Industrial hemp combine harvester

A combine harvester, industrial technology, applied in the fields of harvesters, agricultural machinery and implements, applications, etc., can solve the problem of not being suitable for hemp harvesting, achieve continuous high-density operation, improve operation efficiency, and improve comprehensive utilization of resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

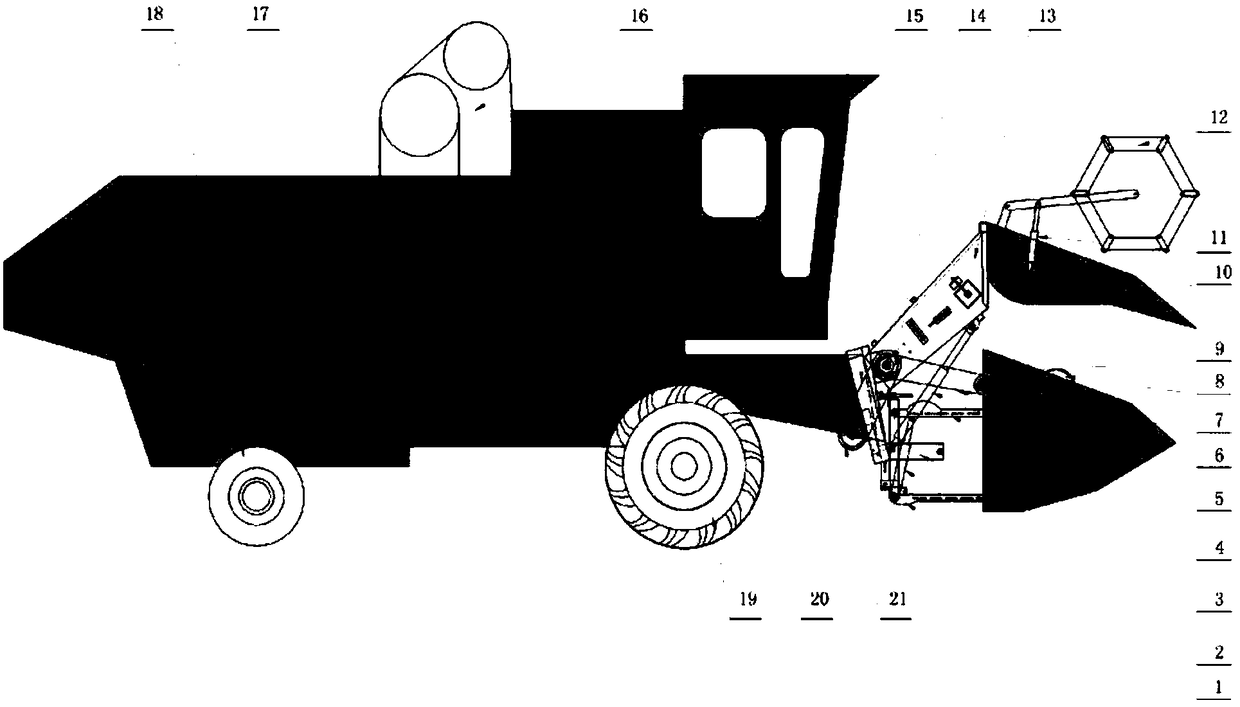

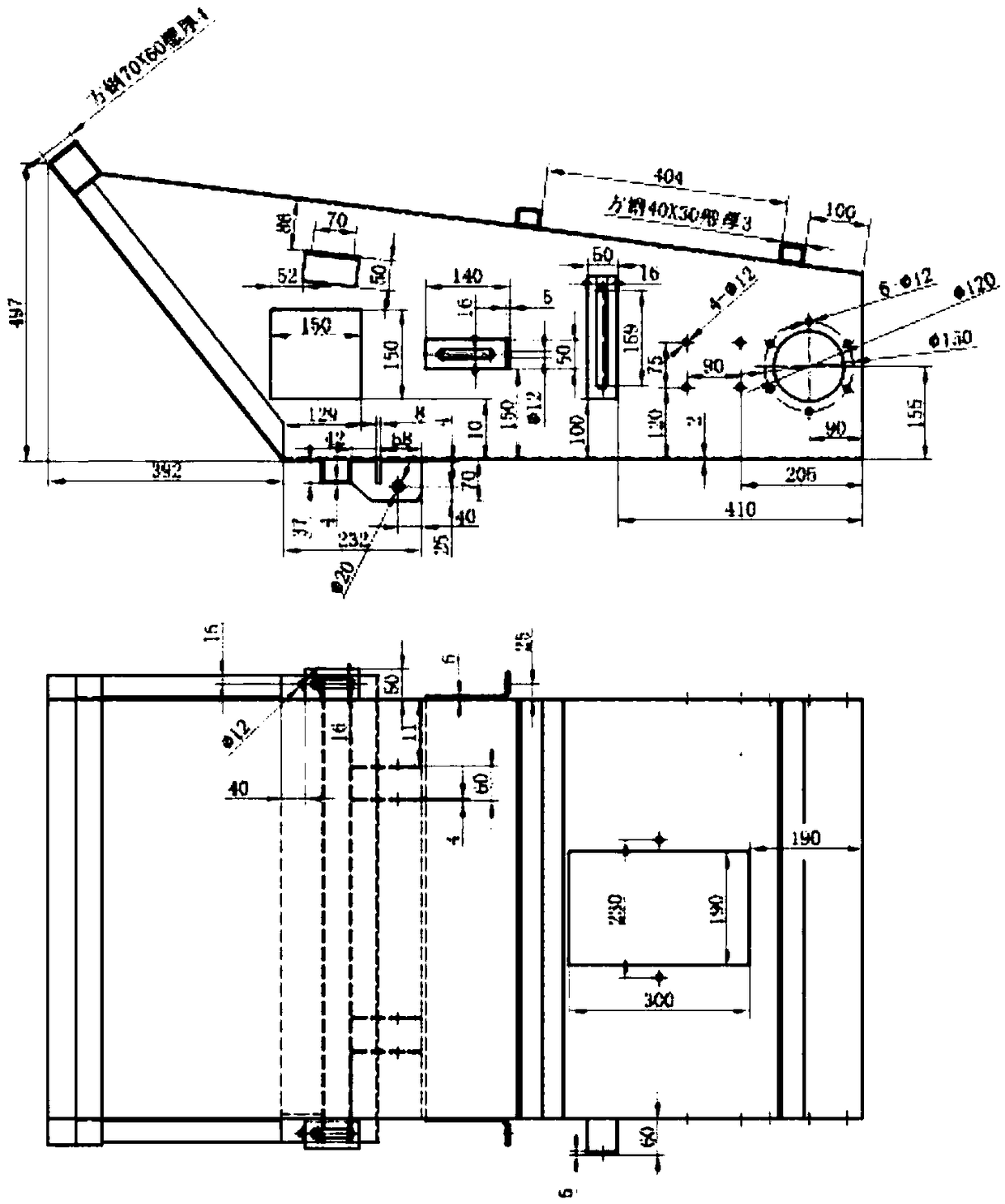

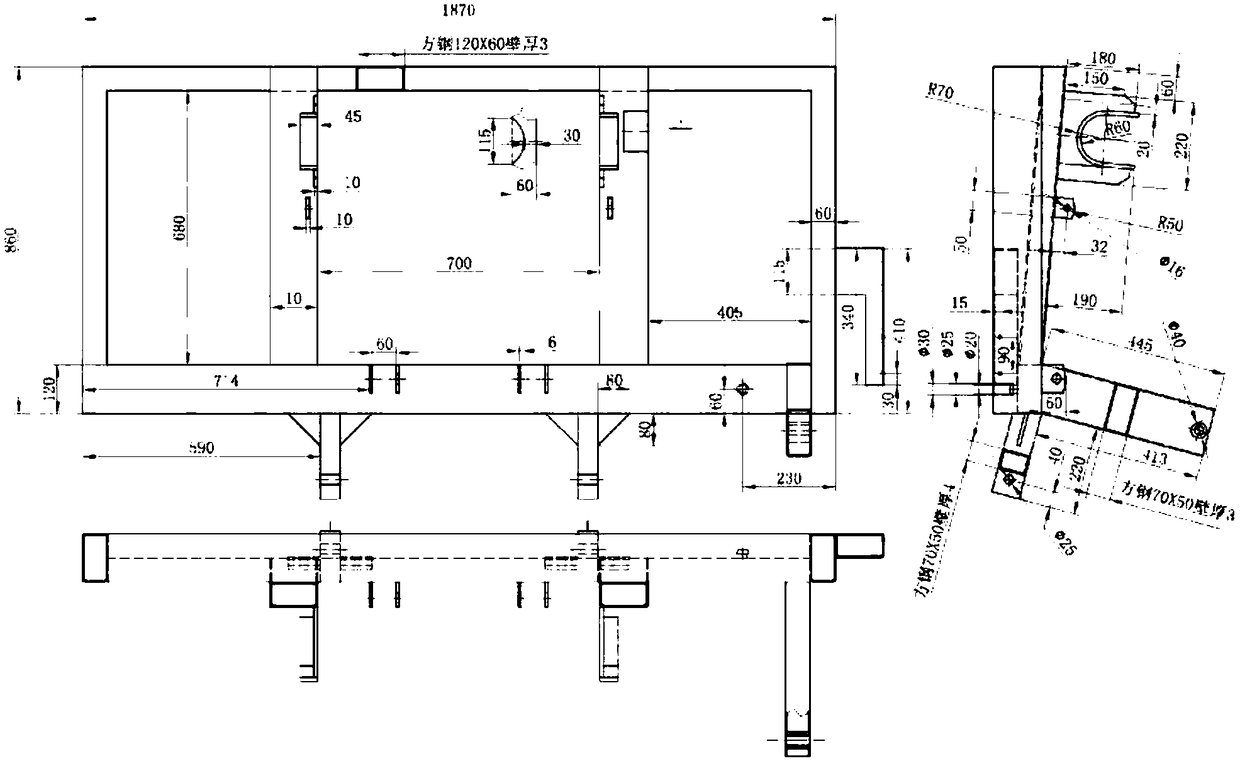

[0030] like figure 1 Shown, be the structural representation of the present invention, industrial hemp combine harvester, comprise cab 15, engine 16, combine harvester body 17, combine harvester steering wheel 18, combine harvester driving wheel 19, combine harvester former Crossing the bridge 20 also includes a harvesting device, and the harvesting device includes a disc cutter system, a two-stage bridge crossing system 13, a lifting spinning frame system, a reel 12, a harvesting platform 10, and a cutting and drying platform 9, and the harvesting device is installed on the combine harvester The front end of the combine harvester is connected to the front end of the combine harvester body through the original bridge of the combine harvester. The first half of the harvesting device is the reel, the harvesting platform, and the windrowing platform. The reel is located above the harvesting platform, and the harvesting platform is located above the windrowing platform. The harves...

Embodiment 2

[0037] The same as the technical solution of embodiment 1, the difference is that the distance h between the cutting table cutter and the hemp ear tip and the advancing speed V of the harvester are as follows:

[0038] 3.3V+6.7≥h≥2.2V+7.8, where 10m / s≥V≥1m / s, h is in cm. like Figure 9 shown.

[0039] Within this relationship, it can be guaranteed that the machine can harvest the hemp seeds most efficiently, and the hemp seeds will not be lost as much as possible.

[0040] A further preferred h=2.5V+7.5, in this state, the machine can achieve the best operating and harvesting state, that is, the most energy saving and the highest harvesting efficiency.

[0041] The most preferred solution is h=2.5V+7.5, further V=1.25.

Embodiment 3

[0043] The same as the technical solution of embodiment 1, the difference is that the reel rotational angular velocity w 1 The relationship with the operating speed V of the harvester is:

[0044] 1.67V 2 +18.33≥w 1 ≥V 2 +14, 4m / s≥V≥1m / s, w 1 The unit is rev / min. like Figure 10 shown.

[0045] Within this range, it can effectively ensure that the grains will not accumulate due to too slow transmission speed, and will not cause idling and waste energy due to too fast transmission speed.

[0046] The most optimal solution is w 1 =1.143V 2 +14.857, further V=2.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com