Circulating feeding push device of automobile limiting block

A technology of a propulsion device and a limit block, which is applied in the field of auto parts, can solve problems such as low conveying efficiency, and achieve the effects of improving efficiency, reasonable structure design, and shortening feeding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

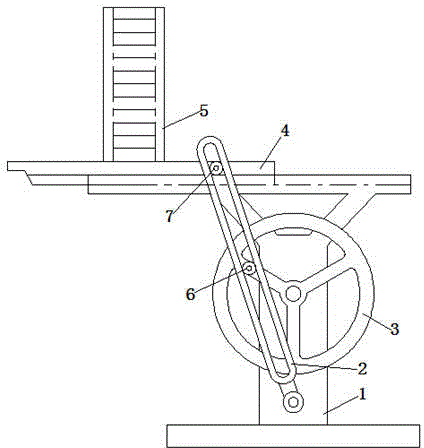

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail by embodiment:

[0013] The vehicle limit block circular feeding propulsion device includes a frame 1, the bottom and middle of the frame 1 are respectively hinged and installed with a power rod 2 and a power wheel 3 is rotated, and the top of the frame 1 is provided with a chute and a push rod is slidably installed 4. A stocker 5 is fixedly installed above the upper left end of the frame 1. The section of the stocker 5 is a rectangular ring structure; the power rod 2 is a waist-shaped structure as a whole including a waist-shaped groove, and the power wheel 3 and the push rod 4 rotate respectively. Push roller 6 and driven roller 7 are installed, and push roller 6 and driven roller 7 are all positioned in the waist-shaped groove of power rod 2, and the left end of push rod 4 is a thinner push head.

[0014] The above-mentioned embodiments are only preferred implementati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com