Cylinder sleeve cutting equipment capable of achieving scrap suction conveniently

A technology for cutting equipment and cylinder liners, which is applied in the direction of shearing machine equipment, metal processing equipment, shearing devices, etc., and can solve the problems that the degree of automation of cutting efficiency needs to be improved, the cutting accuracy and feeding efficiency are affected, and the cutting effect cannot be guaranteed. , to achieve the effect of stable feeding, uniform and stable length, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The content of the present invention will be described below in conjunction with specific embodiments.

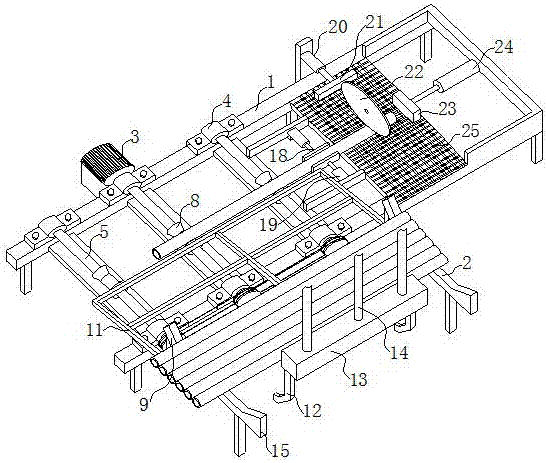

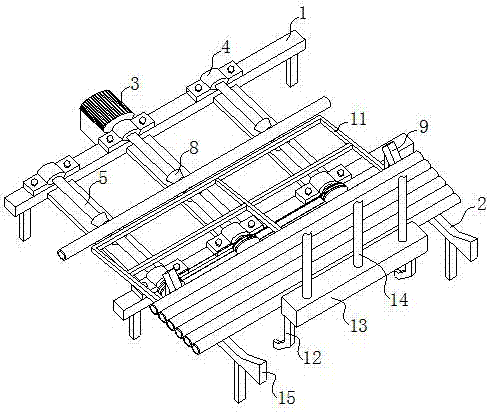

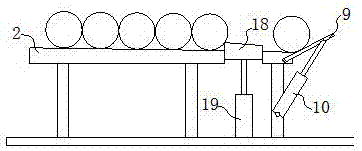

[0037] Such as figure 1 with Figure 7 As shown, the present invention proposes a cylinder liner cutting device for facilitating chip suction, and a cylinder liner cutting device for facilitating chip suction, including a cutting device and a chip suction device. The cutting device is used to cut the cylinder liner. The dust suction device is used to suck away the waste generated in the cutting process.

[0038] Reference figure 1 , The cutting device includes a cutting table 25, the cutting table 25 is knitted by plain weave steel wire, the cutting table 25 is provided with a baffle plate 23 on one side, the baffle plate 23 is located in the feed stroke of the cylinder liner Above, the baffle plate 23 is drivingly connected to the movable end of the third hydraulic cylinder 24 and is driven by the third hydraulic cylinder 24 to move horizontally. The direction of moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com