Patents

Literature

84results about How to "Realize cut-to-length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

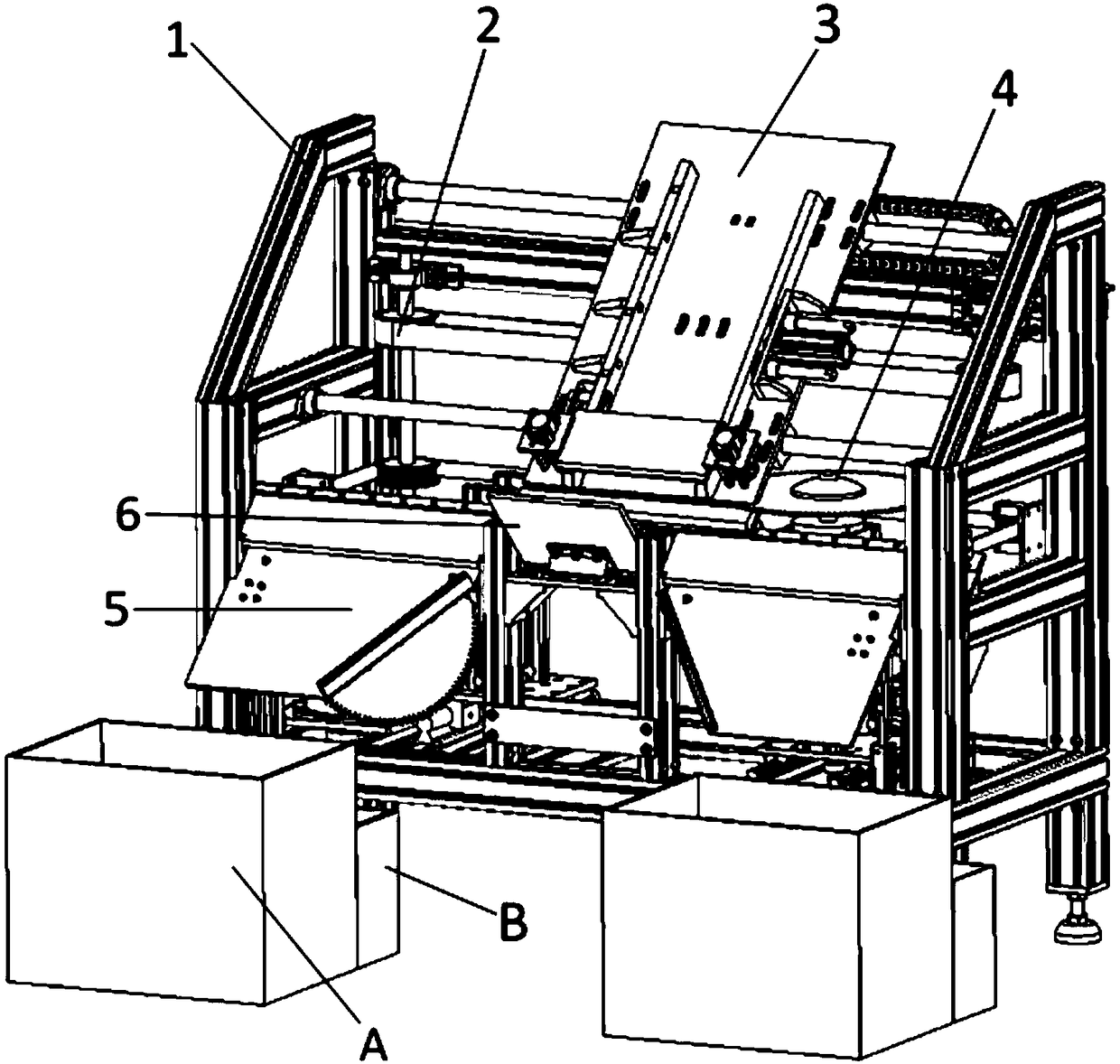

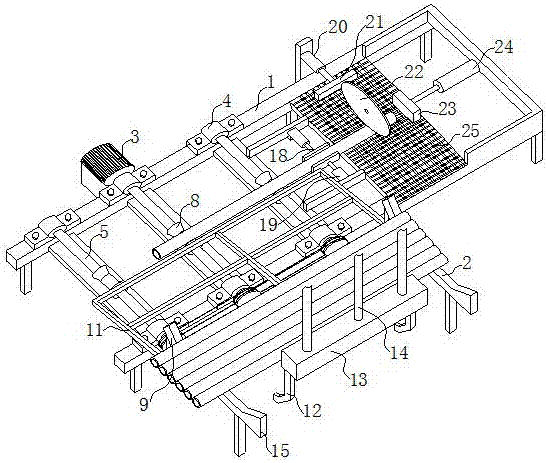

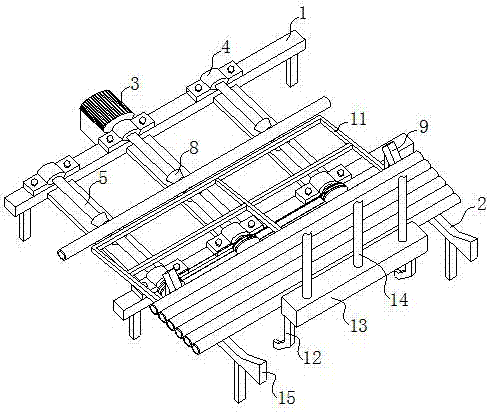

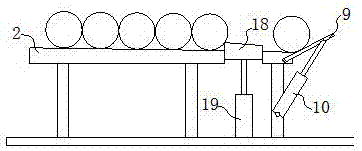

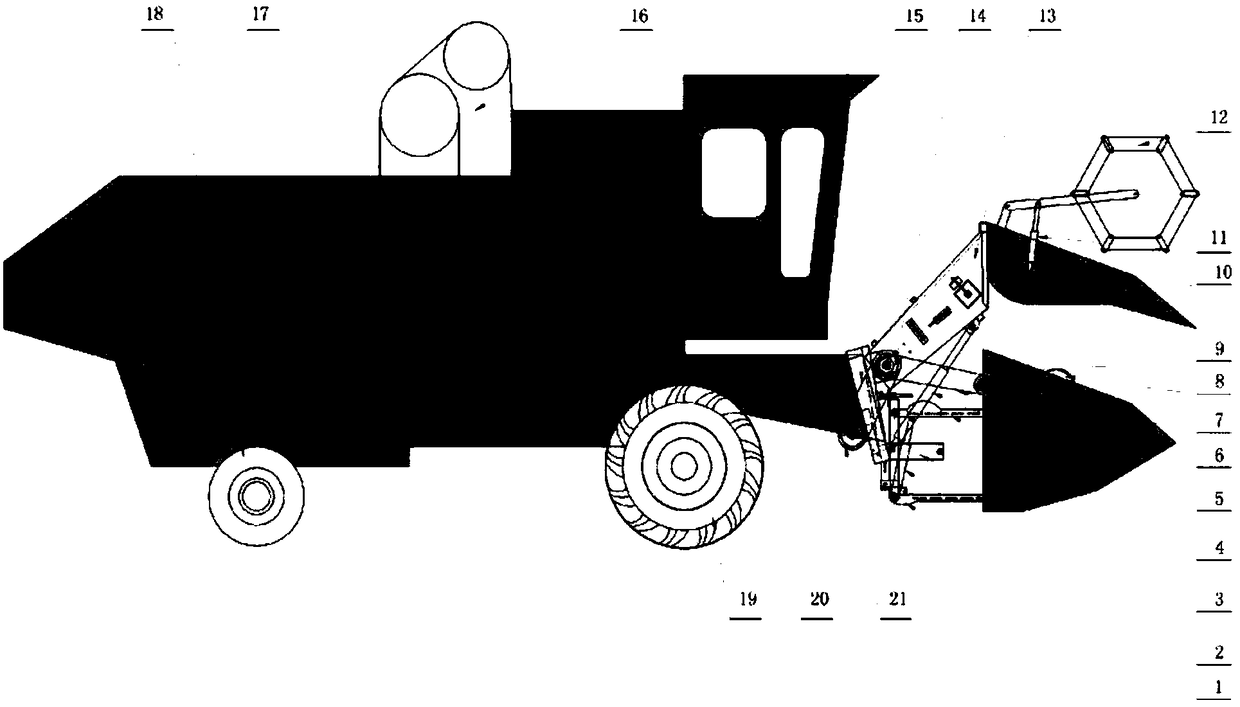

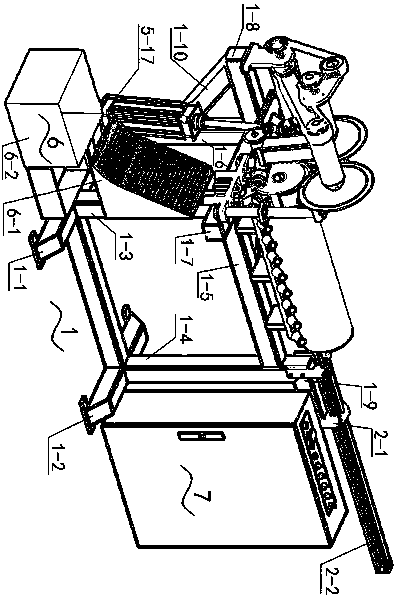

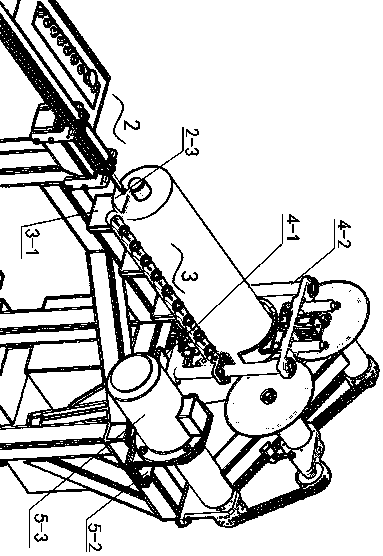

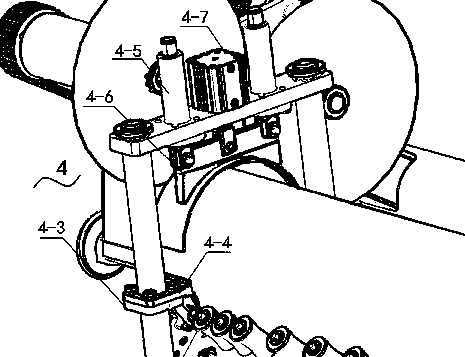

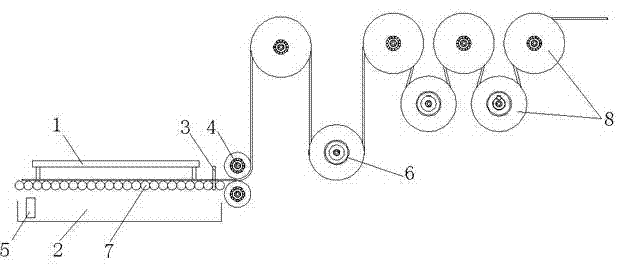

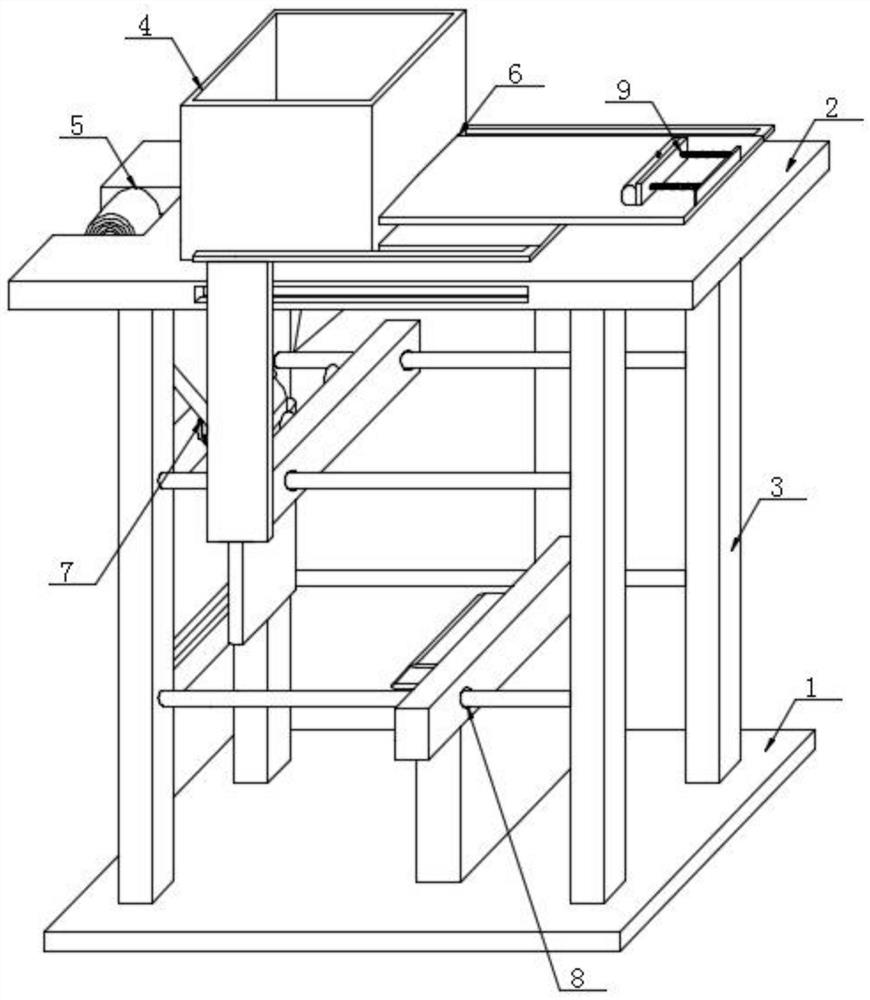

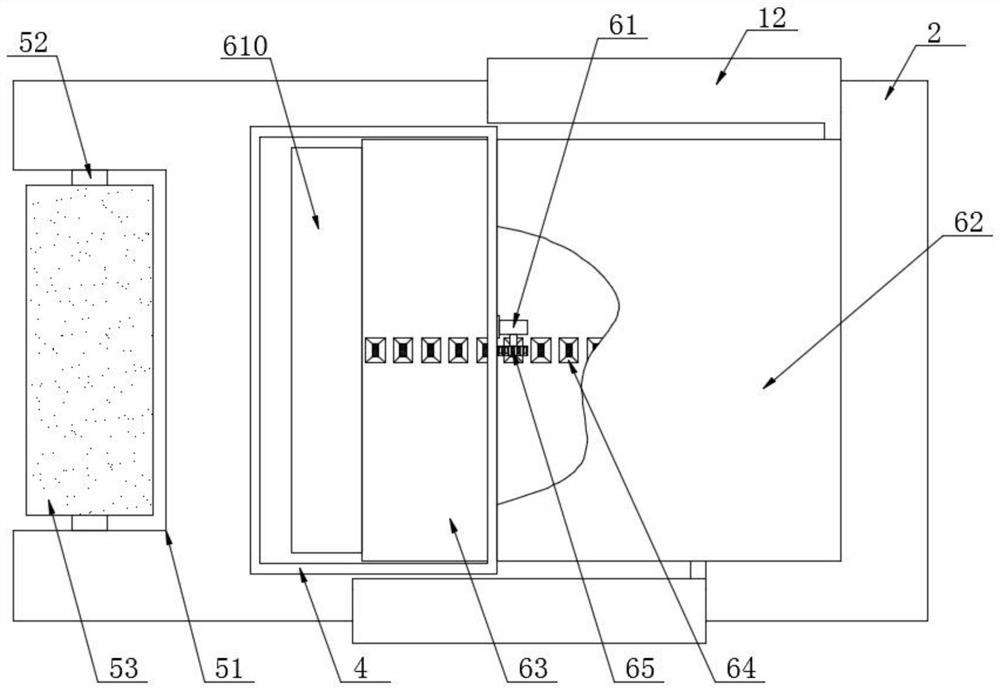

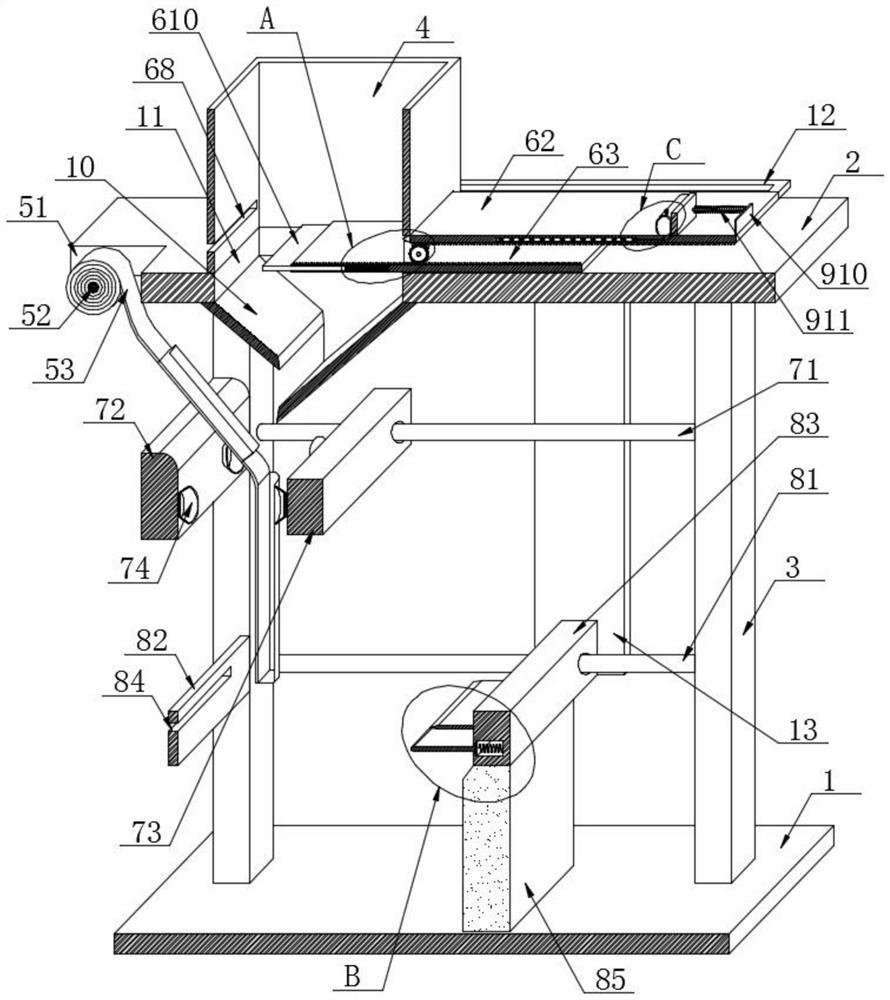

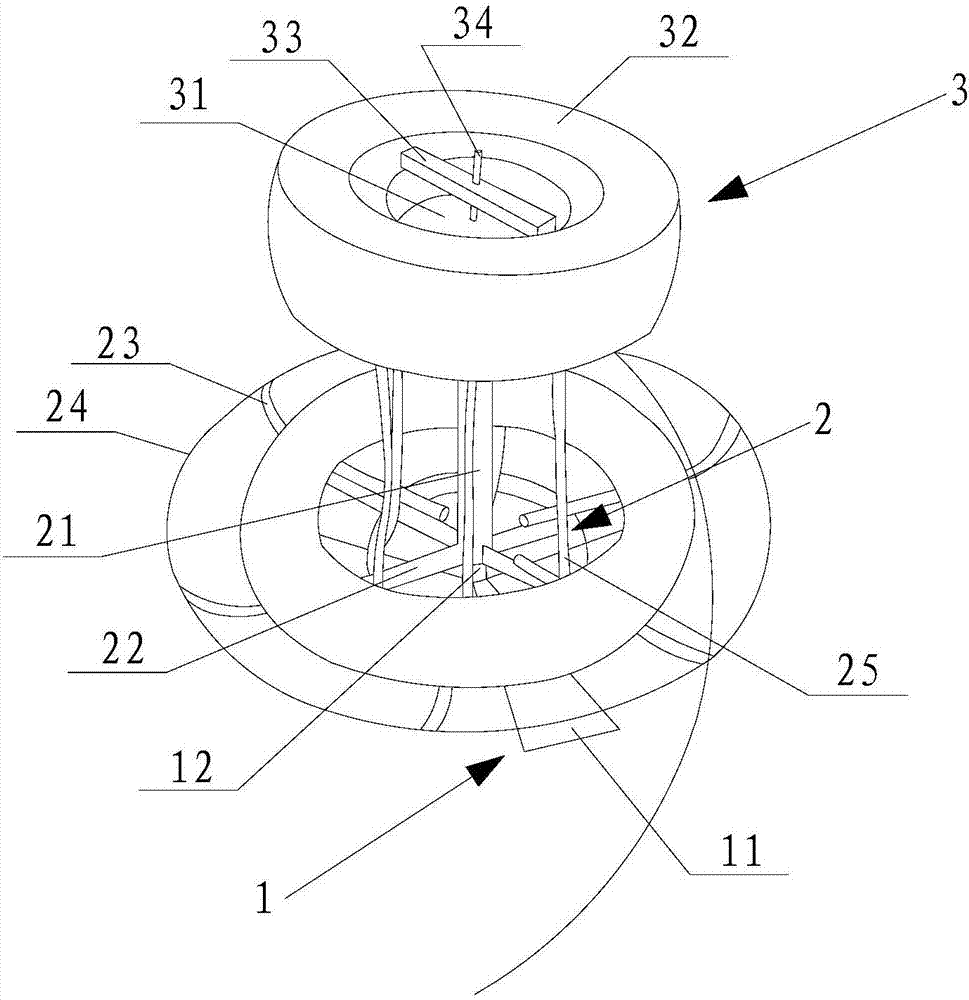

Comb tooth type ricinus communis combine harvester with fruit picking and straw fixed length fixed quantity and bundling functions

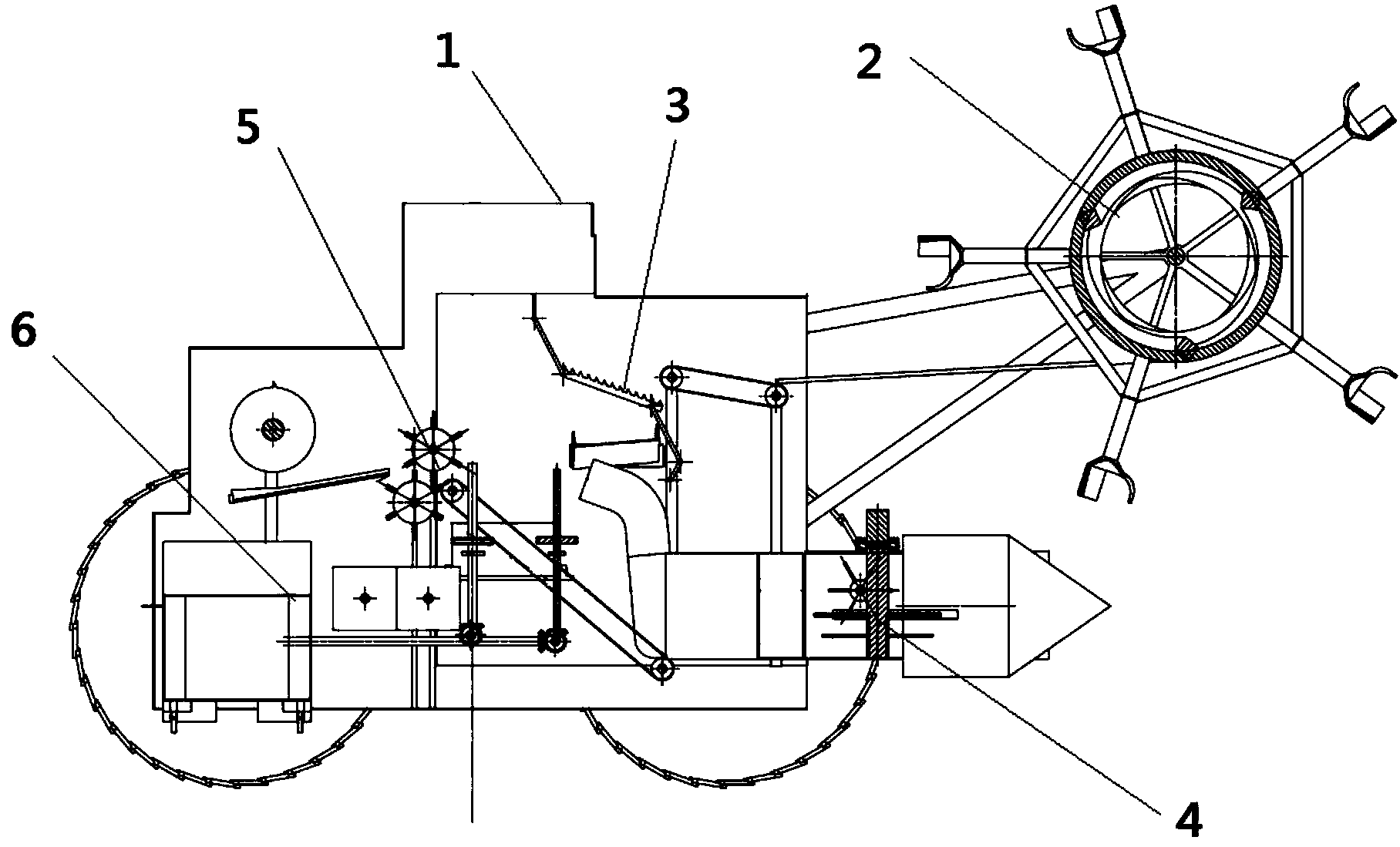

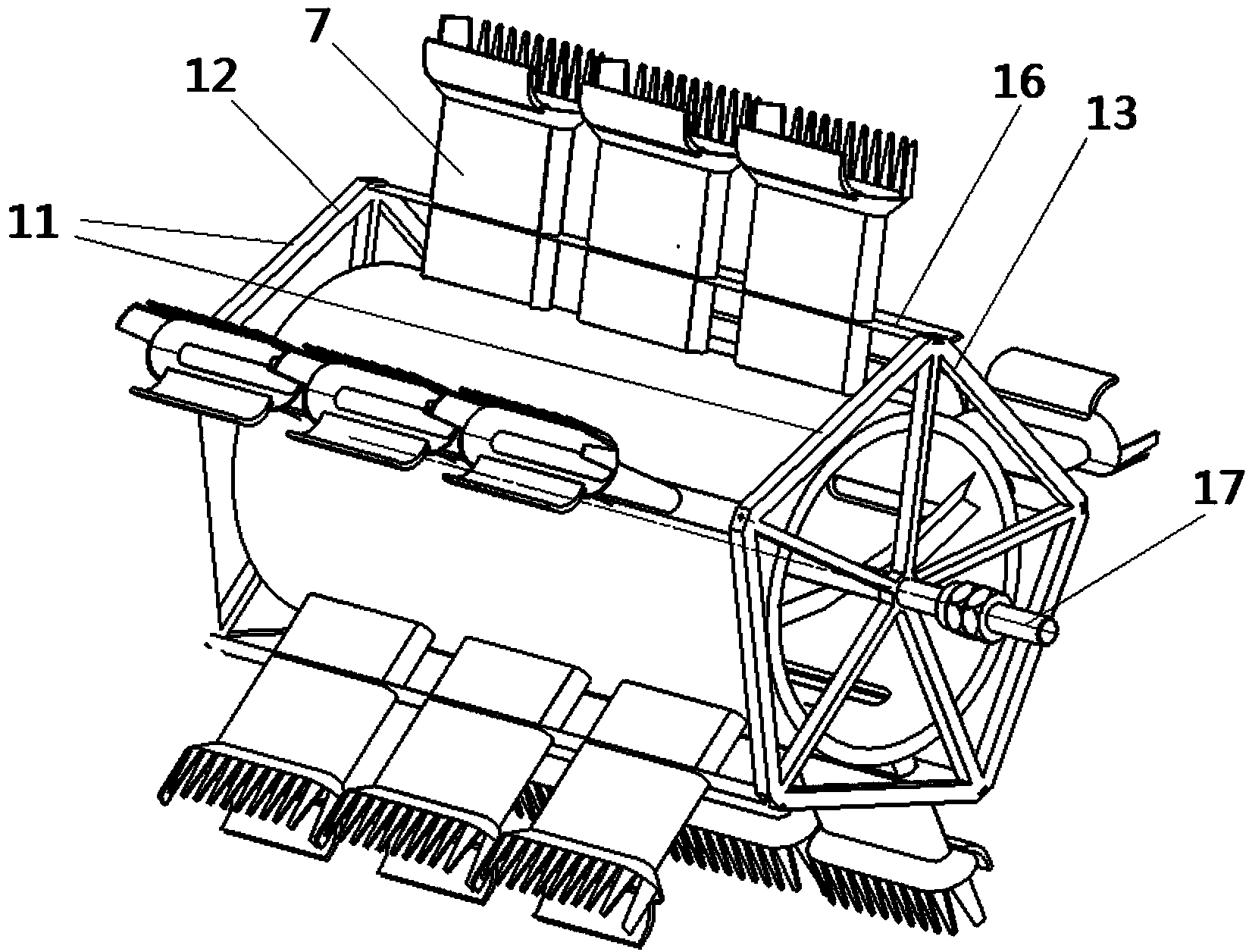

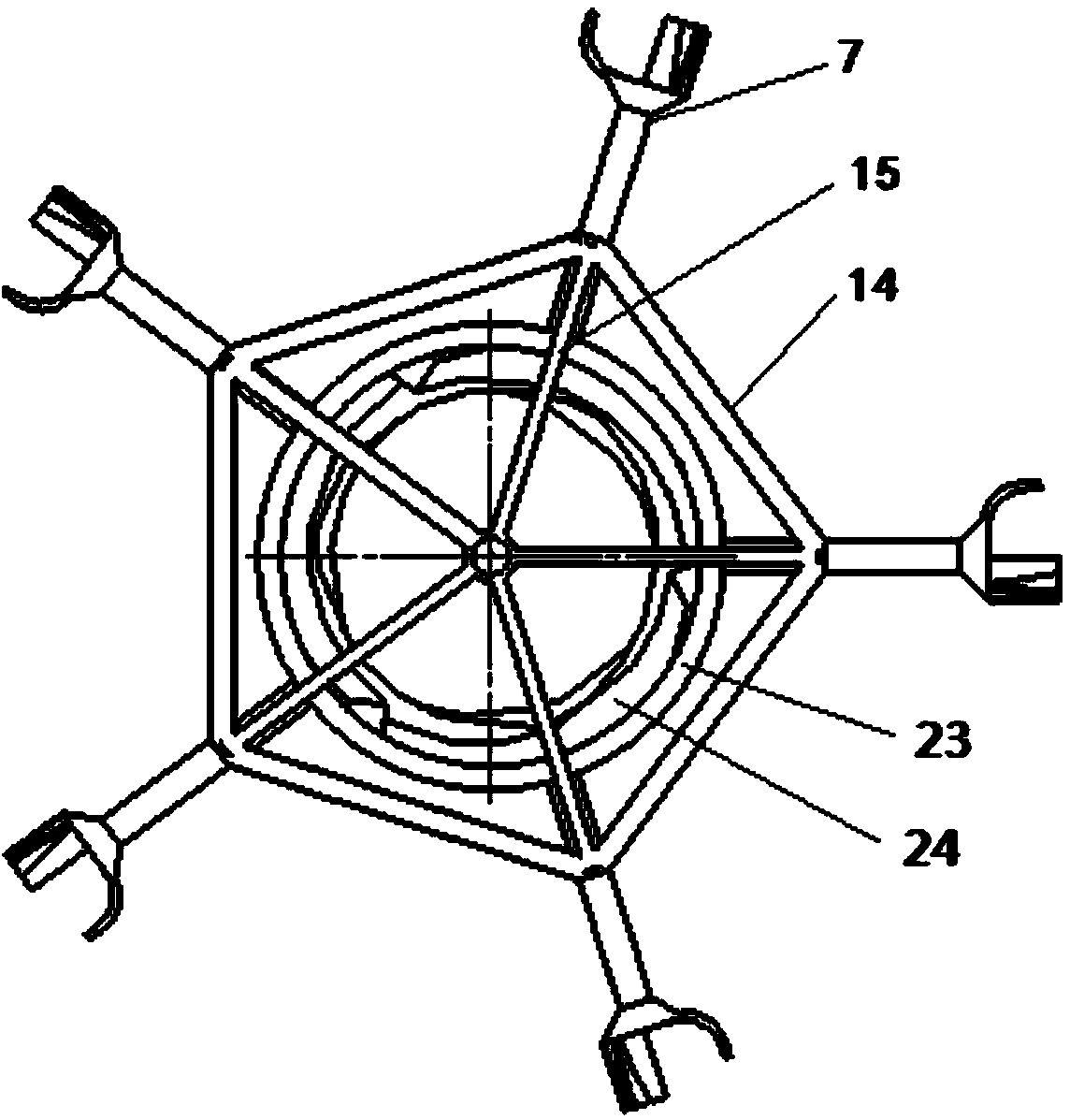

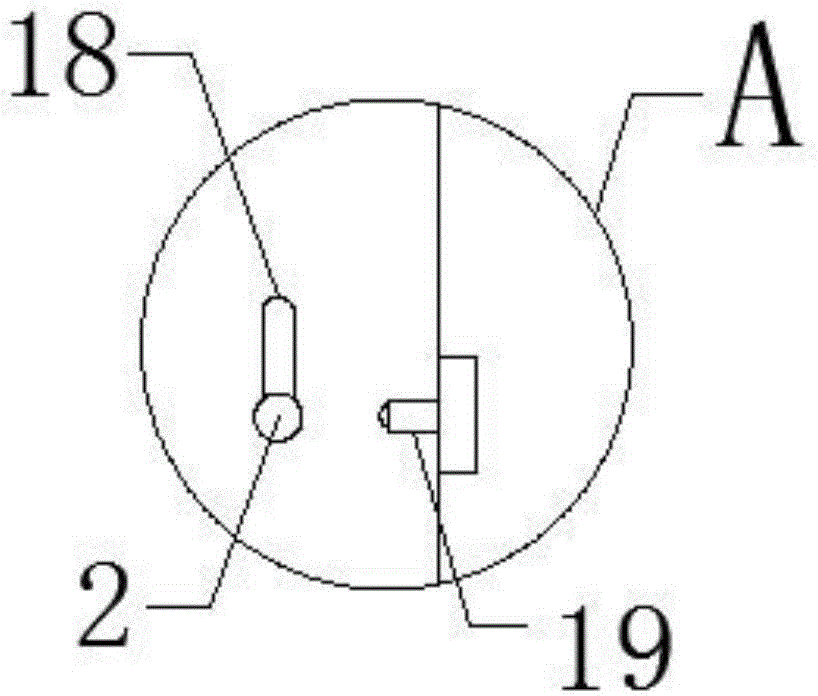

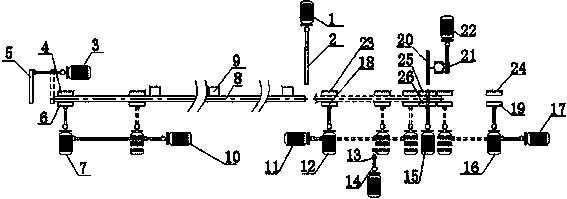

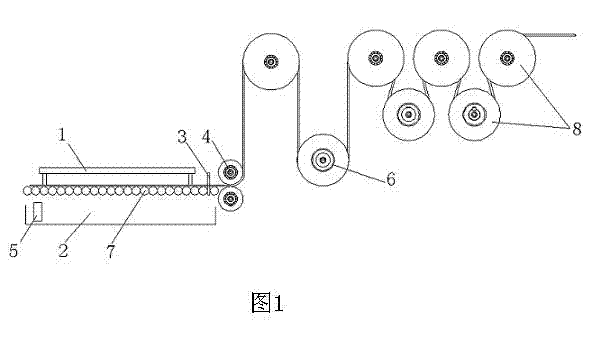

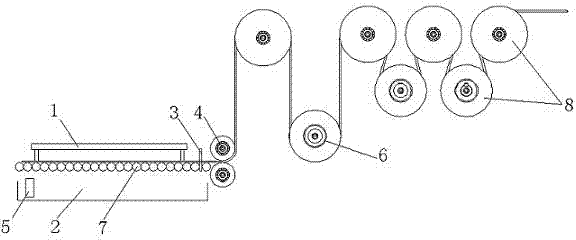

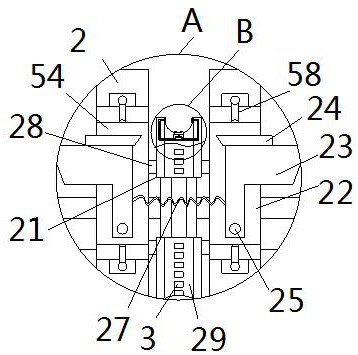

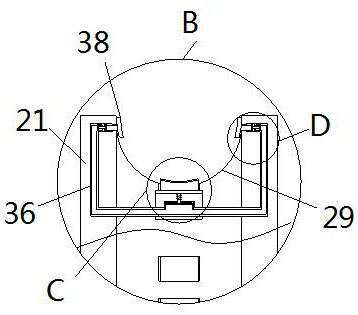

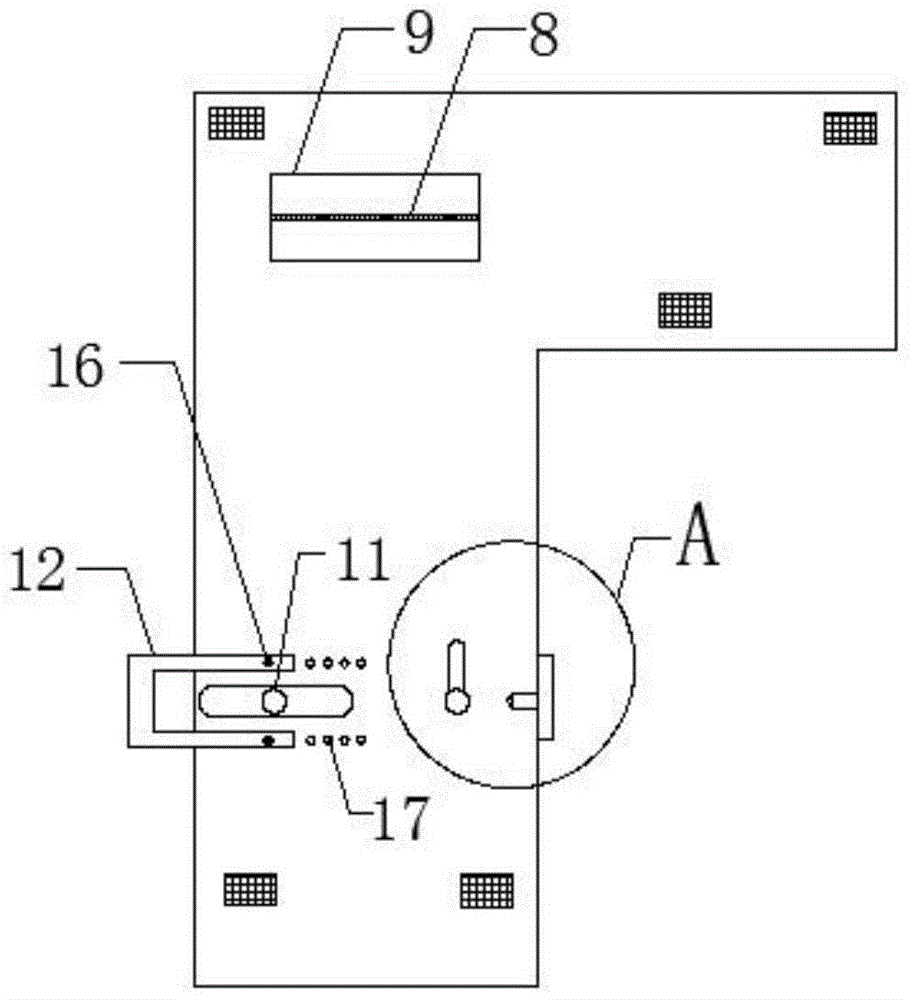

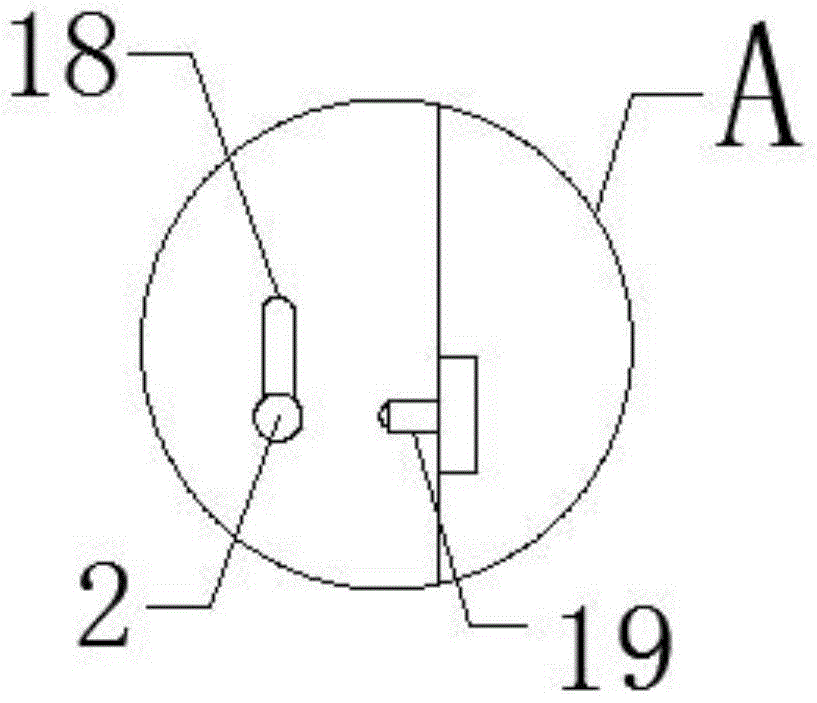

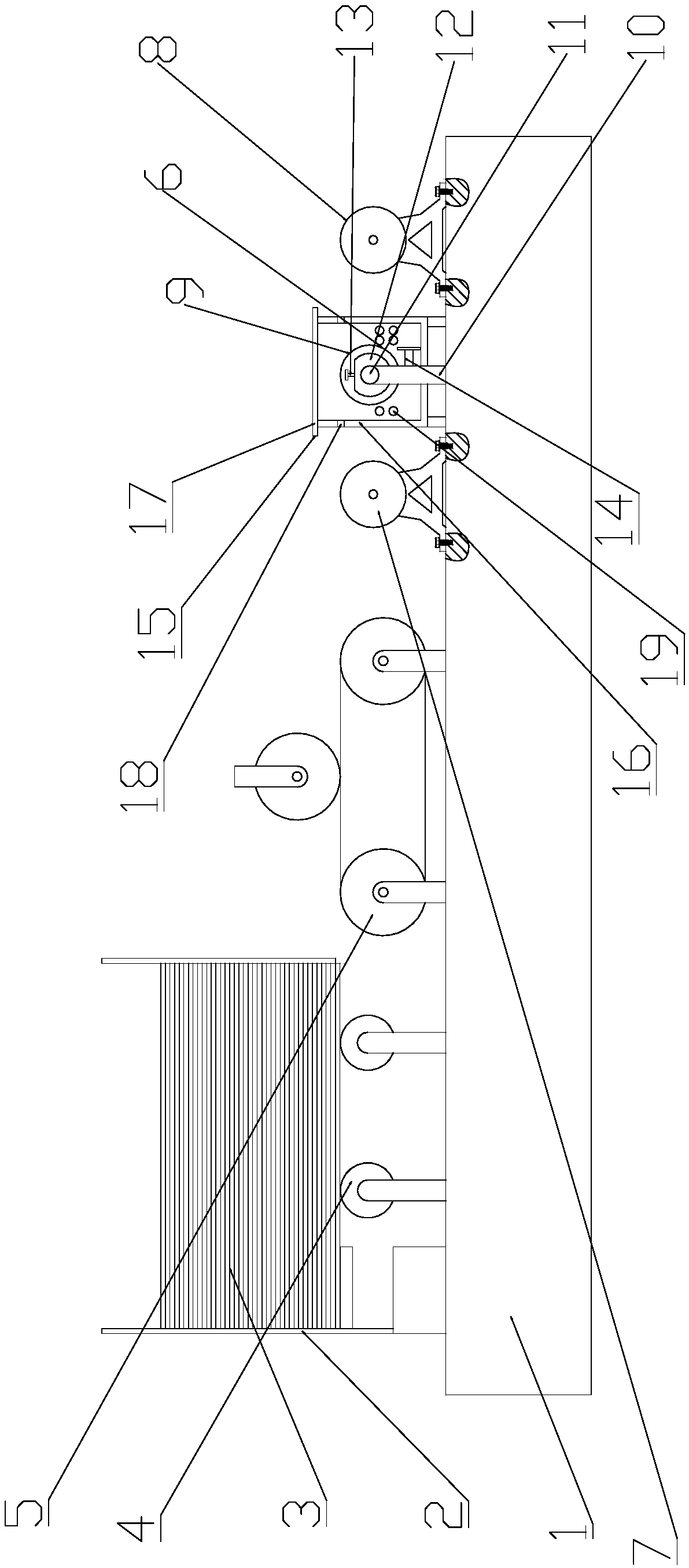

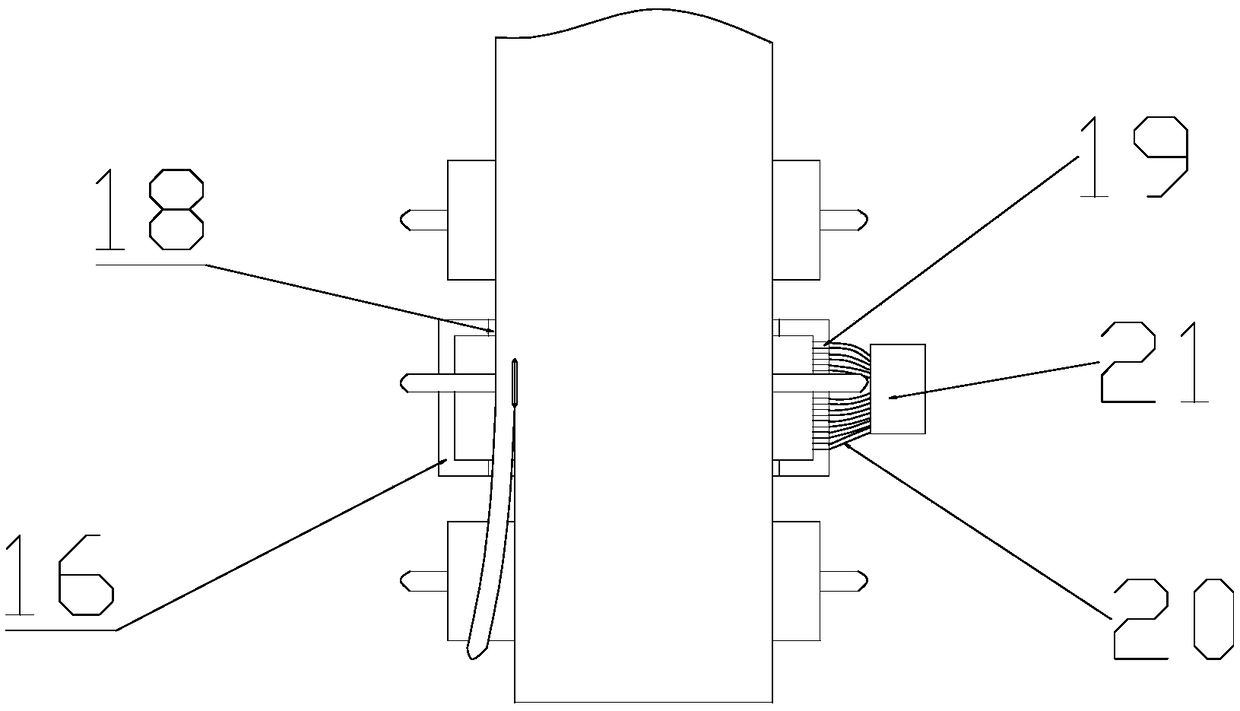

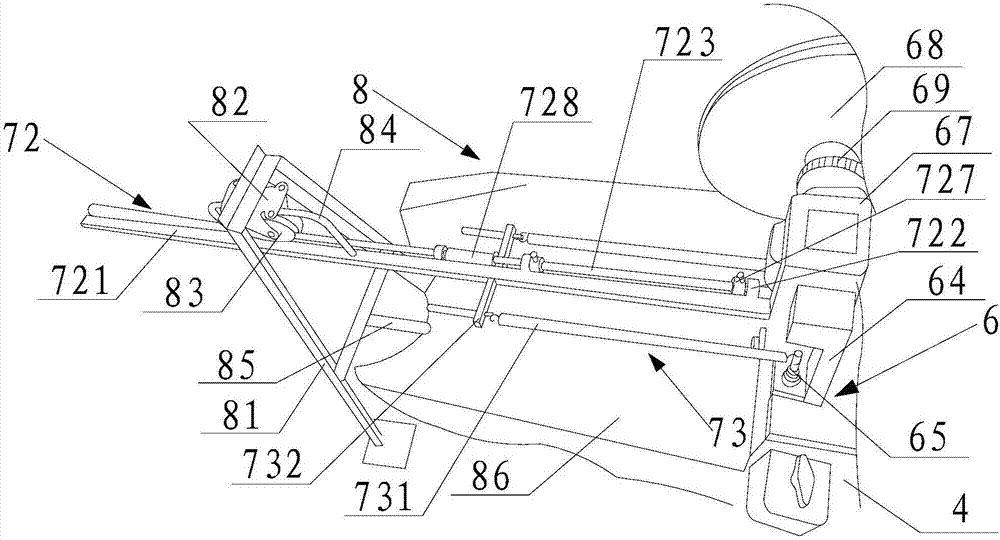

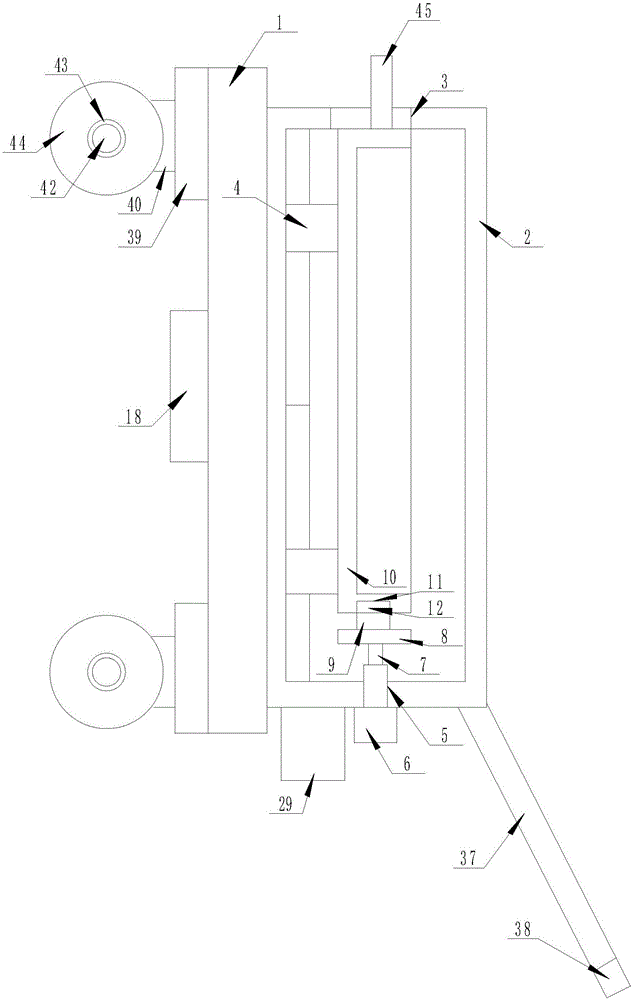

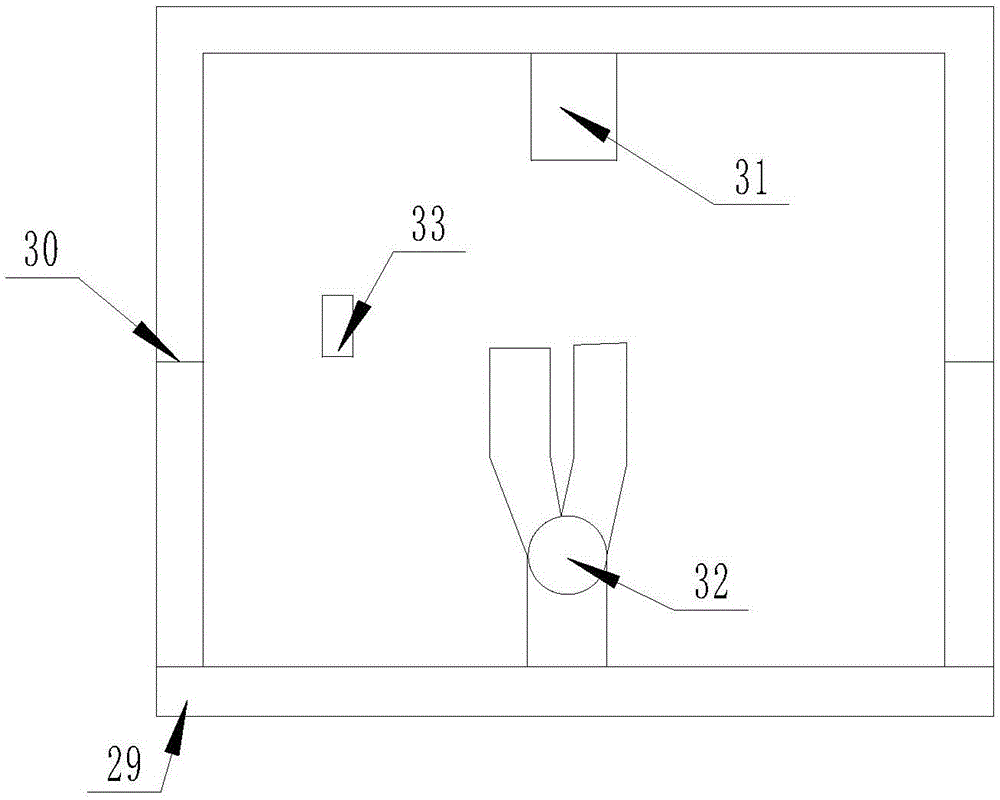

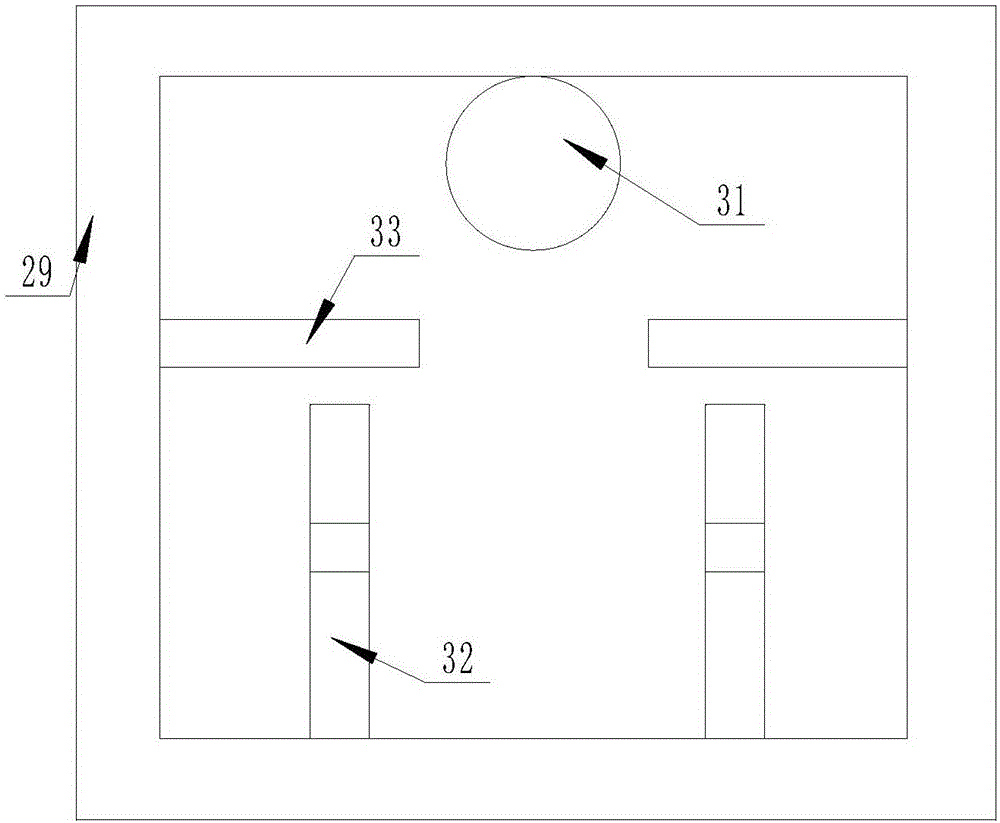

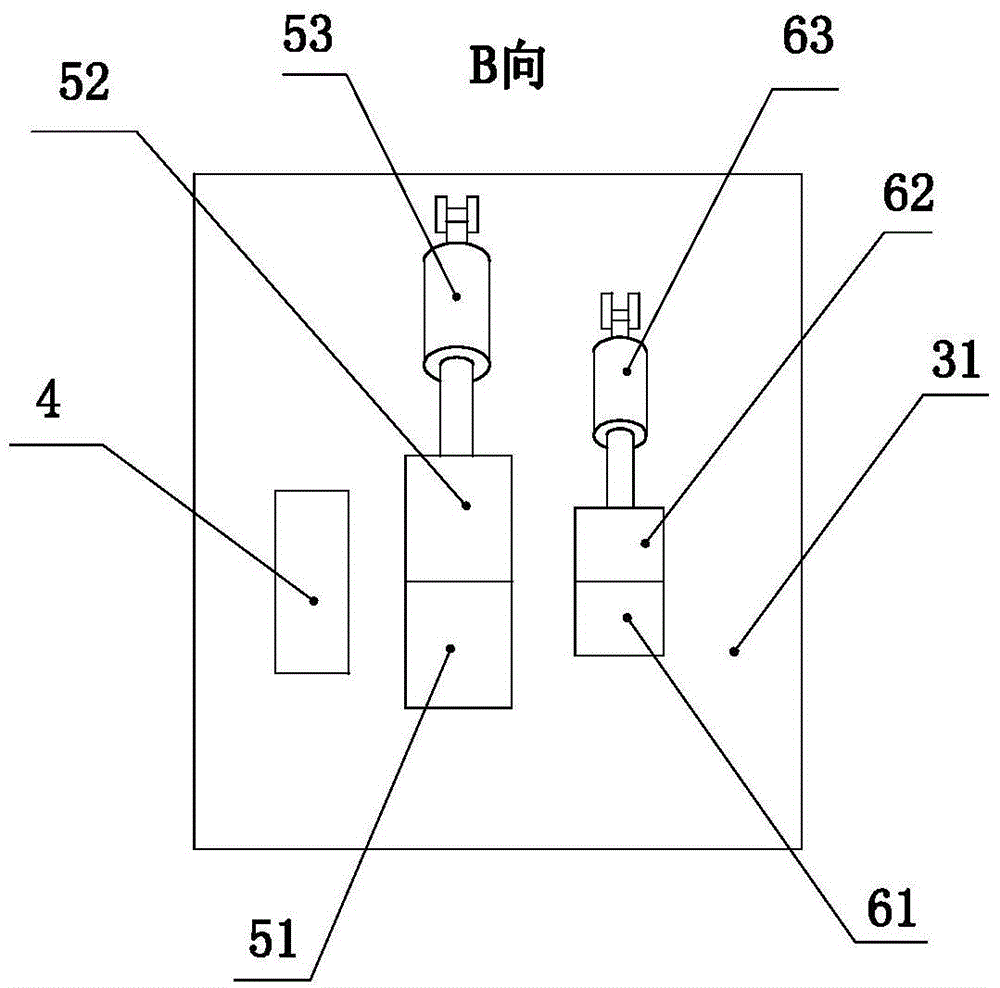

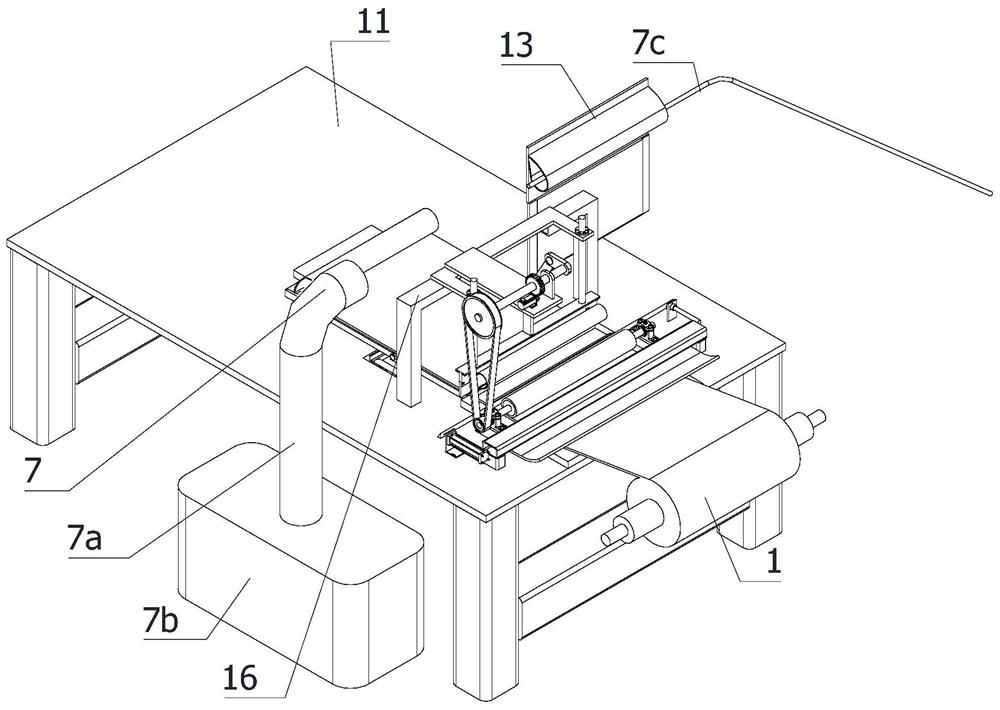

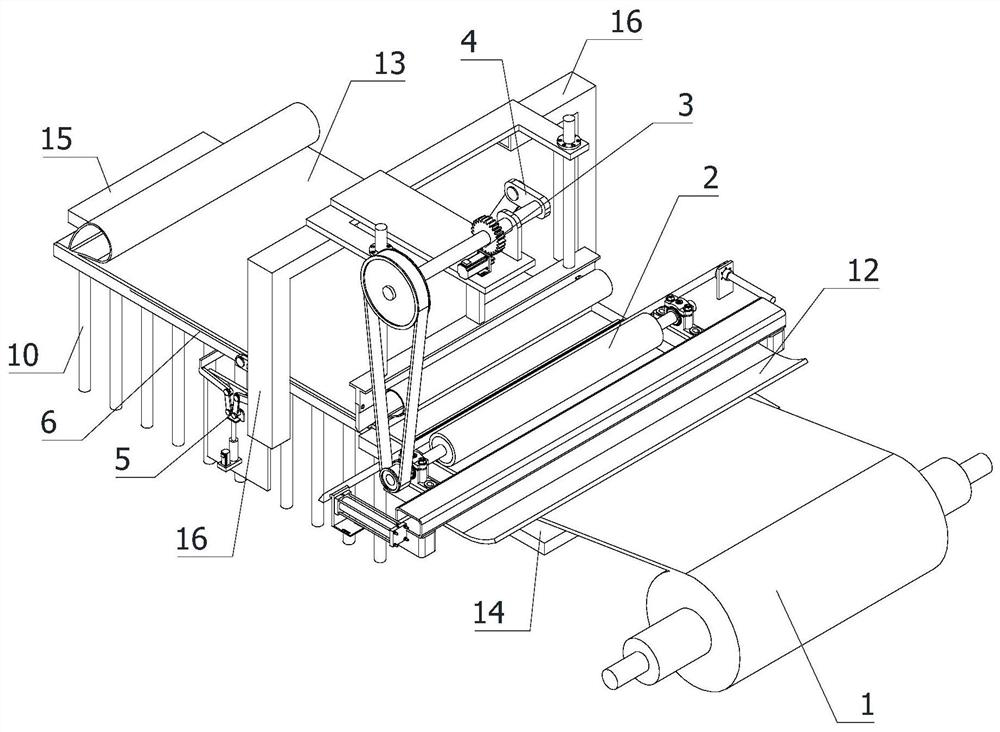

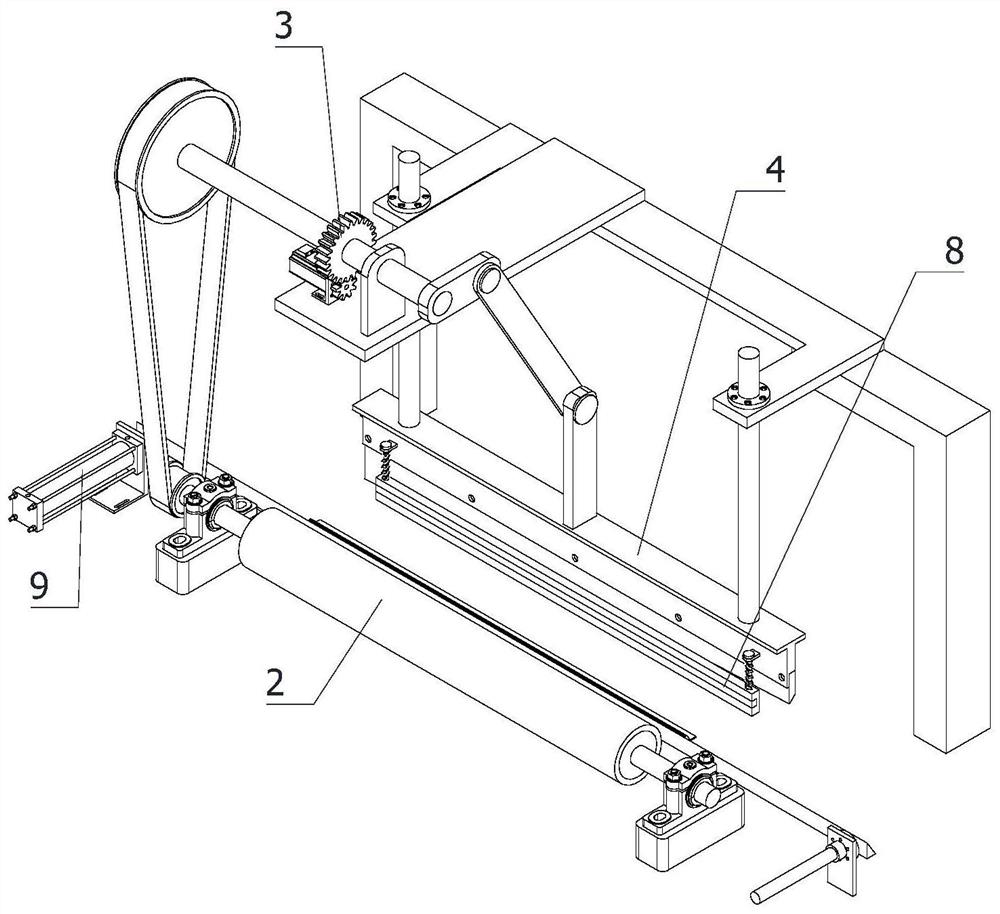

The invention relates to a comb tooth type ricinus communis combine harvester with fruit picking and straw fixed length fixed quantity and bundling functions. The combine harvester is reasonable in structure and integrates picking, separating and cleaning of castor seeds with fixed length segmentation, fixed quantity compaction and automatic bundling of straw. A comb tooth picking system and a feed-in disc type header system are located at the front end of a harvester body, a separating and cleaning system and a hob type fixed length segmentation system are located at the middle end of the harvester body, and fixed quantity compaction and bundling systems are located at the rear end of the harvester body; a comb tooth picking device which rotates anticlockwise is adopted for the comb tooth picking system to pick off the castor seeds and send the castor seeds to the separating and cleaning system, the castor seeds after being collected and separated through a grain collection bin are arranged below an outlet of the separating and cleaning system, a divider is arranged in the front of the harvester body, ricinus communis straw is fed into the disc type header system, the cutoff straw is fed into the hob type fixed length segmentation system through a stalk lifting conveyer belt, and an outlet of the hob type fixed length segmentation system is connected with the fixed quantity compaction and bundling systems; all the systems are driven by a power device through corresponding transmission devices.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

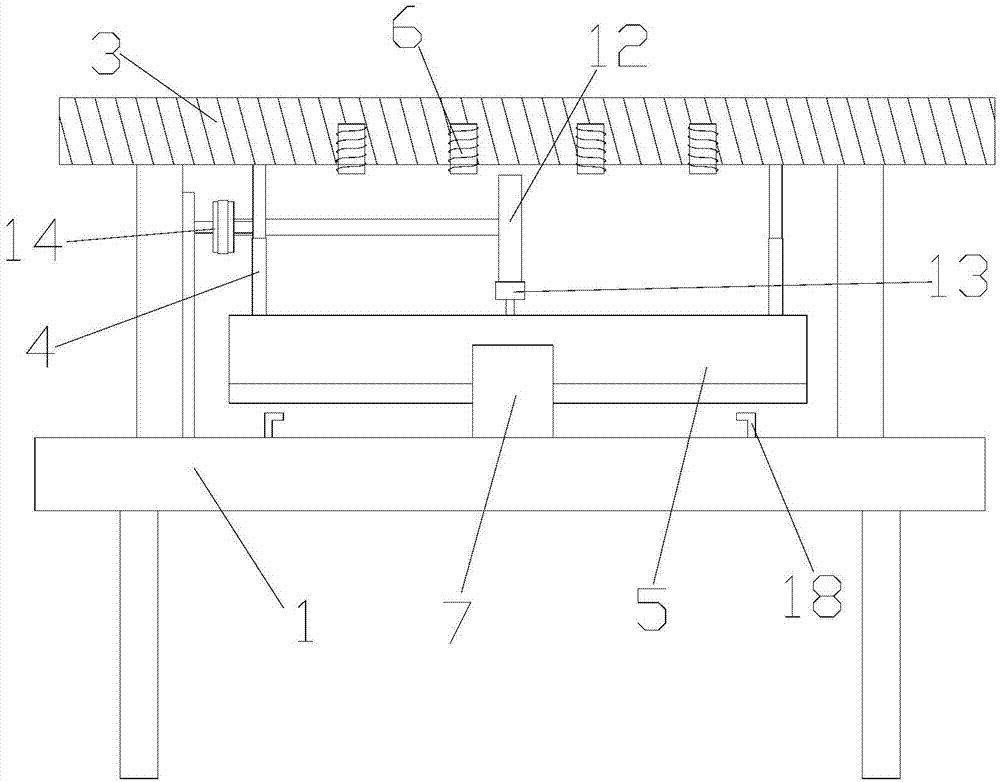

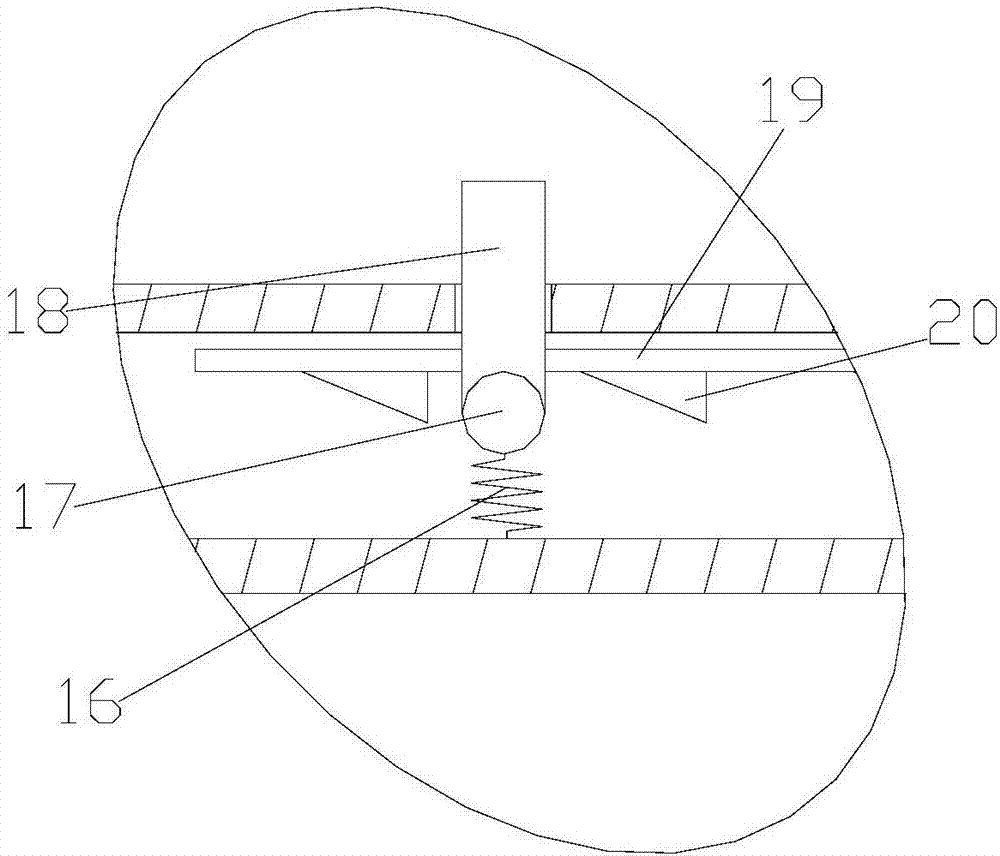

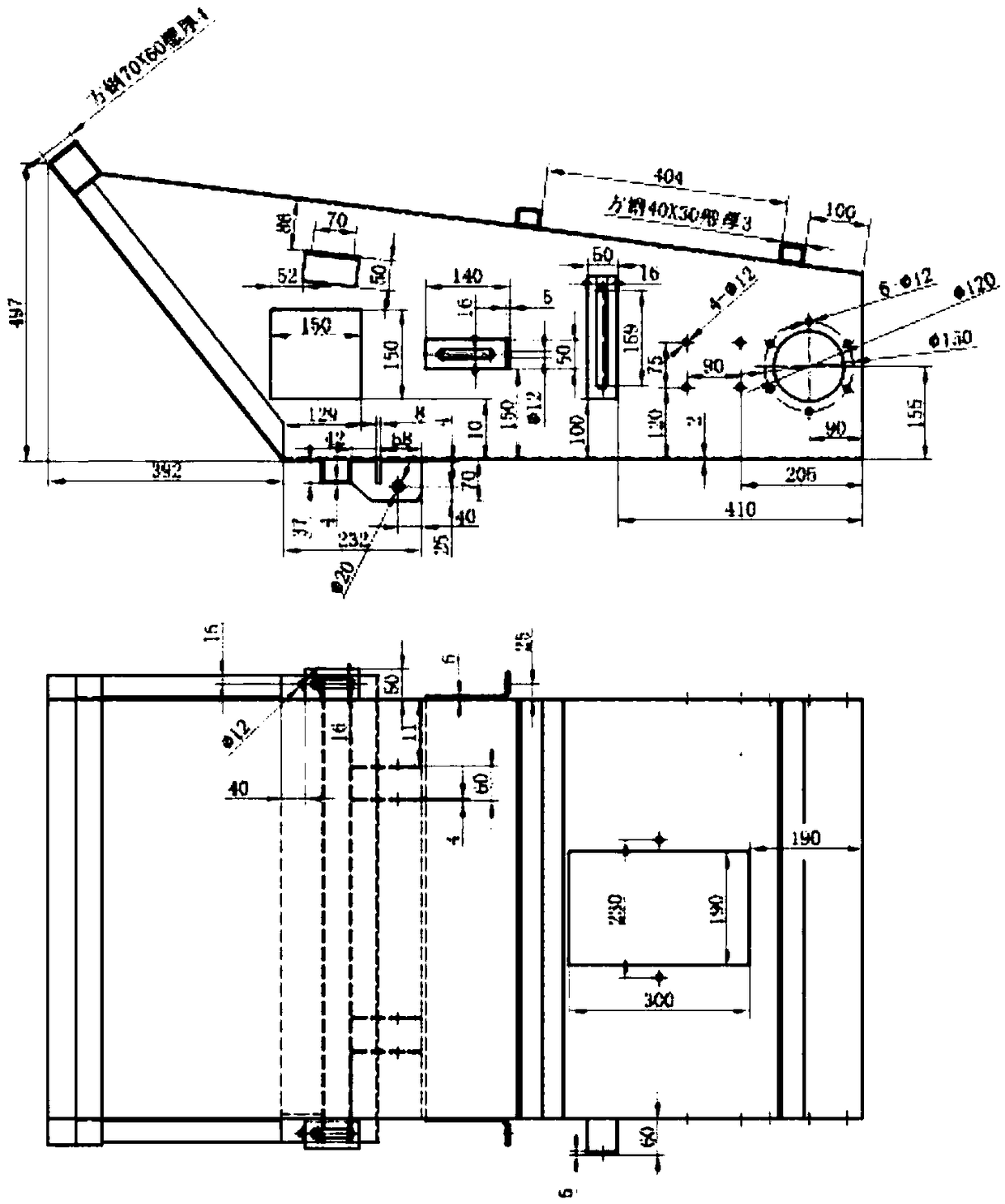

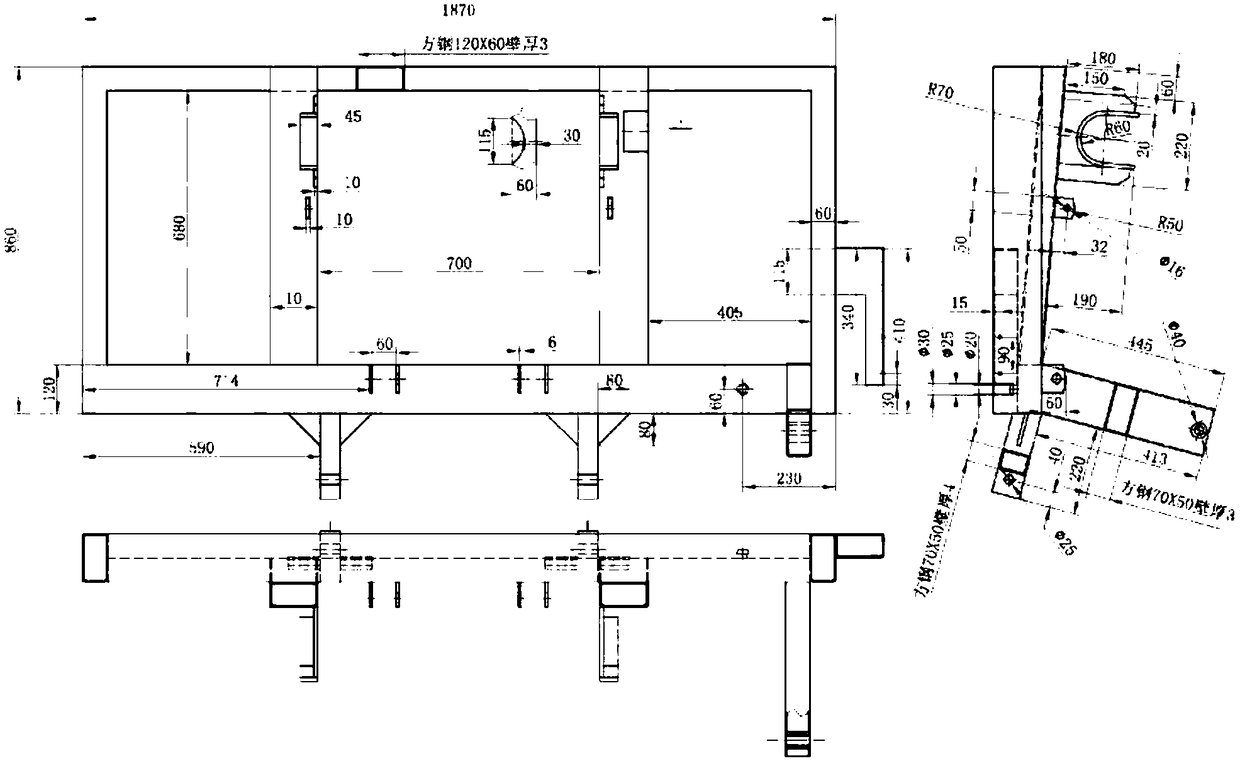

Plate fixed-length cutting device

PendingCN107984017ARealize cut-to-lengthUniform sizeShearing machinesShearing machine accessoriesPortal frameFixed length

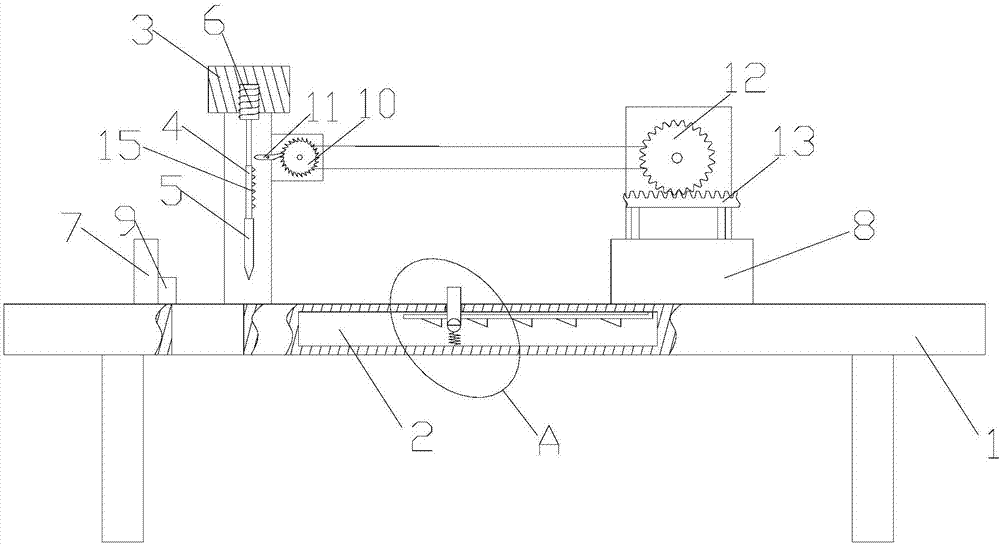

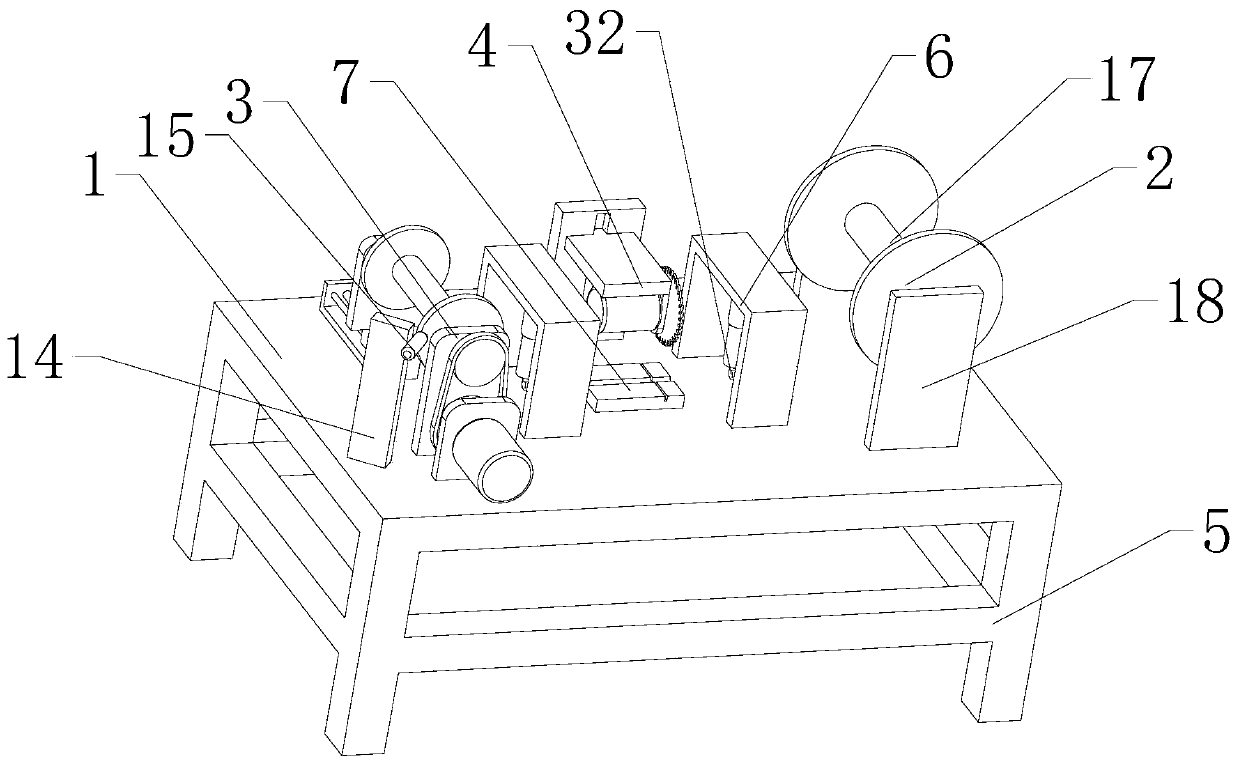

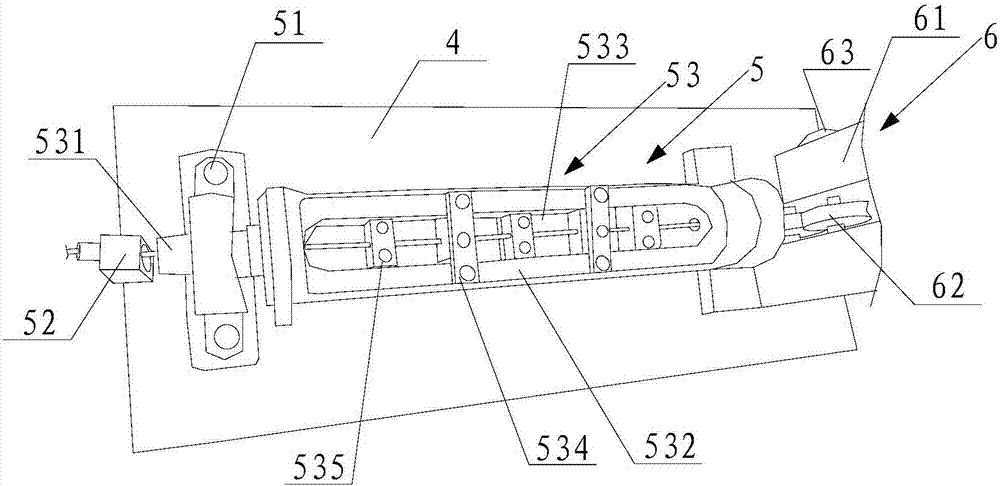

The invention discloses a plate fixed-length cutting device which comprises a working table. The working table is provided with a fixed-length feeding mechanism and a cutting mechanism, and a compression mechanism is arranged in a manner of being matched with the fixed-length feeding mechanism; the cutting mechanism comprises a portal frame, a cutter is connected to a transverse beam of the portalframe through a plurality of stretchable rods, a plurality of solenoids are evenly distributed on the lower surface of the transverse beam of the portal frame, the fixed-length feeding mechanism comprises a positioning plate and a clamping feeding plate, and the positioning plate is provided with outage switches electrically connected with all the solenoids; a transmission mechanism comprises a ratchet wheel and pawl assembly and a gear and rack assembly, a transferring piece is arranged between the ratchet wheel and pawl assembly and the gear and rack assembly, a plurality of protruding blocks arranged at intervals are arranged on the outer wall of one stretchable rod, pawls in the ratchet wheel and pawl assembly are driven by the protruding blocks in the stretchable process of the stretchable rods to do reciprocating swing, and the gear and rack assembly runs through the transferring piece. Compared with the prior art, the plate cutting efficiency is improved, and fixed-length cutting is carried out.

Owner:重庆坤钰映辉汽车零部件有限公司

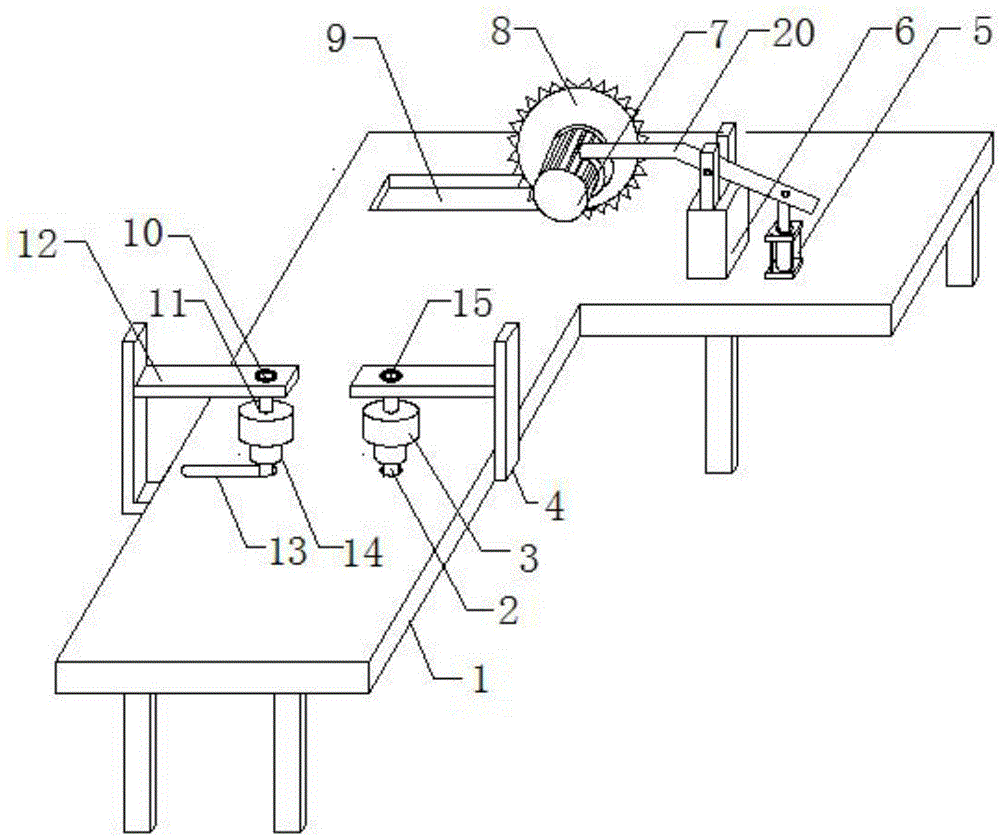

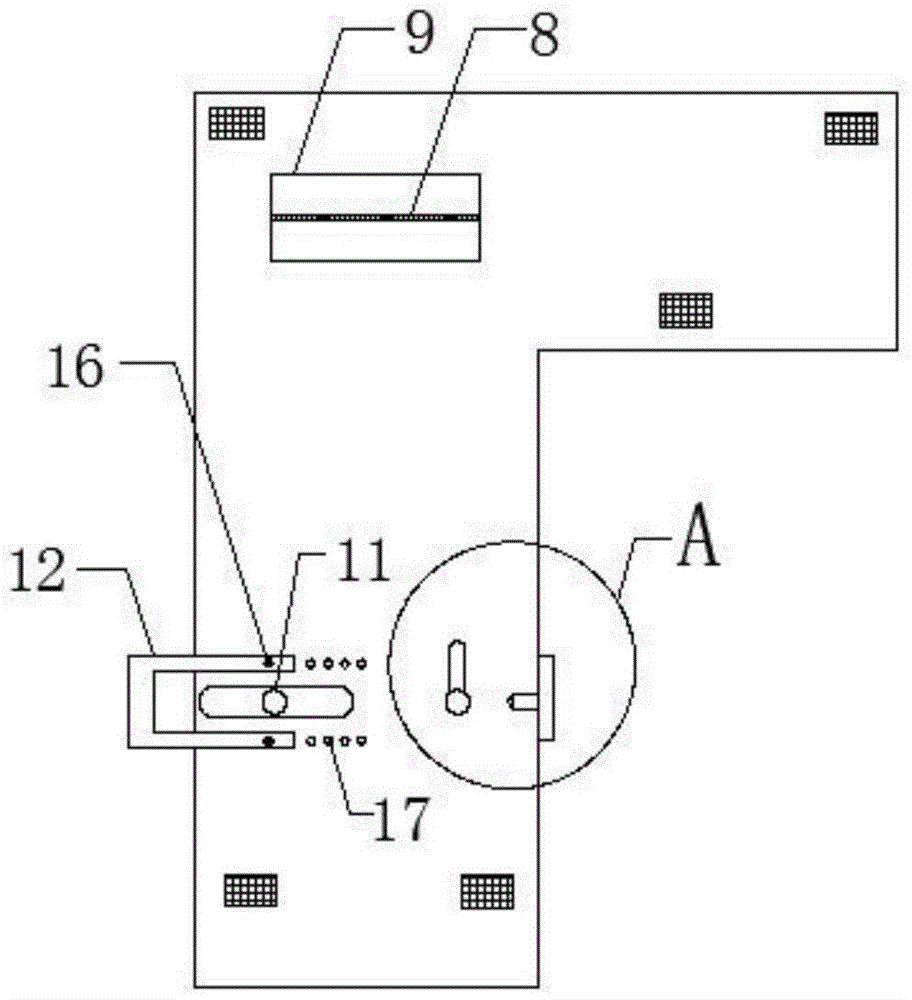

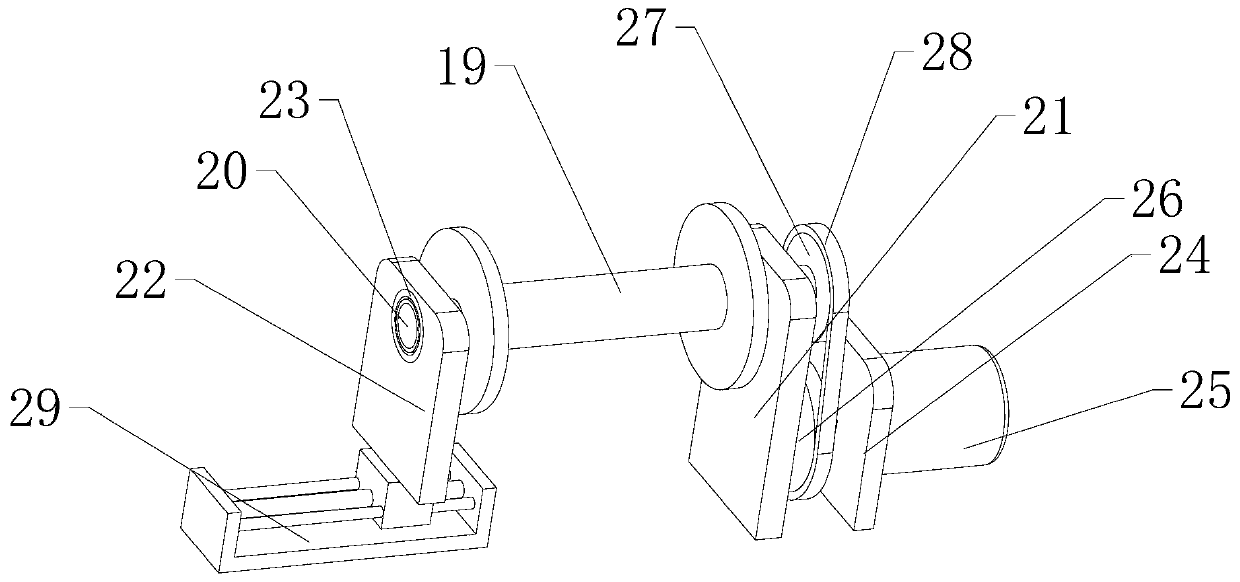

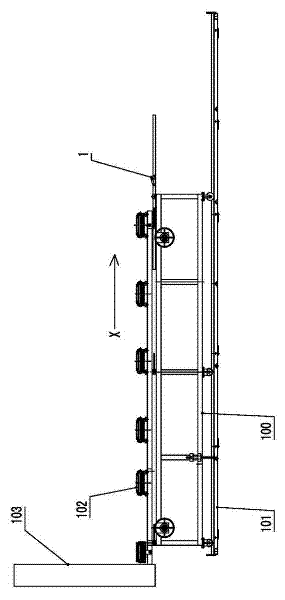

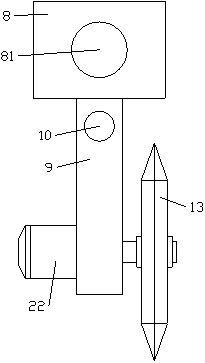

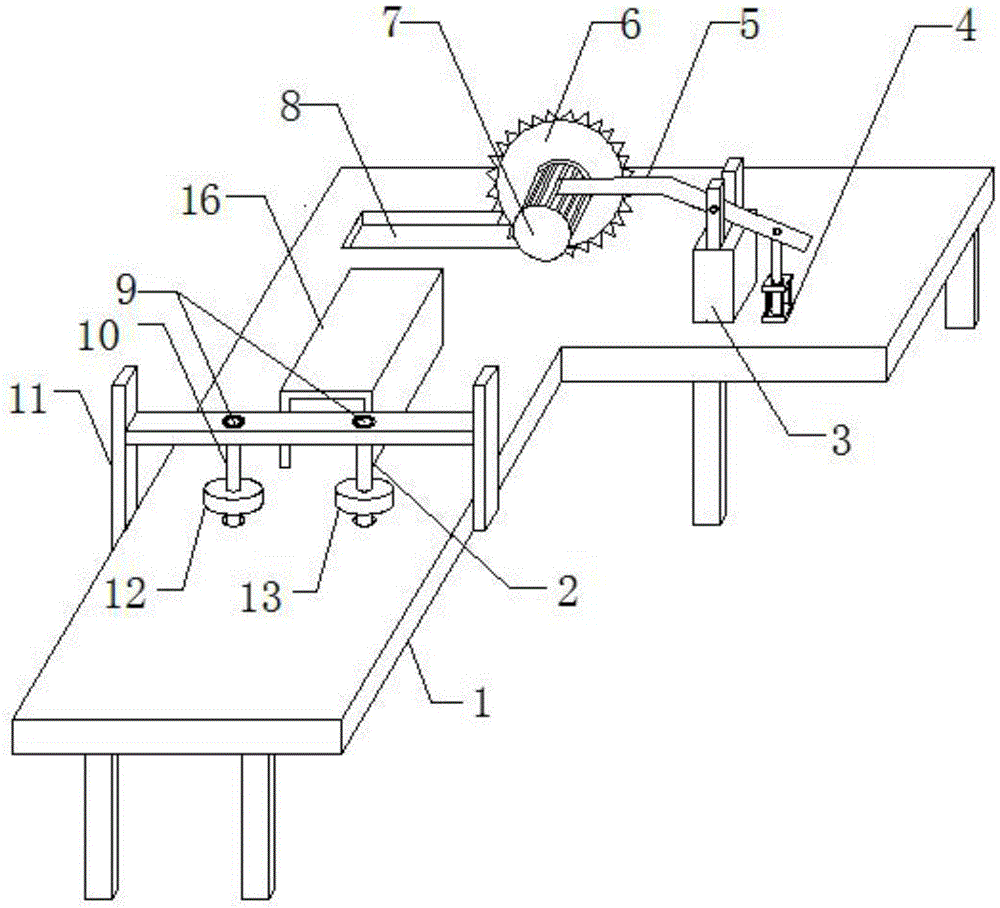

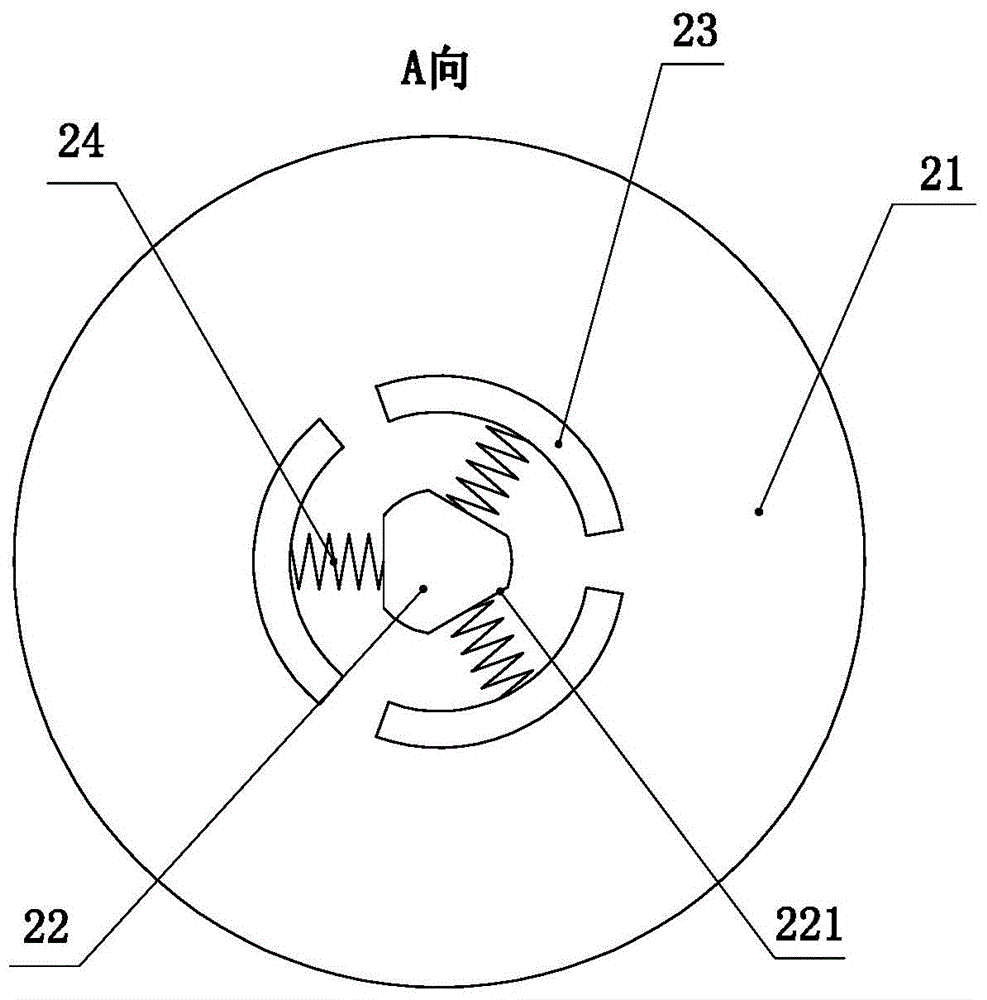

Multi-width copper square pipe fixed-length cutting device

ActiveCN104148726ARealize cut-to-lengthTube shearing machinesShearing machine accessoriesReciprocating motionEngineering

The invention relates to a multi-width copper square pipe fixed-length cutting device which comprises a base. A left support and a right support are correspondingly arranged at the front end of the base. The left support is movably connected with the base and the right support is fixedly connected with the base. A left bearing and a right bearing are arranged in the left support and the right support respectively. A left rotary shaft and a right rotary shaft are installed in the left bearing and the right bearing respectively. The bottom ends of the left rotary shaft and the right rotary shaft both penetrate through the base. The bottom end of the right rotary shaft is fixedly connected with a pivoted lever. The left rotary shaft and the right rotary shaft are sleeved with a left idler wheel and a right idler wheel respectively. A channel allowing a copper square pipe to pass through is formed between the two idler wheels. The back face of the base is further provided with a touch delay switch matched with the pivoted lever. The touch delay switch is connected with a cutting device body and a reciprocating moving mechanism, wherein the cutting device body and the reciprocating moving mechanism are arranged at the rear end of the base. According to the multi-width copper square pipe fixed-length cutting device, the problem that manual scribing measurement accuracy in the prior art is poor is solved, cutting efficiency of the copper square pipe is improved to a great extent, and the cutting device is suitable for cutting copper square pipes of different widths.

Owner:TANGSHAN RENSHI CEMENT EQUIP

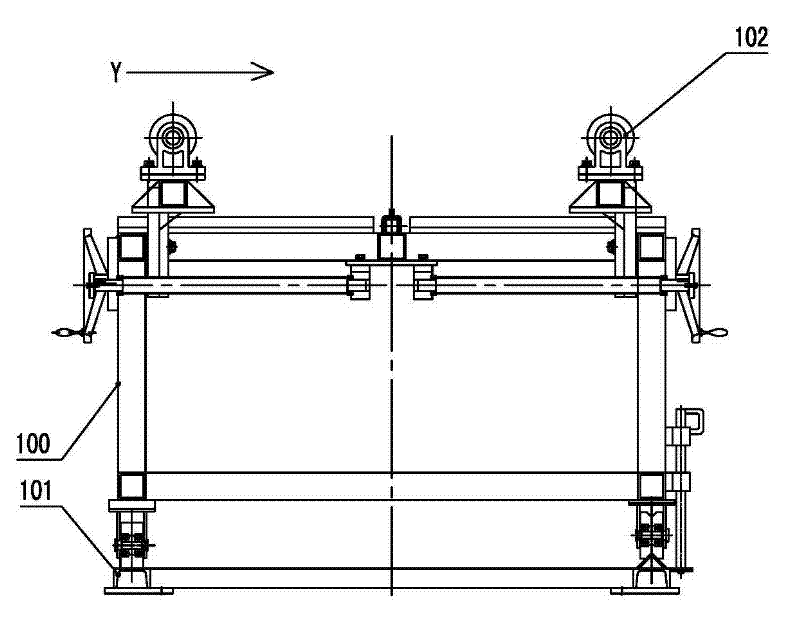

Clamping feeding device for full-automatic tailing-free steel tube cutting machine

InactiveCN103785894AReduce labor intensityImprove labor productivityMetal sawing devicesSteel tubeEngineering

The invention relates to a clamping feeding device for a full-automatic tailing-free steel tube cutting machine. The clamping feeding device comprises a rack, wherein a material aligning device, a first material pushing device, a second material pushing device and a material receiving device are arranged on the rack; the first material pushing device is positioned below the material aligning device; the second material pushing device is positioned on the right side of the first material pushing device; and the material receiving device is positioned on the right side of the second material pushing device. When the clamping feeding device is used, a steel tube is placed in the material aligning device, the first material pushing device is placed on one side of the steel tube, the second material pushing device and the material receiving device are placed on the other side of the steel tube, the first material pushing device and the material receiving device are positioned on the same horizontal line, a cutting device is also fixed above the rack and is positioned between the second material pushing device and the material receiving device, and a limiting device is arranged between the second material pushing device and the cutting device. By using the clamping feeding device, the steel tube can be automatically clamped, fed and cut, labor is replaced by the device, tailing-free machining can be realized, and the production efficiency and the material utilization rate are greatly improved.

Owner:IND RES INST ZHIJIANG COLLEGE OF ZHEJIANG UNIV OF TECH

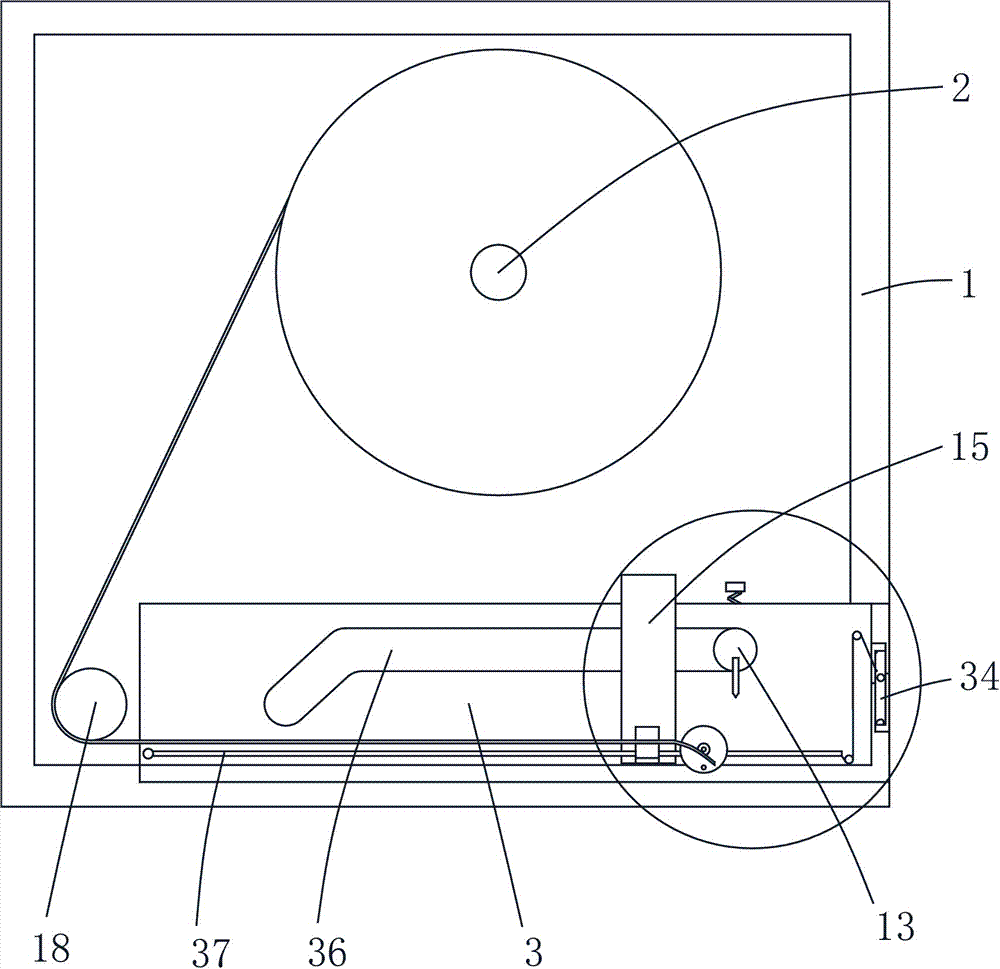

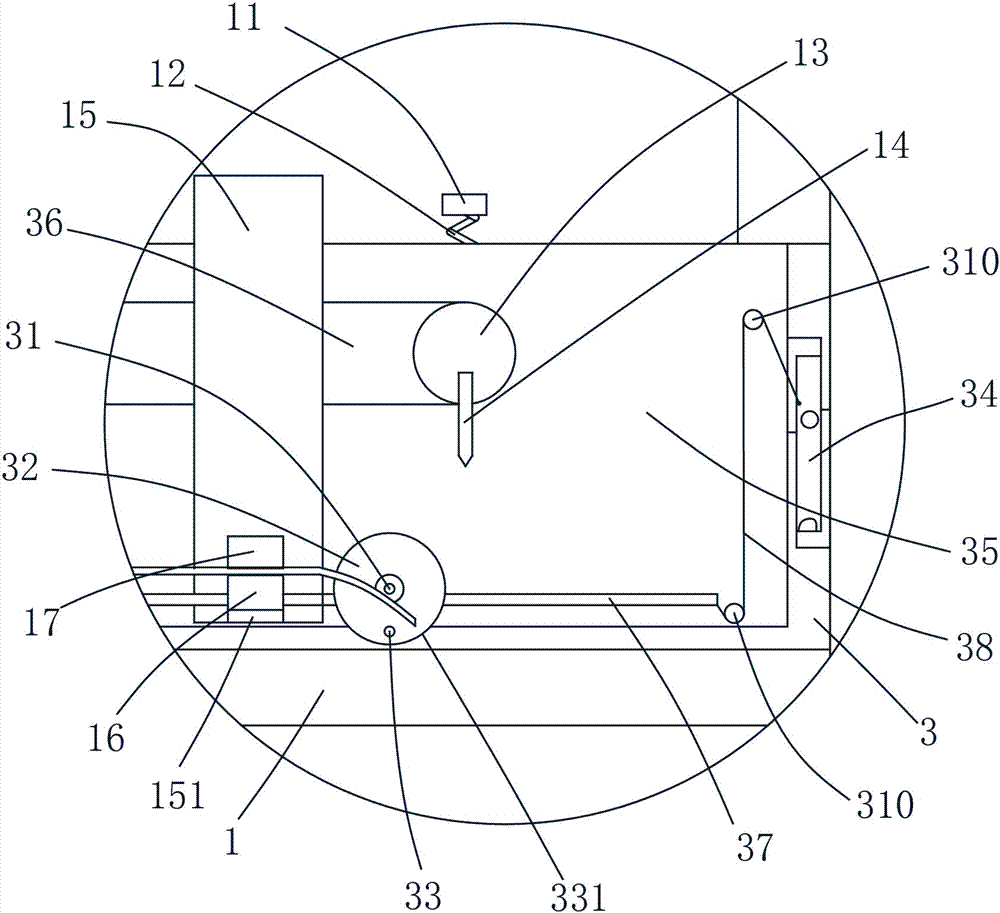

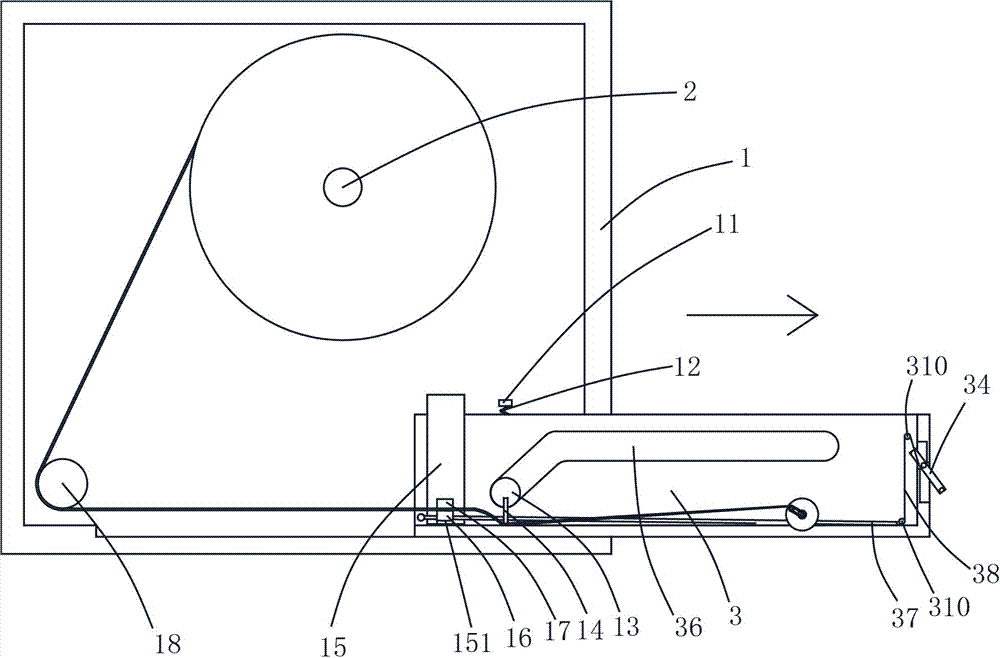

Fixed-length cutting device of communication cable

PendingCN110814226AEfficient cuttingRealize cut-to-lengthFilament handlingMetal working apparatusElectric machineryStructural engineering

The invention relates to the field of communication cable processing, in particular to a fixed-length cutting device of a communication cable. The fixed-length cutting device comprises a workbench, anunwinding device, a winding device and a cutting mechanism. The cutting mechanism is mounted at the middle position of the workbench. The unwinding device and the winding device are arranged at the two ends of the workbench correspondingly. Guide press mechanisms are further arranged on the two sides of the cutting device. A cutting jig plate is arranged on the side of the cutting mechanism. Thecutting device comprises a mounting plate, a supporting plate, a cutting motor, a cutting wheel and a mounting seat. The supporting plate is mounted on the workbench. An electric sliding rail is further arranged on the supporting plate. The mounting plate is in sliding connection to the electric sliding rail. The mounting seat is arranged on the mounting plate. The cutting motor is fixedly mountedon the mounting seat. The cutting wheel is fixedly connected with the output end of the cutting motor. A supporting rod is arranged on the side of the winding device. An inductor is fixedly mounted on the supporting rod. By means of the device, cutting efficiency is improved, and manpower is saved.

Owner:湖州新东方线缆有限公司

Automatic cutting device capable of cutting wood in batches

PendingCN109366618ARealize cut-to-lengthGuaranteed cut to lengthFeeding devicesCircular sawsEngineeringMechanical engineering

The invention relates to an automatic cutting device capable of cutting wood in batches. The automatic cutting device comprises a rack, a moving unit, a discharging unit, a cutting unit and a step length control unit. The discharging unit is slidably connected with the rack and can slide back and forth in the length direction of the rack. The cutting unit and the step length control unit are arranged below the discharging unit and are arranged side by side in the length direction of the rack. The moving unit is connected with the discharging unit and can drive the discharging unit to move to the position of the cutting unit or the position of the step length control unit. According to the automatic cutting device capable of cutting wood in batches, when wood (such as triangular wood) is cut, the wood can be cut in batches while the requirement for processing precision is met, the cutting process can be conducted fully automatically, and thus, the production efficiency is improved.

Owner:SHANDONG YIHUA FURNITURE CO LTD

Cylinder sleeve cutting equipment capable of achieving scrap suction conveniently

InactiveCN107414165AEasy to cleanAvoid damageShearing machinesMaintainance and safety accessoriesHydraulic cylinderEngineering

The invention discloses cylinder sleeve cutting equipment capable of achieving scrap suction conveniently. The cylinder sleeve cutting equipment capable of achieving scrap suction conveniently comprises a cutting table, and the cutting table is formed through plain warp-weft weaving of steel wires. A blocking plate is arranged on one side of the cutting table and located on the feeding stroke of a cylinder sleeve. The blocking plate is connected with the movable end of a third hydraulic cylinder in a driven mode and driven by the third hydraulic cylinder to move horizontally, and the moving direction of the blocking plate is parallel to the feeding direction of the cylinder sleeve. A pushing plate is arranged on the other side of the cutting table. The pushing plate is connected with the movable end of a seventh hydraulic cylinder in a driven mode and driven by the seventh hydraulic cylinder to move horizontally, and the moving direction of the pushing plate is perpendicular to the feeding direction of the cylinder sleeve. A scrap suction device comprises a scrap suction pipe, a scrap collection box and a draught fan, wherein a feeding port of the scrap suction pipe is located below the cutting table, a discharging port of the scrap suction pipe communicates with the scrap suction box, and the draught fan is located on one side of the scrap suction box. According to the cylinder sleeve cutting equipment capable of achieving scrap suction conveniently, waste scraps generated in the cutting process can be removed, the labor intensity is low, the machining time is short, and the machining efficiency is high.

Owner:ZYNP GRP ANHUI CO LTD

Cutting device of glass tube

PendingCN108298806ARealize cut-to-lengthGuaranteed not to shiftGlass severing apparatusReciprocating motionFixed length

The invention belongs to the technical field of glass tube cutting, and particularly relates to a cutting device of a glass tube. The cutting device of the glass tube comprises a fixed machine frame,a moveable machine frame, a cylinder, a cutting head and a clamping head. The moveable machine frame is connected with the fixed machine frame through a vertical guide rail. The cylinder is verticallyinstalled and is rotatably connected with the moveable machine frame. The cutting head is moveably connected with the cylinder. The clamping head is moveably connected with the fixed machine frame. The cutting device of the glass tube further comprises a lifting device for driving the moveable machine frame to do up-down reciprocating motion relative to the fixed machine frame, a rotation devicefor driving the cylinder to rotate relative to the moveable machine frame, a cutting head telescopic device for driving the cutting head to do reciprocating motion along the radial direction of the cylinder, and a fracture fixing device for driving the clamping head to do reciprocating motion along the radial direction of the cylinder so as to clamp or loosen the glass tube. The cutting device ofthe glass tube is capable of cutting the continuously discharged glass tube in a fixed length, the production efficiency is high, the product quality is stable, and the cutting device is suitable forthe glass tubes in different diameters.

Owner:HEYUAN PX WATER JET CUTTING MACHINERY

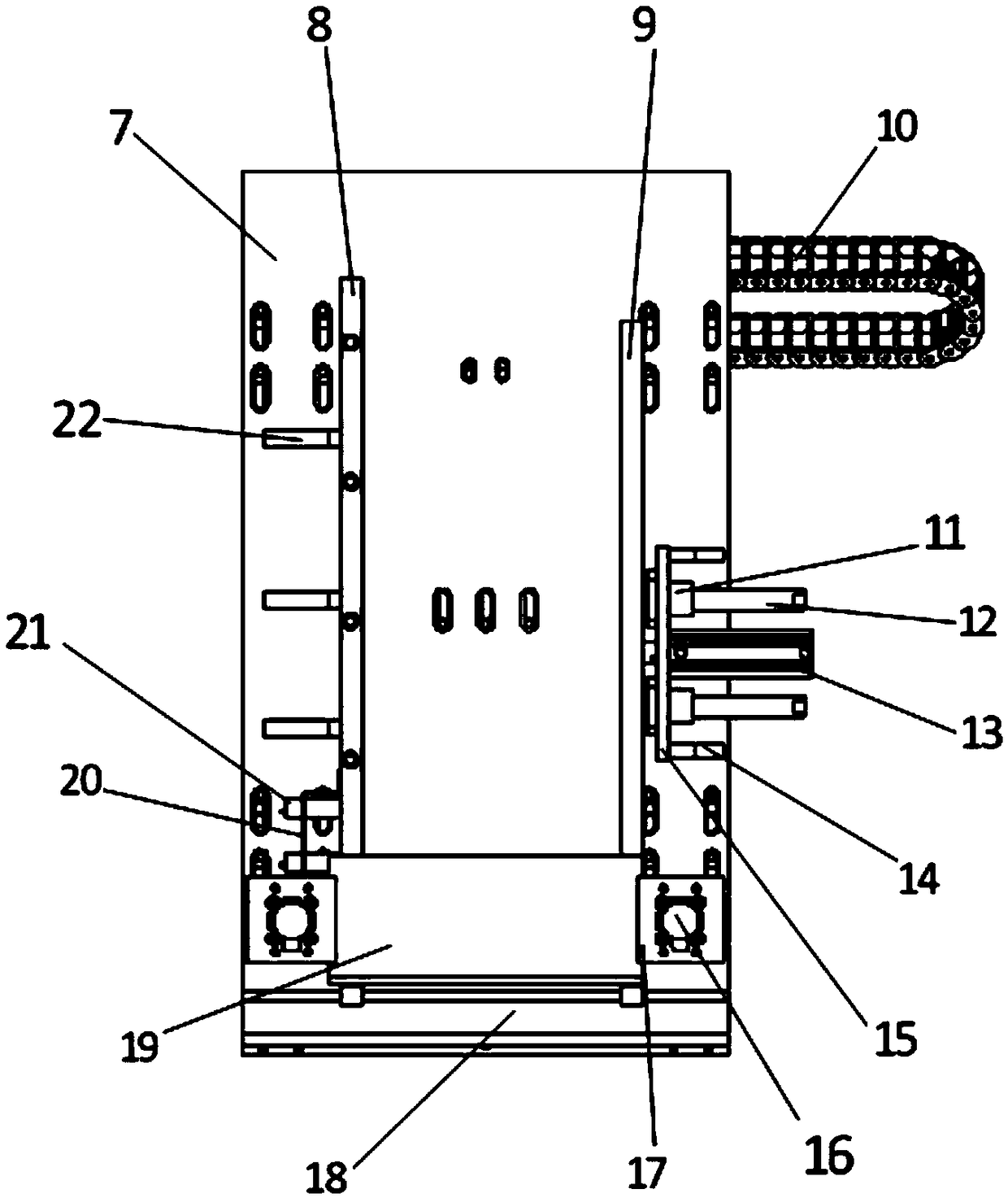

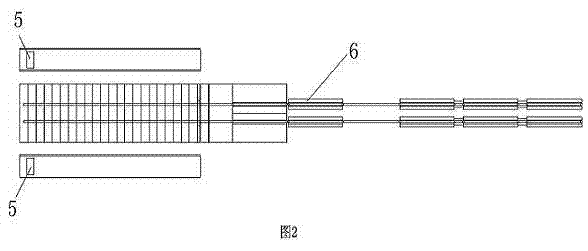

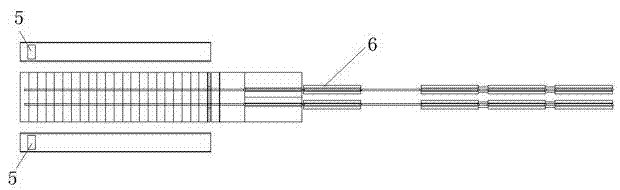

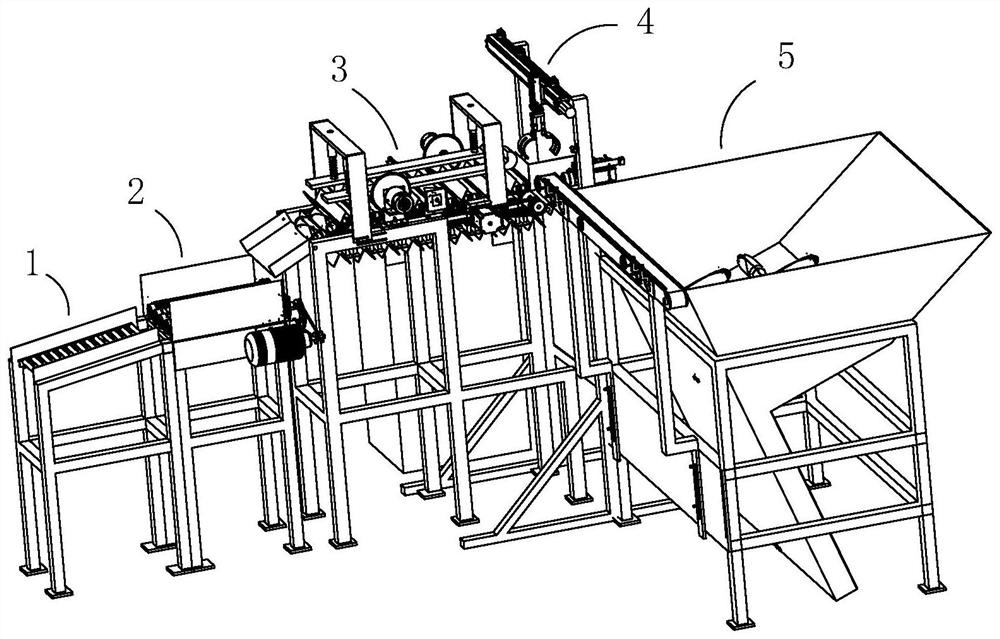

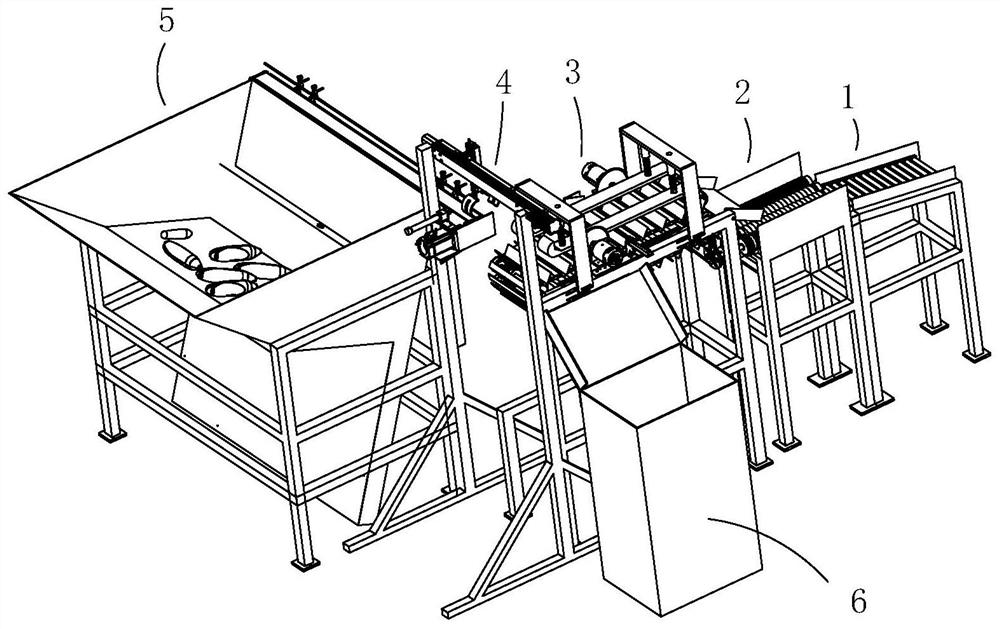

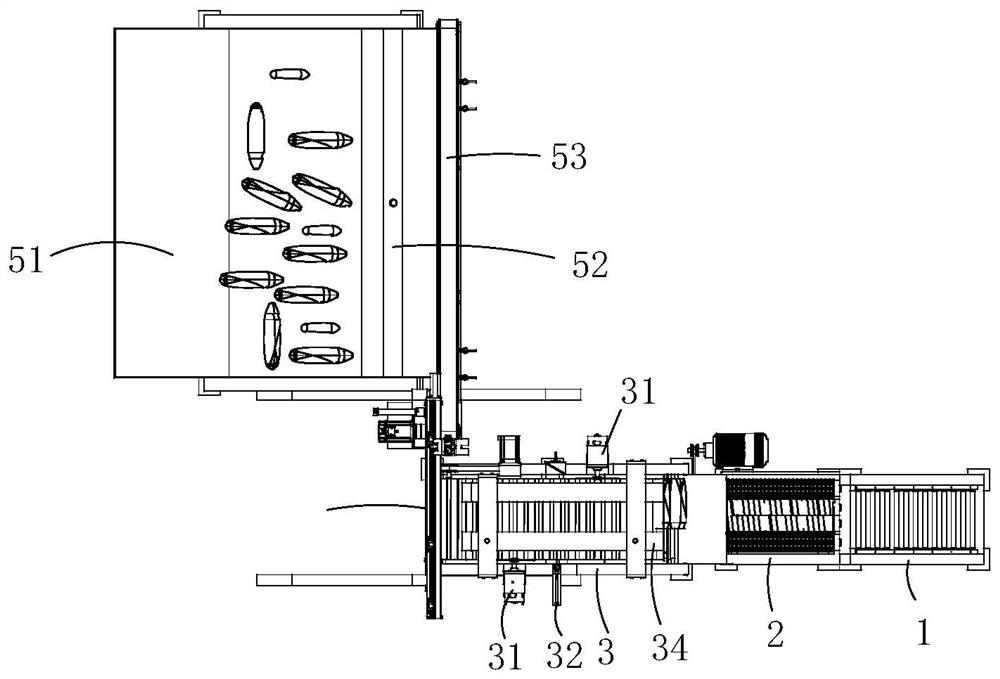

Automatic production line and automatic production method for ultrafiltration membrane

InactiveCN102247762AReduce labor intensityIncrease productivityUltrafiltrationUltrafiltrationEngineering

The invention provides an automatic production line for an ultrafiltration membrane and an automatic production method for processing the ultrafiltration membrane by adopting the production line. The production line comprises an ultrafiltration membrane fiber delivery device which runs through the whole production line as well as an automatic membrane fiber cutoff device and an automatic membranefiber collection device which are sequentially arranged from front to back, wherein the ultrafiltration membrane fiber delivery device comprises a wheel set delivery mechanism, a double-roll pulling device and a rolling type transport platform which are sequentially arranged from front to back and a buffer device which is arranged between the wheel set delivery mechanism and the double-roll pulling device; the buffer device at least comprises a fixed roll and a movable roll which can freely slide up and down within the limited range; and the movable roll is arranged between the fixed roll andthe wheel set delivery mechanism. The automatic production of membrane fibers is realized, the labor intensity of operators is greatly reduced, the production efficiency is improved, the pollution tothe membrane fibers is also reduced, and the fixed-length production and counting of the membrane fibers can be ensured and the waste of the membrane fibers is avoided.

Owner:刘镇江

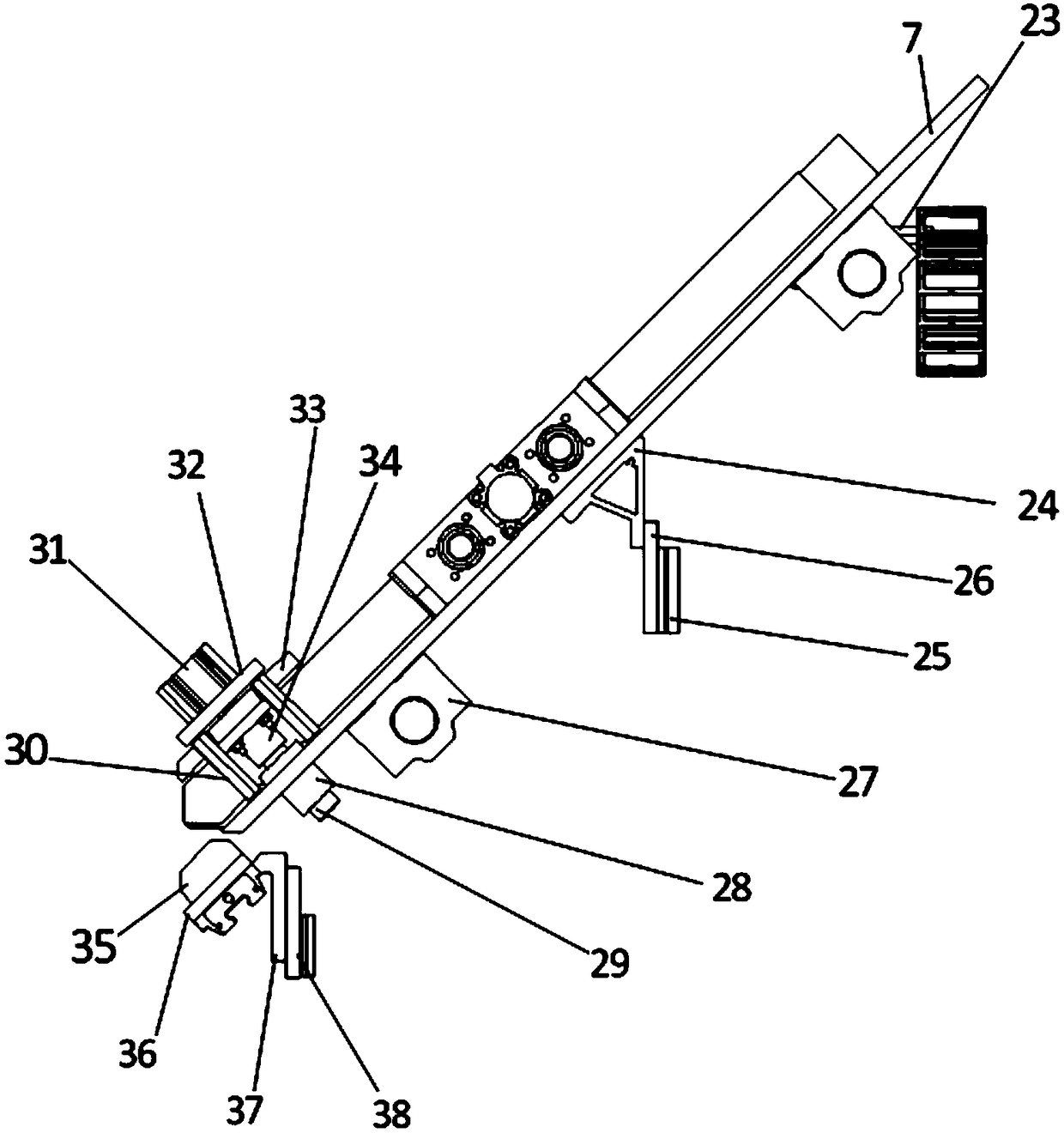

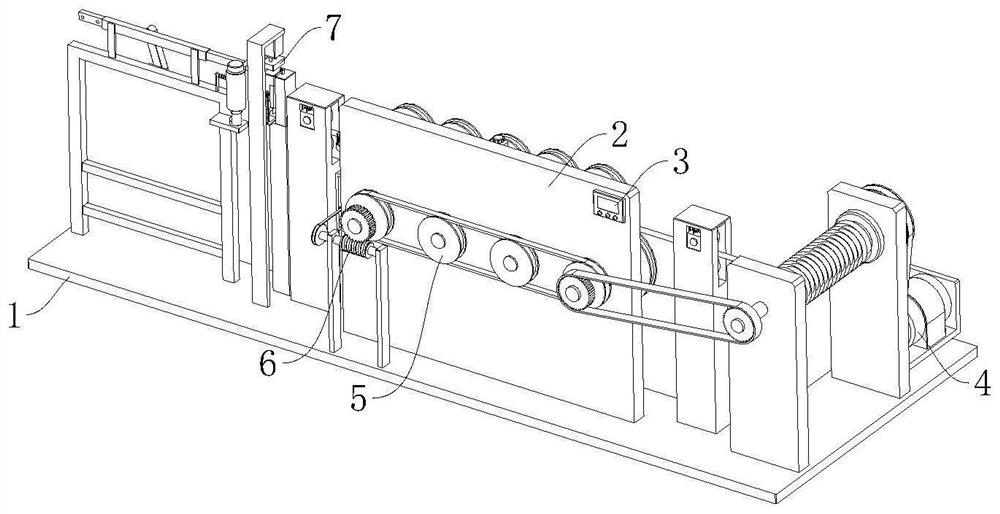

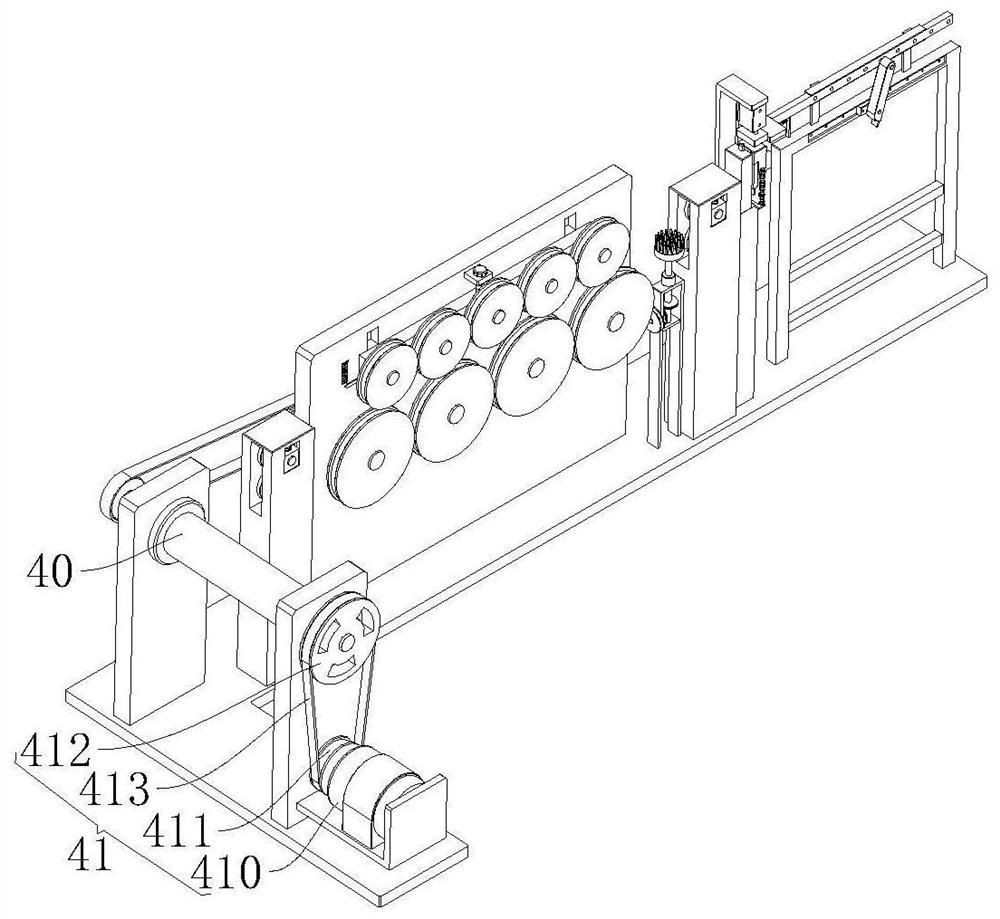

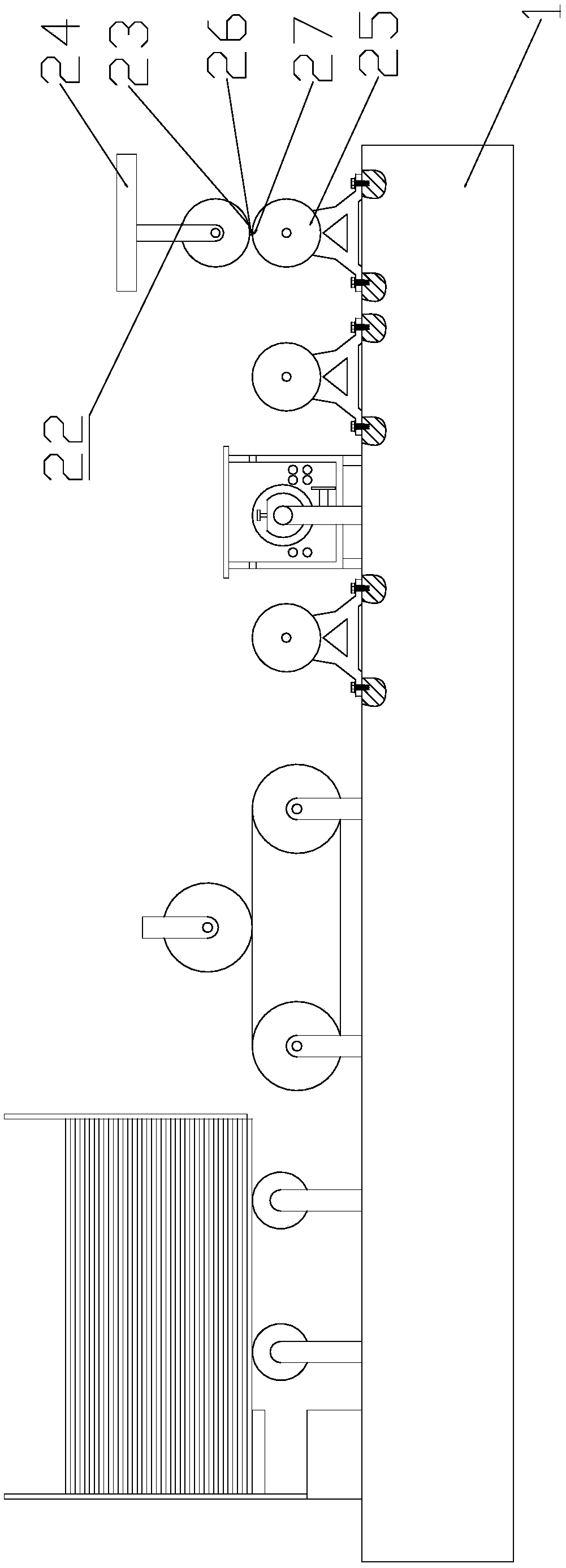

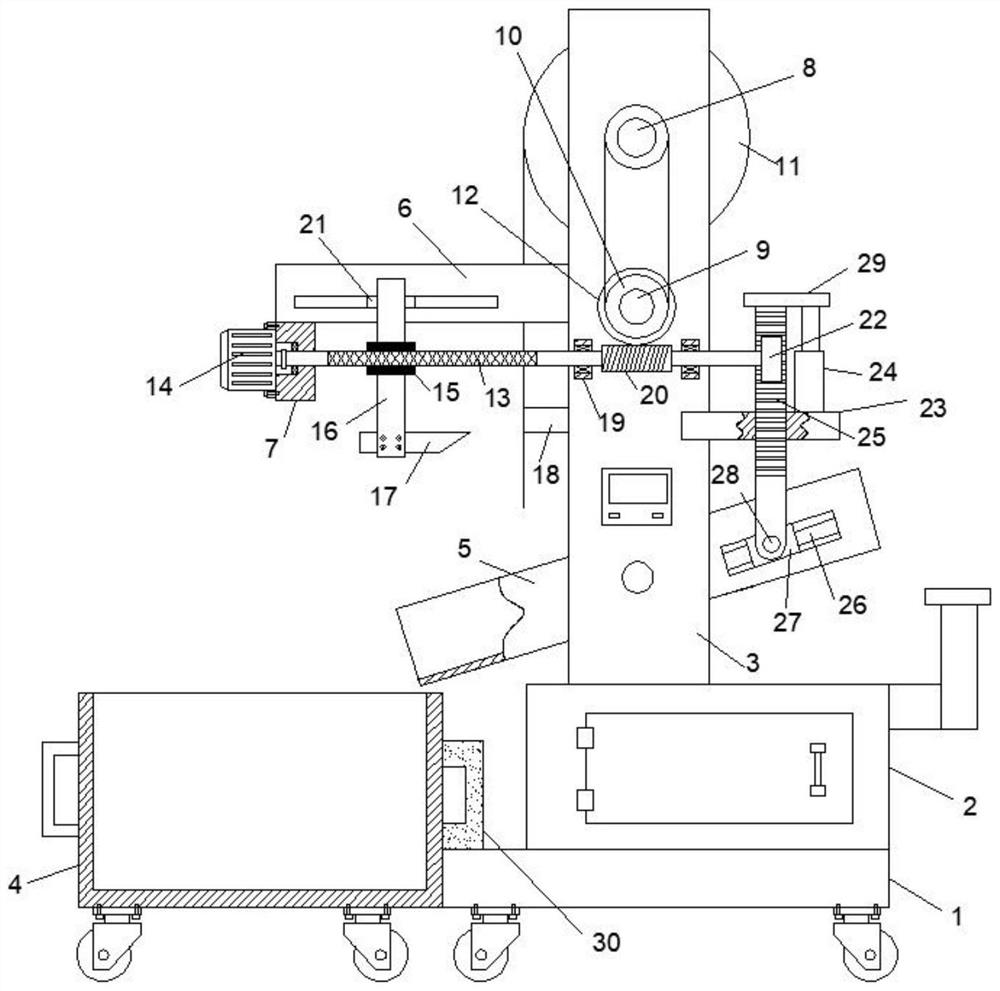

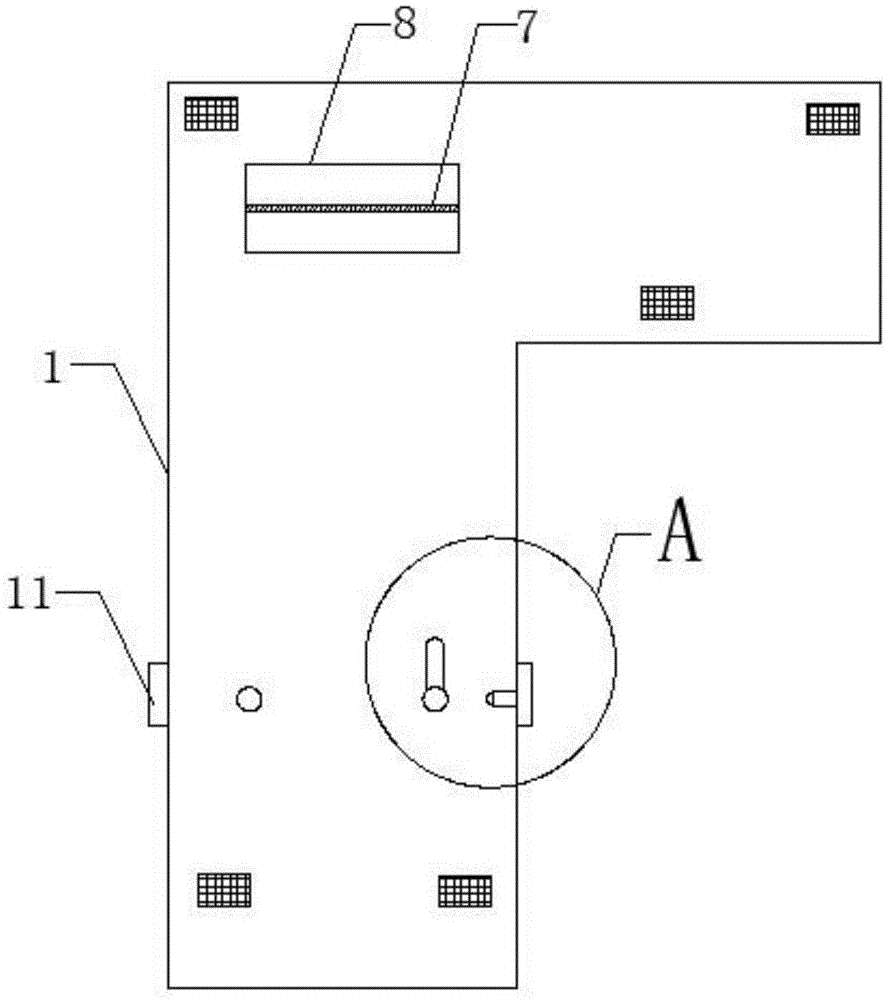

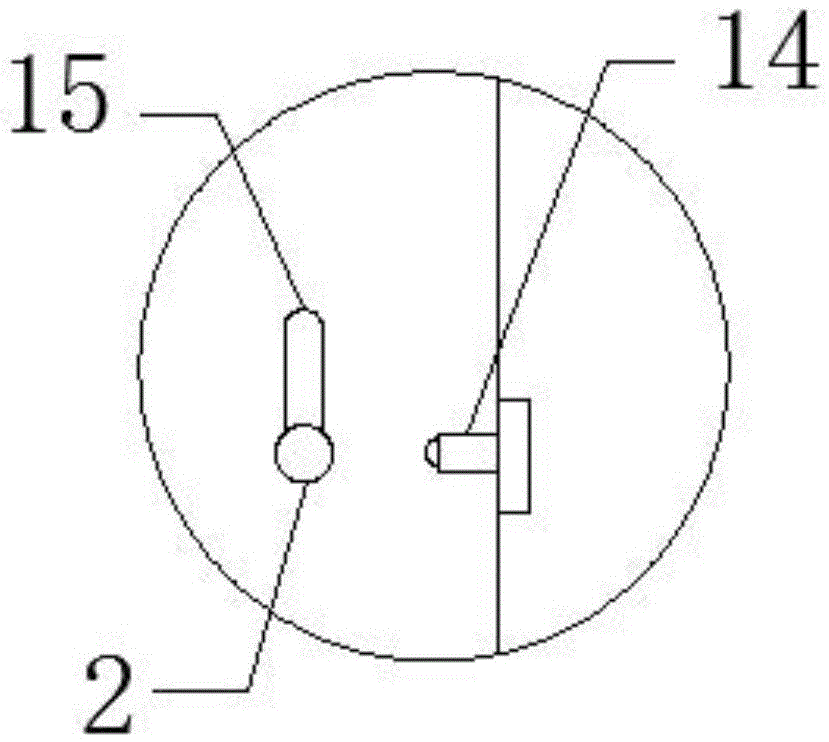

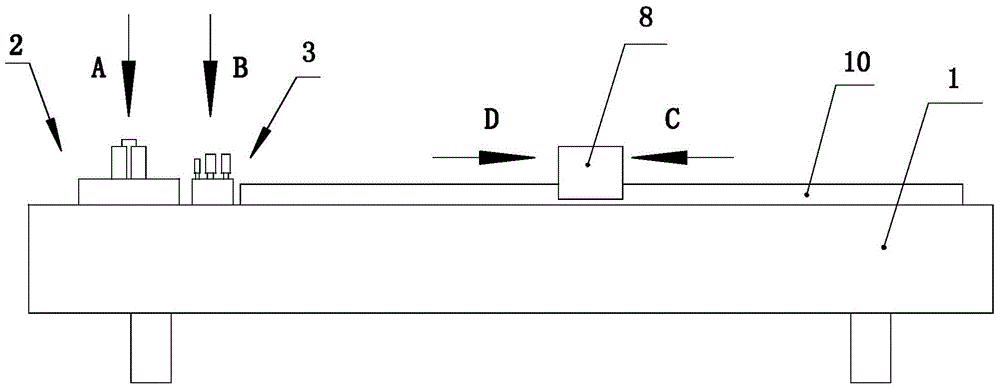

Industrial hemp combine harvester

The invention relates to the technical field of the design of harvesting machinery in agriculture and forestry, specifically to a disc cutter system for an industrial hemp combine harvester. The disccutter system for the industrial hemp combine harvester comprises total power input belt wheels 21, harvesting platform driving belt wheels 14, disc cutter intermediate transmission belt wheels 7, disc cutter transmission belts 6 and disc cutter blades 8, wherein the total power input belt wheels are arranged at two sides of the lower end of an original combine harvester gap bridge; the harvestingplatform driving belt wheels are arranged at the lower end of a harvesting platform gap bridge; the disc cutter intermediate transmission belt wheels are arranged on a swathing platform; each total power input belt wheel is connected with one harvesting platform driving belt wheel through a transmission belt; and each harvesting platform driving belt wheel is a two-stage belt wheel and is connected with one disc cutter intermediate transmission belt wheel through the disc cutter transmission belt. The industrial hemp combine harvester provided by the invention firstly combines the disc cuttersystem with the swathing platform, overcomes the problem of influence on operation due to generation of heaping and hanging of male hemp during harvesting of female hemp, and further improves operation efficiency.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

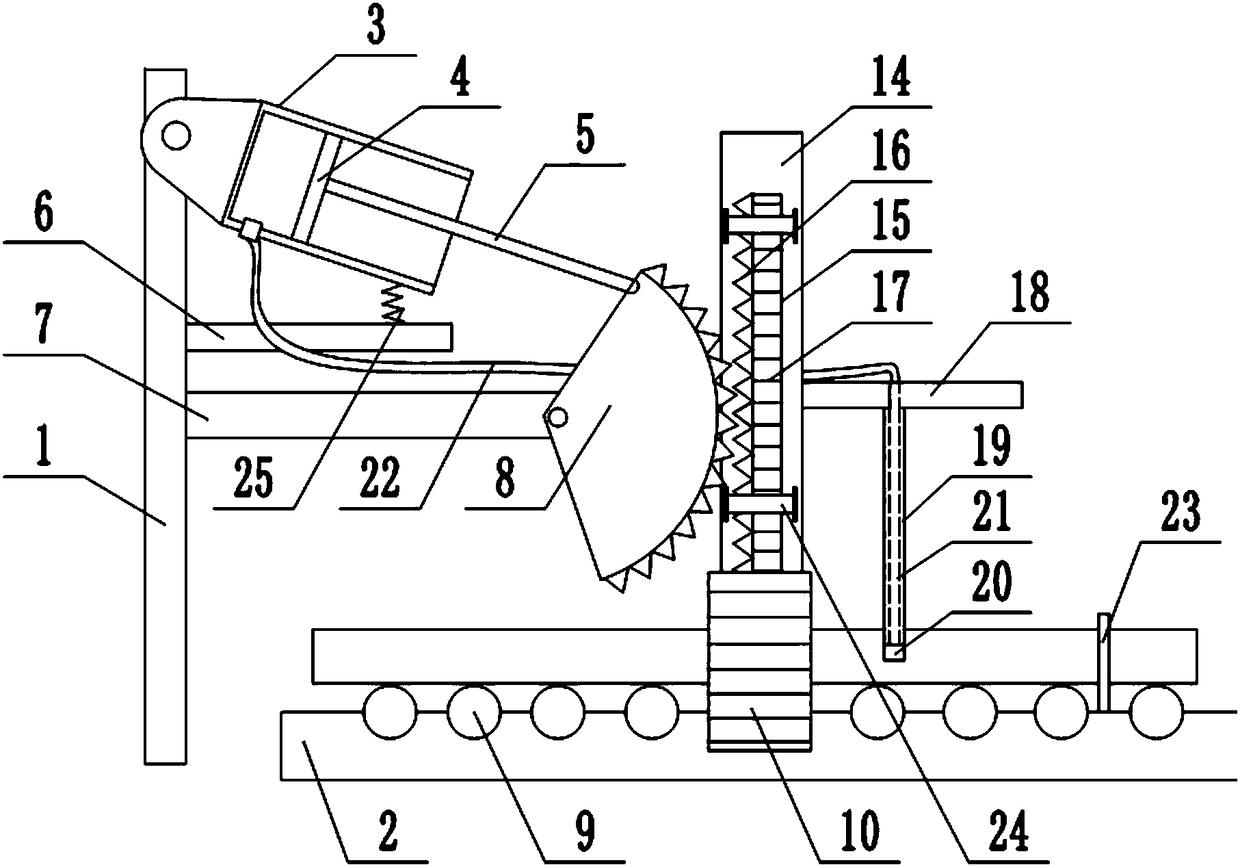

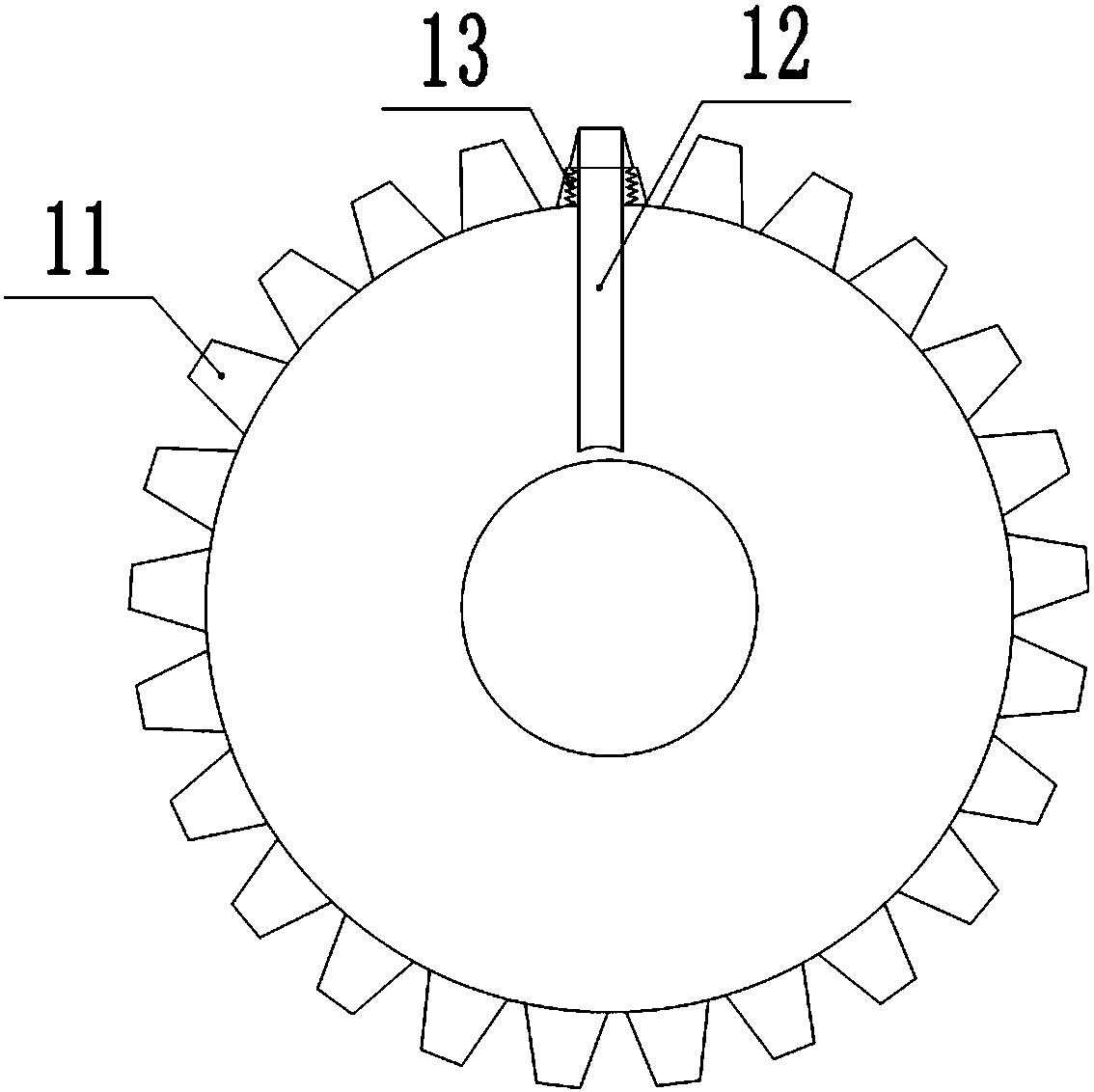

Tube part cutting device

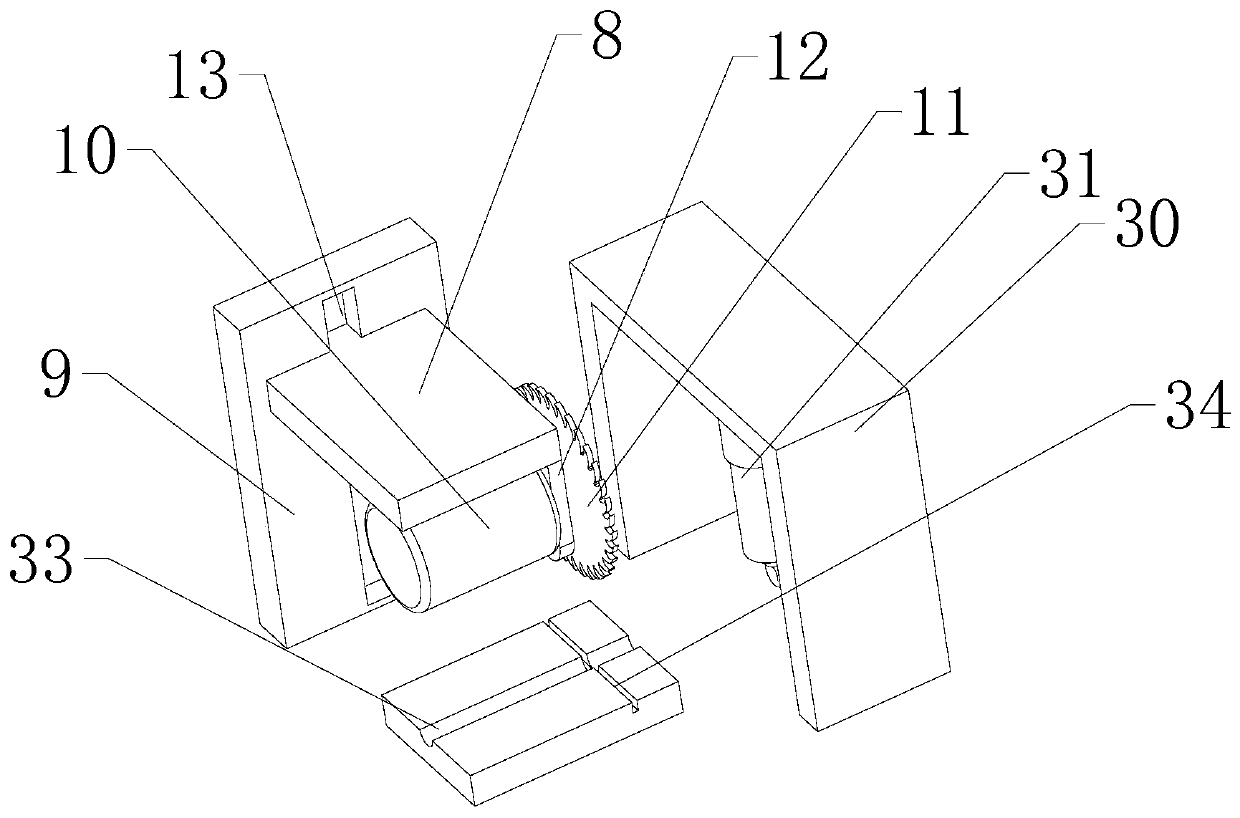

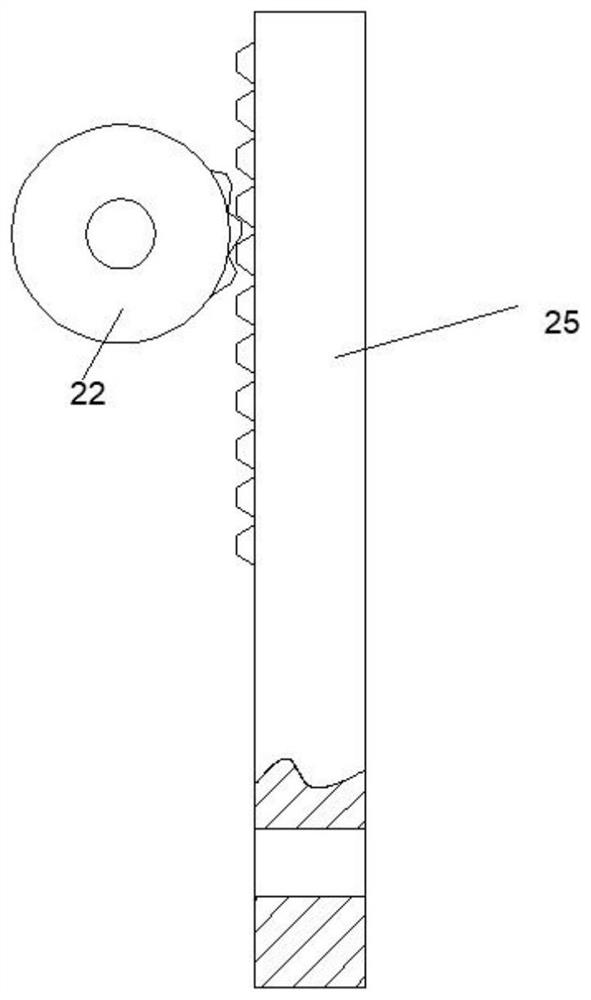

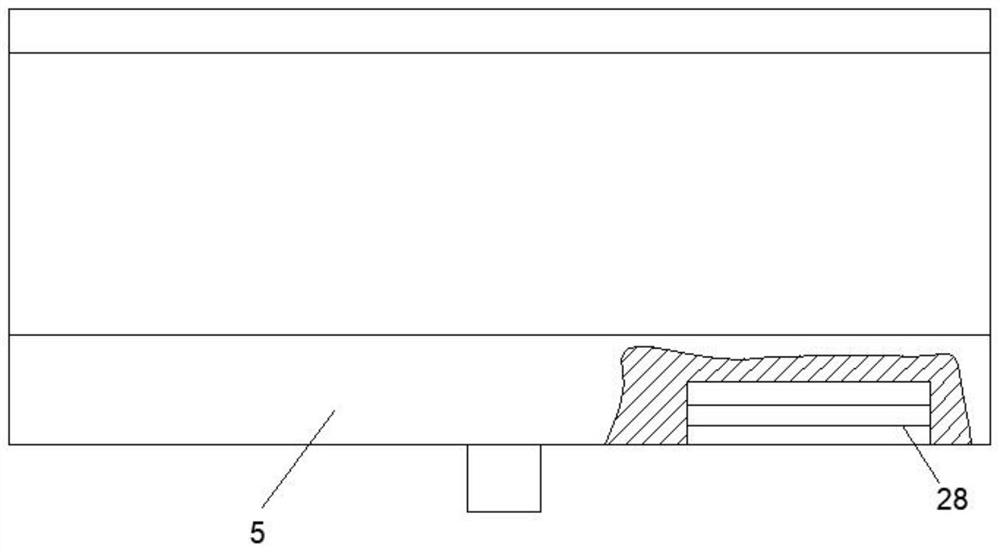

InactiveCN108213550AAchieve rotationImprove securityTube shearing machinesMaintainance and safety accessoriesGear wheelSlide plate

The invention relates to a tube part cutting device. The tube part cutting device comprises a rack and a worktable, wherein an air cylinder is arranged on the rack, a sliding plate is slidably connected in the air cylinder, a connecting rod is fixed to the sliding plate, a fan-shaped gear is rotatably connected to a second supporting plate on the rack, and the end, far from the sliding plate, of the connecting rod is rotatably connected to the fan-shaped gear; a supporting roller is rotatably connected to the worktable, a clamping gear is also rotatably connected to the worktable, a through hole is formed in the middle of the clamping gear, a stretchable driving gear is arranged on the clamping gear, the driving gear is fixedly connected to a leaning rod, a telescopic spring is arranged inthe driving gear, a vertical plate is also fixedly connected to the worktable, a rack is slidably connected to the vertical plate, a first grinding tooth part and a second grinding tooth part are arranged on the rack, a transverse plate is fixedly connected to the vertical plate, a cutter bar is fixedly connected to the transverse plate, a tool bit is arranged at the bottom end of the cutter bar,a gas guide pipe is arranged in the cutter bar, an air jet hole is formed in the cutter bar, and an air outlet pipe is connected between the gas guide pipe and the air outlet. The tube part cutting device provided by the invention solves the problem that the cutting section of a tube part is irregular.

Owner:重庆市长寿区维凤商贸有限公司

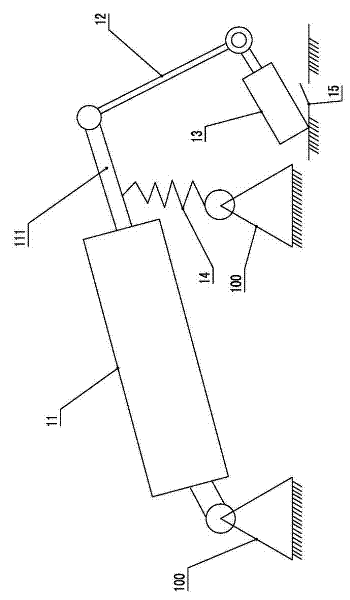

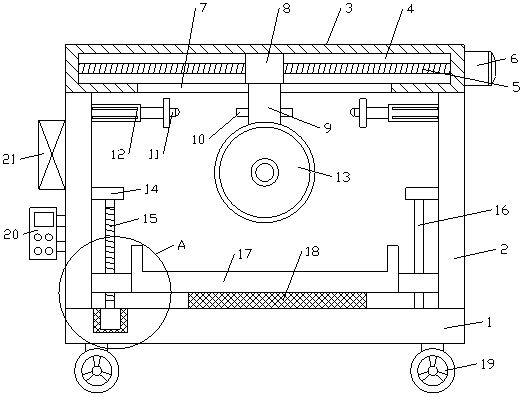

Fixed-length sensing device as well as automatic fixed-length cutting device and method of plastic-steel winding pipe

ActiveCN102198608AAutomate the processRealize cut-to-lengthAutomatic control devicesMeasurement/indication equipmentsEngineeringFixed length

The invention relates to a fixed-length sensing device as well as an automatic fixed-length cutting device and method of a plastic-steel winding pipe. The fixed-length sensing device provided by the invention comprises a rack, a roller shaft, a connecting rod, a limiting switch, a return spring and a limiting switch triggering part for triggering the switch-on and switch-off of the limiting switching, wherein one end of the roller shaft is hinged with the rack, and the other end of the roller shaft is hinged with one end of the connecting rod; the other end of the connecting rod is hinged with the limiting switch triggering part; and one end of the return spring is hinged with the rack and the other end of the return spring is fixedly connected with the roller shaft. The roller shaft is provided with a running roller rotating around the roller shaft. The invention also provides the automatic fixed-length cutting device and of the plastic-steel winding pipe. The invention has the beneficial effects that the limiting switch is triggered by virtue of the limiting switch triggering part, thus being beneficial to realization of automatic fixed-length cutting of the plastic-steel winding pipe.

Owner:华瀚管道系统科技有限公司

Wire cutting device for communication engineering

InactiveCN112605316ARealize cut-to-lengthReduce labor intensityMetal working apparatusWire rodWire cutting

The invention relates to the technical field of wire cutting devices, and discloses a wire cutting device for communication engineering. The wire cutting device comprises a workbench, wherein a servo motor is fixedly arranged at the right side of the top of the workbench; a rotating rod is fixedly connected to the output end of the right side of the servo motor; two sets of rotating plates and a set of limiting plates are arranged in the middle of the outer wall of the rotating rod; and the limiting plates are located between the two rotating plates. According to the wire cutting device for communication engineering, a wire is clamped in clamping grooves of the limiting plates in the front-back horizontal direction, the rotating rod rotates to drive two sets of rotating plates A and rotating plates B to do circular motion at the same time, and two sets of extrusion blocks close to each other drive respective blades to cut the wire on the limiting plates, so that the rotating plates and linkage blocks rotate by a circle to extrude and cut the wire in the clamping grooves once, fixed-length cutting of the wire for communication engineering is achieved, the labor intensity of wire cutting is reduced, and the wire cutting efficiency is improved.

Owner:山东鲁南大数据产业发展有限公司

Multifunctional cable cutting equipment

ActiveCN113178810APlay a reset rolePrevent unevenApparatus for cutting/splicing cablesCleaning using toolsEngineeringStructural engineering

The invention relates to the field of cable processing, in particular to multifunctional cable cutting equipment which comprises a base and a vertical plate and further comprises a controller, an unwinding mechanism, a straightening mechanism, a cleaning mechanism and a downward cutting mechanism. The unwinding mechanism comprises an unwinding roller and a driving assembly, the cleaning mechanism comprises a brush and a rotating assembly, and the rotating assembly is arranged at the top of the base. The brush is rotatably arranged at the top of the base, the downward cutting mechanism comprises a cutter, a stamping block and a sliding assembly, the sliding assembly is arranged at the top of the base, the stamping block is arranged above the cutter, the cutter is arranged below the stamping block in a sliding mode, and the driving assembly is electrically connected with the controller. According to the multifunctional cable cutting equipment, the cutting efficiency is high, fixed-length cutting can be achieved, the fixed length can be adjusted, and meanwhile the effect of protecting the cutter can be achieved.

Owner:芜湖市科特电线电缆有限公司

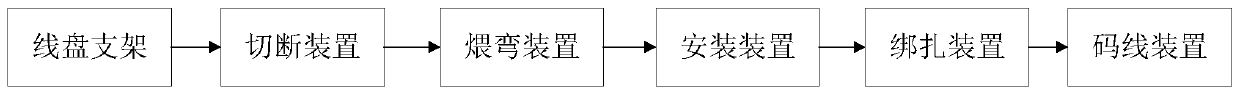

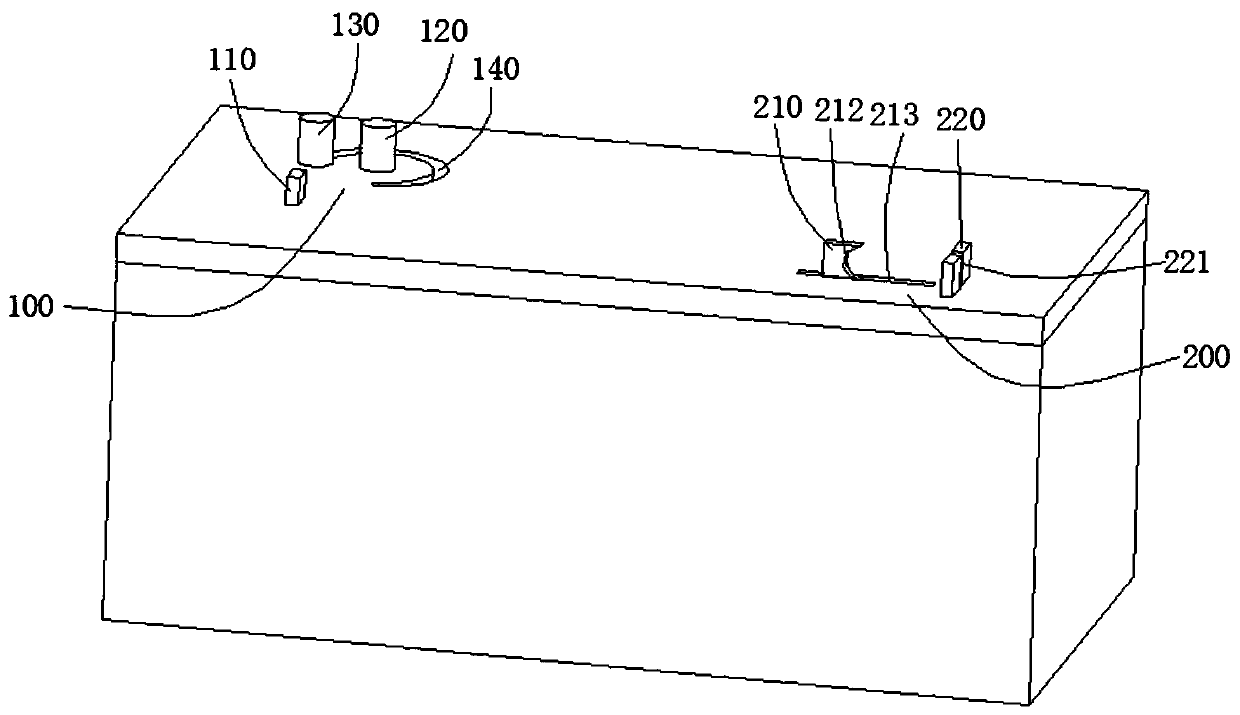

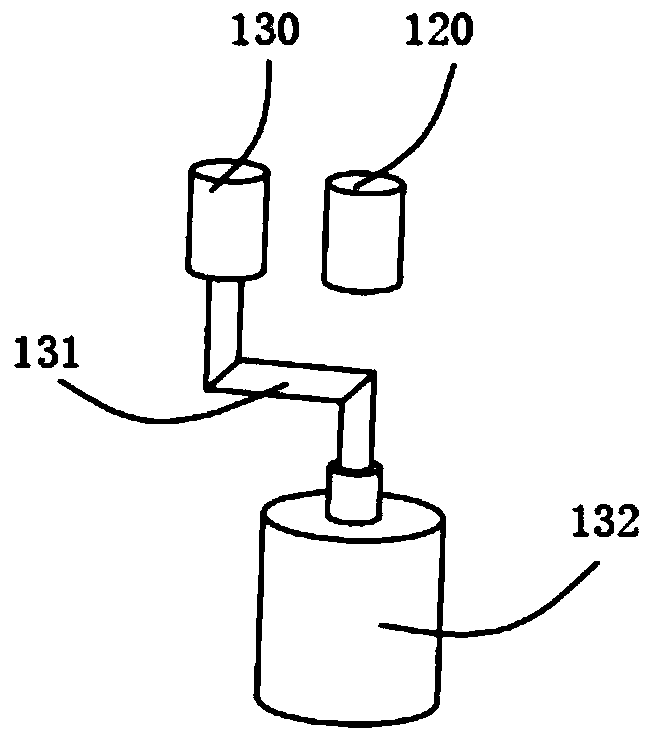

Stay wire preassembly platform

InactiveCN110625032AImprove construction qualityImprove the qualification rate of one installationEngineeringMechanical engineering

The invention discloses a stay wire preassembly platform. The stay wire preassembly platform comprises a stew-bending device, a mounting device and a binding device. The stew-bending device is used for stew-bending the end of a stay wire, the mounting device is used for mounting a wire clamp on the stew-bent portion of the stay wire, the binding device is used for binding the stew-bent portion ofthe stay wire, and therefore the wire clamp is fixed to the end of the stay wire. The wire clamp is mounted on the stay wire through the stew-bending device, the mounting device and the binding device, the wire clamp mounting operation is easy, high efficiency is achieved, and meanwhile automatic and assembly work is achieved.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP +1

Special spinning dividing and cutting machine for organic silica gel coating layer cloth

ActiveCN109736066AMeet the conditions of useImprove cutting efficiencySevering textilesEngineeringSilica gel

The invention discloses a special spinning dividing and cutting machine for organic silica gel coating layer cloth. The special spinning dividing and cutting machine comprises a bracket assembly, a pushing assembly, a conveying assembly, a clamping assembly, a cutting assembly and a recycling assembly. The dividing and cutting operations of rolled organic silica gel coating layer cloth can be realized, so that the surface of the cloth can be effectively protected; and meanwhile, the fixed length cutting is realized, the precision of the dividing and cutting processes of the cloth is guaranteed, the control is accurate, the use condition of the organic silica gel coating layer cloth is satisfied, the utilization rate is increased, and the dividing and cutting efficiencies of the organic silica gel coating layer cloth are substantially improved.

Owner:恒岳(辽宁)环境技术有限公司

Ultrafiltration membrane automation protection method

InactiveCN103084071AReduce labor intensityIncrease productivitySemi-permeable membranesUF - UltrafiltrationEngineering

The invention provides an ultrafiltration membrane automation protection method. Membrane filaments are formed and delivered by combining an automatic traction device and an automatic delivery device, and are cut off when the membrane filaments achieve the preset lengths; the membrane filaments after being cut off are collected automatically; and a buffer device capable of adjusting the delivery distance automatically is arranged between the automatic traction device and a membrane filament automatic delivery device for cutting off the operation front ends, so that the cut operation front ends of the membrane filaments keep the tensioning state all the time. According to the invention, the membrane filaments are produced automatically; the labor intensity of operators is lowered greatly; the production efficiency is improved; the pollution to the membrane filaments is also reduced; and the fixed-length production of the membrane filaments, counting can be ensured, and membrane filament waste is prevented.

Owner:刘镇江

Food cutting machine with adjustable cutting length

InactiveCN109049065AAchieve reductionRealize cut-to-lengthMetal working apparatusEngineeringFixed length

The invention discloses a food cutting machine with the adjustable cutting length. The food cutting machine with the adjustable cutting length comprises a base, a support cross beam, a screw rod, a first positive-negative-rotation motor, a rectangular sliding block, a touch rod, reversing switches, a cutting wheel, a workpiece groove and castors. According to the food cutting machine with the adjustable cutting length provided by the invention, through the cooperation of the screw rod, the workpiece groove, a lifting slide block and a second positive-negative-rotation motor, food on the workpiece groove is driven to move upwards, so that the cutting wheel rotating at high speed contacts the food; furthermore, through the cooperation of the screw rod, the first positive-negative-rotation motor, the rectangular sliding block and a support vertical plate, the cutting wheel rotating at high speed moves in the horizontal direction, so that the food is cut; and the cutting length is determined through the distance between the two reversing switches, and the distance between the two reversing switches can be adjusted, so that the food can be cut at fixed length.

Owner:黄清平

Automatic fresh corn processing production line

ActiveCN112544246ARealize cut-to-lengthMoisturize and keep freshThreshersMetal working apparatusAgricultural scienceAgricultural engineering

The invention provides an automatic fresh corn processing production line, and belongs to the technical field of fresh corn processing. The automatic fresh corn processing production line comprises afeeding mechanism, a grabbing mechanism, a head-tail cutting mechanism, a peeling mechanism and a conveying mechanism which are arranged in sequence; the cutting mechanism comprises a cutting-off support, a cutting-off conveying assembly, cutting-off assemblies, a pressing assembly and a positioning assembly, wherein the cutting-off conveying assembly, the cutting-off assembly, the pressing assembly and the positioning assembly are installed on the cutting-off support; a plurality of positioning grooves are formed in the cut-off conveying assembly; the cutting-off assemblies are mounted at thetwo sides of the cutting-off conveying assembly correspondingly and arranged in a staggered manner; the positioning assembly comprises a linear actuator and an elastic positioner which are symmetrically installed at the two sides of the cut-off conveying assembly, and the positioning assembly is located between the two cut-off assemblies; and the pressing assembly is located above the cut-off conveying assembly. According to the automatic fresh corn processing production line, automatic feeding and conveying, head-tail fixed-length cutting and bract stripping of fresh corn can be completed, the damage rate of the corn is reduced, the fresh-keeping degree of the fresh corn is improved, and the production profit of the fresh corn in unit area is increased.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

A fixed-length cutting device for multi-width copper square pipes

ActiveCN104148726BRealize cut-to-lengthTube shearing machinesShearing machine accessoriesReciprocating motionEngineering

The invention relates to a fixed-length cutting device for multi-width copper square pipes, which includes a base. The front end of the base is correspondingly provided with left and right brackets. The left bracket is movably connected to the base, and the right bracket is fixedly connected to the base. , the left and right side bearings are respectively provided with left and right side bearings, and the left and right side shafts are respectively installed in the left and right side bearings; the bottom ends of the left and right side shafts all pass through the base, and the right side The bottom end of the rotating shaft is fixedly connected with the rotary rod; the left and right rotating shafts are respectively covered with left and right rollers, and a channel for copper square pipes to pass is formed between the two rollers; the reverse side of the base is also provided with a A touch delay switch matched with the swivel rod, the touch delay switch is connected with the cutting device and the reciprocating mechanism arranged at the rear end of the base. The cutting device of the invention solves the problem of poor measurement accuracy of manual scribing in the prior art, greatly improves the cutting efficiency of copper square pipes, and is suitable for cutting copper square pipes with different widths.

Owner:TANGSHAN RENSHI CEMENT EQUIP

Multifunctional die cutting machine of corrugated papers for cartons

InactiveCN109291506AAccurate adjustment positionRealize cut-to-lengthPaper-makingBox making operationsCartonPulp and paper industry

The invention relates to the technical field of carton production equipment, in particular to a multifunctional die cutting machine of corrugated papers for cartons. The machine comprises a base, a raw material box, the corrugated papers, a discharge roller, an unfolding roller and a cutting blade; a left support roller is arranged on the right side of the unfolding roller; a right support rolleris arranged on the right side of the left support roller; the left support roller and the right support roller are fixed on the upper end surface of the base through bolts; an adjustable cutter framemechanism is arranged between the left support roller and the right support roller; and a dustproof mechanism covers the outer side of the adjustable cutter frame mechanism. The machine is simple in structure and low in cost, can synchronously realize fixed-width and fixed-length cutting of the corrugated papers to achieve speediness and convenience, meanwhile, effectively absorbs paper scraps generated during cutting, guarantees the health of workers, and is high in practicability and broad in market prospect.

Owner:温雄权

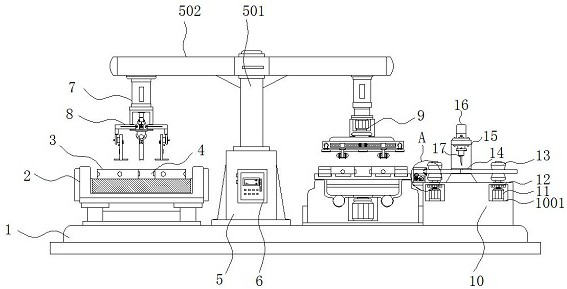

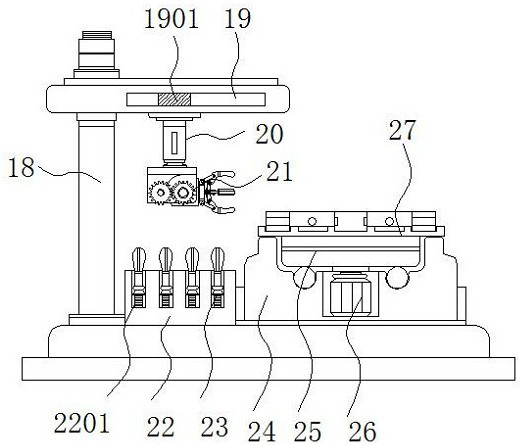

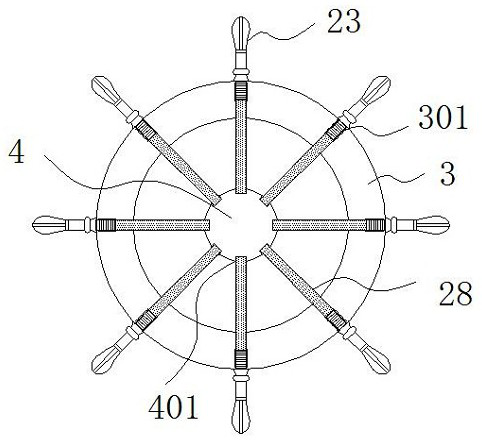

Rudder decorating part assembly device capable of achieving fixed-length cutting of rudder stock

InactiveCN112427946ASave human resourcesGuaranteed smooth assemblyAssembly machinesPositioning apparatusStructural engineeringConveyor belt

The invention discloses a rudder decorating part assembly device capable of achieving fixed-length cutting of a rudder stock. The assembly device specifically comprises a base, a feeding mechanism, acalibration mechanism and a tightening mechanism, and a conveyor belt is installed on one side of the top of the base; a main ring and a center piece are arranged or placed at the top end of the conveyor belt, and a charging platform is fixed to the other side of the top of the base; driving bins are formed in the two sides of the inner top end of the charging platform, and the two ends of the topof each driving bin are each provided with a driving roller through a rotating shaft; and the rudder stock is arranged between the driving rollers. According to the rudder decorating part assembly device capable of achieving fixed-length cutting of the rudder stock, through arrangement of the calibration mechanism, the positions of the main ring and the center piece can be calibrated; threaded holes correspond to the positions of grooves, and directly face a sleeve; the threaded holes do not need to be aligned to the grooves manually, and manpower resources are saved; and follow-up assembly can be conducted smoothly and conveniently.

Owner:龙土志

Health-care chewable tablet forming machine

ActiveCN113558265AImprove processing efficiencyRealize cut-to-lengthFood preservationFood shapingEngineeringMechanical engineering

The invention discloses a health-care chewable tablet forming machine, and particularly relates to the technical field of chewable tablet processing. The health-care chewable tablet forming machine comprises a base plate, wherein a supporting plate is arranged at the top of the base plate; stand columns are fixedly arranged at four corners between the base plate and the supporting plate; a material box is fixedly arranged at the top of the supporting plate; a discharging hopper is fixedly arranged at a position, corresponding to the material box, of the bottom of the supporting plate; a through groove II communicating with the discharging hopper is formed in a position, corresponding to the material box, of the top of the supporting plate in a penetrating mode; a bag placing mechanism is arranged on one side of the material box, and a cutting-off and discharging mechanism is arranged on the other side of the material box; and a bag opening mechanism and a seal cutting-off mechanism are sequentially arranged between the base plate and the supporting plate from top to bottom. According to the health-care chewable tablet forming machine, fixed-length cutting-off of raw materials and automatic packaging of the cut-off raw materials are realized, excessive manual intervention is not needed in the whole process, the processing efficiency of chewable tablets is greatly improved, and meanwhile, the cut-off raw materials are protected by utilizing a sodium acetate solution spraying method.

Owner:ANHUI TIANMA BIOLOGICAL SCI & TECH

Intelligent textile new material cutting device for textile

InactiveCN112281464ARealize cut-to-lengthConvenient for centralized processingSevering textilesMetal working apparatusStructural engineeringMechanical engineering

The invention discloses an intelligent textile new material cutting device for textile. The intelligent textile new material cutting device comprises a movable base; a storage cabinet is fixed to thetop of the movable base; a collecting box is installed on the left side of the movable base in a butt joint mode; a vertical mounting plate is fixed to the top of the storage cabinet; a discharging mechanism, a cutting mechanism and a material guiding mechanism are installed on the mounting plate; the discharging mechanism and the material guiding mechanism are both connected with the cutting mechanism in a linkage mode; the material guiding mechanism is installed below the cutting mechanism; and the discharging mechanism comprises an upper rotating shaft rod and a lower rotating shaft rod which are rotationally mounted at the upper end of the mounting plate, and the upper rotating shaft rod is located above the lower rotating shaft rod. The whole device is simple in structure and low in manufacturing cost, not only can be used for cutting off materials, but also can automatically discharge, cut off and guide the materials for centralized treatment, is smooth in material guiding and good in effect, adopts vertical cutting off, and can reduce the occupied area.

Owner:闫卉

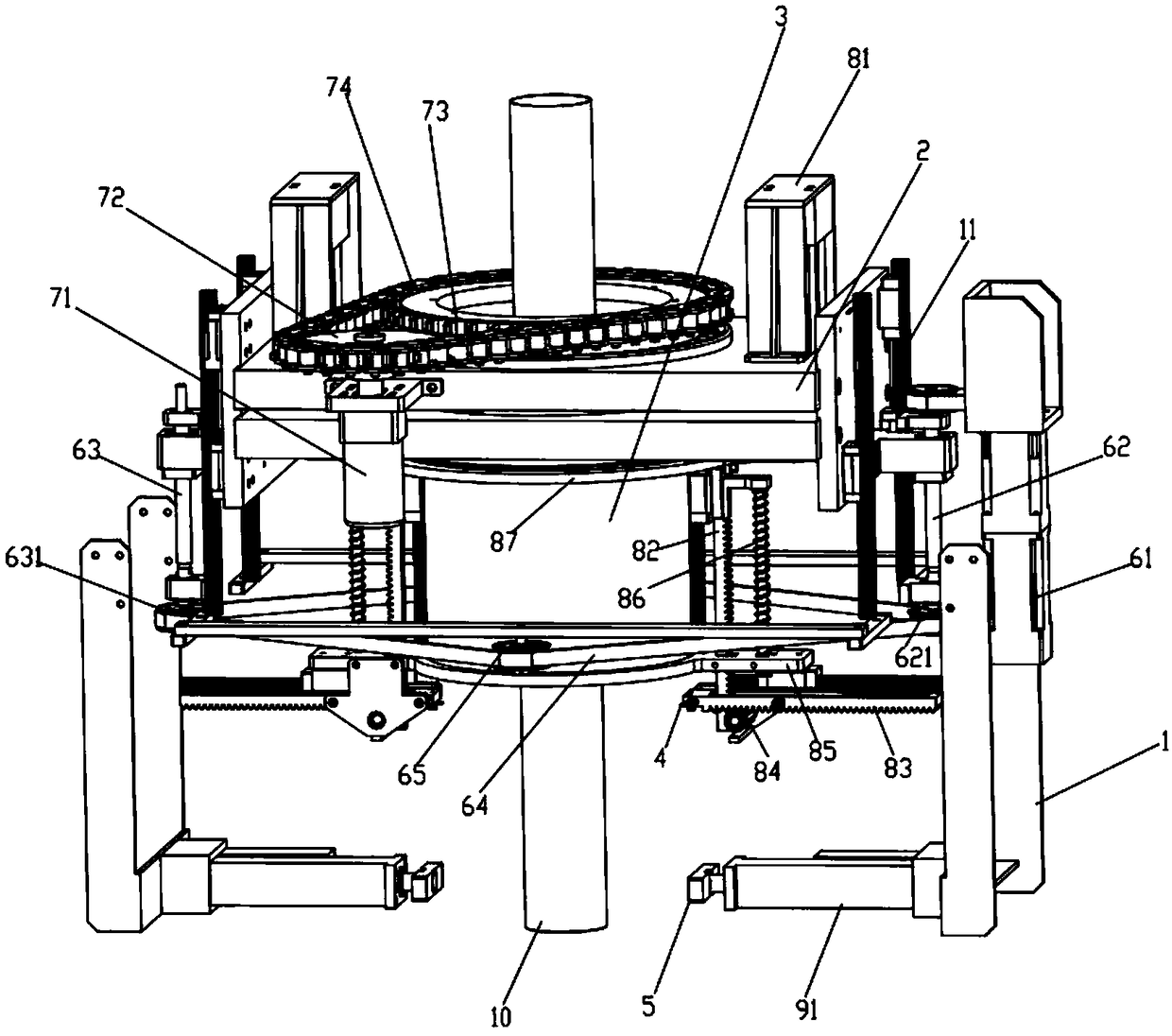

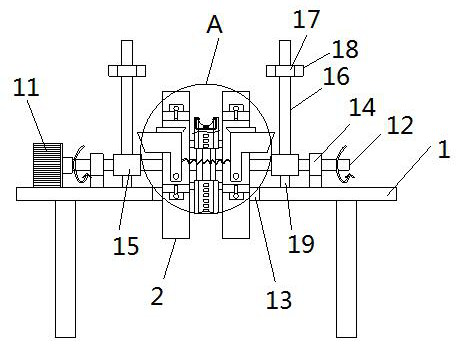

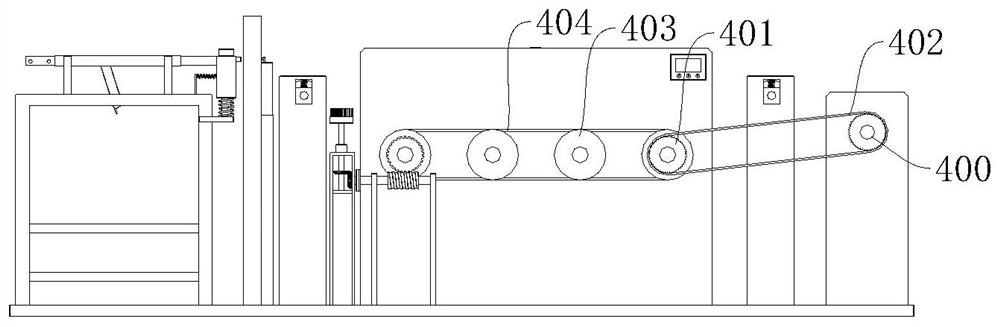

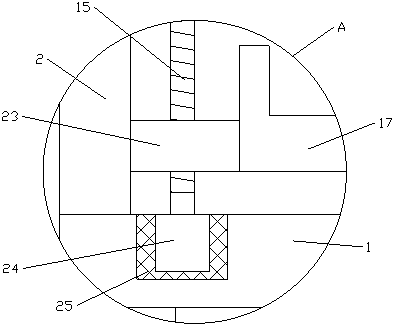

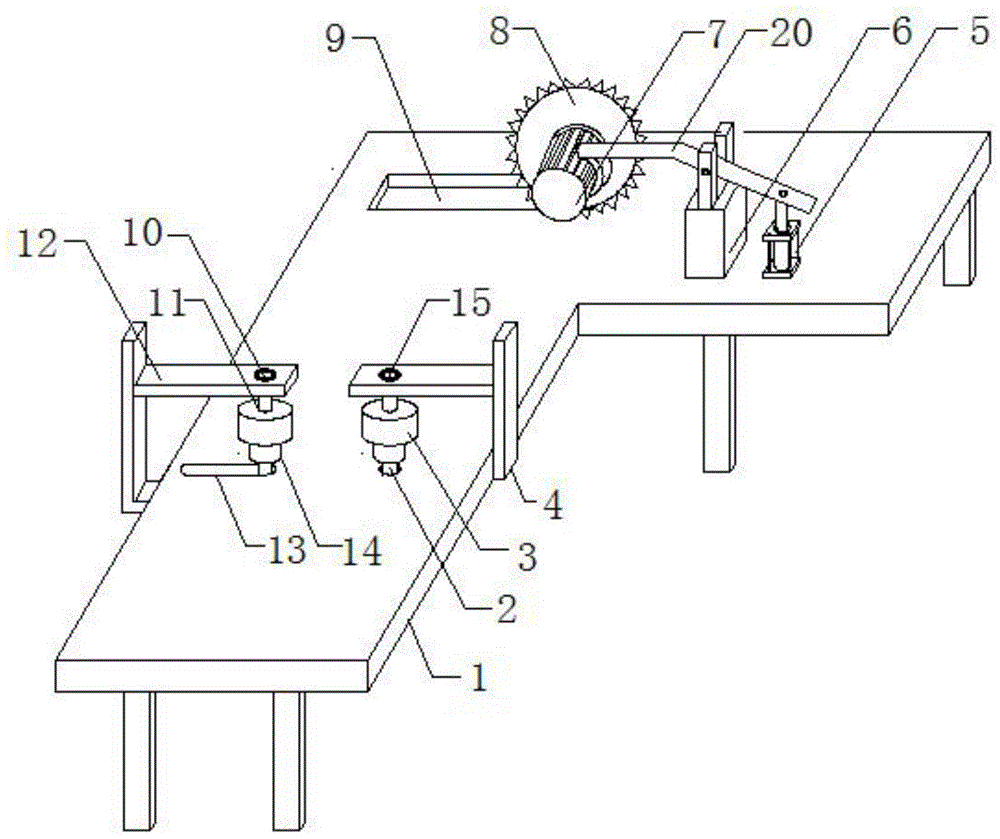

Automatic fixed-length cutting device of handle steel wire of hand-carried packing bucket

The invention relates to an automatic fixed-length cutting device of a handle steel wire of a hand-carried packing bucket. The automatic fixed-length cutting device of the handle steel wire of the hand-carried packing bucket comprises a supporting mechanism, a rotating mechanism, an operation table, a feeding mechanism, a linear adjustment mechanism, a cutting mechanism, a discharging mechanism, a material placing rod resetting mechanism and a material collecting mechanism. The feeding mechanism comprises a supporting frame installed on the upper surface of the operation table, a feeding roller group rotationally installed on the supporting frame, a limiting surrounding baffle installed on the upper surface of the operation table and located on one side of the supporting frame and an eccentric squeezing wheel rotationally installed within the limiting surrounding baffle. Through cooperation of the multiple mechanisms such as the rotating mechanism and the feeding mechanism, straightening, fixed-length cutting and collecting can be conducted on the steel wire, and therefore the production efficiency is greatly improved.

Owner:SUZHOU HUAPENG PACKAGING CO LTD

Binding device for fixed-length burnout of straw

InactiveCN106379575ARealize cut-to-lengthSimple structureDomestic stoves or rangesEmission preventionCombustionEngineering

The invention discloses a binding device for fixed-length burnout of straw. The binding device comprises a strip-shaped bearing plate; the upper surface of the strip-shaped bearing plate is fixedly connected with a strip-shaped application box body; a periodic combustion mechanism is arranged inside the strip-shaped application box body; a moving mechanism is arranged at the lower surface of the strip-shaped bearing plate; a smoke processing mechanism is arranged at the upper portion of the strip-shaped application box body; a binding mechanism is arranged on the side surface of the strip-shaped application box body; a push mechanism is arranged on the side surface of the strip-shaped application box body; a storage battery is arranged at the lower surface of the strip-shaped bearing plate; a controller is arranged on the side surface of the strip-shaped bearing plate. The binding device disclosed by the invention has the beneficial effects of simple structure and high practicability.

Owner:牟伟

Drawer-type paper roll box

The invention discloses a drawer-type paper roll box, comprising a box body; a spindle for mounting a paper roll is disposed in the box body, a drawer is arranged at the bottom of the box body, a winding shaft is rotationally arranged on each side of the drawer, the winding shafts are connected with a rotary disc through unidirectional bearings, a winding rod is arranged on the rotary disc, a first pulley is fixed to the winding shaft at the outer side of the drawer, a second pulley is also rotationally arranged at the outer side of the drawer, the first pulley and the second pulley are driven through a belt, a gear is coaxially fixed to the second pulley, the box body is provided with a rack matching with the gear, two sides of the drawer are provided with guide holes, a first fixing block is arranged in the box body, a sliding rod penetrating the guide holes is connected to the bottom of the first fixing block through a first spring, and a cutter is arranged at the bottom of the sliding rod. The drawer-type paper roll box is more convenient for a user to use normally and is operable by one hand, and waste of tissues in non-normal use is effectively limited.

Owner:XINCHANG YUANZHOU IND DESIGN CO LTD

A copper cutting device

ActiveCN104174923BRealize cut-to-lengthMetal-working feeding devicesTube shearing machinesReciprocating motionCopper

The invention relates to a copper material cutting device, comprising a base, a gantry frame is arranged at the front end of the base, two bearings are correspondingly arranged in the gantry frame, a rotating shaft is respectively arranged in the two bearings, and the bottom end of the rotating shaft runs through the base, wherein The bottom end of one rotating shaft is fixedly connected with the revolving rod, and the other end of the revolving rod has an arc-shaped structure; rollers are respectively set on the two rotating shafts, and a channel for copper materials to pass is formed between the two rollers; the gantry A guide sleeve is arranged at the rear; a proximity switch adapted to the rotary rod is also arranged on the reverse side of the base, and the proximity switch is connected with the cutting device mechanism and the reciprocating mechanism arranged at the rear end of the base. The cutting device of the present invention solves the problems of poor measurement accuracy and low cutting efficiency of manual scribing in the prior art, and greatly improves the cutting efficiency of copper materials.

Owner:安徽统凌科技新能源有限公司

Power pay-off fixed-length cutting device

An electric line paying-off fixed-length cutting device is used for solving the problem of inconvenience of straightening and cutting of hard lines and comprises a base, a hard line placement assembly, a clamping assembly, a cutting assembly, a guide rail and a running assembly. The hard line placement assembly is arranged at the left end of the base and comprises a tray, a vertical pillar, springs and arc plates, wherein the tray is horizontally arranged and installed on the base rotationally; the vertical pillar extends upwards from the center of the tray, the multiple arc plates are arranged on the periphery of the vertical pillar, and each spring is arranged between the corresponding arc plate and the vertical pillar; the clamping assembly is arranged on an installation plate at the right end of a guider and used for clamping the hard lines; the cutting assembly is arranged on an installation plate at the right end of the clamping assembly and used for cutting the hard lines; the running assembly is used for tensing the hard lines. The electric line paying-off fixed-length cutting device can achieve straightening and fixed-length cutting of the hard lines, thereby relieving labor intensity for people. The work efficiency is high.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Packaging bag processing equipment

ActiveCN112373124ARealize cut-to-lengthFixed length to avoidBag making operationsBio-packagingManufacturing engineeringHot pressing

The invention relates to the field of packaging bag processing, in particular to packaging bag processing equipment. The equipment comprises a supporting table and a feeding rolling frame used for supplying materials to the equipment. The equipment is characterized by further comprising a packaging paper transferring mechanism, a driving mechanism, an undercutting mechanism, a discharging mechanism, an elastic pressing mechanism, a horizontal flattening mechanism, a guide plate, two bidirectional upthrust mechanisms and thermal pressing mechanisms; according to the processing equipment, the packaging paper transferring mechanism, the driving mechanism and the undercutting mechanism are combined, a large belt wheel and the undercutting mechanism are driven to move at the same time through adriving shaft, and fixed-length cutting of packaging paper is achieved; and when a cutter on the undercutting mechanism is used for cutting the packaging paper and being lifted, cutting can be achieved in the period of time to block a package, the packaging paper is still conveyed, so that the side, in contact with the cutter, of the packaging paper is wrinkled upwards, and the packaging paper isprevented from being pushed and blocked by workers.

Owner:广东中洲包装材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com