Fluoride salt charging vehicle operated through wireless remote controller

A technology of wireless remote control and fluoride salt, which is applied in the field of feeding in aluminum electrolysis production workshops, can solve the problems of inability to add regularly and quantitatively, increase the cost of multi-functional unit equipment, and increase the volatilization of fluoride salt, etc., and achieve weight reduction , save the working time of feeding and the number of ground personnel, and improve the effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

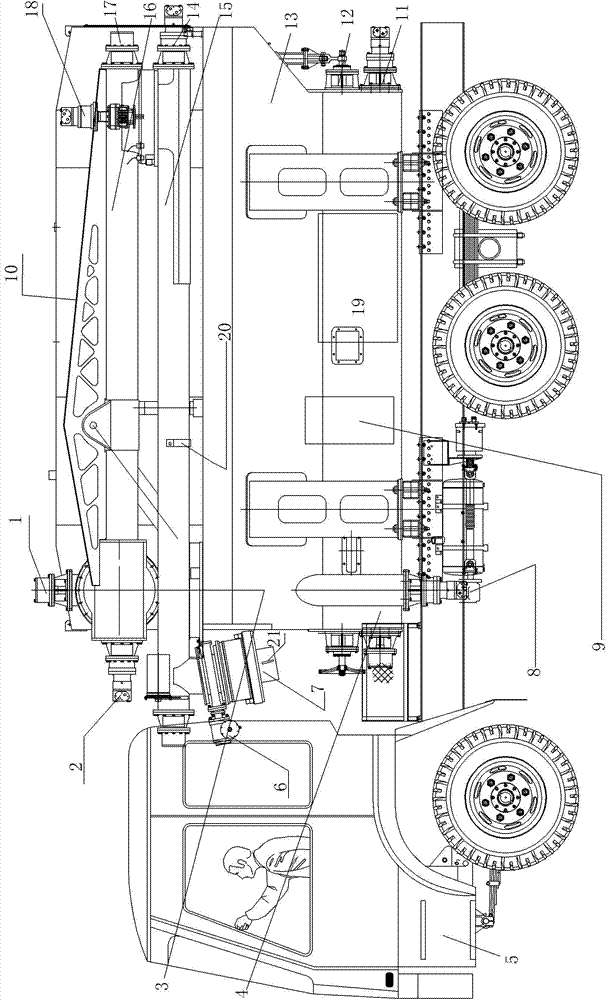

[0037] As shown in the figure, the present invention includes a car body, on which a silo is arranged, and a horizontal screw feeder is arranged at the lower end of the silo, and the rear inlet of the horizontal screw feeder is connected with the outlet at the rear lower end of the hopper.

[0038] The front outlet of the horizontal screw feeder is connected to the lower inlet of the vertical screw feeder at the front of the silo, the upper outlet of the vertical screw feeder is connected to the front inlet of the upper horizontal screw above the silo, and the upper horizontal screw feeder is connected to the upper end of the silo. There is a lower horizontal screw feeder between them, the rear end outlet of the upper horizontal screw feeder is connected with the rear end inlet of the lower horizontal screw feeder, and the front end of the lower horizontal screw feeder is the feeding port; the upper end of the silo is provided with a feeding port .

[0039] Described car body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com