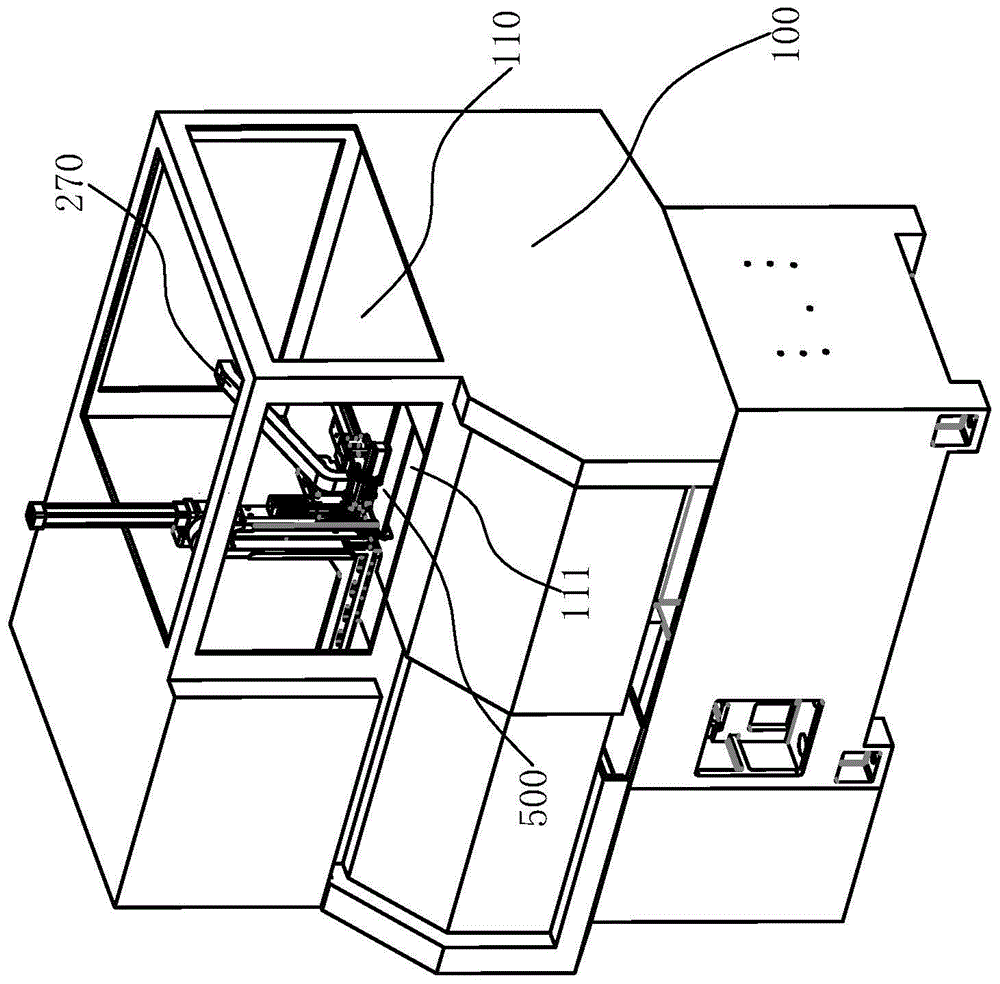

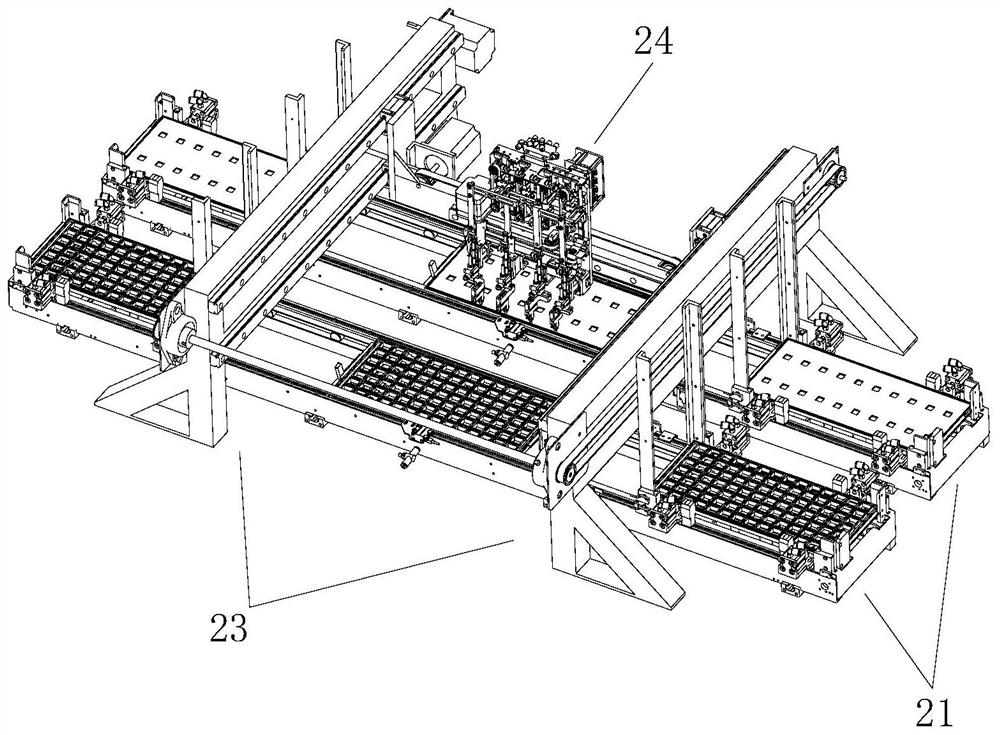

Chip tray changing equipment

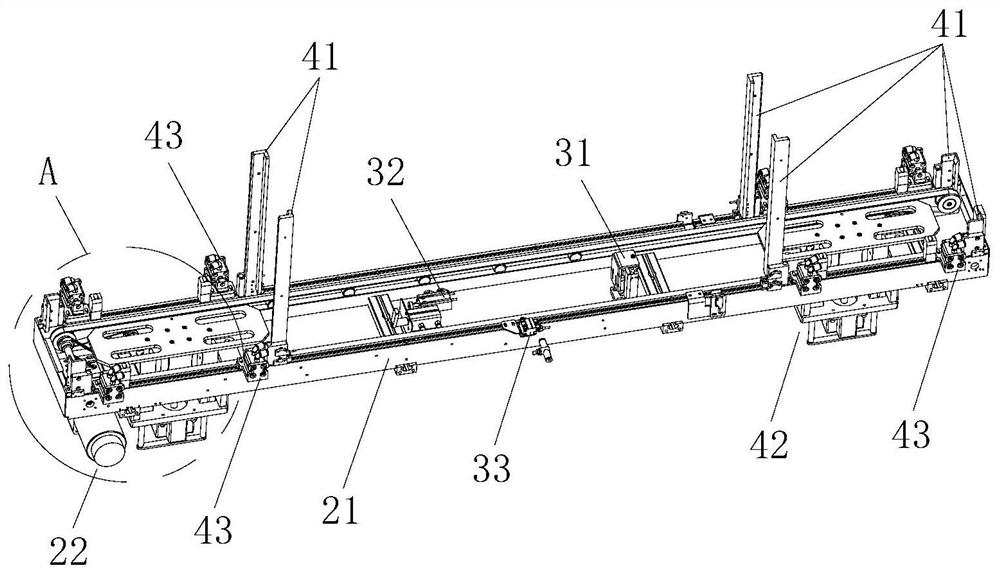

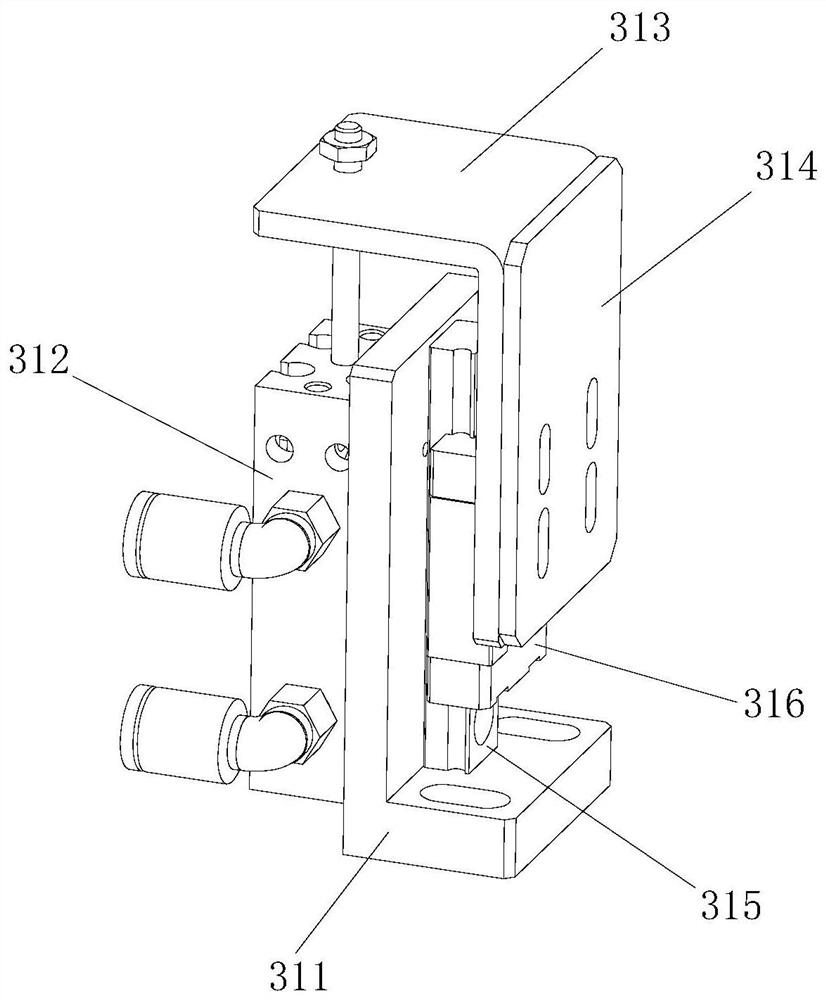

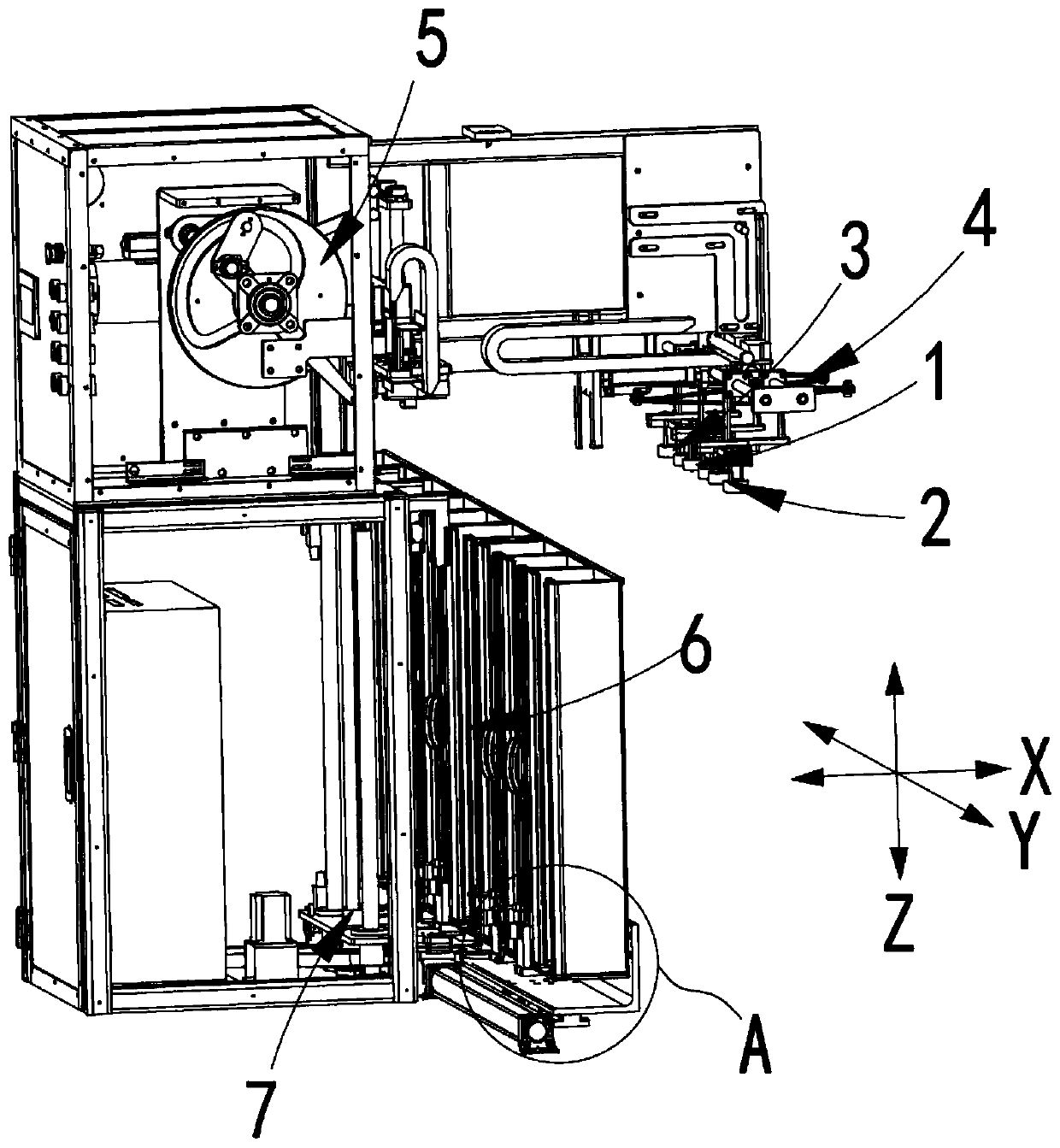

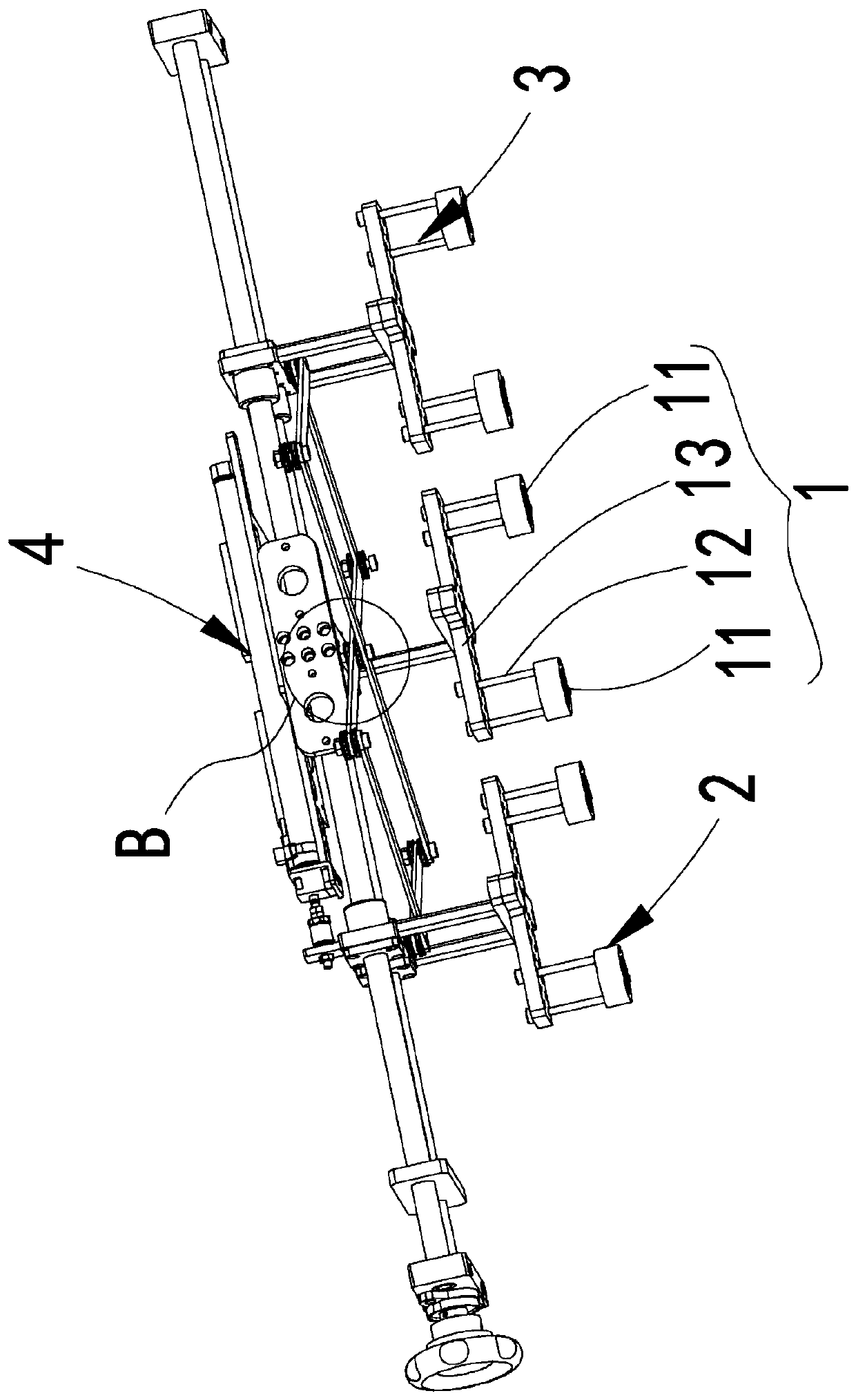

ActiveCN113120609AImprove disk changing efficiencyHigh mobile positioning accuracyStacking articlesDe-stacking articlesEngineeringSingle chip

The invention discloses chip tray changing equipment which comprises at least two tray changing material tray conveying rails and a tray changing module. Each tray changing material tray conveying rail comprises a tray changing track main frame, a material tray conveying device and a material tray positioning device, wherein the material tray conveying device and the material tray positioning device are installed on the tray changing track main frame, the material tray conveying device is used for conveying universal material trays or special material trays to move on the tray changing track main frame, and the material tray positioning device is used for positioning the universal material trays or the special material trays; and the tray changing module comprises a tray changing moving frame and a tray changing gripper, the tray changing moving frame is used for driving the tray changing gripper to move, and the tray changing gripper can grab single chips or grab at least two chips in an opening and closing interval adjusting manner. The chip tray changing equipment can change the chips on the universal material trays into the special material trays, and also can change the chips on the special material trays into the universal material trays; the material trays can be adaptively positioned in stations; the disc changing gripper can be opened and closed to adjust the distance; and the chip tray changing efficiency is effectively improved.

Owner:SHENZHEN GRAND INNOSYS CORP

Automatic bearing outer ring running pulley groove polishing machine

InactiveCN106863072ASimple structureEasy to assembleGrinding machinesGrinding feedersEngineeringPiston rod

The invention discloses an automatic grinding machine for roller grooves of bearing outer rings, which comprises: a frame, a plurality of clamping cylinders are evenly arranged on the outer side of the upper end of the frame, and the piston rods of the clamping cylinders are respectively arranged There is an L-shaped block, and an arc-shaped slot that cooperates with the outer circular surface of the outer ring of the bearing is arranged on the inner side of the upper end of the L-shaped block, and a bearing is arranged on the frame at the upper end of the L-shaped block. Outer ring feeding device, the structure of the bearing outer ring feeding device includes: a circular feeding housing arranged in the middle of the frame and a square feeding housing obliquely arranged on the upper side of the bearing feeding cylinder. The circular housing is provided with a circular feed passage running through its two ends, and a square feed passage communicated with the circular feed passage is provided in the square feed housing, and the feed device on the outer ring of the bearing One side of the frame at the upper end is provided with a transverse cylinder.

Owner:YANCHENG SANCHUAN BEARING MFG

Cylinder sleeve cutting equipment capable of achieving scrap suction conveniently

InactiveCN107414165AEasy to cleanAvoid damageShearing machinesMaintainance and safety accessoriesHydraulic cylinderEngineering

The invention discloses cylinder sleeve cutting equipment capable of achieving scrap suction conveniently. The cylinder sleeve cutting equipment capable of achieving scrap suction conveniently comprises a cutting table, and the cutting table is formed through plain warp-weft weaving of steel wires. A blocking plate is arranged on one side of the cutting table and located on the feeding stroke of a cylinder sleeve. The blocking plate is connected with the movable end of a third hydraulic cylinder in a driven mode and driven by the third hydraulic cylinder to move horizontally, and the moving direction of the blocking plate is parallel to the feeding direction of the cylinder sleeve. A pushing plate is arranged on the other side of the cutting table. The pushing plate is connected with the movable end of a seventh hydraulic cylinder in a driven mode and driven by the seventh hydraulic cylinder to move horizontally, and the moving direction of the pushing plate is perpendicular to the feeding direction of the cylinder sleeve. A scrap suction device comprises a scrap suction pipe, a scrap collection box and a draught fan, wherein a feeding port of the scrap suction pipe is located below the cutting table, a discharging port of the scrap suction pipe communicates with the scrap suction box, and the draught fan is located on one side of the scrap suction box. According to the cylinder sleeve cutting equipment capable of achieving scrap suction conveniently, waste scraps generated in the cutting process can be removed, the labor intensity is low, the machining time is short, and the machining efficiency is high.

Owner:ZYNP GRP ANHUI CO LTD

Air cylinder sleeve cutting device capable of achieving automatic feeding and discharging

InactiveCN107553192ARealize automatic unloadingRealize automatic feeding processMetal working apparatusPositioning apparatusHydraulic cylinderEngineering

The invention discloses an air cylinder sleeve cutting device capable of achieving automatic feeding and discharging. The air cylinder sleeve cutting device comprises a feeding device, a cutting device body and a discharging device; the feeding device is used for transferring an air cylinder sleeve to the cutting device body, and the cutting device body is used for cutting the air cylinder sleeve;the discharging device is used for transferring the cut air cylinder sleeve out and comprises a discharging plate, a seventh hydraulic cylinder and a conveyor belt; the discharging plate is located on one side of the cutting device body, is connected with the movable end of the seventh hydraulic cylinder in a driving mode and is driven by the seventh hydraulic cylinder to horizontally move; the movement direction of the discharging plate is perpendicular to the transferring direction of the feeding device, and the conveyor belt is located on the other side of the cutting device body and located on the moving stroke of the discharging plate; and the transferring direction of the conveyor belt is in parallel with that of the feeding device. According to the air cylinder sleeve cutting device capable of achieving automatic feeding and discharging, automatic feeding and discharging of the air cylinder sleeve can be achieved, the labor intensity is relieved, the processing time is shortened, and the processing efficiency is improved.

Owner:ZYNP GRP ANHUI CO LTD

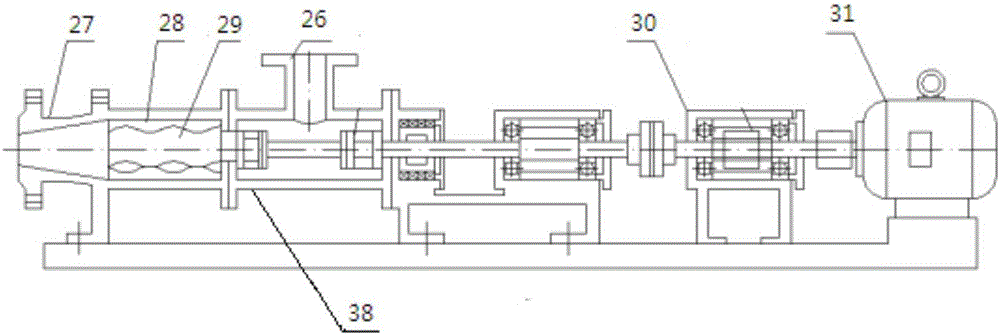

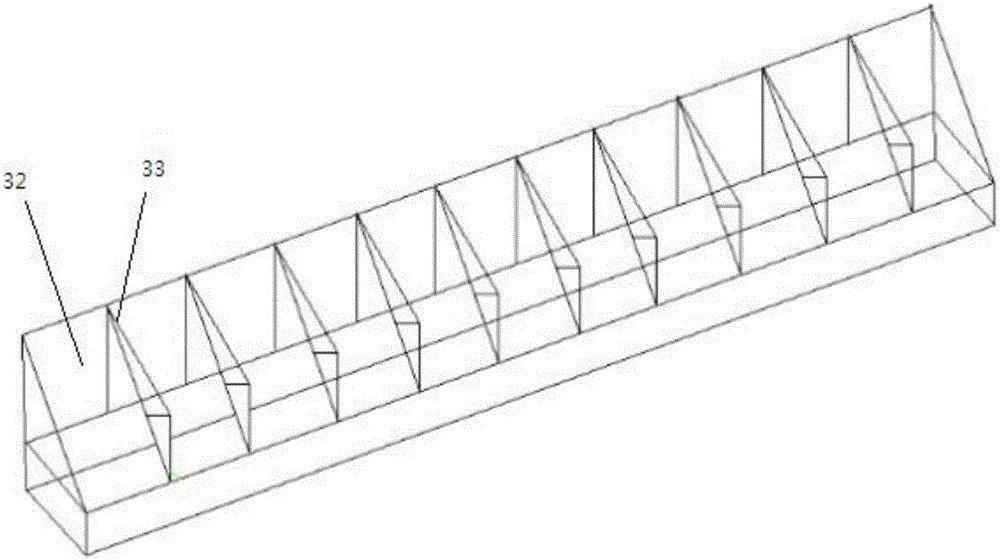

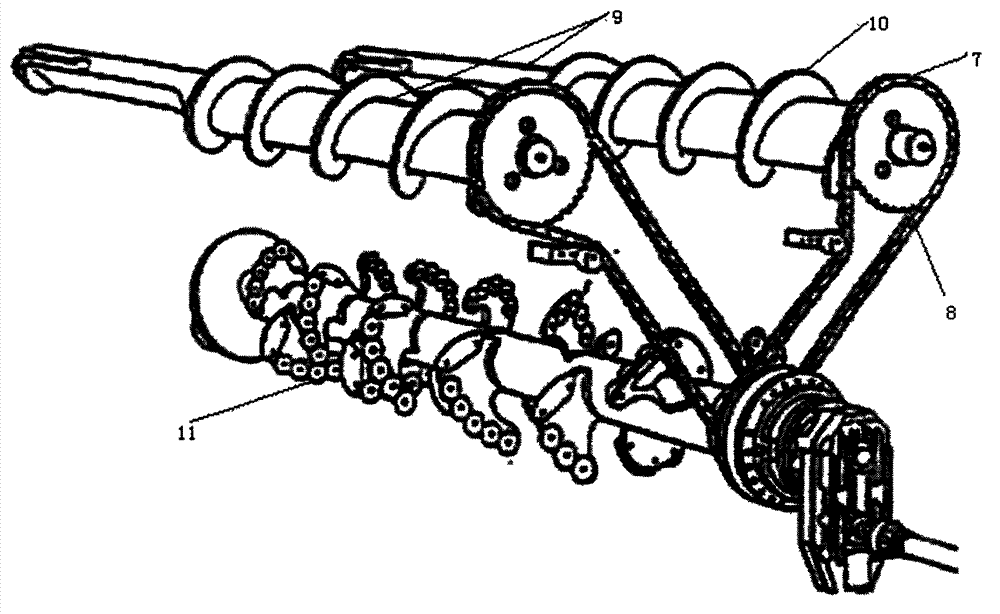

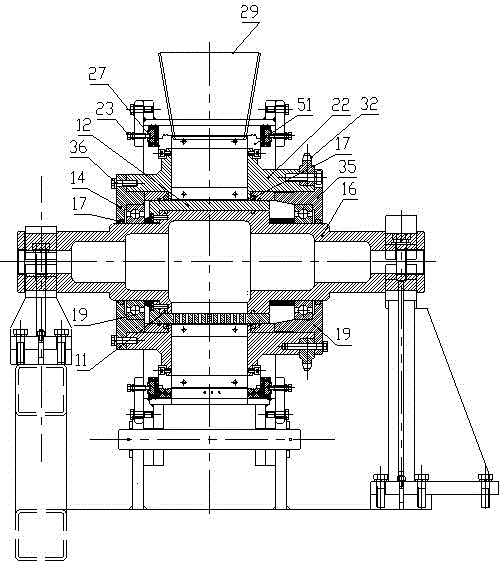

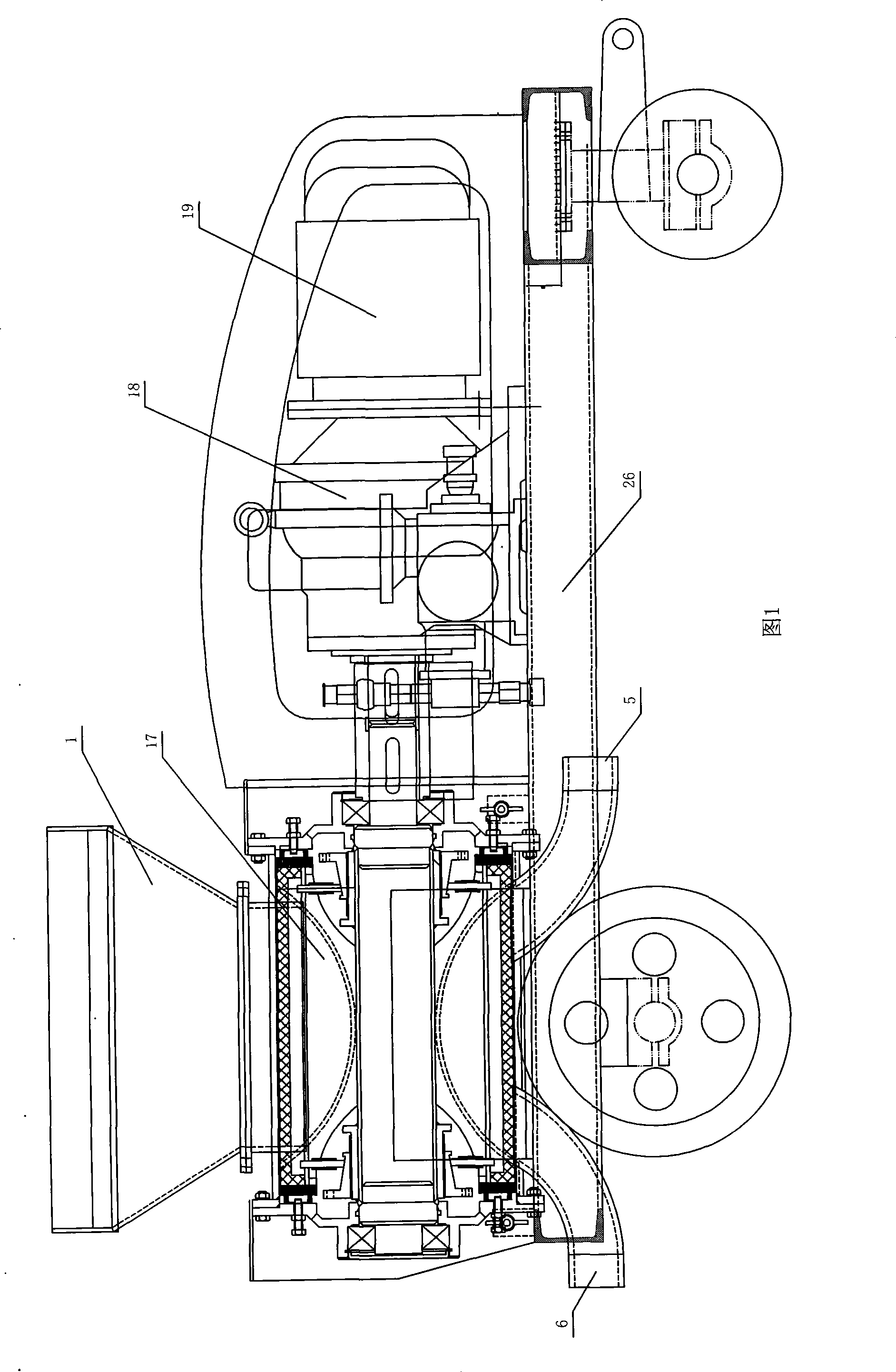

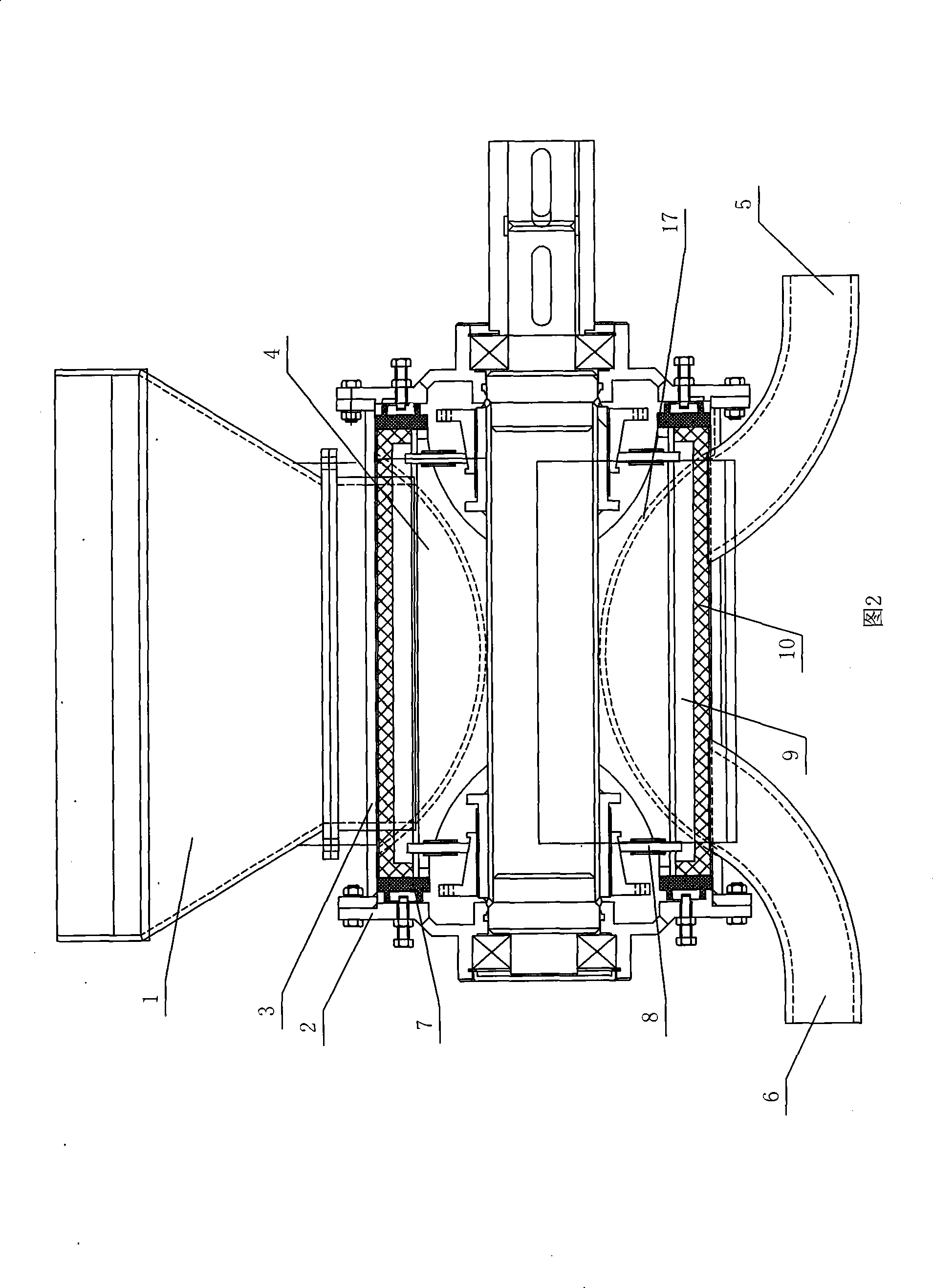

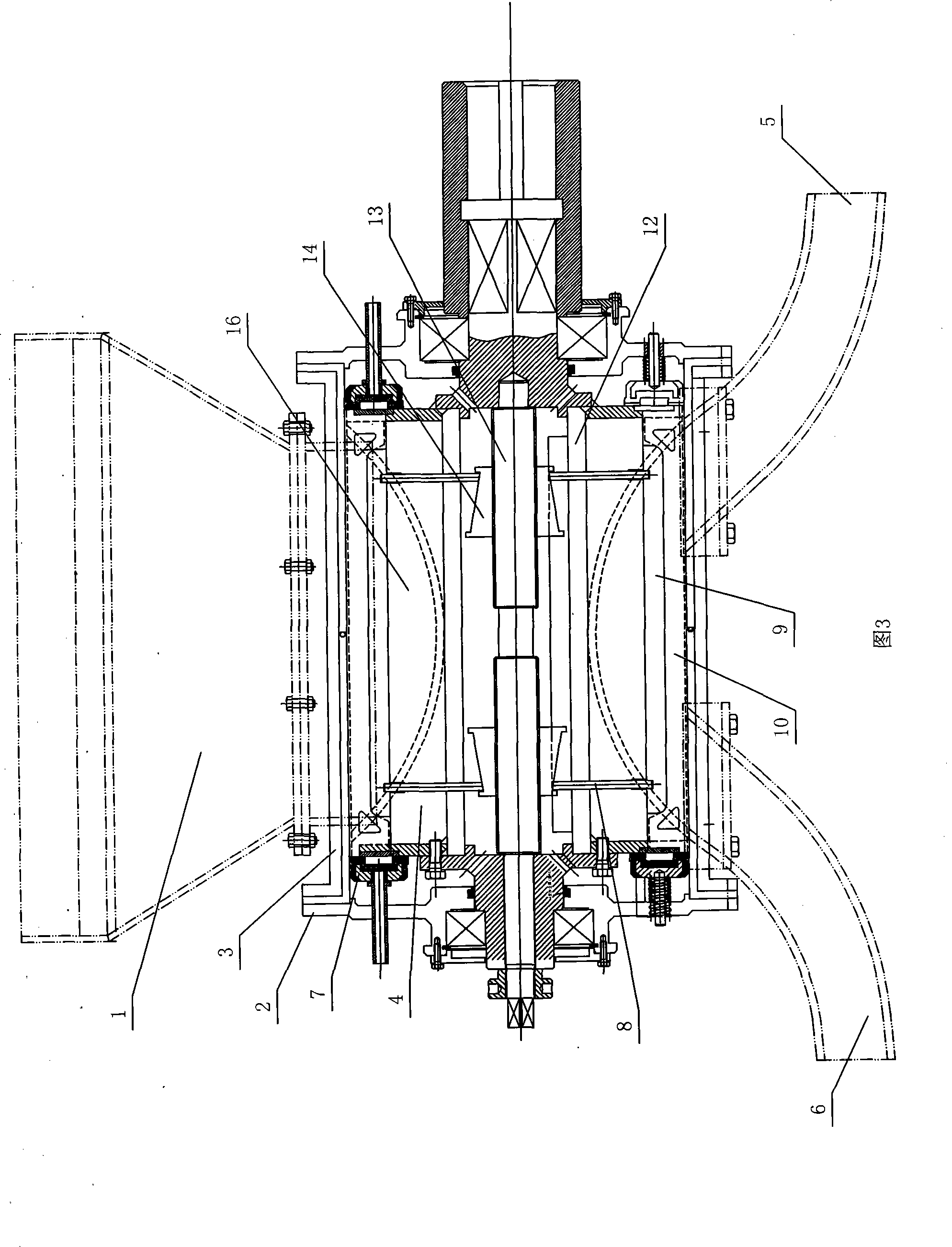

Total mixed ration stirring feeding machine

The invention belongs to a total mixed ration stirring feeding machine. Total mixed ration (TMR) feeding technology is adopted, the TMR is short for Total mixed ration. The total mixed ration stirring feeding machine is mainly composed of a drive system, a stirring box body, a weighing bottom frame, a discharging device, a spiral stirring cage shaft system and an electronic weighing system. The spiral stirring cage shaft system is composed of a chain, a gear, a stirring wheel, a movable cutter and a fixed cutter. Fodder can be accurately calculated, and a fodder storage can be effectively managed. Gross weight in a fodder mixing machine can be displayed, and food consumption of every animal can be measured. Cutting-off rough fodder, cutting-off concentrated fodder and microelements and other additives are independently mixed according to nutritional requirements of dairy cattle at different fodder stages. The purpose of scientific feeding is achieved, especially for accurate weighing of some microconstituents (such as nitrogen additives, man-made additives, syrup), and therefore high-quality fodder can be produced. Every daily ration the cattle eat is full rate daily ration which is stable in concentrate-roughage ratio and consistent in nutrition density.

Owner:乌鲁木齐牧田园农业科技有限公司

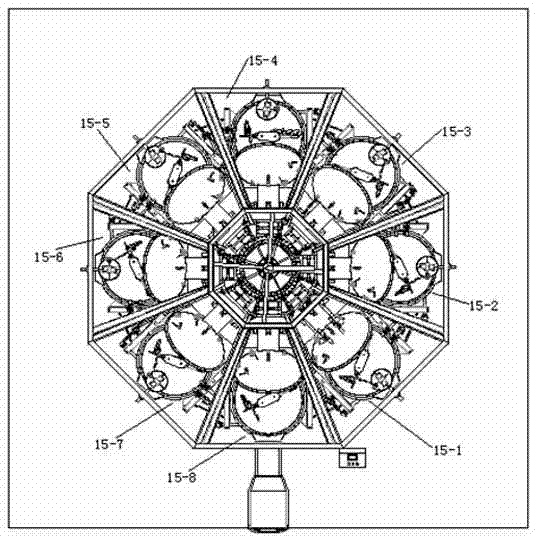

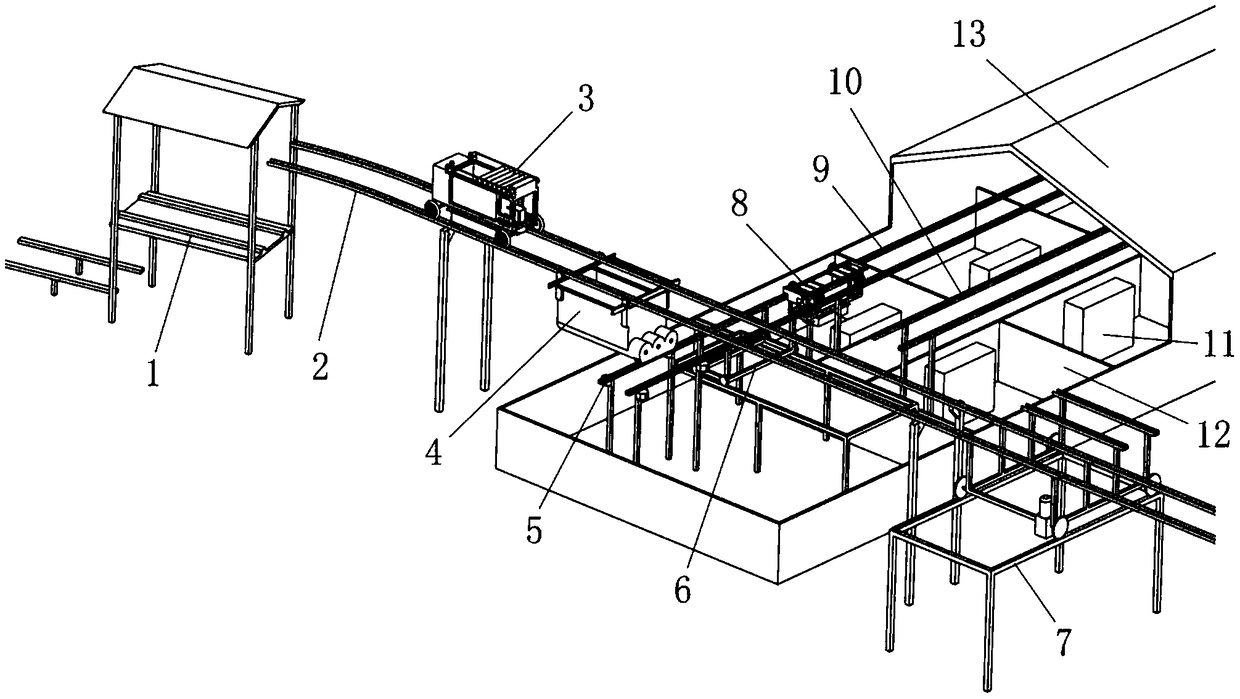

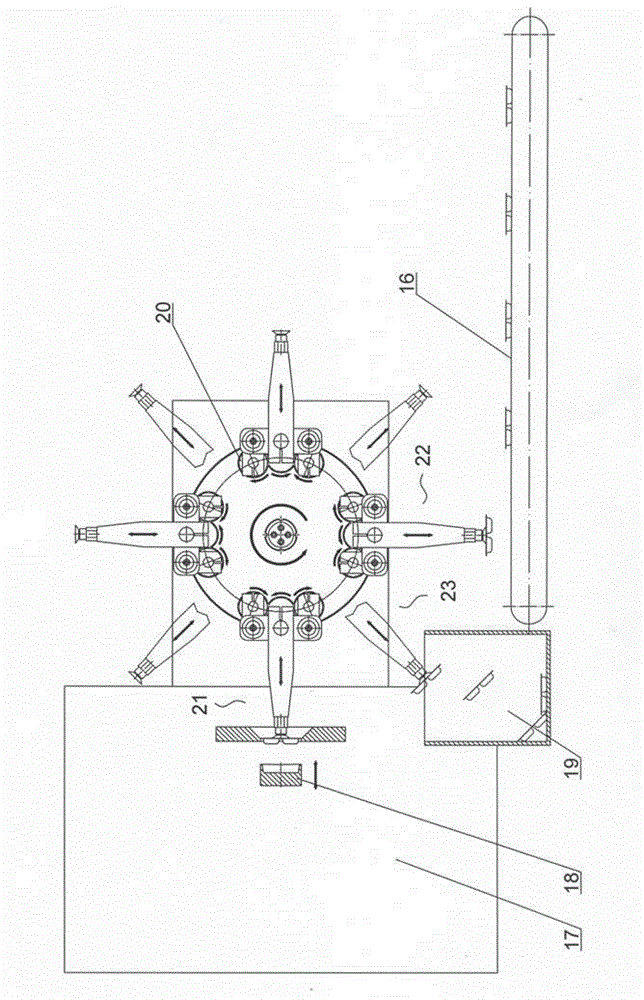

Rotation station type full-automatic frying and boiling production line

ActiveCN104705359AExact formulaSave work spaceBaking plantsFood preparationProduction lineEngineering

The invention relates to a rotation station type full-automatic frying and boiling production line which comprises a rack body for fixation and connection, a discharge trolley, an automation control center as well as a rotary device, a steam device, a power device, a feeding device and automatic frying units, wherein the rack body is fixed on the ground; the rotary device is arranged inside the rack body; a plurality groups of automatic frying units are arranged above the rotary device; the steam device penetrates through the rack body and is communicated with the frying pots of the automatic frying units; pot washing cold water tubes and hot water tubes are arranged above pot covers on the rack body; the production line comprises eight stations, including a washing station, six feeding frying stations and a discharge station. The rotation station type full-automatic frying and boiling production line provided by the invention is smart in structural design, the working space is saved, the feeding and discharging equipment set is reduced, the material blending precision is improved due to the adoption of a feeding-after-measuring mode, and meanwhile the working efficiency of material frying is greatly improved.

Owner:BAODING JIALI FOOD MACHINE

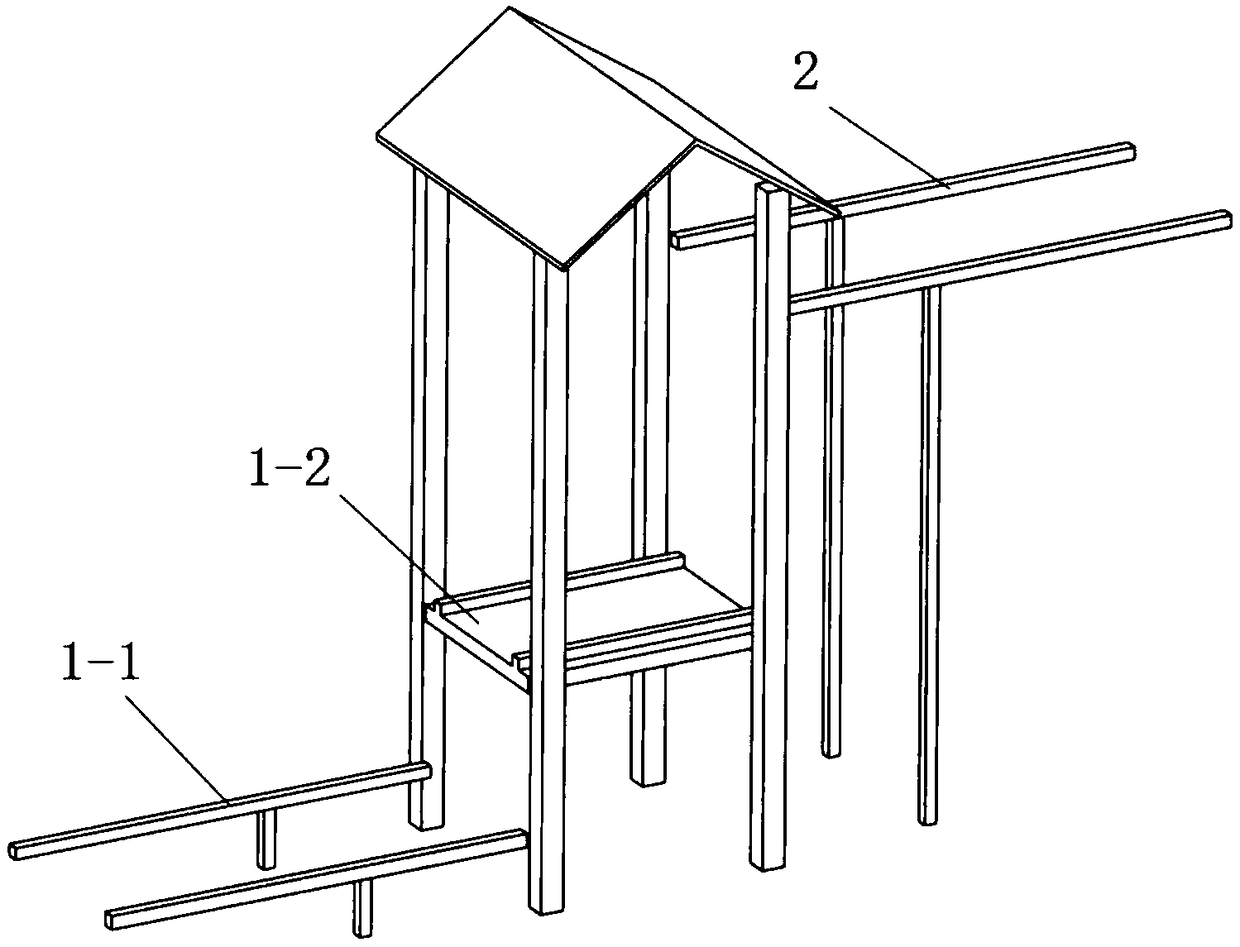

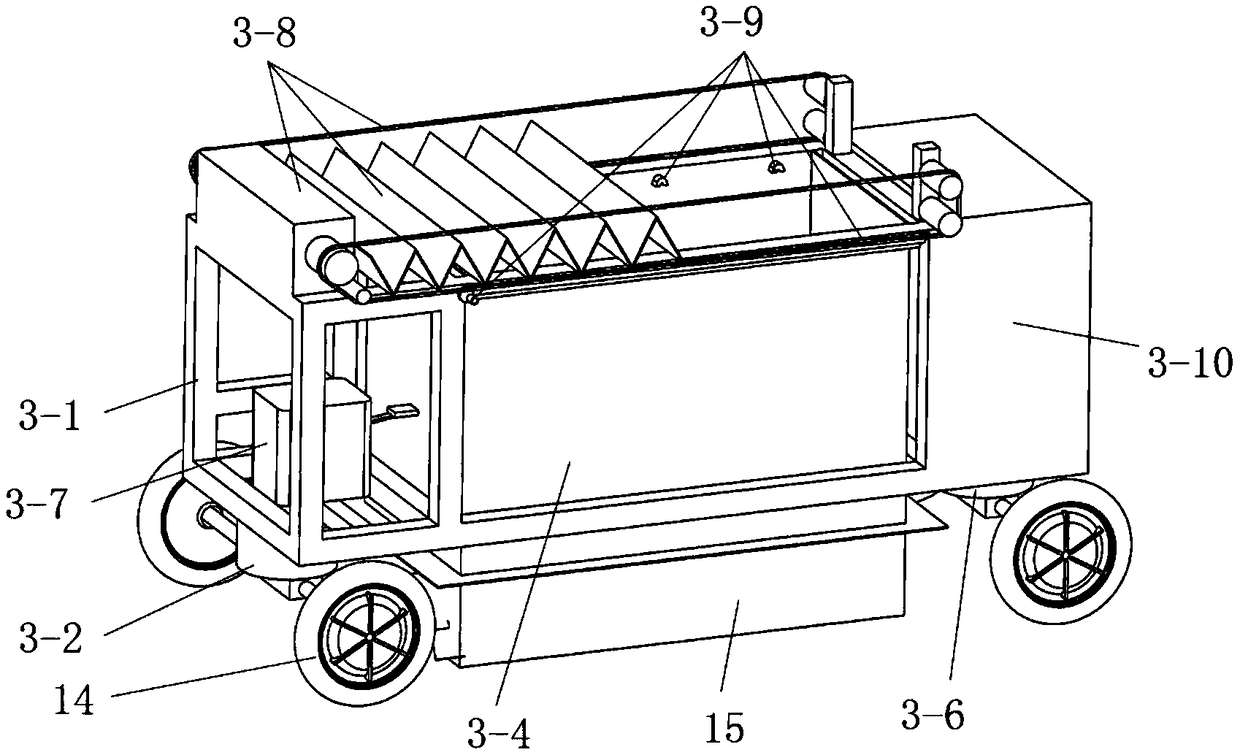

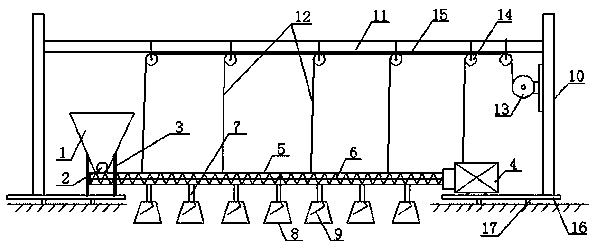

Overhead rail type feed conveying device

ActiveCN109156377AStrong terrain adaptabilitySave feeding timeAnimal feeding devicesMechanical conveyorsCartLivestock

The invention discloses an overhead rail type feed conveying device belonging to the field of livestock and poultry breeding. A feed track runs through a pigsty, a material feed cart moves on the feedtrack, a transfer bin is hoisted under the feeding track in the pigsty, a weighing platform is also located in the pigsty is installed under the transfer bin, a first-row feed distribution track anda second-row feed distribution track which do not interfere with each other are arranged on one side of a track translation mechanism toward the pigpens, and aggregate food troughs are arranged in several pigpens below the first-row feed distribution track and the second-row feed distribution track; the feeding rail is provided with an interrupting part at any straight part outside the pigsty, andan avoiding rail mechanism is installed at the relative position of the interrupting part. Compared with the traditional pipeline conveying, the invention has the problems that the pipeline is easy to be worn, easy to be broken down, difficult to be repaired and maintained, the residual feed in the pipeline is not easy to be cleaned, and the conveying system of the rail car works more reliably, is easier to be used and maintained, and has longer service life.

Owner:CHINA AGRI UNIV

Novel automatic feeding system for fish pond

InactiveCN104255628ALow costWill not affect normal operationPisciculture and aquariaReduction driveSlide plate

The invention relates to a novel automatic feeding system for a fish pond. The novel automatic feeding system is characterized in that the novel automatic feeding system comprises a shifting device and a feeding device, wherein the shifting device comprises guide rails arranged on the ground on two sides of the fish pond, sliding blocks arranged on the guide rails in a sliding mode, and sliding plates arranged on the sliding blocks, the feeding device comprises two stand columns, a beam, a delivery device and discharging pipelines, the stand columns are fixed on the sliding plates on two sides of the fish pond respectively, the beam is arranged between the stand columns, the delivery device consists of a conveying gear motor, a conveying spiral stirring spring, a conveying pipeline, and a V-shaped hopper, the conveying pipeline is connected with the beam through a plurality of fixed pulleys, the fixed pulleys are connected with the conveying pipeline through fixed pulley steel wire ropes, each fixed pulley steel wire rope is connected with a main steel wire rope, and the tail end of the main steel wire rope is connected with a speed reducer arranged on one of the stand columns. According to the automatic feeding system for the fish pond, automatic feeding is achieved through the feeding device, and movement of the feeding system is achieved through the shifting device so as to finally achieve full coverage of feeding of a plurality of fish ponds.

Owner:ZHEJIANG OCEAN UNIV

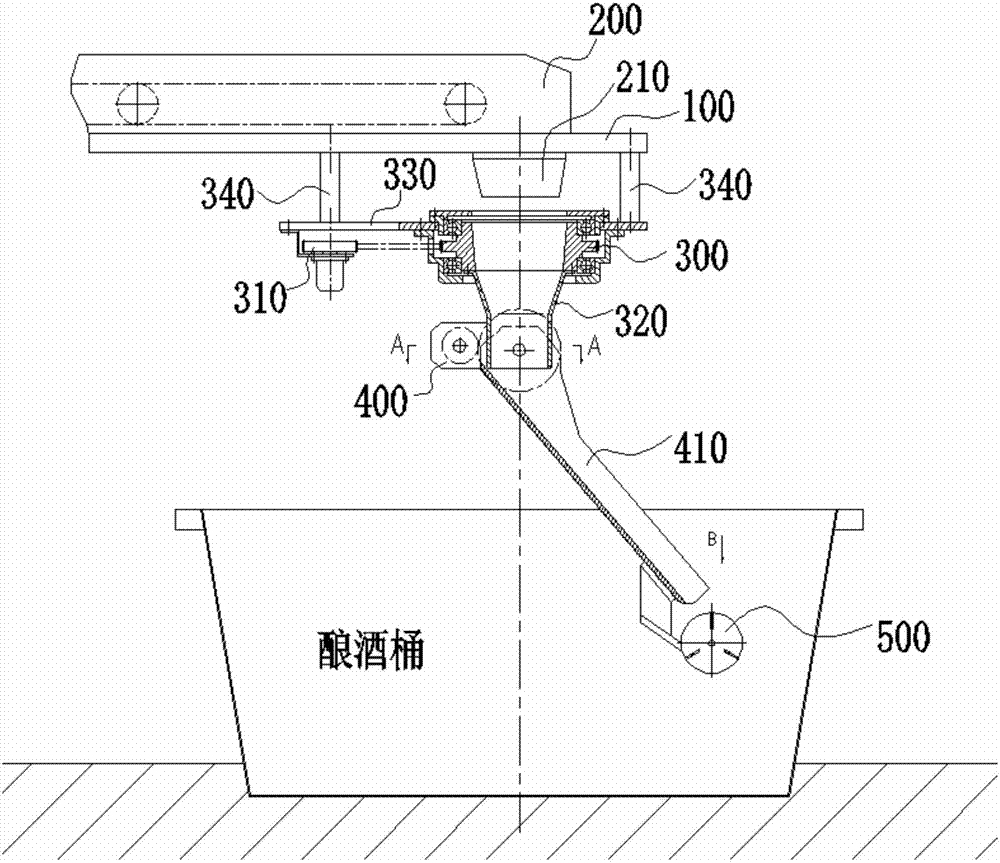

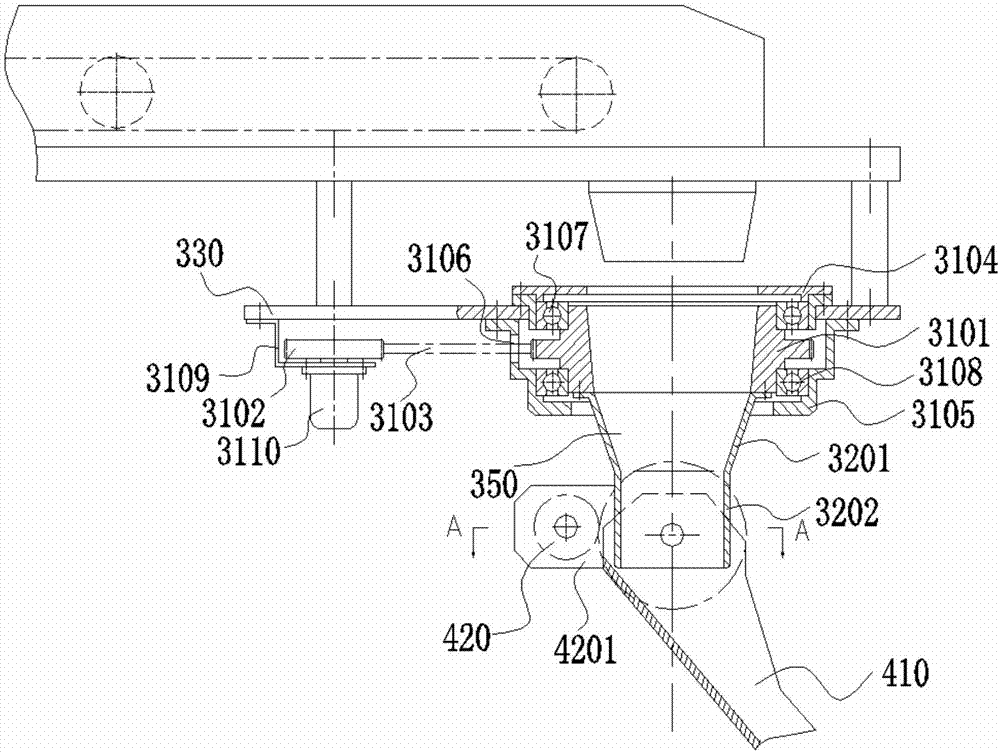

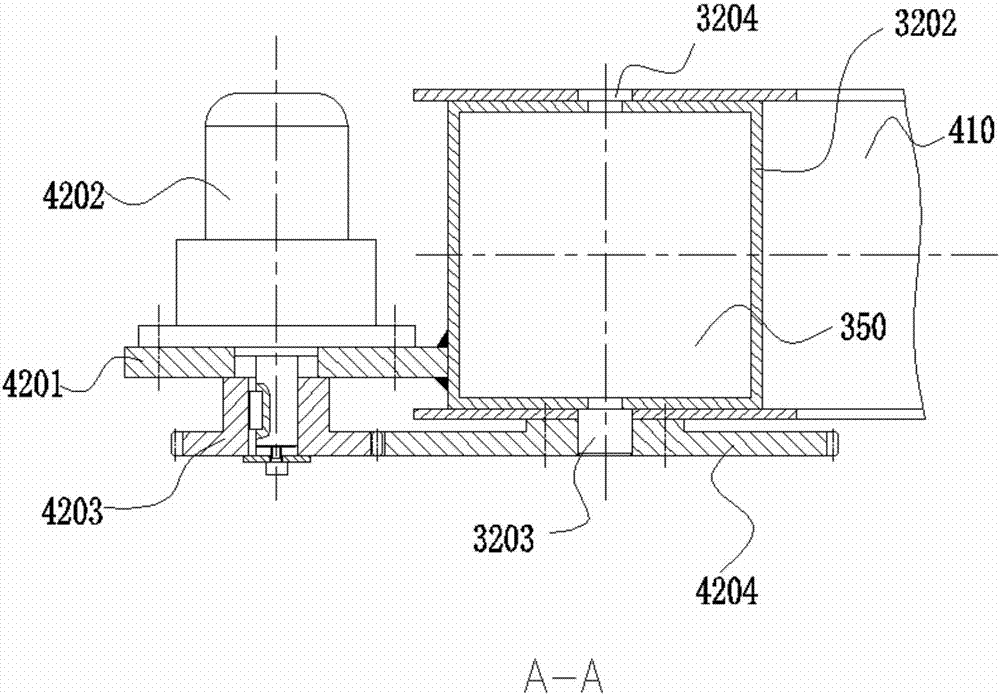

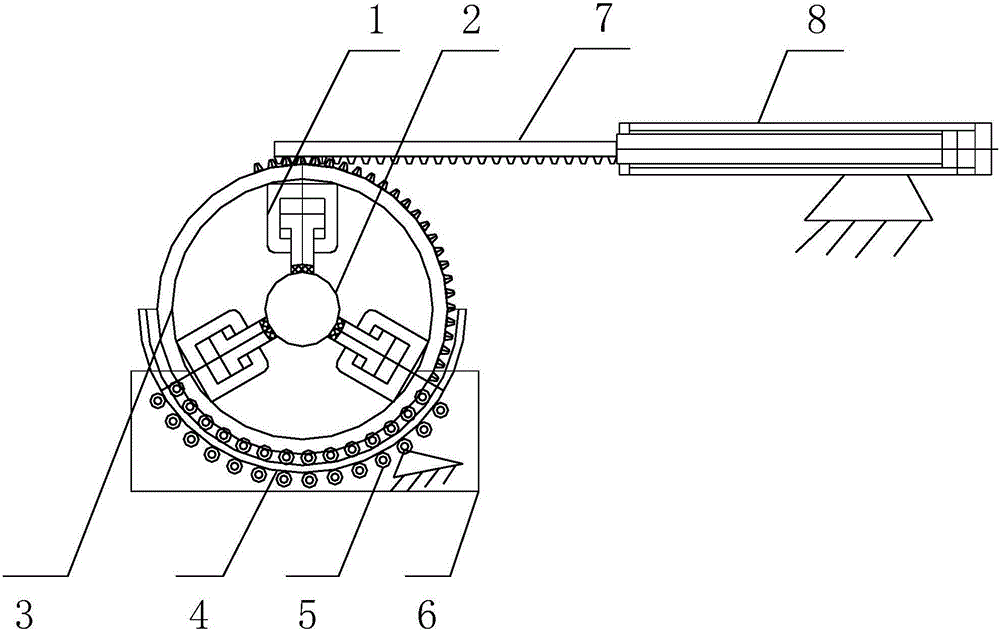

Rotary scattering device with automatically adjusted diameter

PendingCN107253617AThe radius of gyration is automatically adjustableUniform clothLoading/unloadingGreen materialsEngineering

The invention relates to the technical field of automatic rice steamer filling machines in winery, in particular to a rotary scattering device with an automatically adjusted diameter. The rotary scattering device comprises a mechanical arm, a discharge mechanism, a rotary mechanism and a distributing mechanism, wherein the discharge mechanism is installed above the mechanical arm and comprises a discharge hopper penetrates through the lower end face of the mechanical arm, the rotary mechanism is arranged below the mechanical arm and comprises a rotary gear assembly and a square-circular rotary sleeve suitable for being driven by the rotary gear assembly to rotate, the distributing mechanism comprises a conveying inclined groove rotationally connected to the bottom of the square-circular rotary sleeve and suitable for being driven by the square-circular rotary sleeve to rotate, and a rotating assembly suitable for driving the conveying inclined groove to rotate relative to the square-circular rotary sleeve to adjust the distributing radius, and green materials are evenly distributed by the distributing mechanism through the discharge hopper after being rotated by the rotary mechanism. The rotary scattering device is used for solving the technical problem of scattering rapidness and evenness.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

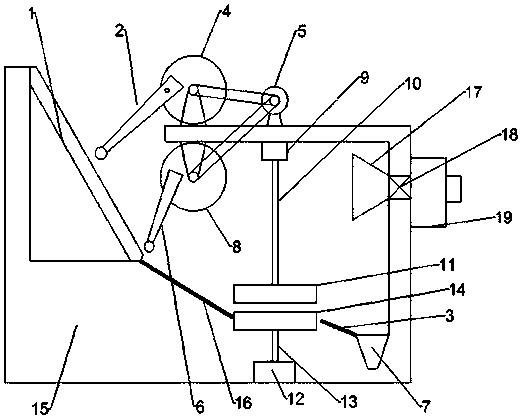

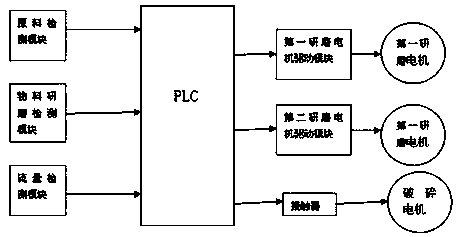

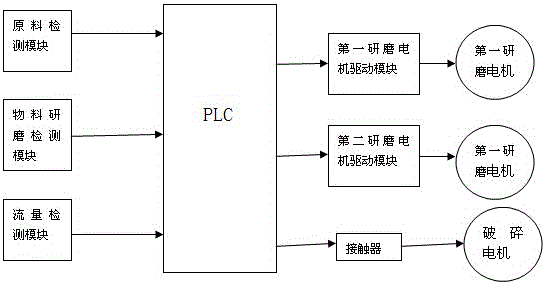

Clean-type two-jaw breaking grinding machine and control system thereof

InactiveCN108325692AAchieve a brokenAchieve secondary crushingUsing liquid separation agentDirt cleaningMotor driveControl system

The invention discloses a clean-type two-jaw breaking grinding machine and a control system thereof. The clean-type two-jaw breaking grinding machine comprises a breaking stationary jaw, a first breaking movable jaw, a first breaking flywheel, a breaking motor, a second breaking movable jaw, a second breaking flywheel, a first grinding motor, a first grinding main shaft, a first grinding disc, a second grinding motor, a second grinding main shaft, a second grinding disc, a rack, a breaking discharge channel, a grinding discharge channel, a discharge hopper, a dust hopper, an air pump and a dust collecting box; and the control system consists of a raw material detection module, a material grinding detection module, a flow detection module, a PLC, a first grinding motor driving module, a second grinding motor driving module and a contactor. The clean-type two-jaw breaking grinding machine can achieve primary breaking, secondary breaking and grinding on a raw material, so that the degreeof size reduction of the raw material is raised, and the breaking time is shortened; and the air pump can be started during machining to suck dust, so that the cleaning property and safety are improved.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

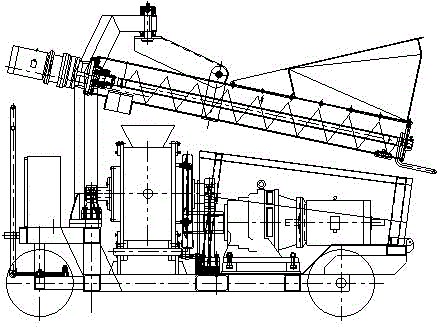

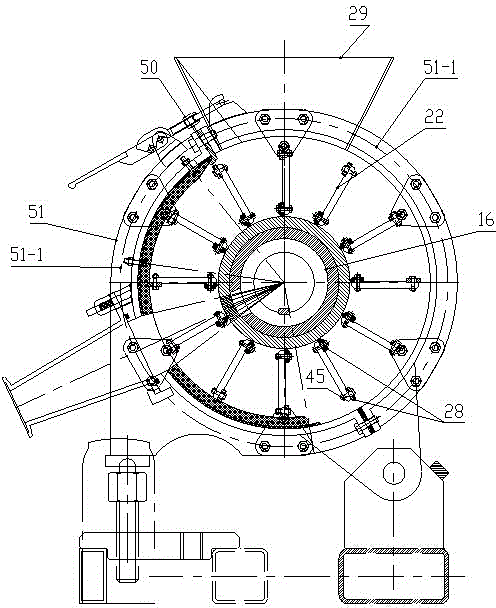

Impeller type wet spraying machinery

ActiveCN104790983AAvoid cloggingReduce processing difficultyUnderground chambersFoundation engineeringImpellerEngineering

The invention provides impeller type wet spraying machinery which comprises a material supply device, a material feeding main machine, a power device and a rack. Both the material feeding main machine and the power device are arranged on the rack. The power device is connected with the material feeding main machine in a drive mode. The material feeding main machine comprises a transverse stator ring, a rotor and a hollow middle shaft. The stator ring, the rotor and the hollow middle shaft are coaxially arranged. Sealing structures are arranged between the two sides of the stator ring and the rotor, sealing structures are arranged between the two sides of the rotor and the hollow middle shaft, and the rotor is located between the hollow middle shaft and the stator ring. The rotor is provided with material cavities at intervals in the peripheral direction of the rotor, and the material cavities are through holes. The stator ring comprises two arc-shaped ring bodies. The two arc-shaped ring bodies form a whole circle. The ends of the two arc-shaped ring bodies are connected, and the other ends of the two arc-shaped rings are connected through a locking device. The upper portion of the stator ring is provided with a feeding opening, and the bottom of the stator ring is provided with a discharging opening. According to the impeller type wet spraying machinery, compared with a vertical pulp shooting machine, the feeding time and the pulp spraying interval time are reduced, working efficiency is improved, the structure is more compact compared with a horizontal pulp shooting machine, the air inlet mode is more ingenious, and the rotor machining difficulty and the manufacturing cost are lowered.

Owner:河南省耿力工程设备有限公司

Double-jaw crushing and grinding machine and control system thereof

InactiveCN106607114AAchieve a brokenAchieve secondary crushingCocoaGrain treatmentsMotor driveControl system

The invention discloses a double-jaw crushing and grinding machine and a control system thereof. The machine comprises a fixed crushing jaw, a first moving crushing jaw, a first crushing fly wheel, a crushing motor, a second moving crushing jaw, a second rushing fly wheel, a first grinding motor, a first grinding spindle, a first grinding disk, a second grinding motor, a second grinding spindle, a second grinding disk, a rack, a crushing discharging chute, a grinding discharging chute and a discharging hopper. The control system comprises a raw material detection module, a material grinding detection module, a flow detection module, a programmable logic controller (PLC), a first grinding motor driving module, a second grinding motor driving module and a contactor. With the machine, primary crushing, secondary crushing and grinding of raw materials can be realized, the crushing degree of the raw materials is increased, and the crushing time is shortened.

Owner:罗浩

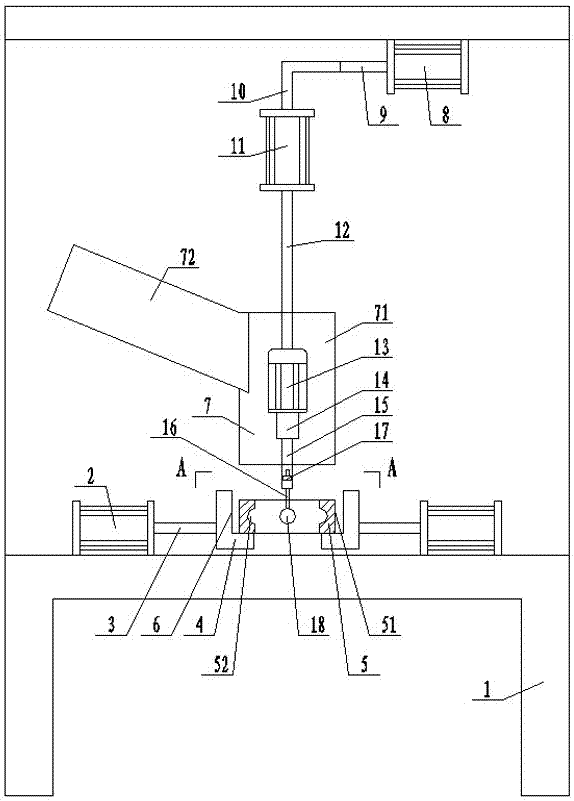

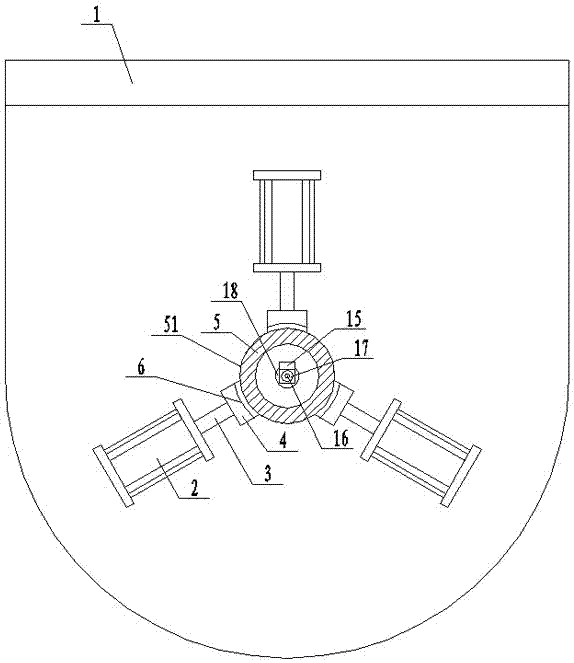

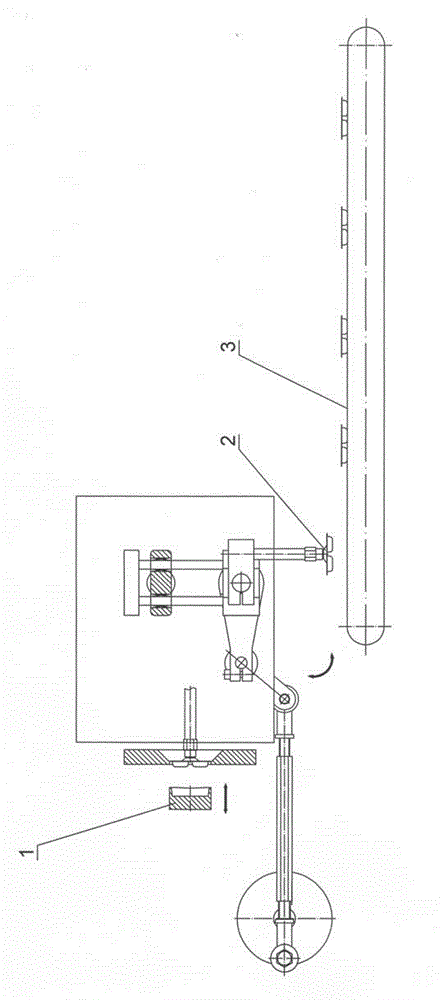

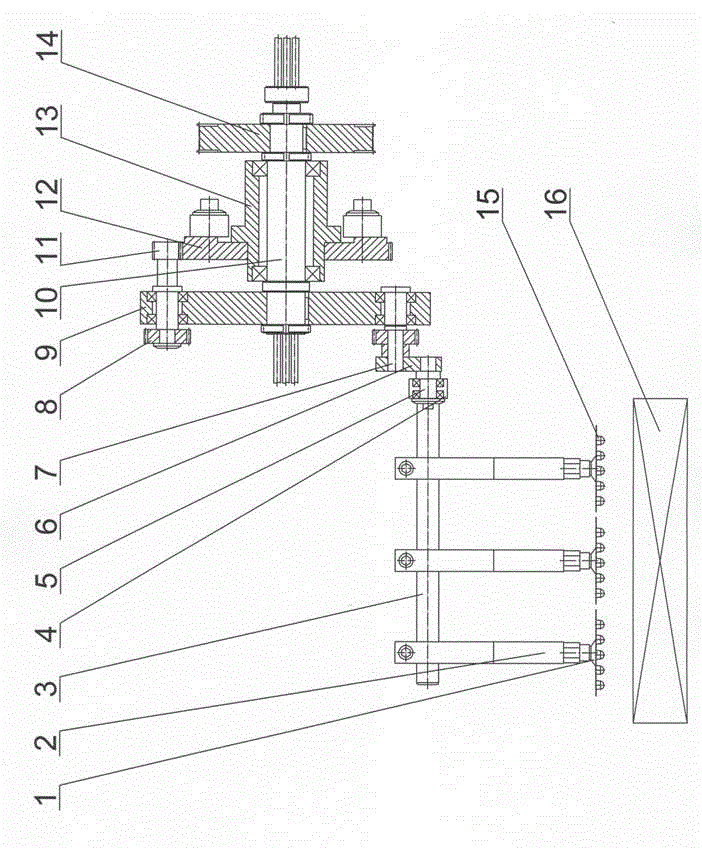

Automatic feeding device for plasma rotating electrode powdering and application method thereof

The invention relates to an automatic feeding device for plasma rotating electrode powdering and an application method thereof. The automatic feeding device comprises N storage boxes with serial numbers, a discharging mechanism and a control system. Each storage box is provided with a connecting channel of a vacuum or inert protection gas system. A discharging opening is formed in the bottom of each storage box. The discharging mechanism is arranged under the discharging openings and comprises at least three block type holding heads, a controllable rotating assembly, a controllable translation assembly and a discharging opening opening and closing assembly. The control system is in control connection with a discharging control valve of each storage box and is further in control connection with the controllable rotating assembly and the controllable translation assembly. The automatic feeding device has the beneficial effects that automatic feeding of bars is achieved, the feeding accuracy is improved, the feeding time is shortened, and stub bar losses are eliminated; and the utilization rate of the bars is increased, production efficiency is greatly improved, and high applicability is achieved.

Owner:四川天塬增材制造材料有限公司

Horizontal type spraying machine

The invention discloses a horizontal sprayer which comprises a feeding host and a hopper arranged at the upper part of the feeding host, wherein the feeding host is composed of a framework and a rotor; a rotor shaft is connected with a power outputting device in a driving manner; the feeding host comprises a stator and the rotor which are horizontally arranged on the framework; material grooves are arranged on the circumference of the cylindrical surface of the rotor at intervals; a hopper is arranged above the stator; a lower opening of the hopper is communicated with a stator cavity and located corresponding to the position of the material grooves on the rotor; an air inlet and an air outlet which are communicated with the cavity are arranged below the stator, and the opening position is corresponding to the position of a single material groove on the rotor; the air inlet is communicated with an air outputting port of a high pressure gas generating device. The horizontal sprayer can carry out an impulse-type continuous spraying operation, shorten the feeding time; the time interval for each spraying is short; and the maintenance is reduced and the work efficiency is improved.

Owner:李卫平

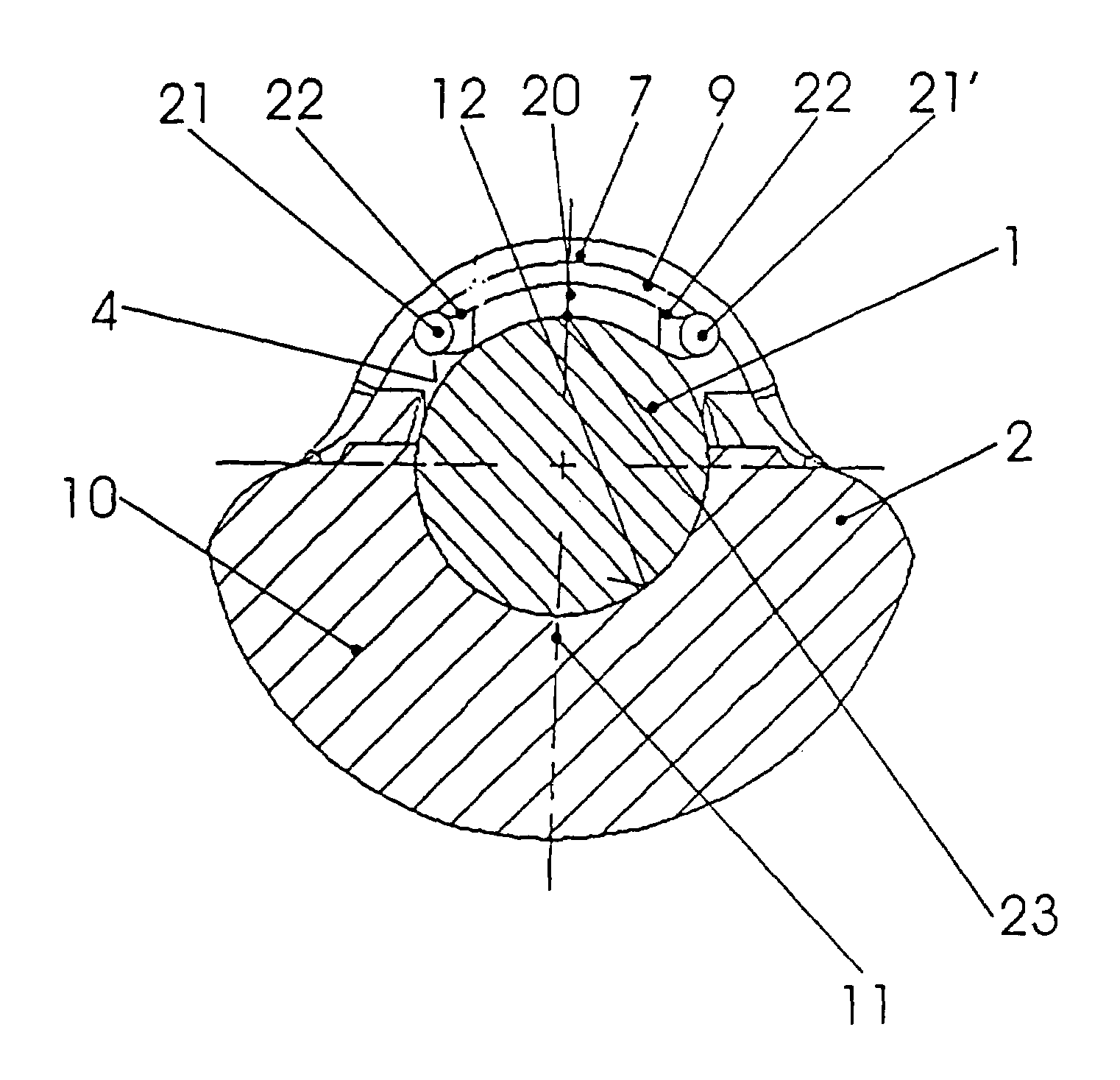

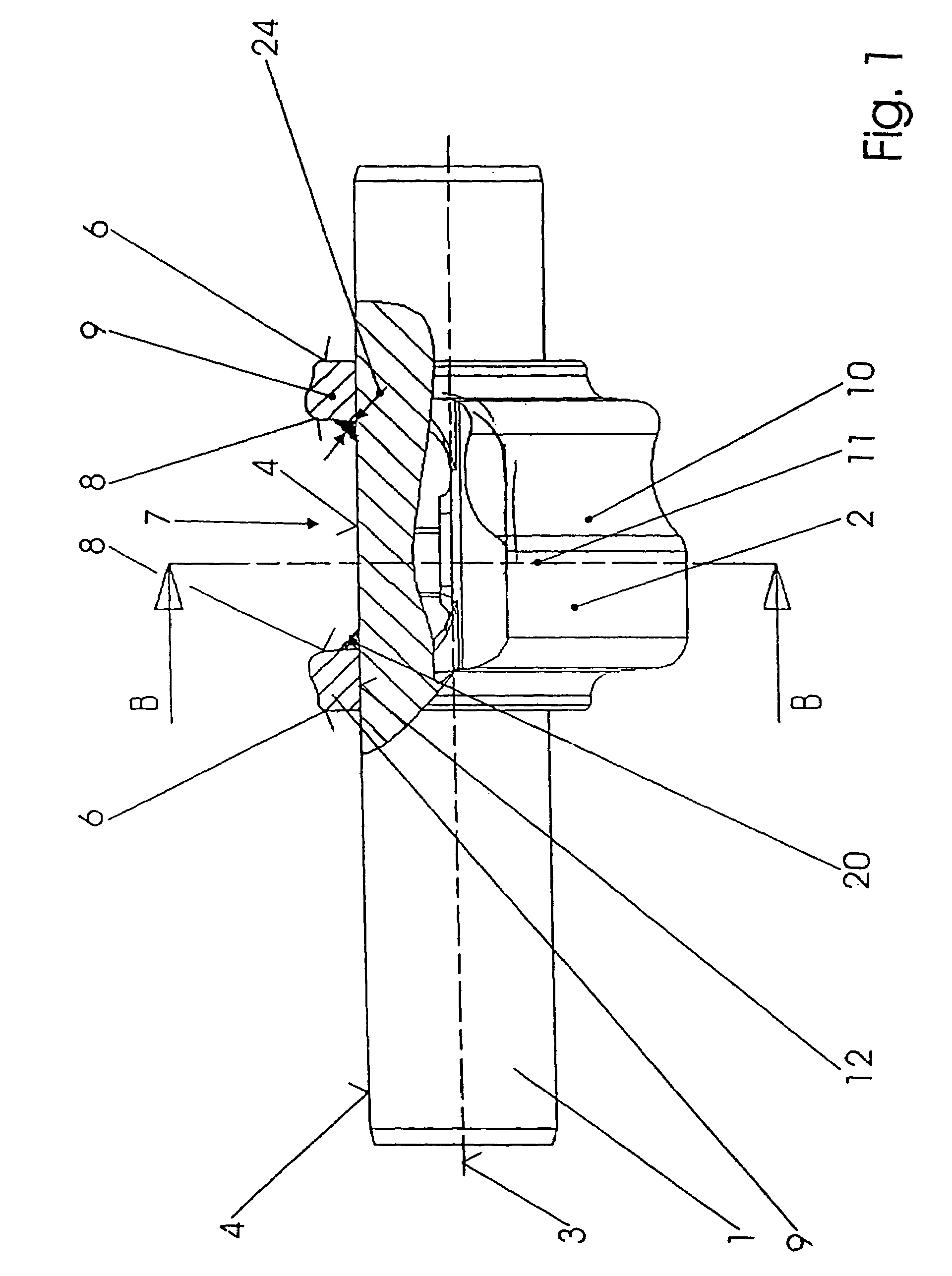

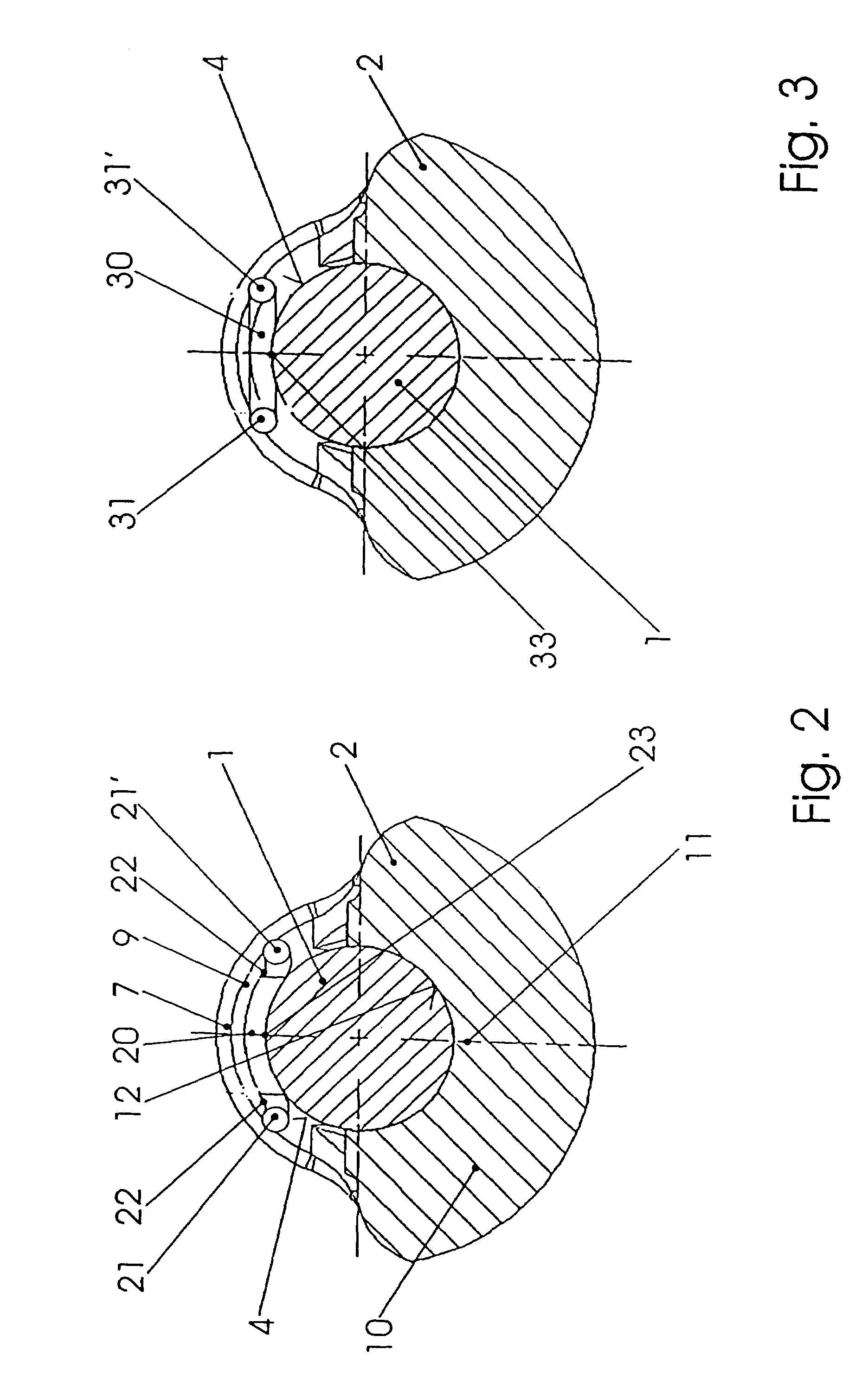

Shaft comprising a part connected thereto by welding

InactiveUS7137897B2Suppress introduction of heatLimiting introductionCrankshaftsEccentric-shaftsEngineeringMechanical engineering

A shaft (1) with a co-rotating element (2) which is secured to it and has a surface located perpendicular to the axis (3) of the shaft, the welding taking place in the fillet formed between the seating surface (4) of the shaft (1) and axially normal surface (6, 8) of the element. To achieve a durable join without adversely affecting true running, a welding bead (20) starts at a starting point (21) on the surface (6; 8) located perpendicular to the axis (3) of the shaft (1), leads to the fillet and then leads back to an end point (21′) on the surface (6; 8) located transversely with respect to the axis of the shaft.

Owner:MAGNA STEYR POWERTRAIN

Circulating feeding push device of automobile limiting block

InactiveCN104925514AReasonable structural designIngenious structural designConveyor partsEngineeringMaterial storage

The invention discloses a circulating feeding push device of an automobile limiting block. The circulating feeding push device comprises a rack, a power rod is arranged at the bottom of the rack in a hinged mode, a power wheel is arranged in the middle of the rack in a rotating mode, the top of the rack is provided with a sliding groove and provided with a push rod in a sliding mode, a material storage device is fixedly arranged above the upper left end of the rack, and the section of the material storage device is of a rectangular ring structure. The power rod is overall of a kidney-shaped structure and comprises a kidney-shaped groove, a push roll and a driven roll are rotatably arranged on the power wheel and the push rod respectively, and the push roll and the driven roll are located in the kidney-shaped groove of the power rod. The circulating feeding push device is reasonable and ingenious in structural design, power is provided through the power rod and the power wheel, the material storage device and other structures are matched, the feeding motion of the limiting block can be carried out fast, feeding time is shortened, and efficiency in the whole processing process is improved.

Owner:WUHU CHUANGZHI MACHINERY TECH

Urinalysis device

ActiveCN107561210AAvoid situations that cannot be effectively detectedEffectively cut off and discardChemical analysis using titrationPulp and paper industryUrinalysis

The invention discloses a urinalysis device which comprises a test paper roll, a drive unit, a titration unit, a pre-detection unit and an inspection unit; after being arranged in a titration positionof the titration unit, the pre-detection unit is used for detecting whether just-titrated test paper is discolored or not, and when a detection result is that the test paper is not discolored, the drive unit is controlled to drive the just-titrated test paper to reversely move to the titration position for the re-titration of a titration needle. Based on the technical scheme adopted by the invention, the pre-detection on whether the titration needle effectively titrates or not is realized, so that the situation that the test paper can not be effectively detected due to poor titration is avoided.

Owner:JOMOO KITCHEN & BATHROOM

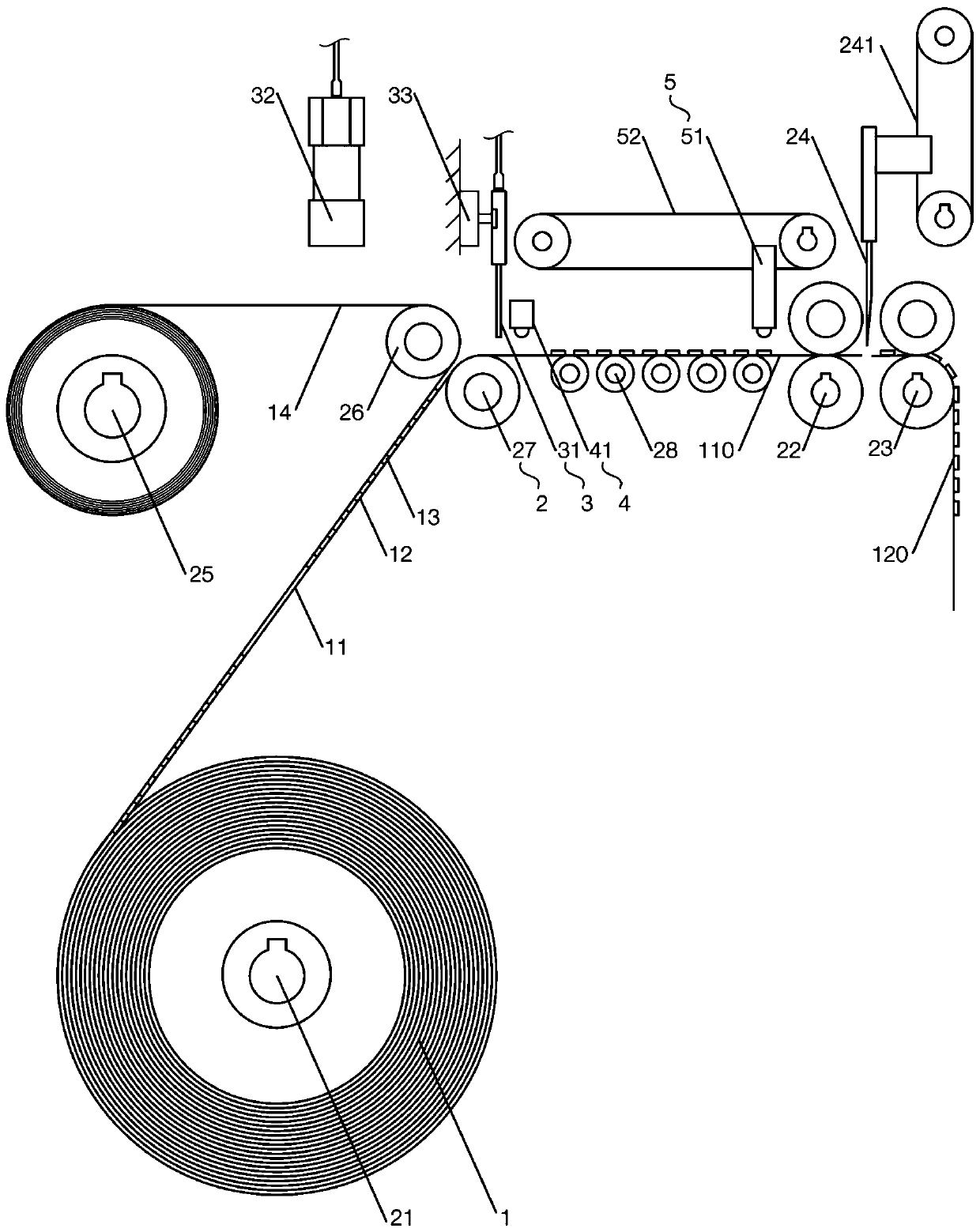

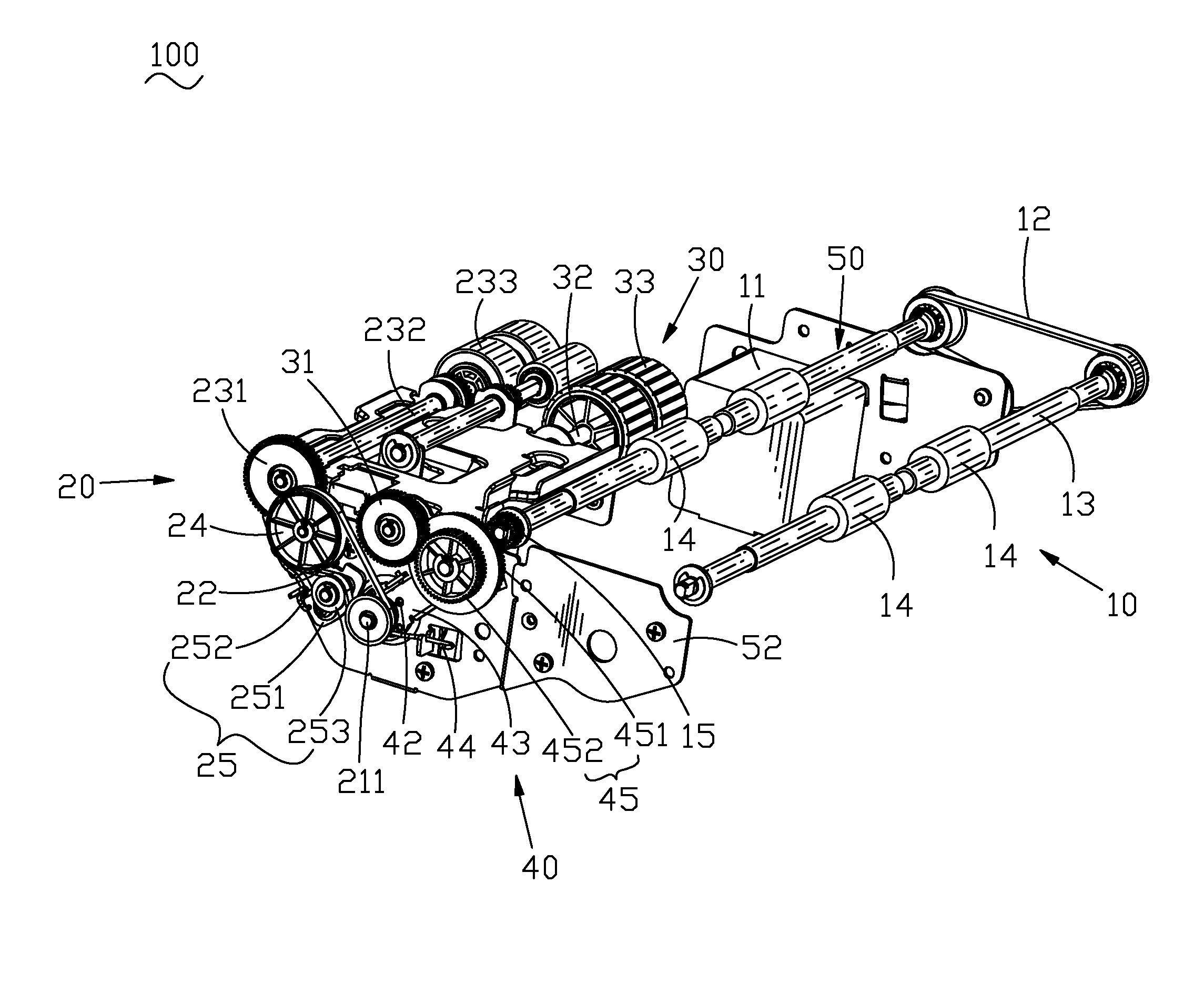

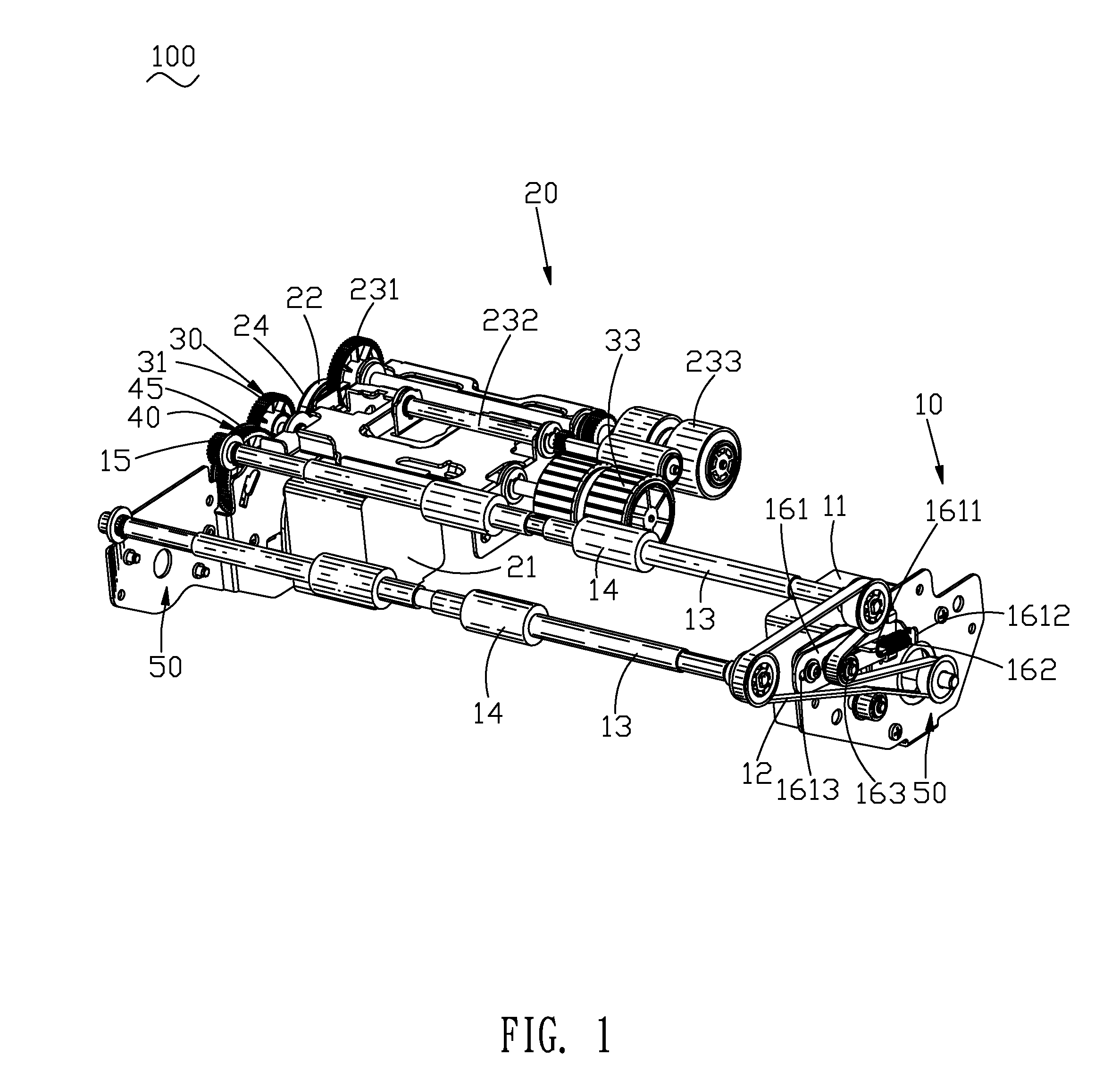

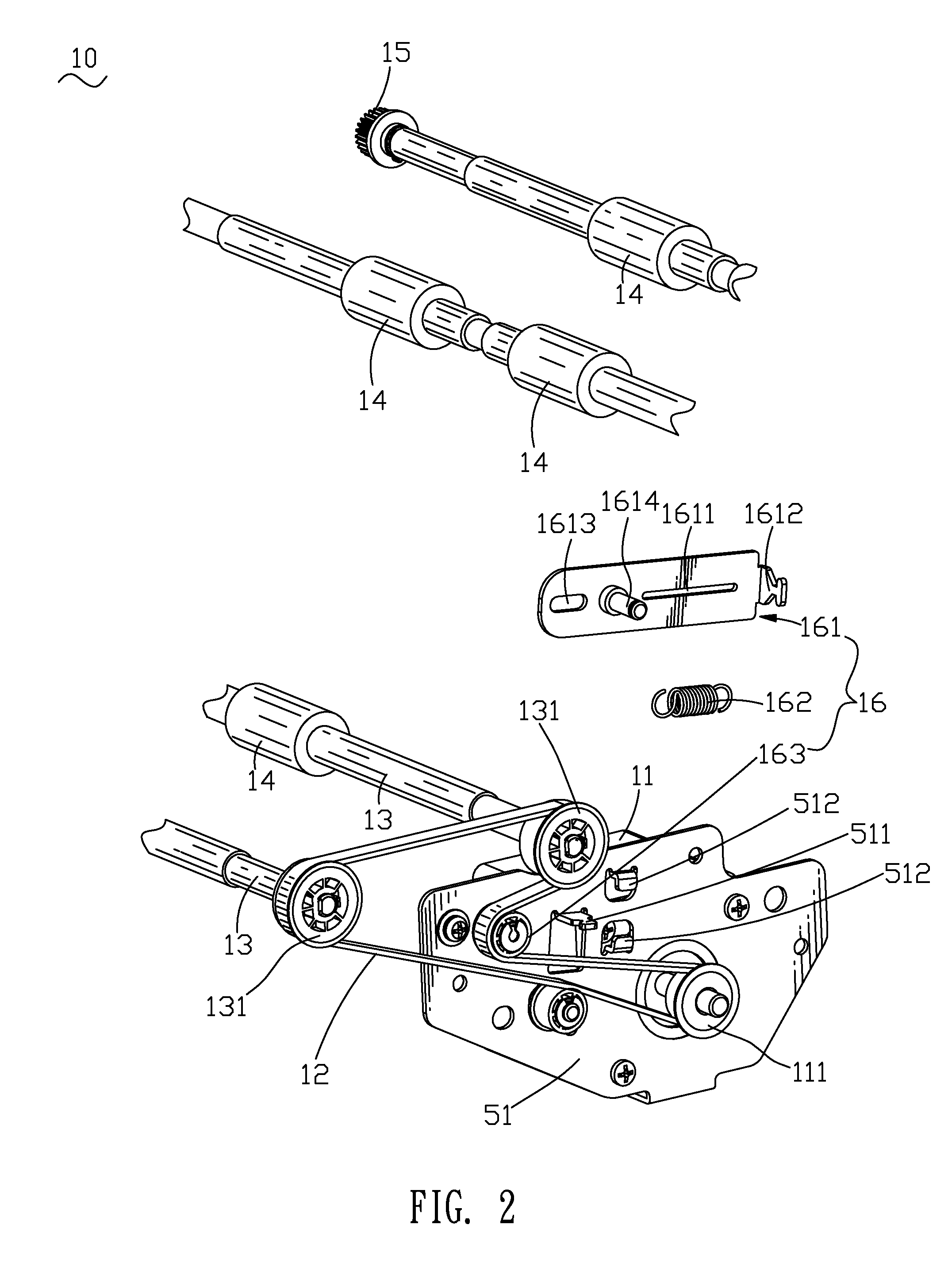

Paper feeding mechanism

InactiveUS8336871B2Reduce spacingSave feeding timeArticle feedersArticle separationClutchElectric motor

A paper feeding mechanism mounted to a shell includes a pickup mechanism, a transporting mechanism, a separation mechanism and a one-way clutch mechanism. The pickup mechanism includes a pickup motor having a rotating roller, a pickup roller and a pickup wheel. The transporting mechanism includes a transporting motor, a transporting roller, a transporting wheel and a transporting gear. The separation mechanism includes a separation roller, a separation gear and a separation wheel. The one-way clutch mechanism includes a one-way axle, a wiggling arm, a restoration elastic element fastened between the wiggling arm and the shell, and a releasing gear. The one-way axle passes through one end of the wiggling arm. The rotating roller of the pickup motor passes through the one-way axle. The releasing gear mounted to the other end of the wiggling arm is engaged with the transporting gear and the separation gear.

Owner:FOXLINK IMAGE TECH

Tapping device of anti-explosion threading box

The invention discloses a tapping device of an anti-explosion threading box. The tapping device is characterized by comprising a tapping supporting table, a workpiece feeding mechanism, a placing frame, a tapping mechanism and a workpiece receiving groove which are arranged on a workbench, wherein the workpiece feeding mechanism is perpendicular to the tapping supporting table, the tapping mechanism is perpendicular to the workpiece feeding mechanism and is arranged on the side surface of the tapping supporting table, the placing frame is arranged on the upper surface of the outer end of the workpiece feeding mechanism, and the workpiece receiving groove is formed below the workbench; and a supporting column is arranged in the tapping supporting table, a rotating table is connected to thesupporting column in a sleeving mode, a workpiece pushing driving mechanism is arranged at the top of the supporting column, a workpiece pushing block is arranged on the workpiece pushing driving mechanism, a tapping rotating table is arranged on the rotating table, and limiting blocks are arranged on the tapping rotating table. According to the tapping device, a machined part in the placing frameis fed into the junction of the end part of the workpiece feeding mechanism and the tapping rotating table through the workpiece feeding mechanism, meanwhile, the machined part is fed into the position between the limiting blocks of the tapping rotating table through the workpiece pushing block, then feeding and discharging are synchronously carried out through the rotating table and the workpiece pushing block, and therefore the efficiency is improved.

Owner:扬中市宏光防爆电器有限公司

Fluoride salt charging vehicle operated through wireless remote controller

InactiveCN106868548AEasy to control outputEasy to connect and dischargeEngineeringAluminum electrolysis

The invention relates to the field of charging of aluminum electrolysis production workshops and particularly relates to a fluoride salt charging vehicle operated through a wireless remote controller. The fluoride salt charging vehicle operated through the wireless remote controller is used for auxiliary charging in an aluminum electrolysis production workshop and is safe in operation and high in working efficiency. The fluoride salt charging vehicle comprises a vehicle body. A stock bin is arranged on the vehicle body. The fluoride salt charging vehicle is structurally characterized in that the lower end of the stock bin is provided with a horizontal screw feeder, and an inlet in the rear end of the horizontal screw feeder is connected with an outlet in the rear lower end of the stock bin; an outlet in the front end of the horizontal screw feeder is connected with an inlet, perpendicular to the front end of the stock bin, of the lower end of a vertical screw feeder; an outlet in the upper end of the vertical screw feeder is connected with an inlet in the front end of an upper horizontal screw feeder above the stock bin; a lower horizontal screw feeder is arranged between the upper horizontal screw feeder and the upper end of the stock bin; an outlet in the rear end of the upper horizontal screw feeder is connected with an inlet in the rear end of the lower horizontal screw feeder; and the front end of the lower horizontal screw feeder is provided with a discharge port.

Owner:NFC (SHENYANG) METALLURGICAL MACHINERY CO LTD

Single power two-way moving mechanism and flat feeding machine

PendingCN110775624AExquisite designSimple structureConveyorsPackagingElectric machineControl engineering

The invention discloses a single power two-way moving mechanism and a flat feeding machine. The single power two-way moving mechanism comprises a first guide seat, at least one support column extending in the X-axis direction can be slidably connected with the first guide seat in an inserting mode, and the support columns are connected with rotating shafts driven by motors through a first transmission mechanism; and the first guide seat is provided with at least one lifting shaft extending in the Z-axis direction, the lifting shafts can be slidably connected on a fixed second guide seat in a inserting mode, and the lifting shafts are connected with the rotating shafts through a second transmission mechanism. The scheme is delicate in design and simple in structure, a single motor is adopted, the first transmission mechanism and the second transmission mechanism are combined to realize lifting of the lifting shafts and the fore-and-aft telescopic movement of the support columns, a powersource is effectively reduced, the equipment cost is lowered, energy consumption is saved, the fore-and-aft telescopic movement and the lifting movement have no interference with each other, the overall rhythm is fast, control is simple, and the efficiency is high.

Owner:张天山

Feeding mechanism for medicine packaging production line

The invention discloses an improved feeding mechanism for a medicine packaging production line. The feeding mechanism comprises a rack, a transporting device and a material absorbing and conveying device. The feeding mechanism is characterized in that the material absorbing and conveying device comprises two or more material absorbing components and a transmission component. The material absorbing components comprise sucking discs and sucking disc seats. The transmission component comprises a rotary disc and a transmission assembly which drives the rotary disc to rotate and drives the sucking disc seats to move in the radial direction. The two or more material absorbing components are evenly arranged on the rotary disc. The material absorbing components are conveyed from the material absorbing station to the material placing position in circulating and conveying modes. In this way, only material absorbing time is needed, the feeding time is greatly lowered, and medicine plate conveying at the high-speed is achieved. The limiting speed of automatic plate taking, automatic waste removing and automatic conveying of a bubble cap machine are broken, the entire automatic packaging industry is driven to be rapidly developed, and the active using effect is provided for the extensive market.

Owner:上海江南制药机械有限公司

Automatic feeding device for chicken farm

InactiveCN104885969AReduce labor intensitySave feeding timeAvicultureEngineeringMechanical engineering

The invention discloses an automatic feeding device for a chicken farm, and the automatic feeding device is short in feeding time. The automatic feeding device comprises a rack, wherein two sides of the upper end of the rack are glidingly arranged in a circulating electric track through slide blocks; the circulating electric track is fixedly arranged on a roof; storage box feeding chambers are formed in the head end and the tail end of the circulating electric track respectively; a storage box is arranged on the rack; a discharging hole of the storage box is connected with a conveying pipe arranged at the lower end of the rack; a spiral conveyer is arranged in the conveying pipe; one end of the spiral conveyer is connected with a driving device arranged on the rack; a plurality of feeding holes are symmetrically formed in two sides of the lower end of the conveying pipe; one end of the conveying pipe is connected with the feeding holes, and the other end of the conveying pipe is matched with a feed trough formed in a stepped chicken coop; the stepped chicken coop is arranged on the ground.

Owner:骆伯松

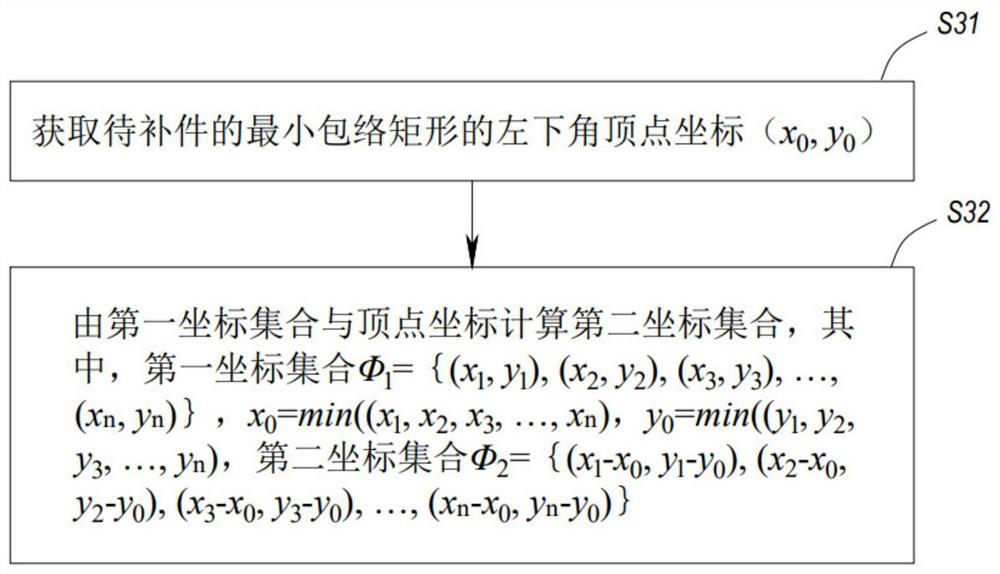

Laser cutting system and laser cutting supplementing method

ActiveCN112719627AReduce idle timeEasy to operateLaser beam welding apparatusSoftware engineeringLaser cutting

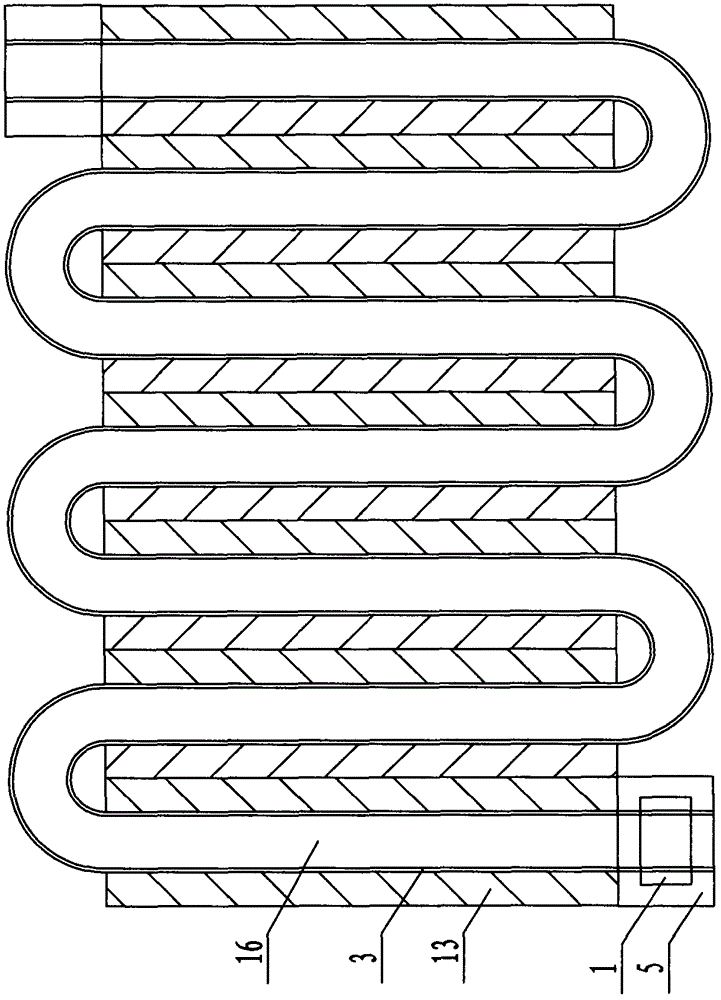

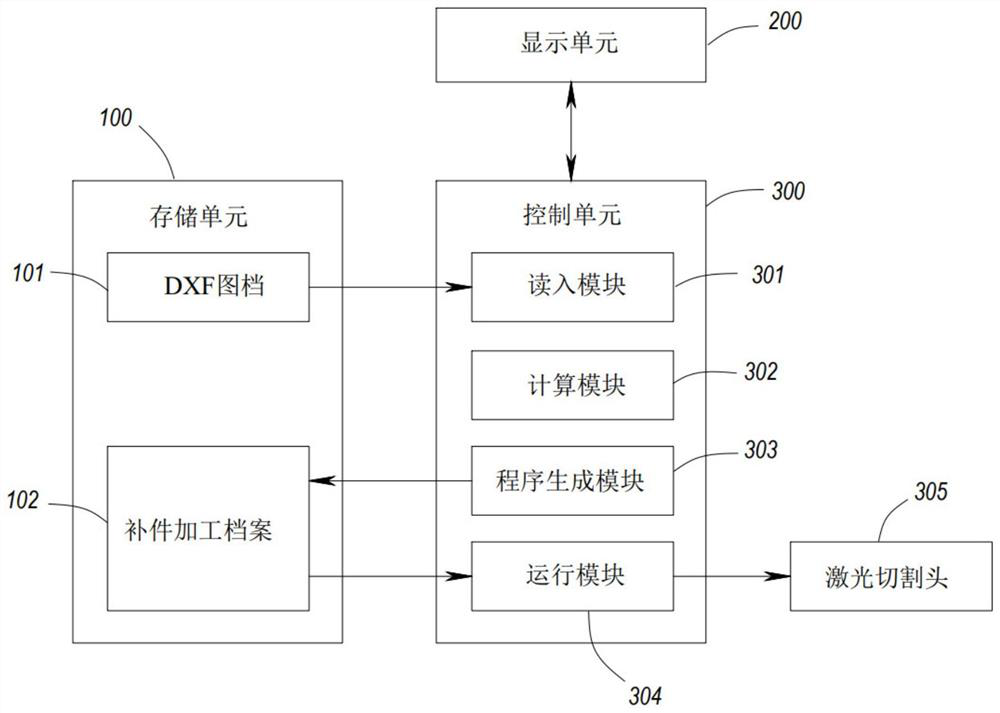

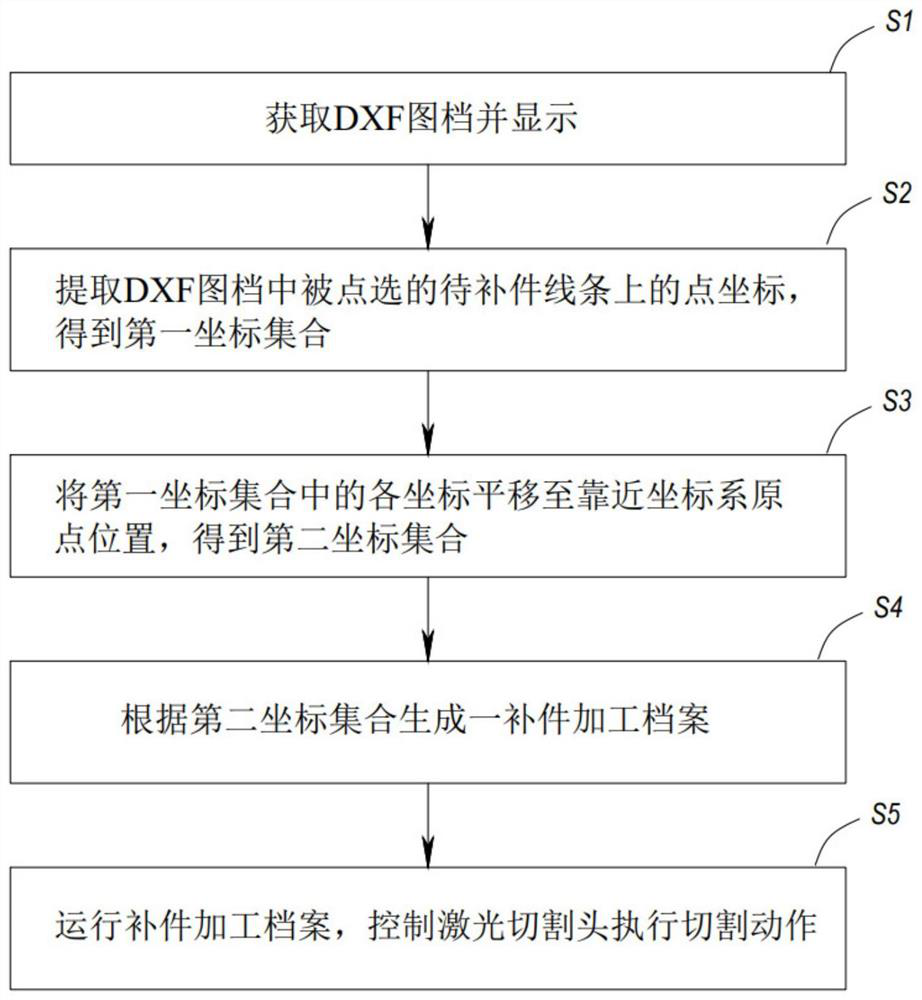

The invention discloses a laser cutting system. The laser cutting system comprises a storage unit used for storing a DXF drawing file and a supplementing processing file, a display unit used for displaying the DXF drawing file and providing an interface for clicking a to-be-supplemented piece and a menu for generating a supplemented piece processing file instruction for a user, and a control unit; the control unit comprises a read-in module used for reading in the DXF drawing file, a calculation module used for extracting point coordinates from a line of the to-be-supplemented piece to form a first coordinate set after receiving the instruction for generating a supplemented piece processing file, calculating vertex coordinates of a lower left corner of a minimum envelope rectangle of the to-be-supplemented piece and calculating a second coordinate set obtained after translating the point coordinates in the first coordinate set to a lower left corner of a coordinate system, a program generation module used for generating a supplementing processing file according to the second coordinate set and an operation module used for operating the supplementing processing file. A plate is placed at the lower left corner of the coordinate system, a laser cutting head directly cuts the supplemented plate at the lower left corner of the coordinate system, a user does not need to find the position of the to-be-supplemented piece, and the idle running time of the laser cutting head is shortened.

Owner:新代科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com