Impeller type wet spraying machinery

A technology of wet spraying machine and impeller type, which is applied in the direction of shaft lining, tunnel lining, underground chamber, etc., can solve the problems of increasing the difficulty and manufacturing cost of the rotor, the structure of the spraying machine is not compact, and the reduction of work efficiency, etc., to achieve The effect of reducing feeding time and spraying interval time, ingenious air intake mode, reducing processing difficulty and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

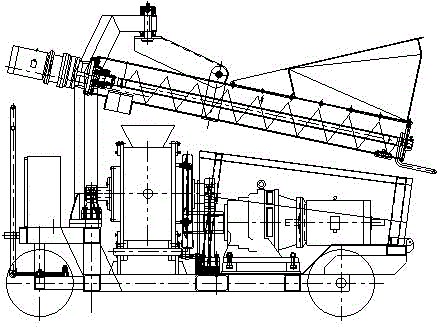

[0031] Such as figure 1 Shown, the impeller type wet spraying machine of the present invention comprises feeding device, hopper, feeding host, power unit and frame.

[0032] Wherein, the upper part of the feeding device is located above the feeding main machine, and the feeding device is arranged obliquely. The feed port corresponds to the position of the blanking port. The feeding host is installed on the frame and driven by the power unit.

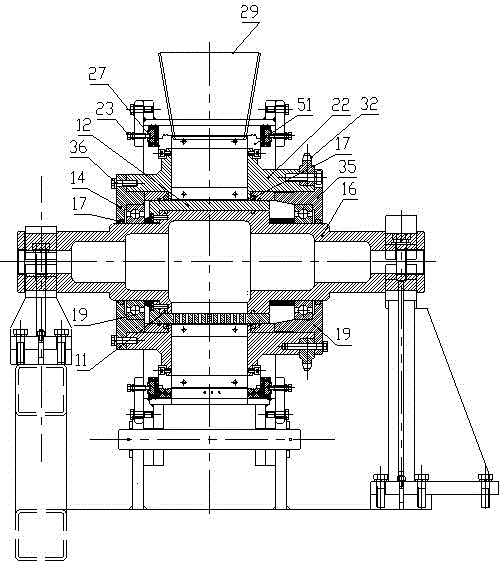

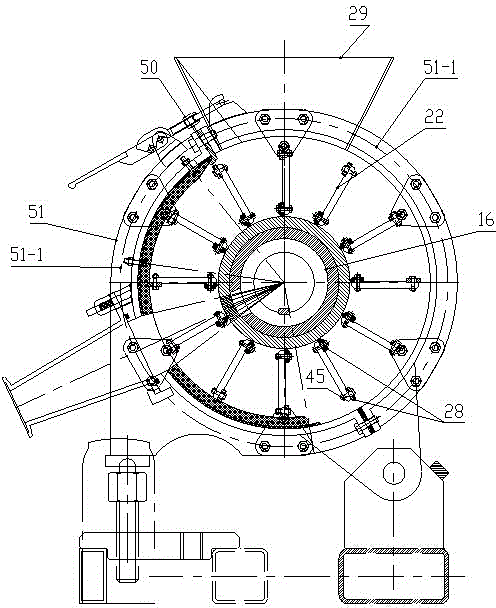

[0033] Such as figure 2 , 3 As shown, the feeding host includes a horizontally arranged rotor 22, a stator ring 51, and a hollow intermediate shaft 16. The hollow intermediate shaft 16, the rotor 22, and the stator ring 51 are coaxially arranged, and the rotor 22 is located between the hollow intermediate shaft 16 and the stator ring 51. , along the circumferential direction of the rotor 22, material cavities are arranged at intervals, the material cavities are separated by partitions arranged on the rotor 22, and the material cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com