Fully-mixed daily-ration granulated feed for mutton-type sheep

A pellet feed and full mixing technology, applied in the direction of animal feed, animal feed, and animal feed molding or processing, can solve the problem of increasing the feed intake of mutton sheep, achieve obvious ecological and social benefits, high nutritional value, reduce The effect of feed waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

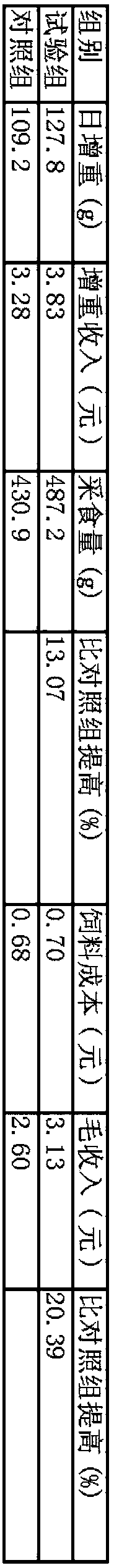

Image

Examples

Embodiment 1

[0032] (1) Kneading and crushing the stalks of Radix Paeoniae Alba into 8mm pellets; 4% vitamin premix, 25% trace element premix, 6% allicin, 2.5% salinomycin sodium, 20% compound enzyme Preparation, 1.5% ethoxyquin and the balance are zeolite powder to form a composite premix;

[0033] (2) Take 55 parts of Radix Paeoniae Alba straw pellets in (1), 1 part of compound premix, 22 parts of corn, 9 parts of wheat, 9 parts of soybean meal, 1 part of bentonite, 1.5 parts of calcium hydrogen phosphate, 0.5 parts of stone powder, small Mix 0.5 parts of soda and 0.5 parts of table salt evenly;

[0034] (3) Put the mixed material in (2) into a feed pellet press, carry out tempering and aging at a steam pressure of 0.3 MPa, a temperature of 80° C., and a flat die diameter of 15 mm, and then extrude, form and pelletize to obtain pellet feed.

Embodiment 2

[0036] (1) Kneading and crushing the Radix Paeoniae Alba stalks into 12mm pellets; 5% vitamin premix, 20% trace element premix, 8% allicin, 2.5% salinomycin sodium, 15% compound enzyme Preparation, 1% ethoxyquin and the balance being zeolite powder to form a composite premix;

[0037] (2) Mix 50 parts of Radix Paeoniae Alba straw pellets, 2 parts of compound premix, 24 parts of corn, 10 parts of wheat, 10 parts of soybean meal, 0.5 parts of bentonite, 0.8 parts of calcium hydrogen phosphate, 0.7 parts of stone powder, and Mix 1 part soda and 1 part salt;

[0038] (3) Put the mixed material in (2) into a feed pellet press machine, carry out conditioning and aging at a steam pressure of 0.4 MPa, a temperature of 75° C., and a flat die diameter of 8 mm, then extrude, form, and pelletize to obtain pellet feed.

Embodiment 3

[0040] (1) Kneading and crushing the Radix Paeoniae Alba stalks into 10mm pellets; 4.5% vitamin premix, 22% trace element premix, 7% allicin, 2.5% salinomycin sodium, 17% compound enzyme Preparation, 1% ethoxyquin and the balance being zeolite powder to form a composite premix;

[0041] (2) Mix 60 parts of Radix Paeoniae Alba straw pellets, 1.5 parts of compound premix, 20 parts of corn, 6 parts of wheat, 6 parts of soybean meal, 2 parts of bentonite, 1.2 parts of calcium hydrogen phosphate, 1 part of stone powder, and Mix 0.8 parts of soda and 1.5 parts of table salt evenly;

[0042] (3) Put the mixed material in (2) into a feed pellet press, carry out tempering and aging at a steam pressure of 0.3 MPa, a temperature of 75° C., and a flat die diameter of 10 mm, and then extrude, form, and pelletize to obtain pellet feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com