Automatic production line and automatic production method for ultrafiltration membrane

An automatic production line and ultrafiltration membrane technology, applied in chemical instruments and methods, ultrafiltration, membrane technology, etc., can solve the problems of affecting the packaging effect, easy contamination of membrane filaments, and difficulty in sizing production, so as to improve production efficiency, Realize the effect of fully automated production and management, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

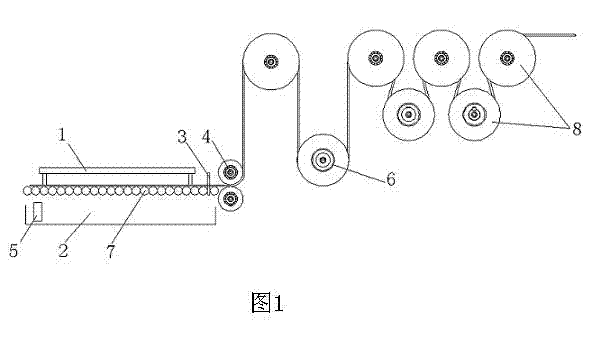

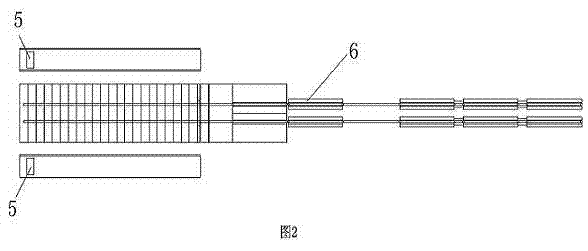

[0024] The invention provides an ultrafiltration membrane automatic production line, such as figure 1 and figure 2 As shown, the ultrafiltration membrane automatic production line includes an ultrafiltration membrane filament transmission device that runs through the entire production line, and an automatic membrane filament cutting device 3 and an automatic membrane filament collection device that are arranged in sequence. The automatic membrane filament collection device is used to collect The membrane filaments cut by the automatic membrane filament cutting device. The production line can be fully automated, and no manual operation is required from the film filament feeding, cutting to length, and automatic collection.

[0025] The film silk conveying device preferably includes a wheel group conveying mechanism, a pair of roller pulling devices and a rolling transport platform 7 arranged in sequence, and the pair of roller pulling devices and the rolling transport platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com