Overhead rail type feed conveying device

A conveying device and track-type technology, which is applied in the field of livestock and poultry breeding, can solve the problems of large power consumption, difficulty in ensuring the level, and increased conveying resistance, and achieve the effects of strong terrain adaptability, shortened feeding time, and large blanking outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

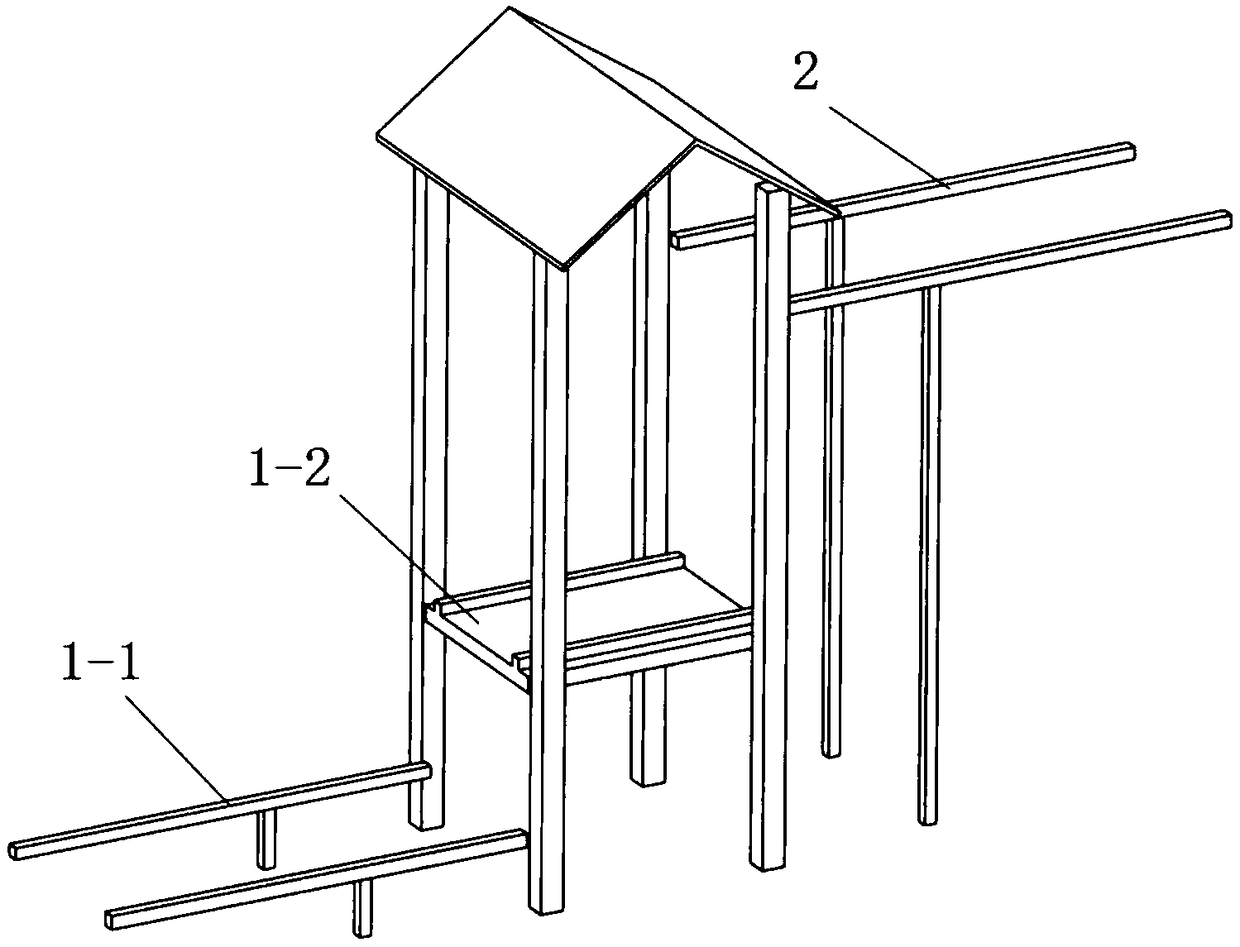

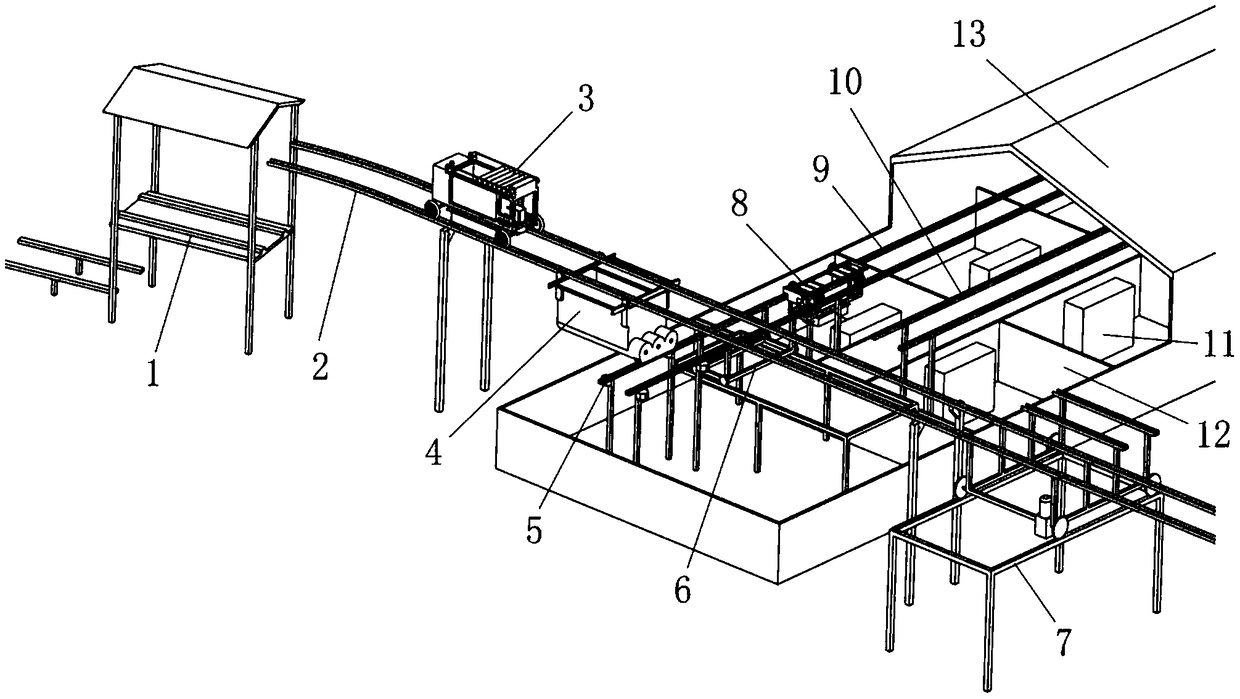

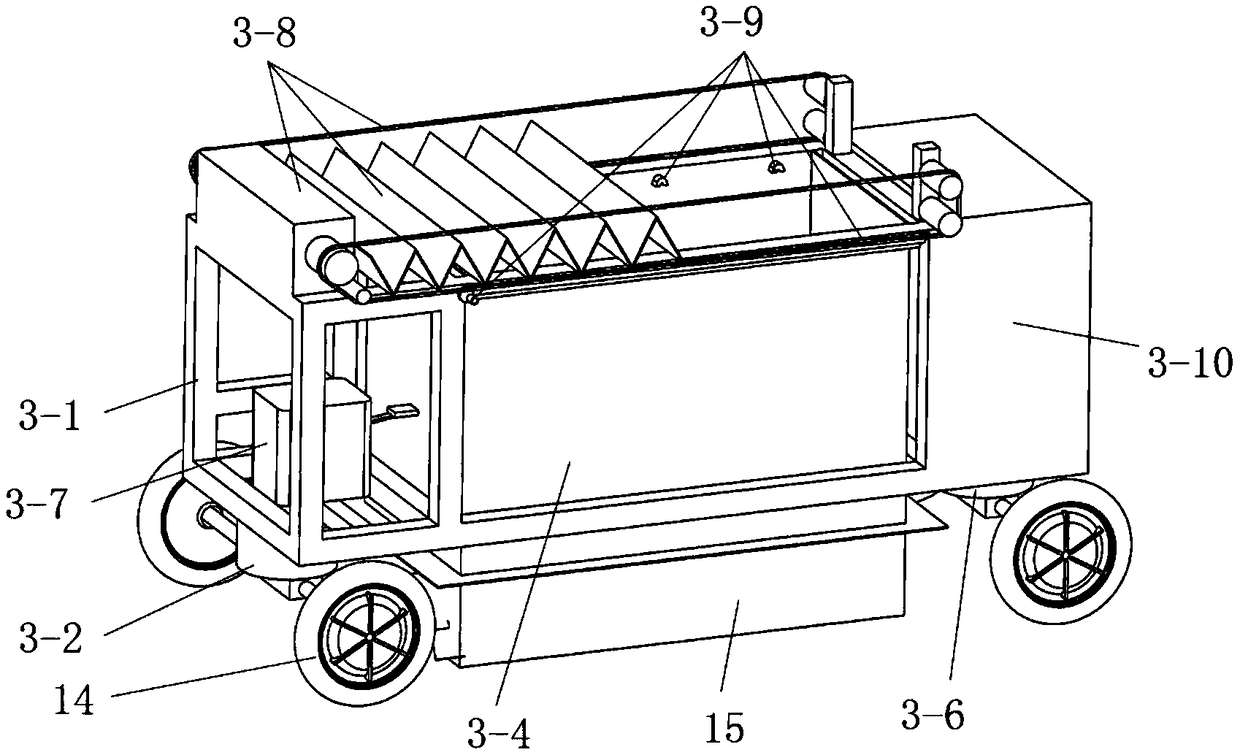

[0050] Such as figure 1 with figure 2 As shown, the embodiment of the present invention includes: a central control system, a lifting track mechanism 1 outside the pig house 13, a feeding track 2, a feeding car 3, a transfer warehouse 4 and an avoidance track mechanism 7, and a weighing platform 5 in the pig house 13 , track translation mechanism 6, distribution cart 8, first row of distribution rail 9, second row of distribution rail 10 and collection type trough 11; wherein the feeding cart 3 moves on the feeding rail 2, and the transfer warehouse 4 is hoisted on the feeding rail 2 Located at the bottom of the pig house 13, a weighing platform 5 that is also located in the pig house 13 is installed under the transfer warehouse 4. The side of the weighing platform 5 facing the pen 12 is provided with a rail translation mechanism 6, and the rail translation mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com