Feeding mechanism for medicine packaging production line

A packaging production line and feeding mechanism technology, applied in packaging and other directions, can solve the problems of short time to complete the action, low work efficiency, and failure to reach the designated work station, etc., and achieve the effects of shortening the feeding time, stable transmission, and precise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

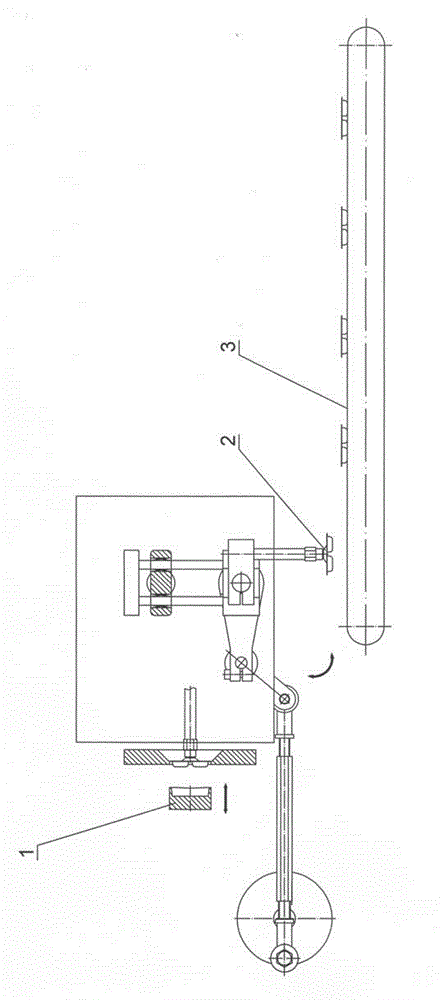

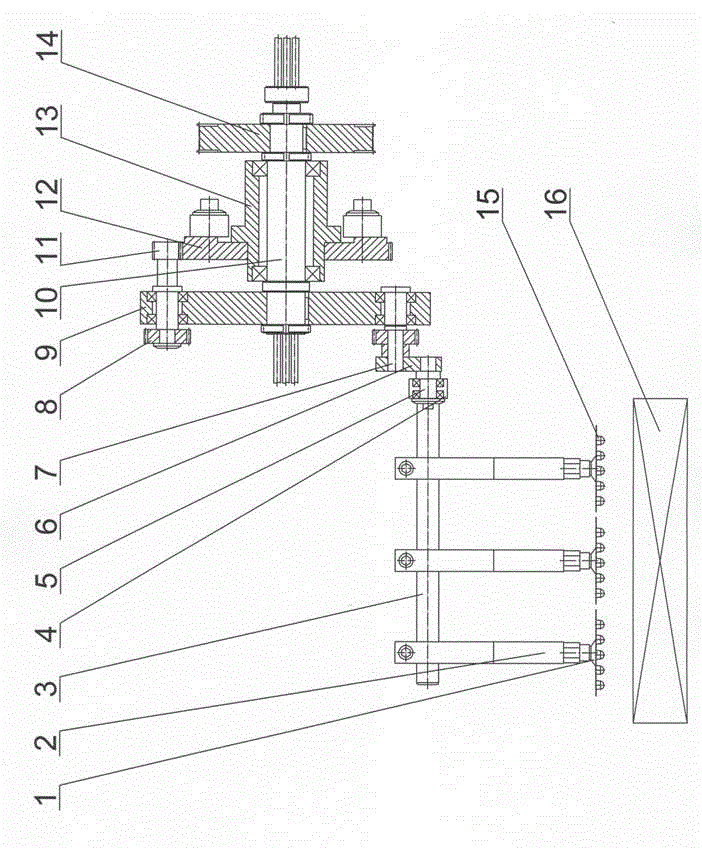

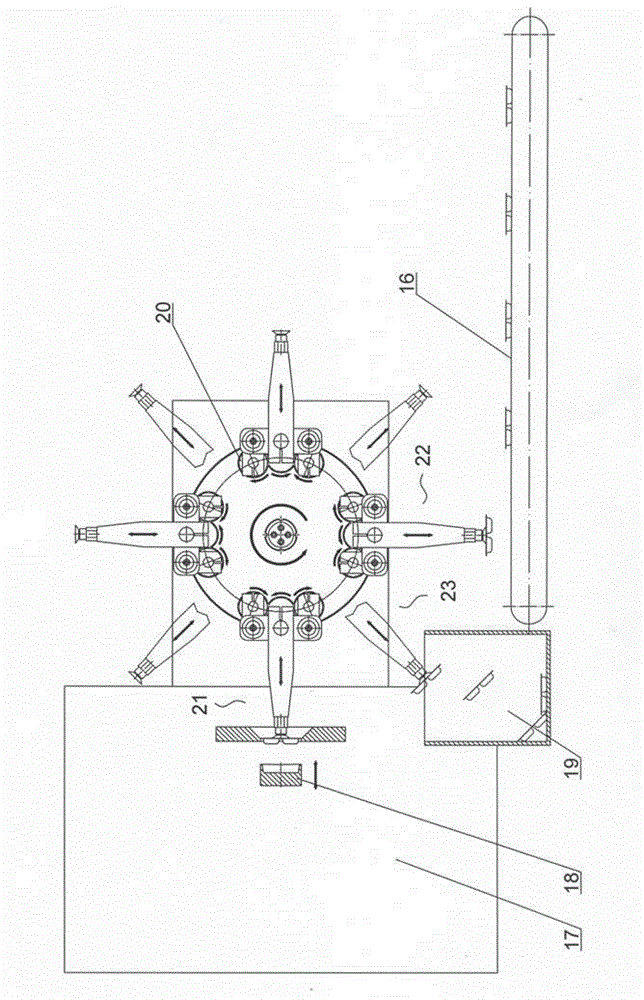

[0017] With reference to the accompanying drawings, the feeding mechanism of this kind of pharmaceutical packaging production line includes a frame 17, a conveying device 16, a material suction conveying device and a recovery box 19, and the conveying device 16 is a conveyor belt, and the conveyor belt 16 is arranged on the forming mold 18, the suction conveying device sends the medicine plate after the forming mold 18 has been processed to the conveyor belt 16, and the recovery box 19 is arranged between the suction station 21 and the discharge station 22; The material conveying device includes a suction part and a transmission part. The suction part is provided with at least two groups. In this embodiment, the suction part is provided with four groups. The suction part includes a suction cup 1 and a suction cup seat 2 , the transmission part includes a turntable 9 and a transmission assembly that drives the turntable 9 to rotate and drives the suction cup seat 2 to move radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com