Total mixed ration stirring feeding machine

A fully mixed and box-based technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of feed waste pollution, livestock health impact, and inapplicability to large-scale livestock and poultry breeding, etc., to reduce feed costs, The effect of keeping the pH value of the rumen stable and improving the milk production of livestock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

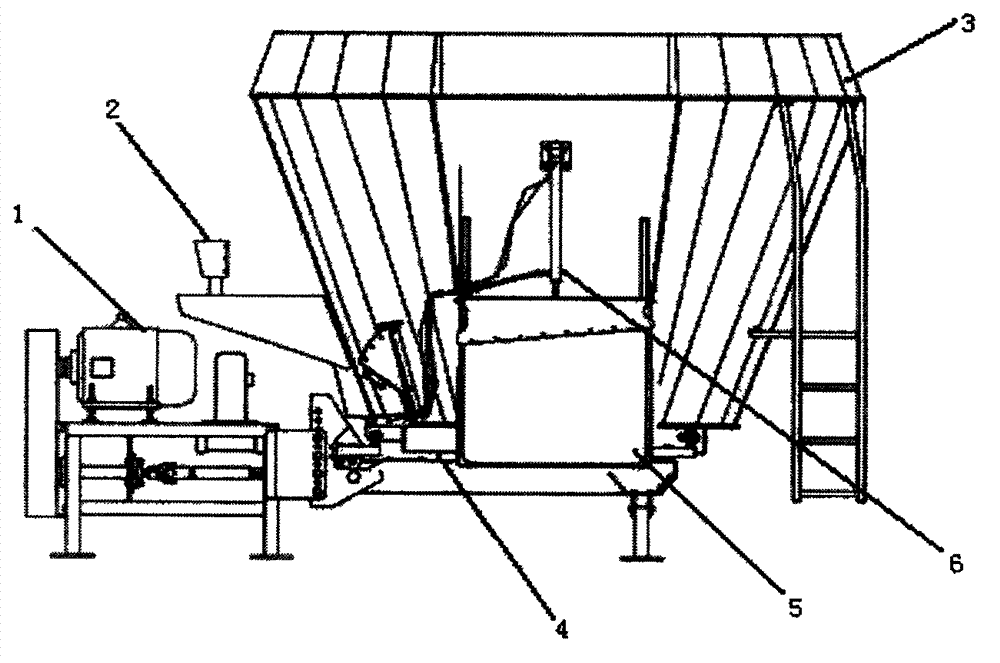

[0033] Raw materials are sent into the mixing box (3) by means of a loader, and the spiral cage shaft system cuts, kneads and mixes the materials, so as to achieve the effect of cutting the rough feed into short and kneading fine, and mixing the coarse and fine feed evenly; the equipment is driven by the drive system (1) Drive, which can realize the modulation of TMR diet.

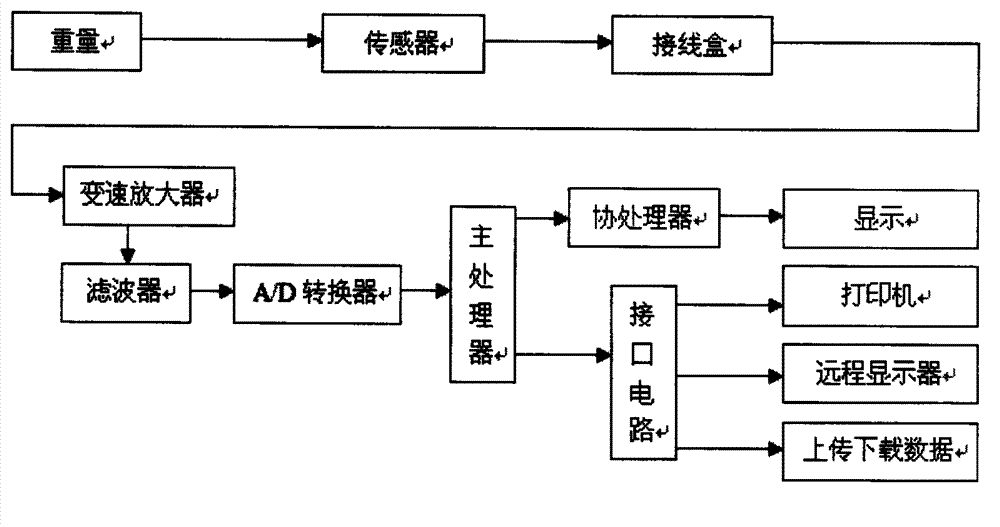

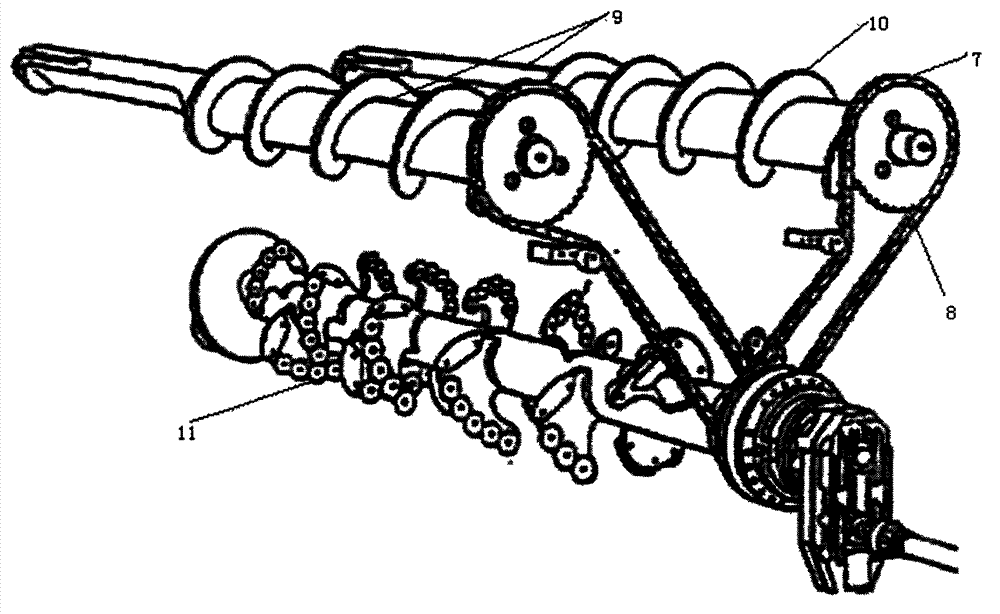

[0034] The signal output by the sensor is amplified, filtered and A / D converted to the weighing signal by the variable speed amplifier, and then digitally processed to display the weighing signal on the screen (in addition, in order to make the actual use more convenient, there are many Other functions, such as early warning setting, setting, calibration, zero reset, detection of power supply voltage, recipe setting, etc.). Reduce the speed to the required speed by adjusting the speed ratio between the gears or the speed ratio between the gear and the chain. The transmission power of the chain (7) is real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com