Rotation station type full-automatic frying and boiling production line

A fully automatic, station-based technology, used in baking, baking workshops, food preparation, etc., can solve the problems of waste of resources, large space occupation, and many supporting facilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

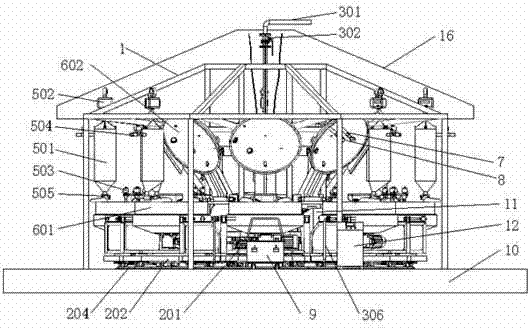

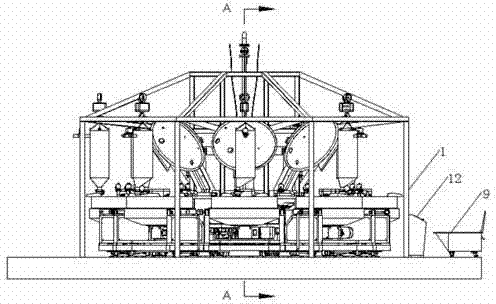

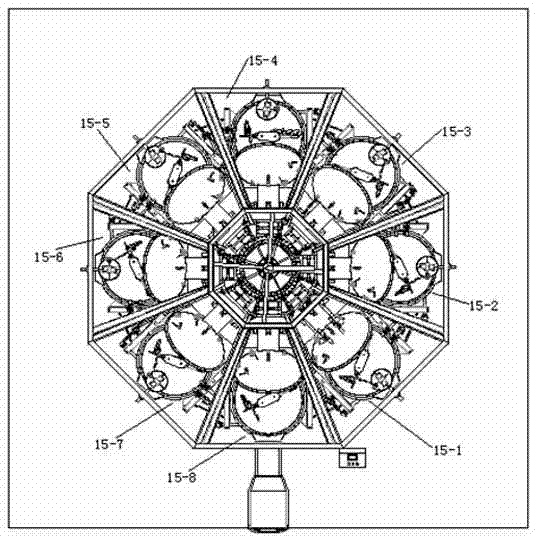

[0035] Such as Figure 1-8 As shown, a rotary station type fully automatic frying and cooking production line includes a frame body 1 for fixed connection, a discharge car 9 and an automatic control center, and also includes a rotary device 2, a steam device 3, an electric device 4, and a feeding device 5 and an automatic frying unit 6, the frame body 1 is fixed on the ground 10, the rotary device 2 is arranged in the frame body 1, and multiple sets of automatic frying units 6 are arranged above the rotary device 2, the The automatic frying unit 6 includes a frying pan 601 installed on the rotary device and a pot cover 602 connected to the frame body 1, and the steam device 3 passes through the frame body 1 and the frying pan of the automatic frying unit 6 601 is connected; the top of the pot cover 602 on the frame body 1 is provided with a cold water pipe 7 and a hot water pipe 8 for cleaning the frying pan.

[0036]Such as Figure 6 , Figure 7 As shown, the slewing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com