Automatic feeding device for plasma rotating electrode powdering and application method thereof

A technology of rotating electrodes and feeding devices, which is applied in the field of automatic feeding devices, can solve the problems of long plasma arc stop time, poor feeding accuracy, and low automation, and achieves shortened feeding time, timely and accurate feeding, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

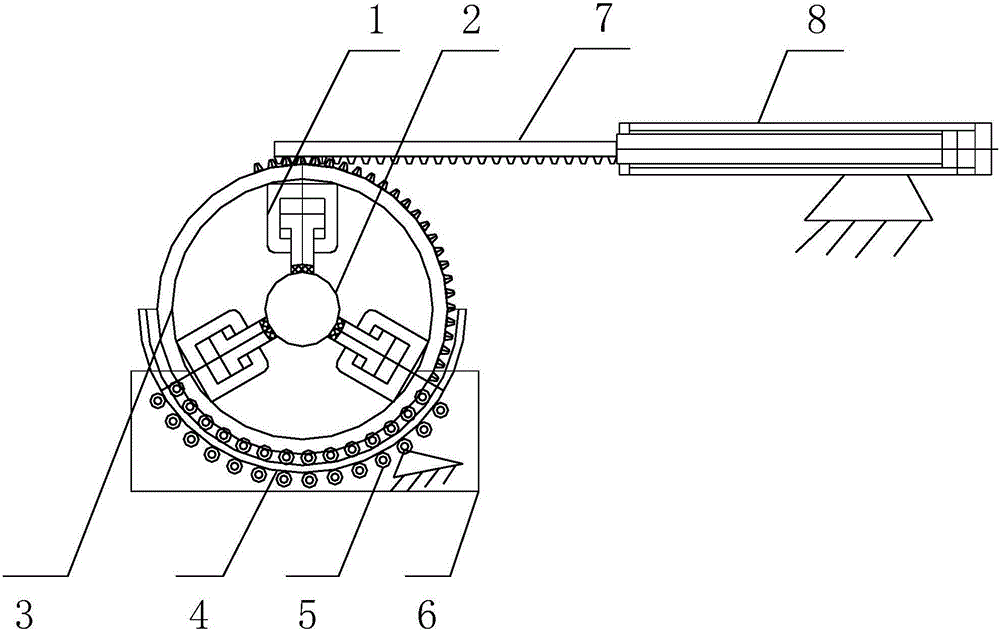

[0025] Attached below figure 1 The steps of the automatic feeding device for plasma rotary electrode powder making and its using method of the present invention are described in detail.

[0026]An automatic feeding device for plasma rotary electrode powder making, the automatic feeding device includes: N numbered storage boxes, a blanking mechanism and a control system; wherein, N is an integer greater than 1; N numbered The storage boxes are respectively the first storage box, the second storage box, ... the Nth storage box, and the N numbered storage boxes are arranged in a straight line; each storage box is provided with a connection with a vacuum or an inert protective gas system channel; the bottom of each storage box is provided with a discharge port; each storage box is also provided with a discharge control valve; the blanking mechanism is arranged directly below the discharge port; the blanking mechanism includes at least three pieces of The holding head, the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com