Gypsum plaster and preparation system thereof

A technology for plastering gypsum and preparation system, which is applied in the field of plastering gypsum to achieve the effect of improving environmental protection and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

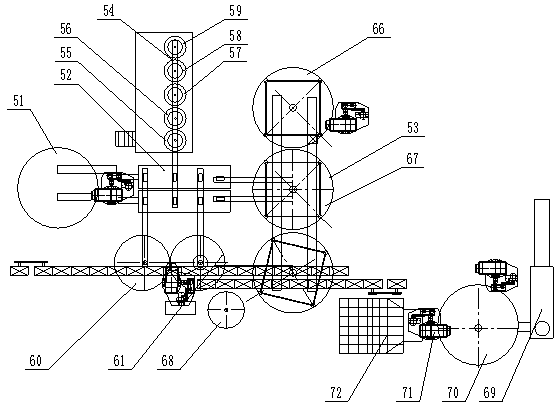

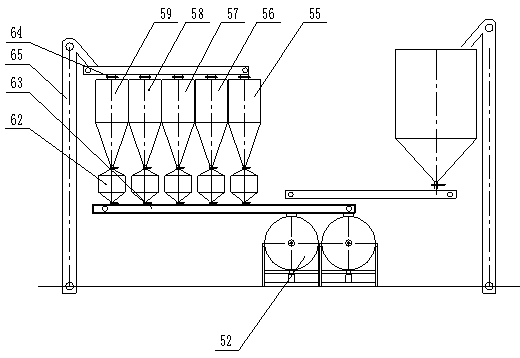

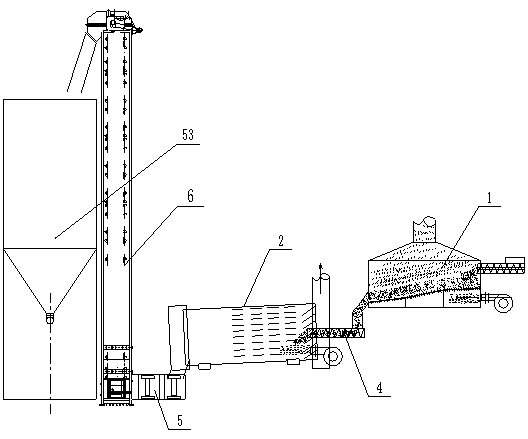

[0062] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0063] During concrete implementation: a kind of plastering gypsum, it is characterized in that, adopts following raw material: major ingredient is hemihydrate gypsum powder; Auxiliary material comprises retarder, methyl cellulose, industrial flour, wood cellulose, pearl powder and quartz sand, Obtained by stirring and mixing.

[0064] In this way, using the hemihydrate gypsum powder as the raw material, the industrial by-product gypsum can be used to reuse the waste, which is greatly beneficial to environmental protection and reduces the production cost of the product. Combined with various auxiliary materials to mix evenly, various materials cooperate with each other to ensure the product quality of plastering gypsum.

[0065] Specifically, the mass ratio of various materials is 10-30% of quartz sand, 3-15% of pearl powder (closed), 0.05-0.1% of retarder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com